Thermal-Mass and Microbiological Analysis of Forced Air Flow through the Stone Heat Accumulator Bed

Abstract

:1. Introduction

2. Materials and Methods

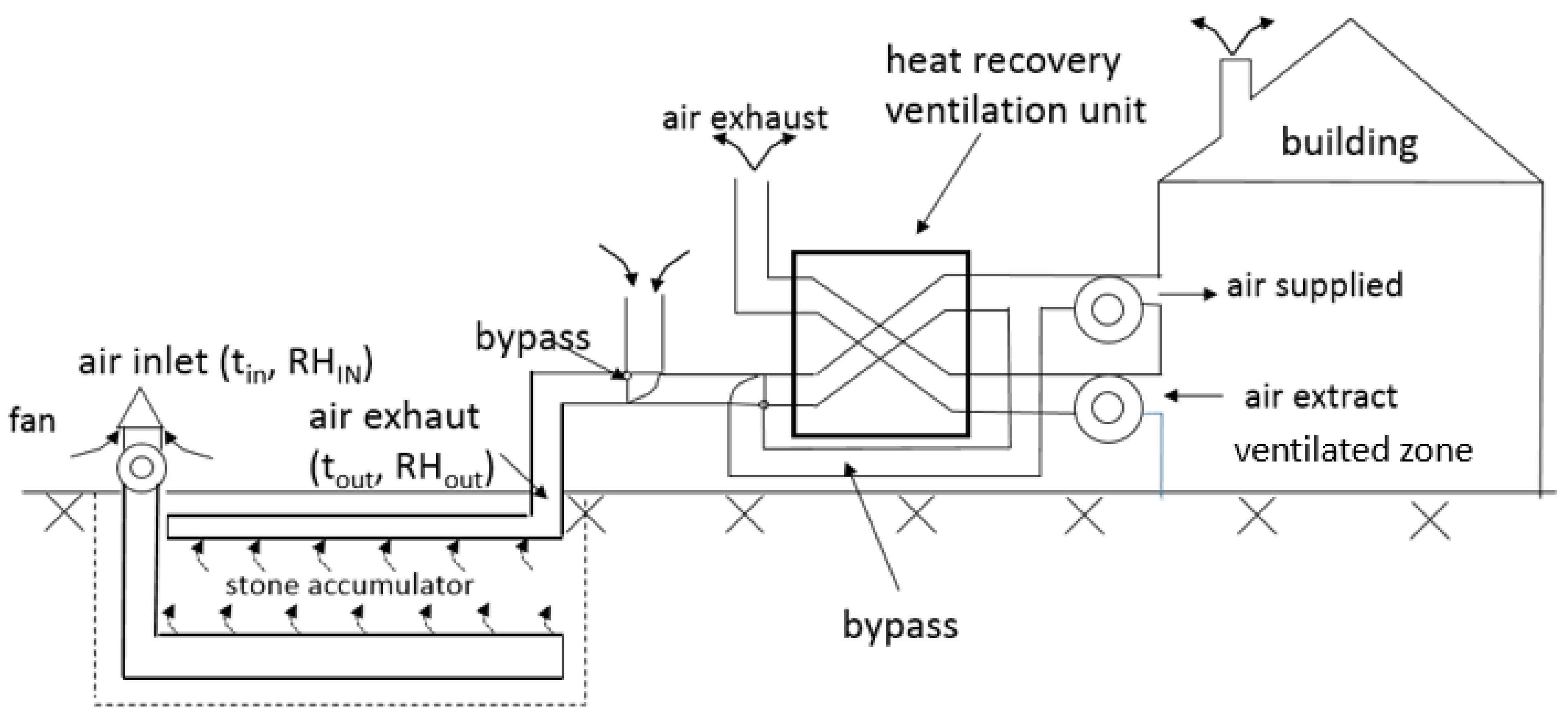

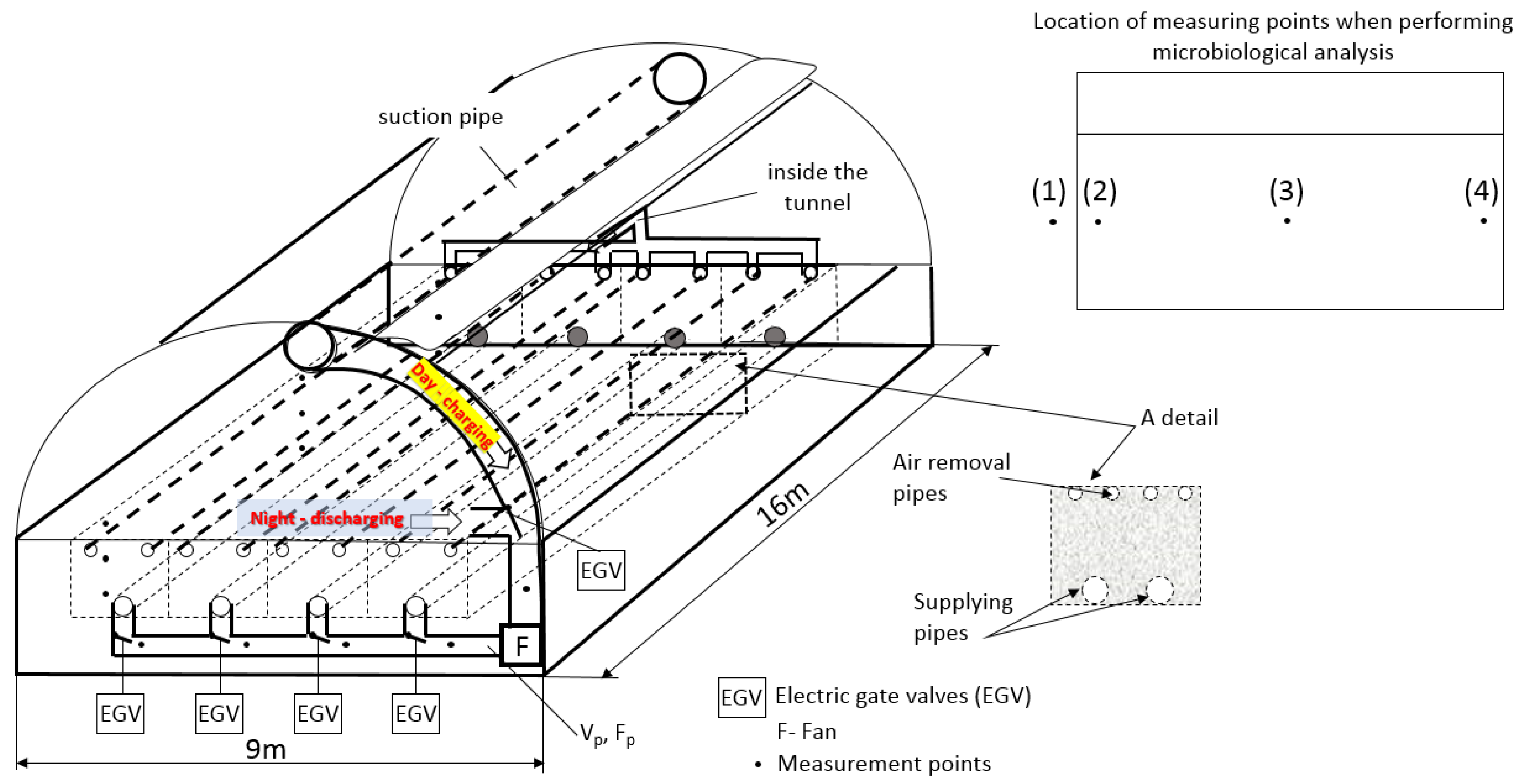

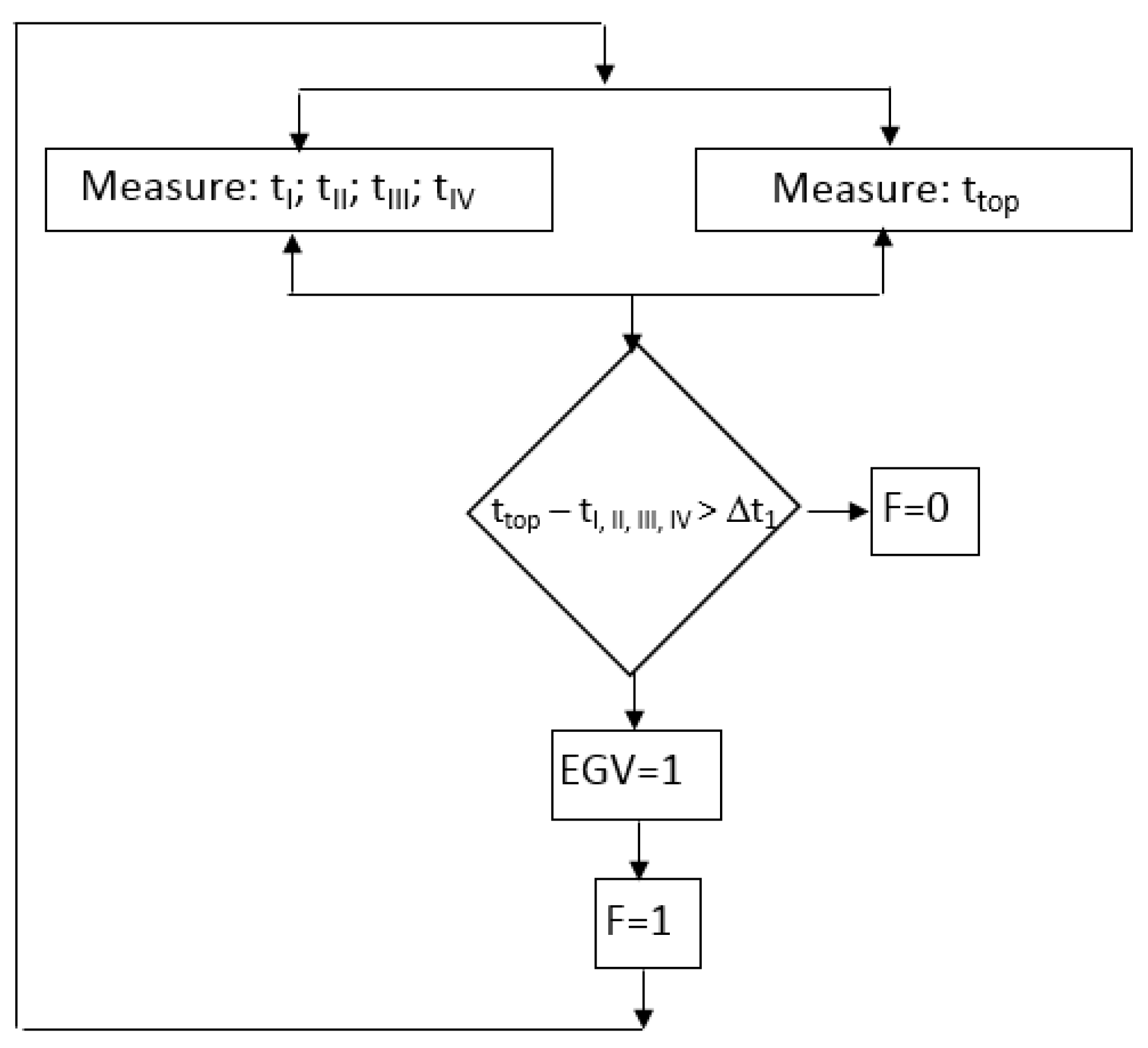

2.1. Experimental Bench in a Greenhouse—Construction and Principle of Operation of a Stone Accumulator

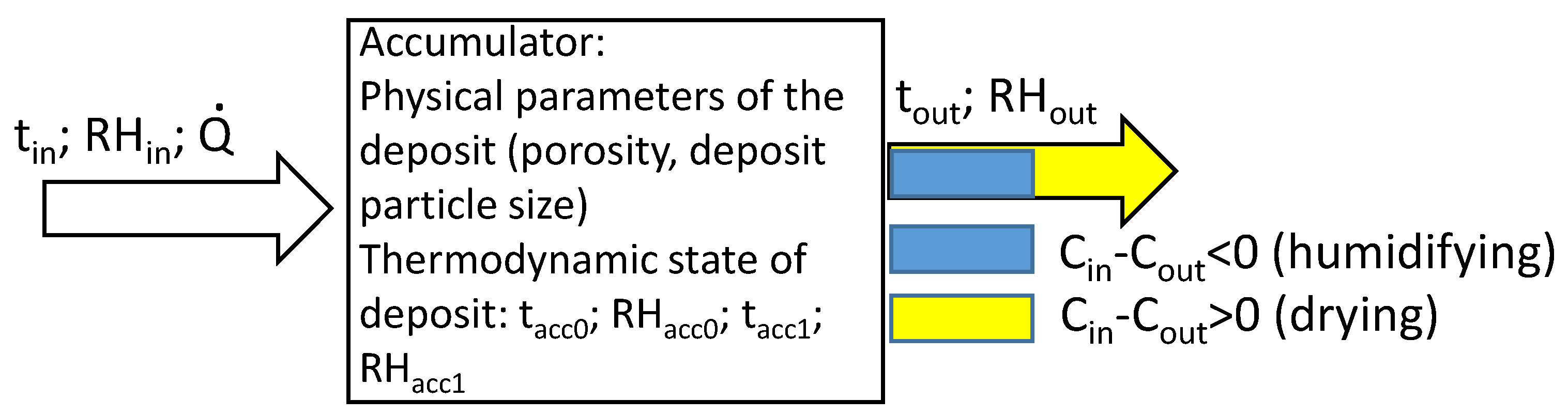

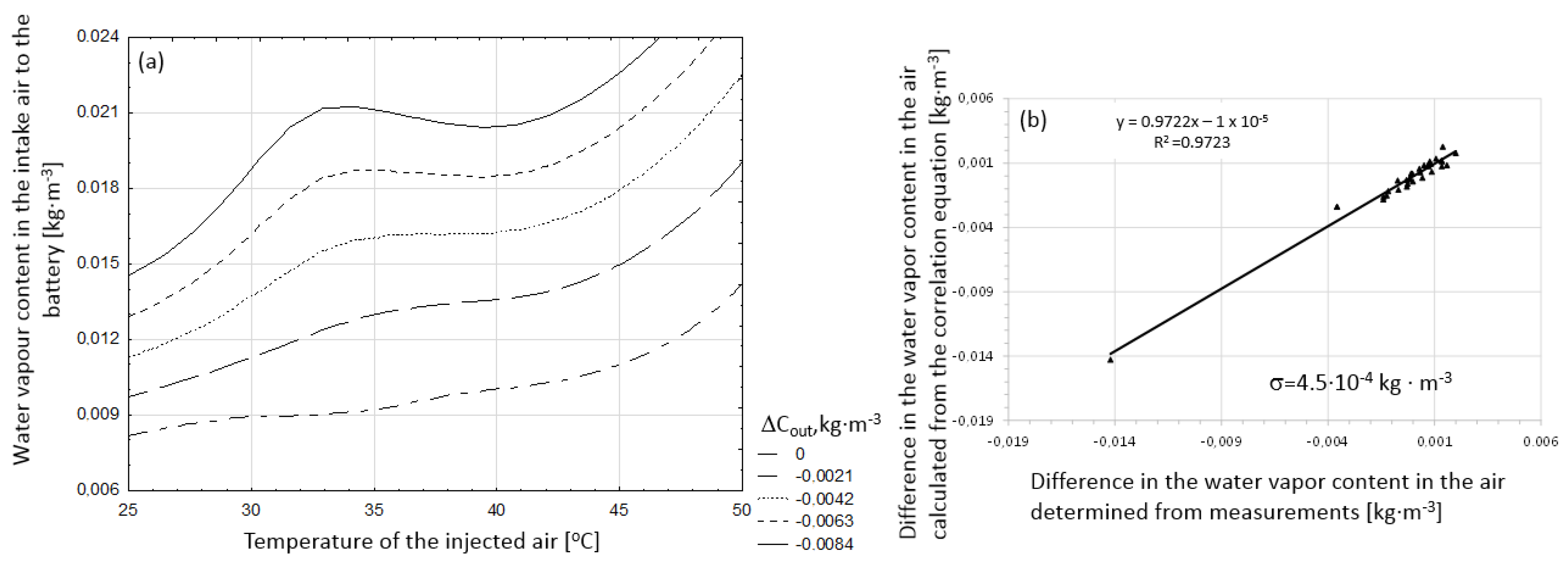

2.2. Thermal-Mass Analyses and Calculations

- Qh—heat in the accumulator as a result of the difference in air enthalpy (J)

- QL—heat in the battery as a result of water phase transition (J)

- —mass flow of water exchanged in the accumulator (kg·s−1)

- ρa—air density (kg·m−3)

- Hin, Hout—enthalpy of injected air (inlet air) (Hin) and air flowing out of the accumulator (outlet air) (Hout) (J·kg−1)

- Vair—inlet airflow (m3·s−1)

- Cin, Cout—absolute humidity of inlet (Cin) and outlet air (Cout) (kg·m−3)

2.3. Dust Concentration Analysis and Microbiological Analyses

2.4. Statistical Analysis

3. Results and Discussion

3.1. Thermo-Mass Analysis

3.2. Dust Concentration Analysis and Microbiological Analysis of the Air in the Facility

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Głowacki, J.; Kopyciński, P.; Mamica, Ł.; Malinowski, M. Identyfikacja i delimitacja obszarów gospodarki o obiegu zamkniętym w ramach ”zrównoważonej konsumpcji”. In Gospodarka o Obiegu Zamkniętym w Polityce i Badaniach Naukowych; Kulczycka, J., Ed.; Wyd. Inst. GSMiE PAN: Kraków, Poland, 2019; pp. 167–179. ISBN 978-83-955544-5-2. (In Polish) [Google Scholar]

- Kurpaska, S.; Knaga, J.; Latała, H.; Cupiał, M.; Konopacki, P.; Hołownicki, R. The comparison of different types of heat accumulators and benefits of their use in horticulture. Sensors 2020, 20, 1417. [Google Scholar] [CrossRef]

- Tripathi, L.; Mishra, A.K.; Dubey, A.K.; Tripathi, C.B.; Baredar, P. Renewable energy: An overview on its contribution in current energy scenario of India. Renew. Sustain. Energy Rev. 2016, 60, 226–233. [Google Scholar] [CrossRef]

- Bottero, M.; Dell’Anna, F.; Morgese, V. Evaluating the Transition Towards Post-Carbon Cities: A Literature Review. Sustainability 2021, 13, 567. [Google Scholar] [CrossRef]

- Kania, G.; Kwiecień, K.; Malinowski, M.; Gliniak, M. Analyses of the Life Cycles and Social Costs of CO2 Emissions of Single-Family Residential Buildings: A Case Study in Poland. Sustainability 2021, 13, 6164. [Google Scholar] [CrossRef]

- Księżopolski, K.; Drygas, M.; Pronińska, K.; Nurzyńska, I. The Economic Effects of New Patterns of Energy Efficiency and Heat Sources in Rural Single-Family Houses in Poland. Energies 2020, 3, 6358. [Google Scholar] [CrossRef]

- Pater, S.; Magiera, J. Ocena zapotrzebowania na energię budynku mieszkalnego przy wykorzystaniu dwóch niezależnych programów obliczeniowych. Tech. Chem. 2011, 108, 165–184. (In Polish) [Google Scholar]

- Agarwal, M.; Agarwal, G.D. Heat storage materials, geometry and applications: A review. J. Energy Inst. 2017, 90, 1–11. [Google Scholar] [CrossRef]

- Misztal, K. Odnawialne źródła energii na terenie Polski. In W kierunku Gospodarki o Obiegu Zamkniętym. Perspektywa miast; Kulczycka, J., Ed.; Wyd. MSAP: Kraków, Poland, 2017; pp. 125–135. ISBN 978–83–89410–38–2. [Google Scholar]

- Jastrzębski, P.; Saługa, P.W. Simulation of the use of a heat accumulator in combined heat and power plants. Energy Pol. J. 2018, 21, 75–88. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.; Wagner, N.; Gorini, R. The role of renewable energy in the global energy transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Khan, M.I.; Khan, I.A.; Chang, Y.-C. An overview of global renewable energy trends and current practices in Pakistan—A perspective of policy implications. Renew. Sustain. Energy Rev. 2020, 12, 056301. [Google Scholar] [CrossRef]

- Sacharczuk, J.; Taler, D. A concrete heat accumulator for use in solar heating systems—A mathematical model and experimental verification. Arch. Thermodyn. 2014, 35, 281–295. [Google Scholar]

- Sarbu, I.; Sebarchievici, C. A Comprehensive Review of Thermal Energy Storage. Sustainability 2018, 10, 191. [Google Scholar] [CrossRef]

- Stanisz, K.; Gomuła, S. Evolution of the coefficient of performance of the heat pump in conjunction with heat batteries of different capacities. JCEEA 2015, 32, 419–427. [Google Scholar] [CrossRef]

- Dinker, A. Statistical Analyses. Energy Consumption in Households in 2018; Zakł Wyd Stat GUS: Warszawa, Poland, 2019; ISSN 2084-8137. (In Polish) [Google Scholar]

- Jastrzębski, P.; Saługa, P.W. Innovative methods of heat storage. Zesz Nauk. Inst. Gosp. Sur. Min. Energ. PAN 2018, 105, 225–232. (In Polish) [Google Scholar] [CrossRef]

- Mania, T.; Kawa, J. Inżynieria Instalacji Magazynowania Energii Ciepła; Mroziński, A., Ed.; Wyd Grafpol: Bydgoszcz, Poland, 2016; ISBN 978-83-64423-37-6. (In Polish) [Google Scholar]

- Ma, Z.; Glatzmaier, G.C.; Kutscher, C.F. Thermal Energy Storage and its Potential Applications in Solar Thermal Power Plants and Electricity Storage. In Proceedings of the ASME 5th International Conference on Energy Sustainability, Washington, DC, USA, 7–10 August 2011; pp. 447–456. [Google Scholar] [CrossRef]

- Krasnov, A.S.; Zimenkova, T.S.; Kaznacheev, S.A.; Aksenov, N.A. Application of thermal accumulator with solid heat accumulating material as a method of cooling of life support and freight protection systems for vacuum magnetic levitation transport. Transp. Syst. Technol. 2018, 4, 43–57. [Google Scholar] [CrossRef]

- COM 640 Final. Communication from the Commission to the European Parliament, the European Council, the Council, the Economic and Social Committee and the Committee of the Regions. 2019. Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/?uri=CELEX%3A52019DC0640 (accessed on 11 July 2021).

- Lim, Y.-H.; Yun, H.-W.; Song, D. Indoor Environment Control and Energy Saving Performance of a Hybrid Ventilation System for a Multi-residential Building. 6th International Building Physics Conference. Energy Procedia 2015, 78, 2863–2868. [Google Scholar] [CrossRef]

- Knissel, J.; Peußner, D. Energy efficient heat exchanger for ventilation systems. Energy Build. 2017, 159, 246–253. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Q.; Zhai, Z.J.; Ma, X. Potential of ventilation systems with thermal energy storage using PCMs applied to air conditioned buildings. Renew. Energy 2019, 138, 39–53. [Google Scholar] [CrossRef]

- Lapertot, A.; Cuny, M.; Kadoch, B.; Le Métayera, O. Optimization of an earth-air heat exchanger combined with a heat recovery ventilation for residential building needs. Energy Build. 2021, 235, 110702. [Google Scholar] [CrossRef]

- Gun, G. Dynamic interactions between the ground heat exchanger and environments in earth–air tunnel ventilation of buildings. Energy Build. 2014, 85, 12–22. [Google Scholar] [CrossRef]

- Hołownicki, R.; Konopacki, P.; Kurpaska, S.; Latała, H.; Broniarek, R.; Rutkowski, K.; Treder, W.; Nowak, J. A Way of Using Natural Heat Energy in a Heat Accumulator and a Heat Accumulator. Patent PL 220435 B1, 7 September 2012. Available online: https://ewyszukiwarka.pue.uprp.gov.pl/search/pwp-details/P.400690 (accessed on 1 April 2020). (In Polish).

- Kurpaska, S.; Kiełbasa, P.; Sobol, Z.; Tabor, S.; Gliniak, M.; Bojdo, K. Analysis of air flow resistance through a porous stone bed. Biosyst. Eng. 2020, 198, 323–337. [Google Scholar] [CrossRef]

- Kurpaska, S.; Latała, H.; Rutkowski, K.; Hołownicki, R.; Konopacki, P.; Nowak, J.; Treder, W. Storing heat surplus from a plastic tunnel in a rock—Bed storage. Inż. Roln. 2012, 2, 157–167. [Google Scholar]

- Sharpe, T.; McGill, G.; Dancer, S.J.; King, M.F.; Fletcher, L.; Noakes, C.J. Influence of ventilation use and occupant behaviour on surface microorganisms in contemporary social housing. Sci. Rep. 2020, 10, 11841. [Google Scholar] [CrossRef] [PubMed]

- Sivasubramani, S.K.; Niemeier, R.T.; Reponen, T.; Grinshpun, A. Fungal spore source strength tester: Laboratory evaluation of a new concept. Sci. Total. Environ. 2004, 329, 75–86. [Google Scholar] [CrossRef] [PubMed]

- Augustynowicz, J.; Nierebiński, M.; Jóźwiak, A.; Prędecka, A.; Russel, S. Wpływ podstawowych parametrów fizykochemicznych na liczbę bakterii psychofilnych i mezofilnych w wodach rzeki Wisły. Woda-Sr.-Obsz. Wiej. 2017, 17, 5–13. (In Polish) [Google Scholar]

- Brock, T.D.; Rose, A.H. Chapter VII Psychrophiles and Thermophiles. In Methods in Microbiology; Norris, J.R., Robbons, D.W., Eds.; Academic Press: Cambridge, MA, USA, 1969; Volume 3B, pp. 161–168. [Google Scholar] [CrossRef]

- Frąk, M.; Majewski, G.; Zawistowska, K. Analysis of the quantity of microorganisms adsorbed on particulate matter PM10. Sci. Rev. Eng. Environ. Sci. 2014, 64, 140–149. [Google Scholar]

- Wolny-Koładka, K.; Malinowski, M. Assessment of the microbiological contamination of air in a municipal solid waste treatment company. Ecol. Chem. Eng. Ser. A 2015, 22, 175–183. [Google Scholar] [CrossRef]

- Wolny-Koładka, K.; Malinowski, M.; Pieklik, A.; Kurpaska, S. Microbiological air contamination in university premises and the evaluation of drug resistance of staphylococci occurring in the form of a bioaerosol. Indoor Built. Environ. 2019, 28, 235–246. [Google Scholar] [CrossRef]

- Adam, R.I.; Bhangar, S.; Pasut, W.; Arens, E.A.; Taylor, J.W.; Lindow, S.E.; Nazaroff, W.W.; Bruns, T.D. Correction: Chamber Bioaerosol Study: Outdoor Air and Human Occupants as Sources of Indoor Airborne Microbes. PLoS ONE 2015, 10, e0133221. [Google Scholar] [CrossRef]

- Konopacki, P.; Hołownicki, R.; Sabat, R.; Kurpaska, S.; Latała, H. Storage of heat in a stone battery. Inż. Roln. 2012, 2, 113–121. [Google Scholar]

- Hansen, V.M.; Winding, A.; Madsen, A.M. Exposure to bioaerosols during the growth season of tomatoes in an organic greenhouse using Supresivit (Trichoderma harzianum) and Mycostop (Streptomyces griseoviridis). Appl. Environ. Microbiol. 2010, 76, 5874–5881. [Google Scholar] [CrossRef] [PubMed]

- Monso, E.; Magarolas, R.; Badorrey, I.; Radon, K.; Nowak, D.; Morera, J. Occupational asthma in greenhouse flower and ornamental plant growers. Am. J. Respir. Crit. Care Med. 2002, 165, 954–960. [Google Scholar] [CrossRef] [PubMed]

- Madsen, A.M.; Tendal, K.; Thilsing, T.; Frederiksen, M.W.; Baelum, J.; Hansen, J.V. β-glucan, and bacteria in nasal lavage of greenhouse workers and their relation to occupational exposure. Ann. Occup. Hyg. 2013, 57, 1030–1040. [Google Scholar] [CrossRef] [PubMed]

- Kozdrój, J. Metagenoms—A source of new information on soil micro-organisms. Post. Mikrobiol. 2013, 52, 185–200. (In Polish) [Google Scholar]

- Marcazzan, G.M.; Vaccaro, S.; Valli, G.; Vecchi, R. Characterisation of PM10 and PM2.5 particulate matter in the ambient air of Milan, Italy. Atmos. Environ. 2001, 35, 4639–4650. [Google Scholar] [CrossRef]

- The Polish Government. Regulation of the Minister of the Environment on the concentrations of selected substances in ambient air. J. Laws. 2012; 1031. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20120001031/O/D20121031.pdf (accessed on 31 March 2020). (In Polish)

- PN-Z-04008-08; Ochrona Czystości Powietrza. Pobieranie Próbek. Pobieranie Próbek Powietrza Atmosferycznego (imisja) do Badań Mikrobiologicznych Metodą Aspiracyjną i Sedymentacyjną. Polski Komitet Normalizacyjny: Warszawa, Poland, 1989. (In Polish)

- Operator’s Manual MAS-100TM professional Microbial Air Monitoring System for the Microbiological Testing of Air. Brussels, Belgium. Available online: https://archive-resources.coleparmer.com/Manual_pdfs/39182-90,-82.pdf (accessed on 31 March 2020).

- Bohme, K.; Fernandez-No, I.C.; Barros-Velazquez, J.; Gallardo, J.M.; Calo-Mata, P.; Cañas, B. Species differentiation of seafood spoilage and pathogenic Gram-negative bacteria by MALDI-TOF mass fingerprinting. J. Proteome. Res. 2010, 9, 3169–3183. [Google Scholar] [CrossRef]

- Seng, P.; Rolain, J.M.; Fournier, P.E.; La Scola, B.; Drancourt, M.; Raoult, D. MALDI-TOF-mass spectrometry applications in clinical microbiology. Future Microbiol. 2010, 5, 1733–1754. [Google Scholar] [CrossRef]

- Croxatto, A.; Prod’hom, G.; Greub, G. Applications of MALDI-TOF mass spectrometry in clinical diagnostic microbiology. FEMS Microbiol. Rev. 2012, 36, 380–407. [Google Scholar] [CrossRef]

- Kosikowska, U.; Stępień-Pyśniak, D.; Pietras-Ożga, D.; Andrzejczuk, J.; Juda, M.; Malm, A. Application of MALDI-TOF MS for identification of clinical isolates of bacteria from humans and animals. Diagn. Lab. 2015, 51, 23–30. (In Polish) [Google Scholar] [CrossRef]

- Attar, I.; Naili, N.; Khalifa, N.; Hazami, M.; Lazaar, M.; Farhat, A. Experimental study of an air conditioning system to control a greenhouse microclimate. Energy Convers. Manag. 2014, 79, 543–553. [Google Scholar] [CrossRef]

- Ozgener, L.; Ozgener, O. Energetic performance test of an underground air tunnel system for greenhouse heating. Energy 2010, 35, 4079–4085. [Google Scholar] [CrossRef]

- Paksoy, H.; Beyhan, B. Thermal energy storage (TES) systems for greenhouse technology. In Advances in Thermal Energy Storage Systems: Methods and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2014; pp. 433–548. [Google Scholar] [CrossRef]

- Llorach-Massana, P.; Peña, J.; Rieradevall, J.; Montero, J.I. Analysis of the technical, environmental and economic potential of phase change materials (PCM) for root zone heating in Mediterranean greenhouses. Renew. Energy 2017, 103, 570–581. [Google Scholar] [CrossRef]

- Kurpaska, S.; Latała, H.; Kiełbasa, P.; Sporysz, M.; Gliniak, M.; Famielec, S.; Łapczyńska-Kordon, B. Experimental and modeling approach to heat and mass transfer in a porous bed of a rock-bed heat accumulator. Int. J. Heat Mass. Transfer. 2021, 179, 121654. [Google Scholar] [CrossRef]

- PN-89/Z-04111/02; Ochrona Czystości Powietrza. Badania Mikrobiologiczne. Oznaczanie Liczby Bakterii w Powietrzu Atmosferycznym (Imisja) Przy Pobieraniu Próbek Metodą Aspiracyjną i Sedymentacyjną. Polski Komitet Normalizacyjny: Warszawa, Poland, 1989. (In Polish)

- PN-89/Z-04111/03; Ochrona Czystości Powietrza. Badania Mikrobiologiczne. Oznaczanie Liczby Grzybów Mikroskopowych w Powietrzu Atmosferycznym (Imisja) Przy Pobieraniu Próbek Metodą Aspiracyjną i Sedymentacyjną. Polski Komitet Normalizacyjny: Warszawa, Poland, 1989. (In Polish)

- Gandara, A.; Mota, L.C.; Flores, C.; Perez, H.R.; Green, C.F.; Gibbs, S.G. Isolation of Staphylococcus aureus and antibiotic-resistant Staphylococcus aureus from residential indoor bioaerosols. Environ. Health Perspect. 2006, 114, 1859–1864. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.Y.; Kim, C.N. Airborne microbiological characteristics in public buildings of Korea. Build Environ. 2007, 42, 2188–2196. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, Y. Characteristics of antibiotic resistance of airborne Staphylococcus isolated from metro stations. Int. J. Environ. Res. Public Health 2013, 10, 2412–2426. [Google Scholar] [CrossRef]

- Li, X.; Qiu, Y.; Yu, A.; Shi, W.; Chen, G.; Zhang, Z.; Liu, D. Characteristics of airborne Staphylococcus aureus (including MRSA) in Chinese public buildings. Aerobiologia 2015, 31, 11–19. [Google Scholar] [CrossRef]

- Górny, R.L.; Dutkiewicz, J. Bacterial and fungal aerosols in indoor environment in Central and Eastern European countries. Ann. Agric. Environ. Med. 2002, 9, 17–23. [Google Scholar]

- Lee, J.H.; Jo, W.K. Characteristics of indoor and outdoor bioaerosols at Korean high-rise apartment buildings. Environ. Res. 2006, 101, 11–17. [Google Scholar] [CrossRef]

- Kozdrój, J.; Fraczek, K.; Ropek, D. Assessment of bioaerosols in indoor air of glasshouses located in a botanical garden. Build Environ. 2019, 166, 106436. [Google Scholar] [CrossRef]

| Symbol | Description | Day of Sampling |

|---|---|---|

| A | Before starting up the greenhouse | 0 |

| B | After start-up and achieving maximum fan efficiency | 0 |

| C | After 1 week of fan operation | 7 |

| D | After 2 weeks of fan operation | 15 |

| E | After 3 weeks of fan operation | 21 |

| F | After one month (4 weeks) of continuous operation of the greenhouse fans | 28 |

| Bacteria | Fungi | Actinomycetes | Degree of Air Pollution |

|---|---|---|---|

| <1000 | 3000–5000 | <10 | unpolluted |

| 1000–3000 | 5000–10,000 | 10–100 | moderately polluted |

| >3000 | >10,000 | >100 | heavily polluted |

| Date of Sampling | Sampling Point | |||

|---|---|---|---|---|

| 1 (Control) | 2 | 3 | 4 | |

| Bacteria | ||||

| A | 23 ab | 50 ab | 67 ab | 113 abc |

| B | 7 a | 37 ab | 43 ab | 80 ab |

| C | 170 abc | 97 ab | 180 abc | 260 abc |

| D | 30 ab | 60 ab | 88 ab | 129 abc |

| E | 15 a | 47 ab | 67 ab | 90 ab |

| F | 155 abc | 107 ab | 210 abc | 273 abc |

| Fungi | ||||

| A | 1227 a | 670 a | 740 a | 980 a |

| B | 1660 ab | 983 a | 1567 ab | 1963 ab |

| C | 2543 ab | 1040 a | 1747 ab | 1273 a |

| D | 2003 ab | 980 a | 1940 ab | 1503 ab |

| E | 1567 ab | 940 a | 800 a | 1010 a |

| F | 1789 ab | 983 a | 1090 a | 1665 ab |

| Actinomycetes | ||||

| A | 3 a | 0 a | 0 a | 3 a |

| B | 0 a | 3 a | 23 * ab | 17 * ab |

| C | 7 a | 7 a | 7 a | 7 a |

| D | 0 a | 8 a | 4 a | 0 a |

| E | 0 a | 5 a | 0 a | 3 a |

| F | 5 a | 0 a | 3 a | 5 a |

| Staphylococci | ||||

| A | 3 a | 37 ab | 7 a | 0 a |

| B | 0 a | 0 a | 7 a | 13 a |

| C | 10 a | 3 a | 13 a | 47 ab |

| D | 4 a | 41 ab | 7 a | 54 ab |

| E | 0 a | 6 a | 7 a | 11 a |

| F | 8 a | 3 a | 15 a | 0 a |

| Date of Sampling | Sampling Point | |||

|---|---|---|---|---|

| PM10 | 1 (control) | 2 | 3 | 4 |

| A | 22 a | 45 * ab | 42 * ab | 47 * ab |

| B | 32 a | 62 * ab | 58 * ab | 57 * ab |

| C | 37 a | 51 * ab | 53 * ab | 48 * ab |

| D | 25 a | 41* ab | 43* ab | 45* ab |

| E | 30 a | 38 a | 37 a | 39 a |

| F | 26 a | 29 a | 33 a | 32 a |

| PM2.5 | 1 (control) | 2 | 3 | 4 |

| A | 21 * a | 32 * a | 37 * a | 33 * a |

| B | 30 * a | 46 * ab | 46 * ab | 43 * ab |

| C | 33 * a | 52 * ab | 49 * ab | 48 * ab |

| D | 37 * a | 37 * a | 40 * ab | 45 * ab |

| E | 33 * a | 33 * a | 30 * a | 29 * a |

| F | 30 * a | 29 * a | 28 * a | 30 * a |

| T (°C) | 1 (control) | 2 | 3 | 4 |

| A | 15.1 a | 27 a | 29.7 a | 33.3 a |

| B | 24.7 b | 30.5 a | 27.6 a | 27.7 b |

| C | 19.6 a | 26.5 a | 28.5 a | 29.4 b |

| D | 28 b | 31.9 b | 30.5 b | 31.2 b |

| E | 29.5 b | 36.9 b | 35 b | 34.5 b |

| F | 22.4 a | 25.5 a | 24.3 a | 23.2 a |

| T (°C) mean | 23.2 a | 29.7 b | 29.3 b | 29.9 b |

| RH (%) | 1 (control) | 2 | 3 | 4 |

| A | 70 a | 9 b | 11 a | 12 a |

| B | 60 a | 12 b | 15 a | 17 a |

| C | 49 a | 42 a | 38 b | 45 b |

| D | 58 a | 28 b | 30 b | 31 b |

| E | 74 a | 26 b | 27 b | 24 a |

| F | 80 a | 19 a | 20 a | 22 a |

| RH (%) mean | 65.2 | 22.6 | 23.5 | 25.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurpaska, S.; Wolny-Koładka, K.; Malinowski, M.; Tomaszek, K.; Latała, H. Thermal-Mass and Microbiological Analysis of Forced Air Flow through the Stone Heat Accumulator Bed. Energies 2023, 16, 4456. https://doi.org/10.3390/en16114456

Kurpaska S, Wolny-Koładka K, Malinowski M, Tomaszek K, Latała H. Thermal-Mass and Microbiological Analysis of Forced Air Flow through the Stone Heat Accumulator Bed. Energies. 2023; 16(11):4456. https://doi.org/10.3390/en16114456

Chicago/Turabian StyleKurpaska, Sławomir, Katarzyna Wolny-Koładka, Mateusz Malinowski, Klaudia Tomaszek, and Hubert Latała. 2023. "Thermal-Mass and Microbiological Analysis of Forced Air Flow through the Stone Heat Accumulator Bed" Energies 16, no. 11: 4456. https://doi.org/10.3390/en16114456