Prospects of Bioethanol from Agricultural Residues in Bangladesh

Abstract

:1. Introduction

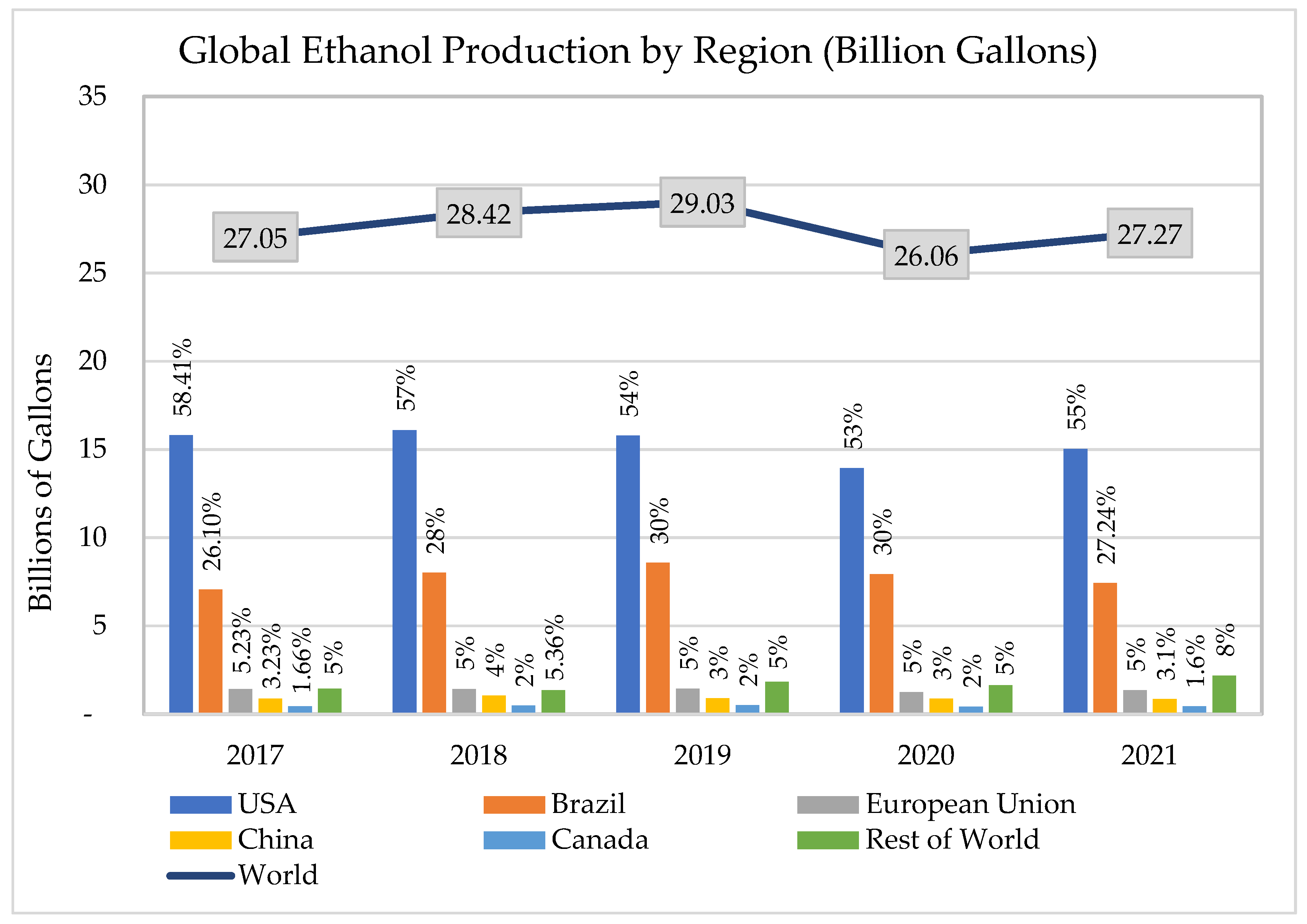

2. Fuel Properties of Bioethanol

3. Current Trend of Bioethanol Production in the World

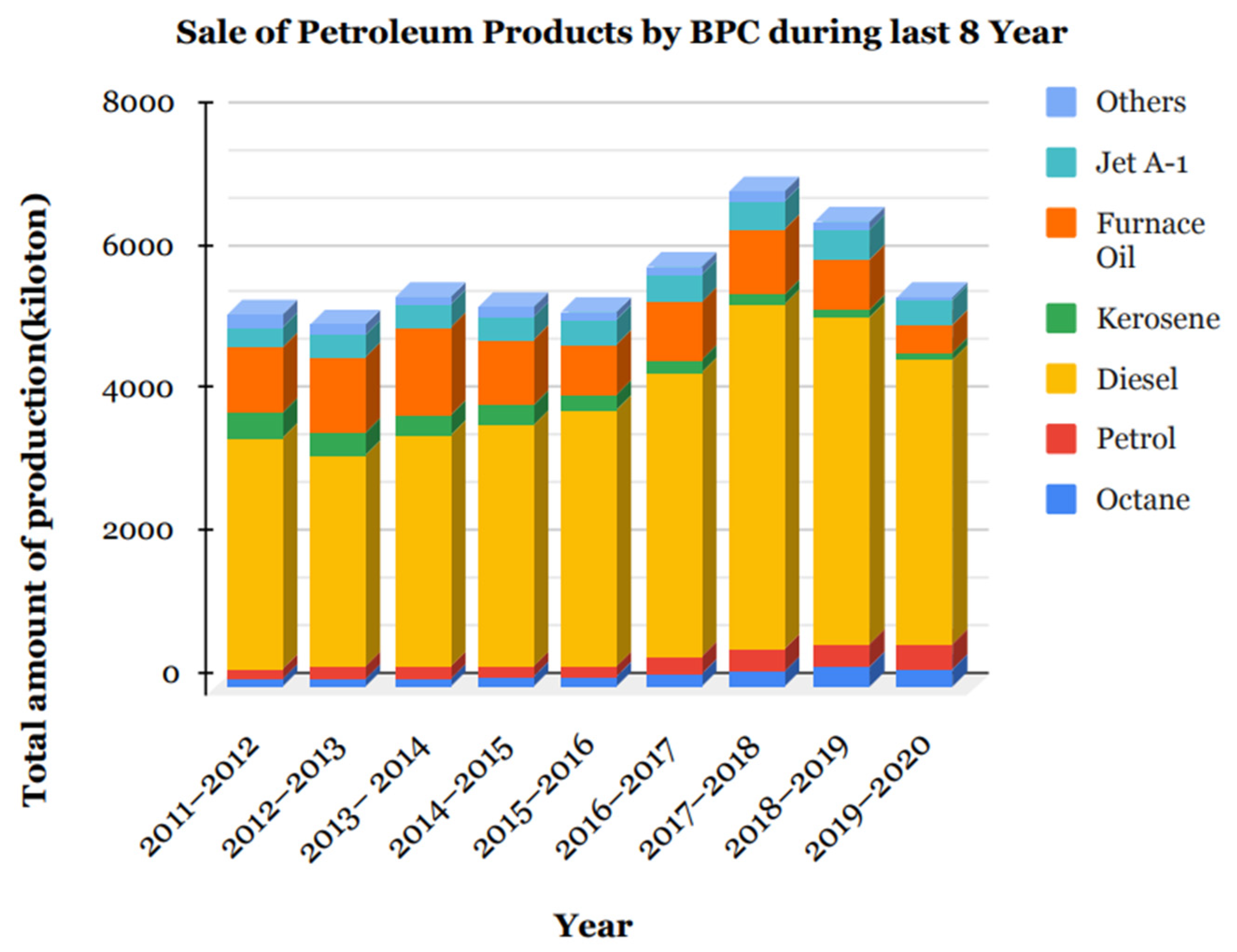

4. Current Energy Status and Fuel Consumption Pattern in Bangladesh

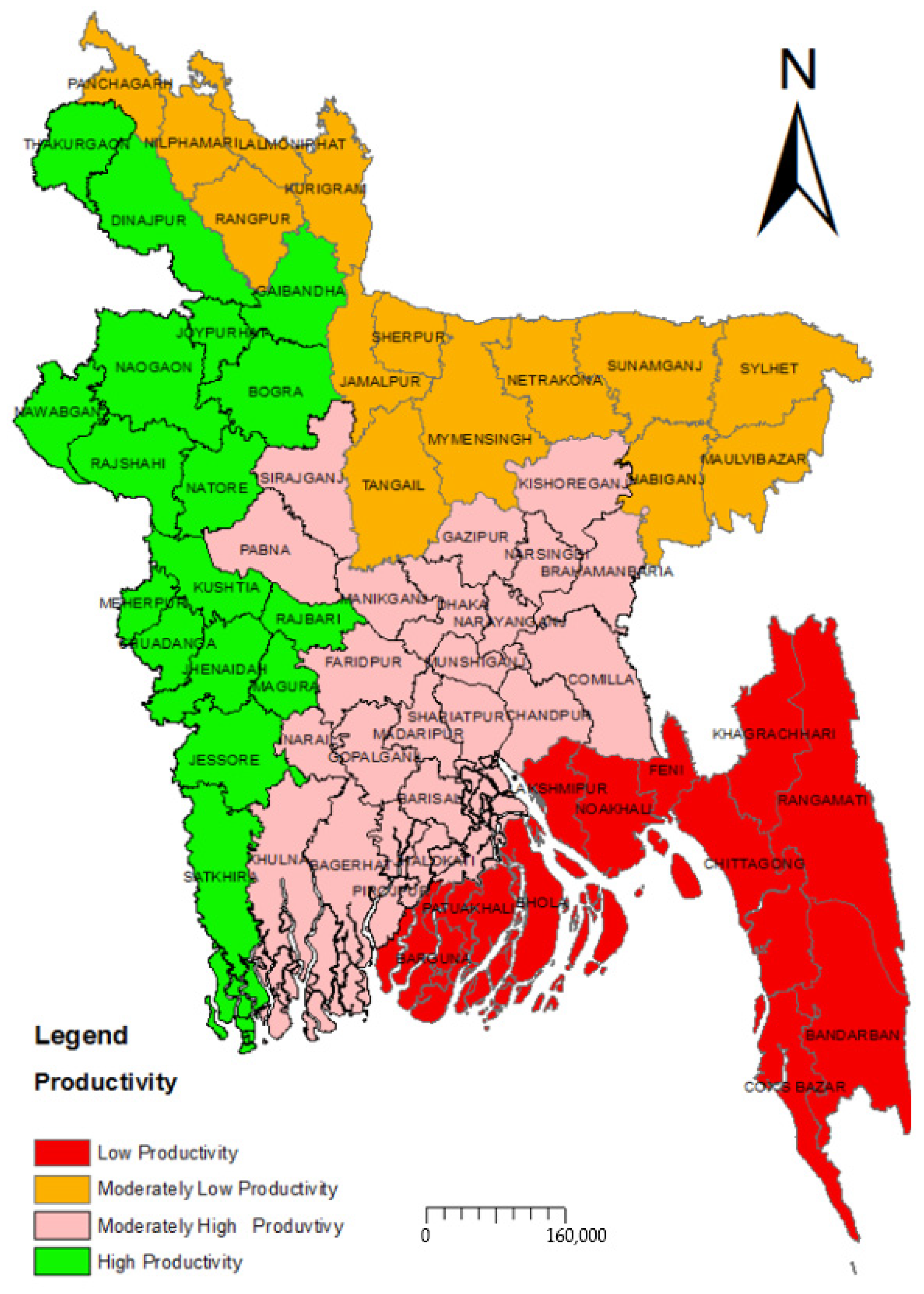

5. Biomass Potentiality in Bangladesh

5.1. Availability of Agricultural Residues

5.2. Utilization of Agricultural Residues

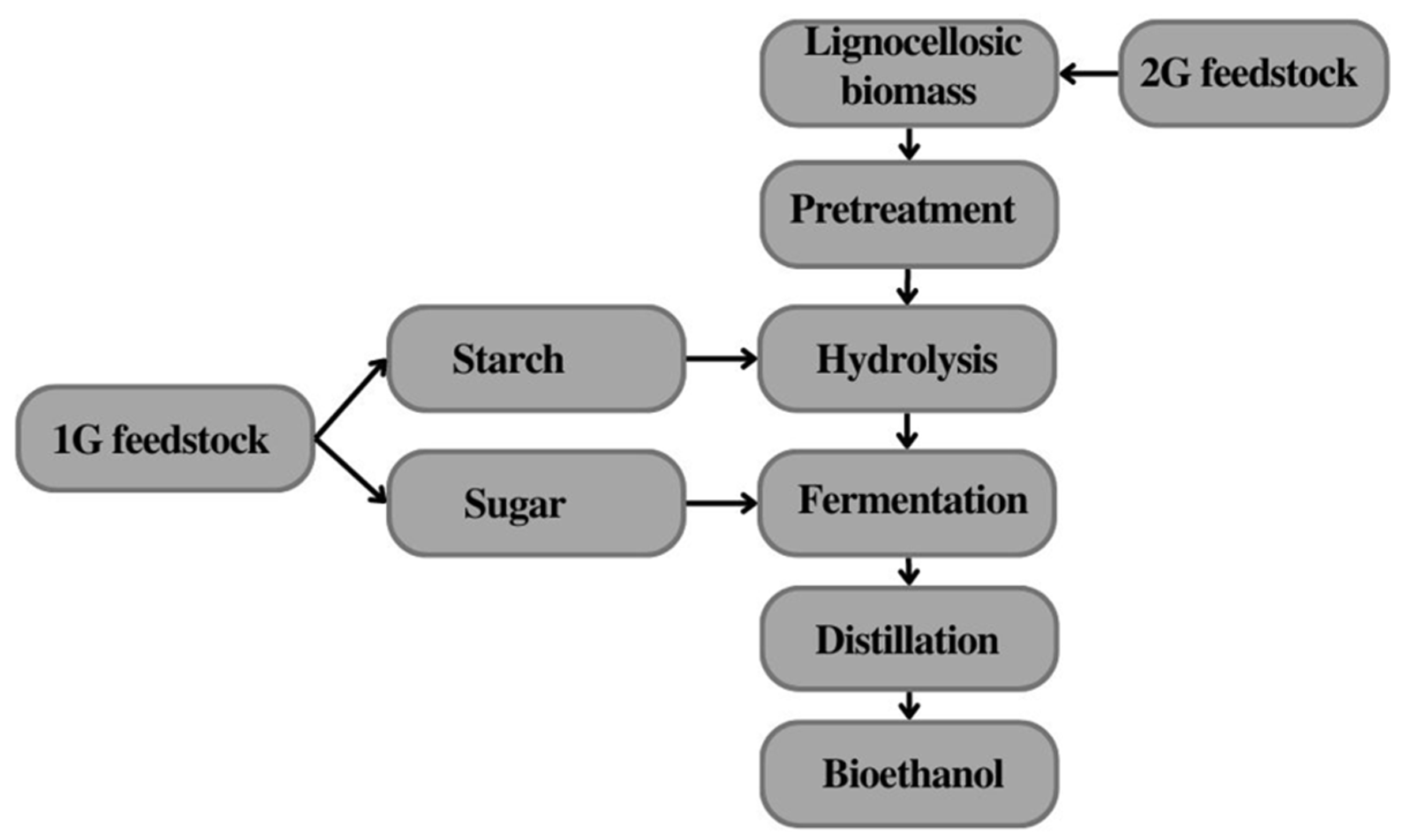

6. Feedstock for Bioethanol

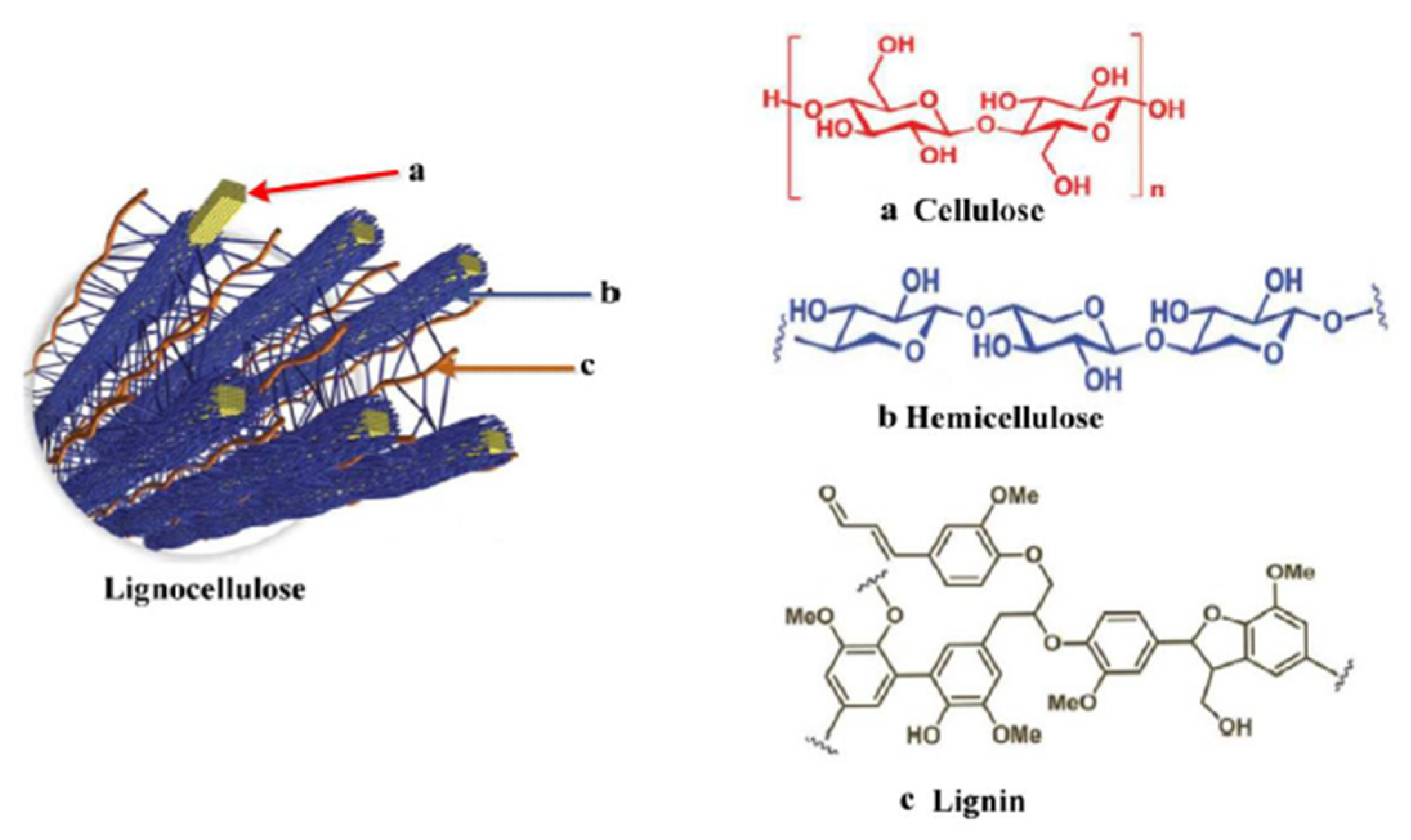

6.1. Cellulose

6.2. Hemicellulose

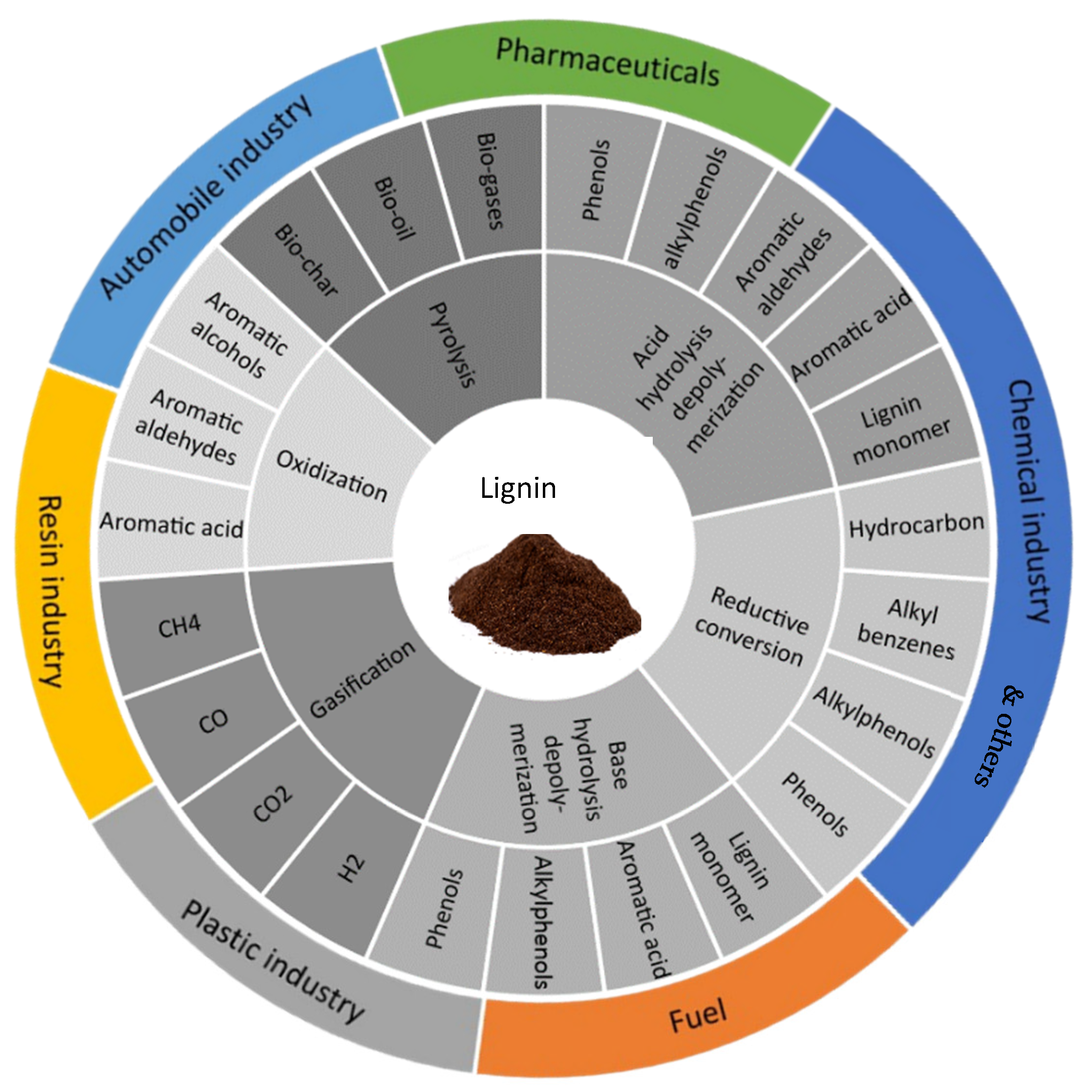

6.3. Lignin

Utilization of Lignin

7. Bioethanol Conversion from Lignocellulosic Biomass

7.1. Pretreatment

7.2. Hydrolysis

7.3. Fermentation

8. Bioethanol Potential in Bangladesh

9. Challenges of Bioethanol Production from Agricultural Residues

- The biggest impediment to the development of bioethanol power plants is a lack of efficient technology for the pretreatment, hydrolysis, and fermentation processes, as well as adequate infrastructure.

- Generation of 2G bioethanol is two or three times more costly than fossil fuel because of high pretreatment and enzyme costs.

- The production of 2G bioethanol requires a significant amount of energy during growth, harvesting, transportation, and feedstock processing. As a result, developing new bioethanol production technologies with a positive energy balance remains a challenge.

- As crops are season-dependent, different crops are produced in different places at different times in Bangladesh. Additionally, farmers frequently change the crops cultivated on the same land. Therefore, it is always difficult to determine the best place to make bioethanol.

- As Bangladesh currently does not produce bioethanol commercially, there is a lack of clear, long-term, compatible policies and enough economic incentive policies.

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- World Energy Outlook 2019—Analysis—IEA. Available online: https://www.iea.org/reports/world-energy-outlook-2019 (accessed on 6 December 2021).

- BP Energy Outlook Statistical Review of World Energy Globally Consistent Data on World Energy Markets and Authoritative Publications in the Field of Energy, 70th ed. 2021, pp. 8–20. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2021-full-report.pdf (accessed on 6 April 2022).

- Balat, M.; Balat, H.; Öz, C. Progress in Bioethanol Processing. Prog. Energy Combust. Sci. 2008, 34, 551–573. [Google Scholar] [CrossRef]

- Raud, M.; Kikas, T.; Sippula, O.; Shurpali, N.J. Potentials and Challenges in Lignocellulosic Biofuel Production Technology. Renew. Sustain. Energy Rev. 2019, 111, 44–56. [Google Scholar] [CrossRef]

- Butler, T.J.; Likens, G.E. Acid Rain | Definition, Causes, Effects, & Formulas | Britannica. Available online: https://www.britannica.com/science/acid-rain (accessed on 15 January 2023).

- Ribeiro, S.K.; Figueroa, M.J.; Creutzig, F.; Dubeux, C.; Hupe, J.; Kobayashi, S.; de Melo Brettas, L.A.; Thrasher, T.; Webb, S.; Zou, J. Energy End-Use: Transport. In Global Energy Assessment; Cambridge University Press: Cambridge, UK, 2012; pp. 575–648. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2016; IEA: Paris, France, 2016; pp. 127–137. [Google Scholar]

- Demirbaş, A. Bioethanol from Cellulosic Materials: A Renewable Motor Fuel from Biomass. Energy Sources 2005, 27, 327–337. [Google Scholar] [CrossRef]

- IEA Implementation of Bioenergy in Brazil—2021 Update. Available online: https://www.ieabioenergy.com/wp-content/uploads/2021/11/CountryReport2021_Brazil_final.pdf (accessed on 23 March 2022).

- Clauser, N.M.; González, G.; Mendieta, C.M.; Kruyeniski, J.; Area, M.C.; Vallejos, M.E. Biomass Waste as Sustainable Raw Material for Energy and Fuels. Sustainability 2021, 13, 794. [Google Scholar] [CrossRef]

- Kumar, B.; Bhardwaj, N.; Agrawal, K.; Verma, P. Bioethanol Production: Generation-Based Comparative Status Measurements. In Biofuel Production Technologies: Critical Analysis for Sustainability; Springer: Singapore, 2020; pp. 155–201. [Google Scholar] [CrossRef]

- Ghosal, A.; Banerjee, S.; Chaterjee, S. Biofuel Precursor From Potato Waste. Int. J. Res. Eng. Technol. 2013, 2, 213–219. [Google Scholar] [CrossRef]

- Sarkar, N.; Ghosh, S.K.; Bannerjee, S.; Aikat, K. Bioethanol Production from Agricultural Wastes: An Overview. Renew. Energy 2012, 37, 19–27. [Google Scholar] [CrossRef]

- OECD-FAO Agricultural Outlook | OECD ILibrary. Available online: https://www.oecd-ilibrary.org/sites/89d2ac54-en/index.html?itemId=/content/component/89d2ac54-en (accessed on 10 April 2023).

- Hahn-Hägerdal, B.; Galbe, M.; Gorwa-Grauslund, M.F.; Lidén, G.; Zacchi, G. Bio-Ethanol—The Fuel of Tomorrow from the Residues of Today. Trends Biotechnol. 2006, 24, 549–556. [Google Scholar] [CrossRef] [PubMed]

- Claassen, P.A.M.; Lopez Contreras, A.M.; Sijtsma, L.; Weusthuis, R.A.; Van Lier, J.B.; Van Niel, E.W.J.; Stams, A.J.M.; De Vries, S.S. Utilisation of Biomass for the Supply of Energy Carriers. Appl. Microbiol. Biotechnol. 1999, 52, 741–755. [Google Scholar] [CrossRef]

- Ahmed, R. A Comprehensive Assessment of the Availability and Use of Biomass Fuels for Various End-Uses with Special Attention To Power Generation. Available online: http://sreda.portal.gov.bd/sites/default/files/files/sreda.portal.gov.bd/page/049ce602_4203_49ac_8237_59e6776e255f/2021-06-22-04-52-31df1f5baf3ce33a4d5737629a391869.pdf (accessed on 6 December 2021).

- Bint-E-Naser, S.F.S.K.L.H.; Hossain, L.; Khan, M.S. Prospects and Constraints of Bioethanol Production in Bangladesh: An Overview. In Biofuels: Advances & Perspectives; Kaushik, G., Chaturvedi, S., Chel, A., Eds.; Studium Press LLC: Houston, TX, USA, 2018; pp. 69–86. ISBN 978-93-85046-22-3. [Google Scholar]

- Saini, J.K.; Saini, R.; Tewari, L. Lignocellulosic Agriculture Wastes as Biomass Feedstocks for Second-Generation Bioethanol Production: Concepts and Recent Developments. 3 Biotech 2015, 5, 337–353. [Google Scholar] [CrossRef] [Green Version]

- Wyman, C.E.; Hinman, N.D. Ethanol—Fundamentals of Production from Renewable Feedstocks and Use as a Transportation Fuel. Appl. Biochem. Biotechnol. 1990, 24–25, 735–753. [Google Scholar] [CrossRef]

- Wang, M.; Han, J.; Dunn, J.B.; Cai, H.; Elgowainy, A. Well-to-Wheels Energy Use and Greenhouse Gas Emissions of Ethanol from Corn, Sugarcane and Cellulosic Biomass for US Use. Environ. Res. Lett. 2012, 7, 045905. [Google Scholar] [CrossRef] [Green Version]

- Abel, R.C.; Coney, K.; Johnson, C.; Thornton, M.J.; Zigler, B.T.; Mccormick, R.L. Global Ethanol-Blended-Fuel Vehicle Compatibility Study. Available online: https://www.nrel.gov/docs/fy22osti/81252.pdf (accessed on 16 April 2023).

- Mostofa, M. An Introduction to Bioethanol and Its Prospects in Bangladesh: A Review. J. Energy Res. Rev. 2019, 2, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Miskat, M.I.; Ahmed, A.; Chowdhury, H.; Chowdhury, T.; Chowdhury, P.; Sait, S.M.; Park, Y.K. Assessing the Theoretical Prospects of Bioethanol Production as a Biofuel from Agricultural Residues in Bangladesh: A Review. Sustainability 2020, 12, 8583. [Google Scholar] [CrossRef]

- Mohd Azhar, S.H.; Abdulla, R.; Jambo, S.A.; Marbawi, H.; Gansau, J.A.; Mohd Faik, A.A.; Rodrigues, K.F. Yeasts in Sustainable Bioethanol Production: A Review. Biochem. Biophys. Rep. 2017, 10, 52–61. [Google Scholar] [CrossRef]

- Hoang, T.D.; Nghiem, N. Recent Developments and Current Status of Commercial Production of Fuel Ethanol. Fermentation 2021, 7, 314. [Google Scholar] [CrossRef]

- Mordor Intelligence. Bio-Ethanol Market | 2021–26 | Industry Share, Size, Growth—Mordor Intelligence. Available online: https://www.mordorintelligence.com/industry-reports/bio-ethanol-market (accessed on 5 December 2021).

- Bajpai, P. Global Production of Bioethanol. In Developments in Bioethanol. Green Energy and Technology; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Lopes, M.L.; de Paulillo, S.C.L.; Godoy, A.; Cherubin, R.A.; Lorenzi, M.S.; Giometti, F.H.C.; Bernardino, C.D.; de Amorim Neto, H.B.; de Amorim, H.V. Ethanol Production in Brazil: A Bridge between Science and Industry. Braz. J. Microbiol. 2016, 47, 64–76. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Flach, B.; Lieberz, S.; Bolla, S. GAIN Report—EU Biofuels Annual 2019. Available online: https://apps.fas.usda.gov/newgainapi/api/report/downloadreportbyfilename?filename=BiofuelsAnnual_TheHague_EU-28_7-15-2019.pdf (accessed on 23 June 2022).

- Kline, K.L.; Oladosu, G.A.; Wolfe, A.K.; Perlack, R.D.; Dale, V.H. Biofuel Feedstock Assessment for Selected Countries; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2008; ISBN 1800553684. [Google Scholar]

- Renewable Fuels Association Alternative Fuels Data Center: Maps and Data—Global Ethanol Production by Country or Region. Available online: https://afdc.energy.gov/data/10331 (accessed on 10 April 2023).

- Finance Division, Ministry of Finance. Chapter 2-GDP, Saving and Investment. Available online: https://mof.portal.gov.bd/site/page/28ba57f5-59ff-4426-970a-bf014242179e/Bangladesh-Economic-Review-2021 (accessed on 25 December 2021).

- SREDA (National Renewable Energy Database) RE Generation Mix | National Database of Renewable Energy. Available online: http://www.renewableenergy.gov.bd/ (accessed on 16 April 2023).

- Uddin, M.N.; Rahman, M.A.; Mofijur, M.; Taweekun, J.; Techato, K.; Rasul, M.G. Renewable Energy in Bangladesh: Status and Prospects. Energy Procedia 2019, 160, 655–661. [Google Scholar] [CrossRef]

- Bangladesh Power Development Board-Government of the People\’s Republic of Bangladesh. Available online: https://www.bpdb.gov.bd/site/page/e7f4aaea-7605-4588-a705-e615c574cb88/- (accessed on 16 April 2023).

- Mahmud, S.; Haider, A.S.M.R.M.R.; Shahriar, S.T.; Salehin, S.; Hasan, A.S.M.M.M.M.; Johansson, M.T. Bioethanol and Biodiesel Blended Fuels—Feasibility Analysis of Biofuel Feedstocks in Bangladesh. Energy Rep. 2022, 8, 1741–1756. [Google Scholar] [CrossRef]

- Bangladesh Oil Consumption, 1971—2021 | CEIC Data. Available online: https://www.ceicdata.com/en/indicator/bangladesh/oil-consumption (accessed on 16 April 2023).

- Quader, A.S.M.M. Hydrocarbon Units, Energy and Mineral Resources Division. Available online: https://hcu.portal.gov.bd/site/publications/262c9321-5292-4e07-a398-89b82151167b/Report-on-Energy-Scenario-of-bd-2019-2020 (accessed on 10 January 2022).

- World Bank. Bangladesh BD: Agricultural Land: % of Land Area | Economic Indicators | CEIC. Available online: https://www.ceicdata.com/en/bangladesh/land-use-protected-areas-and-national-wealth/bd-agricultural-land--of-land-area (accessed on 27 February 2022).

- Islam, M.S.; Mondal, T. Potentiality of Biomass Energy for Electricity Generation in Bangladesh. Asian J. Appl. Sci. Eng. 2013, 2, 202–209. [Google Scholar]

- Crop—Banglapedia. Available online: https://en.banglapedia.org/index.php/Crop (accessed on 26 December 2021).

- Bhuiya, M.R. Agricultural Regionalization of Bangladesh Based on Productivity and Analysis of Spatial Dependencies of for Productivity between the Districts of Bangladesh; Bangladesh Institute of Planners: Dhaka, Bangladesh, 2013; Volume 6, pp. 181–189. ISSN 2075-9363. [Google Scholar]

- Lal, R. World Crop Residues Production and Implications of Its Use as a Biofuel. Environ. Int. 2005, 31, 575–584. [Google Scholar] [CrossRef] [PubMed]

- Rofiqul Islam, M.; Rabiul Islam, M.; Rafiqul Alam Beg, M. Renewable Energy Resources and Technologies Practice in Bangladesh. Renew. Sustain. Energy Rev. 2008, 12, 299–343. [Google Scholar] [CrossRef]

- Mondal, M.A.H.; Denich, M. Assessment of Renewable Energy Resources Potential for Electricity Generation in Bangladesh. Renew. Sustain. Energy Rev. 2010, 14, 2401–2413. [Google Scholar] [CrossRef]

- Huda, A.S.N.; Mekhilef, S.; Ahsan, A. Biomass Energy in Bangladesh: Current Status and Prospects. Renew. Sustain. Energy Rev. 2014, 30, 504–517. [Google Scholar] [CrossRef]

- Hossain, A.K.; Badr, O. Prospects of Renewable Energy Utilisation for Electricity Generation in Bangladesh. Renew. Sustain. Energy Rev. 2007, 11, 1617–1649. [Google Scholar] [CrossRef]

- Bangladesh Bureau of Statistics. Yearbook of Agricultural Statistics—2020. Available online: http://www.bbs.gov.bd/site/page/3e838eb6-30a2-4709-be85-40484b0c16c6/Yearbook-of-Agricultural-Statistics (accessed on 1 March 2022).

- Halder, P.K.; Paul, N.; Beg, M.R.A. Assessment of Biomass Energy Resources and Related Technologies Practice in Bangladesh. Renew. Sustain. Energy Rev. 2014, 39, 444–460. [Google Scholar] [CrossRef]

- Sadrul, A.K.M.; Ahiduzzam, M. Green Electricity from Rice Husk: A Model for Bangladesh. In Thermal Power Plants—Advanced Applications; IntechOpen: London, UK, 2013; ISBN 978-953-51-1095-8. [Google Scholar]

- Infrastructure Development Company Limited (IDCOL). Available online: https://idcol.org/home/other_re (accessed on 27 April 2023).

- Sarkar, M.A.R.; Ehsan, M.; Islam, M.A. Issues Relating to Energy Conservation and Renewable Energy in Bangladesh. Energy Sustain. Dev. 2003, 7, 77–87. [Google Scholar] [CrossRef]

- Islam, A.; Chan, E.-S.; Taufiq-Yap, Y.H.; Mondal, M.A.H.; Moniruzzaman, M.; Mridha, M. Energy Security in Bangladesh Perspective—An Assessment and Implication. Renew. Sustain. Energy Rev. 2014, 32, 154–171. [Google Scholar] [CrossRef]

- Diouf, J. The State of Food and Agriculture; FAO: Rome, Italy, 2008; Volume 95, ISBN 978-92-5-105980-7. [Google Scholar]

- Yusuf, A.A.; Inambao, F.L. Bioethanol Production Techniques from Lignocellulosic Biomass as Alternative Fuel: A Review. Int. J. Adv. Res. Eng. Technol. 2019, 10, 259–288. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Global Potential Bioethanol Production from Wasted Crops and Crop Residues. Biomass Bioenergy 2004, 26, 361–375. [Google Scholar] [CrossRef]

- Maurya, D.P.; Singla, A.; Negi, S. An Overview of Key Pretreatment Processes for Biological Conversion of Lignocellulosic Biomass to Bioethanol. 3 Biotech 2015, 5, 597–609. [Google Scholar] [CrossRef] [Green Version]

- Singh, J.; Sharma, A.; Sharma, P.; Singh, S.; Das, D.; Chawla, G.; Singha, A.; Nain, L. Valorization of Jute (Corchorus Sp.) Biomass for Bioethanol Production. Biomass Convers. Biorefin. 2020, 12, 5209–5220. [Google Scholar] [CrossRef]

- Muktham, R.; Bhargava, S.K.; Bankupalli, S.; Ball, A.S. A Review on 1st and 2nd Generation Bioethanol Production-Recent Progress. J. Sustain. Bioenergy Syst. 2016, 6, 72–92. [Google Scholar] [CrossRef] [Green Version]

- Haghighi Mood, S.; Hossein Golfeshan, A.; Tabatabaei, M.; Salehi Jouzani, G.; Najafi, G.H.; Gholami, M.; Ardjmand, M. Lignocellulosic Biomass to Bioethanol, a Comprehensive Review with a Focus on Pretreatment. Renew. Sustain. Energy Rev. 2013, 27, 77–93. [Google Scholar] [CrossRef]

- Hamelinck, C.N.; van Hooijdonk, G.; Faaij, A.P.C. Ethanol from Lignocellulosic Biomass: Techno-Economic Performance in Short-, Middle- and Long-Term. Biomass Bioenergy 2005, 28, 384–410. [Google Scholar] [CrossRef]

- Kumar, S.; Sani Editors, R.K. Biorefining of Biomass to Biofuels Opportunities and Perception. In Biofuel and Biorefinery Technologies; Sachin, K., Rajesh, K.S., Eds.; Springer: Cham, Switzerland, 2018; Volume 4, p. 92. ISBN 9783319676777. [Google Scholar]

- Scheller, H.V.; Ulvskov, P. Hemicelluloses. Annu. Rev. Plant Biol. 2010, 61, 263–289. [Google Scholar] [CrossRef]

- Sánchez, C. Lignocellulosic Residues: Biodegradation and Bioconversion by Fungi. Biotechnol. Adv. 2009, 27, 185–194. [Google Scholar] [CrossRef] [PubMed]

- Taherzadeh, M.J.; Karimi, K. Pretreatment of Lignocellulosic Wastes to Improve Ethanol and Biogas Production: A Review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brandt, A.; Gräsvik, J.; Hallett, J.P.; Welton, T. Deconstruction of Lignocellulosic Biomass with Ionic Liquids. Green Chem. 2013, 15, 550–583. [Google Scholar] [CrossRef] [Green Version]

- Xu, R.; Zhang, K.; Liu, P.; Han, H.; Zhao, S.; Kakade, A.; Khan, A.; Du, D.; Li, X. Lignin Depolymerization and Utilization by Bacteria. Bioresour. Technol. 2018, 269, 557–566. [Google Scholar] [CrossRef] [PubMed]

- Lim, H.Y.; Yusup, S.; Loy, A.C.M.; Samsuri, S.; Ho, S.S.K.; Manaf, A.S.A.; Lam, S.S.; Chin, B.L.F.; Acda, M.N.; Unrean, P.; et al. Review on Conversion of Lignin Waste into Value-Added Resources in Tropical Countries. Waste Biomass Valorization 2021, 12, 5285–5302. [Google Scholar] [CrossRef]

- Gillet, S.; Aguedo, M.; Petitjean, L.; Morais, A.R.C.; da Costa Lopes, A.M.; Łukasik, R.M.; Anastas, P.T. Lignin Transformations for High Value Applications: Towards Targeted Modifications Using Green Chemistry. Green Chem. 2017, 19, 4200–4233. [Google Scholar] [CrossRef]

- Wang, H.; Pu, Y.; Ragauskas, A.; Yang, B. From Lignin to Valuable Products–Strategies, Challenges, and Prospects. Bioresour. Technol. 2019, 271, 449–461. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Prussi, M.; Ferrero, S.; Oriani, L.; Ottonello, P.; Torre, P.; Cherchi, F. Review of Pretreatment Processes for Lignocellulosic Ethanol Production, and Development of an Innovative Method. Biomass Bioenergy 2012, 46, 25–35. [Google Scholar] [CrossRef]

- Mosier, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.Y.; Holtzapple, M.; Ladisch, M. Features of Promising Technologies for Pretreatment of Lignocellulosic Biomass. Bioresour. Technol. 2005, 96, 673–686. [Google Scholar] [CrossRef] [PubMed]

- Sharma, B.; Larroche, C.; Dussap, C.G. Comprehensive Assessment of 2G Bioethanol Production. Bioresour. Technol. 2020, 313, 123630. [Google Scholar] [CrossRef]

- Galbe, M.; Zacchi, G. Pretreatment: The Key to Efficient Utilization of Lignocellulosic Materials. Biomass Bioenergy 2012, 46, 70–78. [Google Scholar] [CrossRef]

- Lamichhane, G.; Acharya, A.; Poudel, D.K.; Aryal, B.; Gyawali, N.; Niraula, P.; Phuyal, S.R.; Budhathoki, P.; Bk, G.; Parajuli, N. Recent Advances in Bioethanol Production from Lignocellulosic Biomass. Int. J. Green Energy 2021, 18, 731–744. [Google Scholar] [CrossRef]

- Menon, V.; Rao, M. Trends in Bioconversion of Lignocellulose: Biofuels, Platform Chemicals & Biorefinery Concept. Prog. Energy Combust. Sci. 2012, 38, 522–550. [Google Scholar] [CrossRef]

- Hideno, A.; Inoue, H.; Tsukahara, K.; Fujimoto, S.; Minowa, T.; Inoue, S.; Endo, T.; Sawayama, S. Wet Disk Milling Pretreatment without Sulfuric Acid for Enzymatic Hydrolysis of Rice Straw. Bioresour. Technol. 2009, 100, 2706–2711. [Google Scholar] [CrossRef]

- Sun, Y.; Cheng, J. Hydrolysis of Lignocellulosic Materials for Ethanol Production: A Review. Bioresour. Technol. 2002, 83, 1–11. [Google Scholar] [CrossRef]

- Zheng, J.; Rehmann, L. Extrusion Pretreatment of Lignocellulosic Biomass: A Review. Int. J. Mol. Sci. 2014, 15, 18967–18984. [Google Scholar] [CrossRef] [Green Version]

- Karunanithy, C.; Muthukumarappan, K. Influence of Extruder Temperature and Screw Speed on Pretreatment of Corn Stover While Varying Enzymes and Their Ratios. Appl. Biochem. Biotechnol. 2010, 162, 264–279. [Google Scholar] [CrossRef]

- Saleem, M.E.; Omar, R.; Kamal, S.M.M.; Biak, D.R.A. Microwave-Assisted Pretreatment of Lignocellulosic Biomass: A Review. J. Eng. Sci. Technol. 2015, 10, 97–109. [Google Scholar]

- Díaz, M.J.; Moya, M.; Castro, E. Bioethanol Production from Steam-Exploded Barley Straw by Co-Fermentation with Escherichia Coli SL100. Agronomy 2022, 12, 874. [Google Scholar] [CrossRef]

- De Bari, I.; Liuzzi, F.; Ambrico, A.; Trupo, M. Arundo Donax Refining to Second Generation Bioethanol and Furfural. Processes 2020, 8, 1591. [Google Scholar] [CrossRef]

- He, Q.; Ziegler-Devin, I.; Chrusciel, L.; Obame, S.N.; Hong, L.; Lu, X.; Brosse, N. Lignin-First Integrated Steam Explosion Process for Green Wood Adhesive Application. ACS Sustain. Chem. Eng. 2020, 8, 5380–5392. [Google Scholar] [CrossRef]

- Acevedo-García, V.; Padilla-Rascón, C.; Díaz, M.J.; Moya, M.; Castro, E. Fermentable Sugars Production from Acid-Catalysed Steam Exploded Barley Straw. Chem. Eng. Trans. 2018, 70, 1939–1944. [Google Scholar] [CrossRef]

- Balan, V.; Bals, B.; Chundawat, S.P.S.; Marshall, D.; Dale, B.E. Lignocellulosic Biomass Pretreatment Using AFEX. In Biofuels: Methods and Protocols; Mielenz, J.R., Ed.; Humana Press: Totowa, NJ, USA, 2009; pp. 61–77. ISBN 978-1-60761-214-8. [Google Scholar]

- Balan, V. Current Challenges in Commercially Producing Biofuels from Lignocellulosic Biomass. ISRN Biotechnol. 2014, 2014, 463074. [Google Scholar] [CrossRef] [Green Version]

- Wan, C.; Li, Y. Fungal Pretreatment of Lignocellulosic Biomass. Biotechnol. Adv. 2012, 30, 1447–1457. [Google Scholar] [CrossRef] [PubMed]

- Balat, M. Production of Bioethanol from Lignocellulosic Materials via the Biochemical Pathway: A Review. Energy Convers. Manag. 2011, 52, 858–875. [Google Scholar] [CrossRef]

- Bartocci, P.; Tschentscher, R.; Yan, Y.; Yang, H.; Bidini, G.; Fantozzi, F. Biofuels: Types and Process Overview. In Biofuel Production Technologies: Critical Analysis for Sustainability, Clean Energy Production Technologies; Srivastava, N., Ed.; Springer: Singapore, 2020; pp. 1–36. ISBN 9789811386374. [Google Scholar]

- Wu, X.; Zhang, J.; Xu, E.; Liu, Y.; Cheng, Y.; Addy, M.; Zhou, W.; Griffith, R.; Chen, P.; Ruan, R. Microbial Hydrolysis and Fermentation of Rice Straw for Ethanol Production. Fuel 2016, 180, 679–686. [Google Scholar] [CrossRef]

- Brethauer, S.; Studer, M.H. Consolidated Bioprocessing of Lignocellulose by a Microbial Consortium. Energy Environ. Sci. 2014, 7, 1446–1453. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Wang, Q.; Liu, T.; Guo, J.; Jin, Y.; Xiao, H.; Song, J. Exploring the Promoting Mechanisms of Bovine Serum Albumin, Lignosulfonate, and Polyethylene Glycol for Lignocellulose Saccharification from Perspective of Molecular Interactions with Cellulase. Arab. J. Chem. 2022, 15, 103910. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, W.; Han, X.; Zeng, Y.; Zhang, J.; Gao, Z.; Xie, J. Intensification of Sugar Production by Using Tween 80 to Enhance Metal-Salt Catalyzed Pretreatment and Enzymatic Hydrolysis of Sugarcane Bagasse. Bioresour. Technol. 2021, 339, 125522. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Ding, D.; Liu, Z.; Cheng, J.; Li, X.; Hui, L. Synergistic Effect of Moderate Steam Explosion Pretreatment and Bovine Serum Albumin Addition for Enhancing Enzymatic Hydrolysis of Poplar. BioEnergy Res. 2021, 14, 534–542. [Google Scholar] [CrossRef]

- Soriyan, O.O.; Owoyomi, O.; Bamgbose, J.T. The Effect of Mixed Surfactants of Sodium Dodecyl Sulfate and Triton X-100 on the Base Hydrolysis of Malachite Green. React. Kinet. Catal. Lett. 2009, 98, 77–82. [Google Scholar] [CrossRef]

- Hou, S.; Shen, B.; Zhang, D.; Li, R.; Xu, X.; Wang, K.; Lai, C.; Yong, Q. Understanding of Promoting Enzymatic Hydrolysis of Combined Hydrothermal and Deep Eutectic Solvent Pretreated Poplars by Tween 80. Bioresour. Technol. 2022, 362, 127825. [Google Scholar] [CrossRef]

- Saha, K.; Maheswari R, U.; Sikder, J.; Chakraborty, S.; da Silva, S.S.; dos Santos, J.C. Membranes as a Tool to Support Biorefineries: Applications in Enzymatic Hydrolysis, Fermentation and Dehydration for Bioethanol Production. Renew. Sustain. Energy Rev. 2017, 74, 873–890. [Google Scholar] [CrossRef]

- Cheng, M.-H.; Kadhum, H.J.; Murthy, G.S.; Dien, B.S.; Singh, V. High Solids Loading Biorefinery for the Production of Cellulosic Sugars from Bioenergy Sorghum. Bioresour. Technol. 2020, 318, 124051. [Google Scholar] [CrossRef]

- Tippkötter, N.; Duwe, A.-M.; Wiesen, S.; Sieker, T.; Ulber, R. Enzymatic Hydrolysis of Beech Wood Lignocellulose at High Solid Contents and Its Utilization as Substrate for the Production of Biobutanol and Dicarboxylic Acids. Bioresour. Technol. 2014, 167, 447–455. [Google Scholar] [CrossRef] [PubMed]

- Ostadjoo, S.; Hammerer, F.; Dietrich, K.; Dumont, M.J.; Friscic, T.; Auclair, K. Efficient Enzymatic Hydrolysis of Biomass Hemicellulose in the Absence of Bulk Water. Molecules 2019, 24, 4206. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tesfaw, A.; Assefa, F. Current Trends in Bioethanol Production by Saccharomyces Cerevisiae: Substrate, Inhibitor Reduction, Growth Variables, Coculture, and Immobilization. Int. Sch. Res. Not. 2014, 2014, 532852. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Suriyachai, N.; Weerasaia, K.; Laosiripojana, N.; Champreda, V.; Unrean, P. Optimized Simultaneous Saccharification and Co-Fermentation of Rice Straw for Ethanol Production by Saccharomyces Cerevisiae and Scheffersomyces Stipitis Co-Culture Using Design of Experiments. Bioresour. Technol. 2013, 142, 171–178. [Google Scholar] [CrossRef]

- Madu, J.O.; Agboola, B.O. Bioethanol Production from Rice Husk Using Different Pretreatments and Fermentation Conditions. 3 Biotech 2017, 8, 15. [Google Scholar] [CrossRef]

- Ferreira, V.; Faber, M.D.; Mesquita, S.D.; Pereira, N. Simultaneous Saccharification and Fermentation Process of Different Cellulosic Substrates Using a Recombinant Saccharomyces Cerevisiae Harbouring the β-Glucosidase Gene. Electron. J. Biotechnol. 2010, 13, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Jin, M.; Sarks, C.; Gunawan, C.; Bice, B.D.; Simonett, S.P.; Avanasi Narasimhan, R.; Willis, L.B.; Dale, B.E.; Balan, V.; Sato, T.K. Phenotypic Selection of a Wild Saccharomyces Cerevisiae Strain for Simultaneous Saccharification and Co-Fermentation of AFEXTM Pretreated Corn Stover. Biotechnol. Biofuels 2013, 6, 108. [Google Scholar] [CrossRef] [Green Version]

- Saha, B.C.; Cotta, M.A. Ethanol Production from Alkaline Peroxide Pretreated Enzymatically Saccharified Wheat Straw. Biotechnol. Prog. 2006, 22, 449–453. [Google Scholar] [CrossRef]

- Sophanodorn, K.; Unpaprom, Y.; Whangchai, K.; Homdoung, N.; Dussadee, N.; Ramaraj, R. Environmental Management and Valorization of Cultivated Tobacco Stalks by Combined Pretreatment for Potential Bioethanol Production. Biomass Convers. Biorefin. 2022, 12, 1627–1637. [Google Scholar] [CrossRef]

- Tse, T.J.; Wiens, D.J.; Reaney, M.J.T. Production of Bioethanol—A Review of Factors Affecting Ethanol Yield. Fermentation 2021, 7, 268. [Google Scholar] [CrossRef]

| Fuel Characteristic | Bioethanol | E5 |

|---|---|---|

| Density at 15 °C (gm/cm3) | 0.790 | 0.834 |

| Calorific value (kJ/kg) | (Lower) 26,700 | (Higher) 43,632 |

| Kinematic viscosity at 40 °C (mm2/s) | 1.130 | 2.53 |

| Cetane number | 5.8 | - |

| Octane number | 110 | 96 |

| Flashpoint (°C) | 13 | 24 |

| Moisture level (mg/kg) | 2024 | 100 |

| Boiling point (°C) | 78 | - |

| Countries | Production (107 Gallons) | Feedstock |

|---|---|---|

| United States | 1390 | Corn |

| Brazil | 793 | Sugarcane, Corn, and Soybeans |

| European Union | 125 | Sugar Beet and its Derivatives, Corn, and Wheat |

| China | 88 | Corn, Soybeans, Wheat, and Sugarcane |

| India | 48 | Sugarcane and Molasses |

| Canada | 46 | Wheat and Corn |

| Thailand | 40 | Sugarcane, Molasses, and Cassava |

| Argentina | 23 | Soybeans, Corn, Wheat, and Sugarcane |

| Agricultural Residues | Recovery Factor (%) | |

|---|---|---|

| Field Residues | Straw, Stalks, and Leaves | 35 |

| Process Residues | Husks, Bagasse, Seeds, Bran, and cob | 100 |

| Crops (Field + Process) | Crop Production 2019–2020 (105) ton | Residue Yield × Recovery Factor | Residue Recovery (105) ton |

|---|---|---|---|

| Rice Straw | 366.03 | 1.695 × 0.35 | 217.15 |

| Rice husk | 0.267 × 1 | 97.73 | |

| Rice Bran | 0.083 × 1 | 28.57 | |

| Wheat Straw | 10.29 | 1.75 × 0.35 | 6.30 |

| Corn Stalks | 40.16 | 2 × 0.35 | 28.11 |

| Corn Cob | 0.3 × 1 | 6.13 | |

| Corn Husk | 0.3 × 1 | 12.05 | |

| Jute Stalks | 80.45 | 2 × 0.35 | 56.32 |

| Pulses | 3.98 | 1.9 × 0.35 | 2.65 |

| Sugarcane | 36.83 | 0.3 × 0.35 | 3.87 |

| Tobacco | 0.86 | 2 × 0.35 | 0.60 |

| Vegetables and Others | 45.75 | 0.4 × 0.35 | 6.41 |

| Total | 584.34 | 465.87 |

| Primary Source | Residues | Utilization |

|---|---|---|

| Rice | Straw | (i) Fuel; (ii) Animal feed; (iii) Animal bedding; (iv) Housing material |

| Husk | (i) Fuel; (ii) Cattle feed; (iii) Poultry feed; (iv) Fish feed | |

| Bran | (i) Fuel; (ii) Animal feed | |

| Wheat | Straw | (i) Fuel; (ii) Housing materials |

| Jute | Stalk | (i) Fuel; (ii) Housing materials |

| Sugarcane | Leaf | (i) Fuel; (ii) Animal feed |

| Bagasse | (i) Fuel | |

| Corn | Stalk | (i) Fuel; (ii) Animal feed |

| Cob | (i) Fuel | |

| Husk | (i) Fuel | |

| Pulse | Straw | (i) Fuel; (ii) Animal feed |

| Tobacco | Plants | (i) Fuel |

| Vegetables | Plants | (i) Fuel; (ii) Animal feed |

| Residues | %wt. on a Dry Matter Basis | ||

|---|---|---|---|

| Cellulose | Hemicellulose | Lignin | |

| Rice straw | 28–36 | 23–28 | 12–14 |

| Wheat straw | 33–38 | 26–32 | 17–19 |

| Maize stover | 35–40 | 21–25 | 19–21 |

| Jute | 37–48 | 12.18–12.3 | 27.9–35.3 |

| Sugarcane | 25–45 | 28–32 | 15–25 |

| Tobacco | 30.22 | 40.28 | 21.06 |

| Pretreatment | Condition | Main Advantage | Main Disadvantage | Pretreated Residue Examples | Sugar Yield/ Cost [77] | Ref. |

|---|---|---|---|---|---|---|

| ||||||

| Milling and grinding | Ball mill: 0.2–2 mm final particle size | No chemical used Reduces cellulose crystallinity | Consumes more power | Hardwood, corn straw, corn stover, sugarcane, bagasse | L/H | [19,78,79] |

| Extrusion | Screw speed: 75 rpm, barrel temperature: 125 °C | No degradation products formed | Considerable aberration of metal face | Corn cobs, switchgrass, wheat bran, | H/H | [80,81] |

| Microwave | 1% NaOH, 600 W, 4 min | Quick heat transfer | High reactor cost | Sugarcane bagasse | L/H | [82] |

| ||||||

| Acid-catalyzed steam explosion (ACSE) | T = 160–200 °C, dilute H3PO4 or H2SO4 (1–3% w/v), t = 5–30 min | Increased enzymatic accessibility | Higher acquisition and handling costs | Barley straw, Arundo donax, green wood | H/H | [83,84,85,86] |

| Ammonia fiber explosion (AFEX) | T: 90–140 °C, P: 1.12–1.36 MPa, t: 30–60 min; ammonia: dry biomass = 1:1–1:2 | Volatile ammonia is recoverable and reusable | Inefficient for lignin-rich biomasses | Wheat straw, barley straw, rice husk, corn stover | H/H | [19,87] |

| ||||||

| Ozonolysis | Ozone | No inhibitors formed | Requires a significant amount of ozone | Wheat straw, cotton straw | H/H | [19,79] |

| Fungus or bacteria | No chemicals required | Slow process | Corn stover, wheat straw | L/L | [88,89] |

| Process | Main Advantage | Main Disadvantage |

|---|---|---|

| SHF | Ability to complete each step under the best possible conditions | Cellulase and glucosidase enzymes are inhibited by glucose produced during hydrolysis |

| SSF | Lower enzyme requirements; higher product yields | SSF conditions are more difficult to optimize |

| SSCF | Reduced capital costs; higher ethanol productivity | Diverse assimilation rates of pentose and hexose, and expensive cellulase enzymes are required |

| CPB | One microbe produces all of the necessary enzymes, as well as sugars and ethanol | Conversion time is longer than for other processes |

| Feedstock | Pretreatment/Hydrolysis | Microorganism | Modes | Ethanol Yield | Ref. |

|---|---|---|---|---|---|

| Rice straw | Alkali (NaOH)/ Accellerase® 1500 enzyme | S. cerevisiae, Candida tropicalis | Batch SSCF | 28.6 g/L | [104] |

| Rice husk | 0.1 M of FeCl3, HCl, and NaOH in triplicates at 121 °C for 15 min/Trichoderma reesei ATCC 26,921 enzyme | S. cerevisiae | SSF | 3.8% | [105] |

| Sugar cane | Acid (H2SO4) followed by alkaline delignification (NaOH)/Trichoderma reesei | Recombinant S. cerevisiae containing the β-glucosidase gene | Batch SSF | 51.7 g/L | [106] |

| Corn stover | AFEX/mix enzyme (Ctec 2, Htec 2, and Multifect pectinase) | S. cerevisiae Y35 | SHF | 45.5 g/L | [107] |

| White straw | 2.15% (v/v) H2O2, 35 °C/T. longibrachiatum, A. niger, T. reesei | E. coli strain FBR5 | SSF | 66 g/L | [108] |

| Jute stalks | Alkali (2% NaOH)/commercial cellulase and β-glucosidase enzymes | S. cerevisiae JRC6 | SHF | 7.55 g/L | [59] |

| Tobacco | Alkali 2% (CaO)/liquid hydrolysates and β-glucosidase | S. cerevisiae | SHF | 75.74 g/L | [109] |

| Crop Residue | Residue Recovery (105 tons) | Bioethanol Potential (Liters/ton) [110] | Bioethanol Production (GL) |

|---|---|---|---|

| Rice straw | 217.15 | 9.03 | |

| Rice husk | 97.73 | 416.00 | 4.07 |

| Rice bran | 28.57 | 1.19 | |

| Wheat straw | 6.30 | 406.00 | 0.26 |

| Corn stalks | 28.11 | 1.32 | |

| Corn cob | 6.13 | 470.00 | 0.29 |

| Corn husk | 12.05 | 0.57 | |

| Jute stalks | 56.32 | 418.47 a | 2.36 |

| Pulses | 2.65 | 108.21 | 0.03 |

| Sugarcane bagasse | 3.87 | 351.00 | 0.135 |

| Tobacco | 0.60 | 372.47 | 0.02 |

| Vegetables and others | 6.41 | 110.00 b | 0.07 |

| Total | 465.87 | 19.325 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahbubul, I.M.; Himan, M. Prospects of Bioethanol from Agricultural Residues in Bangladesh. Energies 2023, 16, 4657. https://doi.org/10.3390/en16124657

Mahbubul IM, Himan M. Prospects of Bioethanol from Agricultural Residues in Bangladesh. Energies. 2023; 16(12):4657. https://doi.org/10.3390/en16124657

Chicago/Turabian StyleMahbubul, Islam Mohammed, and Miah Himan. 2023. "Prospects of Bioethanol from Agricultural Residues in Bangladesh" Energies 16, no. 12: 4657. https://doi.org/10.3390/en16124657

APA StyleMahbubul, I. M., & Himan, M. (2023). Prospects of Bioethanol from Agricultural Residues in Bangladesh. Energies, 16(12), 4657. https://doi.org/10.3390/en16124657