Study on the Selection of Single-Screw Steam Compressors in Industrial Steam Supply

Abstract

:1. Introduction

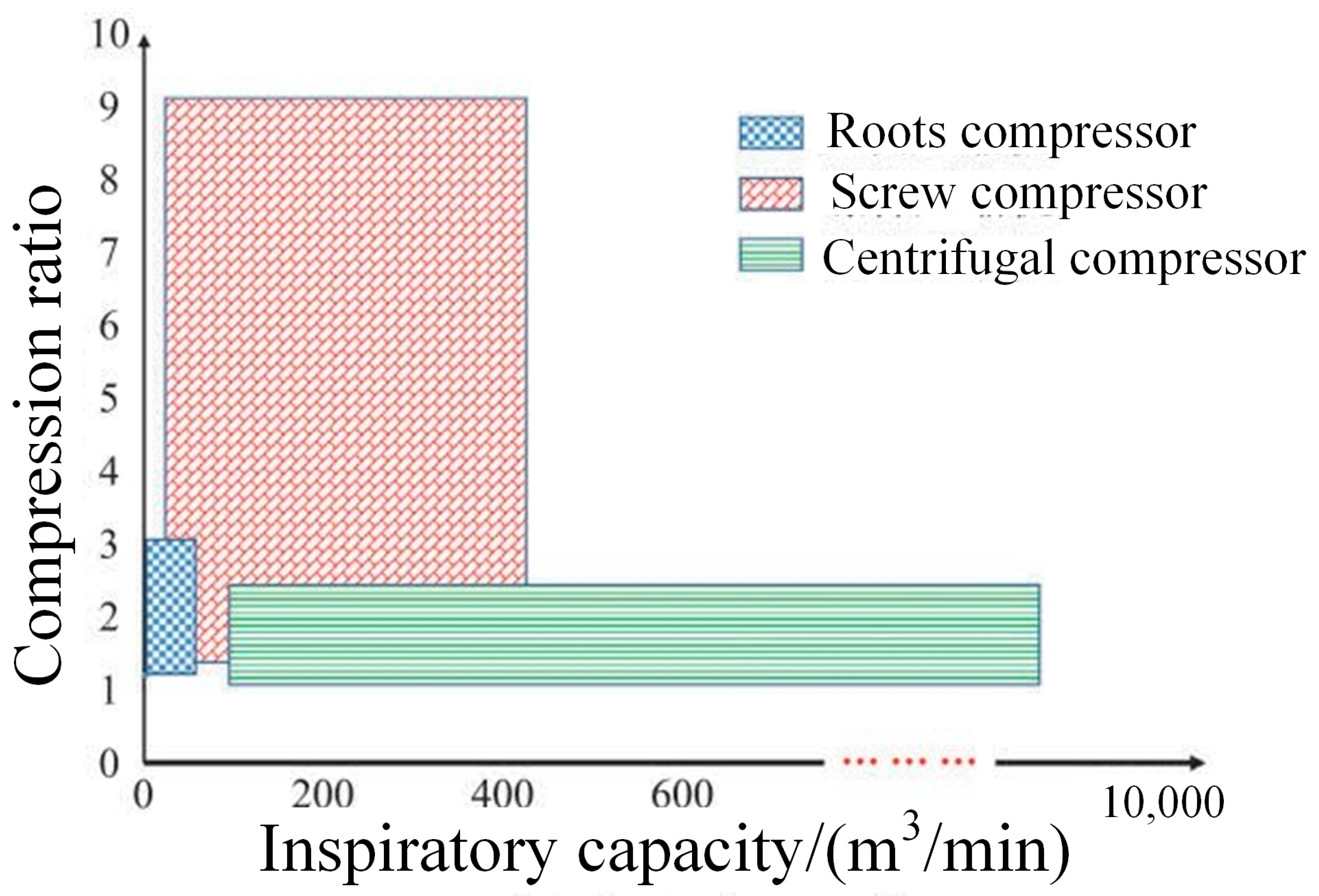

2. Numerical Framework and Method

2.1. Steam Compression System and Parameters

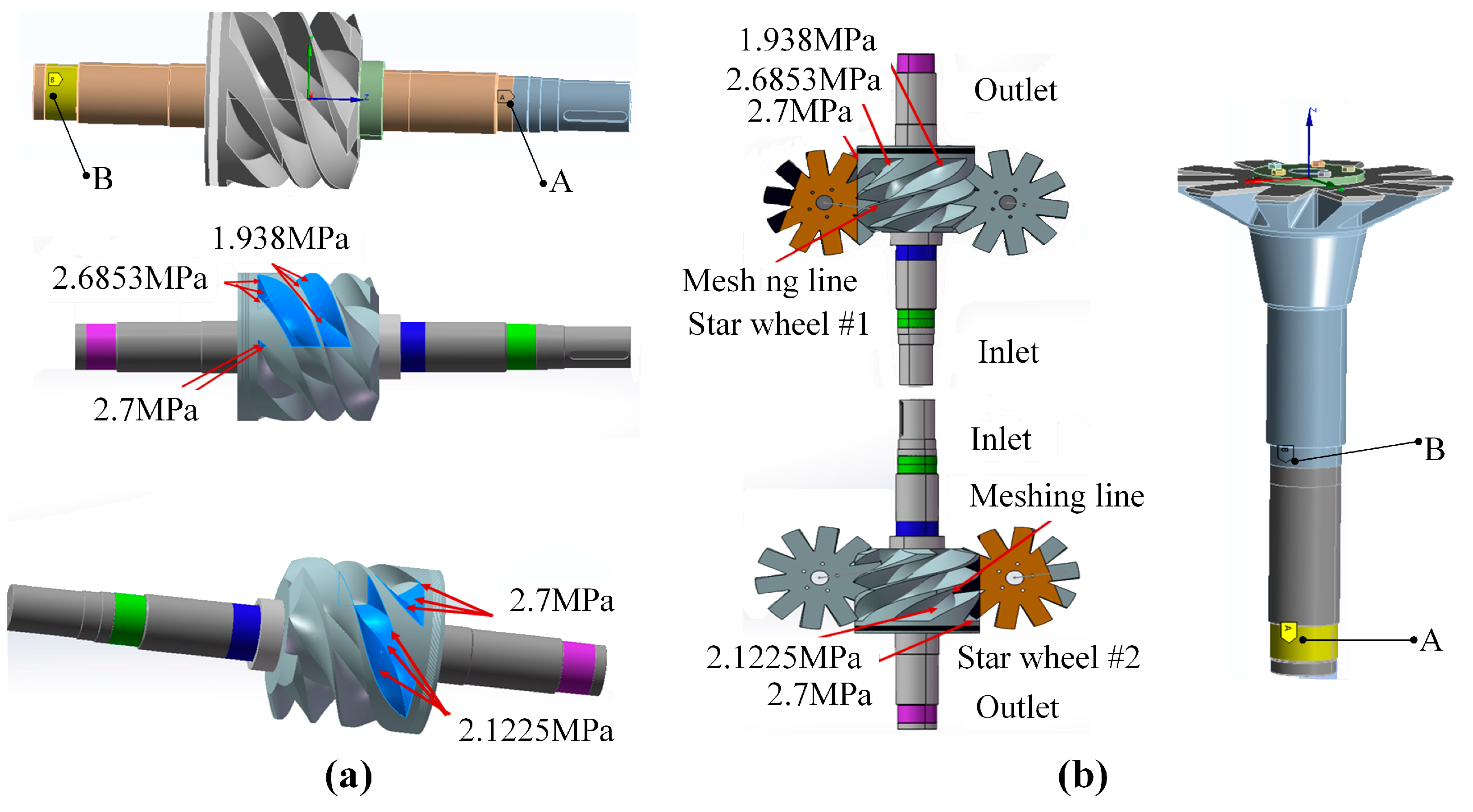

2.2. Geometric Model

2.3. Thermal Deformation Analysis

2.4. Boundary Condition

- (1)

- Cabinet assembly. The gas inlet chamber, star wheel chamber, and exhaust gas chamber all adopt the convective heat transfer boundary condition. The outside of the cabinet is cooled by the forced air, and the ambient temperature is set as 35 °C with an air flow velocity of 1.5 m/s. The cooling water (160 °C) is sprayed into the compression chamber through the blowhole. The specific temperature boundary parameters are as follows: Region A, blowhole, constant temperature, t = 160 °C; Region B, gas inlet area (inlet hole, star wheel chamber, gas inlet chamber), h = 819.77 W/(m2·K), t = 210 °C; Region C and Region D, outlet area (outlet chamber and vent), h = 2503.3 W/(m2·K), t = 230 °C; Region E, outer surface of cabinet assembly, h = 4.78 W/(m2·K), t = 35 °C (as shown in Table 4).

- (2)

- Screw assembly. Region A involves the screw, part of the screw shaft, and the shaft sleeve at the inlet side of the cabinet (h = 819.77 W/(m2·K), t = 210 °C). Region B is a section perpendicular to the axis direction at the beginning of the exhaust port (h = 2503.3 W/(m2·K), t = 230 °C). Region C is the shaft wall surface where the two bearings are in contact, and the lubricating oil is used to cool the bearing (h = 493.54 W/(m2·K), t = 50 °C), as shown in Table 4.

- (3)

- Star wheel assembly. Region A includes the side of the screw bracket, part of the screw shaft surface in the star wheel cavity, the surface of the star wheel blade that is not meshed, the star wheel’s pressure plate, and the bolt surface (h = 819.77 W/(m2·K), t = 210 °C). The boundary conditions of Region B are similar to those of Region A in the screw assembly (h = 819.77 W/(m2·K), t = 210 °C), as shown in Table 4.

3. Results and Discussion

3.1. Analysis of Differential Expansion

3.1.1. Inlet/Outlet Temperature of 210 °C/230 °C

3.1.2. Inlet/Outlet Temperature of 300 °C/350 °C

3.1.3. Inlet/Outlet Temperature of 350 °C/350 °C

3.1.4. Inlet/Outlet Temperature of 535 °C/480 °C

3.2. Analysis of Equipment Selection

3.3. Application Expansion of Compressors

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Takeshita, T.; Aki, H.; Kawajiri, K.; Ishida, M. Assessment of utilization of combined heat and power systems to provide grid flexibility alongside variable renewable energy systems. Energy 2021, 214, 118951. [Google Scholar] [CrossRef]

- Liu, J.X.; Xi, Z.; Li, X.H.; Yang, Q.P.; Xu, H.X.; Du, G.D. Numerical study on the overall performance and flow field characteristics of industrial steam compressor. Shanxi Prov. Inst. Mech. Eng. 2014. [Google Scholar] [CrossRef]

- Mabrouk, A.A.; Nafey, A.S.; Fath, H.E.S. Analysis of a new design of a multi-stage flash–mechanical vapor compression desalination process. Desalination 2007, 204, 482–500. [Google Scholar] [CrossRef]

- Huang, Z.K.; Zhang, P.; Du, X.; Zhang, F.F.; Liu, Y.H.; Sun, B.; Li, X.; Wang, J.D.; Liang, Y.P. Adjusting Method of Steam Compressor in Application System of Upgrading and Heat Supplying of Exhausted Steam of Thermal Power Generating Unit Steam Turbine. CN106930792B, 8 December 2017. [Google Scholar]

- Zhang, P.; Huang, Z.K.; Du, X.; Zhang, F.F.; Liu, Y.H.; Sun, B.; Li, X.; Wang, J.D.; Liang, Y.P. Reconstruction Method for Boosting Steam Supply Branch Network of Steam Compressor and Reducing Extraction Parameters. CN106968736B, 21 August 2018. [Google Scholar]

- Chen, T.; Li, Y.; Shen, Y.B.; Zhang, P.; Huang, Z.K.; Wang, E.Z.; Sun, R.; Wei, G.Y.; Liu, Y.H. A Heat Supply System Combined with Steam Compressor and High Back Pressure Heat Supply and Its Regulating Method. CN112228940B, 3 May 2022. [Google Scholar]

- Zhao, B. Performance Analysis on Water Vapor Recompression System. Master’s Thesis, Beijing University of Technology, Beijing, China, 2012. [Google Scholar]

- Mansour, A.; Muller, N. A review of flash evaporation phenomena and resulting shock waves. Exp. Therm. Fluid Sci. 2019, 107, 146–168. [Google Scholar] [CrossRef]

- Zhang, W.; Li, X.H.; Hui, M. Technology of high performance MVR vapor compressor and it’s application. Energy Sav. Nonferrous Metall. 2016, 32, 35–38+43. [Google Scholar]

- Zhang, H.F.; Yang, L.W.; Zhang, Z.T.; Lin, X.J.; Yang, J.L.; Zhang, C. Experimental study of operating characteristics of mechanical vapor Recompression heat pump evaporator system driven by roots Blower. Energy Conserv. Technol. 2015, 33, 113–117. [Google Scholar]

- Shen, J.B.; Xing, Z.W.; Zhang, K.; He, Z.L.; Wang, X.L. Development of a water-injected twin-screw compressor for mechanical vapor compression desalination systems. Appl. Therm. Eng. 2016, 95, 125–135. [Google Scholar] [CrossRef]

- Matsuda, R.J.; Qi, P.Y. Screw Steam Compression Heat Pump. Mech. Electr. Equip. 1986, 4, 18–26. Available online: http://www.cnki.com.cn/Article/CJFDTotal-JDSP198604003.htm (accessed on 22 March 2023).

- Patel, H.H.; Lakhera, V.J. A critical review of the experimental studies related to twin screw compressors. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2020, 234, 157–170. [Google Scholar] [CrossRef]

- Zimmern, B. Worm Rotary Compressors with Liquid Joints. U.S. Patent 3180565, 6 May 1965. [Google Scholar]

- Cha, Q.; Liu, X.Q.; Fang, Y.R.; Cha, S.L. Present situation and development trend of single screw compressor. Fluid Mach. 1997, 2, 40–42. [Google Scholar]

- Yang, J.L.; Zhang, C.; Zhang, Z.T.; Yang, L.W.; Lin, W.Y. Study on mechanical vapor recompression system with wet compression single screw compressor. Appl. Therm. Eng. 2016, 103, 205–211. [Google Scholar] [CrossRef]

- Hu, B.; Wu, D.; Wang, R.Z. Water vapor compression and its various applications. Renew. Sust. Energ. Rev. 2018, 98, 92–107. [Google Scholar] [CrossRef]

- Yang, J.L.; Yang, L.W.; Zhang, Z.T. Review on Energy-saving Technology with MVR. Chin. J. Turbomach. 2016, 58, 84–88. [Google Scholar]

- Wang, L.W.; Zhuang, J.F.; Yang, L.W.; Lin, W.Y.; Zhang, Z.T.; Yang, L.P.; Zhang, J.H. Experimental study on performance of MVR system driven by single screw water vapor compressor. J. Univ. Chin. Acad. Sci. 2015, 32, 38–48. [Google Scholar]

- Degueurce, B.; Banquet, F.; Densant, J.; Favrat, D. Use of a twin screw compressor for steam compression. Hydraul. Pneum. Mech. Power 1984, 30, 335–337. [Google Scholar]

- Chamoun, M.; Rulliere, R.; Haberschill, P.; Peureux, J.L. Modelica-based modeling and simulation of a twin screw compressor for heat pump applications. Appl. Therm. Eng. 2013, 58, 479–489. [Google Scholar] [CrossRef]

- Li, J.; Feng, Q.K.; Liu, F.L.; Wu, W.F. Experimental studies of the tooth wear resistance with different pro-files in single screw compressor. Tribol. Int. 2013, 57, 210–215. [Google Scholar] [CrossRef]

- Wu, W.F.; Zhang, Z.; Peng, C.Y.; Li, X.W.; Yang, Y.F.; Lei, W.W. Refreshed internal working characteristics of the single screw compressor based on experimental investigation. Int. J. Refrig. 2022, 143, 118–125. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, W.F. Numerical investigation of thermal deformation of meshing pairs in single screw compressor. Appl. Therm. Eng. 2021, 188, 116614. [Google Scholar] [CrossRef]

- Novelo, D.A.B.; Igie, U. Aero engine compressor cooling by water injection—Part 1: Evaporative compressor model. Energy 2018, 160, 1224–1235. [Google Scholar] [CrossRef]

- Wang, Z.L.; Wang, Z.B.; Wang, J.; Jiang, W.C.; Feng, Q.K. Theoretical and experimental study on thermodynamic performance of single screw refrigeration compressor with Multicolumn Envelope Meshing Pair. Appl. Therm. Eng. 2016, 103, 139–149. [Google Scholar] [CrossRef]

| Item | Unit | Value |

|---|---|---|

| Load ratio | % | 100 |

| Inlet steam pressure | MPa | 1.9 |

| Inlet steam temperature | °C | 535 |

| Desuperheating water pressure | MPa | 9 |

| Desuperheating water temperature | °C | 160 |

| Outlet steam target pressure | MPa | 2.7 |

| Outlet steam target temperature | °C | 480 |

| Outlet steam flow rate | t·h−1 | 45 |

| Case | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Inlet/outlet steam temperature (°C) | 210/230 | 300/350 | 350/350 | 535/480 |

| Item | Unit | Value |

|---|---|---|

| Density | Kg/m3 | 4620 |

| Coefficient of thermal expansion | 1/°C | 9.4 × 10−6 |

| Young’s modulus | Pa | 9.6 × 1010 |

| Poisson’s ratio | 0.36 | |

| Bulk modulus | Pa | 1.1429 × 1011 |

| Shear modulus | Pa | 3.5294 × 1010 |

| Tensile yield strength | Pa | 9.3 × 108 |

| Compressive yield strength | Pa | 9.3 × 108 |

| Tensile ultimate strength | Pa | 1.07 × 109 |

| Isotropic thermal conductivity | W/m °C | 21.9 |

| Specific heat | J/kg °C | 522 |

| Item | Unit | Value |

|---|---|---|

| Inlet/outlet steam temperature | °C | 210/230 |

| Inlet/outlet steam pressure | MPa | 1.9/2.7 |

| Ambient temperature | °C | 35 |

| Exhaust flow rate | m3·min−1 | 131.8 |

| Water spray volume | t·h−1 | 1.16 |

| Water spray temperature | °C | 160 |

| Screw diameter | mm | 706 |

| Center distance | mm | 550 |

| Star wheel diameter | mm | 728 |

| Star wheel teeth width | mm | 112 |

| Cabinet, screw, star wheel material | Titanium alloy | |

| Component | Region | Boundary Condition | Heat Transfer Coefficient (W/(m2·K)) | Temperature (°C) |

|---|---|---|---|---|

| Cabinet assembly | A | blowhole | — | 160 |

| B | gas inlet | 819.77 | 210 | |

| C | outlet | 2503.3 | 230 | |

| D | outlet | 2503.3 | 230 | |

| E | outer surface | 4.78 | 35 | |

| Screw assembly | A | multi-region | 819.77 | 210 |

| B | multi-region | 2503.3 | 230 | |

| C | multi-region | 493.54 | 50 | |

| Star wheel assembly | A | multi-region | 819.77 | 210 |

| B | multi-region | 819.77 | 210 |

| Number | Coordinate System | Constraint Type | Application Surface | Explanation |

|---|---|---|---|---|

| a | Global Cartesian coordinate system | Displacement | Inner ring of the sealing end face | No deformation in the axial direction (X), free deformation in the other two directions (Y and Z). |

| b | Cylindrical coordinate system | Displacement | Wall of the inner ring of the bearing at the inlet and outlet ends | Free deformation in radial (X) and axial (Z) directions, no deformation in the Y direction. Namely, the axial position remains unchanged. |

| c | Global Cartesian coordinate system | Frictionless support | Bottom surface of the bracket | No deformation in the Y direction, free deformation in the X and Z directions. Namely, no deformation in the support direction, and other directions can be deformed freely without friction. |

| Case | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Inlet/outlet steam temperature, °C | 210/ 230 | 300/ 350 | 350/ 350 | 535/ 480 |

| #1 Star wheel axial deformation, mm | −1.03 | −1.63 | −1.99 | −3.26 |

| #2 Star wheel axial deformation, mm | −1.07 | −1.67 | −2.00 | −3.22 |

| Average axial deformation of screw origin, mm | −0.99 | −1.48 | −1.72 | −2.69 |

| Differential expansion of #1 star wheel and screw, mm | 0.04 | 0.15 | 0.26 | 0.57 |

| Differential expansion of #2 star wheel and screw, mm | 0.08 | 0.19 | 0.28 | 0.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Ke, X.; Wang, W.; Tang, X.; Lyu, J.; Tang, Q. Study on the Selection of Single-Screw Steam Compressors in Industrial Steam Supply. Energies 2023, 16, 4199. https://doi.org/10.3390/en16104199

Zhang P, Ke X, Wang W, Tang X, Lyu J, Tang Q. Study on the Selection of Single-Screw Steam Compressors in Industrial Steam Supply. Energies. 2023; 16(10):4199. https://doi.org/10.3390/en16104199

Chicago/Turabian StyleZhang, Pan, Xiwei Ke, Weiliang Wang, Xueyu Tang, Junfu Lyu, and Qinghong Tang. 2023. "Study on the Selection of Single-Screw Steam Compressors in Industrial Steam Supply" Energies 16, no. 10: 4199. https://doi.org/10.3390/en16104199

APA StyleZhang, P., Ke, X., Wang, W., Tang, X., Lyu, J., & Tang, Q. (2023). Study on the Selection of Single-Screw Steam Compressors in Industrial Steam Supply. Energies, 16(10), 4199. https://doi.org/10.3390/en16104199