1. Introduction

Nowadays legislators are introducing increasingly stringent limits on internal combustion engines (ICE) to ensure the lowest tailpipe emissions. In this scenario, the latest Euro 7 regulation certainly represents a demanding task for the automotive industry. In particular, the attention is shifting towards a real-world verification of emissions, with a homologation process that considers the true conditions of vehicle use [

1,

2]. However, the increasing electrification of the powertrain, like the hybridization, on one hand has the potential of reducing fuel consumption and CO

2 emissions, while on the other hand poses additional challenges with regard to other pollutant emissions, such as nitrogen oxides [

3,

4]. For example, it is very important to predict the impact of multiple, long or short engine-off periods on the conversion efficiency of the after-treatment system. Hence, the capability to correctly predict the engine behavior under real driving conditions, typically by means of a digital twin of the production vehicle, is becoming more and more important [

5].

More specifically, 1D thermo-fluid dynamic simulations of IC engines have been commonly employed during the last decades to investigate and optimize the performance and emissions [

6]. In early works such as [

7], the IC engine has been usually represented by a 0D look-up table map, to be coupled to other models representing the powertrain and the vehicle. The low computational effort required by this approach has contributed to its widespread use. However, the IC engine is a volumetric machine, which, for example, cannot instantly respond to any torque request [

8], due to the typical transient thermo-fluid dynamic phenomena occurring in the whole engine system. This is especially important for the vehicle longitudinal dynamics simulation. Later works highlighted the importance of using a transient 1D thermo-fluid dynamic model to correctly predict the IC engine emissions and performance under transient conditions [

9].

When modelling a modern hybrid vehicle, many additional sub-systems have to be included, and this is often done by simulating each component as a standalone device, using the output of a model as input for the other. In this study a complete co-simulation methodology is described, to allow a real time interaction between the vehicle sub-models. A good example of how this approach can be exploited for the thermal management analysis is found in [

10]. This framework avoids multiple iterative simulation loops, hence reducing the total development process.

Overall, the main innovative contributions described in this work are the following:

The internal combustion engine is not represented by a simple look-up table, containing the values of performances and emissions at different operating points. A complete 0D/1D thermo-fluid dynamic model is used to build up a satisfactory virtual engine, which generally increases the confidence in the model’s predictions, since the relevant unsteady phenomena are included in the simulation. This eventually leads to significant advantages, such as:

- a.

better prediction of engine response to torque request: a more reasonable trend is achieved, since torque gradients are smoothed, leading to a more realistic transient calculation, rather different from the immediate torque availability provided by the engine look-up table.

- b.

The co-simulation predictions are therefore more reliable, since its output is influenced by the inter-connected IC engine model.

- c.

Eventually, a better calibration of the vehicle system can be achieved by means of simulation, to quickly reach the emission compliance.

A new numerical method is used and validated to allow a fast simulation by the 1D model: the fast simulation method (FSM). This methodology allows the reduction in the CPU/real time ratio by up to 85 %, allowing to tackle the most challenging task: the driving cycle simulations by means of 1D models. In this way, it is possible to use the high-fidelity 1D engine model instead of an engine map (look-up table), thanks to the relevant reduction of computational time.

The co-simulation environment achieved affects each sub-model’s behavior by the inter-connected sub-models. This enhances and exploits the predictivity of the IC engine 1D model. For example, the back pressure felt by the 1D engine model is computed by the after-treatment model, which is well suited to cope with this task. Conversely, a map-based engine model is not sensitive to a dynamically changing boundary condition, such as the exhaust backpressure.

This manuscript is divided into the following sections: after the introduction,

Section 2 highlights the vehicle characteristics, describing the conventional and hybrid powertrain architectures. In the same section the methodology used to obtain the driving cycle mission profile is reported.

Section 3 is dedicated to the modelling and validation of the IC engine under steady state conditions. In

Section 4 the co-simulation framework is discussed, presenting the different sub-models involved in the co-simulation environment. In

Section 5 the sub-models representing the various vehicle components, such as the transmission and vehicle dynamics, are described.

Section 6 discusses the conventional powertrain co-simulation model, while in

Section 7 the calculated results are reported, highlighting the effect of different ambient temperature on the predicted emissions. Finally,

Section 8 describes the hybridized powertrain co-simulation, highlighting the effect of different ambient temperatures on the electrified powertrain.

The development of the several vehicles sub-models has been performed in the framework of the European Project Vision-xEV [

11] and the sub-models used have been built and validated by academic or industrial partners, as acknowledged in this manuscript.

2. 12-m Heavy-Duty Bus Characteristics

The chosen vehicle is a 12-m heavy-duty urban bus, powered by a 210 kW, 6-cylinder turbo-diesel engine. Its main characteristics are reported in

Figure 1.

Urban busses make perfect candidates for low voltage hybridization, thanks to the highly transient cycles they are usually subject to during their operational life, with a high number of start/stop events and braking opportunities [

12]. On the other hand, even on pure ICE vehicles of this kind, the exhaust after-treatment thermal management can be critical in these conditions, due to the low average load of the engine and the long times spent at idling, which translate into low exhaust gas enthalpy and a struggle to keep the ATS above the light-off temperature. Improving fuel consumption, which further erodes the exhaust gas enthalpy, can have an adverse effect on the tailpipe emissions of the vehicle.

For this study, the choice was made to adopt a 48 V P1 hybrid architecture shown in

Figure 2, which constitutes an optimum for this kind of vehicle in terms of the balance between fuel consumption reduction potential and capital costs, thus minimizing the total cost of ownership.

The choice of the mission is of paramount importance when defining the simulation setup: to obtain significant results, it should be consistent with the relevant homologation requirements and real-world working conditions of the vehicle. For this application the urban mission shown in

Figure 3 has been chosen. The cycle is the ”Urban” cycle proposed in VECTO [

13].

This mission speed target is defined as a function of the driven distance and has instantaneous velocity variations, which means that the actual speed profile will depend on each vehicle’s performance and on the aggressiveness of the driver model. This choice was made so that the mission can be accomplished regardless of the performance of the vehicle.

To obtain a repeatable profile which does not depend on the powertrain configuration, the mission has been pre-processed using a simplified vehicle model, to generate a time-dependent speed profile shown in

Figure 4.

The simplified vehicle model is composed of a map-based engine, a transmission, a vehicle body and a driver, using VECTO-like rules [

13] on overspeed, coasting to transform the target speed from distance based to time based. The coasting functionality allows the vehicle to disconnect the engine from the driveline and proceed by inertia for a time interval, if the speed of the vehicle at the end of the coasting session does not deviate too much from the mission profile. Overspeed is activated when the vehicle approaches a slope by raising the target speed by a pre-defined value, to accumulate kinetic energy.

3. 1D Crank-Angle Resolved Thermos-Fluid Dynamic Engine Model

A complete 1D model has been built using the Gasdyn code [

14,

15] to predict performances and emissions of the 6.7L, 6-cylinder turbocharged heavy duty (HD) diesel engine, proposed as main propulsion system for the hybrid mid-size urban bus under consideration. The main engine geometrical data are presented in

Table 1. The other engine parameters, such as valve lift profiles and flow coefficients, together with the turbocharger maps were available and provided by the manufacturer.

In particular, the 1D model consists of a detailed description of the entire intake and exhaust systems geometry and devices along the intake and exhaust lines [

15]. The exhaust after-treatment system has not been included in the 1D model, modelled as an increased back-pressure imposed at the outlet boundary condition, according to the experimental measurements. A map-based approach for the simulation of turbine and compressor has been exploited [

16]. The manufacturer turbocharger maps supplied had a limited number of mapped points and consisted of a small number of measured rotational speeds; hence, these maps have been extrapolated to cover a wider range of possible operating conditions [

17]. In fact, the instantaneous mass flow rate through the turbocharge can vary due to the unsteady flow in the ducts. Regarding the fuel injection data, the complete map of the number of events, fuel rail pressure and start of injection (SOI) was available from the manufacturer.

The engine architecture features a wastegate valve to control the engine boost pressure, which affects only one side of the exhaust system, as depicted by the 1D schematic in

Figure 5. To control the engine load, a proportional-integrative-derivative (PID) controller is used to achieve the target boost pressure and indicated torque, by controlling the wastegate opening and injected fuel mass (per cycle, per cylinder). The target boost pressure value has been imposed, according to the experimental measured pressure. Downstream of the compressor an intercooler is present to cool down the fresh charge.

First of all, it is important to achieve a predictive model under steady state conditions, because during the driving cycle simulation the same 1D model is used, continuously varying the engine speed and load request, hence running the model across the whole range of operating conditions.

Figure 5 presents the 1D schematic of the 6-cylinder diesel engine, including the twin-entry, fixed geometry turbine with wastegate valve. It was important to build a detailed 1D schematic to correctly represent the twin-entry turbine in the exhaust system, as this configuration has a significant influence on the shape of pressure pulses and the energy available at the entry of the turbine.

Figure 6 shows the map of the experimentally investigated operating conditions used to perform the steady state validation of the 1D model. The 189 validation operating points are at constant engine speed and load, spread along the whole range of engine speeds and from low load to full load.

In the 1D thermo-fluid dynamic tool, the gas flow is assumed to be unsteady, compressible and one-dimensional [

18]. The conservation laws of mass, energy and momentum are written as a non-linear hyperbolic system of partial differential equations, which is mathematically closed by adding the hypothesis on the properties of the working fluid. In this case the gas is assumed to be a perfect gas. Heat transfer and friction between the gas and the pipe walls are considered by dedicated source terms in the respective conservation equations, as described in [

19,

20].

Two numerical solvers have been exploited for the simulations in the 1D fluid dynamic code, depending on the application:

A robust, second order accurate, finite difference numerical scheme based on the Corberán–Gascón total variation diminishing (CG-TVD) method, for a detailed calculation on a refined mesh, which allows to smoothly capture the unsteady flows and waves occurring in the 1D domain [

21,

22].

A finite volume numerical solver for coarse meshes, to carry out a quick simulation: the fast simulation method (FSM). This is based on the “1D cell” method, which derives from the more general 3D cell method proposed in [

23]. This finite volume method is based on the solution of the mass, energy and momentum conservation equations in time and is very conservative even with large mesh size, increasing the time step size and reducing the CPU/real time ratio. The method is explicit in time like the CG-TVD, while the main difference is that it is applied on a time-space staggered grid, evaluating quantities in the cell centers and fluxes in the ports, which are staggered by half time step and half mesh size [

24].

Figure 7 shows the schematic of the numerical method.

The time step is always computed according to the Courant–Friedrichs–Lewy (CFL) criterion [

25] to guarantee numerical stability. The boundary conditions connecting the 1D elements solution are resolved by a characteristic-based approach, to handle open ends, junctions, valves and the turbocharger, which is solved with a map-based approach [

26].

The three differential conservation equations of mass, energy and momentum written in discrete form for the 1D cell method are reported below (Equations (1)–(3)):

In Equation (2),

is the specific total internal energy of the cell, and

is the specific total enthalpy of the cell. The perfect gas thermodynamics relationship holds, and the total energy

and enthalpy

are expressed as:

Moreover, u is the gas velocity, is the gas density, is the pipe section, is the gas pressure and is the cell volume. and are the time step size and the mesh size, respectively. and are the source terms of the corresponding equations, which take account of heat transfer and friction at the duct walls. The symbol t indicates the time while the subscript refers to the ports of the 1D cell method.

A brief description of the combustion model for the diesel engine is reported below. It has been developed [

27] to handle current multi-pulse injection systems, ensuring fast run times. The 0D thermodynamic combustion model subdivides the chamber into three zones, as highlighted in

Figure 8: fresh charge, fuel (vaporized) and burned gas, applying the first law of thermodynamics to evaluate the pressure and temperature variations.

In this case the combustion rate is computed by means of multiple double-Wiebe laws [

28,

29], taking account of the in-cylinder conditions: pressure and temperature, gas composition (fresh charge, fuel and residuals) and injection timings. Each pulse injected during the compression/combustion phases burns with a rate defined by the following expression, as a function of the crank angle

:

where the first term into the brackets (1st Wiebe function) describes the premixed combustion phase, whereas the second term (2nd Wiebe function) describes the diffusive combustion phase. The coefficient

determines the dominating Wiebe function, while

,

,

and

are the typical coefficients of the Wiebe function. The angles

,

,

and

are the starting and final angles of the Wiebe function, calibrated for each simulated operating point according to the comparison with the experimental, instantaneous in-cylinder pressure. The results of this approach are presented in [

14], where it is shown how this equation is able to describe the rate of burned mass fraction with respect to the experimental one.

The pollutant emission prediction relies on chemical equilibrium models and empirical correlations, as described in [

30,

31]. In particular, in this study where diesel combustion is involved, the main pollutant of interest is NO

x.

The result of the 1D model simulation, carried out on 189 engine operating points, is now presented. The experimental data have been normalized with respect to a constant value to preserve the trends. For each comparison the experimental and predicted values, the percentage difference and the absolute difference between experimental data and calculated results are reported.

Figure 9 shows the contour plots of the measured and computed brake-specific fuel consumption (BSFC in g/kWh), with the relative and absolute errors on the whole steady engine map. The agreement with the measured data is satisfactory and the trend is well captured. This is the most important validation to achieve a predictive model, which can be used for the simulation of a driving cycle with good confidence about the total fuel consumption.

In addition,

Appendix A reports further results concerning the steady state validation of the 1D model.

Figure A1 and

Figure A2 describe the calculated equivalence ratio and the air mass flow rate, showing a good agreement with measured data, with reasonable discrepancies. The correct prediction of the mass flow rate is very important for the prediction of the pollutant emissions across the exhaust after-treatment system, since its conversion efficiency depends on the mass flow and temperature of the incoming exhaust gases from the cylinders.

Similarly,

Figure A3 and

Figure A4 report the predicted gas temperature and pressure at the turbine inlet, showing a very good agreement with experimental measurements, with only a very small percentage error.

The virtual engine model demonstrated a high accuracy with regard to the in-cylinder peak pressure, reported in

Figure A5, as well as to the turbocharger rotational speed, reported in

Figure A6. This shows a good matching of the turbocharger model to the real turbomachine.

Finally, the calculated cylinder-out concentrations of NO

x pollutant emission have been compared to the measured data on the whole engine map.

Figure A7 highlights the contour maps and the percentage errors. The NO

x prediction is fairly good, with an average error of around 10–20%, but with peak error of 150% in the region of high engine speeds and very low loads. However, this error occurs when the NO

x concentration is very small. The in-cylinder experimental pressure data have been used to improve the calibration of the combustion model and the prediction of NO

x.

Transient Validation

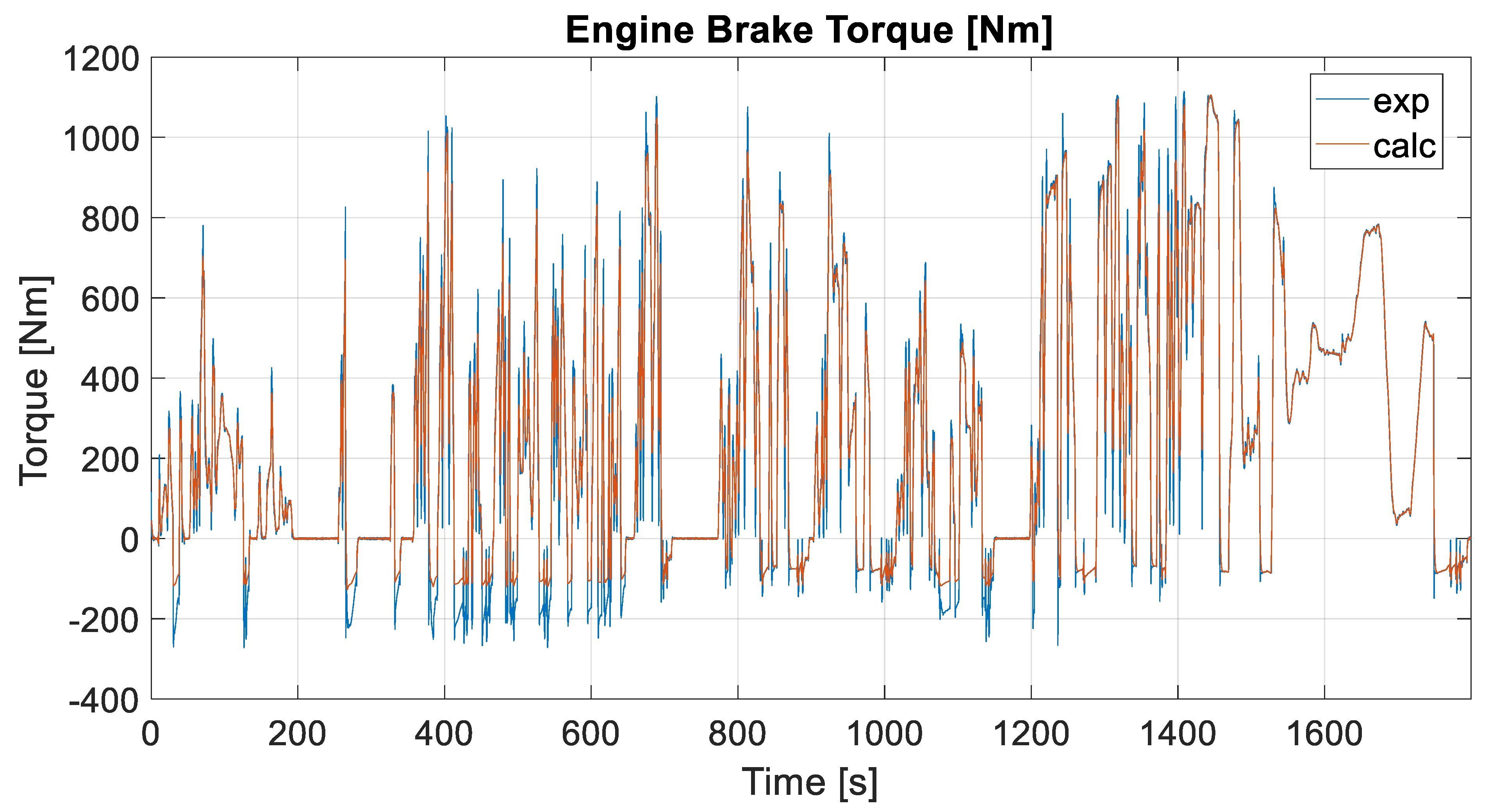

In this paragraph the validation performed under transient conditions is presented. The same 1D engine model is run, varying the engine speed and brake torque required, to simulate the engine behavior during a WHTC driving cycle. The engine speed is imposed, while the engine torque requested to the engine corresponds to the measured torque during the driving cycle. The 1D model exploits an internal PID controller to achieve the requested engine torque, as time proceeds. The resulting engine speed profile is reported in

Appendix B,

Figure A8.

Figure 10 shows the torque profile comparison: the 1D model responds correctly to the changes of torque requested during the WHTC cycle. A comparison of cumulative fuel consumption along the transient is presented in

Figure A9, and the results are satisfactory, showing a final error below 5%. This allows for the use of the 1D model in the complete vehicle simulation platform.

7. Conventional Architecture Results

The simulation has been run on the whole RDE cycle, which has a duration of 7980 s, with a simulation time to real time ratio around 3:1. The simulation has been repeated for three different ambient conditions: 0 °C, 25 °C and 40 °C, all at the same ambient pressure. This gave the opportunity to check how the ambient temperature affects the fuel consumption and the cooling system, something that is not usually possible to achieve when using a map-based simulation approach. The results are summarized in

Table 2. The fuel consumption results confirm that the IC engine model correctly predicts an increase in fuel consumption as the ambient temperature rises. Due to the air-to-air charge cooler used on this engine, the average charge air temperature in the intake manifold increases by about the same amount as the ambient temperature. This has a detrimental effect on volumetric efficiency, reducing the amount of air trapped inside the cylinder during each cycle by over 10% when comparing the same engine speed and load point at 0 °C and 40 °C. The air excess lambda will then be lower, and the combustion efficiency worsens, leading to higher BSFC.

A difference can be noticed in the NO

x emissions as well, as reported in

Figure 15: at 40 °C the higher temperatures and increased fuel consumption produces an increase of more than 15 g in the cumulated NO

x engine out emissions, compared with the 25 °C ambient temperature case. For the 0 °C case the results are not reported; however, the authors suggest expecting a reduced amount, in agreement with the trend of

Figure 15. This is due to the lower fuel quantity consumed and the cooler in-cylinder fresh charge temperatures.

Another consideration regarding the potential of this co-simulation approach is certainly represented by the different response of a complete fluid dynamic-based engine model, compared with the map-based modelling approach. Having a crank angle-resolved fluid dynamic engine model allows for considering the actual engine response and torque build-up, while a map-based approach can only take into account the mechanical inertia of the driveline in the simulation, which helps defining the speed at which the engine gains or loses RPMs but neglects the effect of fluid-dynamic inertia.

In

Figure 16 the results of a map-based approach are compared with those obtained using the complete engine model. The first chart shows torque gradients that the real engine would never be able to match, while the results with the complete engine model have much smoother torque pick-ups and drops, especially when transitioning towards negative torque values.

This is particularly important during the development phase in which the engine only, not the vehicle, is to be tested on the bench and the simulations are requested to provide a time-based torque profile, corresponding to a specific vehicle driving a mission. Using the profile calculated by a map-based engine model frequently results in unrealistic transient performance expectations that the test engine is not able to follow.

8. Hybrid Model Performance: Ambient Temperature Effect

In this section the capabilities of the integrated simulation approach are demonstrated in the analysis of a 48 V P1 hybrid system at different ambient temperatures.

As mentioned in previous sections, an urban bus is a perfect candidate to exploit the benefits of low-voltage hybridization: the frequent start-stops and the low vehicle top speed achieved during the mission determine a constant supply of kinetical energy that can be recovered with a relatively low power electric machine, thus avoiding the cost and complications of resorting to a high-voltage application, which would have a negative impact on the overall cost of ownership of the vehicle.

During the usual development process, it is difficult to have access to the information necessary to characterize the thermal behavior of the electric components: normally in the first stages of a project, the electric machine and battery are modelled using simple performance and internal losses maps, which has an impact on the reliability of the simulation results. However, thanks to the integrated simulation approach, it was possible to integrate in the co-simulation the high-fidelity models of the electric machine and battery developed by the European project partners, which allow for more detailed performance results.

In parallel to the simulation framework setup, the requirements of the P1 hybrid components have been defined. The electric machine characteristics have been selected using data gathered during the simulation of similar applications and are reported in

Figure 17. The battery cells configuration has been chosen starting from the cell characteristics by considering the system voltage and the capacity needed to feed a relatively powerful e-machine, such as the one that has been chosen in this case.

Together with the hardware components also the control strategy was elaborated. The control strategy is responsible of finding the best torque split value between the internal combustion engine and the electric machine, while respecting the constraints on the maximum temperature of the air-cooled battery, which should not exceed 45 °C, and excluding any kind of boosting and start-stop function when the engine was still heating up, to avoid prolonging the ATS warm-up phase and raising the tailpipe emissions. This is another benefit of the integrated simulation framework approach, since having the inputs from all the vehicle sub-systems helps refine the control strategy of the hybrid system in ways that are not possible with the traditional simulation procedures, which prevent over- or under-stating the benefit of hybridization in the real world.

The cooling system has also been updated to include a separate low temperature circuit to serve the electric machine. The radiator has been put in front of the one for the high-temperature cooling circuit, thus cooled using the same fan, while the pump is driven by a viscous clutch and its operational speed is controlled by a simple temperature-based logic.

For this study, the bus vehicle model has been modified to describe the hybrid bus. In particular the following models have been added to the co-simulation framework to achieve a complete model of a hybrid bus.

These additional models have been developed by the partners during the EU project Vision-xEV activities.

Battery model developed by the University Vrije Universiteit Brussel

Electric machine model by the University of Ljubljana

Energy manager model provided by the Universitat Politècnica de Valencia

Figure 18 presents the coupled simulation environment with each sub-model connected to the required models.

As with the baseline case, the chosen ambient conditions were 0 °C, 25 °C and 40 °C. The initial state of charge of the battery for all cases was chosen to be 50%.

The main goal was to assess the impact on the whole vehicle system of different behavior of the sub-systems under very high or very low temperatures.

The engine fuel consumption chart displayed in

Figure 19 shows that the improvement in fuel consumption compared to the baseline cases is around 15% and confirms the fact that this mix of vehicle and mission is a perfect match for low voltage hybridization.

Analyzing the distribution of the operating points of the electric machine on its performance chart in

Figure 20, it is readily apparent that for this application the electric machine is slightly oversized. The electric machine works almost always at part load and is used within a limited range of speed, which suggests that using a smaller electric machine would yield very similar results.

Thanks to the integrated simulation approach, a detailed analysis of the efficiency of the electric machine can also be made. The model of the electric machine [

34] correctly computes the effects of thermal derating on the efficiency presented in

Figure 21, which dips below 50% in the final part of the mission. This kind of data is of paramount importance in determining the actual performance of the hybrid system on the mission, and it greatly improves the quality of the simulation results.

On the battery side, thanks to the model [

35], an accurate calculation of the losses in the battery is made, further enhancing the quality of the simulation results.

Analyzing the IC engine and electric machine power split for the three different cases of

Figure 22,

Figure 23 and

Figure 24, respectively, what is immediately apparent is that the ambient temperature has a meaningful impact on the duration of the warm-up phase, which stretches from 140 s long at 40 °C up to 600 s at 0 °C. As can be seen by the profile of the engine speed and electric machine torque, during this phase the electric machine is used only for energy recuperation during braking events, and the start-stop functionality is disabled; thus, the engine speed never drops below 650 RPM.

What is also clearly noticeable is the derating in the performance of the electric machine. After the first 2000 s the maximum and minimum torque that it can provide starts decreasing, and by the end of the mission for the 0 °C and 25 °C the maximum positive torque is limited to 15 Nm, while the peak negative torque has diminished to −90 Nm. This imbalance also causes the battery SOC to saturate at 100%, since the motor is not able to spend as much energy as it recuperates during the braking events.

The behavior of the system is different for the case at 40 °C ambient temperature. In this case the use of the electric machine is limited at the energy manager level by the battery temperature, which is not supposed to exceed 45 °C. In the traces below it is noticeable that the energy manager relies much more on the internal combustion engine and friction brakes and requests the intervention of the electric machine less often than in the previous cases, which is why the performance derating starts showing only towards the end of the mission, allowing the final battery SOC to be maintained below 60%.

Overall, what is clear from the machine behavior is that the thermal derating plays a major role in defining the performance of the hybrid system, much more than the battery temperature, unless the ambient conditions force it to operate with a very high ambient temperature. Should this be the case for a significant percentage of the vehicle’s life, then a water-cooled battery should be investigated.

For what concerns the electric machine cooling, presented in

Figure 25, the coolant temperature does not show significant spikes during the mission, and the values are always close to the ambient temperature of each case, which means that the system is well suited for the cooling of the machine. The pump has an almost negligible power draw of 60 W at 0 °C and 25 °C, since the coolant temperature is always low enough that the pump itself stays at the idle speed of 200 RPM most of the mission, but at 40 °C the pump is forced to spin at 600 RPM to keep the coolant temperature in check. This translates into a not negligible 1 kWh of additional energy spent by the pump during the mission, compared to the lower temperature cases.

On the high-temperature cooling circuit shown in

Figure 26, there does not seem to have been a significant change in the performance of the radiator and fan following the addition of the low-temperature cooling circuit radiator in front of it. The overall energy consumption of the fan is negative, due to a windmilling effect of the fan cooler blades, predicted by the cooling system model, due to the air flowing though the fan at the given vehicle speed.

A summary of the vehicle performance is reported in

Table 3. It is possible to see that the low ambient temperature helps the cooling of the battery, withdrawing less power for the respective cooling and improving fuel efficiency. Consequently, also the regenerative power of the electric motor reduces with the increase of ambient temperature, since the electric machine is less efficient at higher temperature.