Abstract

Within the context of climate change and the environmental impact of the building industry, insulation materials contribute to improving the thermal performance of buildings, thus reducing energy demand and carbon emissions during the operation phase. Although most of them are responsible for significant carbon emissions during their production, bio-based insulation materials can provide good performance with low carbon emissions. This paper aims to investigate natural insulation materials’ properties and environmental impacts through a literature review. Due to the growing importance of Environmental Product Declarations (EPDs) on specification requirements, many manufacturers already disclose environmental data related to their products, allowing for a comparison between thermal insulation solutions. In academic research, embodied environmental impacts are not as explored as physical properties. In addition, from the analysis of results, it is possible to conclude that the characterization of the physical properties of this type of material is normally focused on thermal conductivity. Nevertheless, most studies overlook other important parameters of these materials, such as the thermal capacity, lifetime, and environmental impacts. This is something that is necessary to overcome in future developments to allow for a comprehensive comparison between the properties of different (conventional and bio-based) insulation materials.

1. Introduction

Climate change’s consequences on the world are already well known, and the most recent publications show an increased urge to deal with the transition to a more sustainable way of life on the planet. According to the latest Intergovernmental Panel on Climate Change (IPCC) report [1], limiting global warming to 1.5 °C or even 2 °C is hardly possible without a significant reduction in greenhouse gas (GHG) emissions. Emissions should be reduced by 45% from 2010 levels before 2030 to limit temperature rises and not cause an irreversible impact [2].

On this topic, construction is a key sector in which to intervene. In Europe, for example, buildings are responsible for 40% of the energy used, 36% of energy-related GHG emissions, and 80% of household energy use is related to thermal comfort [3]. Furthermore, the built environment is responsible for 50% of all the materials extracted and 35% of all waste produced [4]. In G7 countries, GHG emissions from the residential building material cycle can be reduced by 80 to 100% by 2050, with the efficient use of materials and by using recyclable materials [5].

In the European context, some strategies to address decarbonization have been developed under the scope of the European Green Deal [6], which aims at Europe becoming the first climate-neutral continent by reducing greenhouse gas emissions by 55% by 2030. As a consequence, the Energy Performance Building Directive (EPBD) recast 2022 will have a deep impact on the future thermal regulations of member states [7]. The revision envisages double renovation rates in the next ten years as well as demanding the calculation of the life cycle Global Warming Potential (GWP) for new buildings from 2030 onwards. Not only energy performance will be considered but also healthy indoor climate conditions, adaptation to climate change, and carbon storage in buildings, among others.

Therefore, it is necessary to develop methodologies to support adequate decision making in the choice of materials to promote energy efficiency since it can lead to a considerable reduction in life cycle energy use and GHG emissions. This reduction can be between 35% and 40% [5], and most of it can result from the use of renewable-based materials [8]. The new circular economy action plan [4] emphasizes the importance of recycled materials to reduce emissions in the production stage. This highlights the importance of using natural and recyclable materials, as synthetic materials have a more complex recycling process.

In this context, building insulation is crucial to reduce operational energy, especially to reduce heat losses. However, insulation materials are one of the largest contributors to emissions and, therefore, to the environmental impacts of the construction materials. Research on 503 buildings found that 26.1% of total carbon emissions came from insulation material production [9], the largest after concrete production that represents 33% [9]. Nonetheless, with recent concerns to improve energy efficiency, more insulation tends to be used in buildings. It is estimated that the global market of thermal insulation materials will continue to grow, and plastic-based foam insulations, such as Extruded Polystyrene (XPS) or Expanded Polystyrene (EPS), which already represented 41% of the insulation product market in 2015, will have the highest growth rate [10].

Embodied carbon in insulation products varies a lot, but there is a clear difference in solutions based on biological materials since they can have a carbon-negative balance [11].

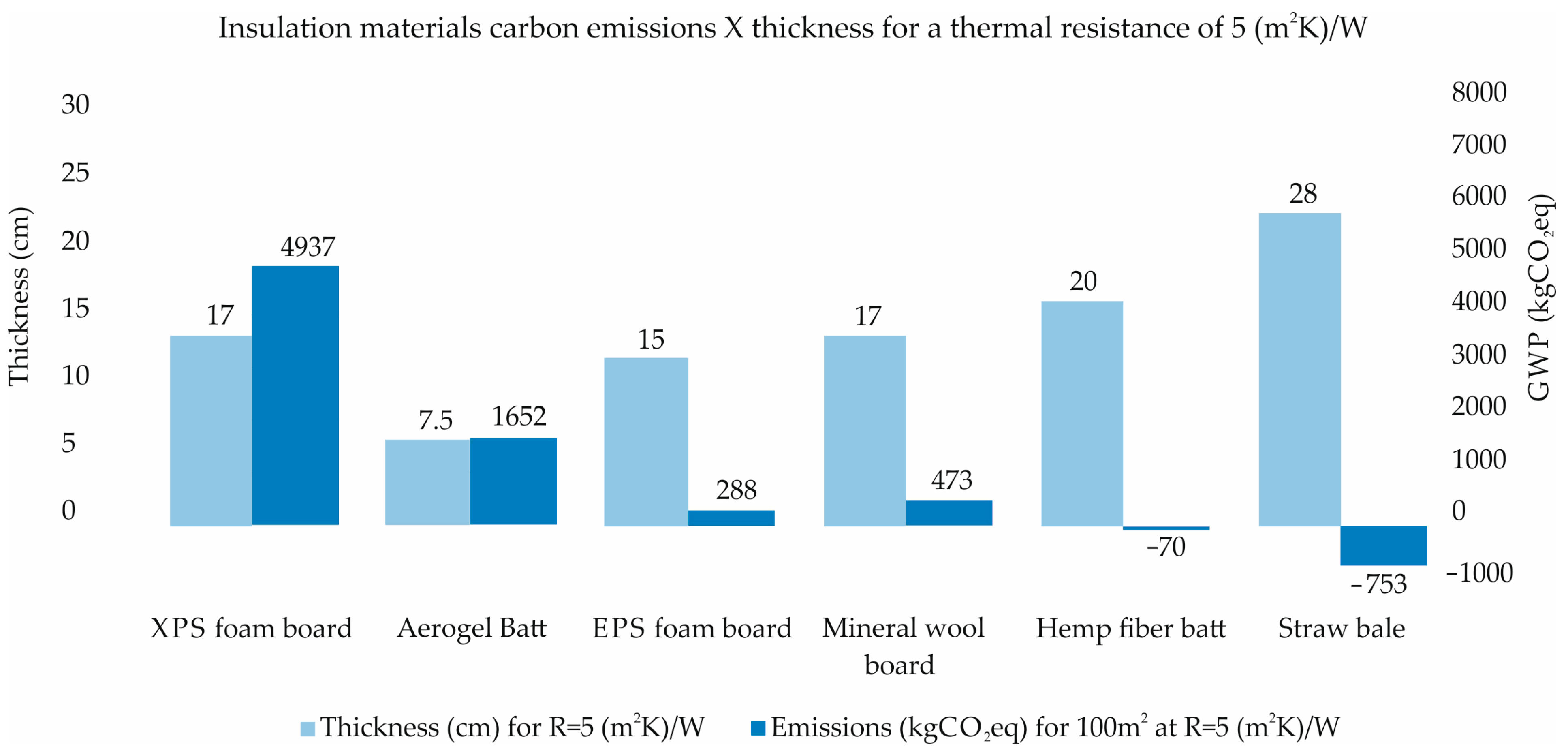

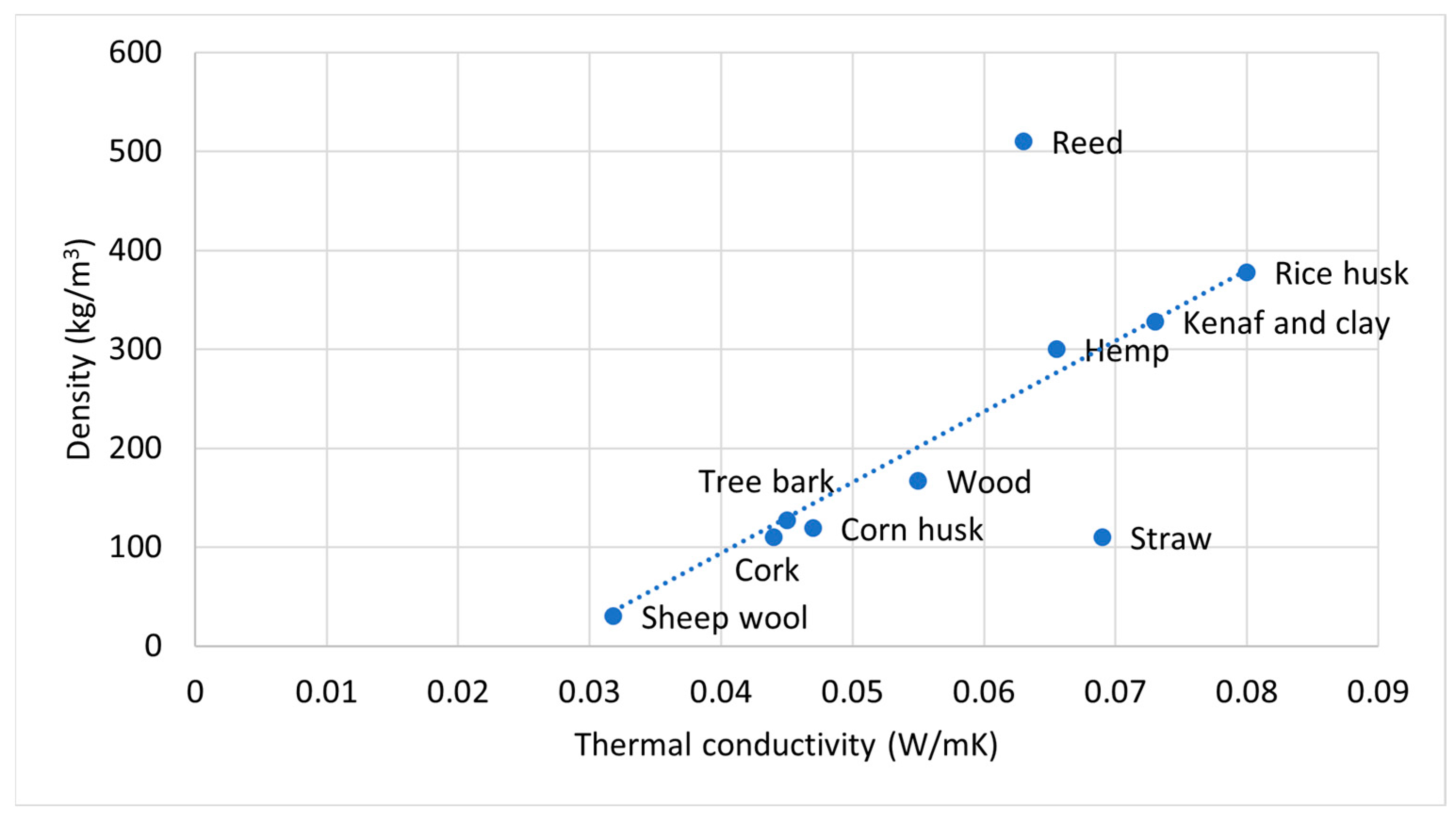

Figure 1 shows a comparison between different insulation materials, considering a functional unit of 100 m2 and a thermal resistance of 5 (m2K)/W. From the graphs, it is possible to verify that bio-based materials have the best GWP performance over plastic- and mineral-based solutions. However, despite carbon sequestration due to biogenic carbon, a thicker layer of the material might be needed to provide the same thermal resistance. A comparison between insulation material thickness and carbon dioxide emissions for a thermal resistance of 5 (m2K)/W can be observed, adapted from [9].

Figure 1.

Comparison between insulation material thickness and carbon dioxide emissions for a thermal resistance of 5 (m2K)/W. Adapted from [9].

Thus, taking Figure 1 into consideration, it is essential to develop new insulation solutions that have low embodied environmental impacts and can fulfil the functional requirements for maximum comfort.

When it comes to building renovation, which is specially addressed in the latest European directive, EPBD recast 2022 [7], it is essential to understand that in the past, passive strategies, including the use of bio-based insulation materials, were the main principle to deal with thermal comfort. For example, some vernacular timber buildings on Portugal’s coastline used an external cavity wall filled with reed to provide thermal insulation [12]. All over the world, natural fibers have been used in thatched roofs, as well as in woven walls made of weeds or bamboo covered by clay plasters [13]. In the Baltic Sea region, a common reed (Phragmites australis) was used as an insulation layer outside of a log wall due to its good thermal insulation capacity and water vapor permeability [14].

In energy renovation, although external insulation is the best solution, in some cases, internal insulation is the only option. In both scenarios, natural materials should be chosen to comply with functional requirements and technical features of the existing structure/support [15]. In some construction systems, such as natural-based ones (e.g., earthen walls, timber, etc.), conventional thermal insulation materials can create or aggravate possible anomalies, mainly due to their low vapor permeability [16].

In this sense, due to the potential of bio-based thermal insulation solutions to improve both the thermal and environmental performance of buildings, this study aims to investigate and compare the functional and environmental characteristics of bio-based materials through an extensive literature review. The research focuses on organic bio-based-derived and innovative materials, which can improve the thermal comfort of buildings at a lower potential environmental impact, both for renovation and in new constructions.

2. Materials and Methods

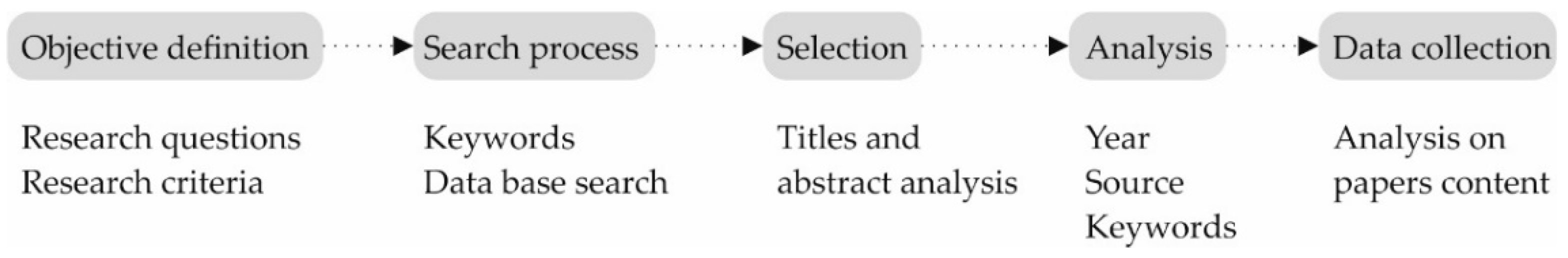

In this section, a detailed description of the methodology used is presented. The systematic literature review followed the framework presented in Figure 2.

Figure 2.

Methodology’s framework.

The research questions that guided this work are:

- Are bio-based materials suitable for building insulation?

- What are the main properties to consider in an insulating material?

- What is the environmental impact of bio-based insulation materials versus conventional insulation materials?

The research method was based on a review through a bibliometric approach to identify trends in natural insulation materials and their environmental impact.

The literature review was carried out through the Scopus database due to its representativity among academic works. Since this review focuses on the effectiveness of natural insulation materials, both from functional and environmental perspectives, four categories of keywords were selected for the search: natural building materials, thermal efficiency, carbon footprint, and some known natural materials.

The following keywords were used: “insulation”; “insulated”; “natural insulation”; “thermal insulation”; “insulated wall”; “thermal conductivity”; “thermal behavior”; “innovative bio-based panels”; “climate-neutral construction”; “natural construction”; “bioconstruction”; “green building”; “energy efficiency”; “thermal efficiency”; “thermal characterization”; “thermal performance”; “emissions”; “embodied carbon”; “carbon storage”; “biogenic carbon”; “carbon footprint”; “environmental impact”; and, “life cycle assessment”; “reed”; “hemp”; “straw”; “wool”; and “natural fiber”.

Exclusion criteria were applied to language (only publications in English were selected), publication type (only journal articles and conference proceedings), and year of publication (only the last 5 years’ publications were considered, meaning 2022, 2021, 2020, 2019, and 2018).

The “Transparent Report Meta-Analyses (PRISMA)” [17] checklist was followed according to its four steps. In the identification step, 1243 results were found considering different keyword combinations. For the next step, called the screening stage, duplications were excluded, and 1179 results remained. In the third step, the eligibility check was conducted, and 81 publications were selected. The eligibility check step excluded publications about other ecological materials that are not for building insulation purposes or not related to the construction industry. In the fourth step of PRISMA, the inclusion step, the record continued to include the same 81 publications (Table 1).

Table 1.

Database search and results.

The table below represents the keyword combinations made and the results found.

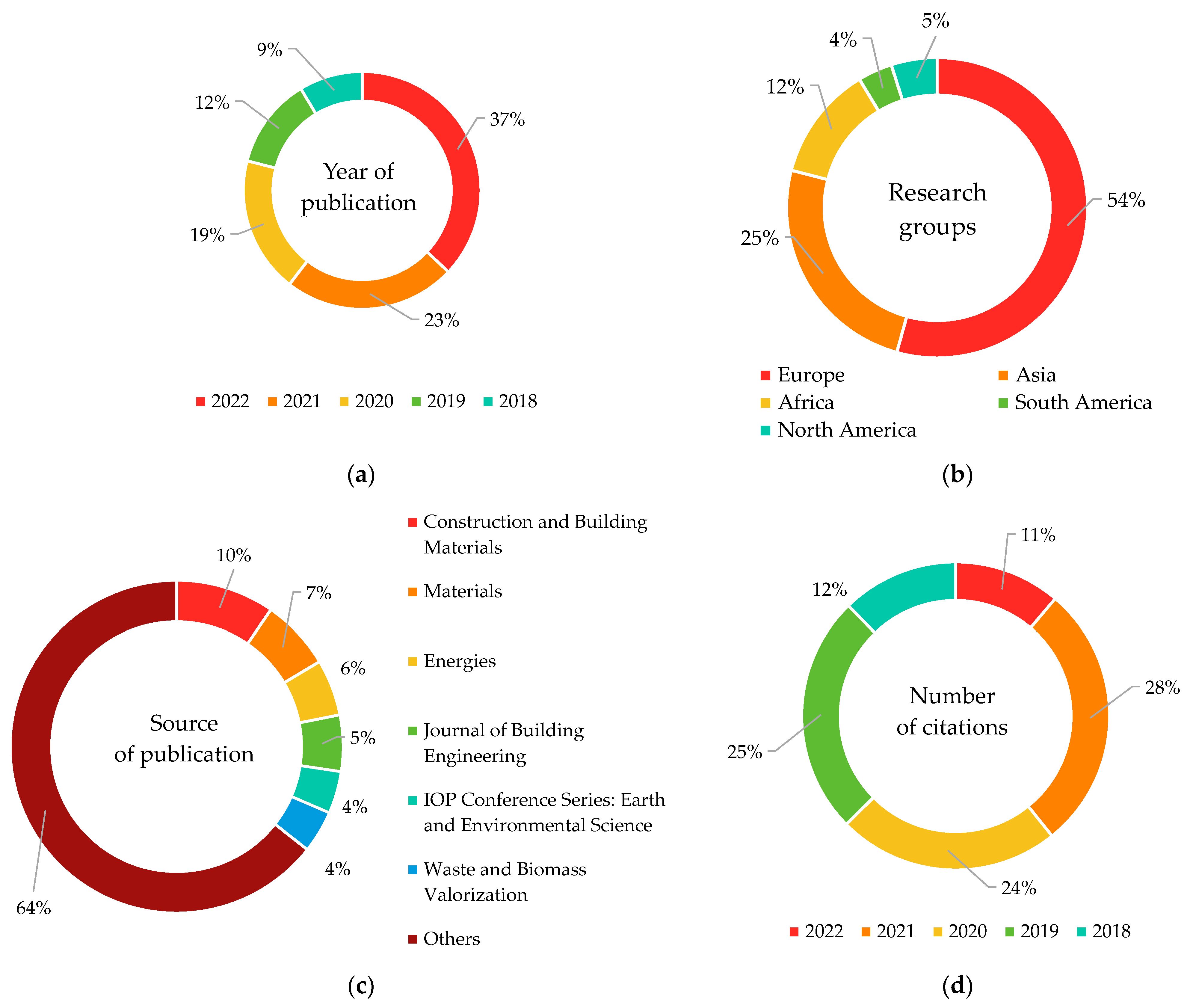

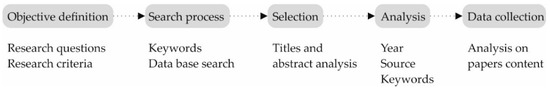

Most of the publications are from Europe (54%) and Asia (25%); surprisingly, very few American and no Oceanic academic publications were found among the selected publications. The year with the largest number of publications was 2022, followed by 2021, showing a crescent interest in the field. The Journal Construction and Building Materials was the source responsible for 10% of them. The publications had a total of 839 citations on Scopus, 28% in 2021, 25% in 2019, and 24% in 2020. Figure 3 shows an overview of the publications selected to visualize the research context.

Figure 3.

Publication’s overview. (a) Year of publications, (b) research group’s location, (c) source of publications, (d) number of citations per year.

To complement and allow for comparison, information with commercially available insulation products and environmental product declarations (EPDs) from different databases was also reviewed.

Three sets of parameters were reviewed and analyzed, as presented in the following sections: physical parameters, mechanical parameters, and environmental parameters.

2.1. Physical Parameters

Insulation materials are usually first classified by their physical properties. Density has a great influence on all other parameters, as further explained, and, therefore, it is an essential feature. The density unit commonly used is kg/m3 and is defined by the material’s mass per unit of volume, as presented in Equation (1):

where is the density, m is the mass, and V is the volume of the sample.

Bulk density can also define the number of voids present on a sample and whether the material is compacted or loose, which influences other characteristics.

Thermal conductivity is probably the most important feature of insulation materials, as it stands by the capacity to conduct heat and, therefore, to insulate. It is denoted by the letter “κ” or “λ” and its SI unit is W/mK (Watts per meter Kelvin). Thermal conductivity measurement will depend on the heat flux through a material and is defined by Fourier’s law, in which its differential form is expressed in Equation (2):

where is the heat flux density in W/m2 (Watts per square meter), κ is the thermal conductivity, and is the temperature gradient expressed in Kelvin per meter. The lower the thermal conductivity, the better the insulation property of the material.

The standard ISO 9869-1 [18] is one of the standards most used to define thermal insulation of building elements. It defines the thermal resistance and the thermal conductance of a material or solution. Equations (3) and (4) represent calculations according to the ISO:

where is the thermal resistance, q is the heat flux density, Tsi and Tse stand for the temperature of the internal surface and temperature of the external surface, respectively, U is the thermal transmittance, and Ti and Te are internal temperature and external temperature, respectively.

R-value and U-value depend on the thickness of the material or construction solution. Usually, researchers address these properties when comparing building solutions.

When talking about the thermal properties of insulation materials, it is essential to also explore the heat capacity of each material as well as diffusivity and effusivity properties. Once thermal conductivity is a measurement at a steady state, it is important to know how long it takes to achieve that state. That is the reason why heat capacity becomes an essential feature.

The higher the heat capacity, the smaller the thermal diffusivity, meaning that the heat will move more slowly through the material. Additionally, a greater thermal capacity will result in greater thermal effusivity, which means that the material will be cool to touch.

Thermal effusivity and thermal diffusivity are linked to the thermal conductivity, heat capacity, and density of a material. Equations (5) and (6) represent how effusivity ( and diffusivity () are calculated, respectively:

where is thermal conductivity; is the specific heat capacity; and is the density.

Another point of attention in evaluating thermal performance is thermal stability, which, according to standard ASTM E2550 [19], is the temperature at which the material starts to decompose or react. Thermal stability can be measured using a thermogravimetric analyzer (TGA) and defines the ability of the material to maintain its properties under extreme temperatures.

Beyond thermal properties, but also within the physical parameters, water absorption is a crucial property to provide durability to the material and avoid building pathologies. The water absorption coefficient, also known as sorptivity, is the moisture transport into the material. According to the standard ISO 62 [20], the water absorption coefficient is expressed using Equation (7):

where c is the change in mass; m2 is the mass of the material after water immersion; and m1 is the mass of the material after drying and before immersion.

Another related property is the water vapor diffusion resistance factor, the μ-value. This factor is the ratio of the water vapor permeability of the air and the material’s water vapor permeability, which stands for the water vapor transmission rate through a certain area of the material at a unit thickness.

The last analyzed physical property is fire resistance, addressed in the standard EN ISO 13501-01 [21]. Fire resistance classification in Europe varies from A to F and will determine whether the insulation material can help stop the fire or collaborate to spread it in the building. Through the standard, it is also possible to classify the material in terms of smoke production and flaming droplets and particles.

2.2. Mechanical Parameters

In addition to physical parameters, mechanical characteristics should be analyzed on insulation materials to evaluate durability and application methods. Five properties are usually assessed on insulation materials, such as: compressive strength, flexural strength, tensile strength, modulus of rupture, and modulus of elasticity.

Compressive strength measurement is useful to assess the behavior of fragile materials and the relationship between linear deformation as a function of the applied load.

The flexural strength test evaluates how the material reacts in an elastic regime; it is also useful to determine the modulus of rupture (MOR). Tensile strength assesses the material deformation while a stretching effort is made; it will also define the modulus of elasticity (MOE) of the material.

Compressive, flexural, and tensile strengths and modulus of elasticity and rupture are measured in megapascals (MPa) or Newton per square millimeters (N/mm2).

2.3. Environmental Parameters

Considering the environmental issues discussed in the Introduction, beyond physical and mechanical parameters, it is essential to evaluate environmental parameters as well.

Considering a life cycle approach for the environmental assessment of buildings [22], this review considers the product stage only, from modules A1 to A3, as it is the minimum that must be considered in EPDs.

Under this stage, from raw material supply to manufacturing, including transport, three main parameters are analyzed: use of primary energy, considering renewable and non-renewable energy (measured in MJ), global warming potential (measured in kgCO2 eq.), and, when applicable, biogenic carbon.

3. Results and Discussion

3.1. Sample Characterisation

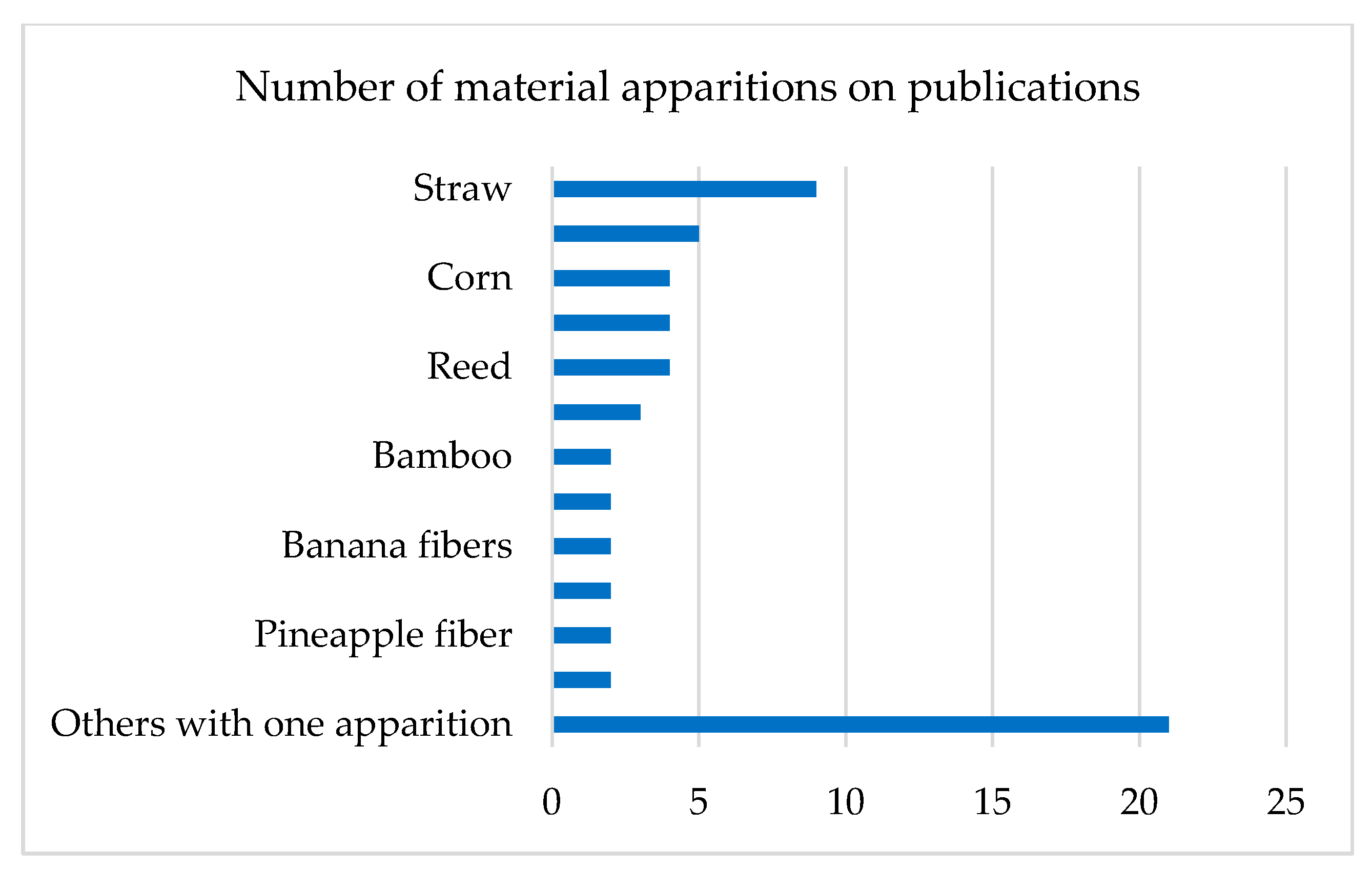

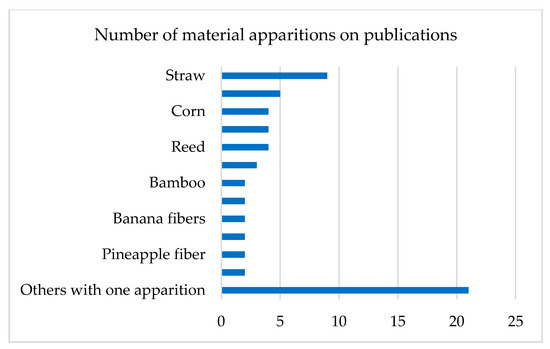

Among the selected academic publications, 33 different materials were addressed. The most studied material was straw, followed by sheep wool, as shown in Figure 4. The analysis of academic research suggests a tendency to focus on plant fibers, especially agricultural waste and fast-growing plants.

Figure 4.

Number of occurrences in publications by type of material.

Most publications addressed composite materials (77%, or 37 publications), while only 23% (11) focused on the raw material as a product. Among composite materials, 51% (19) used some chemical material, such as polypropylene composites, magnesium phosphate cement, or polyvinyl alcohol, mostly with a binder purpose. However, 49% (18) of total publications do not use any kind of artificial additive.

3.2. Physical Parameter Analysis

As previously cited, the following physical properties were analyzed: density; thermal conductivity; heat capacity; thermal effusivity; thermal diffusivity; thermal stability; water absorption and/or vapor permeability; and fire resistance. The physical properties of materials were the most cited parameters, especially density and thermal conductivity.

3.2.1. Density and Thermal Conductivity

Regarding thermal conductivity, several measurement methods have been used between steady-state and transient methods. No method preferences were observed, and no relationship was established between the values obtained and the measurement methods.

The most cited material in academic research, straw, presents great potential as an insulating material, which explains its importance in the research field. The lowest thermal conductivity for a wheat straw insulation panel, with a 4 cm length straw, was 0.046 W/mK for a density of 105 to 112 kg/m3 [23].

Changes in the way the material is used in the product can change its characteristics. By changing the orientation of fibers on a straw bale, with heat flow perpendicular to straw orientation, it is possible to improve thermal resistance and, therefore, reduce the thickness of the insulation product by 28% [24].

The second most cited material in the literature was sheep wool, a known commercial material with high insulation potential. Sheep wool’s best values rely on the raw material characteristics, having a thermal conductivity of 0.0318 for a density of 30 kg/m3 [25]. Due to its insulation properties, some studies used wool as an aggregate to improve the thermal and/or mechanical performances of other materials, such as gypsum board [26] and brick [27].

Reed, as cited before, was a material used in vernacular buildings to improve thermal comfort, and research shows that its thermal conductivity can reach 0.056 W/mK for a density of 137 kg/m3 [28]. For a specific species known as giant reed (Arundo donax) and highly spread in Europe due to its invasive characteristics, the thermal conductivity is 0.063 W/mK for a density of 510 kg/m3 [29].

On the other hand, cork has a consolidated path in the construction industry. Its lower thermal conductivity is 0.044 W/mK for an agglomerated cork panel [30]. Other materials did not show such great thermal performance, except when used as aggregates for inorganic materials, such as cement.

Wood fiber insulation board has a thermal conductivity of 0.035 W/mK for a 100–150 kg/m3 density [31], similar to sheep wool [25]. Nevertheless, this value is obtained when the wood fiberboard is prepared with melamine formaldehyde-urea (MFU) resin adhesive [31], which, theoretically, would increase the embodied potential environmental impact of this insulation product. Without chemical binders, wood insulation thermal conductivity values could increase to 0.048–0.055 W/mK [32], still presenting a good performance.

The banana–polystyrene composite presented a thermal conductivity of 0.0183 W/mK [33]. In addition, an aerogel composite of pineapple leaves and cotton waste showed good thermal performance and simultaneously a very low density [34]. These data reveal a great potential of plant fibers, namely of some types of leaves.

Hemp products showed similar values to those of tree bark [35,36] and have a thermal conductivity of around 0.05 W/mK [37]. However, hemp-based insulation has the disadvantage of high water absorption capacity, as values above 20% can double the thermal conductivity, and water absorption can lead to a 198% increase in mass and 40% in volume [37].

In the case of husk-based materials, their performance seems to depend on the origin of the species. Corn husk presented a thermal conductivity of 0.047 W/mK [23], whereas a composite with rice husk shows a value of 0.08 W/mK [38], and wheat husk presented a thermal conductivity of 0.1 W/mK [38].

In addition to the intention of creating insulation materials, many research works still show low thermal performances, meaning high thermal conductivity (TC) values for an insulation product, as for mussel shell (TC of 0.12 W/mK) [39], groundnut shell (TC of 0.27 W/mK) [40], or wine waste composite (TC of 0.35 W/mK) [41].

Concerning natural materials and their heterogeneity, most authors confirmed a wide range of values for thermal conductivity depending on various aspects, such as density [35,42] or particle size [39].

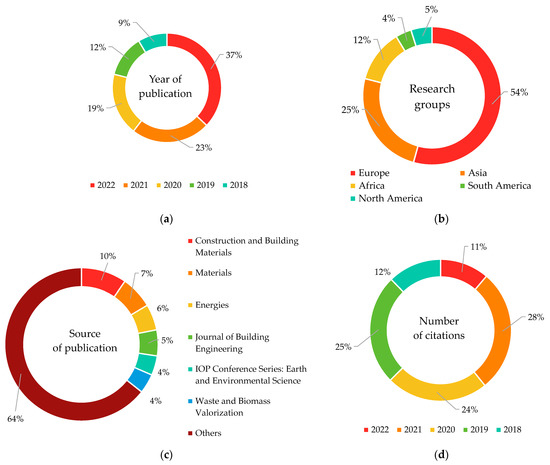

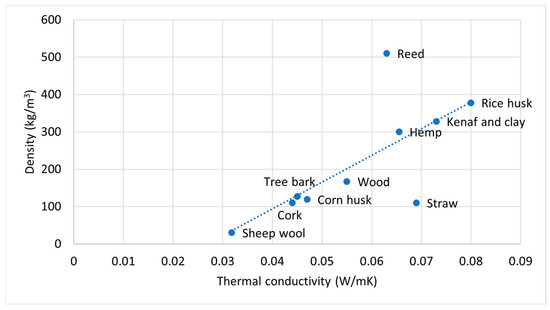

Lifang Liu et al. [43] showed that on a bio-insulation material based on wheat straw, the bigger the straw length, the lower the thermal conductivity and the lower the density of the sample. Further, for the Sabai grass polypropylene composite, the higher the density, the higher the thermal conductivity of the sample [44]. The same happened for wood fiber insulation boards [31]. It shows that there is a direct relation between density and thermal conductivity. Figure 5 shows this trend by presenting the relationship between the density and thermal conductivity.

Figure 5.

Relation between density and thermal conductivity.

Viel, Collet, and Lanos [45] stated that thermal conductivity may depend on the density but is also impacted by the type of binder used in the material.

The use of binder aggregates must be studied, as it can cause changes in thermal conductivity. A composite with hemp shiv and polyvinyl alcohol (PLA) showed a higher thermal conductivity than other samples without any binder [45]. However, any mix with hemp shives still has lower thermal conductivity than corn cob residues [45].

Using natural fibers as aggregates can improve other physical characteristics of already commercialized materials. For example, Guna et al. [46] managed to improve airborne sound insulation and lower the thermal conductivity by 70% by adding mulberry stems on a gypsum board for ceiling applications.

3.2.2. Heat Capacity, Effusivity, and Diffusivity

Regarding the thermal effusivity property, Cottrill et al. [47] highlighted that thermal effusivity is still quite unexplored, and studies tend to focus on improving thermal conductivity only. This fact corroborates the results of this review, since only two publications mention effusivity values. Muthuraj et al. [38] identified that a rice husk composite has lower thermal conductivity (0.08 W/mK) among other materials and also has a lower effusivity, meaning less thermal energy exchange.

Salazar et al. [48], through an innovative measurement method, confirmed that as the porosity of a material increases and, consequently, the density lowers, the thermal effusivity decreases, moving close to air effusivity. While air thermal effusivity is 5.5 W∙s1/2/m2K, XPS has a thermal effusivity of 54 W∙s1/2/m2K, and the cork insulation board presents a value of 180 W∙s1/2/m2K [48].

Only two publications addressed the relationship between thermal conductivity and heat capacity characteristics, and divergent results on the relationship lead to a point to be further explored. On an almond skin composite, thermal diffusivity and heat capacity were measured, and the study revealed that the best solution (almond skin, gum Arabic, and water) concerning thermal conductivity had the lowest thermal diffusivity (0.18 × 10−6 m2s−1) and the highest volumetric heat capacity (0.416 × 10−6 J/m−3K−1) [49]. On the other hand, oven-dried wood waste presenting a lower density (117 kg/m3) and lower thermal conductivity (0.0528 W/mK) showed the lowest volumetric heat capacity (0.1026 × 106 J/m3K) and higher thermal diffusivity (0.5153 × 10−6 m2s) among other samples with the same material [32]. Heat capacity and diffusivity are inversely proportional, yet just a few studies addressed these properties, and, thus, more research should be performed on their relationship with thermal conductivity and density.

Some manufacturers do not make clear the diffusivity value but, instead, present the time lag of the material, i.e., how long heat takes to pass through. For example, rice straw panels [50] have a time lag of 10:30 h for 300 mm thickness, which shows a good heat capacity of the material and, therefore, a great thermal diffusivity.

3.2.3. Water Absorption

A few research studies show water-related features. These studies usually consider water absorption after 24 h of the immersed material, with a value expressed as a percentage.

A sample of wheat straw and clay had about 0.02% of moisture content after one hour immersed in water and about 0.06% of moisture content after 24 h [51]; this is due to the hydrophilic characteristic of clay used in the research. Still, wheat straw bale, known for its good thermal performance, showed an initial moisture content of 11 to 16% and water absorption of 65% to 75% [52]. Biomass fibers of wheat straw of a density of 0.312 kg/m3 had a water absorption rate of 365%, while seagrass fibers of 0.721 kg/m3 showed 293% of water absorption [42]. Water absorption is affected by the particle sizes of the specimen, with smaller particles leading to higher water absorption [35]. Regardless of the material, water absorption also varies according to the type of processing and how the material is presented, as additives and previous handling can completely alter the final characteristics.

Arundo donax reed composite had a water absorption rate from 57.3% to 88.16% [53], while the raw material reached just 52.6% [29].

The lowest presented value of water absorption came from the mussel shell, from 2.17% to 2.56% [39].

3.2.4. Water Vapor Permeability

Specialist builders agree that insulation and coatings must maintain the permeability and breathability of walls, as in vernacular buildings [54]. Thermal insulation should provide fast moisture redistribution to avoid condensation zones [15].

Research on five bio-based materials for insulation (wood fiberboard, flax fibers, hemp fibers, jute fibers, and sheep wool) concluded that other than good thermal conductivity values, they have a high moisture diffusivity, comparable to hydrophilic mineral wool, therefore, allowing one to avoid the use of water vapor barriers [15]. Lafond and Blanchet [55] compared bio-based insulation materials with expanded polystyrene and concluded that thermal conductivity can have the same range, but vapor permeability tends to be up to three-times better, depending on the geometry of internal structures.

On manufacturers’ datasheets of products, instead of addressing water absorption, they usually mention the water vapor diffusion resistance factor (μ-value).

Regarding commercialized products, the water vapor coefficient varies from 1 μ to 2 μ for most natural materials, for example, for grass insulation [56], but reaches 200 μ for extruded polystyrene [57]. Although grass insulation and extruded polystyrene have similar values for density and thermal conductivity, their behavior towards water and moisture is completely different. Despite higher water absorption rates in natural fibers, which can increase thermal conductivity, using breathable insulation will prevent the risk of condensation and mold and, therefore, promote better indoor air quality.

In academic research, no references to vapor permeability were found, which identifies a research gap in the field.

3.2.5. Fire Resistance

Considering fire resistance, very little academic research addresses this topic. Although natural insulation materials may be considered combustible, in certain conditions, they are safer than conventional insulation materials. For example, they release less smoke during combustion in comparison to expanded polystyrene, which can produce 32-times more smoke than wood batt insulation [55].

On a compressed product such as a straw bale, an optimal fire resistance can be achieved. During a 15 min fire resistance test, a straw bale sample of 108 Kg/m3 density with a 5 mm clay plaster layer had its straw charred to a 55 mm depth only and did not spread flames due to its high density [58].

Two publications that address polypropylene and polystyrene composites classify fire resistance by the American standard UL94 for plastic flammability [46,59]. Once a composite of 90% sheep wool and 10% polypropylene has a V-0 rate [59], indicating that burning stops within 10 s on a vertical part, mulberry composites have a rate from V-1 to V-2 [46], meaning that burning stops within 30 s on a vertical part, allowing for non-flammable and flammable drops of plastic, respectively.

Following the standard expected in the methodology, despite a fire resistance classification of Euroclass E for most materials’ specifications, some materials already installed, with plaster or inside walls, can present a better classification. For example, strawbale covered by plaster presents a classification of Euroclass B/S1/d0, according to its EPD [60].

To summarize the topic of physical parameters, Table A1 in Appendix A shows an overview of parameters found in the literature.

3.3. Mechanical Parameter Analysis

Most academic publications address the mechanical behavior of developed products to evaluate their durability and to determine for which building elements they are suitable, such as floors, ceilings, or walls.

As a normal tendency in conventional building materials, the mechanical properties improve proportionally to the material’s density [61]. However, for mixed materials, this is not always true, as one element can weaken the other [61], which is usually the case with natural fiber composite materials.

In a specific study, Guna et al. [44] affirmed that as density increases, tensile and flexural strength decrease. This happens because as density increases, the amount of natural fiber in the composite increases and the amount of polypropylene binder left is not enough to keep the composite together [44]. In another study, on a mulberry stem and a polypropylene sample, increasing the amount of natural fiber from 80% to 90% increased the tensile strength by 11%; however, by increasing again to 95% of natural fibers, the tensile strength dropped by 18% [46], also probably due to the lack of binder material.

Concerning compressive strength, while EPS has a value of 0.14 MPa, corn husk composite presents 0.024 MPa, and wheat husk composite 0.057 MPa [23]. Wheat straw can reach 0.15 MPa of flexural strength, a similar value to the one of EPS, for which the standard is 0.20 MPa. In contrast, corn husk could reach 0.80 MPa [23].

Hussein et al. [62] investigated insulation boards made of rice straw and flax shives and concluded that compressive strength from flax shives was much higher, reaching up to 12.4 MPa, mainly due to its smaller particles.

Ancillary materials, such as binders and additives, play an important role in mechanical performance since mixing natural fibers with clay could considerably improve the compressive strength of the final material. The compressive strength of a wheat straw composite with clay could reach 3.13 MPa, and by increasing the amount of clay, it could reach 5.9 MPa [51]. Sheep wool clay mix shows a compressive strength as high as 4.9 MPa [51].

A bi-layered composite of cork particles and inorganic polymer revealed a compressive strength of 0.93 MPa, which is a good value considering that it is a low-thermal-conductivity material [63].

Table 2 highlights the mechanical performance of materials found in the literature.

Table 2.

Mechanical characteristics of reviewed materials.

3.4. Environmental Parameter Analysis

Regarding the importance of the environmental impact assessment discussed above, some publications highlight the importance to consider it [23,37,71], but only a few present values for the environmental performance of the products studied.

Rojas et al. [23] highlighted that the embodied energy from the use of wheat straw would be recovered in the second year of the building, i.e., in less than 5% of the building’s lifetime.

Considering a lifetime of 60 and 30 years, a novel bio-insulation composite has a biogenic carbon of 54 and 49 gCO2-eq resulting in a positive Global Warming Potential value of 30 and 36 gCO2-eq, respectively, due to the manufacturing process involved [71]. Carcassi et al. [71] raised attention to the importance of a longer lifetime of bio-based insulation products to maintain high carbon sequestration in buildings. Despite being an interesting idea to grow building products such as mycelium-based insulation, the final product still has a disadvantage compared to other bio-based insulation products, namely the need for a higher thickness to achieve the same insulation and a slightly higher potential environmental impact when compared to negative-carbon materials such as straw.

The use of bio-based materials should be considered in locations close to where they are harvested to avoid unnecessary transportation and, consequently, possible environmental impacts. Parlato, Porto, and Valenti [25] evaluated the resource availability in Italy and concluded that raw sheep wool waste could generate around 1.5 million soft mats, fulfilling the Italian market demand, which, nowadays, imports its products from different countries.

A dynamic life cycle analysis that includes embodied biogenic carbon showed that fast-growing biogenic materials, such as discarded biomass from agricultural crops, can lead to a significant reduction in greenhouse gas emissions [11]. Land available for growing wood and straw can provide enough materials for the European renovation market. However, hemp and cork can only supply a local market, since a large-scale supply chain is not reasonable [72].

Table 3 consists of values from existing insulation materials extracted from several databases, considering the product stage from A1 to A3, namely raw material acquisition and manufacturing.

Table 3.

Environmental performance of insulation materials.

Environmental Product Declarations (EPDs) from different databases were used in this analysis as no academic research showed a clear method to evaluate the presented environmental parameters. For the comparison, we used a functional unit of 1 m2 with a thermal resistance of 2.5 m2K/W.

Among the analyzed materials, wheat straw bale and grass insulation need to have the greatest thickness, 12 and 10.25 cm, respectively, to achieve a thermal resistance of 2.5 m2K/W. On the other hand, the polyurethane (PU) rigid panel, expanded polystyrene (EPS), and extruded polystyrene (XPS) only need a thickness of 5.5, 7.5, and 8.5 cm, respectively, to achieve the same performance.

Nevertheless, when primary energy use is considered, expanded corkboard, grass insulation, and wheat strawbale have the highest values, probably due to the harvest process involved. The lowest values for primary energy use stand with the insulation board with cotton and denim natural fibers, as well as sheep wool loose-fill insulation, followed by conventional insulation, EPS, XPS, and PU rigid panels.

Concerning global warming potential, the lowest values were among straw, grass, wood fiber, and hemp wool, probably due to the high biogenic carbon once GWP presents as negative values. As expected, conventional materials have the highest values.

It is important to highlight expanded corkboard insulation values for GWP. The value on the EPD from a Portuguese manufacturer presented the lowest value from the table; this can be deduced already considering the biogenic carbon, since the value is negative and no information on biogenic carbon alone is mentioned. On the other hand, information on the same material from the French Ministry for ecological transition, generic data provided due to the lack of national EPD, shows the highest value for GWP and without information on the origin of the material. From these data, we can point out the importance of using specific manufacturing information instead of generic data that can lead to mistakes in the final evaluation.

Some materials addressed in academic research as possible insulation materials, such as reeds and leaves of various plants, did not have EPD or environmental assessment, making comparison impossible.

Regarding the environmental analysis of insulation materials, natural materials stand out, especially fast-growing plant fibers due to their biogenic carbon. The shift in mindset from using conventional materials to using natural materials that can store more carbon and compensate for emissions is promoting the use of bio-based materials, as in the normal life cycle scenario of plant carbon would return to the atmosphere in a shorter time. Biogenic carbon emissions are related to the time needed for biomass regeneration [76]. Fast-growing bio-based materials can help to compensate for carbon emissions, as it is nearly impossible to have zero embodied GHG emissions, especially due to highly processed materials still being needed in some foundations and as a stabilizer for some materials [77]. Keena et al. [78] highlighted that bio-based solutions for built environments have lower environmental impacts, in a life cycle approach, per functional unit than other conventional solutions.

4. Conclusions

This review highlighted the extensive nature of bio-based insulation materials and their multitude of combinations. Despite the great number of publications found in the bibliographic databases, most of them are focused on conventional materials or improvements in materials based on synthetic components. The characterization of natural materials should be made to promote the least processed materials possible.

Many times, natural materials are treated as aggregates for composites, despite some findings that show that raw materials provide better thermal performance, as for sheep wool [25]. Potential bio-based insulation materials should be tested in their raw form and then with different binders, preferably natural, to improve their mechanical, functional, and environmental characteristics.

Additionally, few research studies addressed the environmental performance of bio-based insulation materials. More comprehensive environmental studies will highlight the environmental advantages of using this type of material, which would contribute to promoting its use. It is seen that ecological innovations can replace conventional materials and ensure the same energy efficiency during the operation phase of buildings.

The results obtained provide an overview of recent studies and identify a gap in research for an environmental impact assessment on insulation materials. There is a gap concerning the number of environmental product declarations between conventional insulation materials, such as XPS and EPS, and bio-based unconventional insulation materials, such as natural fibers. Research on this matter must be conducted to provide information for future EPDs on bio-based insulation materials.

A lack of characterization of thermal mass and thermal inertia, which can be characterized by the heat capacity and diffusivity parameters, was also identified among recent publications, providing better solutions for constructions, especially those for the renovation of vernacular buildings. The complete characterization of the applied material and that to be applied allows for the simple and low-cost renovation of the building stock, without pathologies, such as extreme condensation and poor use of the passive energy efficiency potential generated by the materials used. As building rehabilitation is an important topic in current and future regulations, it is important to think of vernacular buildings as an opportunity to produce healthier housing through natural materials.

Since the most recent European building directive, EBPD recast 2022 [7], aims to reduce life cycle greenhouse gas emissions and energy consumption by setting energy and CO2 emission performance targets, it encourages the development of environmentally friendly products.

The research findings disclosed the potential of using natural fibers as insulation materials. However, further research is needed focusing on the life cycle assessment of new products to make them adequate for future regulations. Based on the outputs of this study, some recommendations can be made for future research:

- To analyze the heat capacity of materials as a way to understand long-term thermal behavior and explore the decrement delay of materials;

- To use natural binders and optimize manufacturing processes to reduce potential environmental impacts;

- To perform a cradle-to-cradle life cycle assessment of existing insulation materials to better understand their impacts and how they fit into the circular economy targets.

This review concludes that bio-based insulation materials have significant potential to improve building performance, fulfil requirements, and promote a more sustainable industry, despite further needed work.

For future research, it is suggested to include other parameters in the analysis, such as local availability, cost-effectiveness, and potential applications of bio-based insulation materials for several types of buildings.

Author Contributions

Conceptualization, L.C., J.F. and R.M.; methodology, L.C., J.F. and R.M.; validation, L.C., J.F. and R.M.; formal analysis, L.C., J.F. and R.M.; investigation, L.C., J.F. and R.M.; resources, L.C., J.F. and R.M.; data curation, L.C., J.F. and R.M.; writing—original draft preparation, L.C., J.F. and R.M.; writing—review and editing, L.C., J.F. and R.M.; visualization, L.C., J.F. and R.M.; supervision, R.M. and J.F.; funding acquisition, L.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was partly financed by FCT/MCTES through national funds (PIDDAC) under the R&D Unit Institute for Sustainability and Innovation in Structural Engineering (ISISE), under reference UIDB/04029/2020, and under the Associate Laboratory Advanced Production and Intelligent Systems ARISE under reference LA/P/0112/2020. This research was supported by national funds through FCT (the Foundation for Science and Technology) within the scope of the doctoral Grant PRT/BD/152839/2021, attributed to the 1st author, under MIT Portugal Program.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Appendix A

Table A1.

Physical characteristics of reviewed materials.

Table A1.

Physical characteristics of reviewed materials.

| Studied Material | Density (Kg/m3) | Thermal Conductivity (W/mK) | Specific Heat Capacity (J/Kg∙K) | Thermal Stability (°C) | Effusivity (Ws1/2/(m2K) | Diffusivity (m2/s) | Water/Moisture Absorption after 24 h (%) or Water Vapour Diffusion Resistance (µ-Value) | Fire Resistance | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Wheat Strawbale, stalk orientation perpendicular to heat flow | 86.42–135.09 | 0.066–0.071 | - | - | - | - | - | Non-combustibility | [58] |

| Wheat Strawbale, stalk orientation parallel to heat flow | 91.82–114.46 | 0.077–0.084 | - | - | - | - | - | Non-combustibility | [58] |

| Wheat Strawbale | 126–129 | 0.078–0.056 | - | - | - | - | - | - | [24] |

| Wheat straw and clay | 343–567 | 0.07–0.079 | - | - | - | - | - | - | [51] |

| Wheat straw insulation panel | 235–894 | 0.092–0.186 | - | - | - | - | 32–102% | - | [43] |

| Wheat straw | 105–112 | 0.046 | - | - | - | - | - | - | [23] |

| Konjac glucomannan/starch-based aerogel strengthened by wheat straw | 43 | 0.04641 | - | - | - | - | - | - | [64] |

| Untreated Rice straw particle board | 500 | 0.086 | - | - | - | - | - | - | [62] |

| Eucalyptus Globulus leaves and wheat straw fibres | 217 | 0.049–0.065 | - | - | - | - | - | - | [65] |

| 100% Sheep wool soft mats | 30 | 0.0318 | - | - | - | - | - | - | [25] |

| 80% sheep wool 20% polyester fibres semi-rigid panel | 25 | 0.04 | - | - | - | - | - | - | [25] |

| 100% Sheep wool loose-fill fibres | 75–100 | 0.035 | - | - | - | - | - | - | [25] |

| 90% sheep wool, 10% polypropylene | - | 0.058–0.083 | - | 250, 1% weight loss until 250 °C | - | - | 21–34% | Fire retardant rate of V-0 according to UL-94 rating | [59] |

| Wool and clay insulation panel | 452 | 0.0621 | - | - | - | - | - | - | [51] |

| Reed panel (no specified species) | 137.6 | 0.056 | 5080 | - | 200.1 | 0.08 × 10−6 | - | - | [28] |

| Reed (Arundo donax) particles and citric acid monohydrate | 600–850 | 0.081–0.093 | - | - | - | - | 57.3–88.16% | - | [53] |

| Reed (Arundo donax) 1 | 510 | 0.063 | 1000 | - | - | - | 52.6% | - | [29] |

| Bi-layered composite with cork | 461 | 0.0949 | - | - | - | - | - | - | [63] |

| 60% cork fiber 40% gypsum | - | 0.0623 | - | - | - | - | 45% | - | [66] |

| agglomerated cork panel with an air cavity and OSB | 110–369 | 0.044–0.083 | 1.98 × 10−3–5.17 × 10−3 | - | - | 0.0726–0.1061 | - | - | [30] |

| Corn husk | 119–128 | 0.047 | - | - | - | - | - | - | [23] |

| Composite of corn pith and alginate | 60–100 | 0.042–0.048 | - | - | - | 0.65–0.70 | 35% | - | [79] |

| Cornstalk and magnesium phosphate cement | 557–1854 | 0.051–0.998 | - | - | - | - | 165.25–222% | - | [67] |

| Rice husk composite | 378 | 0.08 | 524 | 250 | 194 | 421 × 10−7 | 43% | - | [38] |

| Wheat husk | 448 | 0.1 | 718 | 250 | 242 | 312 × 10−7 | 40% | - | [38] |

| Wood fibres insulation board | 100–250 | 0.035–0.046 | - | - | - | - | 50–627% | - | [31] |

| Wood waste without binders | 117–167 | 0.053–0.056 | - | - | - | 0.3080 × 10−6–0.5153 × 10−6 | - | - | [32] |

| Aerogel composite of pineapple leaf and cotton waste fibres | 19–46 | 0.039–0.043 | - | - | - | - | - | - | [34] |

| Tree bark | 127–484 | 0.045–0.065 | - | - | - | - | - | - | [36] |

| Larch and popcorn tree bark | 180 | 0.059 | - | - | - | - | - | - | [35] |

| 90% Banana leaf fibres, 10% pure polystyrene | -- | 0.0183 | - | 180 | - | - | - | - | [33] |

| Hemp fibre panels | 200–300 | 0.0544–0.0655 | - | - | - | - | 189.2–202.8% | - | [37] |

| Mycobamboo (Bamboo + Mycelium) | 229 | 0.08 | - | - | - | - | - | - | [71] |

| Air-laid feather-fibre fabric | 59 | 0.033 | - | - | - | - | - | - | [80] |

| Sugarcane Bagasse | 100–200 | 0.034–0.042 | - | - | - | - | - | - | [68] |

| Manau rattan Aerogel | 150–410 | 0.030–0.056 | - | - | - | - | - | - | [81] |

| Almond Skins composite panels | 235–373 | 0.074–0.082 | - | - | - | 0.180 × 10−6 –0.219 × 10−6 | Water vapour diffusion = 13–14.9 µ | - | [49] |

| Whole mussel shell | 281 | 0.12 | - | - | - | - | 2.17% | - | [39] |

| Mussel shell gravel | 684 | 0.15 | - | - | - | - | 2.17% | - | [39] |

| Coarse mussel shell sand | 1205 | 0.2 | - | - | - | - | 2.56% | - | [39] |

| Sabai grass polypropylene composite | 500 | 0.096 | - | <250 | - | - | - | - | [44] |

| 15% paper 45% cement composite | 1920 | 0.107 | - | - | - | - | - | - | [69] |

| Mulberry stems (polystyrene composite) | 50 | 0.136–0.175 | - | - | - | - | 9.5–24.3% | Fire retardant rate of V-1 according to UL-94 rating. V-2 for 95/05 composite | [46] |

| Kenaf and clay | 328 | 0.073 | - | - | - | - | - | - | [51] |

| Flax shives particles board | 500 | 0.099 | - | - | - | - | - | - | [62] |

| Cotton/Denim natural fibres insulation board, Inno-Therm/Métisse | 20–25 | 0.039 | 1600 | - | - | - | Water vapour diffusion = 2.2 µ | Euroclass E | [70] |

| Wood fibre insulation board, STEICO Flex | 60 | 0.036 | 2100 | - | - | - | Water vapour diffusion = 2 µ | Euroclass E | [82] |

| Expanded Insulation Cork Board, Amorin isolamentos S.A. | 130 | 0.040 | - | - | - | - | - | Euroclass E | [75] |

| Grass insulation, Gramitherm | 40 | 0.041 | 1500 | - | - | - | Water vapour diffusion = 1 µ | Euroclass E | [56] |

| Wheat Strawbale from conventional agriculture | 100 | 0.048 | 1558 | - | - | - | Water vapour diffusion = 2 µ | Euroclass E | [83] |

| Sheep wool insulation, Optimal Lehner Isolena | 18 | 0.038 | 1760 | - | - | - | Water vapour diffusion = 1 µ | Euroclass D | [84] |

| Extruded Polystyrene (XPS) Danopren | 32.41 | 0.034 | -- | - | - | - | Water vapour diffusion = 200 µ | Euroclass E | [57] |

1 Two layers of reed (4 cm) perpendicular to each other.

References

- IPCC. Climate Change 2022—Mitigation of Climate Change—Working Group III; Cambridge University Press: Cambridge, UK, 2022; p. 1454. [Google Scholar]

- IPCC. Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change; IPCC: Cambridge, UK; New York, NY, USA, 2018. [Google Scholar]

- European Commission. European Green Deal: Commission Proposes to Boost Renovation and Decarbonisation of Buildings; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Comissão das Comunidades Europeias. Um Novo Plano de Ação Para a Economia Circular; European Commission: Brussels, Belgium, 2020; p. 21. [Google Scholar]

- UNEP; IRP. Resource Efficiency and Climate Change: Material Efficiency Strategies for a Low-Carbon Future; A Report of the International Resource Panel; International Resource Panel (IRP): Paris, France, 2020. [Google Scholar]

- European Commission. European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Parliament. Revision of the Energy Performance of Buildings Directive: Fit for 55 Package; European Commission: Brussels, Belgium, 2022. [Google Scholar]

- Piccardo, C.; Dodoo, A.; Gustavsson, L.; Tettey, U.Y.A. Comparative Life-Cycle Analysis of Building Materials for the Thermal Upgrade of an Existing Building. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012044. [Google Scholar] [CrossRef]

- Magwood, C.; Bowden, E.; Trottier, M. Emissions of Materials Benchmark Assessment for Residential Construction Report; Efficiency Canada: Ottawa, ON, Canada, 2022. [Google Scholar]

- Pavel, C.C.; Blagoeva, D.T. Competitive Landscape of the EU’s Insulation Materials Industry for Energy-Efficient Buildings; EUR 28816 EN; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-96383-4. [Google Scholar] [CrossRef]

- Pittau, F.; Lumia, G.; Heeren, N.; Iannaccone, G.; Habert, G. Retrofit as a Carbon Sink: The Carbon Storage Potentials of the EU Housing Stock. J. Clean. Prod. 2019, 214, 365–376. [Google Scholar] [CrossRef]

- Fernandes, J.; Mateus, R.; Gervásio, H.; Silva, S.M.; Branco, J.; Almeida, M. Thermal Performance and Comfort Conditions Analysis of a Vernacular Palafitic Timber Building in Portuguese Coastline Context. Sustainability 2020, 12, 10484. [Google Scholar] [CrossRef]

- Chiou, Y.S.; Elizalde, J.S. Thermal Performances of Three Old Houses: A Comparative Study of Heterogeneous Vernacular Traditions in Taiwan. Sustainability 2019, 11, 5538. [Google Scholar] [CrossRef]

- Stenman, H. (Ed.) Reed Construction in the Baltic Sea Region; Turku University of Applied Sciences: Turku, Finland, 2008; ISBN 9789522160362. [Google Scholar]

- Jerman, M.; Palomar, I.; Kočí, V.; Černý, R. Thermal and Hygric Properties of Biomaterials Suitable for Interior Thermal Insulation Systems in Historical and Traditional Buildings. Build. Environ. 2019, 154, 81–88. [Google Scholar] [CrossRef]

- Fernandes, J.; Mateus, R.; Gervásio, H.; Silva, S.M.; Bragança, L. Passive Strategies Used in Southern Portugal Vernacular Rammed Earth Buildings and Their Influence in Thermal Performance. Renew. Energy 2019, 142, 345–363. [Google Scholar] [CrossRef]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; Group, P. Preferred Reporting Items for Systematic Review and Meta-Analysis Protocols (PRISMA-P) 2015 Statement. Syst. Rev. J. 2015, 4, 1. [Google Scholar] [CrossRef]

- EN ISO 9869; Thermal Insulation—Building Elements—In-Situ Measurement of Thermal Resistance and Thermal Transmittance. International Organization for Standardization (ISO): Geneva, Switzerland, 2014; p. 48.

- ASTM E2550-21; Standard Test Method for Thermal Stability by Thermogravimetry. ASTM International: West Conshohocken, PA, USA, 2021; p. 5.

- ISO 62:2008; Plastics-Determination of Water Absorption. International Organization for Standardization (ISO): Geneva, Switzerland, 2008.

- EN 13501-1:2018; Fire Classification of Construction Products and Building Elements. European Standard: Plzen, Czech Republic, 2018.

- ISO EN 15978:2011; Global Methodology For The Environmental Assessment of Buildings. International Organization for Standardization (ISO): Geneva, Switzerland, 2011.

- Rojas, C.; Cea, M.; Iriarte, A.; Valdés, G.; Navia, R.; Cárdenas-R, J.P. Thermal Insulation Materials Based on Agricultural Residual Wheat Straw and Corn Husk Biomass, for Application in Sustainable Buildings. Sustain. Mater. Technol. 2019, 20, e00102. [Google Scholar] [CrossRef]

- Platt, S.; Maskell, D.; Walker, P.; Laborel-Préneron, A. Manufacture and Characterisation of Prototype Straw Bale Insulation Products. Constr. Build. Mater. 2020, 262, 120035. [Google Scholar] [CrossRef]

- Parlato, M.C.M.; Porto, S.M.C.; Valenti, F. Assessment of Sheep Wool Waste as New Resource for Green Building Elements. Build. Environ. 2022, 225, 109596. [Google Scholar] [CrossRef]

- Guna, V.; Yadav, C.; Maithri, B.R.; Ilangovan, M.; Touchaleaume, F.; Saulnier, B.; Grohens, Y.; Reddy, N. Wool and Coir Fiber Reinforced Gypsum Ceiling Tiles with Enhanced Stability and Acoustic and Thermal Resistance. J. Build. Eng. 2021, 41, 102433. [Google Scholar] [CrossRef]

- Rivera-Gómez, C.; Galán-Marín, C.; López-Cabeza, V.P.; Diz-Mellado, E. Sample Key Features Affecting Mechanical, Acoustic and Thermal Properties of a Natural-Stabilised Earthen Material. Constr. Build. Mater. 2021, 271, 121569. [Google Scholar] [CrossRef]

- Tsapko, Y.V.; Tsapko, A.Y.; Bondarenko, O.P. Modeling of Thermal Conductivity of Reed Products. IOP Conf. Ser. Mater. Sci. Eng. 2020, 907, 012057. [Google Scholar] [CrossRef]

- Barreca, F.; Martinez Gabarron, A.; Flores Yepes, J.A.; Pastor Pérez, J.J. Innovative Use of Giant Reed and Cork Residues for Panels of Buildings in Mediterranean Area. Resour. Conserv. Recycl. 2019, 140, 259–266. [Google Scholar] [CrossRef]

- Barreca, F.; Cardinali, G.D.; Fichera, C.R.; Praticò, P. Utilization of Cork Residues for High Performance Walls in Green Buildings. Agric. Eng. Int. CIGR J. 2018, 20, 47–55. [Google Scholar]

- Lee, M.; Lee, S.-M.; Kang, E.-C. Changes in Characteristics of Wood Fiber Insulation Board According to Density. BioResources 2019, 14, 6529–6543. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A.D. Wood Waste as an Alternative Thermal Insulation for Buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Mohamed, G.R.; Mahmoud, R.K.; Fahim, I.S.; Shaban, M.; Abd El-Salam, H.M.; Mahmoud, H.M. Bio-Composite Thermal Insulation Materials Based on Banana Leaves Fibers and Polystyrene: Physical and Thermal Performance. J. Nat. Fibers 2021, 19, 4806–4821. [Google Scholar] [CrossRef]

- Do, N.H.N.; Tran, V.T.; Tran, Q.B.M.; Le, K.A.; Thai, Q.B.; Nguyen, P.T.T.; Duong, H.M.; Le, P.K. Recycling of Pineapple Leaf and Cotton Waste Fibers into Heat-Insulating and Flexible Cellulose Aerogel Composites. J. Polym. Environ. 2021, 29, 1112–1121. [Google Scholar] [CrossRef]

- Kain, G.; Tudor, E.M.; Barbu, M.C. Bark Thermal Insulation Panels: An Explorative Study on the Effects of Bark Species. Polymers 2020, 12, 2140. [Google Scholar] [CrossRef] [PubMed]

- Busquets-Ferrer, M.; Czabany, I.; Vay, O.; Gindl-Altmutter, W.; Hansmann, C. Alkali-Extracted Tree Bark for Efficient Bio-Based Thermal Insulation. Constr. Build. Mater. 2021, 271, 121577. [Google Scholar] [CrossRef]

- Gaujena, B.; Agapovs, V.; Borodinecs, A.; Strelets, K. Analysis of Thermal Parameters of Hemp Fiber Insulation. Energies 2020, 13, 6385. [Google Scholar] [CrossRef]

- Muthuraj, R.; Lacoste, C.; Lacroix, P.; Bergeret, A. Sustainable Thermal Insulation Biocomposites from Rice Husk, Wheat Husk, Wood Fibers and Textile Waste Fibers: Elaboration and Performances Evaluation. Ind. Crops Prod. 2019, 135, 238–245. [Google Scholar] [CrossRef]

- Martínez-García, C.; González-Fonteboa, B.; Carro-López, D.; Pérez-Ordóñez, J.L. Mussel Shells: A Canning Industry by-Product Converted into a Bio-Based Insulation Material. J. Clean. Prod. 2020, 269, 122343. [Google Scholar] [CrossRef]

- Guna, V.; Ilangovan, M.; Rather, M.H.; Giridharan, B.V.; Prajwal, B.; Vamshi Krishna, K.; Venkatesh, K.; Reddy, N. Groundnut Shell/Rice Husk Agro-Waste Reinforced Polypropylene Hybrid Biocomposites. J. Build. Eng. 2020, 27, 100991. [Google Scholar] [CrossRef]

- Taurino, R.; Ferretti, D.; Cattani, L.; Bozzoli, F.; Bondioli, F. Lightweight Clay Bricks Manufactured by Using Locally Available Wine Industry Waste. J. Build. Eng. 2019, 26, 100892. [Google Scholar] [CrossRef]

- Olacia, E.; Pisello, A.L.; Chiodo, V.; Maisano, S.; Frazzica, A.; Cabeza, L.F. Sustainable Adobe Bricks with Seagrass Fibres. Mechanical and Thermal Properties Characterization. Constr. Build. Mater. 2020, 239, 117669. [Google Scholar] [CrossRef]

- Liu, L.; Zou, S.; Li, H.; Deng, L.; Bai, C.; Zhang, X.; Wang, S.; Li, N. Experimental Physical Properties of an Eco-Friendly Bio-Insulation Material Based on Wheat Straw for Buildings. Energy Build. 2019, 201, 19–36. [Google Scholar] [CrossRef]

- Guna, V.; Ilangovan, M.; Adithya, K.; Akshay, A.K.; Srinivas, C.V.; Yogesh, S.; Nagananda, G.S.; Venkatesh, K.; Reddy, N. Biofibers and Biocomposites from Sabai Grass: A Unique Renewable Resource. Carbohydr. Polym. 2019, 218, 243–249. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Lanos, C. Development and Characterization of Thermal Insulation Materials from Renewable Resources. Constr. Build. Mater. 2019, 214, 685–697. [Google Scholar] [CrossRef]

- Guna, V.; Ilangovan, M.; Reddy, N.; Radhakrishna, P.G.; Maharaddi, V.H.; Jambunath, A.; Rao, A.P. Biobased Insulating Panels from Mulberry Stems. J. Thermoplast. Compos. Mater. 2021, 36, 453–472. [Google Scholar] [CrossRef]

- Cottrill, A.L.; Liu, A.T.; Kunai, Y.; Koman, V.B.; Kaplan, A.; Mahajan, S.G.; Liu, P.; Toland, A.R.; Strano, M.S. Ultra-High Thermal Effusivity Materials for Resonant Ambient Thermal Energy Harvesting. Nat. Commun. 2018, 9, 664. [Google Scholar] [CrossRef]

- Salazar, A.; Oleaga, A.; Mendioroz, A.; Apiñaniz, E. Thermal Effusivity Measurements of Thermal Insulators Using the Photopyroelectric Technique in the Front Configuration. Meas. J. Int. Meas. Confed. 2018, 121, 96–102. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Martellotta, F. Performance Characterization of Broad Band Sustainable Sound Absorbers Made of Almond Skins. Materials 2020, 13, 5474. [Google Scholar] [CrossRef] [PubMed]

- FBT Isolation. Fiche Produit—Panneaux Isolants Semi-Rigides En Paille de Riz de Camargue, sans Additif; FBT Isolation: Dagneux France, 2019. [Google Scholar]

- Erkmen, J.; Yavuz, H.I.; Kavci, E.; Sari, M. A New Environmentally Friendly Insulating Material Designed from Natural Materials. Constr. Build. Mater. 2020, 255, 119357. [Google Scholar] [CrossRef]

- Robinson, J.; Aoun, H.K.; Davison, M. Determining Moisture Levels in Straw Bale Construction. Procedia Eng. 2017, 171, 1526–1534. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, M.T.; Ferrandez-Garcia, C.E.; Garcia-Ortuño, T.; Ferrandez-Garcia, A.; Ferrandez-Villena, M. Experimental Evaluation of a New Giant Reed (Arundo Donax L.) Composite Using Citric Acid as a Natural Binder. Agronomy 2019, 9, 882. [Google Scholar] [CrossRef]

- Guelberth, C.R.; Chiras, D. The Natural Plaster Book, 2nd ed.; New Society Publishers: Gabriola Island, BC, Canada, 2005; ISBN 00865714495. [Google Scholar]

- Lafond, C.; Blanchet, P. Technical Performance Overview of Bio-Based Expanded Polystyrene. Buildings 2020, 10, 81. [Google Scholar] [CrossRef]

- Gramitherm. Technical Data Gramitherm: Insulation Material Made from Grass; Gramitherm Europe SA: Sambreville, Belgium, 2021. [Google Scholar]

- DANOSA. Environmental Product Declaration of Danopren: Extruded Polystyrene (XPS) Insulation Board; DANOSA—Derivados S.A. Normalized Asfálticos: Guadalajara, Spain, 2019. [Google Scholar]

- Janowska-Renkas, E.; Król, A.; Pochwała, S.; Pałubski, D.; Adamska, M.; Klementowski, I. The Fire Resistance and Heat Conductivity of Natural Construction Material Based on Straw and Numerical Simulation of Building Energy Demand. Energies 2022, 15, 1155. [Google Scholar] [CrossRef]

- Guna, V.; Ilangovan, M.; Vighnesh, H.R.; Sreehari, B.R.; Abhijith, S.; Sachin, H.E.; Mohan, C.B.; Reddy, N. Engineering Sustainable Waste Wool Biocomposites with High Flame Resistance and Noise Insulation for Green Building and Automotive Applications. J. Nat. Fibers 2021, 18, 1871–1881. [Google Scholar] [CrossRef]

- FDES Collective. Fiche de Declaration Environnementale et Sanitaire. Isolation En Bottes de Paille de Plein Champs Issues de L’ Agriculture Conventionnelle; FDES: Telangana, India, 2022. [Google Scholar]

- Mohamed, O.; Hawat, W. Al Density, Compressive Strength and Modulus of Elasticity: Three Properties That Influence the Efficiency of Structural Concrete; IOP Publishing Ltd.: Bristol, UK, 2021. [Google Scholar]

- Hussein, Z.; Ashour, T.; Khalil, M.; Bahnasawy, A.; Ali, S.; Hollands, J.; Korjenic, A. Rice Straw and Flax Fiber Particleboards as a Product of Agriculturalwaste: An Evaluation of Technical Properties. Appl. Sci. 2019, 9, 3878. [Google Scholar] [CrossRef]

- Novais, R.M.; Senff, L.; Carvalheiras, J.; Labrincha, J.A. Bi-Layered Porous/Cork-Containing Waste-Based Inorganic Polymer Composites: Innovative Material towards Green Buildings. Appl. Sci. 2020, 10, 2995. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, K.; Xiao, M.; Riffat, S.B.; Su, Y.; Jiang, F. Thermal Conductivity, Structure and Mechanical Properties of Konjac Glucomannan/Starch Based Aerogel Strengthened by Wheat Straw. Carbohydr. Polym. 2018, 197, 284–291. [Google Scholar] [CrossRef]

- Ali, M.; Alabdulkarem, A.; Nuhait, A.; Al-Salem, K.; Iannace, G.; Almuzaiqer, R.; Al-turki, A.; Al-Ajlan, F.; Al-Mosabi, Y.; Al-Sulaimi, A. Thermal and Acoustic Characteristics of Novel Thermal Insulating Materials Made of Eucalyptus Globulus Leaves and Wheat Straw Fibers. J. Build. Eng. 2020, 32, 101452. [Google Scholar] [CrossRef]

- Sair, S.; Mandili, B.; Taqi, M.; El Bouari, A. Development of a New Eco-Friendly Composite Material Based on Gypsum Reinforced with a Mixture of Cork Fibre and Cardboard Waste for Building Thermal Insulation. Compos. Commun. 2019, 16, 20–24. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B.; Yousefi Oderji, S.; Mohsan, M. Development of a New Bio-Composite for Building Insulation and Structural Purpose Using Corn Stalk and Magnesium Phosphate Cement. Energy Build. 2018, 173, 719–733. [Google Scholar] [CrossRef]

- Mehrzad, S.; Taban, E.; Soltani, P.; Samaei, S.E.; Khavanin, A. Sugarcane Bagasse Waste Fibers as Novel Thermal Insulation and Sound-Absorbing Materials for Application in Sustainable Buildings. Build. Environ. 2022, 211, 108753. [Google Scholar] [CrossRef]

- Ouargui, A.; Belouaggadia, N.; Elbouari, A.; Ezzine, M. Development of a Cellulose-Based Insulating Composite Material for Green Buildings: Case of Treated Organic Waste (Paper, Cardboard, Hash). IOP Conf. Ser. Mater. Sci. Eng. 2018, 353, 012018. [Google Scholar] [CrossRef]

- Le Relais Métisse l’isolation Durable. Available online: http://inno-therm.com/wp-content/uploads/Cata-Metisse-2014.pdf (accessed on 31 November 2022).

- Carcassi, O.B.; Minotti, P.; Habert, G.; Paoletti, I.; Claude, S.; Pittau, F. Carbon Footprint Assessment of a Novel Bio-Based Composite for Building Insulation. Sustainability 2022, 14, 1384. [Google Scholar] [CrossRef]

- Göswein, V.; Reichmann, J.; Habert, G.; Pittau, F. Land Availability in Europe for a Radical Shift toward Bio-Based Construction. Sustain. Cities Soc. 2021, 70, 102929. [Google Scholar] [CrossRef]

- INIES. Les Données Environmentales et Sanitaires de Référence Pour Le Bâtiment: Espace Consultation. Available online: https://www.base-inies.fr/iniesV4/dist/consultation.html (accessed on 2 November 2022).

- WAP Sustainanbility Consulting. Havelock Wool EPD; WAP Sustainanbility Consulting: Nashville, TN, USA, 2020. [Google Scholar]

- DAPHabitat System. Environmental Product Declaration—Expanded Insulation Corkboard (ICB); DAPHabitat System: Aveiro, Portugal, 2015; pp. 1–17. [Google Scholar]

- Pittau, F.; Krause, F.; Lumia, G.; Habert, G. Fast-Growing Bio-Based Materials as an Opportunity for Storing Carbon in Exterior Walls. Build. Environ. 2018, 129, 117–129. [Google Scholar] [CrossRef]

- Carcassi, O.B.; Habert, G.; Malighetti, L.E.; Pittau, F. Material Diets for Climate-Neutral Construction. Environ. Sci. Technol. 2022, 56, 5213–5223. [Google Scholar] [CrossRef] [PubMed]

- Keena, N.; Raugei, M.; Lokko, M.L.; Aly Etman, M.; Achnani, V.; Reck, B.K.; Dyson, A. A Life-Cycle Approach to Investigate the Potential of Novel Biobased Construction Materials toward a Circular Built Environment. Energies 2022, 15, 7239. [Google Scholar] [CrossRef]

- Palumbo, M.; Lacasta, A.M.; Giraldo, M.P.; Haurie, L.; Correal, E. Bio-Based Insulation Materials and Their Hygrothermal Performance in a Building Envelope System (ETICS). Energy Build. 2018, 174, 147–155. [Google Scholar] [CrossRef]

- Dieckmann, E.; Onsiong, R.; Nagy, B.; Sheldrick, L.; Cheeseman, C. Valorization of Waste Feathers in the Production of New Thermal Insulation Materials. Waste Biomass Valorization 2021, 12, 1119–1131. [Google Scholar] [CrossRef]

- Han, X.; Wu, W.; Tian, Z.; Wang, J.; Zhang, L.; Han, J.; Li, S.; Jiang, S. “Top-down” Fabrication of Anisotropic, Lightweight, Super-Amphiphobic, and Thermal Insulating Rattan Aerogels. Compos. Commun. 2022, 33, 101199. [Google Scholar] [CrossRef]

- STEICO Steico Flex 036 Product Sheet. Available online: https://www.steico.com/fileadmin/user_upload/importer/downloads/4028b6097384810e01749655fc5a27d1/STEICOflex_036_en_i.pdf (accessed on 30 November 2022).

- ETA-017/0247; Thermal Insulation Made of Straw Bales. DIBt: Berlin, Germany, 2017.

- Lehner. Sheep Wool Insulation Isolena Optimal: Product Data Sheet; Lehner: Tamengos, Portugal, 2019. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).