Assessment of the Impact of Lubricating Oil Contamination by Biodiesel on Trunk Piston Engine Reliability

Abstract

:1. Introduction

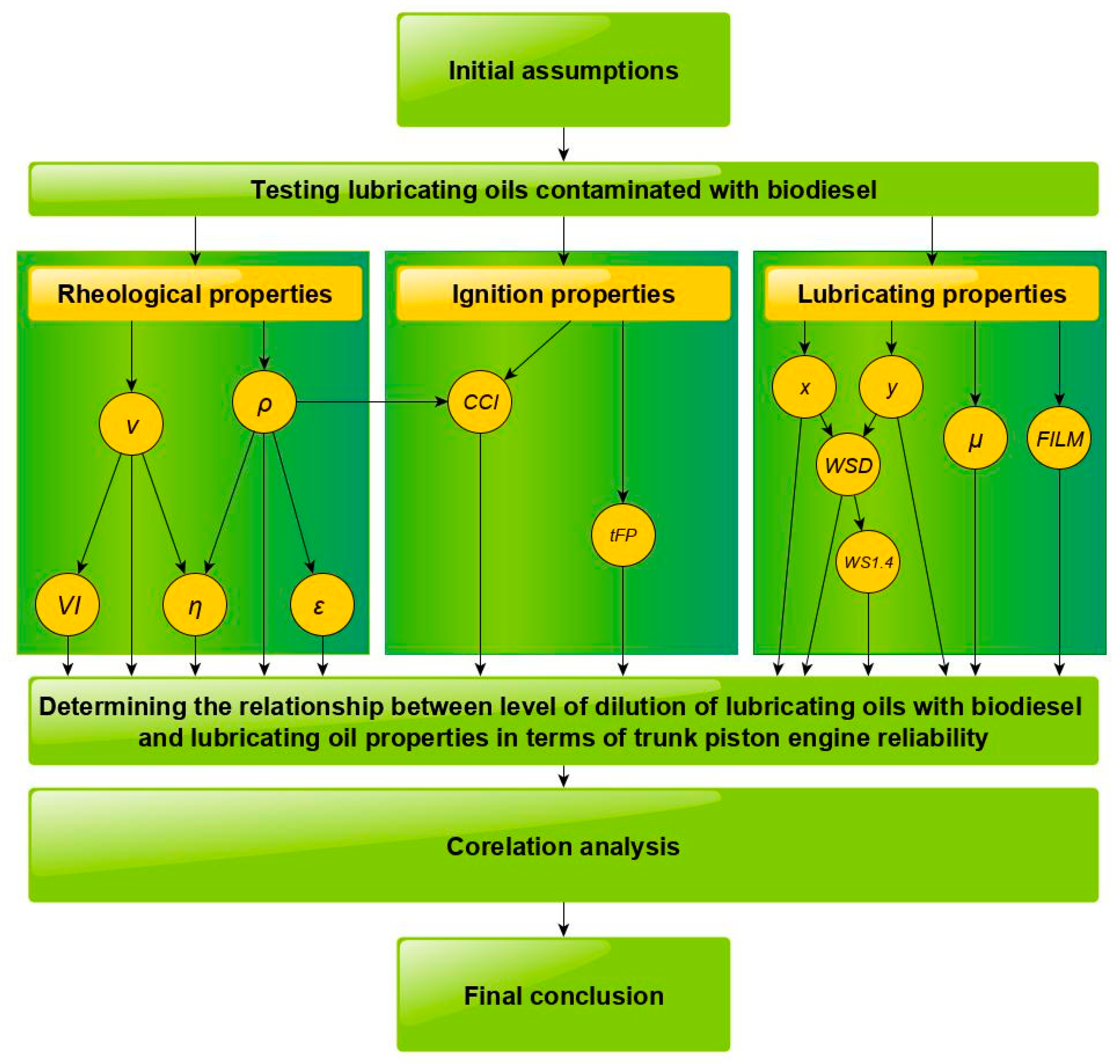

2. Materials and Methods

2.1. Analyzed Mixtures of the Lubricating Oil and Diesel Oil

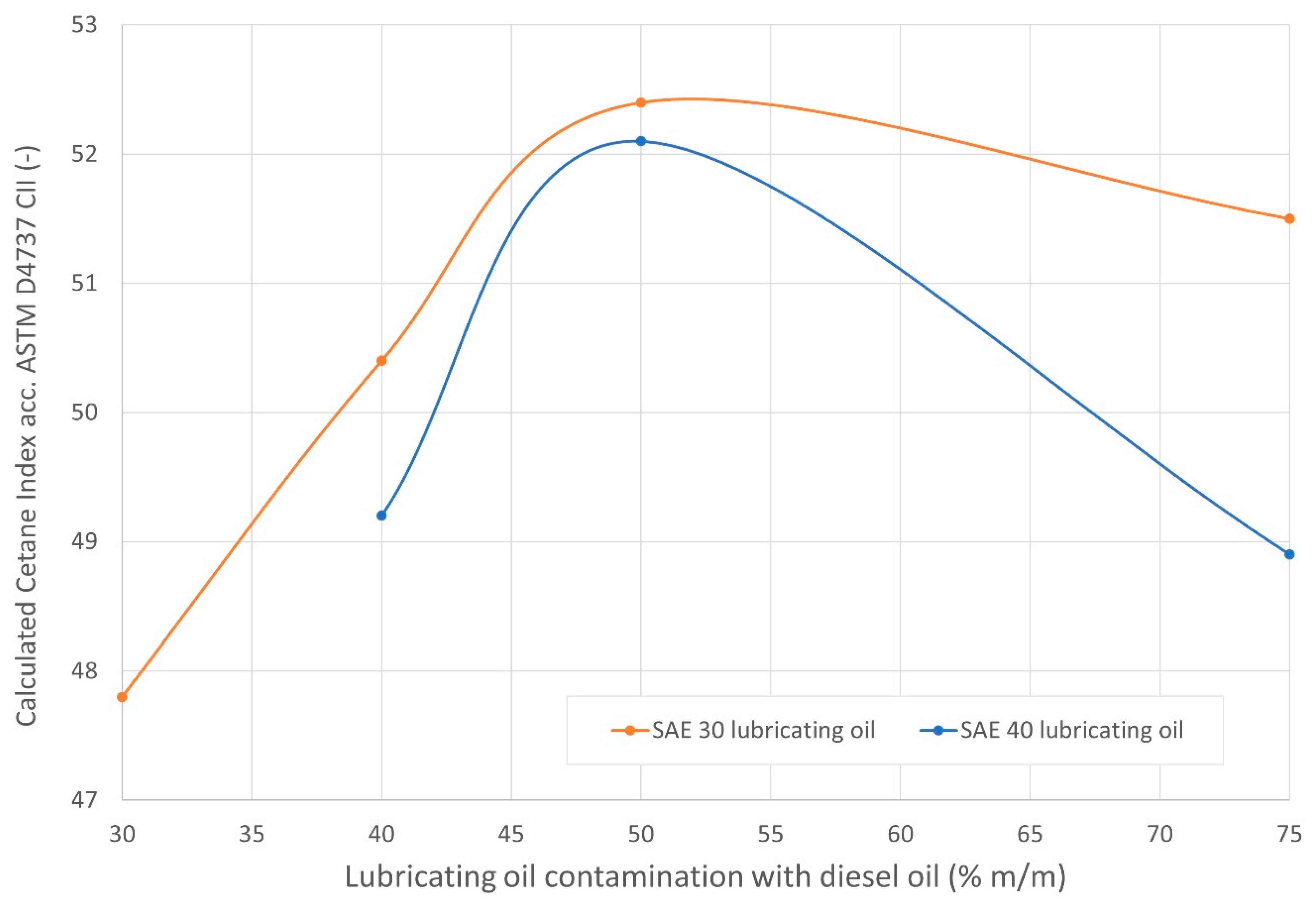

2.2. Ignition Properties of the Oil Diluted with Diesel Oil

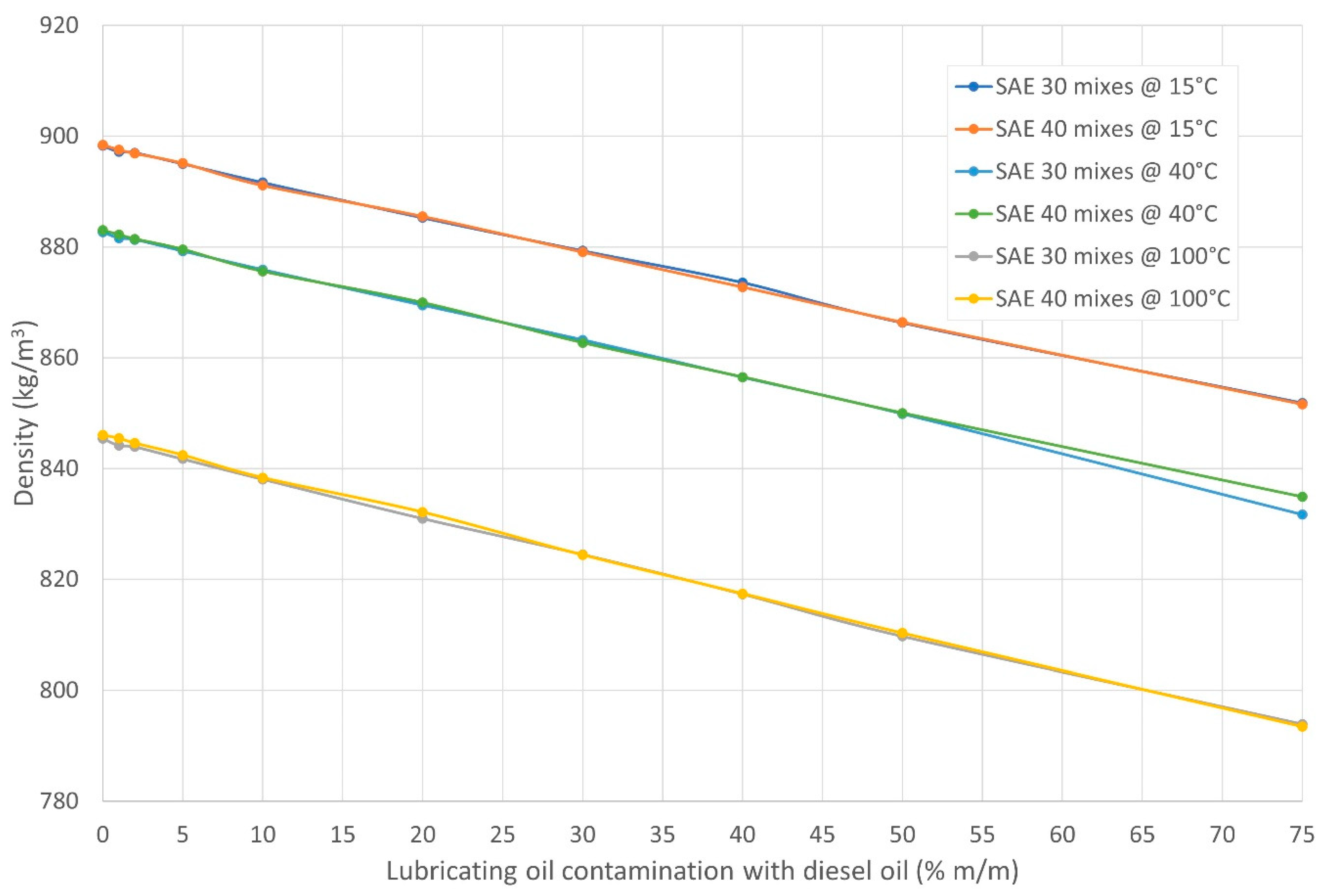

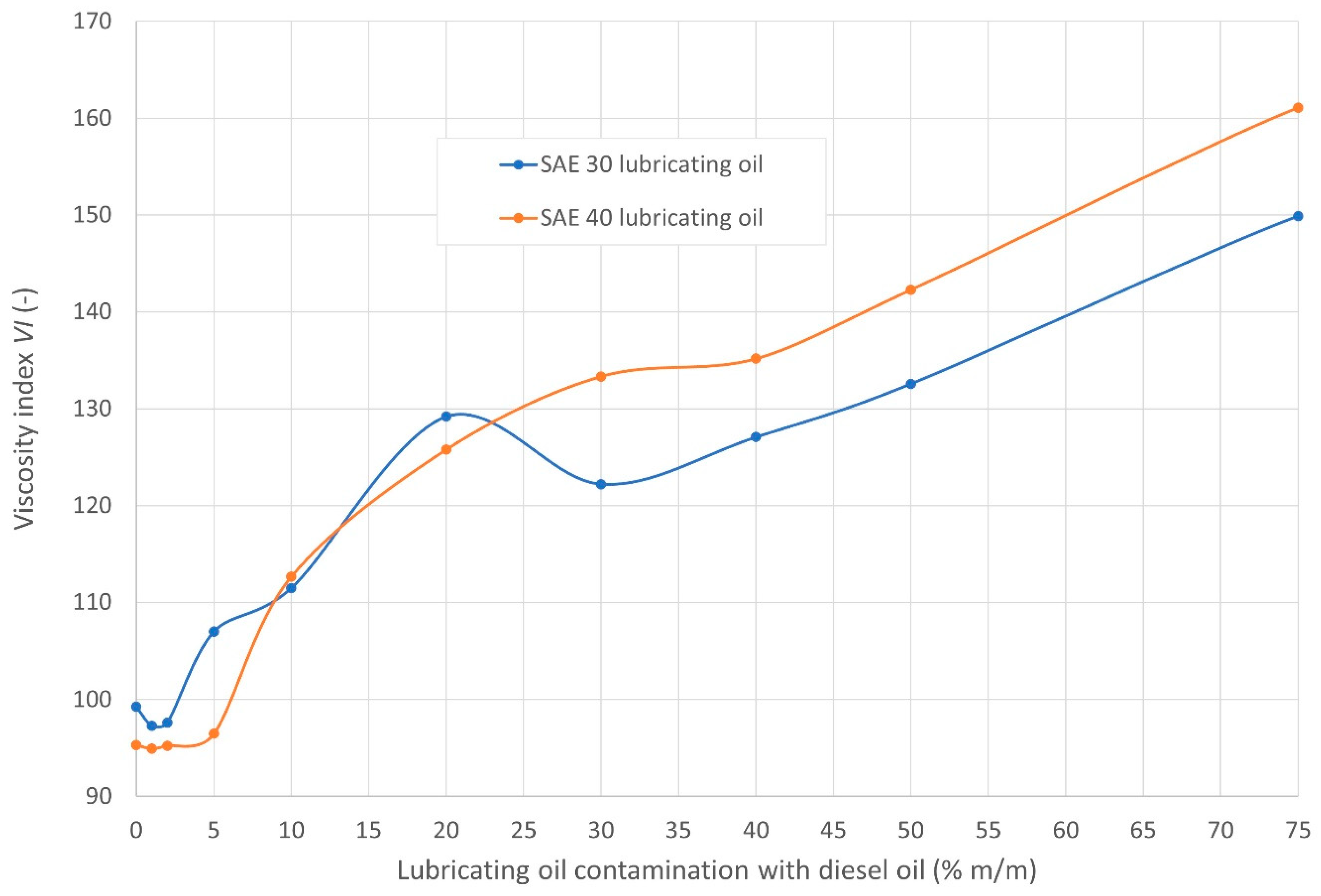

2.3. Rheological Properties of the Lubricating Oil Diluted with Diesel Oil

2.4. Tribological Properties of the Lubricating Oil Diluted with Diesel Oil

3. Results and Discussion

3.1. Ignition Properties of Oil Diluted with Diesel Oil

3.2. Rheological Properties of the Lubricating Oil Diluted with Diesel Oil

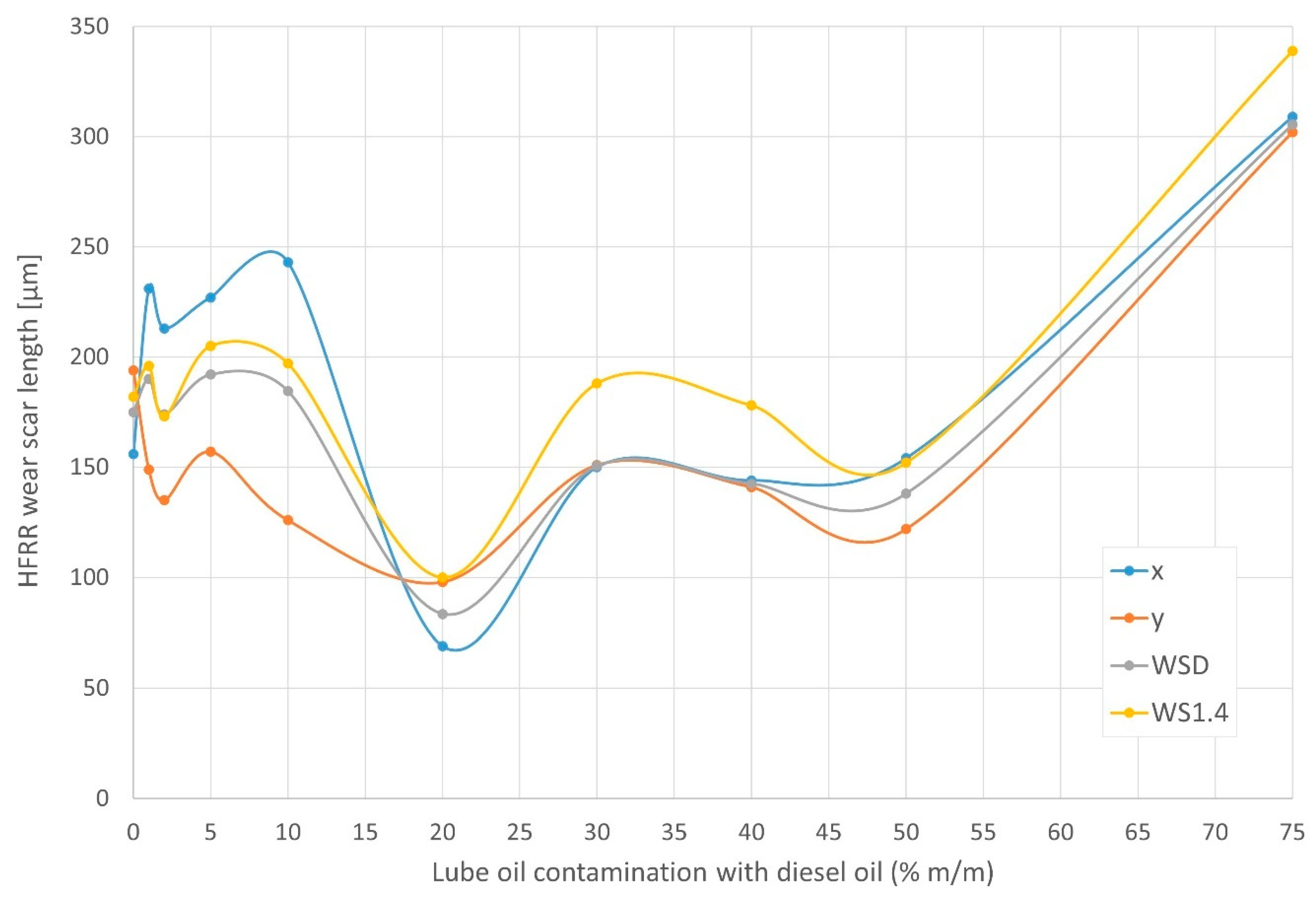

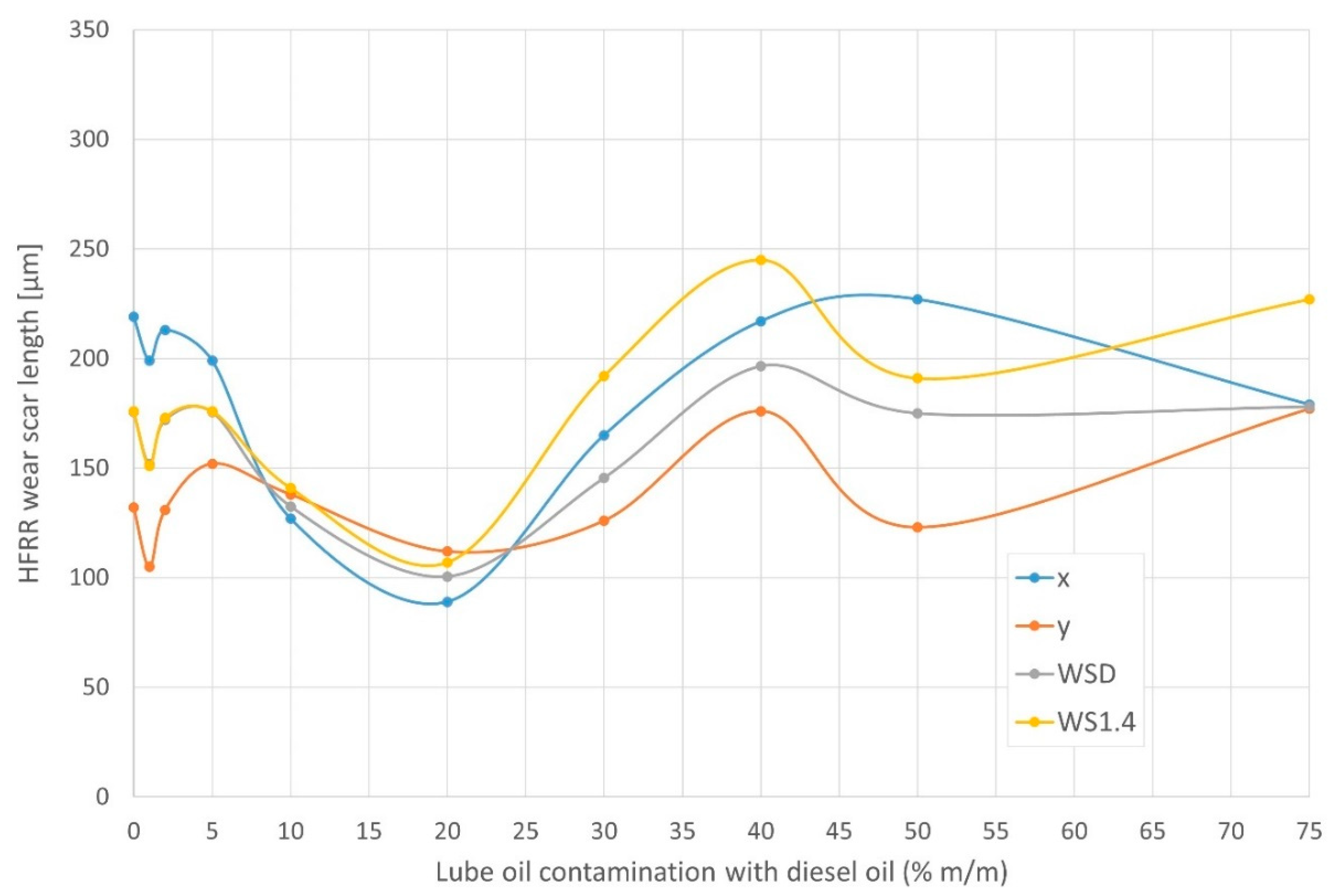

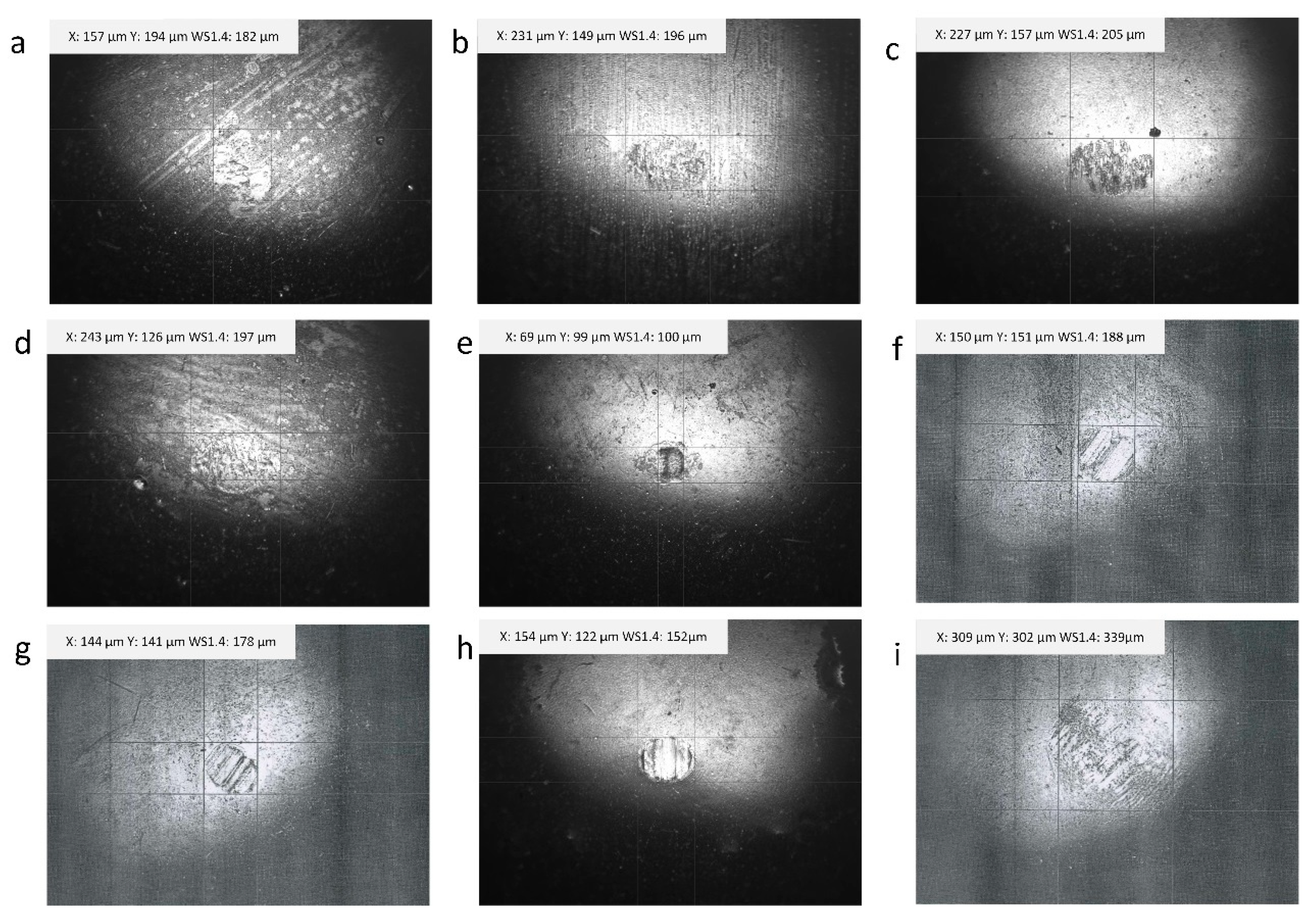

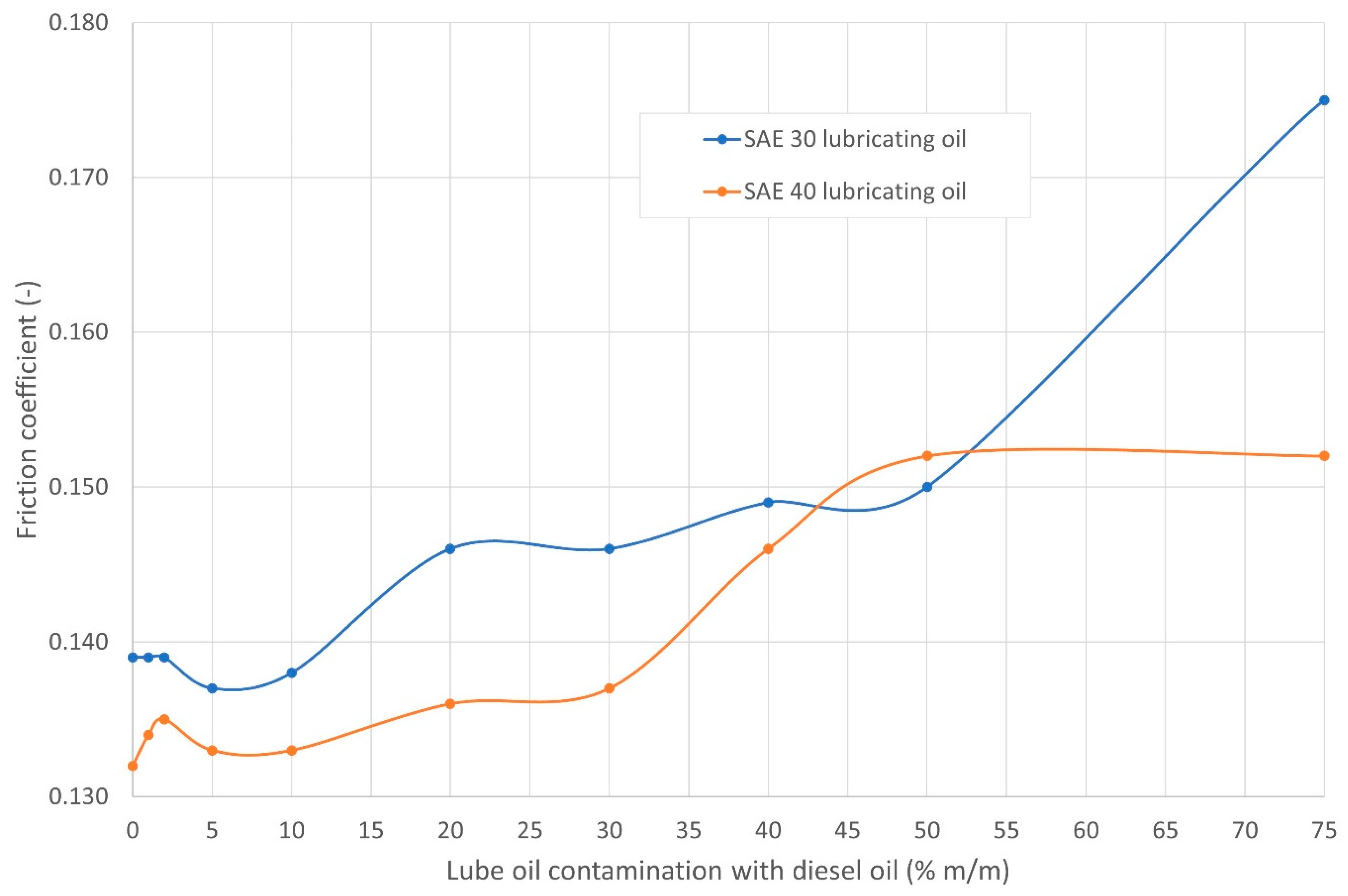

3.3. Tribological Properties of the Lubricating Oil Diluted with Diesel Oil

3.4. Aggregated Assessment of the Impact of Lubricating Oil Dilution with Distillation Fuel

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ∇ | vector differential operator (nabla) |

| A | heat transfer surface |

| a1, a2, a3, and a4 | proportionality factors |

| ASTM | ASTM International standard (formerly American Society for Testing and Materials) |

| AVP | mean absolute vapor pressure |

| AVP1 | absolute vapor pressure at the beginning of the test |

| AVP2 | absolute vapor pressure at the end of the test |

| CBPCRiOŚ | Center for Testing Fuels, Working Fluids, and Environmental Protection (pol. Centrum Badania Paliw, Cieczy Roboczych i Ochrony Środowiska) |

| CFR | Cooperative Fuels Research, manufacturer of test engines |

| CCI | calculated cetane index |

| average planning speed | |

| DCN | derived cetane number measured (in accordance with the ASTM D 7668 standard [67]) |

| d | wall thickness of the heat conductor |

| d1 | diameter of the cylinder liner on the warmer side |

| d2 | diameter of the cylinder liner on the cooler side |

| DO | diesel oil |

| ECN | estimated cetane number |

| F | sliding/friction force |

| FAME | fatty acid methyl esters |

| FILM | percentage drop in oil film resistance |

| HFFR | High-Frequency Reciprocating Rig |

| l | length (height) of the cylinder liner |

| P | pressure force, normal force between the object and the surface |

| p | unit pressure |

| pr | reference pressure |

| R1, R2 | oil film resistance at the beginning and end of the oil lubricity test |

| Sgr | product of planning speed and pressure values |

| T | absolute temperature |

| t | temperature measurement |

| ∇T | temperature field gradient (grad T) |

| temperature difference on both sides of the heat conductor | |

| t0 | temperature of the surface of the piston on the side of the exhaust gases |

| tA, tB | temperatures of surfaces A and B |

| tFP | flash point temperature |

| TR | friction force |

| ttop | material melting temperature |

| Q | thermal energy |

| heat stream | |

| unit heat stream of friction | |

| U1, U2 | electrical contact potential at the beginning and end of the oil lubricity test |

| W | mechanical work |

| WS1.4 | HFFR normalized wear scar diameter (lubricity) |

| WSD | uncorrected average wear scar diameter |

| x | HFFR wear scar diameter perpendicular to the direction of oscillation |

| y | HFFR wear scar diameter in a direction parallel to the direction of oscillation. |

| ε | coefficient of change in the density of the substance when heated by 1 °C |

| λ | thermal conductivity coefficient |

| η | dynamic viscosity of a fluid |

| μ | friction coefficient |

| ν | kinematic viscosity of a lubricant |

| ρ | lubricant density |

| τ | working time |

Appendix A. Mathematical Derivation of Relation between Unit Heat Flux and Sliding Velocity

Appendix B. Measurement Data Obtained in the Experiment

| Diesel Oil Content (% m/m) | Lubricating Oil SAE 30 with DO Mixes | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 5 | 10 | 20 | 30 | 40 | 50 | 75 | |

| Kinematic viscosity ν @100 °C (mm2/s) | 11.72 | 11.05 | 10.96 | 10.32 | 8.40 | 6.40 | 4.82 | 3.70 | 3.01 | 1.86 |

| Dynamic viscosity η @100 °C (mPa∙s) | 9.91 | 9.33 | 9.25 | 8.69 | 7.04 | 5.32 | 3.97 | 3.03 | 2.44 | 1.48 |

| Viscosity index VI (−) | 99.3 | 97.3 | 97.6 | 107.0 | 111.5 | 129.2 | 122.2 | 127.1 | 132.6 | 149.9 |

| Density ρ @100 °C (kg/m3) | 845.42 | 844.16 | 843.91 | 841.72 | 838.07 | 830.97 | 824.49 | 817.34 | 809.72 | 793.92 |

| Coefficient of temperature density change ε (kg/(m3·K)) | 0.622 | 0.624 | 0.625 | 0.627 | 0.630 | 0.639 | 0.645 | 0.662 | 0.666 | 0.681 |

| HFFR x wear scar diameter (μm) | 156 | 231 | 213 | 227 | 243 | 69 | 150 | 144 | 154 | 309 |

| HFFR y wear scar diameter (μm) | 194 | 149 | 135 | 157 | 126 | 98 | 151 | 141 | 122 | 302 |

| HFRR average wear scar diameter WSD (μm) | 175.0 | 190.0 | 174.0 | 192.0 | 184.5 | 83.5 | 150.5 | 142.5 | 138.0 | 305.5 |

| HFFR normalized wear scar diameter (lubricity) WS1.4 (μm) | 182 | 196 | 173 | 205 | 197 | 100 | 188 | 178 | 152 | 339 |

| HFFR mean friction coefficient μ (−) | 0.139 | 0.139 | 0.139 | 0.137 | 0.138 | 0.146 | 0.146 | 0.149 | 0.150 | 0.175 |

| HFFR oil film resistance FILM (%) | 100 | 100 | 100 | 100 | 100 | 99 | 96 | 97 | 97 | 58 |

| Flash point temperature tFP (°C) | 180.0 | 166.0 | 160.0 | 134.0 | 110.0 | 96.0 | 79.5 | 72.5 | 78.0 | 62.5 |

| Cetane index CII acc. ASTM D4737 | N/A | N/A | N/A | N/A | N/A | N/A | 47.8 | 50.4 | 52.4 | 51.5 |

| Diesel Oil Content (% m/m) | Lubricating Oil SAE 40 with DO Mixes | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 5 | 10 | 20 | 30 | 40 | 50 | 75 | |

| Kinematic viscosity ν @100 °C (mm2/s) | 15.21 | 15.05 | 14.51 | 12.90 | 10.24 | 7.91 | 5.61 | 4.27 | 3.45 | 1.97 |

| Dynamic viscosity η @100 °C (mPa∙s) | 12.87 | 12.72 | 12.25 | 10.87 | 8.58 | 6.58 | 4.63 | 3.49 | 2.79 | 1.57 |

| Viscosity index VI (−) | 95.3 | 94.9 | 95.2 | 96.5 | 112.7 | 125.8 | 133.3 | 135.2 | 142.3 | 161.1 |

| Density ρ @100 °C (kg/m3) | 846.04 | 845.45 | 844.58 | 842.43 | 838.35 | 832.13 | 824.41 | 817.43 | 810.31 | 793.48 |

| Coefficient of temperature density change ε (kg/(m3·K)) | 0.616 | 0.613 | 0.615 | 0.620 | 0.621 | 0.628 | 0.643 | 0.651 | 0.660 | 0.684 |

| HFFR x wear scar diameter (μm) | 219 | 199 | 213 | 199 | 127 | 89 | 165 | 217 | 227 | 179 |

| HFFR y wear scar diameter (μm) | 132 | 105 | 131 | 152 | 138 | 112 | 126 | 176 | 123 | 177 |

| HFRR average wear scar diameter WSD (μm) | 175.5 | 152.0 | 172.0 | 175.5 | 132.5 | 100.5 | 145.5 | 196.5 | 175.0 | 178.0 |

| HFFR normalized wear scar diameter (lubricity) WS1.4 (μm) | 176 | 151 | 173 | 176 | 141 | 107 | 192 | 245 | 191 | 227 |

| HFFR mean friction coefficient μ (−) | 0.132 | 0.134 | 0.135 | 0.133 | 0.133 | 0.136 | 0.137 | 0.146 | 0.152 | 0.152 |

| HFFR oil film resistance FILM (%) | 100 | 100 | 100 | 100 | 100 | 96 | 91 | 85 | 78 | 83 |

| Flash point temperature tFP (°C) | 178 | 160 | 150 | 132 | 100 | 93 | 77.5 | 75.5 | 74 | 62.5 |

| Cetane index CII acc. ASTM D4737 | N/A | N/A | N/A | N/A | N/A | N/A | N/A | 49.2 | 52.1 | 48.9 |

Appendix C. HFFR Apparatus Data

| Parameter | Value |

|---|---|

| Mechanical part | |

| Oscillation frequency | 10–220 Hz |

| Oscillation pitch | 20–2000 μm |

| Load (replaceable weights) | 0–1.0 kg |

| The maximum friction force depends on the amplitude | 10.0 N |

| Standard samples | |

| Ball diameter (top sample) | 6.0 mm |

| Plate diameter (bottom sample) | 10.0 mm |

| Plate thickness (bottom sample) | 3.0 mm |

| Temperature control and heater | |

| Adjustment range | 0–200 °C |

| Main temperature sensor | Pt 100 in a stainless steel sheath |

| Alarm temperature sensor | Pt 100 in a stainless steel sheath |

| Heating elements | 2 pcs, 24 V, 15 W |

| Maximum temperature without additional heating | ~120 °C above ambient temperature |

| Power supply and measurement system | |

| The initial voltage of the polarization in the measurement system of the electrical contact resistance of the samples | 15 mV |

| Force measurement accuracy | <0.35% of the measuring range |

| Main power | 240 V, 50 Hz, 400 W |

| Overcurrent protection | 3.15 A, fuse, 20 mm |

| HFR2 microscope | |

| Microscope magnification with standard lenses | 100× |

| Microscope measurement resolution | 1 μm |

| Supply voltage | 240 V, 50 Hz |

References

- Wiaterek, D.; Chybowski, L. Assessing the topicality of the problem related to the explosion of crankcases in marine main propulsion engines (1972–2018). Sci. J. Marit. Univ. Szczec. 2022, 71, 33–40. [Google Scholar]

- Borkowski, T.; Kowalak, P.; Myśków, J. Vessel main propulsion engine performance evaluation. J. KONES 2012, 19, 53–60. [Google Scholar] [CrossRef]

- Kowalak, P.; Myśków, J.; Tuński, T.; Bykowski, D.; Borkowski, T. A method for assessing of ship fuel system failures resulting from fuel changeover imposed by environmental requirements. Eksploat. Niezawodn.—Maint. Reliab. 2021, 23, 619–626. [Google Scholar] [CrossRef]

- Szczepanek, M. Biofuels as an alternative fuel for West Pomeranian fishing fleet. J. Phys. Conf. Ser. 2019, 1172, 012074. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Z.; Feng, Y.; Diao, Z.; Liu, Z. The Effects of Ultra-Low Viscosity Engine Oil on Mechanical Efficiency and Fuel Economy. Energies 2021, 14, 2320. [Google Scholar] [CrossRef]

- Ferguson, G.W. Diesel Engine Crankcase Explosion Investigation; Technical Paper 510104; SAE International: Warrendale, PA, USA, 1951; pp. 1–28. [Google Scholar] [CrossRef]

- CIMAC. Guideline on the Relevance of Lubricationt Flash Point in Connection with Crankcase Explosions; CIMAC Working Group 8 ”Marine Lubricants”: Frankfurt, Germany, 2013. [Google Scholar]

- Graddage, M. Crankcase Explosions—Detection or Prevention? In Crankcase Explosions; IMAREST: London, UK, 2002; pp. 126–147. [Google Scholar]

- Metalock Engineering UK. Crankcase Explosion. Following Catastrophic Engine Failure When a Con-Rod Breaks through the Crankcase Door, Water Jacket and Liner Area, Does This Mean a New Engineblosk? Available online: https://www.metalockengineering.com/en/metalock-engineering-uk-limited/news/crankcase-explosion/ (accessed on 20 June 2022).

- Cicek, K.; Celik, M. Application of failure modes and effects analysis to main engine crankcase explosion failure on-board ship. Saf. Sci. 2013, 51, 6–10. [Google Scholar] [CrossRef]

- Technomics International. Case Study—Fuel Dilution of Engine Oil in Locomotives. Available online: https://www.techenomics.net/case-studies/fuel-dilution-engine-oil/ (accessed on 8 June 2022).

- Krupowies, J. Badania Zmian Parametrów Fizykochemicznych Silnikowych Olejów Smarowych Eksploatowanychna Statkach Polskiej Żeglugi Morskiej; Studia Nr.; Wyższa Szkoła Morska w Szczecinie: Szczecin, Poland, 1996. [Google Scholar]

- Castrol. Oil Contamination Identification. A List of the Top Offenders. Available online: https://www.castrol.com/content/dam/castrol/country-sites/en_us/united-states/home/hd-focus-newsletter/labcheck-oil-contamination-infographic.pdf (accessed on 7 June 2023).

- Gearhead Oil Analysis. Engine Oil Analysis. Available online: https://shop.gearheadlab.com/pages/engine-oil-analysis (accessed on 7 June 2023).

- Chybowski, L. The Initial Boiling Point of Lubricating Oil as an Indicator for the Assessment of the Possible Contamination of Lubricating Oil with Diesel Oil. Energies 2022, 15, 7927. [Google Scholar] [CrossRef]

- Chybowski, L. Study of the Relationship between the Level of Lubricating Oil Contamination with Distillation Fuel and the Risk of Explosion in the Crankcase of a Marine Trunk Type Engine. Energies 2023, 16, 683. [Google Scholar] [CrossRef]

- Sejkorová, M.; Hurtová, I.; Jilek, P.; Novák, M.; Voltr, O. Study of the Effect of Physicochemical Degradation and Contamination of Motor Oils on Their Lubricity. Coatings 2021, 11, 60. [Google Scholar] [CrossRef]

- Winterbone, D.E.; Turan, A. Advanced Thermodynamics for Engineers; Elsevier: Amsterdam, The Netherlands, 2015; ISBN 9780444633736. [Google Scholar]

- Włodarski, J.; Podsiadło, A.; Kluj, S. Uszkodzenia Systemu Tłok-Cylinder (TC) Okrętowych Silników Spalinowych; Wydawnictwo Akademii Morskiej w Gdyni: Gdynia, Poland, 2011. [Google Scholar]

- Gawdzińska, K.; Chybowski, L.; Bejger, A.; Krile, S. Determination of technological parameters of saturated composites based on sic by means of a model liquid. Metalurgija 2016, 55, 659–662. [Google Scholar]

- Ratajczak, M.; Ptak, M.; Chybowski, L.; Gawdzińska, K.; Będziński, R. Material and Structural Modeling Aspects of Brain Tissue Deformation under Dynamic Loads. Materials 2019, 12, 271. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kozaczewski, W. Konstrukcja Grupy Tłokowo-Cylindrowej Silników Spalinowych; WKiŁ: Warszawa, Poland, 2004. [Google Scholar]

- Chybowski, L.; Szczepanek, M.; Gawdzińska, K.; Klyus, O. Particles Morphology of Mechanically Generated Oil Mist Mixtures of SAE 40 Grade Lubricating Oil with Diesel Oil in the Context of Explosion Risk in the Crankcase of a Marine Engine. Energies 2023, 16, 3915. [Google Scholar] [CrossRef]

- Chybowski, L. Lube Oil—Diesel Oil Mixes—Dataset; Maritime University of Szczecin: Szczecin, Poland, 2022; Version 3. [Google Scholar]

- PKN Orlen, S.A. Olej Napędowy. Ecodiesel Ultra B,D,F, Olej Napędowy Arktyczny Klasy 2, Efecta Diesel B,D,F, Verva ON B,D,F; PKN Orlen S.A.: Płock, Poland, 2021. [Google Scholar]

- Minister Gospodarki, R.P. Rozporządzenie Ministra Gospodarki z Dnia 9 Października 2015 r. w Sprawie Wymagań Jakościowych Dla paliw Ciekłych; Ministerstwo Gospodarki RP: Warszawa, Poland, 2015. [Google Scholar]

- PKN Orlen, S.A. ZN-ORLEN-5—Przetwory naftowe. Olej Napędowy Efecta Diesel; PKN Orlen S.A.: Płock, Poland, 2019. [Google Scholar]

- Society of Automotive Engineers. SAE J300-2021. Engine Oil Viscosity Classification; SAE International: Warrendale, PA, USA, 2021. [Google Scholar]

- DIN 51794:2003-05; Testing of Mineral Oil Hydrocarbons—Determination of Ignition Temperature. German Institute for Standardisation (Deutsches Institut für Normung): Berlin, Germany, 2003.

- PN-EN ISO 3104:2021-03; Petroleum Products—Transparent and Opaque Liquids—Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity. PKN: Warszawa, Poland, 2021.

- Oleje-Smary. AGIP Cladium 120 SAE 30 CD. Available online: https://oleje-smary.pl/pl/p/AGIP-Cladium-120-SAE-30-CD-20-litrow/186 (accessed on 12 July 2022).

- Oleje-Smary. AGIP Cladium 120 SAE 40 CD. Available online: https://oleje-smary.pl/pl/p/AGIP-Cladium-120-SAE-40-CD-20-litrow/188 (accessed on 12 July 2022).

- ITALCO (Far East) Pte Ltd. Product Data Sheet—Eni Cladium 120 (Series); ITALCO: Singapore, 2017. [Google Scholar]

- ISO 2719:2016; Determination of Flash Point—Pensky-Martens Closed Cup Method. 4th ed. ISO: Geneva, Switzerland, 2016.

- ASTM D4737-21; Standard Test Method for Calculated Cetane Index by Four Variable Equation. ASTM: West Conshohocken, PA, USA, 2021.

- PN-EN ISO 12185:2002; Ropa naftowa i przetwory naftowe—Oznaczanie gęstości—Metoda oscylacyjna z U-rurką. PKN: Warszawa, Poland, 2002.

- ASTM D 2270-10(2016); Standard Practice for Calculating Viscosity Index from Kinematic Viscosity at 40 °C and 100 °C. ASTM: West Conshohocken, PA, USA, 2016.

- EN ISO 12156-1:2018; Diesel Fuel—Assesment of Lubricity Using the High-Frequency Reciporating Rig (HFFR)—Part 1: Test Method. ISO: Geneva, Switzerland, 2018.

- PN-EN IEC 60079-10-1:2021-09; Explosive Atmospheres—Part 10-1: Classification of Areas—Explosive Gas Atmospheres. PKN: Warszawa, Poland, 2021.

- Krupowies, J. Badania Zmian Właściwości Oleju Obiegowego Okrętowych Silników Pomocniczych; Wyższa Szkoła Morska w Szczecinie: Szczecin, Poland, 2002. [Google Scholar]

- Anish. Important Lube Oil Properties to Be Considered While Choosing Marine Lube Oil for Your Ship. Available online: https://www.marineinsight.com/guidelines/important-lube-oil-properties-to-be-considered-while-choosing-marine-lube-oil-for-your-ship/ (accessed on 20 June 2023).

- Krupowies, J. Badania i Ocena Zmian Właściwości Użytkowych Olejów Urządzeń Okrętowych; Maritime University of Szczecin: Szczecin, Poland, 2009. [Google Scholar]

- Ramadan, O.; Menard, L.; Gardiner, D.; Wilcox, A.; Webster, G. Performance Evaluation of the Ignition Quality Testers Equipped with TALM Precision Package (TALM-IQTTM) Participating in the ASTM NEG Cetane Number Fuel Exchange Program; Technical Paper 2017-01-0720; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- PAC. Aparat Do Oznaczania Pochodnej Liczby Cetanowej; Inkom Instruments Co.: Warszawa, Poland, 2008. [Google Scholar]

- PAC L.P. Herzog Cetane ID 510; PAC L.P.: Houston, TX, USA, 2019. [Google Scholar]

- Yanowitz, J.; McCormick, R.L. Review: Fuel Volatility Standards and Spark-Ignition Vehicle Driveability. SAE Int. J. Fuels Lubr. 2016, 9, 408–429. [Google Scholar] [CrossRef]

- Chybowski, L.; Grzadziel, Z.; Gawdzinska, K. Simulation and experimental studies of a multi-tubular floating sea wave damper. Energies 2018, 11, 1012. [Google Scholar] [CrossRef] [Green Version]

- Kaminski, P. Experimental Investigation into the Effects of Fuel Dilution on the Change in Chemical Properties of Lubricating Oil Used in Fuel Injection Pump of Pielstick PA4 V185 Marine Diesel Engine. Lubricants 2022, 10, 162. [Google Scholar] [CrossRef]

- Stone, A.S. New low viscosity grade engine oil specification rises from the ashes of category development delays. Fuels Lubes Int. 2017, 23, 18–21. [Google Scholar]

- Martyr, A.J.; Plint, M.A. Engine Testing; Elsevier: Amsterdam, The Netherlands, 2012; ISBN 9780080969497. [Google Scholar]

- Oilmanager. Oil Viscosity and Its Importance. Available online: https://www.techenomics.net/2014/02/oil-viscosity-and-its-importance/ (accessed on 20 June 2023).

- Chybowski, L.; Myśków, J.; Kowalak, P. Analysis of fuel properties in the context of the causes of three marine auxiliary engines failure—A case study. Eng. Fail. Anal. 2023, 150, 107362. [Google Scholar] [CrossRef]

- Anton Paar. ASTM D 2270—Viscosity Index (VI) from 40 °C and 100 °C. Available online: https://wiki.anton-paar.com/pl-pl/wskaznik-lepkosci-vi-od-40c-i-100c-astm-d2270/ (accessed on 7 September 2022).

- Piotrowski, I.; Witkowski, K. Okrętowe Silniki Spalinowe, 3rd ed.; Trademar: Gdynia, Poland, 2013; ISBN 978-83-62227-48-8. [Google Scholar]

- Kolm, R.; Gebeshuber, I.C.; Kenesey, E.; Ecker, A.; Pauschitz, A.; Werner, W.S.M.; Störi, H. Tribochemistry of mono molecular additive films on metal surfaces, investigated by XPS and HFRR. Tribol. Interface Eng. Ser. 2005, 48, 269–282. [Google Scholar] [CrossRef]

- Malinowska, M.; Zera, D. Analiza zmian smarności oleju silnikowego stosowanego w silniku Cegielski-Sulzer 3AL25/30. Zesz. Nauk. Akad. Mor. W Gdyni 2016, 96, 93–104. [Google Scholar]

- Mikołajczyk, J. Tribotestery. Budowa i Przeznaczenie; Wydawnictwo Państwowej Wyższej Szkoły Zawodowej im. Stanisława Staszica w Pile: Piła, Poland, 2019. [Google Scholar]

- Total Polska Sp., z.o.o. Przemysłowe Środki Smarne—Poradnik; Total Polska Sp. z.o.o.: Warszawa, Poland, 2003. [Google Scholar]

- Bhatia, S.C. Biodiesel. In Advanced Renewable Energy Systems; Elsevier: Amsterdam, The Netherlands, 2014; pp. 573–626. [Google Scholar]

- InSight. Research Confirms HFRR Is the Best Test to Accurately Measure Diesel Fuel Lubricity. Available online: http://www.infineuminsight.com/insight/dec-2013/testing-the-test (accessed on 5 May 2018).

- ASTM D 6079; Standard Test Method for Evaluating Lubricity of Diesel Fuels by the High-Frequency Reciprocating Rig (HFRR). ASTM: West Conshohocken, PA, USA, 2023.

- Cursaru, D.; Sorin, V.; Mihai, S.; Ghiţă, D.; Stoica, S.-D.; Dinescu, G. Friction and wear properties of carbon nanowalls coatings. Dig. J. Nanomater. Biostructures 2014, 9, 1105–1114. [Google Scholar]

- PN-EN ISO 12156-1:2008; Oleje Napędowe—Ocena Smarności z Zastosowaniem Aparatu o Ruchu Posuwisto-Zwrotnym Wysokiej Częstotliwości (HFFR)—Część 1: Metoda Badania. PKN: Warszawa, Poland, 2006.

- Nozdrzykowski, K.; Adamczak, S.; Grządziel, Z.; Dunaj, P. The Effect of Deflections and Elastic Deformations on Geometrical Deviation and Shape Profile Measurements of Large Crankshafts with Uncontrolled Supports. Sensors 2020, 20, 5714. [Google Scholar] [CrossRef] [PubMed]

- Włodarski, J. Tłokowe Silniki Spalinowe—Procesy Trybologiczne; WKiŁ: Warszawa, Poland, 1982. [Google Scholar]

- Ashgriz, N. Handbook of Atomization and Sprays; Ashgriz, N., Ed.; Springer: Boston, MA, USA, 2011; ISBN 978-1-4419-7263-7. [Google Scholar]

- ASTM D 7668; Standard Test Method for Determination of Derived Cetane Number (DCN) of Diesel Fuel Oils Ignition Delay and Combustion Delay Using a Constant Volume Combustion Chamber Method. ASTM: West Conshohocken, PA, USA, 2010.

- PCS Instruments. Aparat Do Badania Paliw i Środków Smarnych. Instrukcja Obsługi Systemu HFFR V1.0.3; Inkom Instruments Co.: Warszawa, Poland, n.d.

- PCS Instruments. Instrukcja Obsługi, Mikroskop Do Pomiaru Skazy Zużycia Na Aparacie HFR2; Inkom Instruments Co.: Warszawa, Poland, 1999. [Google Scholar]

| Pair of Materials | Coefficient of Dynamic Dry Friction (−) | Melting Point ttop (°C) | Thermal Conductivity Coefficient λ (W/(m ∙K)) | Coefficient Sgr (W/m2) |

|---|---|---|---|---|

| Cast iron Cast iron | ~0.18 | 1200 1200 | 55 55 | 0.245 0.245 |

| Cast iron Steel | 0.18 | 1200 1400 | 55 40 | 0.245 0.221 |

| Cast iron Chrome | 0.08 | 1200 1920 | 55 92 | 0.550 1.755 |

| Cast iron Molybdenum | ~0.10 | 1200 2620 | 55 142 | 0.442 3.140 |

| Specification of Orlen Efecta Diesel Bio | Declared Value by the Manufacturers [8] | Measured Value [16] |

|---|---|---|

| Cetane index | ≤51 | 52 |

| Initial boiling point | 75–180 °C | 181 °C |

| Boiling temperature range | 92% vol. distils is 360 °C | |

| 36% vol. distils is 250 °C | ||

| Flash point (determined in a closed cup) | 62 °C | 65 °C |

| Auto-ignition temperature (according to DIN51794:2003-05 [29]) | approx. 240 °C | |

| Kinematic viscosity (according to PN-EN ISO 3104:2021-03 [30]) | 1.5–4.5 mm2/s (2.549 mm2/s) at 40 °C approx. 2151 mm2/s at 50 °C | 2897 mm2/s at 40 °C 2443 mm2/s at 50 °C |

| Density | 820–845 kg/m3 at 15 °C | 835.81 kg/m3 at 15 °C |

| Relative vapor density | approx. 6 (air = 1) | |

| Cloud point | −8 °C | |

| Cold filter plugging point | −28 °C | |

| Residual ash (from 10% distillation rests) | 0.010% m/m | |

| FAME additives | max. 7% v/v | |

| Lubricity WD1.4 | 415 μm at 60 °C | 213 μm at 60 °C |

| Oil | Specification | Declared Value by the Manufacturer [31,32,33] | Measured Value [16] |

|---|---|---|---|

| Emi/Agip Cladium 120 SAE 30 API CF | Kinematic viscosity (according to EN ISO 3104) | 108 mm2/s at 40 °C 12.0 mm2/s at 100 °C | 105.01 mm2/s at 40 °C 11.72 mm2/s at 100 °C |

| Viscosity index | 100 | 99.3 | |

| Base number | 12 mg KOH/g | ||

| Flash point marked in the open cup | 225 °C | ||

| marked in the closed cup | 180 °C | ||

| Pour point | −18 °C | ||

| Density | 895 kg/m3 at 15 °C | 898.29 kg/m3 at 15 °C | |

| Emi/Agip Cladium 120 SAE 40 API CF | Kinematic viscosity (according to EN ISO 3104) | 160 mm2/s at 40 °C 15.7 mm2/s at 100 °C | 159.90 mm2/s at 40 °C 15.21 mm2/s at 100 °C |

| Viscosity index | 100 | 95.3 | |

| Base number | 12 mg KOH/g | ||

| Flash point marked in the open cup | 235 °C | ||

| marked in the closed cup | 178 °C | ||

| Pour point | −15 °C | ||

| Density | 900 kg/m3 at 15 °C | 898.44 kg/m3 at 15 °C |

| Measured Parameter | Standard or Procedure Applied |

|---|---|

| Flash point temperature (tFP) | PN-EN ISO 2719:2016 [34] |

| Calculated cetane index (CCI) | ASTM D4737-21 [35] |

| Density (ρ) | PN-EN ISO 12185:2002 [36] |

| Temperature density change (ε) | PN-EN ISO 12185:2002 [36] and calculations |

| Kinematic viscosity (ν) | PN-EN ISO 3104:2004 [30] |

| Dynamic viscosity (η) | PN-EN ISO 12185:2002 [36], PN-EN ISO 3104:2004 [30], and calculations |

| Viscosity index (VI) | ASTM D2270-10(2016) [37] and Anton Paar calculator |

| Lubricity (x, y, WSD, WS1.4) | ISO 12156-1:2018 [38] |

| Oil film resistance drop (FILM) | Procedure implemented in PCS HFFR V1.0.3 apparatus |

| Friction coefficient (μ) | Procedure implemented in PCS HFFR V1.0.3 apparatus |

| The Value of Pearson’s Coefficient rXY | Interpretation of the Relationship between Two Variables |

|---|---|

| 0.000 ≤ rXY < 0.200 | Very low correlation. No relationship. |

| 0.200 ≤ rXY < 0.400 | Low correlation. The relationship is clear. |

| 0.400 ≤ rXY < 0.600 | Moderate correlation. Significant dependence. |

| 0.600 ≤ rXY < 0.800 | High correlation. Significant dependence. |

| 0.800 ≤ rXY ≤ 1.000 | Very high correlation. Very high-to-full dependency. |

| Properties | Parameter | Correlation with Diesel Oil Content in a Mixture with Viscosity-Grade Lubricating Oil | Comment | |

|---|---|---|---|---|

| SAE 30 | SAE 40 | |||

| Ignition | Flash point temperature | Very high, negative | Very high, negative | Very high functional dependence. Flash point temperature decreases with increasing concentration of diesel oil in the tested mixture with lubricating oil. |

| Calculated cetane number | High, positive | Low, negative | No apparent dependency. Observable slight fluctuations in value. All tested mixtures can be classified as fuels with very good ignition properties. | |

| Rheological | Density | Very high, negative | Very high, negative | Very high-to-complete functional dependence. The density and viscosity of the mixtures decrease with increasing concentration of diesel oil in the tested mixture. |

| Kinematic viscosity | ||||

| Dynamic viscosity | ||||

| Coefficient of temperature density change | Very high, positive | Very high, positive | Very high-to-full dependency. The coefficient of temperature change and the viscosity index increase with increasing concentration of diesel oil in the tested mixture. | |

| Viscosity index | ||||

| Tribological | Lubricity | Very low to moderate, positive | Very low to high, positive | No apparent dependency. Fluctuations in the values of parameters describing lubricity are observed. All tested mixtures can be classified as showing good lubricity. |

| HFFR mean friction coefficient | Very high, positive | Very high, positive | Very high-to-full dependency. HFFR mean friction coefficient increases with increasing diesel oil concentration in the tested mixture. | |

| Relative thickness (resistance) of the oil film | Very high, negative | Very high, negative | Very high-to-full dependency. The relative thickness (resistance) of the oil film decreases with increasing concentration of diesel oil in the tested mixture. | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chybowski, L.; Kowalak, P.; Dąbrowski, P. Assessment of the Impact of Lubricating Oil Contamination by Biodiesel on Trunk Piston Engine Reliability. Energies 2023, 16, 5056. https://doi.org/10.3390/en16135056

Chybowski L, Kowalak P, Dąbrowski P. Assessment of the Impact of Lubricating Oil Contamination by Biodiesel on Trunk Piston Engine Reliability. Energies. 2023; 16(13):5056. https://doi.org/10.3390/en16135056

Chicago/Turabian StyleChybowski, Leszek, Przemysław Kowalak, and Piotr Dąbrowski. 2023. "Assessment of the Impact of Lubricating Oil Contamination by Biodiesel on Trunk Piston Engine Reliability" Energies 16, no. 13: 5056. https://doi.org/10.3390/en16135056

APA StyleChybowski, L., Kowalak, P., & Dąbrowski, P. (2023). Assessment of the Impact of Lubricating Oil Contamination by Biodiesel on Trunk Piston Engine Reliability. Energies, 16(13), 5056. https://doi.org/10.3390/en16135056