Neural Network Applications in Electrical Drives—Trends in Control, Estimation, Diagnostics, and Construction

Abstract

1. Preliminaries and Short Description of Methodology

- Definition of the advantages and disadvantages of solutions based on neural networks used in electrical drives;

- Description of the current issues regarding the implementations of the neural models in control, state variable estimation, and diagnostics;

- As exemplary results that prove selected possibilities, the neural estimators (of load speed and shaft torque) used in a drive with an elastic shaft and adaptive controllers of reluctance motor are considered;

- Analysis of the directions in the development of neural network applications in the field of electric drive.

2. Implementation of Neural Models in Electrical Drives

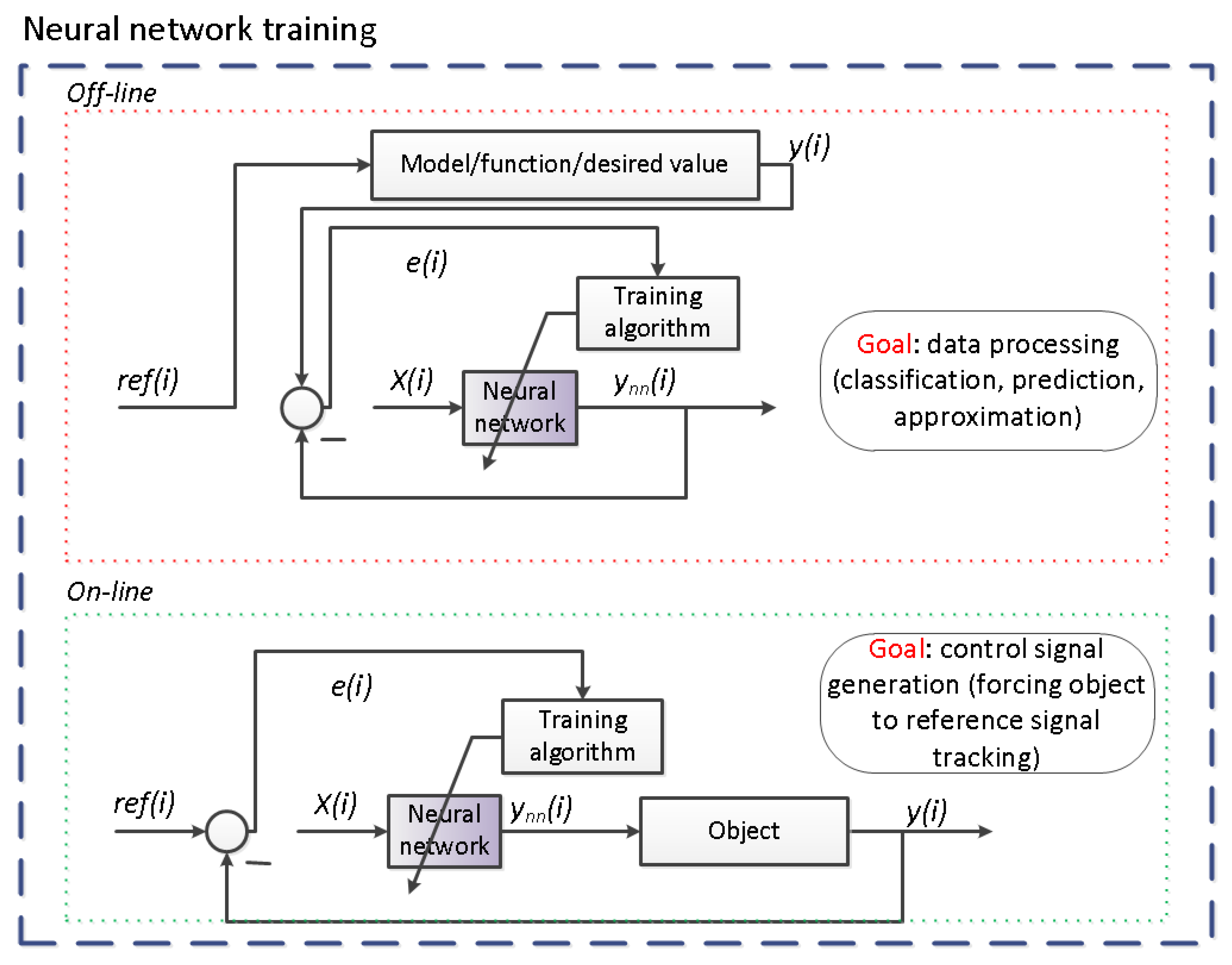

2.1. Neural Controllers

2.2. State Variables Estimation Based on Neural Networks

- Algorithmic methods;

- Hybrid combinations of classical observers with artificial intelligence methods;

- Signal processing approaches (with neural networks).

2.3. Concepts of Neural Network Applications in Power Electronics

2.3.1. Modeling and Optimization of Components, Components Arrangement, and Thermal Investigations

2.3.2. Reliability of Power Converter Components and Sensors

2.3.3. Harmonics Reduction and Control Performance Improvement

2.4. Neural Networks in Diagnostics

- Generating (and analyzing) diagnostic symptoms based on physical signal measurements.

- Application of methods known from control theory and electric machines fundamentals.

- Implementation of artificial intelligence algorithms.

- Neural networks are tools improving the simplification and efficiency of drive condition monitoring;

- Higher precision of faults detection is achieved;

- The time to problems recognition is shortened;

- Automation of the analysis of a complex data set;

- The ability to reduce or eliminate mathematical modeling;

- Robustness against measurement disturbance is achieved;

- Neural networks are easy to implement using available tools (software and hardware).

3. Discussion

4. Conclusions

- Faster calculations to provide a rapid and precise reaction of control algorithms (code optimization and new software/hardware solutions);

- Hardware developments enabling deep learning-based diagnostics;

- Subsequent development of soft computing algorithms to improve the application of neural networks in handling time-varying problems;

- Applications of deep learning techniques in control of electrical drives forcing an accurate reference transient tracking;

- Hardware accelerations support (i.e., improved and faster calculations) for deep learning methods using new libraries of programming languages (e.g., Python, Java, C++);

- Adaptive control methods used for nonlinear, partially identified, and time-varying systems;

- Neural models of complex systems with electric drives using deep learning to reduce complex mathematical description;

- Increase the number of drive constructions in which neural algorithms will be calculated in parallel using the FPGA;

- Development of hardware modules in programmable devices supporting neural networks implementation and training,

- Application of new types of neural networks currently being developed in theoretical work (e.g., graph neural networks);

- Hybrid combinations of neural networks and models based on expert knowledge (e.g., fuzzy logic) in diagnostics and control;

- Application of metaheuristic methods for parameter selection to improve algorithm convergence and robustness;

- Optimization of topology, heat exchange, and component development and arrangement to improve the efficiency and reliability of power converters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, Y.; Wang, X.; Shao, S.; Zhang, J. Active Gate Driver for Dynamic Current Balancing of Parallel-Connected SiC MOSFETs. IEEE Trans. Power Electron. 2023, 38, 6116–6127. [Google Scholar] [CrossRef]

- Guo, Y.; Ba, X.; Liu, L.; Lu, H.; Lei, G.; Yin, W.; Zhu, J. A Review of Electric Motors with Soft Magnetic Composite Cores for Electric Drives. Energies 2023, 16, 2053. [Google Scholar] [CrossRef]

- Vaimann, T.; Kallaste, A. Additive Manufacturing of Electrical Machines—Towards the Industrial Use of a Novel Technology. Energies 2023, 16, 544. [Google Scholar] [CrossRef]

- Aziz, A.G.M.A.; Abdelaziz, A.Y.; Ali, Z.M.; Diab, A.A.Z. A Comprehensive Examination of Vector-Controlled Induction Motor Drive Techniques. Energies 2023, 16, 2854. [Google Scholar] [CrossRef]

- Wogi, L.; Ayana, T.; Morawiec, M.; Jąderko, A. A Comparative Study of Fuzzy SMC with Adaptive Fuzzy PID for Sensorless Speed Control of Six-Phase Induction Motor. Energies 2022, 15, 8183. [Google Scholar] [CrossRef]

- Derugo, P.; Szabat, K.; Pajchrowski, T.; Zawirski, K. Fuzzy Adaptive Type II Controller for Two-Mass System. Energies 2022, 15, 419. [Google Scholar] [CrossRef]

- Ruz-Hernandez, J.A.; Djilali, L.; Ruz Canul, M.A.; Boukhnifer, M.; Sanchez, E.N. Neural Inverse Optimal Control of a Regenerative Braking System for Electric Vehicles. Energies 2022, 15, 8975. [Google Scholar] [CrossRef]

- Buettner, M.A.; Monzen, N.; Hackl, C.M. Artificial Neural Network Based Optimal Feedforward Torque Control of Interior Permanent Magnet Synchronous Machines: A Feasibility Study and Comparison with the State-of-the-Art. Energies 2022, 15, 1838. [Google Scholar] [CrossRef]

- Lin, F.J.; Liu, C.W.; Wang, P.L. Voltage Control of IPMSM Servo Drive in Constant Power Region with Intelligent Parameter Estimation. IEEE Access 2022, 10, 99243–99256. [Google Scholar] [CrossRef]

- Hang, J.; Shu, X.; Ding, S.; Huang, Y. Robust Open-Circuit Fault Diagnosis for PMSM Drives Using Wavelet Convolutional Neural Network With Small Samples of Normalized Current Vector Trajectory Graph. IEEE Trans. Ind. Electron. 2023, 70, 7653–7663. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Tran, H.N.; Nguyen, T.H.; Jeon, J.W. Recurrent Neural Network-Based Robust Adaptive Model Predictive Speed Control for PMSM With Parameter Mismatch. IEEE Trans. Ind. Electron. 2023, 70, 6219–6228. [Google Scholar] [CrossRef]

- Smith, J.S.; Wu, B.; Wilamowski, B.M. Neural Network Training With Levenberg–Marquardt and Adaptable Weight Compression. IEEE Trans. Neural Netw. Learn. Syst. 2019, 30, 580–587. [Google Scholar] [CrossRef] [PubMed]

- Haring, M.; Grotli, E.I.; Riemer-Sorensen, S.; Seel, K.; Hanssen, K.G. A Levenberg–Marquardt Algorithm for Sparse Identification of Dynamical Systems. IEEE Trans. Neural Netw. Learn. Syst. 2022, 1–14. [Google Scholar] [CrossRef]

- Wilamowski, B.M.; Yu, H. Improved Computation for Levenberg–Marquardt Training. IEEE Trans. Neural Netw. 2010, 21, 930–937. [Google Scholar] [CrossRef]

- Skrobek, D.; Krzywanski, J.; Sosnowski, M.; Uddin, G.M.; Ashraf, W.M.; Grabowska, K.; Zylka, A.; Kulakowska, A.; Nowak, W. Artificial Intelligence for Energy Processes and Systems: Applications and Perspectives. Energies 2023, 16, 3441. [Google Scholar] [CrossRef]

- McCulloch, W.S.; Pitts, W. A logical calculus of the ideas immanent in nervous activity. Bull. Math. Biol. 1990, 52, 99–115. [Google Scholar] [CrossRef]

- Hebb, D.O. The Organization of Behavior; John Wiley: New York, NY, USA, 1949. [Google Scholar]

- Widrow, B.; Lehr, M. 30 years of adaptive neural networks: Perceptron, Madaline, and backpropagation. Proc. IEEE 1990, 78, 1415–1442. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Nature 1986, 323, 533–536. [Google Scholar] [CrossRef]

- Wilamowski, B.M.; Yu, H. Neural Network Learning Without Backpropagation. IEEE Trans. Neural Netw. 2010, 21, 1793–1803. [Google Scholar] [CrossRef]

- Malarczyk, M.; Tapamo, J.R.; Kaminski, M. Application of Neural Data Processing in Autonomous Model Platform—A Complex Review of Solutions, Design and Implementation. Energies 2022, 15, 4766. [Google Scholar] [CrossRef]

- Kocot, B.; Czarnul, P.; Proficz, J. Energy-Aware Scheduling for High-Performance Computing Systems: A Survey. Energies 2023, 16, 890. [Google Scholar] [CrossRef]

- Yao, C.; Sun, Z.; Xu, S.; Zhang, H.; Ren, G.; Ma, G. ANN Optimization of Weighting Factors Using Genetic Algorithm for Model Predictive Control of PMSM Drives. IEEE Trans. Ind. Appl. 2022, 58, 7346–7362. [Google Scholar] [CrossRef]

- Ajayi, O.; Heymann, R. Training a Multi-Layered Perceptron using Moth Swarm Algorithm for Predicting Energy Demand of a Data Centre and Weights-Based Analysis of Input Parameters. In Proceedings of the 2021 IEEE AFRICON, Arusha, Tanzania, 13–15 September 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Song, D.; Venugopal, C. A novel coal-rock cutting state identification model based on the Internet of Things. Int. J. Cogn. Comput. Eng. 2023, 4, 179–186. [Google Scholar] [CrossRef]

- Kaminski, M. Neural Network Training Using Particle Swarm Optimization—A Case Study. In Proceedings of the 2019 24th International Conference on Methods and Models in Automation and Robotics (MMAR), Międzyzdroje, Poland, 26–29 August 2019; pp. 115–120. [Google Scholar] [CrossRef]

- Shichkina, Y.; Irishina, Y.; Stanevich, E.; de Jesus Plasencia Salgueiro, A. Application of Genetic Algorithms for the Selection of Neural Network Architecture in the Monitoring System for Patients with Parkinson’s Disease. Appl. Sci. 2021, 11, 5470. [Google Scholar] [CrossRef]

- El-Sousy, F.F.M.; Amin, M.M.; Mohammed, O.A. Robust Adaptive Neural Network Tracking Control with Optimized Super-Twisting Sliding-Mode Technique for Induction Motor Drive System. IEEE Trans. Ind. Appl. 2022, 58, 4134–4157. [Google Scholar] [CrossRef]

- Abotaleb, A.; Elwakil, A.T.; Hadhoud, M. Hybrid Genetic Based Algorithm for CNN Ultra Compression. In Proceedings of the 2019 31st International Conference on Microelectronics (ICM), Cairo, Egypt, 15–18 December 2019; pp. 199–202. [Google Scholar] [CrossRef]

- K, P.K.; Sabeen, S. An Effective Pruning Strategy for Performance Enhancement in Deep Neural Network (DNN)—With Long Short-Term Memory (DNN-LSTM). In Proceedings of the 2022 4th International Conference on Artificial Intelligence and Speech Technology (AIST), Delhi, India, 9–10 December 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Sun, J.; Chen, M.; Kong, L.; Hu, Z.; Veerasamy, V. Regional Load Frequency Control of BP-PI Wind Power Generation Based on Particle Swarm Optimization. Energies 2023, 16, 2015. [Google Scholar] [CrossRef]

- Duan, L.; Liu, H. Sparsity Regularization Model Based on Network Structure. In Proceedings of the 2022 IEEE Asia-Pacific Conference on Image Processing, Electronics and Computers (IPEC), Dalian, China, 14–16 April 2022; pp. 1069–1073. [Google Scholar] [CrossRef]

- MacKay, D.J.C. A Practical Bayesian Framework for Backpropagation Networks. Neural Comput. 1992, 4, 448–472. [Google Scholar] [CrossRef]

- Kaminski, M.; Orlowska-Kowalska, T. Optimisation of neural state variables estimators of two-mass drive system using the Bayesian regularization method. Bull. Pol. Acad. Sci. Tech. Sci. 2011, 59, 33–38. [Google Scholar] [CrossRef]

- Shultz, T.R.; Fahlman, S.E. Cascade Correlation. In Encyclopedia of Machine Learning and Data Mining; Sammut, C., Webb, G.I., Eds.; Springer: Boston, MA, USA, 2017; pp. 171–180. [Google Scholar] [CrossRef]

- Martinetz, T.; Schulten, K. A “Neural-Gas” Network Learns Topologies. Artif. Neural Netw. 1991, 1, 397–402. [Google Scholar]

- Fritzke, B. A Growing Neural Gas Network Learns Topologies. In Proceedings of the 7th International Conference on Neural Information Processing Systems, Cambridge, MA, USA, 1 January 1994; pp. 625–632. [Google Scholar]

- LeCun, Y.; Denker, J.S.; Solla, S.; Howard, R.E.; Jackel, L.D. Optimal Brain Damage. In Proceedings of the Advances in Neural Information Processing Systems (NIPS 1989), Denver, CO, USA, 27–30 November 1989; Volume 2. [Google Scholar]

- Hassibi, B.; Stork, D.; Wolff, G. Optimal Brain Surgeon and general network pruning. In Proceedings of the IEEE International Conference on Neural Networks, Nagoya, Japan, 25–29 October 1993; Volume 1, pp. 293–299. [Google Scholar] [CrossRef]

- Chaber, P.; £awryñczuk, M. Pruning of recurrent neural models: An optimal brain damage approach. Nonlinear Dyn. 2018, 92, 763–780. [Google Scholar] [CrossRef]

- Elman, J.L. Finding structure in time. Cogn. Sci. 1990, 14, 179–211. [Google Scholar] [CrossRef]

- Jordan, M.I. Generic constraints on underspecified target trajectories. In Proceedings of the International Joint Conference on Neural Networks, Washington, DC, USA, 18–21 June 1989; IEEE Press: New York, NY, USA, 1989; Volume 1, pp. 217–225. [Google Scholar]

- Fukushima, K. Neocognitron: A self-organizing neural network model for a mechanism of pattern recognition unaffected by shift in position. Biol. Cybern. 1980, 36, 193–202. [Google Scholar] [CrossRef] [PubMed]

- Nebauer, C. Evaluation of convolutional neural networks for visual recognition. IEEE Trans. Neural Netw. 1998, 9, 685–696. [Google Scholar] [CrossRef] [PubMed]

- Tseng, F.H.; Yeh, K.H.; Kao, F.Y.; Chen, C.Y. MiniNet: Dense squeeze with depthwise separable convolutions for image classification in resource-constrained autonomous systems. ISA Trans. 2023, 132, 120–130. [Google Scholar] [CrossRef] [PubMed]

- Chollet, F. Xception: Deep Learning with Depthwise Separable Convolutions. In Proceedings of the 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017; pp. 1800–1807. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, X.; Lin, M.; Sun, J. ShuffleNet: An Extremely Efficient Convolutional Neural Network for Mobile Devices. In Proceedings of the 2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–23 June 2018; pp. 6848–6856. [Google Scholar] [CrossRef]

- Sangaiah, A.K.; Javadpour, A.; Ja’fari, F.; Zavieh, H.; Khaniabadi, S.M. SALA-IoT: Self-Reduced Internet of Things with Learning Automaton Sleep Scheduling Algorithm. IEEE Sens. J. 2023. [Google Scholar] [CrossRef]

- Xie, H.; Hao, C.; Li, J.; Li, M.; Luo, P.; Zhu, J. Anomaly Detection for Time Series Data Based on Multi-granularity Neighbor Residual Network. Int. J. Cogn. Comput. Eng. 2022, 3, 180–187. [Google Scholar] [CrossRef]

- Wróbel, K.; Serkies, P.; Szabat, K. Model Predictive Base Direct Speed Control of Induction Motor Drives—Continuous and Finite Set Approaches. Energies 2020, 13, 1193. [Google Scholar] [CrossRef]

- Pajchrowski, T.; Siwek, P.; Wójcik, A. Application of the Reinforcement Learning method for adaptive electric drive control with variable parameters. In Proceedings of the 2021 IEEE 19th International Power Electronics and Motion Control Conference (PEMC), Gliwice, Poland, 25–29 April 2021; pp. 687–694. [Google Scholar] [CrossRef]

- Szczepanski, R.; Tarczewski, T.; Niewiara, L.J.; Stojic, D. Identification of mechanical parameters in servo-drive system. In Proceedings of the 2021 IEEE 19th International Power Electronics and Motion Control Conference (PEMC), Gliwice, Poland, 25–29 April 2021; pp. 566–573. [Google Scholar] [CrossRef]

- Szczepanski, R.; Tarczewski, T.; Grzesiak, L.M. Application of optimization algorithms to adaptive motion control for repetitive process. ISA Trans. 2021, 115, 192–205. [Google Scholar] [CrossRef]

- Tarczewski, T.; Niewiara, L.J.; Grzesiak, L.M. Artificial Neural Network-Based Gain-Scheduled State Feedback Speed Controller for Synchronous Reluctance Motor. Power Electron. Drives 2021, 6, 276–288. [Google Scholar] [CrossRef]

- Nguyen, A.T.; Rafaq, M.S.; Choi, H.H.; Jung, J.W. A Model Reference Adaptive Control Based Speed Controller for a Surface-Mounted Permanent Magnet Synchronous Motor Drive. IEEE Trans. Ind. Electron. 2018, 65, 9399–9409. [Google Scholar] [CrossRef]

- Li, H.; Liu, Z. A Robust Predictive Current Control Based on Incremental Model and Adaline N eural Network for PMSM Drives. In Proceedings of the 2021 24th International Conference on Electrical Machines and Systems (ICEMS), Gyeongju, Republic of Korea, 31 October–3 November 2021; pp. 1696–1701. [Google Scholar] [CrossRef]

- Masoudi, S.; Mehrjerdi, H. A Multilayer Perception Trained Method in Speed Control of a Linear Switched Reluctance Motor. IEEE Trans. Power Electron. 2022, 37, 4475–4483. [Google Scholar] [CrossRef]

- Kaminski, M. Nature-Inspired Algorithm Implemented for Stable Radial Basis Function Neural Controller of Electric Drive with Induction Motor. Energies 2020, 13, 6541. [Google Scholar] [CrossRef]

- El-Sousy, F.F.M.; Abuhasel, K.A. Intelligent Adaptive Dynamic Surface Control System With Recurrent Wavelet Elman Neural Networks for DSP-Based Induction Motor Servo Drives. IEEE Trans. Ind. Appl. 2019, 55, 1998–2020. [Google Scholar] [CrossRef]

- Tarczewski, T.; Niewiara, L.J.; Grzesiak, L.M. Torque ripple minimization for PMSM using voltage matching circuit and neural network based adaptive state feedback control. In Proceedings of the 2014 16th European Conference on Power Electronics and Applications, Lappeenranta, Finland, 26–28 August 2014; pp. 1–10. [Google Scholar] [CrossRef]

- Zhao, C.; Zuo, Y.; Wang, H.; Hou, Q.; Zhu, S.; Lee, C.H. Torque Ripple Suppression of PMSM Speed Regulation System Using Neural Network. In Proceedings of the 2022 IEEE 7th Southern Power Electronics Conference (SPEC), Nadi, Fiji, 5–8 December 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Pajchrowski, T.; Siwek, P.; Wójcik, A. Adaptive Neural Controller for Speed Control of PMSM with Torque Ripples. In Proceedings of the 2022 IEEE 20th International Power Electronics and Motion Control Conference (PEMC), Brasov, Romania, 25–28 September 2022; pp. 564–570. [Google Scholar] [CrossRef]

- de Castro, A.G.; Guazzelli, P.R.U.; de Oliveira, C.M.R.; Pereira, W.C.d.A.; de Paula, G.T.; Monteiro, J.R.B.d.A. Optimized Current Waveform for Torque Ripple Mitigation and MTPA Operation of PMSM with Back EMF Harmonics based on Genetic Algorithm and Artificial Neural Network. IEEE Lat. Am. Trans. 2020, 18, 1646–1655. [Google Scholar] [CrossRef]

- Al-Kaf, H.A.G.; Hakami, S.S.; Lee, K.B. Hybrid Current Controller for Permanent-Magnet Synchronous Motors Using Robust Switching Techniques. IEEE Trans. Power Electron. 2023, 38, 3711–3724. [Google Scholar] [CrossRef]

- Han, Y.; Zhu, Q.; Xiao, Y. Data-driven Control of Autonomous Vehicle using Recurrent Fuzzy Neural Network Combined with PID Method. In Proceedings of the 2018 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018; pp. 5239–5244. [Google Scholar] [CrossRef]

- Prasad, R.; Kumar, D.; Chand, S.; Fagiolini, A.; Mudaliar, H.; Benedetto, M.D.; Cirrincione, M. Enhancing Speed Loop PI Controllers with Adaptive Feed-forward Neural Networks: Application to Induction Motor Drives. In Proceedings of the 2022 25th International Conference on Electrical Machines and Systems (ICEMS), Chiang Mai, Thailand, 29 November–2 December 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Khanh Quang, N.; Ngo, V.Q.B.; Kim Anh, N.; Than, H.; That Dong, T.; Duc Tho, N. Neural Network PID Controller for PMSM Drives. In Proceedings of the 2022 7th National Scientific Conference on Applying New Technology in Green Buildings (ATiGB), Da Nang, Vietnam, 11–12 November 2022; pp. 146–149. [Google Scholar] [CrossRef]

- Tran, H.N.; Le, K.M.; Jeon, J.W. Adaptive Current Controller Based on Neural Network and Double Phase Compensator for a Stepper Motor. IEEE Trans. Power Electron. 2019, 34, 8092–8103. [Google Scholar] [CrossRef]

- Zuo, Y.; Xie, S.; Cao, L.; Zhao, C.; Han, B.S.; Hoang, C.C.; Chan, C.Y.; Lee, C.H.T. A Nonlinear PI Controller for Speed Control of Electric Drives Using Radial-Basis Function Neural Network. In Proceedings of the 2022 IEEE 7th Southern Power Electronics Conference (SPEC), Nadi, Fiji, 5–8 December 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Kaminski, M. Adaptive Controller with Neural Signal Predictor Applied for Two-Mass System. In Proceedings of the 2018 23rd International Conference on Methods and Models in Automation and Robotics (MMAR), Międzyzdroje, Poland, 27–30 August 2018; pp. 247–252. [Google Scholar] [CrossRef]

- Wang, L.; Zhu, Z.Q.; Bin, H.; Gong, L. A Commutation Error Compensation Strategy for High-Speed Brushless DC Drive Based on Adaline Filter. IEEE Trans. Ind. Electron. 2021, 68, 3728–3738. [Google Scholar] [CrossRef]

- Lin, F.J.; Huang, M.S.; Chen, S.G.; Hsu, C.W. Intelligent Maximum Torque per Ampere Tracking Control of Synchronous Reluctance Motor Using Recurrent Legendre Fuzzy Neural Network. IEEE Trans. Power Electron. 2019, 34, 12080–12094. [Google Scholar] [CrossRef]

- Yu, J.; Shi, P.; Dong, W.; Chen, B.; Lin, C. Neural Network-Based Adaptive Dynamic Surface Control for Permanent Magnet Synchronous Motors. IEEE Trans. Neural Netw. Learn. Syst. 2015, 26, 640–645. [Google Scholar] [CrossRef]

- El-Sousy, F.F.M.; El-Naggar, M.F.; Amin, M.; Abu-Siada, A.; Abuhasel, K.A. Robust Adaptive Neural-Network Backstepping Control Design for High-Speed Permanent-Magnet Synchronous Motor Drives: Theory and Experiments. IEEE Access 2019, 7, 99327–99348. [Google Scholar] [CrossRef]

- Kaminski, M.; Szabat, K. Adaptive Control Structure with Neural Data Processing Applied for Electrical Drive with Elastic Shaft. Energies 2021, 14, 3389. [Google Scholar] [CrossRef]

- Xu, H.; Xu, L.; Chen, S.; Liu, J.; Cheng, G.; Liang, X.; Mao, W. Brushless DC motor Control System Based on RBF Neural Network. In Proceedings of the 2020 IEEE International Conference on Mechatronics and Automation (ICMA), Beijing, China, 13–16 October 2020; pp. 1704–1709. [Google Scholar] [CrossRef]

- Jakobeit, D.; Schenke, M.; Wallscheid, O. Meta-Reinforcement Learning-Based Current Control of Permanent Magnet Synchronous Motor Drives for a Wide Range of Power Classes. IEEE Trans. Power Electron. 2023, 38, 8062–8074. [Google Scholar] [CrossRef]

- Deng, W.; Zhou, H.; Zhou, J.; Yao, J. Neural Network-Based Adaptive Asymptotic Prescribed Performance Tracking Control of Hydraulic Manipulators. IEEE Trans. Syst. Man Cybern. Syst. 2023, 53, 285–295. [Google Scholar] [CrossRef]

- Bednarz, S.A.; Dybkowski, M. Estimation of the Induction Motor Stator and Rotor Resistance Using Active and Reactive Power Based Model Reference Adaptive System Estimator. Appl. Sci. 2019, 9, 5145. [Google Scholar] [CrossRef]

- Wang, H.; Ge, X.; Liu, Y.C. Second-Order Sliding-Mode MRAS Observer-Based Sensorless Vector Control of Linear Induction Motor Drives for Medium-Low Speed Maglev Applications. IEEE Trans. Ind. Electron. 2018, 65, 9938–9952. [Google Scholar] [CrossRef]

- Accetta, A.; Cirrincione, M.; Pucci, M.; Vitale, G. Closed-Loop MRAS Speed Observer for Linear Induction Motor Drives. IEEE Trans. Ind. Appl. 2015, 51, 2279–2290. [Google Scholar] [CrossRef]

- Yan, X.; Cheng, M. An MRAS Observer-Based Speed Sensorless Control Method for Dual-Cage Rotor Brushless Doubly Fed Induction Generator. IEEE Trans. Power Electron. 2022, 37, 12705–12714. [Google Scholar] [CrossRef]

- Hussien, M.G.; Liu, Y.; Xu, W.; Junejo, A.K.; Allam, S.M. Improved MRAS Rotor Position Observer Based on Control Winding Power Factor for Stand-Alone Brushless Doubly-Fed Induction Generators. IEEE Trans. Energy Convers. 2022, 37, 707–717. [Google Scholar] [CrossRef]

- Szabat, K.; Wróbel, K.; Dróżdż, K.; Janiszewski, D.; Pajchrowski, T.; Wójcik, A. A Fuzzy Unscented Kalman Filter in the Adaptive Control System of a Drive System with a Flexible Joint. Energies 2020, 13, 2056. [Google Scholar] [CrossRef]

- Zerdali, E.; Barut, M. The Comparisons of Optimized Extended Kalman Filters for Speed-Sensorless Control of Induction Motors. IEEE Trans. Ind. Electron. 2017, 64, 4340–4351. [Google Scholar] [CrossRef]

- Ramezani, M.; Ojo, O. The Modeling and Position-Sensorless Estimation Technique for A Nine-Phase Interior Permanent-Magnet Machine Using High-Frequency Injections. IEEE Trans. Ind. Appl. 2016, 52, 1555–1565. [Google Scholar] [CrossRef]

- Zhang, C.; Wu, G.; Rong, F.; Feng, J.; Jia, L.; He, J.; Huang, S. Robust Fault-Tolerant Predictive Current Control for Permanent Magnet Synchronous Motors Considering Demagnetization Fault. IEEE Trans. Ind. Electron. 2018, 65, 5324–5334. [Google Scholar] [CrossRef]

- Sharma, A.B.; Tiwari, S.; Singh, B. Intelligent Speed Estimation in Induction Motor Drive Control using Feed—Forward Neural Network Assisted Model Reference Adaptive System. In Proceedings of the 2020 IEEE Students Conference on Engineering & Systems (SCES), Prayagraj, India, 10–12 July 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, L.; Xu, L.; Dong, F.; Song, J.; Yang, X. Uniform Demagnetization Diagnosis for Permanent-Magnet Synchronous Linear Motor Using a Sliding-Mode Velocity Controller and an ALN-MRAS Flux Observer. IEEE Trans. Ind. Electron. 2022, 69, 890–899. [Google Scholar] [CrossRef]

- Lin, H.; Marquez, A.; Wu, F.; Liu, J.; Luo, H.; Franquelo, L.G.; Wu, L. MRAS-Based Sensorless Control of PMSM with BPN in Prediction Mode. In Proceedings of the 2019 IEEE 28th International Symposium on Industrial Electronics (ISIE), Vancouver, BC, Canada, 12–14 June 2019; pp. 1755–1760. [Google Scholar] [CrossRef]

- Kaminski, M. Adaptive Gradient-Based Luenberger Observer Implemented for Electric Drive with Elastic Joint. In Proceedings of the 2018 23rd International Conference on Methods & Models in Automation & Robotics (MMAR), Miedzyzdroje, Poland, 27–30 August 2018; pp. 53–58. [Google Scholar] [CrossRef]

- Szabat, K.; Orlowska-Kowalska, T. Vibration Suppression in a Two-Mass Drive System Using PI Speed Controller and Additional Feedbacks—Comparative Study. IEEE Trans. Ind. Electron. 2007, 54, 1193–1206. [Google Scholar] [CrossRef]

- Orlowska-Kowalska, T.; Kaminski, M. FPGA Implementation of the Multilayer Neural Network for the Speed Estimation of the Two-Mass Drive System. IEEE Trans. Ind. Inform. 2011, 7, 436–445. [Google Scholar] [CrossRef]

- Kazmierkowski, M.P.; Krishnan, R.; Blaabjerg, F.; Irwin, J. Control in Power Electronics: Selected Problems; Academic Press: Cambridge, MA, USA, 2002. [Google Scholar] [CrossRef]

- Bose, B.K. Power Electronics and Motor Drives: Advances and Trends; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Tarczewski, T.; Skiwski, M.; Grzesiak, L.M.; Zieliński, M. PMSM servo-drive fed by SiC MOSFETs based VSI. Power Electron. Drives 2018, 3, 35–45. [Google Scholar] [CrossRef]

- Neumayr, D.; Bortis, D.; Kolar, J.W. The essence of the little box challenge-part A: Key design challenges & solutions. CPSS Trans. Power Electron. Appl. 2020, 5, 158–179. [Google Scholar] [CrossRef]

- Siddaiah, R.; Koebel, W.J.; Cuzner, R.M. Virtual prototyping of mv & hv modular multilevel power converter using evolutionary optimization based on ρ & η. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 3532–3539. [Google Scholar] [CrossRef]

- Glatt, R.; Silva, F.; Huang, C.; Xue, L.; Wang, M.; Chang, F.; Bui, V.; Murphey, Y.L.; Su, W. Deep Symbolic Optimization for Electric Component Sizingin Fixed Topology Power Converters; Technical Report; Lawrence Livermore National Lab. (LLNL): Livermore, CA, USA, 2021. [Google Scholar]

- Guillod, T.; Papamanolis, P.; Kolar, J.W. Artificial neural network (ANN) based fast and accurate inductor modeling and design. IEEE Open J. Power Electron. 2020, 1, 284–299. [Google Scholar] [CrossRef]

- Chen, H.; Ye, S. Modeling and optimization of EMI filter by using artificial neural network. IEEE Trans. Electromagn. Compat. 2019, 61, 1979–1987. [Google Scholar] [CrossRef]

- Lopez-Garcia, T.B.; Coronado-Mendoza, A.; Domínguez-Navarro, J.A. Artificial neural networks in microgrids: A review. Eng. Appl. Artif. Intell. 2020, 95, 103894. [Google Scholar] [CrossRef]

- Kim, T.H.; Park, J.H.; Jung, K.W.; Kim, J.; Lee, E.H. Application of Convolutional Neural Network to Predict Anisotropic Effective Thermal Conductivity of Semiconductor Package. IEEE Access 2022, 10, 51995–52007. [Google Scholar] [CrossRef]

- Taheri, A.; Moghadam, M.G.; Mohammadi, M.; Passandideh-Fard, M.; Sardarabadi, M. A new design of liquid-cooled heat sink by altering the heat sink heat pipe application: Experimental approach and prediction via artificial neural network. Energy Convers. Manag. 2020, 206, 112485. [Google Scholar] [CrossRef]

- Orłowska-Kowalska, T.; Kowalski, C.T.; Dybkowski, M. Fault-diagnosis and fault-tolerant-control in industrial processes and electrical drives. In Advanced Control of Electrical Drives and Power Electronic Converters; Springer: Berlin, Germany, 2017; pp. 101–120. [Google Scholar] [CrossRef]

- Dybkowski, M.; Klimkowski, K. Artificial neural network application for current sensors fault detection in the vector controlled induction motor drive. Sensors 2019, 19, 571. [Google Scholar] [CrossRef] [PubMed]

- Yating, G.; Wu, W.; Qiongbin, L.; Fenghuang, C.; Qinqin, C. Fault diagnosis for power converters based on optimized temporal convolutional network. IEEE Trans. Instrum. Meas. 2020, 70, 1–10. [Google Scholar] [CrossRef]

- Mei, S.; Wang, Y.; Wen, G. Automatic fabric defect detection with a multi-scale convolutional denoising autoencoder network model. Sensors 2018, 18, 1064. [Google Scholar] [CrossRef]

- Biglarbegian, M.; Baharani, M.; Kim, N.; Tabkhi, H.; Parkhideh, B. Scalable reliability monitoring of GaN power converter through recurrent neural networks. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; pp. 7271–7277. [Google Scholar] [CrossRef]

- Soliman, H.; Abdelsalam, I.; Wang, H.; Blaabjerg, F. Artificial neural network based DC-link capacitance estimation in a diode-bridge front-end inverter system. In Proceedings of the 2017 IEEE 3rd International Future Energy Electronics Conference and ECCE Asia (IFEEC 2017-ECCE Asia), Kaohsiung, Taiwan, 3–7 June 2017; pp. 196–201. [Google Scholar] [CrossRef]

- Tarczewski, T.; Grzesiak, L. PMSM fed by 3-level NPC sinusoidal inverter with discrete state feedback controller. In Proceedings of the 2013 15th European Conference on Power Electronics and Applications (EPE), Lille, France, 2–6 September 2013; pp. 1–9. [Google Scholar] [CrossRef]

- Pinto, J.O.; Bose, B.K. A neural-network-based space vector PWM of a five-level voltage-fed inverter. In Proceedings of the Conference Record of the 2004 IEEE Industry Applications Conference, 2004, 39th IAS Annual Meeting, Seattle, WA, USA, 3–7 October 2004; Volume 4, pp. 2181–2187. [Google Scholar] [CrossRef]

- Saeedifard, M.; Rad, H.S.; Bakhshai, A.; Iravani, R. A fast and universal neuro-based SVM algorithm for multi-level converters. In Proceedings of the APEC 07-Twenty-Second Annual IEEE Applied Power Electronics Conference and Exposition, Anaheim, CA, USA, 25 February–1 March 2007; pp. 1508–1514. [Google Scholar] [CrossRef]

- Setiawan, D.K.; Ashari, M.; Suryoatmojo, H. Harmonics Reduction for Four-Leg Distribution Network-Connected Single Phase Transformerless PV Inverter System Using Diagonal Recurrent Neural Network. In Proceedings of the 2019 International Conference of Artificial Intelligence and Information Technology (ICAIIT), Yogyakarta, Indonesia, 13–15 March 2019; pp. 331–335. [Google Scholar] [CrossRef]

- Surus, R.; Niewiara, L.J.; Tarczewski, T.; Grzesiak, L.M. Finite control set model predictive current control for reluctance synchronous motor. In Proceedings of the 2022 IEEE 20th International Power Electronics and Motion Control Conference (PEMC), Brasov, Romania, 25–28 September 2022; pp. 235–242. [Google Scholar] [CrossRef]

- Dragičević, T.; Novak, M. Weighting factor design in model predictive control of power electronic converters: An artificial neural network approach. IEEE Trans. Ind. Electron. 2018, 66, 8870–8880. [Google Scholar] [CrossRef]

- Wang, D.; Shen, Z.J.; Yin, X.; Tang, S.; Liu, X.; Zhang, C.; Wang, J.; Rodriguez, J.; Norambuena, M. Model predictive control using artificial neural network for power converters. IEEE Trans. Ind. Electron. 2021, 69, 3689–3699. [Google Scholar] [CrossRef]

- Orlowska-Kowalska, T.; Wolkiewicz, M.; Pietrzak, P.; Skowron, M.; Ewert, P.; Tarchala, G.; Krzysztofiak, M.; Kowalski, C.T. Fault Diagnosis and Fault-Tolerant Control of PMSM Drives–State of the Art and Future Challenges. IEEE Access 2022, 10, 59979–60024. [Google Scholar] [CrossRef]

- Zhang, S.; Ye, F.; Wang, B.; Habetler, T.G. Few-Shot Bearing Fault Diagnosis Based on Model-Agnostic Meta-Learning. IEEE Trans. Ind. Appl. 2021, 57, 4754–4764. [Google Scholar] [CrossRef]

- Tallam, R.; Lee, S.; Stone, G.; Kliman, G.; Yoo, J.; Habetler, T.; Harley, R. A survey of methods for detection of stator related faults in induction machines. In Proceedings of the 4th IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives (SDEMPED), Atlanta, GA, USA, 24–26 August 2003; pp. 35–46. [Google Scholar] [CrossRef]

- Huang, W.; Du, J.; Hua, W.; Fan, Q. An open-circuit fault diagnosis method for PMSM drives using symmetrical and DC components. Chin. J. Electr. Eng. 2021, 7, 124–135. [Google Scholar] [CrossRef]

- Sobanski, P.; Kaminski, M. Application of artificial neural networks for transistor open-circuit fault diagnosis in three-phase rectifiers. IET Power Electron. 2019, 12, 2189–2200. [Google Scholar] [CrossRef]

- Gonçalves, P.F.; Cruz, S.M.; Mendes, A.M. Online Diagnostic Method for the Detection of High-Resistance Connections and Open-Phase Faults in Six-Phase PMSM Drives. IEEE Trans. Ind. Appl. 2022, 58, 345–355. [Google Scholar] [CrossRef]

- Jankowska, K.; Dybkowski, M. Experimental Analysis of the Current Sensor Fault Detection Mechanism Based on Neural Networks in the PMSM Drive System. Electronics 2023, 12, 1170. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, H.; Rizzoni, G. Fault Diagnosis for Electric Drive Systems of Electrified Vehicles Based on Structural Analysis. IEEE Trans. Veh. Technol. 2017, 66, 1027–1039. [Google Scholar] [CrossRef]

- Gou, B.; Xu, Y.; Xia, Y.; Wilson, G.; Liu, S. An Intelligent Time-Adaptive Data-Driven Method for Sensor Fault Diagnosis in Induction Motor Drive System. IEEE Trans. Ind. Electron. 2019, 66, 9817–9827. [Google Scholar] [CrossRef]

- Duer, S.; Valicek, J.; Paś, J.; Stawowy, M.; Bernatowicz, D.; Duer, R.; Walczak, M. Neural Networks in the Diagnostics Process of Low-Power Solar Plant Devices. Energies 2021, 14, 2719. [Google Scholar] [CrossRef]

- Sanchez, O.D.; Martinez-Soltero, G.; Alvarez, J.G.; Alanis, A.Y. Real-Time Neural Classifiers for Sensor Faults in Three Phase Induction Motors. IEEE Access 2023, 11, 19657–19668. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaminski, M.; Tarczewski, T. Neural Network Applications in Electrical Drives—Trends in Control, Estimation, Diagnostics, and Construction. Energies 2023, 16, 4441. https://doi.org/10.3390/en16114441

Kaminski M, Tarczewski T. Neural Network Applications in Electrical Drives—Trends in Control, Estimation, Diagnostics, and Construction. Energies. 2023; 16(11):4441. https://doi.org/10.3390/en16114441

Chicago/Turabian StyleKaminski, Marcin, and Tomasz Tarczewski. 2023. "Neural Network Applications in Electrical Drives—Trends in Control, Estimation, Diagnostics, and Construction" Energies 16, no. 11: 4441. https://doi.org/10.3390/en16114441

APA StyleKaminski, M., & Tarczewski, T. (2023). Neural Network Applications in Electrical Drives—Trends in Control, Estimation, Diagnostics, and Construction. Energies, 16(11), 4441. https://doi.org/10.3390/en16114441