On the Increase in the Renewable Fraction in Diesel Blends using Aviation Fuel in a Common Rail Engine

Abstract

1. Introduction

2. Experimental Setup and Engine Tests

2.1. Test Apparatus

2.2. Fuels and Tests

- −

- D60B40: 60% diesel+, 40% WCO biodiesel;

- −

- D70B30: 70% diesel+, 30% WCO biodiesel;

- −

- D80K20: 80% diesel+, 20% Jet A;

- −

- D90K10: 50% diesel+, 10% Jet A;

- −

- D50B40K10: 50% diesel+, 40% WCO biodiesel, 10% Jet A;

- −

- D50B30K20: 50% diesel+, 30% WCO biodiesel, 20 % Jet A.

3. Results

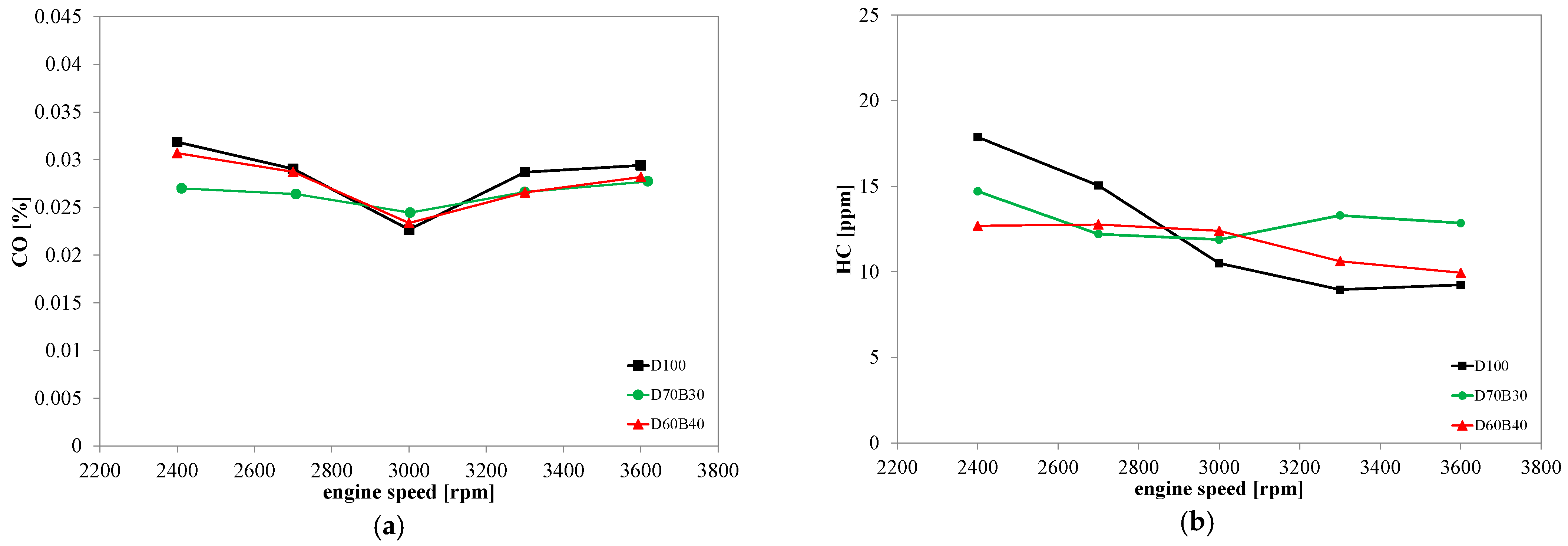

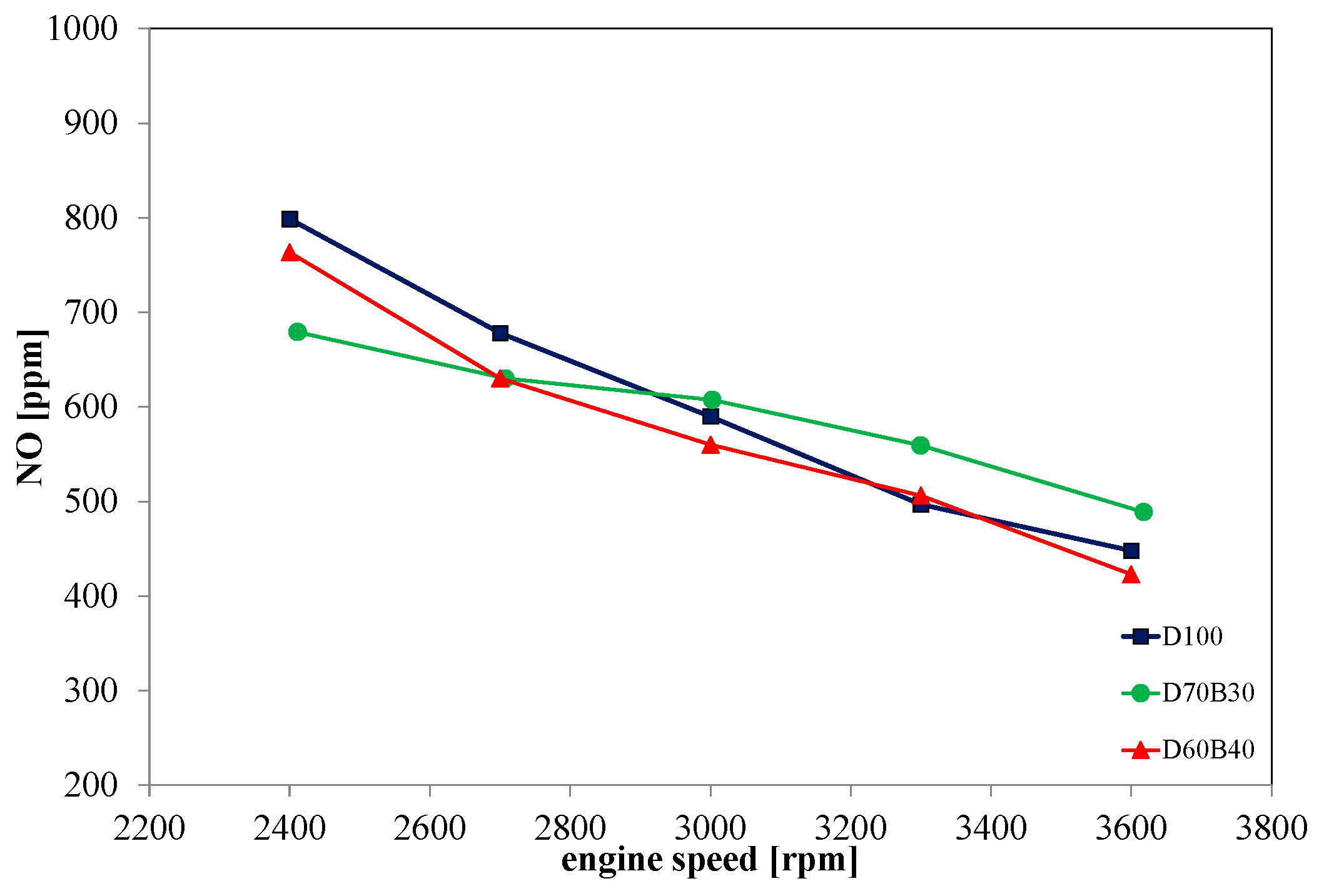

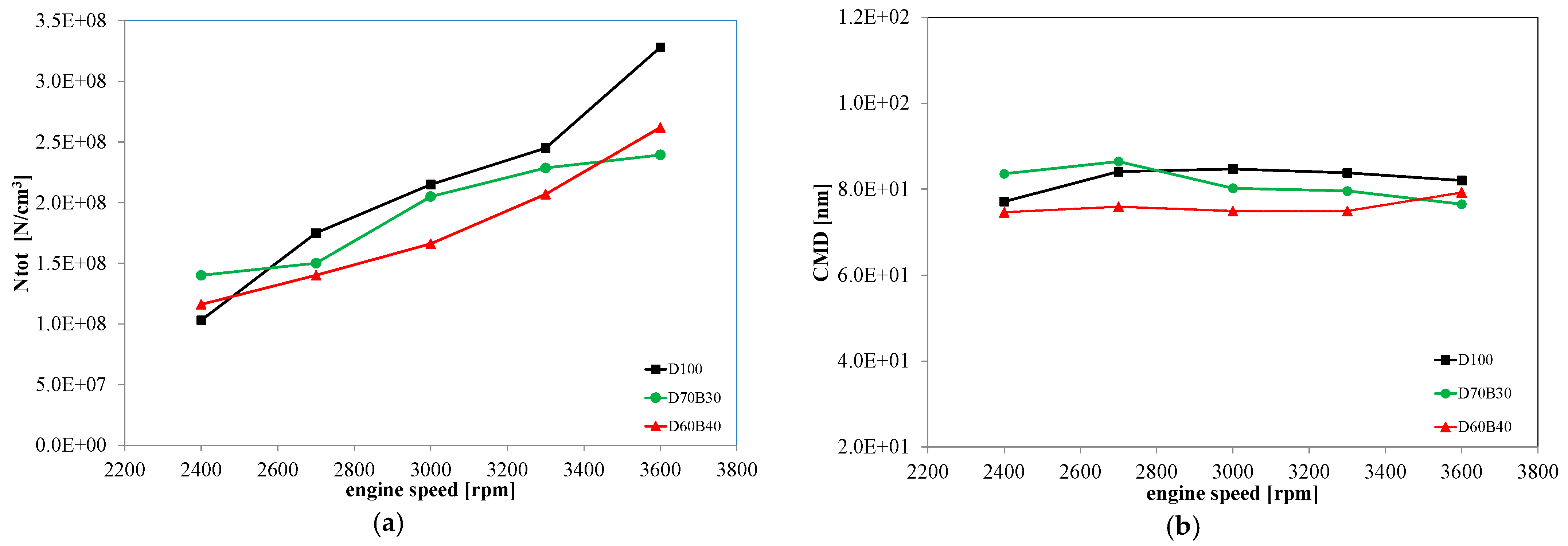

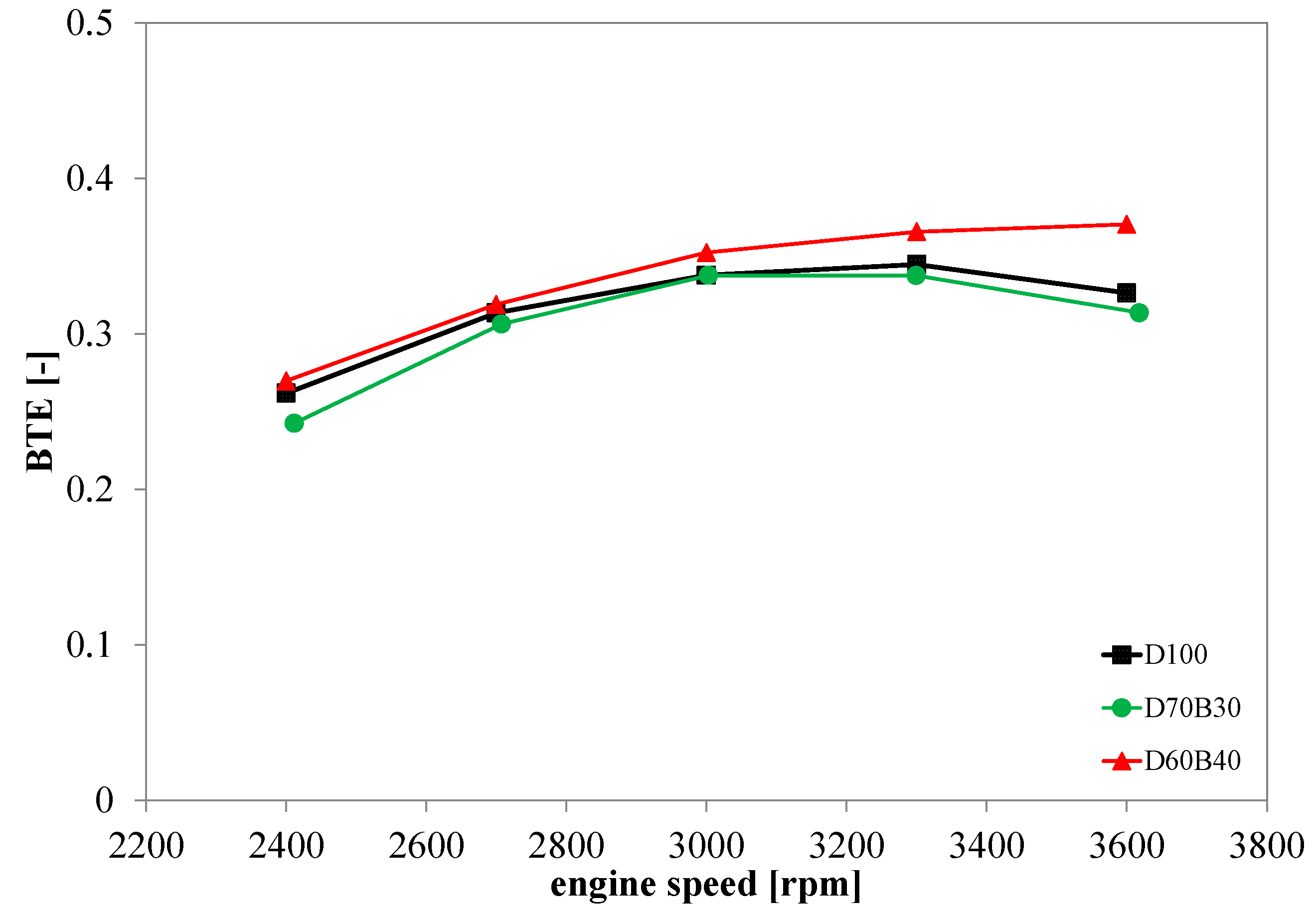

3.1. Diesel+ Blended with Biodiesel from WCO

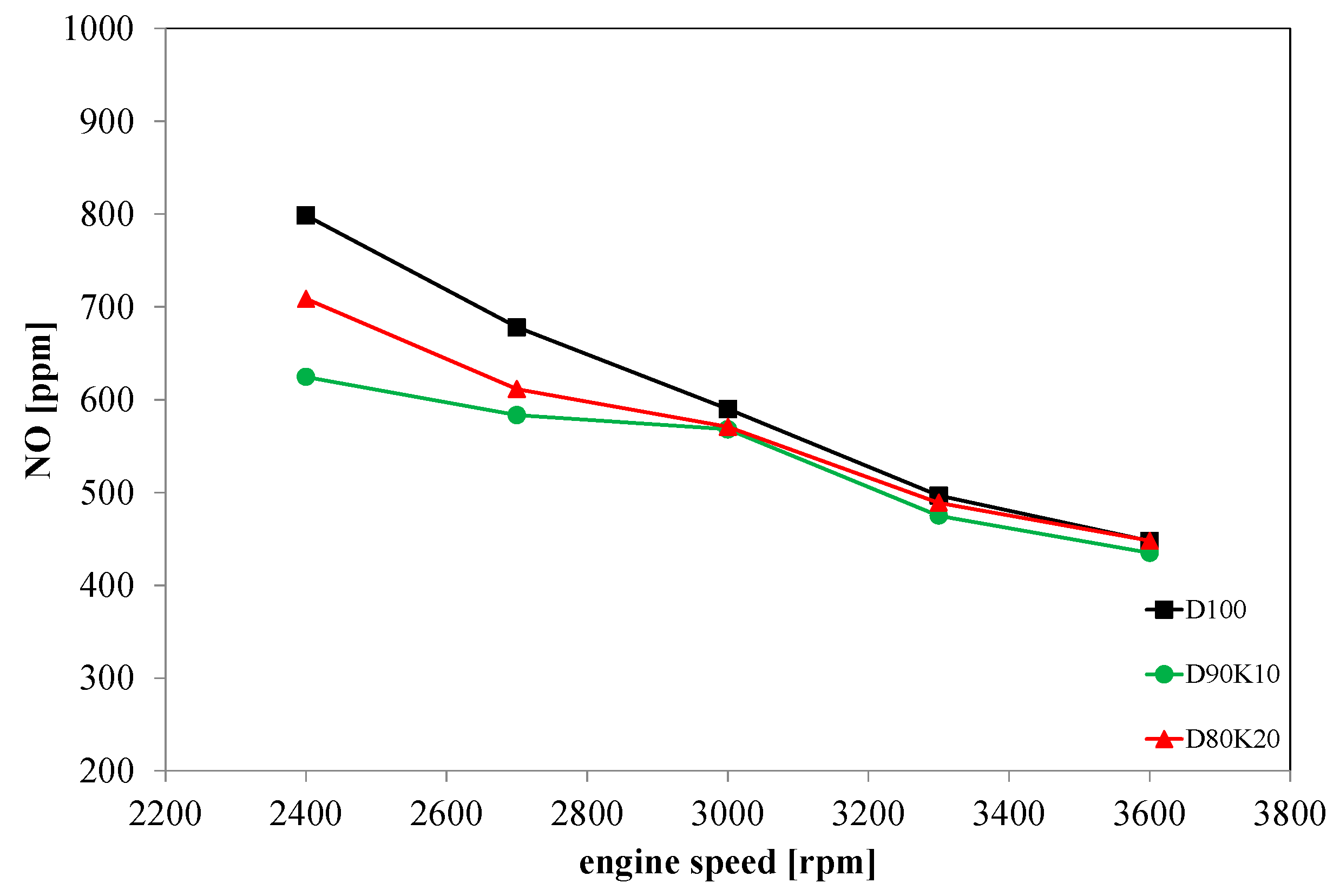

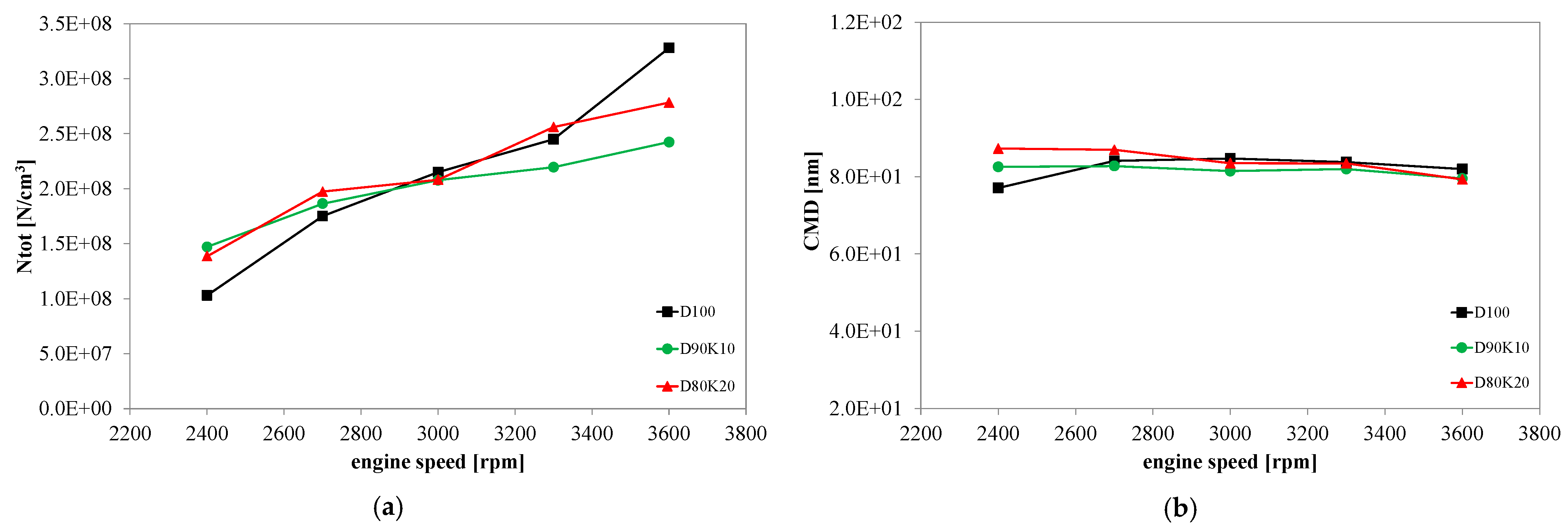

3.2. Diesel+ Blended with Jet A

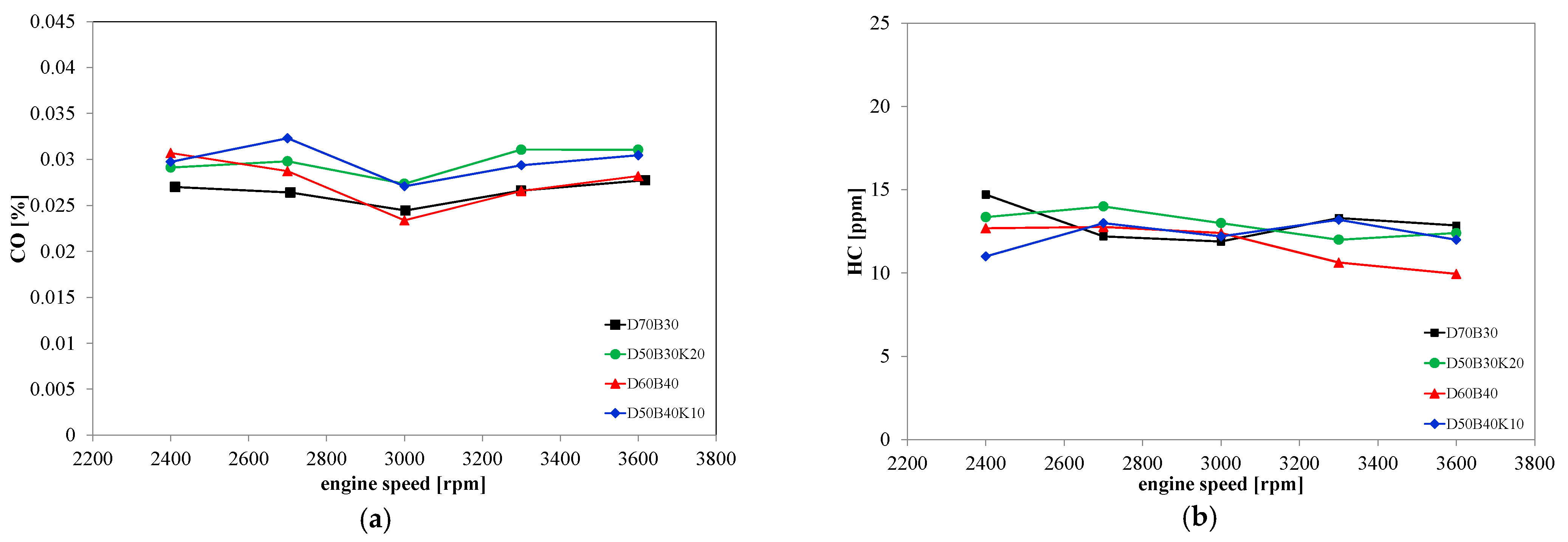

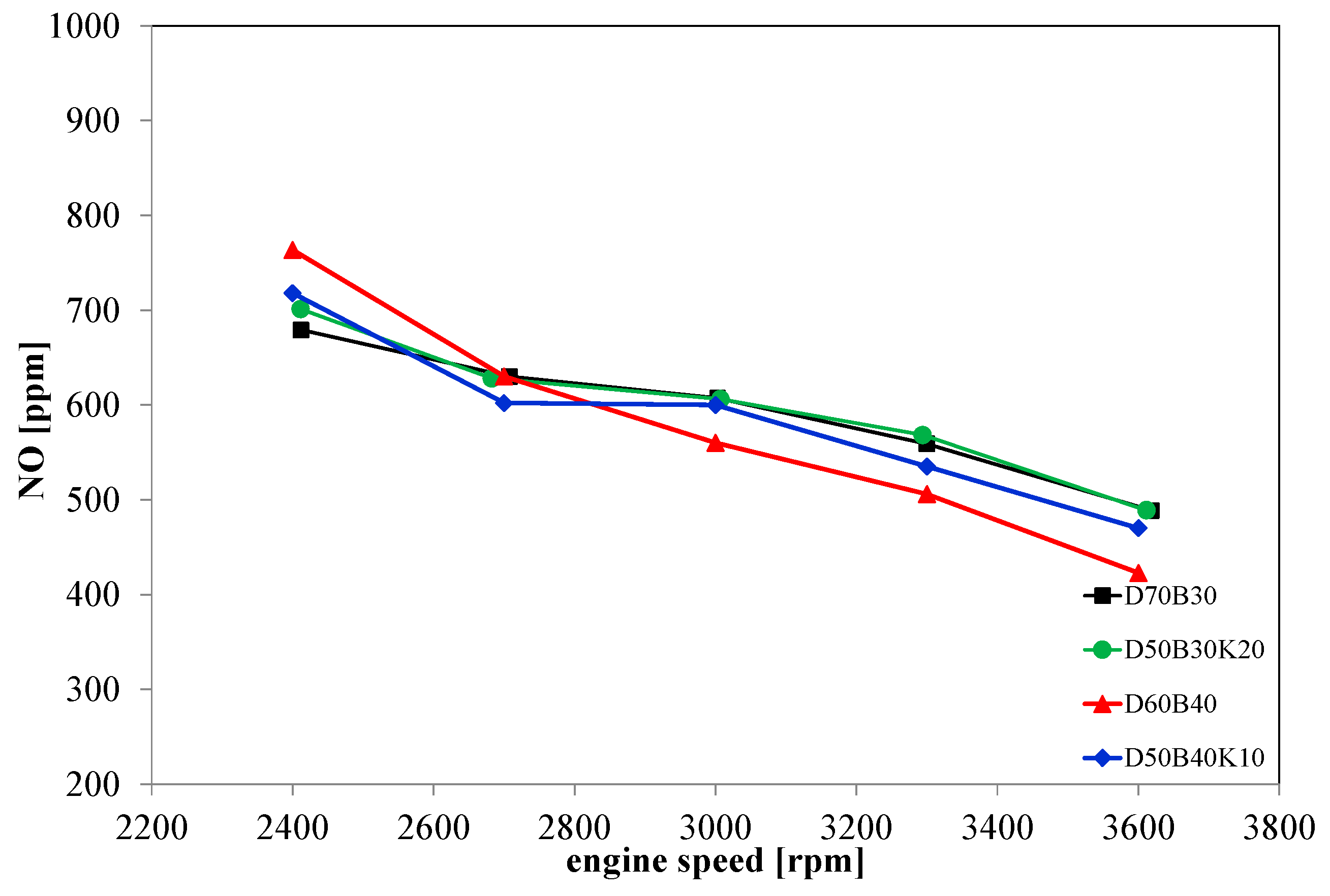

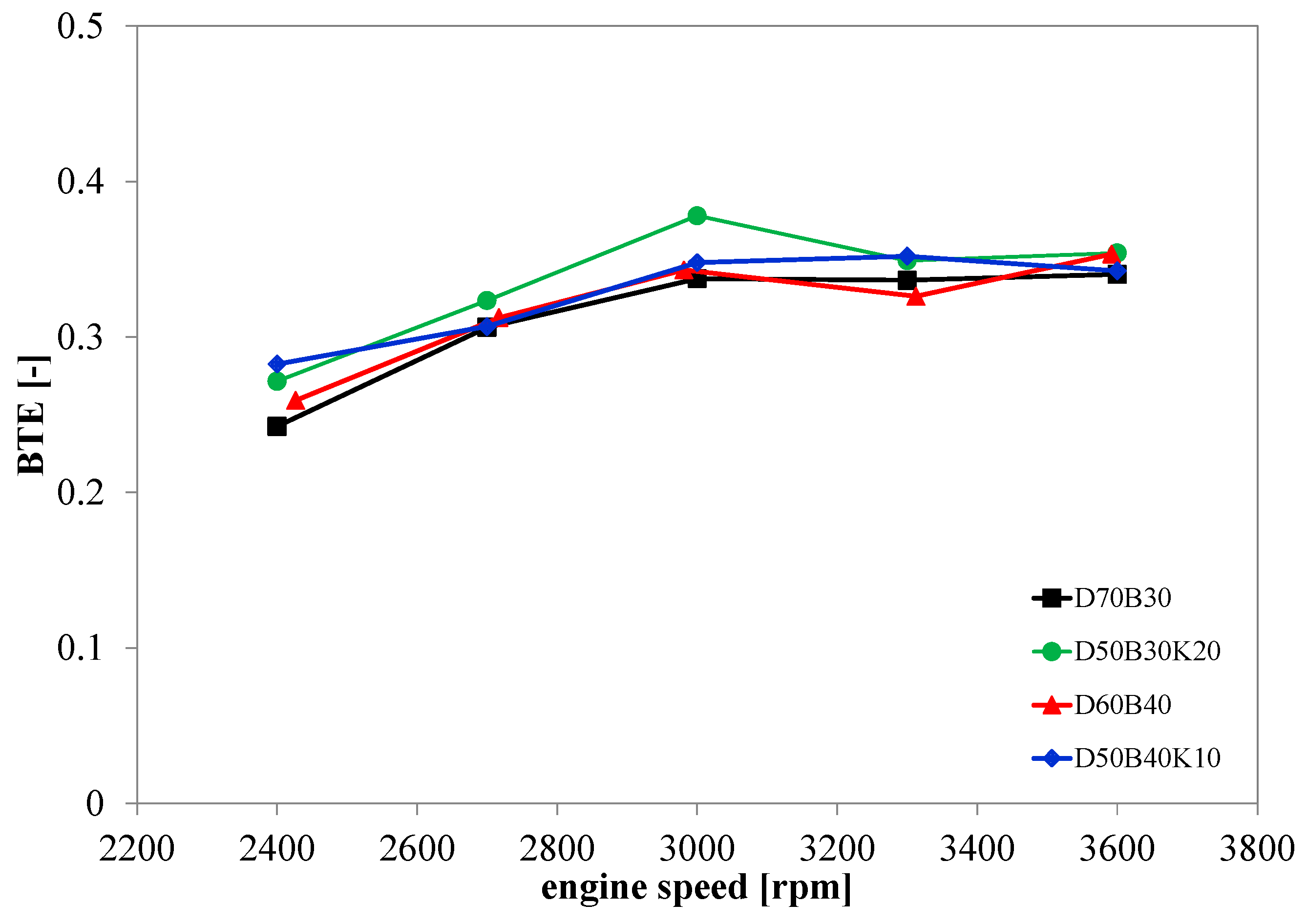

3.3. Diesel+ Blended with Biodiesel from WCO and Jet A

4. Conclusions

- −

- WCO biodiesel has a good opportunity to be used in common rail diesel engines since it is able to enhance hydrocarbon, carbon monoxide and soot emission in comparison with petrol diesel.

- −

- A drawback is represented by the increase in nitrogen oxide emissions.

- −

- Jet A used as an additive in the fuel (10% and 20% by volume) allows benefits in terms of carbon monoxide in the range of low engine speed; HC is penalized. A significant reduction in NOx is also achieved. Concerning particulate matter, an increase in emission characterizes the lower engine velocity, and this is the opposite at higher speeds.

- −

- Mixing Jet A (10% and 20% by volume) in blends of diesel fuel (50%) and biodiesel (40% and 30%, respectively) is responsible for an attenuation of the drawbacks related to biodiesel employment and allows for an enhancement of the pollutant emissions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| BTDC | before top dead center |

| CMD | court mean diameter |

| CRDI | common rail direct injection |

| PNC | particle number concentration |

| RoHR | rate of heat release |

| WCO | waste cooking oil |

References

- Song, H.; Tompkins, B.T.; Bittle, J.A.; Jacobs, T.J. Comparisons of NO emissions and soot concentrations from biodiesel-fuelled diesel engine. Fuel 2012, 96, 446–453. [Google Scholar] [CrossRef]

- Serrano, L.; Lopes, M.; Pires, N.; Ribeiro, I.; Cascão, P.; Tarelho, L.; Monteiro, A.; Nielsen, O.; Gameiro da Silva, M.; Borrego, C. Evaluation on effects of using low biodiesel blends in a EURO 5 passenger vehicle equipped with a common-rail diesel engine. Appl. Energy 2015, 146, 230–238. [Google Scholar] [CrossRef]

- Attia, A.M.A.; Hassaneen, A.E. Influence of diesel fuel blended with biodiesel produced from waste cooking oil on diesel engine performance. Fuel 2015, 167, 316–328. [Google Scholar] [CrossRef]

- Hwang, J.; Jung, Y.; Bae, C. Spray and combustion of waste cooking oil biodiesel in a compression-ignition engine. Int. J. Engine Res. 2015, 16, 664–679. [Google Scholar] [CrossRef]

- Lee, C.S.; Park, S.W.; Kwon, S. An experimental study on the atomization and combustion characteristics of biodiesel-blended fuels. Energy Fuels 2005, 19, 2201–2208. [Google Scholar] [CrossRef]

- Peng, D. Exhaust emission characteristics of various types of biofuels. Adv. Mech. Eng. 2015, 7, 1–7. [Google Scholar] [CrossRef]

- Ajtai, T.; Pintér, M.; Utry, N.; Kiss-Albert, G.; Gulyás, G.; Pusztai, P.; Puskás, R.; Bereczky, A.; Szabados, G.; Szabó, G.; et al. Characterization of diesel particulate emission from engines using commercial diesel and biofuels. Atmos. Environ. 2016, 134, 109–120. [Google Scholar] [CrossRef]

- Shahir, V.K.; Jawahar, C.P.; Suresh, P.R. Comparative study of diesel and biodiesel on CI engine with emphasis to emissions—A review. Renew. Sustain. Energy Rev. 2015, 45, 686–697. [Google Scholar] [CrossRef]

- How, H.G.; Masjuki, J.J.; Kalam, M.A.; Teoh, Y.H. Influence of injection timing and split injection strategies on performance, emissions, and combustion characteristics of diesel engine fueled with biodiesel blended fuels. Fuel 2018, 213, 106–114. [Google Scholar] [CrossRef]

- Oni, B.A.; Oluwatosin, D. Emission characteristics and performance of neem seed and Camelina based biodiesel in diesel engine. Renew. Energy 2020, 149, 725–734. [Google Scholar] [CrossRef]

- Phan, A.N.; Phan, T.M. Biodiesel production from waste cooking oils. Fuel 2009, 87, 3490–3496. [Google Scholar] [CrossRef]

- Gopal, K.N.; Arindan, P.; Sharma, S.; Samanchi, C.; Sathyanarayanan, K.; Elango, T. Investigation of emission and combustion characteristics of a IC engine fuels with waste cooking oil methyl ester and diesel blends. Alex. Eng. J. 2014, 53, 281–287. [Google Scholar] [CrossRef]

- Cheung, C.S.; Man, X.J.; Fong, K.W.; Tsang, O.K. Effect of Waste Cooking Oil Biodiesel on the Emissions of a Diesel Engine. Energy Procedia 2015, 66, 93–96. [Google Scholar] [CrossRef]

- Man, X.J.; Cheung, C.S.; Ning, Z. Effect of Diesel Engine Operating Conditions on the Particulate Size, Nanostructure and Oxidation Properties when Using Wasting Cooking Oil Biodiesel. Energy Procedia 2015, 66, 37–40. [Google Scholar] [CrossRef]

- Hwang, J.; Bae, C.; Gupta, T. Application of waste cooking oil (WCO) biodiesel in a compression ignition engine. Fuel 2016, 176, 20–31. [Google Scholar] [CrossRef]

- Sanli, H. An experimental investigation on the usage of waste frying oil-diesel fuel blends with low viscosity in a Common Rail DI-diesel engine. Fuel 2018, 222, 434–443. [Google Scholar] [CrossRef]

- Yesilyurt, M.K. The effects of the fuel injection pressure on the performance and emission characteristics of a diesel engine fuelled with waste cooking oil biodiesel-diesel blends. Renew Energy 2019, 132, 649–666. [Google Scholar] [CrossRef]

- Borugadda, V.B.; Paul, A.K.; Chaudhari, A.; Kulkarni, V.; Sahoo, N.; Goud, V.V. Influence of Waste Cooking Oil Methyl Ester Biodiesel Blends on the Performance and Emissions of a Diesel Engine. Waste Biomass Valorization 2018, 9, 283–292. [Google Scholar] [CrossRef]

- NATO Logistics Handbook; NATO: Brussels, Belgium, 2007.

- ASTM D1655-09; Standard Specification for Aviation Turbine Fuels. ASTM International: West Conshohocken, PA, USA, 2009.

- Roy, M.M.; Wang, W.; Alawi, M. Performance and emissions of a diesel engine fuelled by biodiesel-diesel, biodiesel-diesel-additive and kerosene-biodiesel blends. Energy Convers. Manag. 2014, 84, 164–173. [Google Scholar] [CrossRef]

- Chen, L.; Ding, S.; Liu, H.; Lu, Y.; Li, Y.; Roskilly, A.P. Comparative study of combustion and emissions of kerosene (RP-3), kerosene-pentanol blends and diesel in a compression ignition engine. Appl. Energy 2017, 203, 91–100. [Google Scholar] [CrossRef]

- Gowdagiri, S.; Cesari, X.M.; Huang, M.; Oehlschlaeger, M.A. A diesel engine study of conventional and alternative diesel and jet fuels: Ignition and emissions characteristics. Fuel 2014, 136, 253–260. [Google Scholar] [CrossRef]

- Rothamer, D.A.; Murphy, L. Systematic study of ignition delay for jet fuels and diesel fuel in a heavy-duty diesel engine. Proc. Combust. Inst. 2013, 34, 3021–3029. [Google Scholar] [CrossRef]

- Bayındır, H.; Zerrakki, I.M.; Argunhan, Z.; Yücel, H.L.; Aydın, H. Combustion, performance and emissions of a diesel power generator fueled with biodiesel-kerosene and biodiesel-kerosene-diesel blends. Energy 2017, 123, 241–251. [Google Scholar] [CrossRef]

- Vonortas, A.; Papayannakos, N. Comparative analysis of biodiesel versus green diesel. Wiley Interdiscip. 2014, 3, 3–23. [Google Scholar] [CrossRef]

- Douvartzides, S.L.; Charisiou, N.D.; Papageridis, K.N.; Goula, M.A. Green Diesel: Biomass Feedstocks, Production Technologies, Catalytic Research, Fuel Properties and Performance in Compression Ignition Internal Combustion Engines. Energies 2019, 12, 809. [Google Scholar] [CrossRef]

- Šimácek, P.; Kubicka, D.; Šebor, G.; Pospíšil, M. Fuel properties of hydroprocessed rapeseed oil. Fuel 2010, 89, 611–615. [Google Scholar] [CrossRef]

- Devendra, S.; Subramanian, K.A.; Singal, K.S. Emissions and fuel consumption characteristics of a heavy duty diesel engine fueled with Hydroprocessed Renewable Diesel and Biodiesel. Appl. Energy 2015, 155, 440–446. [Google Scholar]

- Knothe, G. Biodiesel and renewable diesel: A comparison. Prog. Energy Combust. Sci. 2010, 36, 364–373. [Google Scholar] [CrossRef]

- Kalnes, T.; Marker, T.; Shonnard, D.R. Green Diesel: A Second Generation Biofuel. Int. J. Chem. React. Eng. 2007, 5. [Google Scholar] [CrossRef]

- Anbari, M.; Attar, M.; Xu, H. Correlations between particulate matter emissions and gasoline direct injection spray characteristics. J. Aerosol Sci. 2016, 102, 128–141. [Google Scholar] [CrossRef]

- Chiatti, G.; Chiavola, O.; Recco, E.; Palmieri, F. Impact of waste cooking oil in biodiesel blends on particle size distributions from a city-car engine. J. Energy Inst. 2016, 91, 262–269. [Google Scholar] [CrossRef]

- Chiavola, O.; Chiatti, G.; Recco, E.; Magno, A.; Mancaruso, E.; Vaglieco, B.M. Accelerometer measurement for MFB evaluation in multi-cylinder diesel engine. Energy 2017, 133, 843–850. [Google Scholar]

- Baldiraghi, F.; Di Stanislao, M.; Faraci, G.; Perego, C. Ecofining: New Process for Green Diesel Production from Vegetable Oil. In Sustainable Industrial Chemistry; Wiley-VCH Verlag GmbH & Co., KGaA: Weinheim, Germany, 2009. [Google Scholar]

- Chiatti, G.; Chiavola, O.; Palmieri, F.; Albertini, S. Combustion and Emissions Characterization of Biodiesel Blends a City-Car Engine. Energy Fuels 2014, 28, 5076–5085. [Google Scholar] [CrossRef]

- Eni Oil Products. Available online: https://oilproducts.eni.com/it_IT/prodotti/carburanti-e-combustibili/trazione/gasolio/eni-diesel (accessed on 9 March 2023).

- Murphy, L.; Rothamer, D. Effects of Cetane Number on Jet Fuel Combustion in a Heavy-Duty Compression Ignition Engine at High Load; SAE Technical Paper 2011-01-0335; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Chiavola, O.; Recco, E. Emission performance of a Diesel engine fuelled with petrol diesel, green diesel, and waste cooking oil blends. J. Combust. 2018, 2018, 4819175. [Google Scholar] [CrossRef]

- Kim, H.; Choi, B. The effect of biodiesel and bioethanol blended diesel fuel on nanoparticles and exhaust emissions from CRDI diesel engine. Renew Energy 2010, 35, 157–163. [Google Scholar] [CrossRef]

- Cataluna, R.; Da Silva, R. Effect of cetane number on specific fuel consumption and particulate matter and unburned hydrocarbon emissions from diesel engines. J. Combust. 2012, 2012, 738940. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.; Wang, Z.; Xiao, J. Combustion and emission characteristics of diesel engine fueled with diesel/biodiesel/pentanol fuel blends. Fuel 2015, 156, 211–218. [Google Scholar]

- Yehliu, K.; Boehman, A.L.; Armas, O. Emissions from different alternative diesel fuels operating with single and split fuel injection. Fuel 2010, 89, 423–437. [Google Scholar] [CrossRef]

- Lapuerta, M.; Armas, O.; Rodriguez-Fernandez, J. Effect of biodiesel fuels on diesel engine emissions. Prog. Energy Combust. Sci. 2008, 34, 198–223. [Google Scholar] [CrossRef]

| Engine Type | LDW442CRS Naturally Aspirated |

|---|---|

| Cylinders | 2 |

| Bore | 68 mm |

| Stroke | 60.0 mm |

| Displacement | 440 cm3 |

| Compression ratio | 20:1 |

| Maximum torque | 21 Nm @ 2000 rpm |

| Maximum power | 8.5 kW @ 4400 rpm |

| Mass Fraction | |

|---|---|

| Carbon | 0.812 |

| Oxygen | 0.117 |

| Hydrogen | 0.065 |

| Sulfur | 0.006 |

| Property | Diesel+ | Biodiesel from WCO | Jet A |

|---|---|---|---|

| density (kg/m at 15 °C) | 840 | 877 | 801 |

| lower heating value (MJ/kg) | 43.2 | 37.1 | 43.4 |

| cetane number | 55 | 56 | 47 |

| Engine speed (rpm) | 2400 | 2700 | 3000 | 3300 | 3600 |

| Torque (Nm) | 18.2 | 19.0 | 17.5 | 17.0 | 15.2 |

| SOI pre (cad BTDC) | 18.5 | 18.4 | 15.5 | 6.0 | 18.1 |

| SOI main (cad BTDC) | 5.9 | 5.9 | 6.0 | 16.8 | 6.7 |

| Prail (bar) | 620 | 610 | 610 | 630 | 650 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiavola, O.; Palmieri, F.; Cavallo, D.M. On the Increase in the Renewable Fraction in Diesel Blends using Aviation Fuel in a Common Rail Engine. Energies 2023, 16, 4624. https://doi.org/10.3390/en16124624

Chiavola O, Palmieri F, Cavallo DM. On the Increase in the Renewable Fraction in Diesel Blends using Aviation Fuel in a Common Rail Engine. Energies. 2023; 16(12):4624. https://doi.org/10.3390/en16124624

Chicago/Turabian StyleChiavola, Ornella, Fulvio Palmieri, and Domenico Mario Cavallo. 2023. "On the Increase in the Renewable Fraction in Diesel Blends using Aviation Fuel in a Common Rail Engine" Energies 16, no. 12: 4624. https://doi.org/10.3390/en16124624

APA StyleChiavola, O., Palmieri, F., & Cavallo, D. M. (2023). On the Increase in the Renewable Fraction in Diesel Blends using Aviation Fuel in a Common Rail Engine. Energies, 16(12), 4624. https://doi.org/10.3390/en16124624