Figure 1.

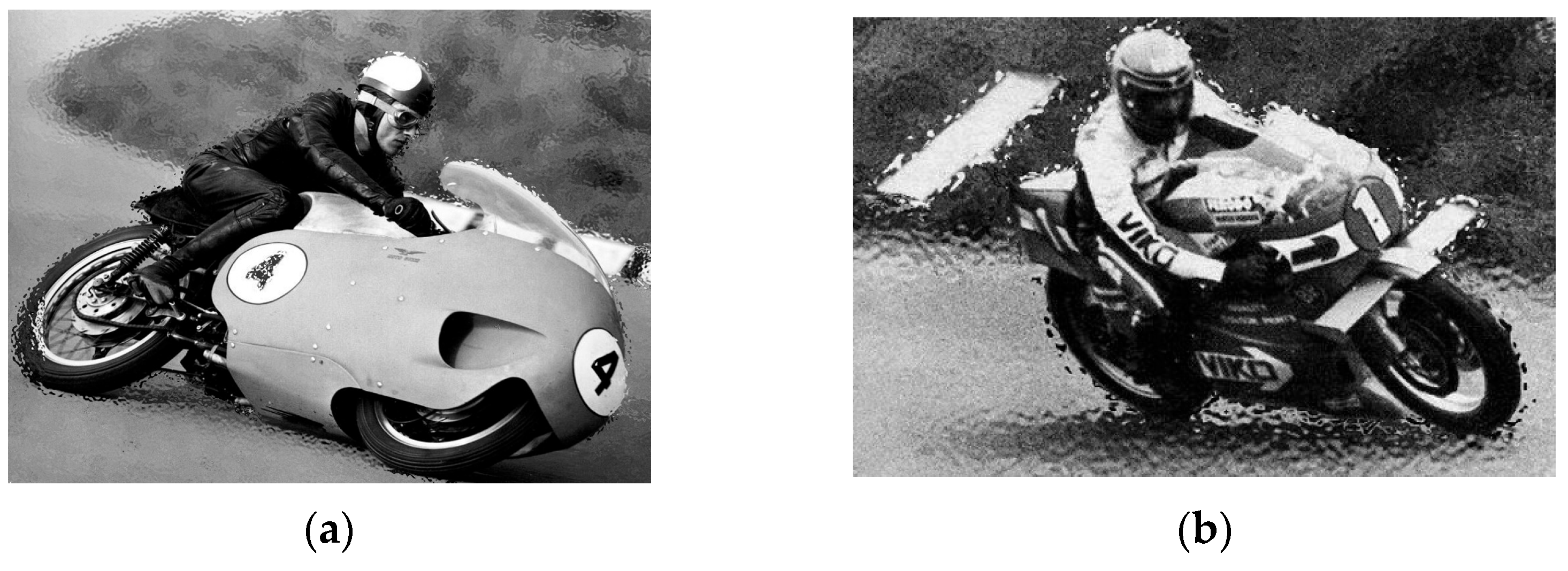

Examples of aerodynamic innovations in World Championship motorcycle fairings: (a) Giulio Cesare Carcano riding the Moto Guzzi; (b) Rodger Freeth on the Yamaha TZ750 with spoilers in 1977.

Figure 1.

Examples of aerodynamic innovations in World Championship motorcycle fairings: (a) Giulio Cesare Carcano riding the Moto Guzzi; (b) Rodger Freeth on the Yamaha TZ750 with spoilers in 1977.

Figure 2.

Image from Márquez’s rear on-board camera at the moment of impact.

Figure 2.

Image from Márquez’s rear on-board camera at the moment of impact.

Figure 3.

Comparison of the different MotoGP fairings in 2017. Source: (González, n.d. [

11]).

Figure 3.

Comparison of the different MotoGP fairings in 2017. Source: (González, n.d. [

11]).

Figure 4.

Michele Pirro, Ducati test rider for Qatar GP 2019.

Figure 4.

Michele Pirro, Ducati test rider for Qatar GP 2019.

Figure 5.

Examples of rear aerodynamic elements in MotoGP: (a) rear wings introduced by Ducati for the 2022 MotoGP season; (b) rear wings introduced by Aprilia on the test motorbike for the 2022 MotoGP season; (c) rear wings introduced by KTM for the 2023 MotoGP season.

Figure 5.

Examples of rear aerodynamic elements in MotoGP: (a) rear wings introduced by Ducati for the 2022 MotoGP season; (b) rear wings introduced by Aprilia on the test motorbike for the 2022 MotoGP season; (c) rear wings introduced by KTM for the 2023 MotoGP season.

Figure 6.

Wider and lower fairing concept introduced by Aprilia in the 2022 MotoGP season.

Figure 6.

Wider and lower fairing concept introduced by Aprilia in the 2022 MotoGP season.

Figure 7.

Motorcycle-rider geometry with axes, aerodynamic forces, and moments: (a) front view of the motorcycle-rider geometry showing aerodynamic lateral force and the axes positioned at the origin; (b) side view of the motorcycle-rider geometry showing the aerodynamic forces (lift and drag), the moments, and the axes positioned at the origin.

Figure 7.

Motorcycle-rider geometry with axes, aerodynamic forces, and moments: (a) front view of the motorcycle-rider geometry showing aerodynamic lateral force and the axes positioned at the origin; (b) side view of the motorcycle-rider geometry showing the aerodynamic forces (lift and drag), the moments, and the axes positioned at the origin.

Figure 8.

Variables of the Ducati flow redirector (values given in

Table 1): (

a) Ducati front view with flow redirector reference variables: horizontal inlet angle (β) and lateral inlet angle (φ); (

b) Ducati side view with flow redirector reference variables: vertical inlet angle (α) and total length (L); (

c) appendage entry with reference variables: total inlet height (H

f) and lower inlet width (A

f); (

d) appendage outlet with reference variables: total outlet height (H

t) and lower outlet width (A

t).

Figure 8.

Variables of the Ducati flow redirector (values given in

Table 1): (

a) Ducati front view with flow redirector reference variables: horizontal inlet angle (β) and lateral inlet angle (φ); (

b) Ducati side view with flow redirector reference variables: vertical inlet angle (α) and total length (L); (

c) appendage entry with reference variables: total inlet height (H

f) and lower inlet width (A

f); (

d) appendage outlet with reference variables: total outlet height (H

t) and lower outlet width (A

t).

Figure 9.

Ground effect when the motorcycle is leaning.

Figure 9.

Ground effect when the motorcycle is leaning.

Figure 10.

Lower part of the fairing acting as a diffuser when the motorcycle is leaning.

Figure 10.

Lower part of the fairing acting as a diffuser when the motorcycle is leaning.

Figure 11.

Flow directed by the appendage clearing the wake of the front wheel on a straight motorcycle.

Figure 11.

Flow directed by the appendage clearing the wake of the front wheel on a straight motorcycle.

Figure 12.

Motorcycle-rider geometry: (a) front view of the motorcycle-rider geometry; (b) side view of the motorcycle-rider geometry.

Figure 12.

Motorcycle-rider geometry: (a) front view of the motorcycle-rider geometry; (b) side view of the motorcycle-rider geometry.

Figure 13.

Fixed dimensions of the flow redirector geometry.

Figure 13.

Fixed dimensions of the flow redirector geometry.

Figure 14.

Motorcycle-rider geometry adapted for CFD simulations: (a) front view; (b) side view.

Figure 14.

Motorcycle-rider geometry adapted for CFD simulations: (a) front view; (b) side view.

Figure 15.

Simulation domain as a function of H.

Figure 15.

Simulation domain as a function of H.

Figure 16.

Refinement zones and mesh layers: (a) isometric image of the domain with refinement zones; (b) isometric image of the geometry with refinement zones; (c) mesh layers: tyre bottom, contact patch, and road; (d) mesh layers: fairing, front wheel cover, and tyre.

Figure 16.

Refinement zones and mesh layers: (a) isometric image of the domain with refinement zones; (b) isometric image of the geometry with refinement zones; (c) mesh layers: tyre bottom, contact patch, and road; (d) mesh layers: fairing, front wheel cover, and tyre.

Figure 17.

Comparison of reference motorcycles to verify the results: (

a) Freddie Spencer’s 1984 Honda NS500; (

b) reference model without rims designed by González-Arcos [

21]; (

c) reference model designed for the present study.

Figure 17.

Comparison of reference motorcycles to verify the results: (

a) Freddie Spencer’s 1984 Honda NS500; (

b) reference model without rims designed by González-Arcos [

21]; (

c) reference model designed for the present study.

Figure 18.

Streamlines of models with straight geometry: (a) side view of streamlines with velocity magnitude (m/s) in model 1::1 without wheel rotation; (b) side view of streamlines with velocity magnitude (m/s) in model 1::1 with rotating wheels; (c) side view of streamlines with velocity magnitude (m/s) in model 4::1 without wheel rotation; (d) side view of streamlines with velocity magnitude (m/s) in model 4::1 with rotating wheels; (e) side view of streamlines with velocity magnitude (m/s) of model 6::1 without wheel rotation; (f) side view of streamlines with velocity magnitude (m/s) of model 6::1 with rotating wheels; (g) side view of streamlines with velocity magnitude (m/s) in model 7::1 without wheel rotation; (h) side view of streamlines with velocity magnitude (m/s) in model 7::1 with rotating wheels.

Figure 18.

Streamlines of models with straight geometry: (a) side view of streamlines with velocity magnitude (m/s) in model 1::1 without wheel rotation; (b) side view of streamlines with velocity magnitude (m/s) in model 1::1 with rotating wheels; (c) side view of streamlines with velocity magnitude (m/s) in model 4::1 without wheel rotation; (d) side view of streamlines with velocity magnitude (m/s) in model 4::1 with rotating wheels; (e) side view of streamlines with velocity magnitude (m/s) of model 6::1 without wheel rotation; (f) side view of streamlines with velocity magnitude (m/s) of model 6::1 with rotating wheels; (g) side view of streamlines with velocity magnitude (m/s) in model 7::1 without wheel rotation; (h) side view of streamlines with velocity magnitude (m/s) in model 7::1 with rotating wheels.

Figure 19.

Cp of the lower fairing in models with a straight geometry: (a) Cp of the lower fairing in model 1::1; (b) Cp of the lower fairing in model 4::1; (c) Cp of the lower fairing in model 6::1; (d) Cp of the lower fairing in model 7::1.

Figure 19.

Cp of the lower fairing in models with a straight geometry: (a) Cp of the lower fairing in model 1::1; (b) Cp of the lower fairing in model 4::1; (c) Cp of the lower fairing in model 6::1; (d) Cp of the lower fairing in model 7::1.

Figure 20.

Streamlines with magnitude of velocity (m/s) around the flow redirector in model 2::1: (a) bottom view of streamlines with velocity magnitude (m/s) in model 2::1 without wheel rotation; (b) bottom view of streamlines with velocity magnitude (m/s) in model 2::1 with rotating wheels; (c) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 2::1 without wheel rotation; (d) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 2::1 with rotating wheels.

Figure 20.

Streamlines with magnitude of velocity (m/s) around the flow redirector in model 2::1: (a) bottom view of streamlines with velocity magnitude (m/s) in model 2::1 without wheel rotation; (b) bottom view of streamlines with velocity magnitude (m/s) in model 2::1 with rotating wheels; (c) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 2::1 without wheel rotation; (d) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 2::1 with rotating wheels.

Figure 21.

Streamlines with magnitude of velocity (m/s) around the flow redirector in model 3::1: (a) bottom view of streamlines with velocity magnitude (m/s) in model 3::1 without wheel rotation; (b) bottom view of streamlines with velocity magnitude (m/s) in model 3::1 with rotating wheels; (c) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 3::1 without wheel rotation; (d) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 3::1 with rotating wheels.

Figure 21.

Streamlines with magnitude of velocity (m/s) around the flow redirector in model 3::1: (a) bottom view of streamlines with velocity magnitude (m/s) in model 3::1 without wheel rotation; (b) bottom view of streamlines with velocity magnitude (m/s) in model 3::1 with rotating wheels; (c) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 3::1 without wheel rotation; (d) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 3::1 with rotating wheels.

Figure 22.

Streamlines with magnitude of velocity (m/s) around the flow redirector in model 5::1: (a) bottom view of streamlines with velocity magnitude (m/s) in model 5::1 without wheel rotation; (b) bottom view of streamlines with velocity magnitude (m/s) in model 5::1 with rotating wheels; (c) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 5::1 without wheel rotation; (d) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 5::1 with rotating wheels.

Figure 22.

Streamlines with magnitude of velocity (m/s) around the flow redirector in model 5::1: (a) bottom view of streamlines with velocity magnitude (m/s) in model 5::1 without wheel rotation; (b) bottom view of streamlines with velocity magnitude (m/s) in model 5::1 with rotating wheels; (c) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 5::1 without wheel rotation; (d) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 5::1 with rotating wheels.

Figure 23.

Streamlines with magnitude of velocity (m/s) around the flow redirector in model 8::1: (a) bottom view of streamlines with velocity magnitude (m/s) in model 8::1 without wheel rotation; (b) bottom view of streamlines with velocity magnitude (m/s) in model 8::1 with rotating wheels; (c) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 8::1 without wheel rotation; (d) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 8::1 with rotating wheels.

Figure 23.

Streamlines with magnitude of velocity (m/s) around the flow redirector in model 8::1: (a) bottom view of streamlines with velocity magnitude (m/s) in model 8::1 without wheel rotation; (b) bottom view of streamlines with velocity magnitude (m/s) in model 8::1 with rotating wheels; (c) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 8::1 without wheel rotation; (d) rear view of the flow redirector and the streamlines with velocity magnitude (m/s) in model 8::1 with rotating wheels.

Figure 24.

Main effects plot for the Cl.

Figure 24.

Main effects plot for the Cl.

Figure 25.

Main effects plot for the Cd.

Figure 25.

Main effects plot for the Cd.

Table 1.

Fixed variables set for the flow redirector design (see

Figure 8).

Table 1.

Fixed variables set for the flow redirector design (see

Figure 8).

| Geometric Variables | Fixed Value |

|---|

| φ | 35° |

| L | 200 mm |

| Hf | 170 mm |

| Af | 65 mm |

| Ht | 110 mm |

| At | 40 mm |

Table 2.

Domain dimensions with respect to the straight geometry for each of the space directions (see

Figure 15).

Table 2.

Domain dimensions with respect to the straight geometry for each of the space directions (see

Figure 15).

| Domain Variables | Value |

|---|

| X+ | 15 m |

| Y+ | 0 m |

| Z+ | 9 m |

| X− | 6 m |

| Y− | 4.5 m |

| Z− | 0 |

Table 3.

Domain dimensions with respect to the leaning geometry for each of the space directions (see

Figure 15).

Table 3.

Domain dimensions with respect to the leaning geometry for each of the space directions (see

Figure 15).

| Domain Variables | Value |

|---|

| X+ | 15 m |

| Y+ | 4.5 m |

| Z+ | 9 m |

| X− | 6 m |

| Y− | 4.5 m |

| Z− | 0 |

Table 4.

Main parameters for the model of the effect of the boundary layer.

Table 4.

Main parameters for the model of the effect of the boundary layer.

| Parameters | Value |

|---|

| y+ | 50 |

| y | 0.41 mm |

| Height of the First Layer | 0.8 mm |

| Type Value First Height | Absolute |

| Growth Rate | 1.15 |

| Number of Layers | 9 |

Table 5.

Characteristics of the meshes in the GCI study.

Table 5.

Characteristics of the meshes in the GCI study.

| Mesh Type | Cells | Cd |

|---|

| Coarse (3) | 6,326,706 | 0.4488 |

| Medium (2) | 8,861,227 | 0.4334 |

| Fine (1) | 13,037,125 | 0.4332 |

Table 6.

GCI study results.

Table 6.

GCI study results.

| Variables | Results |

|---|

| r23 | 1.4006 |

| r12 | 1.4713 |

| ϕ3 | 0.2468 |

| ϕ2 | 0.2384 |

| ϕ1 | 0.2383 |

| P | 12.0057 |

| GCI23 | 0.0564% |

| GCI12 | 0.0008% |

Table 7.

Wall functions used by the OpenFOAM k-ω SST model.

Table 7.

Wall functions used by the OpenFOAM k-ω SST model.

| Parameter | OpenFOAM Wall Function |

|---|

| k | kqRWallFunction |

| omega | omegaWallFunction |

| nut | nutWallFunction |

Table 8.

Simulation turbulence parameters.

Table 8.

Simulation turbulence parameters.

| Parameter | Value |

|---|

| Free Stream Velocity (U) | 50 m/s |

| Turbulent Intensity (I) | 1% |

| Reference Length (l) | 0.7 m |

| Kinematic Viscosity (ν) | 1.5 × 10−5 m2/s |

| Turbulence Kinetic Energy (k) | 0.375 m2/s2 |

| Turbulence Model Constant (Cµ) | 0.09 |

| Specific Turbulent Dissipation Rate (ω) | 1.597 s−1 |

Table 9.

Results verification.

Table 9.

Results verification.

| Comparative Data | Honda RS 500 | (González-Arcos, 2020) Model | Designed Model |

|---|

| S Cd | 0.240 | 0.234 | 0.231 |

Table 10.

Matrix L8 OA used for the study.

Table 10.

Matrix L8 OA used for the study.

| | 1st Modification | 2nd Modification | 3rd Modification | 4th Modification |

|---|

| L8 OA Internal Matrix (Control Factors) | 1 | 2 | 3 | 4 |

| Control Factor | A | B | D | G |

| Test No. (Row)/Factor No. (Column) | α [°] | β [°] | Flow Separator [-] | Leaning Motorcycle [-] |

| 1::1 | 0 | 25 | NO | NO |

| 2::1 | 0 | 25 | YES | YES |

| 3::1 | 0 | 40 | NO | YES |

| 4::1 | 0 | 40 | YES | NO |

| 5::1 | 10 | 25 | NO | YES |

| 6::1 | 10 | 25 | YES | NO |

| 7::1 | 10 | 40 | NO | NO |

| 8::1 | 10 | 40 | YES | YES |

Table 11.

Aerodynamic coefficients for the reference model with a straight motorcycle.

Table 11.

Aerodynamic coefficients for the reference model with a straight motorcycle.

Aerodynamic

Coefficients | Without Rotating Wheels | Rotating Wheels | Difference (%) |

|---|

| Cd | 0.42033 | 0.41131 | −2.15 |

| Cl | 0.04197 | 0.05076 | 20.94 |

Table 12.

Aerodynamic coefficients for the reference model with a leaning motorcycle.

Table 12.

Aerodynamic coefficients for the reference model with a leaning motorcycle.

Aerodynamic

Coefficients | Without Rotating Wheels | Rotating Wheels | Difference (%) |

|---|

| Cd | 0.46209 | 0.44717 | −3.23 |

| Cl | 0.08766 | 0.12009 | 36.00 |

Table 13.

Difference in % between each straight model and the reference model. The objective was to reduce the two aerodynamic coefficients, aiming for a negative percentage.

Table 13.

Difference in % between each straight model and the reference model. The objective was to reduce the two aerodynamic coefficients, aiming for a negative percentage.

| Model | Simulation Type | Aerodynamic Coefficient | Value | Difference from Reference (%) |

|---|

| 1::1 | Without Rotating Wheels | Cd | 0.43751 | 4.09 |

| 1::1 | Without Rotating Wheels | Cl | 0.03713 | −11.53 |

| 1::1 | Rotating Wheels | Cd | 0.40788 | −0.83 |

| 1::1 | Rotating Wheels | Cl | 0.05044 | −0.63 |

| 4::1 | Without Rotating Wheels | Cd | 0.43813 | 4.23 |

| 4::1 | Without Rotating Wheels | Cl | 0.04845 | 15.43 |

| 4::1 | Rotating Wheels | Cd | 0.42670 | 3.74 |

| 4::1 | Rotating Wheels | Cl | 0.06835 | 34.65 |

| 6::1 | Without Rotating Wheels | Cd | 0.44609 | 6.13 |

| 6::1 | Without Rotating Wheels | Cl | 0.03408 | −18.80 |

| 6::1 | Rotating Wheels | Cd | 0.42059 | 2.26 |

| 6::1 | Rotating Wheels | Cl | 0.05572 | 9.77 |

| 7::1 | Without Rotating Wheels | Cd | 0.44617 | 6.15 |

| 7::1 | Without Rotating Wheels | Cl | 0.05484 | 30.66 |

| 7::1 | Rotating Wheels | Cd | 0.41863 | 1.78 |

| 7::1 | Rotating Wheels | Cl | 0.05572 | 9.77 |

Table 14.

Difference in % of each of the leaning models with respect to the reference model. Downforce gain is Cl reduction.

Table 14.

Difference in % of each of the leaning models with respect to the reference model. Downforce gain is Cl reduction.

| Model | Simulation Type | Aerodynamic Coefficient | Value | Difference from Reference (%) |

|---|

| 2::1 | Without Rotating Wheels | Cd | 0.47637 | 3.09 |

| 2::1 | Without Rotating Wheels | Cl | 0.02382 | −72.83 |

| 2::1 | Rotating Wheels | Cd | 0.46619 | 4.25 |

| 2::1 | Rotating Wheels | Cl | 0.04213 | −64.92 |

| 3::1 | Without Rotating Wheels | Cd | 0.46262 | 0.11 |

| 3::1 | Without Rotating Wheels | Cl | −0.00188 | −102.14 |

| 3::1 | Rotating Wheels | Cd | 0.46096 | 3.08 |

| 3::1 | Rotating Wheels | Cl | 0.03024 | −74.82 |

| 5::1 | Without Rotating Wheels | Cd | 0.46216 | 0.02 |

| 5::1 | Without Rotating Wheels | Cl | −0.00714 | −108.15 |

| 5::1 | Rotating Wheels | Cd | 0.45744 | 2.27 |

| 5::1 | Rotating Wheels | Cl | 0.01942 | −83.83 |

| 8::1 | Without Rotating Wheels | Cd | 0.47393 | 2.56 |

| 8::1 | Without Rotating Wheels | Cl | 0.01901 | −78.31 |

| 8::1 | Rotating Wheels | Cd | 0.45479 | 1.70 |

| 8::1 | Rotating Wheels | Cl | 0.03104 | −74.15 |

Table 15.

Best combination for the Cl according to the Taguchi Method.

Table 15.

Best combination for the Cl according to the Taguchi Method.

| Factors | α | β | Flow Separator | Leaning Motorcycle |

|---|

| Level | 2 | 1 | 1 | 2 |

| Value | 10 | 25 | NO | YES |

Table 16.

Best combination for the Cd according to the Taguchi Method.

Table 16.

Best combination for the Cd according to the Taguchi Method.

| Factors | α | β | Flow Separator | Leaning Motorcycle |

|---|

| Level | 1 | 1 | 1 | 1 |

| Value | 0 | 25 | NO | NO |