Experimental Investigation on the Relationship between Biot’s Coefficient and Hydrostatic Stress for Enhanced Oil Recovery Projects

Abstract

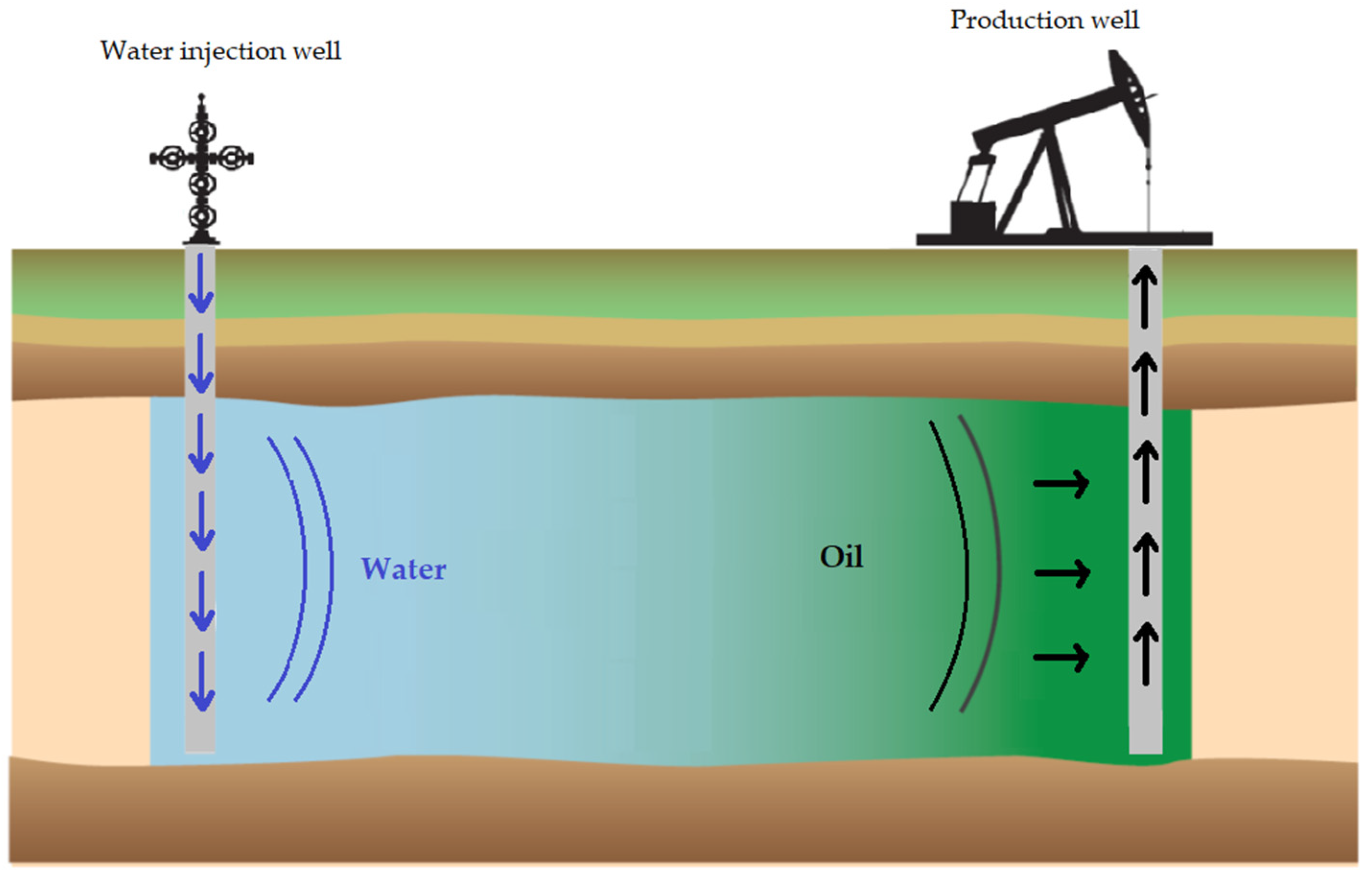

1. Introduction

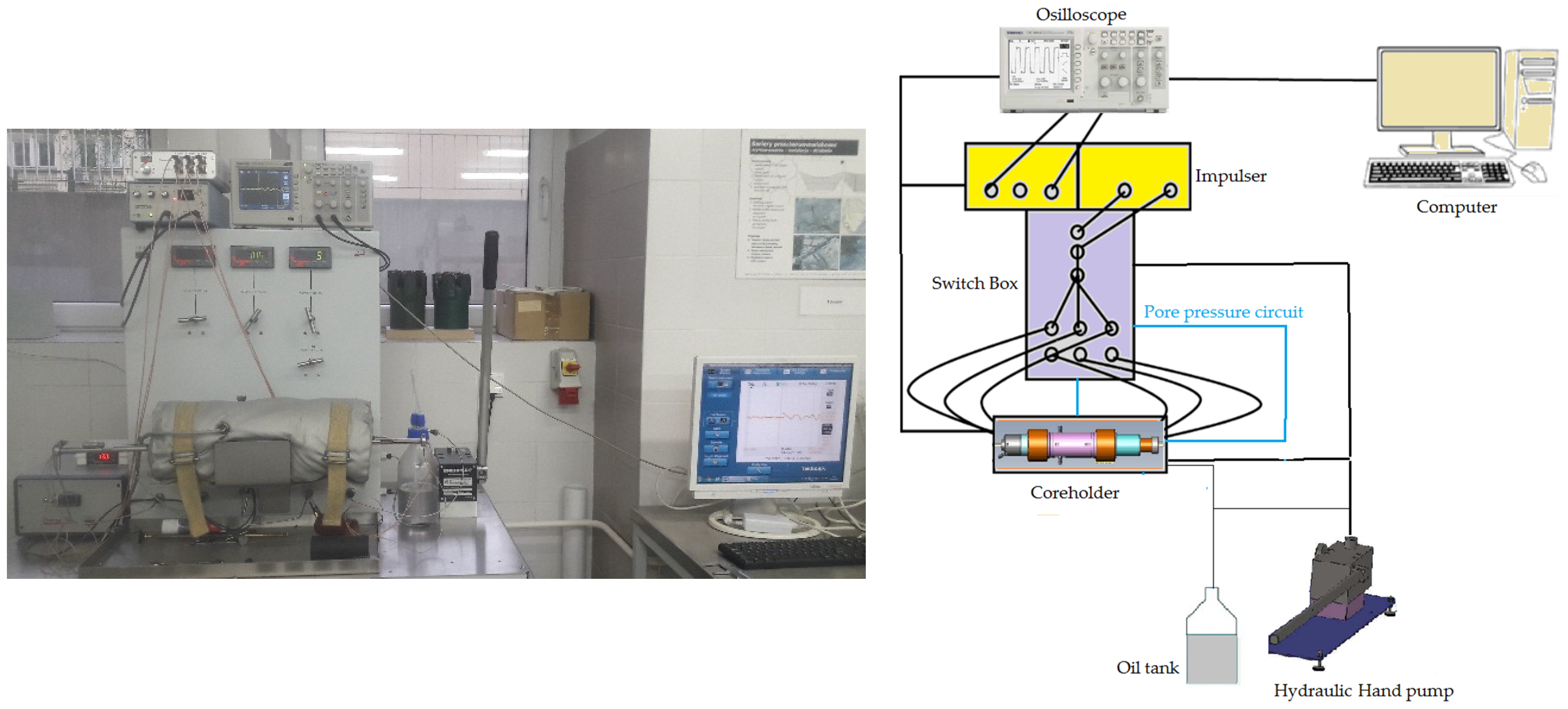

2. Materials and Methods

2.1. Biot’s Coefficient Theory

2.2. UCS Measurement Procedure

2.3. Acoustic Wave Propagation Procedure

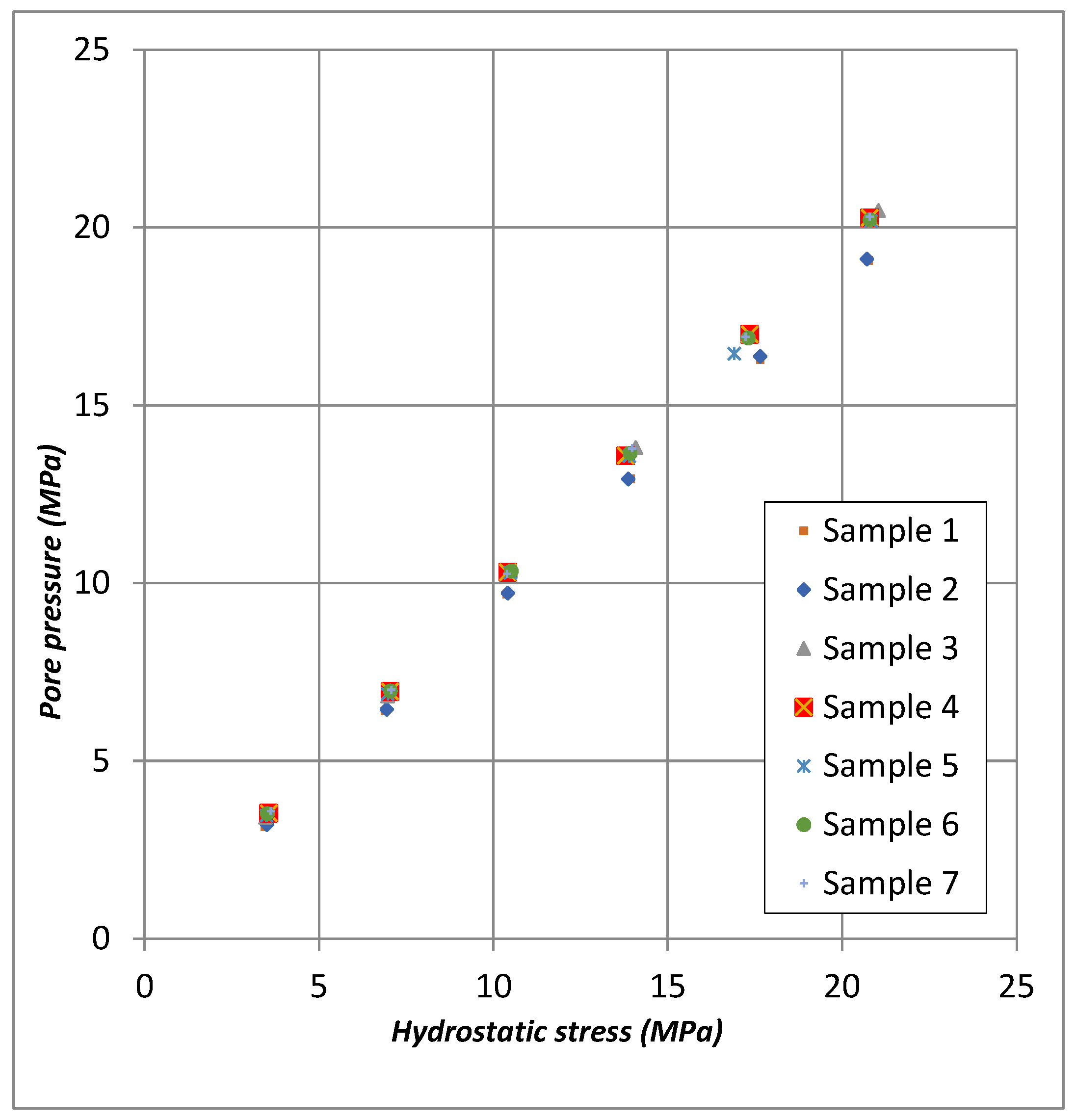

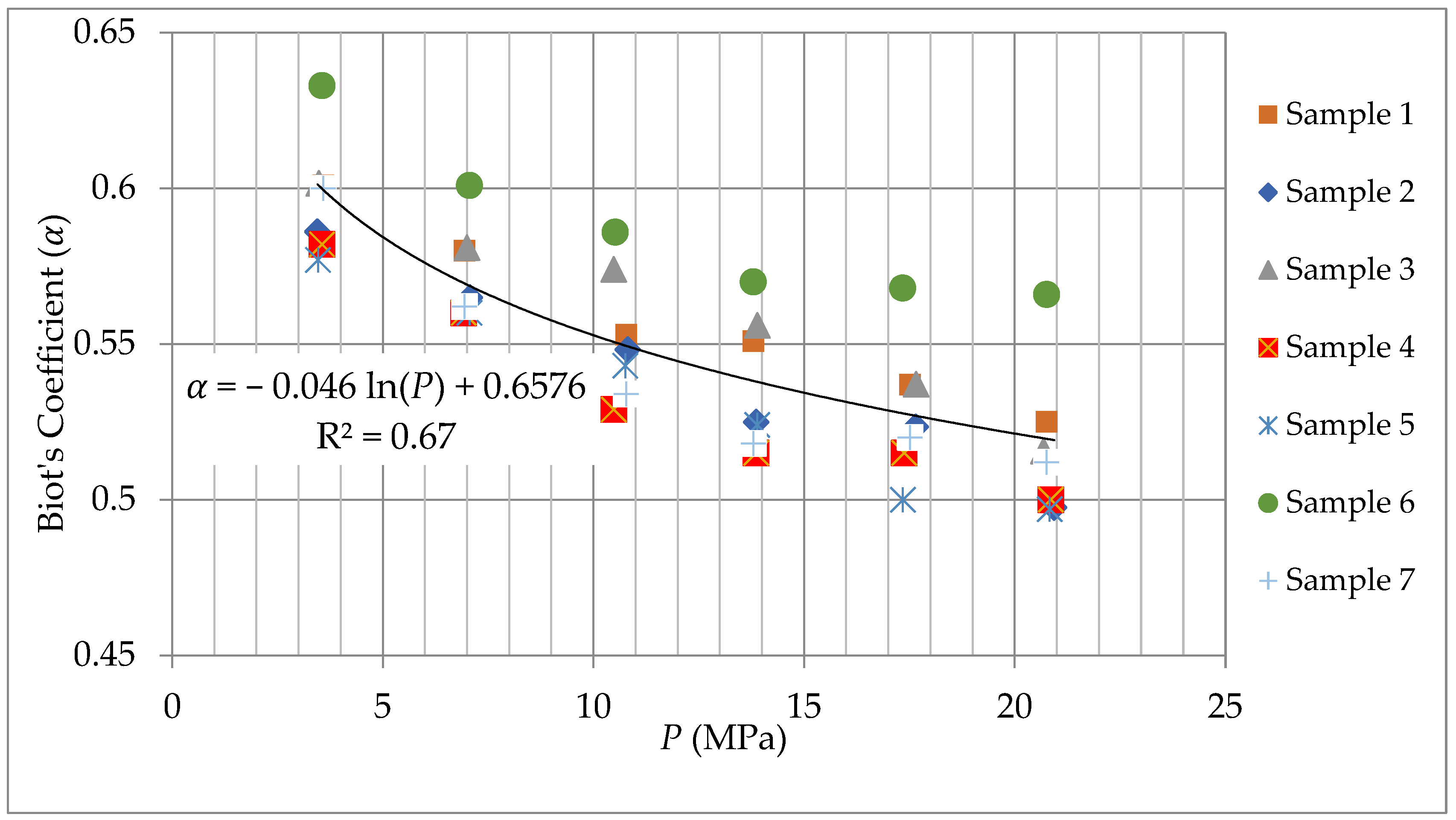

3. Results

- The sample was inserted into the cylindrical chamber, and then, the water valves were completely closed to satisfy the undrained condition.

- Using the hand pump, the hydrostatic stress was increased through regular intervals equal to 3.50 MPa (roughly 500 psi). All tests were performed under a hydrostatic stress less than 50% of the rock’s UCS. In other words, the maximum applied hydrostatic stress was equal to 21 MPa.

- For every interval, the applied hydrostatic stress, pore pressure, compressional wave velocity, and shear wave velocity were recorded.

- Finally, the undrained bulk modulus of each sample was calculated using [29]:

- The pore pressure valves were completely opened to satisfy the drained condition.

- The sample was inserted into the coreholder.

- The hydrostatic stress was incrementally raised from 3.5 MPa to 21 MPa. In each increment, the value of the hydrostatic stress together with the acoustic waves’ velocities were recorded.

- Eventually, using the following equation, the rock bulk modulus under drained conditions, , was computed for each sample [29]:

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, H.F. Theory of Linear Poroelasticity with Applications to Geomechanics and Hydrogeology; Princeton University Press: Oxford, UK, 2000. [Google Scholar]

- Alyafei, N. Fundamentals of Reservoir Rock Properties, 2nd ed.; Hamad Bin Khalifa University Press: Doha, Qatar, 2021; ISBN 9789927137273. [Google Scholar] [CrossRef]

- Höök, M.; Davidsson, S.; Johansson, S.; Tang, X. Decline and depletion rates of oil production: A comprehensive investigation. Phil. Trans. R. Soc. 2014, 372, 20120448. [Google Scholar] [CrossRef]

- Muggeridge, A.; Cockin, A.; Webb, K.; Frampton, H.; Collins, I.; Moulds, T.; Salino, P. Recovery rates, enhanced oil recovery and technological limits. Philos. Trans. A Math. Phys. Eng. Sci. 2013, 372, 20120320. [Google Scholar] [CrossRef]

- Available online: https://www.energy.gov/fecm/enhanced-oil-recovery (accessed on 21 January 2023).

- Elyasi, A.; Goshtasbi, K.; Hashemolhosseini, H. A coupled thermo-hydro-mechanical simulation of reservoir CO2 enhanced oil recovery. Energy Environ. 2016, 27, 524–541. [Google Scholar] [CrossRef]

- Adeosun, T.A.; Adabanija, M.A.; Akinpelu, F.O. Modeling and simulation of reservoir pressure associated with emulsions transport near wellbore for enhanced oil recovery. World Sci. News 2020, 144, 427–449. [Google Scholar]

- Biot, M.A. General Theory of three-dimensional consolidation. J. Appl. Phys. 1941, 12, 155–164. [Google Scholar] [CrossRef]

- Terzaghi, K.; Peck, R.B.; Mesri, G. Soil Mechanics in Engineering Practice, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1996; ISBN 978-0-444-50260-5. [Google Scholar]

- Teklu, T.W.; Alameri, W.; Graves, R.M.; Tutuncu, A.N.; Kazemi, H.; Alsumaiti, A.M. Geomechanics considerations in enhanced oil recovery. In Proceedings of the SPE Canadian Unconventional Resources Conference, Calgary, AB, Canada, 30 October–1 November 2012. [Google Scholar] [CrossRef]

- Wang, S.; Di, Y.; Winterfeld, P.H.; Li, J.; Zhou, X.; Wu, Y.S.; Yao, B. Understanding the multiphysical processes in carbon dioxide enhanced-oil-recovery operations: A numerical study using a general simulation framework. SPE J. 2021, 26, 918–939. [Google Scholar] [CrossRef]

- Lu, M.; Su, Y.; Zhan, S.; Almrabat, A. Modeling for reorientation and potential of enhanced oil recovery in refracturing. Adv. Geo-Energy Res. 2020, 4, 20–28. [Google Scholar] [CrossRef]

- Zhang, G.Q.; Chen, M. Dynamic fracture propagation in hydraulic re-fracturing. J. Pet. Sci. Eng. 2010, 70, 266–272. [Google Scholar] [CrossRef]

- Roussel, N.P.; Sharma, M.M. Role of stress reorientation in the success of refracture treatments in tight gas sands. SPE Prod. Oper. 2012, 27, 346–355. [Google Scholar] [CrossRef]

- Fakcharoenphol, P.; Charoenwongsa, S.; Kazemi, H.; Wu, Y.S. The effect of water-induced stress to enhance hydrocarbon recovery in shale reservoirs. SPE J. 2013, 18, 897–909. [Google Scholar] [CrossRef]

- He, J.; Rui, Z.; Ling, K. A new method to determine Biot’s coefficients of Bakken samples. J. Nat. Gas Sci. Eng. 2016, 35, 259–264. [Google Scholar] [CrossRef]

- Nowakowski, A. The Influence of Rate of Change in Confining and Pore Pressure on Values of the Modulus of Compressibility of the Rock Skeleton and Biot’s Coefficient. Energies 2021, 14, 3056. [Google Scholar] [CrossRef]

- Khalilidermani, M.; Knez, D.; Zamani, M.A.M. Empirical Correlations between the Hydraulic Properties Obtained from the Geoelectrical Methods and Water Well Data of Arak Aquifer. Energies 2021, 14, 5415. [Google Scholar] [CrossRef]

- Knez, D.; Rajaoalison, H. Land Subsidence Assessment for Wind Turbine Location in the South-Western Part of Madagascar. Energies 2022, 15, 4878. [Google Scholar] [CrossRef]

- Franquet, J.A.; Abass, H.H. Experimental evaluation of Biot’s poroelastic parameter-three different methods. In Proceedings of the 37th U.S. Symposium on Rock Mechanics (USRMS), Vail, CO, USA, 6–9 June 1999. [Google Scholar]

- Berryman, J.G. Effective Stress for Transport Properties of Inhomogeneous porous rocks. J. Geophys. Res. 1992, 97, 17409–17424. [Google Scholar] [CrossRef]

- Zhang, J.J. Applied Petroleum Geomechanics, 2nd ed.; Elsevier Inc: Cambridge, MA, USA, 2019; ISBN 978-0-12-814814-3. [Google Scholar] [CrossRef]

- Knez, D.; Zamani, M.A.M. Empirical Formula for Dynamic Biot Coefficient of Sandstone Samples from South-West of Poland. Energies 2021, 14, 5514. [Google Scholar] [CrossRef]

- Wang, C.; Zeng, Z. Overview of Geomechanical Properties of Bakken Formation in Williston Basin, North Dakota. In Proceedings of the 45th U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 26–29 June 2011; pp. 1–11. [Google Scholar]

- Makhnenko, R.Y.; Labuz, J.F. Saturation of Porous Rock and Measurement of the B coefficient. In Proceedings of the 47th US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 23–26 June 2013. [Google Scholar]

- Knez, D.; Khalilidermani, M.; Zamani, M.A.M. Water Influence on the Determination of the Rock Matrix Bulk Modulus in Reservoir Engineering and Rock-Fluid Coupling Projects. Energies 2023, 16, 1769. [Google Scholar] [CrossRef]

- Hart, D.J.; Wang, H.F. Laboratory measurements of a complete set of poroelastic moduli for Berea Sandstone and Indiana Limestone. J. Geophys. Res. 1995, 100, 17741–17751. [Google Scholar] [CrossRef]

- Hajivand, R.D.; Zamani, M.A.M.; Knez, D.; Kazemi, K. Comparing Several Different Numerical Approaches for Large Deformation Modeling with Application in Soil Dynamic Compaction. Transp. Infrastruct. Geotech. 2023. [Google Scholar] [CrossRef]

- Fjaer, E.; Holt, R.M.; Horsrud, P.; Raaen, A.M.; Risnes, R. Petroleum Related Rock Mechanics, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2008; ISBN 978-0-444-50260-5. ISSN 0376-7361. [Google Scholar]

- Raymer, L.L.; Hunt, E.R.; Gardner, J.S. An improved sonic transit time-to-porosity transform. In Proceedings of the 21st Annual Logging Symposium, Lafayette, LA, USA, 8–11 July 1980; pp. 1–13. [Google Scholar]

- Krief, M.; Garta, J.; Stellingwerff, J.; Ventre, J. A petrophysical interpretation using the velocities of P and S waves (full-waveform sonic). Log. Anal. 1990, 31, 355–369. [Google Scholar]

- Detournay, E.; Cheng, A.H.D. Fundamentals of Poroelasticity; Pergamon Press: Oxford, UK, 1993; Volume 2, pp. 113–171. [Google Scholar] [CrossRef]

- Nermoen, A.; Korsnes, R.; Christensen, H.F.; Trads, N.; Hiorth, A.; Madland, M.V. Measuring the Biot stress coefficient and is implications on the Effective Stress Estimate. In Proceedings of the 47th US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 23–26 June 2013. [Google Scholar]

- Zamani, M.A.M.; Knez, D. A new mechanical-hydrodynamic safety factor index for sand production prediction. Energies 2021, 14, 3130. [Google Scholar] [CrossRef]

- Rajaoalison, H.; Knez, D.; Zamani, M.A.M. A Multidisciplinary Approach to Evaluate the Environmental Impacts of Hydrocarbon Production in Khuzestan Province, Iran. Energies 2022, 15, 8656. [Google Scholar] [CrossRef]

- Pride, S.R.; Flekkøy, E.G.; Aursjø, O. Seismic stimulation for enhanced oil recovery. Geophysics 2008, 73, O23–O35. [Google Scholar] [CrossRef]

- Rajaoalison, H.; Knez, D.; Zlotkowski, A. Changes of Dynamic Mechanical Properties of Brine-Saturated Istebna Sandstone under Action of Temperature and Stress. Przemysł Chem. 2019, 98, 801–804. [Google Scholar]

- Knez, D.; Rajaoalison, H. Discrepancy between Measured Dynamic Poroelastic Parameters and Predicted Values from Wyllie’s Equation for Water-Saturated Istebna Sandstone. Acta Geophys. 2021, 69, 673–680. [Google Scholar] [CrossRef]

- Quosay, A.A.; Knez, D.; Ziaja, J. Hydraulic Fracturing: New Uncertainty Based modelling Approach for Process Design Using Monte Carlo Simulation Technique. PLoS ONE 2020, 15, e0236726. [Google Scholar] [CrossRef]

- Quosay, A.A.; Knez, D. Sensitivity Analysis on Fracturing Pressure using Monte Carlo Simulation Technique. Oil Gas Eur. Mag. 2016, 42, 140–144. [Google Scholar]

- Mostafaei, K.; Maleki, S.; Zamani Ahmad Mahmoudi, M.; Knez, D. Risk Management Prediction of Mining and Industrial Projects by Support Vector Machine. Resour. Policy 2022, 78, 102819. [Google Scholar] [CrossRef]

- Khalilidermani, M.; Knez, D. A Survey of Application of Mechanical Specific Energy in Petroleum and Space Drilling. Energies 2022, 15, 3162. [Google Scholar] [CrossRef]

- Knez, D.; Khalilidermani, M. A Review of Different Aspects of Off-Earth Drilling. Energies 2021, 14, 7351. [Google Scholar] [CrossRef]

- Knez, D.; Zamani, M.A.M. A Review of the Geomechanics Aspects in Space Exploration. Energies 2021, 14, 7522. [Google Scholar] [CrossRef]

| Sample Code | Dry Mass (g) | Diameter (mm) | UCS (MPa) |

|---|---|---|---|

| R1 | 93.48 | 38 | 40.2 |

| R2 | 102.95 | 38 | 42.3 |

| R3 | 100.41 | 38 | 44.5 |

| R4 | 100.65 | 38 | 43.1 |

| R5 | 105.68 | 38 | 40.8 |

| Sample Code | Dry Mass (g) | Diameter (mm) | Density (kg/m3) | Porosity (%) |

|---|---|---|---|---|

| S1 | 97.30 | 38 | 2470 | 15.19 |

| S2 | 99.94 | 38 | 2480 | 16.50 |

| S3 | 91.27 | 38 | 2520 | 15.86 |

| S4 | 100.37 | 38 | 2560 | 15.62 |

| S5 | 104.77 | 38 | 2530 | 15.98 |

| S6 | 104.94 | 38 | 2540 | 15.12 |

| S7 | 97.45 | 38 | 2540 | 15.35 |

| Empirical Equation | Calculated Biot’s Coefficient |

|---|---|

| Equation (8) | 0.52–0.60 |

| Equation (9) | 0.52 |

| Equation (10) | 0.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zamani, M.A.M.; Knez, D. Experimental Investigation on the Relationship between Biot’s Coefficient and Hydrostatic Stress for Enhanced Oil Recovery Projects. Energies 2023, 16, 4999. https://doi.org/10.3390/en16134999

Zamani MAM, Knez D. Experimental Investigation on the Relationship between Biot’s Coefficient and Hydrostatic Stress for Enhanced Oil Recovery Projects. Energies. 2023; 16(13):4999. https://doi.org/10.3390/en16134999

Chicago/Turabian StyleZamani, Mohammad Ahmad Mahmoudi, and Dariusz Knez. 2023. "Experimental Investigation on the Relationship between Biot’s Coefficient and Hydrostatic Stress for Enhanced Oil Recovery Projects" Energies 16, no. 13: 4999. https://doi.org/10.3390/en16134999

APA StyleZamani, M. A. M., & Knez, D. (2023). Experimental Investigation on the Relationship between Biot’s Coefficient and Hydrostatic Stress for Enhanced Oil Recovery Projects. Energies, 16(13), 4999. https://doi.org/10.3390/en16134999