Environmental Impact Assessment of Autonomous Transportation Systems

Abstract

1. Introduction

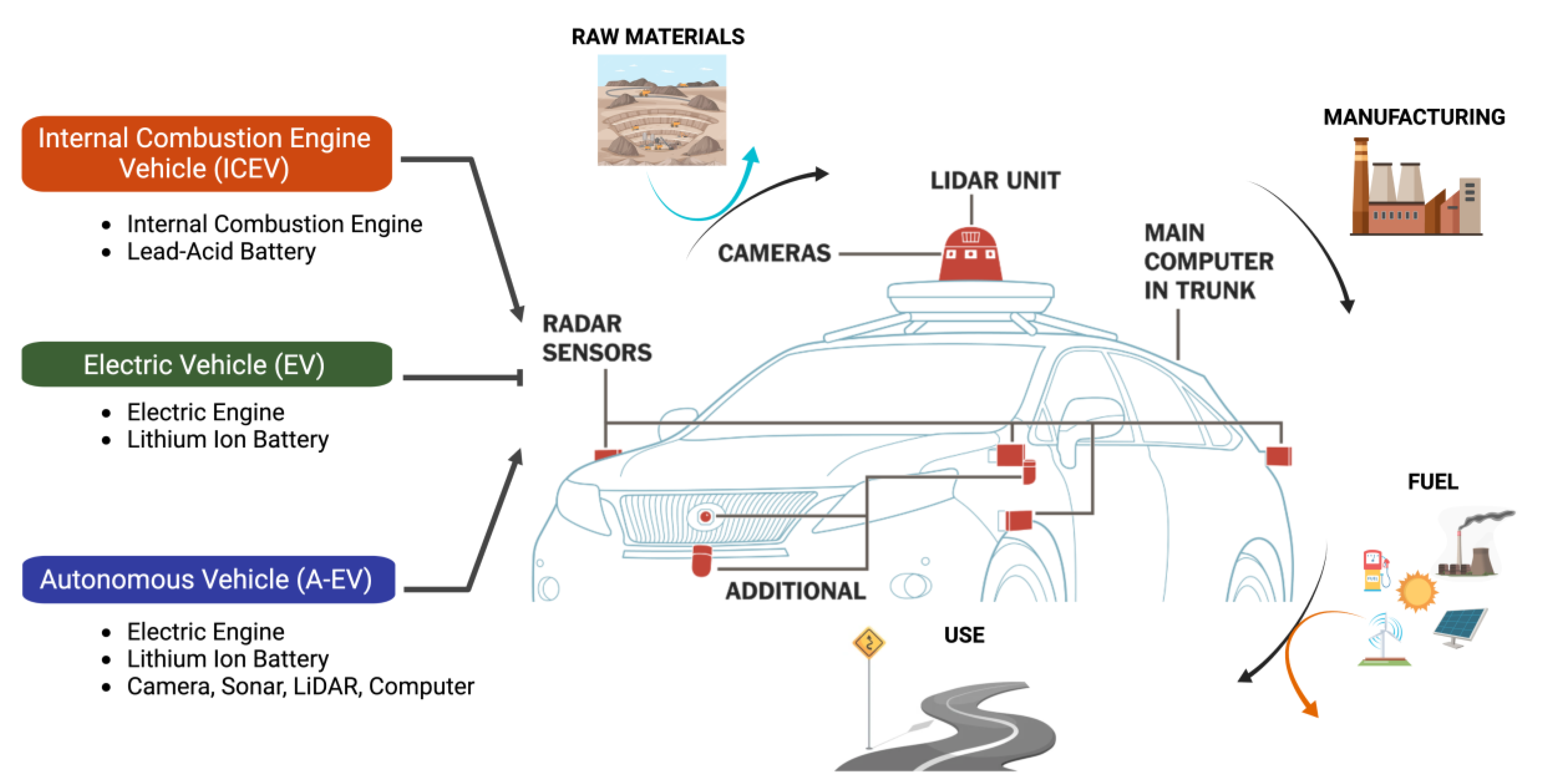

2. Materials and Methods

2.1. Goal and Scope

2.2. Modeling Approach

2.3. Life Cycle Inventories

2.4. Limitations and Uncertainty

3. Results and Discussion

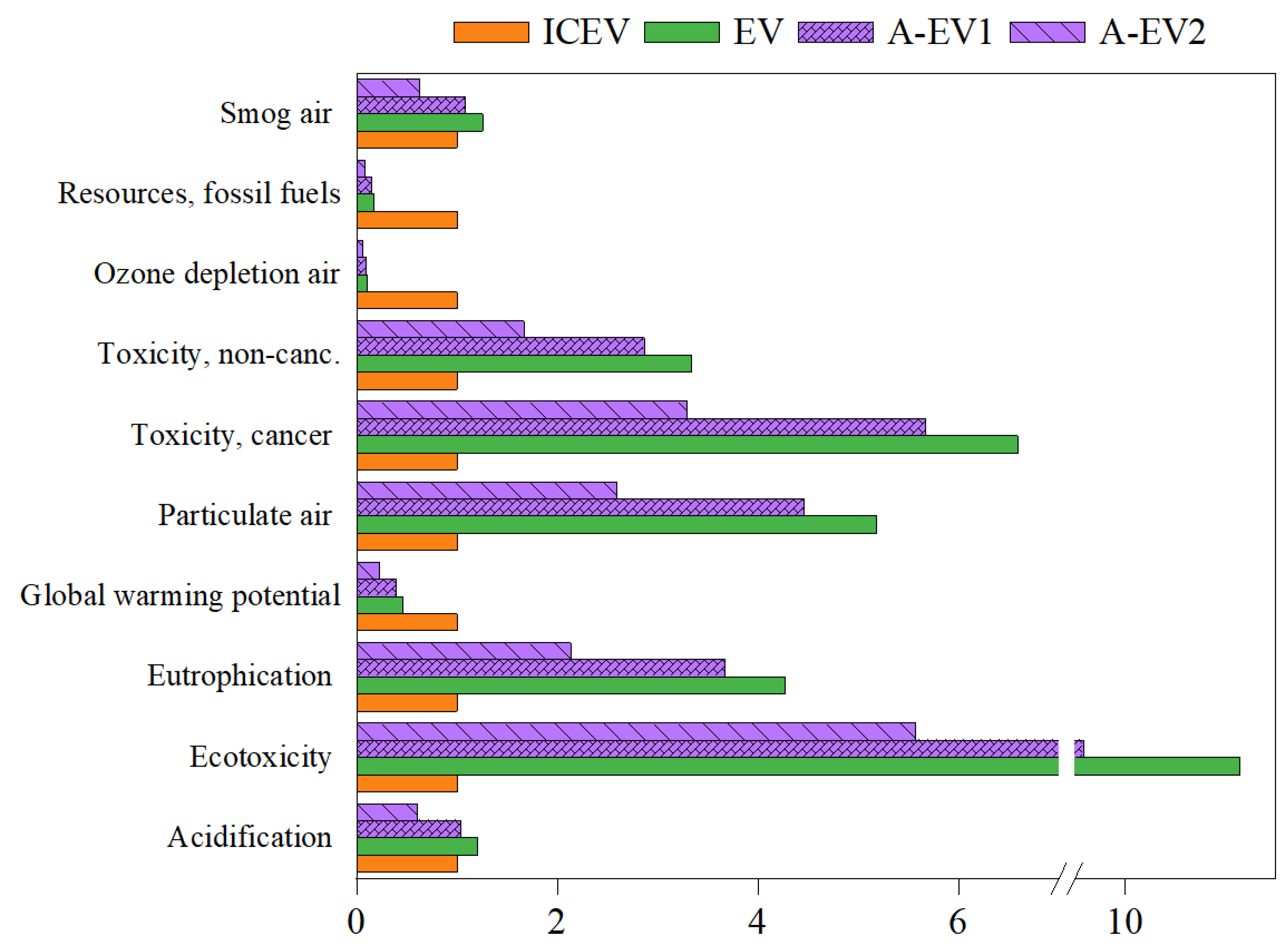

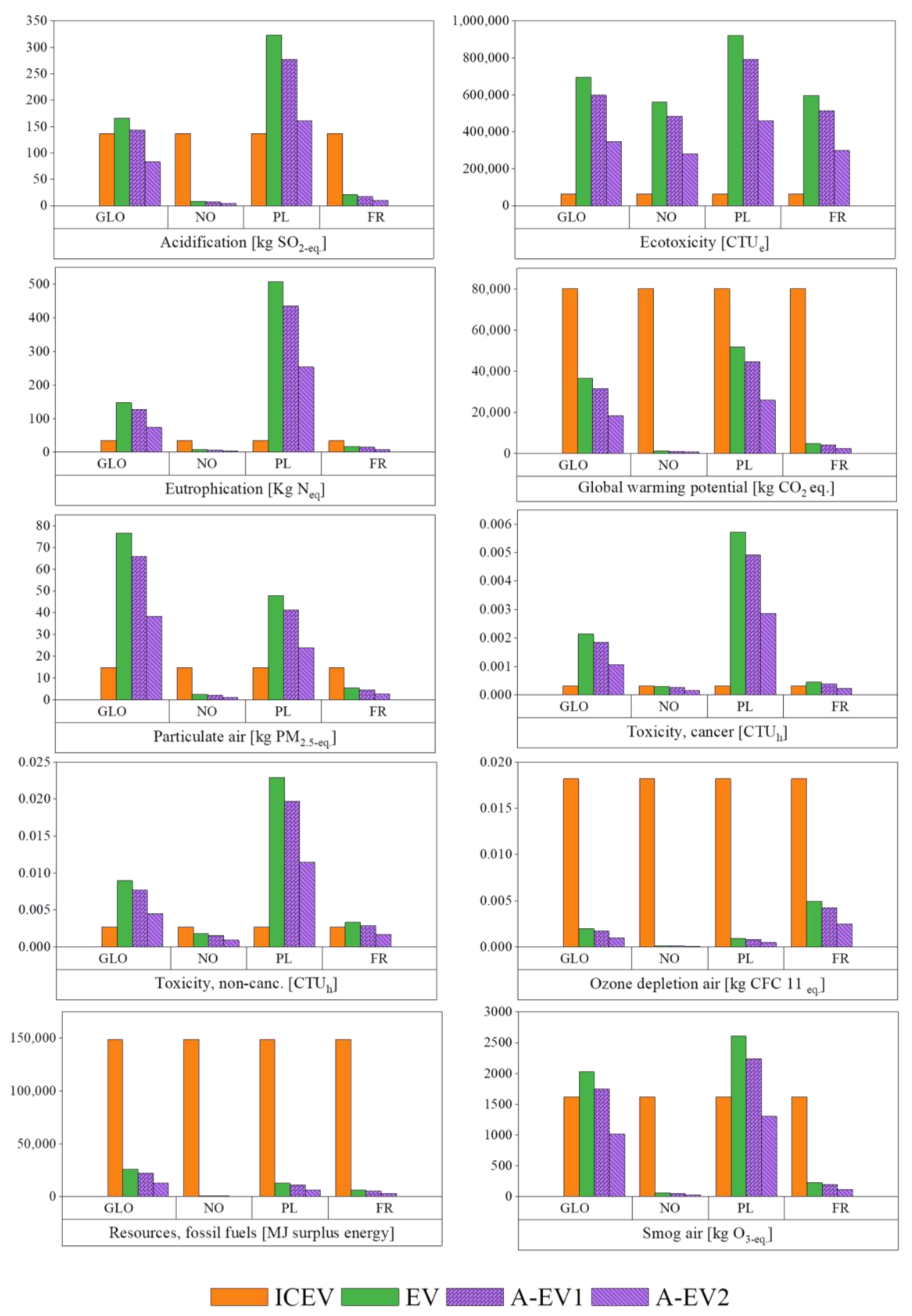

3.1. Life Cycle Impact Assessment

3.2. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Abbreviations | Description |

| A-EV | Autonomous electric vehicles |

| A-EV1 | Autonomous electric vehicles with automation from level zero through two |

| A-EV2 | Autonomous electric vehicles with automation from level-three through five |

| EV | Electric vehicles |

| ICEV | Internal combustion engine vehicles |

| LCA | Life cycle assessment |

| TRACI | Tools for the reduction and assessment of chemical and other environmental impacts |

| PM | Particulate matter |

| NOx | The gases of nitric oxide and nitrogen dioxide |

| BMS | Battery management system |

References

- Roose, B.; Tennyson, E.M.; Meheretu, G.; Kassaw, A.; Tilahun, S.A.; Allen, L.; Stranks, S.D. Local Manufacturing of Perovskite Solar Cells, a Game-Changer for Low- and Lower-Middle Income Countries? Energy Environ. Sci. 2022, 15, 3571–3582. [Google Scholar] [CrossRef]

- United Nations Climate Change the Paris Agreement. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement (accessed on 24 May 2023).

- US Environmental Protection Agency Sources of Greenhouse Gas Emissions. Available online: https://www.epa.gov/ghgemissions/sources-greenhouse-gas-emissions (accessed on 24 May 2023).

- Cage, F. The Long Road to Electric Cars in the U.S. Available online: https://www.reuters.com/graphics/AUTOS-ELECTRIC/USA/mopanyqxwva/ (accessed on 24 May 2023).

- Baars, J.; Domenech, T.; Bleischwitz, R.; Melin, H.E.; Heidrich, O. Circular Economy Strategies for Electric Vehicle Batteries Reduce Reliance on Raw Materials. Nat. Sustain. 2021, 4, 71–79. [Google Scholar] [CrossRef]

- International Energy Agency Global Electric Car Sales Have Continued Their Strong Growth in 2022 after Breaking Records Last Year. Available online: https://www.iea.org/news/global-electric-car-sales-have-continued-their-strong-growth-in-2022-after-breaking-records-last-year (accessed on 24 May 2023).

- Verma, S.; Dwivedi, G.; Verma, P. Life Cycle Assessment of Electric Vehicles in Comparison to Combustion Engine Vehicles: A Review. Mater. Today Proc. 2022, 49, 217–222. [Google Scholar] [CrossRef]

- Wu, S.R.; Shirkey, G.; Celik, I.; Shao, C.; Chen, J. A Review on the Adoption of AI, BC, and IoT in Sustainability Research. Sustainability 2022, 14, 7851. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2013, 17, 53–64. [Google Scholar] [CrossRef]

- Egede, P.; Dettmer, T.; Herrmann, C.; Kara, S. Life Cycle Assessment of Electric Vehicles—A Framework to Consider Influencing Factors. Procedia CIRP 2015, 29, 233–238. [Google Scholar] [CrossRef]

- Gawron, J.H.; Keoleian, G.A.; De Kleine, R.D.; Wallington, T.J.; Kim, H.C. Life Cycle Assessment of Connected and Automated Vehicles: Sensing and Computing Subsystem and Vehicle Level Effects. Environ. Sci. Technol. 2018, 52, 3249–3256. [Google Scholar] [CrossRef] [PubMed]

- Pehrson, I. Integrating Planetary Boundaries into the Life Cycle Assessment of Electric Vehicles A Case Study on Prioritising Impact Categories through Environmental Benchmarking in Normalisation and Weighting Methods When Assessing Electric Heavy-Duty Vehicles; KTH Royal Institute of Technology: Stockholm, Sweden, 2020; Available online: http://kth.diva-portal.org/smash/record.jsf?pid=diva2%3A1470529&dswid=-6750 (accessed on 23 June 2023).

- Faria, R.; Marques, P.; Moura, P.; Freire, F.; Delgado, J.; De Almeida, A.T. Impact of the Electricity Mix and Use Profile in the Life-Cycle Assessment of Electric Vehicles. Renew. Sustain. Energy Rev. 2013, 24, 271–287. [Google Scholar] [CrossRef]

- Balpreet Kukreja. Lifecycle Analysis of Electric Vehicles. Available online: https://sustain.ubc.ca/about/resources/lifecycle-analysis-electric-vehicles (accessed on 16 June 2023).

- European Environment Agency. Electric Vehicles from Life Cycle and Circular Economy Perspectives; European Environment Agency: Copenhagen, Denmark, 2018; ISBN 978-92-9213-985-8. [Google Scholar]

- Pipitone, E.; Caltabellotta, S.; Occhipinti, L. A Life Cycle Environmental Impact Comparison between Traditional, Hybrid, and Electric Vehicles in the European Context. Sustainability 2021, 13, 10992. [Google Scholar] [CrossRef]

- Shafique, M.; Azam, A.; Rafiq, M.; Luo, X. Life Cycle Assessment of Electric Vehicles and Internal Combustion Engine Vehicles: A Case Study of Hong Kong. Res. Transp. Econ. 2022, 91, 101112. [Google Scholar] [CrossRef]

- Shafique, M.; Luo, X. Environmental Life Cycle Assessment of Battery Electric Vehicles from the Current and Future Energy Mix Perspective. J. Environ. Manag. 2022, 303, 114050. [Google Scholar] [CrossRef]

- Koroma, M.S.; Costa, D.; Philippot, M.; Cardellini, G.; Hosen, M.S.; Coosemans, T.; Messagie, M. Life Cycle Assessment of Battery Electric Vehicles: Implications of Future Electricity Mix and Different Battery End-of-Life Management. Sci. Total Environ. 2022, 831, 154859. [Google Scholar] [CrossRef] [PubMed]

- Ziegler, M.S.; Trancik, J.E. Re-Examining Rates of Lithium-Ion Battery Technology Improvement and Cost Decline. Energy Environ. Sci. 2021, 14, 1635–1651. [Google Scholar] [CrossRef]

- Faisal, A.; Kamruzzaman, M.; Yigitcanlar, T.; Currie, G. Understanding Autonomous Vehicles. J. Transp. Land Use 2019, 12, 45–72. [Google Scholar] [CrossRef]

- Taiebat, M.; Stolper, S.; Xu, M. Forecasting the Impact of Connected and Automated Vehicles on Energy Use: A Microeconomic Study of Induced Travel and Energy Rebound. Appl. Energy 2019, 247, 297–308. [Google Scholar] [CrossRef]

- Patella, S.M.; Scrucca, F.; Asdrubali, F.; Carrese, S. Carbon Footprint of Autonomous Vehicles at the Urban Mobility System Level: A Traffic Simulation-Based Approach. Transp. Res. Part D Transp. Environ. 2019, 74, 189–200. [Google Scholar] [CrossRef]

- Yu, Y.; Shi, C.; Shan, D.; Lippiello, V.; Yang, Y. A Hierarchical Control Scheme for Multiple Aerial Vehicle Transportation Systems with Uncertainties and State/Input Constraints. Appl. Math. Model. 2022, 109, 651–678. [Google Scholar] [CrossRef]

- Rajasekhar, M.V.; Jaswal, A.K. Autonomous Vehicles: The Future of Automobiles. In Proceedings of the 2015 IEEE International Transportation Electrification Conference (ITEC), Chennai, India, 27–29 August 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Yu, Y.; Shan, D.; Benderius, O.; Berger, C.; Kang, Y. Formally Robust and Safe Trajectory Planning and Tracking for Autonomous Vehicles. IEEE Trans. Intell. Transp. Syst. 2022, 23, 22971–22987. [Google Scholar] [CrossRef]

- US Department of Transportation Automated Vehicle Safety|NHTSA. Available online: https://www.nhtsa.gov/technology-innovation/automated-vehicles-safety#issue-road-self-driving (accessed on 24 May 2023).

- Stephens, T.S.; Gonder, J.; Chen, Y.; Lin, Z.; Liu, C.; Gohlke, D. Estimated Bounds and Important Factors for Fuel Use and Consumer Costs of Connected and Automated Vehicles; National Renewal Energy Laboratory: Golden, CO, USA, 2016. [Google Scholar]

- Vahidi, A.; Sciarretta, A. Energy Saving Potentials of Connected and Automated Vehicles. Transp. Res. Part C Emerg. Technol. 2018, 95, 822–843. [Google Scholar] [CrossRef]

- Ross, C.; Guhathakurta, S. Autonomous Vehicles and Energy Impacts: A Scenario Analysis. Energy Procedia 2017, 143, 47–52. [Google Scholar] [CrossRef]

- Cox, B.; Mutel, C.L.; Bauer, C.; Mendoza Beltran, A.; Van Vuuren, D.P. Uncertain Environmental Footprint of Current and Future Battery Electric Vehicles. Environ. Sci. Technol. 2018, 52, 4989–4995. [Google Scholar] [CrossRef] [PubMed]

- Biramo, Z.B.; Mekonnen, A.A. Modeling the Potential Impacts of Automated Vehicles on Pollutant Emissions under Different Scenarios of a Test Track. Environ. Syst. Res. 2022, 11, 22. [Google Scholar] [CrossRef] [PubMed]

- Massar, M.; Reza, I.; Rahman, S.M.; Abdullah, S.M.H.; Jamal, A.; Al-Ismail, F.S. Impacts of Autonomous Vehicles on Greenhouse Gas Emissions—Positive or Negative? Int. J. Environ. Res. Public Health 2021, 18, 5567. [Google Scholar] [CrossRef]

- Brown, A.; Gonder, J.; Repac, B.; Meyer, G.; Beiker, S.; Brown, A.; Gonder, J.; Repac, B. An Analysis of Possible Energy Impacts of Automated Vehicles. In Road Vehicle Automation; Lecture Notes in Mobility; Springer: Cham, Switzerland, 2014; pp. 137–153. [Google Scholar] [CrossRef]

- Zhong, S.; Liu, A.; Jiang, Y.; Hu, S.; Xiao, F.; Huang, H.-J.; Song, Y. Energy and Environmental Impacts of Shared Autonomous Vehicles under Different Pricing Strategies. NPJ Urban Sustain. 2023, 3, 8. [Google Scholar] [CrossRef]

- Kontar, W.; Ahn, S.; Hicks, A. Autonomous Vehicle Adoption: Use Phase Environmental Implications. Environ. Res. Lett. 2021, 16, 064010. [Google Scholar] [CrossRef]

- Huber, D.; Viere, T.; Horschutz Nemoto, E.; Jaroudi, I.; Korbee, D.; Fournier, G. Climate and Environmental Impacts of Automated Minibuses in Future Public Transportation. Transp. Res. Part D Transp. Environ. 2022, 102, 103160. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Nazzal, M.A.; Darras, B.M.; Deiab, I.M. Global Warming Potential, Water Footprint, and Energy Demand of Shared Autonomous Electric Vehicles Incorporating Circular Economy Practices. Sustain. Prod. Consum. 2023, 36, 449–462. [Google Scholar] [CrossRef]

- ISO14040:2006; International Organization for Standardization Environmental Management—Life Cycle Assessment—Principles and Framework. Available online: https://www.iso.org/standard/37456.html (accessed on 15 June 2023).

- ISO14044:2006; International Organization for Standardization Environmental Management—Life Cycle Assessment—Requirements and Guidelines. Available online: https://www.iso.org/standard/38498.html (accessed on 15 June 2023).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The Ecoinvent Database Version 3 (Part I): Overview and Methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Sphera Life Cycle Assessment (LCA) Software. LCA for Experts (GaBi). Available online: https://sphera.com/life-cycle-assessment-lca-software/ (accessed on 15 June 2023).

- Bare, J. Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts (TRACI). Version 2.1—User’s Manual; EPA/600/R-12/554; U. S. EPA Office of Research and Development: Washington, DC, USA, 2014.

- Sato, F.E.K.; Nakata, T. Energy Consumption Analysis for Vehicle Production through a Material Flow Approach. Energies 2020, 13, 2396. [Google Scholar] [CrossRef]

- Fernando, C.; Soo, V.K.; Compston, P.; Kim, H.C.; de Kleine, R.; Weigl, D.; Keith, D.R.; Doolan, M. Life Cycle Environmental Assessment of a Transition to Mobility Servitization. Procedia CIRP 2020, 90, 238–243. [Google Scholar] [CrossRef]

- IEA Executive Summary—Norway 2022. Available online: https://www.iea.org/reports/norway-2022/executive-summary (accessed on 15 June 2023).

- IEA Executive Summary—Poland 2022. Available online: https://www.iea.org/reports/poland-2022/executive-summary (accessed on 15 June 2023).

- World Nuclear Ssociation Nuclear Power in France|French Nuclear Energy. Available online: https://world-nuclear.org/information-library/country-profiles/countries-a-f/france.aspx (accessed on 15 June 2023).

- Bello, A.S.; Zouari, N.; Da’ana, D.A.; Hahladakis, J.N.; Al-Ghouti, M.A. An Overview of Brine Management: Emerging Desalination Technologies, Life Cycle Assessment, and Metal Recovery Methodologies. J. Environ. Manag. 2021, 288, 112358. [Google Scholar] [CrossRef]

- Volkart, K.; Bauer, C.; Boulet, C. Life Cycle Assessment of Carbon Capture and Storage in Power Generation and Industry in Europe. Int. J. Greenh. Gas Control 2013, 16, 91–106. [Google Scholar] [CrossRef]

- Celik, I. Eco-Design of Emerging Photovoltaic (PV) Cells. Ph.D. Thesis, University of Toledo, Toledo, OH, USA, 2018; p. 133. [Google Scholar]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent Developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Wang, Y.; Pan, Z.; Zhang, W.; Borhani, T.N.; Li, R.; Zhang, Z. Life Cycle Assessment of Combustion-Based Electricity Generation Technologies Integrated with Carbon Capture and Storage: A Review. Environ. Res. 2022, 207, 112219. [Google Scholar] [CrossRef]

- IEA World Energy Balances: Overview, IEA, Paris. Available online: https://www.iea.org/reports/world-energy-balances-overview/world (accessed on 24 May 2023).

- Zhang, Y.; Wu, D.; Wang, C.; Fu, X.; Wu, G. Impact of Coal Power Generation on the Characteristics and Risk of Heavy Metal Pollution in Nearby Soil. Ecosyst. Health Sustain. 2020, 6, 1787092. [Google Scholar] [CrossRef]

- Celik, I.; Song, Z.; Cimaroli, A.J.; Yan, Y.; Heben, M.J.; Apul, D. Life Cycle Assessment (LCA) of Perovskite PV Cells Projected from Lab to Fab. Sol. Energy Mater. Sol. Cells 2016, 156, 157–169. [Google Scholar] [CrossRef]

- Villalba, G.; Ayres, R.U.; Schroder, H. Accounting for Fluorine: Production, Use, and Loss. J. Ind. Ecol. 2007, 11, 85–101. [Google Scholar] [CrossRef]

- Kucukvar, M.; Onat, N.C.; Kutty, A.A.; Adella, G.M.; Bulak, M.E.; Ansari, F.; Kumbaroglu, G. Environmental Efficiency of Electric Vehicles in Europe under Various Electricity Production Mix Scenarios. J. Clean. Prod. 2022, 335, 130291. [Google Scholar] [CrossRef]

| Phase | Components | ICEV | EV | A-EV | ||||

|---|---|---|---|---|---|---|---|---|

| Materials | Units | Mass | Materials | Units | Mass | Mass | ||

| Manufacturing Phase | Engines | Cast Iron | kg | 102 | Copper | kg | 4.50 | 4.51 |

| Aluminum | kg | 61.4 | Steel | kg | 23.9 | 23.9 | ||

| Steel | kg | 20.5 | NdFeB | kg | 1.30 | 1.32 | ||

| Plastic | kg | 9.20 | - | - | - | - | ||

| Rubber | kg | 9.20 | - | - | - | - | ||

| Copper | kg | 2.00 | - | - | - | - | ||

| Battery | PbSb 2.5% | kg | 1.10 | Battery cell | kg | 152 | 152 | |

| Lead | kg | 0.01 | Anode | kg | 59.0 | 59.0 | ||

| Sulfuric Acid | kg | 0.80 | Cathode | kg | 65.0 | 65.0 | ||

| Water (Deionized) | kg | 0.86 | Separator | kg | 3.30 | 3.30 | ||

| Paper/Glass | kg | 0.38 | Electrolyte | kg | 24.0 | 24.0 | ||

| Polypropylene | kg | 1.04 | Cell container | kg | 1.00 | 1.00 | ||

| Distilled Water | g | 2.00 | Battery case | kg | 81.0 | 81.0 | ||

| Pulp Paper | kg | 0.40 | BMS | kg | 9.40 | 9.42 | ||

| Foil | g | 2.01 | Cooling | kg | 10.0 | 10.0 | ||

| Iron | kg | 0.04 | - | - | - | - | ||

| Additional | - | - | - | Cast Iron | - | - | 0.20 | |

| - | - | - | Aluminum | - | - | 9.40 | ||

| - | - | - | Copper | kg | 0.70 | |||

| - | - | - | Steel | kg | - | 0.30 | ||

| - | - | - | Glass | kg | - | 0.10 | ||

| - | - | - | Rare earth metals | kg | - | 0.20 | ||

| - | - | - | Plastic | kg | - | 1.60 | ||

| - | - | - | Electronics | kg | - | 3.90 | ||

| Energy | Electricity | GJ | 27.0 | Electricity | GJ | 29.0 | 29.0 | |

| Use Phase | Energy Use | Petroleum | lit/km | 0.05 | Electricity | Wh/km | 206 | 177 * 103 ** |

| Impact Categories | EV | A-EV1 | A-EV2 | ICEV | ICEV (150,000 Miles·Passenger) |

|---|---|---|---|---|---|

| Acidification | 1.14 | 1.02 | 0.67 | 1.00 | 1.70 × 102 (kg SO2-eq) |

| Ecotoxicity | 3.86 | 3.51 | 2.34 | 1.00 | 2.14 × 105 (CTUe) |

| Eutrophication | 2.66 | 2.42 | 1.61 | 1.00 | 6.56 × 10 (kg Neq) |

| Global warming | 0.50 | 0.44 | 0.28 | 1.00 | 8.59 × 104 (kg CO2-eq) |

| Human health particulate | 3.32 | 2.94 | 1.91 | 1.00 | 2.69 × 10 (kg PM2.5-eq) |

| Human tox., cancer | 3.38 | 3.07 | 2.06 | 1.00 | 7.57 × 10−4 (CTUh) |

| Human tox., non-can | 1.86 | 1.81 | 1.27 | 1.00 | 6.02 × 10−3 (CTUh) |

| Ozone depletion | 0.12 | 0.11 | 0.07 | 1.00 | 1.85 × 10−2 (kg CFC 11eq) |

| Resources | 0.20 | 0.18 | 0.11 | 1.00 | 1.53 × 105 (MJ energy) |

| Smog Air | 1.22 | 1.08 | 0.71 | 1.00 | 1.95 × 103 (kg O3-eq) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heiberg, S.; Emond, E.; Allen, C.; Raya, D.; Gadhamshetty, V.; Dhiman, S.S.; Ravilla, A.; Celik, I. Environmental Impact Assessment of Autonomous Transportation Systems. Energies 2023, 16, 5009. https://doi.org/10.3390/en16135009

Heiberg S, Emond E, Allen C, Raya D, Gadhamshetty V, Dhiman SS, Ravilla A, Celik I. Environmental Impact Assessment of Autonomous Transportation Systems. Energies. 2023; 16(13):5009. https://doi.org/10.3390/en16135009

Chicago/Turabian StyleHeiberg, Samantha, Emily Emond, Cody Allen, Dheeraj Raya, Venkataramana Gadhamshetty, Saurabh Sudha Dhiman, Achyuth Ravilla, and Ilke Celik. 2023. "Environmental Impact Assessment of Autonomous Transportation Systems" Energies 16, no. 13: 5009. https://doi.org/10.3390/en16135009

APA StyleHeiberg, S., Emond, E., Allen, C., Raya, D., Gadhamshetty, V., Dhiman, S. S., Ravilla, A., & Celik, I. (2023). Environmental Impact Assessment of Autonomous Transportation Systems. Energies, 16(13), 5009. https://doi.org/10.3390/en16135009