The Evolution of Crop-Based Materials in the Built Environment: A Review of the Applications, Performance, and Challenges

Abstract

:1. Introduction

2. Review Methodology

- Narrative Reviews—This is the classic literature review that summarizes the collated literature relevant to a specific subject at a given time.

- Scoping Reviews—Scoping reviews involve systematic searching of all the material on the topic. This enables the researcher to fill in any gaps that appear in the results.

- Systematic Reviews—It is a methodical approach to collating and synthesizing all relevant data about a predefined research question.

- The authors screened titles and abstracts of the retrieved studies focusing on embedded concepts, keywords, and specific terms. They first gathered any relevant research, most of them published mainly after 2015 until 2022 and excluded all research before 2015. Then, the authors also reviewed selected papers from previous years and added them to the database. After discussions and reviews by external researchers, the review has been reduced to the current status. The consulted databases include Elsevier (42.8 percent), Springer (10.7 percent), MDPI (9.5 percent), Taylor and Francis (5.9 percent), and Sage Journals (4.8 percent).

- Then the full texts of the selected studies from Step 1 were reviewed to extract detailed data, considering parameters including physical characteristics, environmental impacts, the role of suggested ideas to replace traditional energy-intensive building materials, life cycle assessment, and their contribution to the circular economy. A short and relevant description and a reference for each contribution were written at that stage.

- In the final step, a qualitative assessment of the data extracted from stage 2 was conducted to identify common themes, trends, and patterns across the studies. furthermore, the studies were grouped based on their detailed focus areas and analyzed the findings within each group. Finally, the key findings from each study were summarized and they are presented in tables. These tables stress any knowledge gaps or inconsistencies in the discussion part (Section 6).

3. Life Cycle Assessment Stages

3.1. Product Stage

3.2. Construction Stage

3.3. Use Stage

3.4. End-of-Life Stage

3.5. Partial Conclusion

4. Applications and Performance

5. Challenges

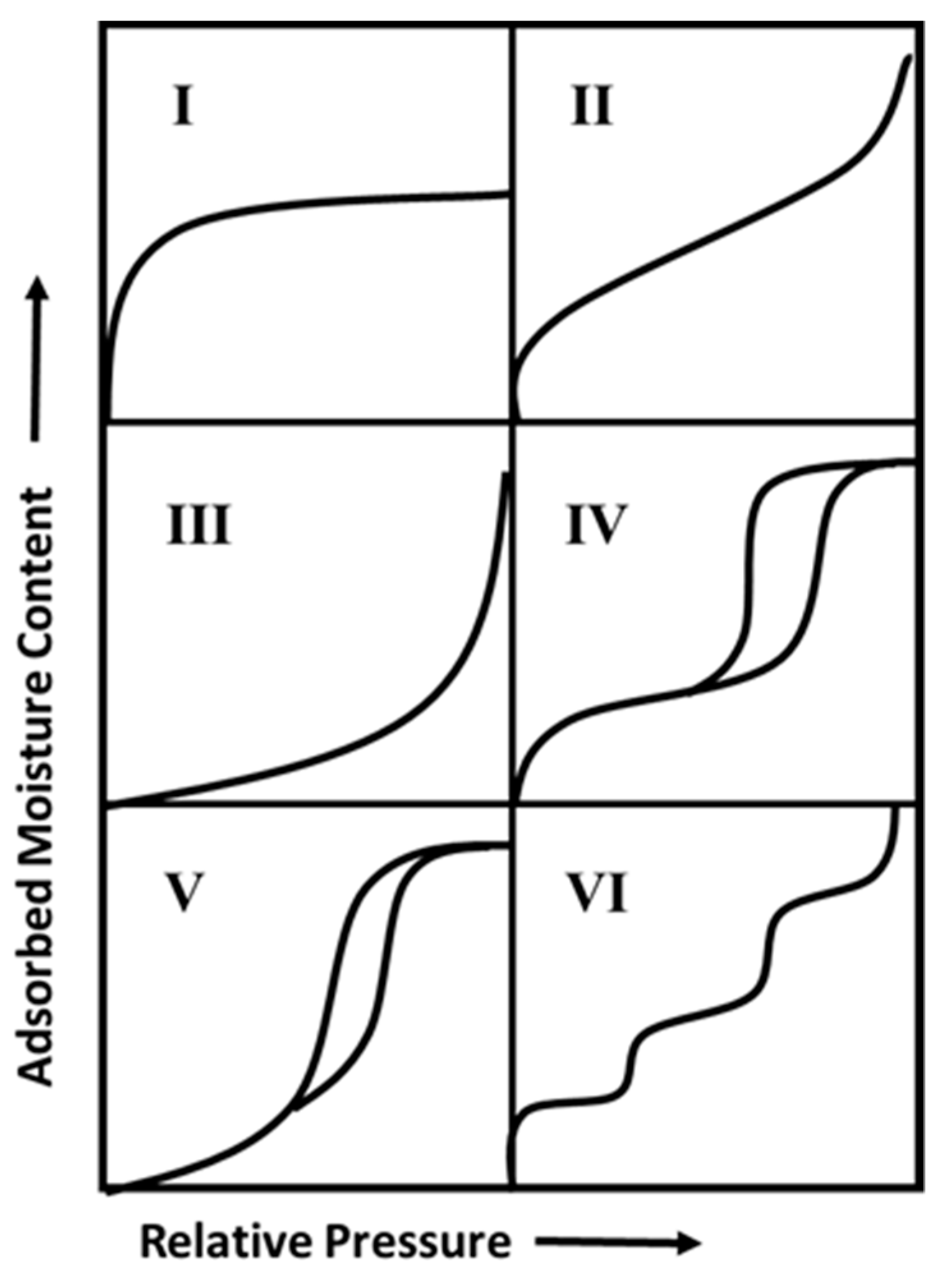

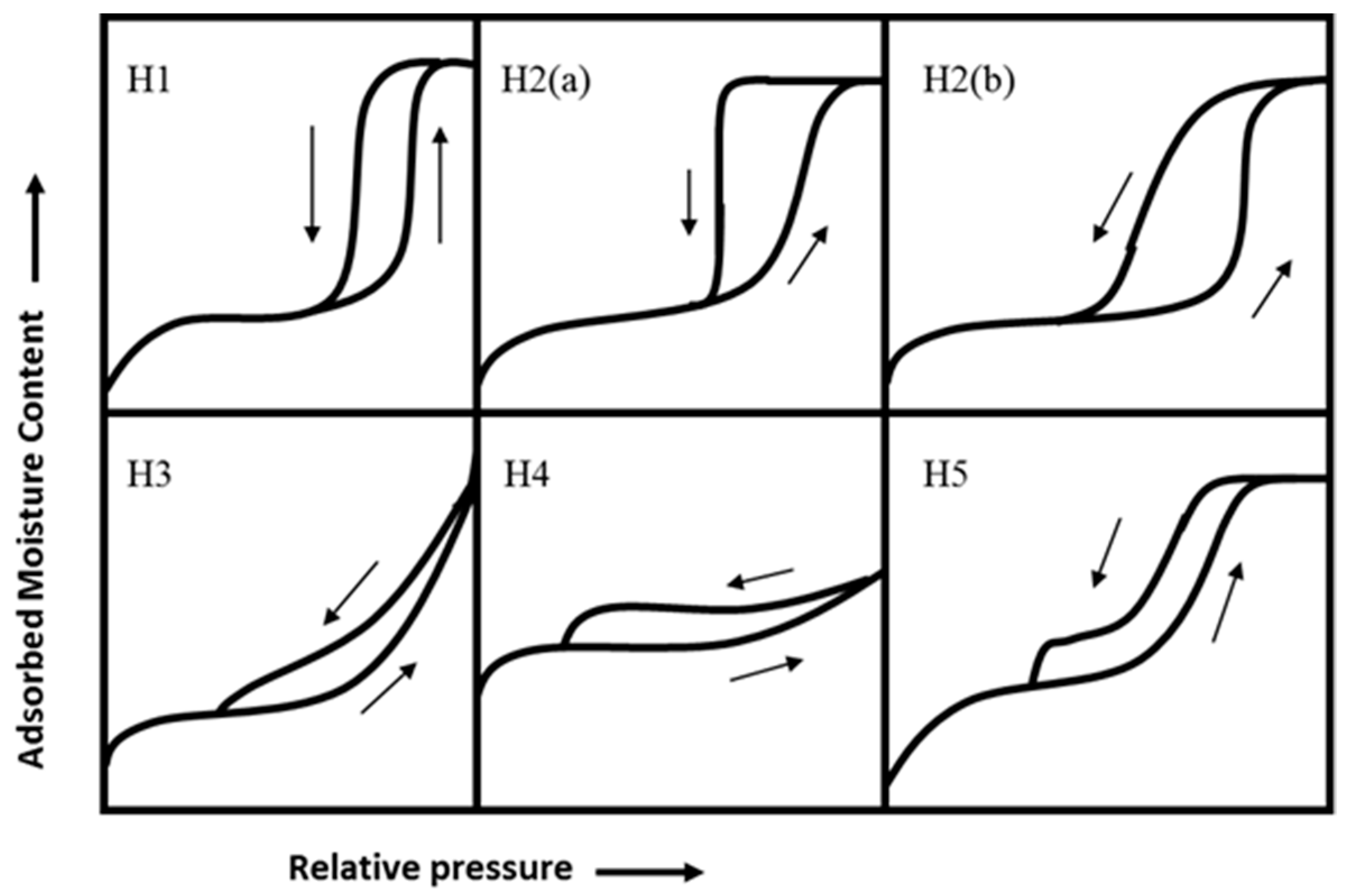

5.1. Sorption Isotherms and Hysteresis

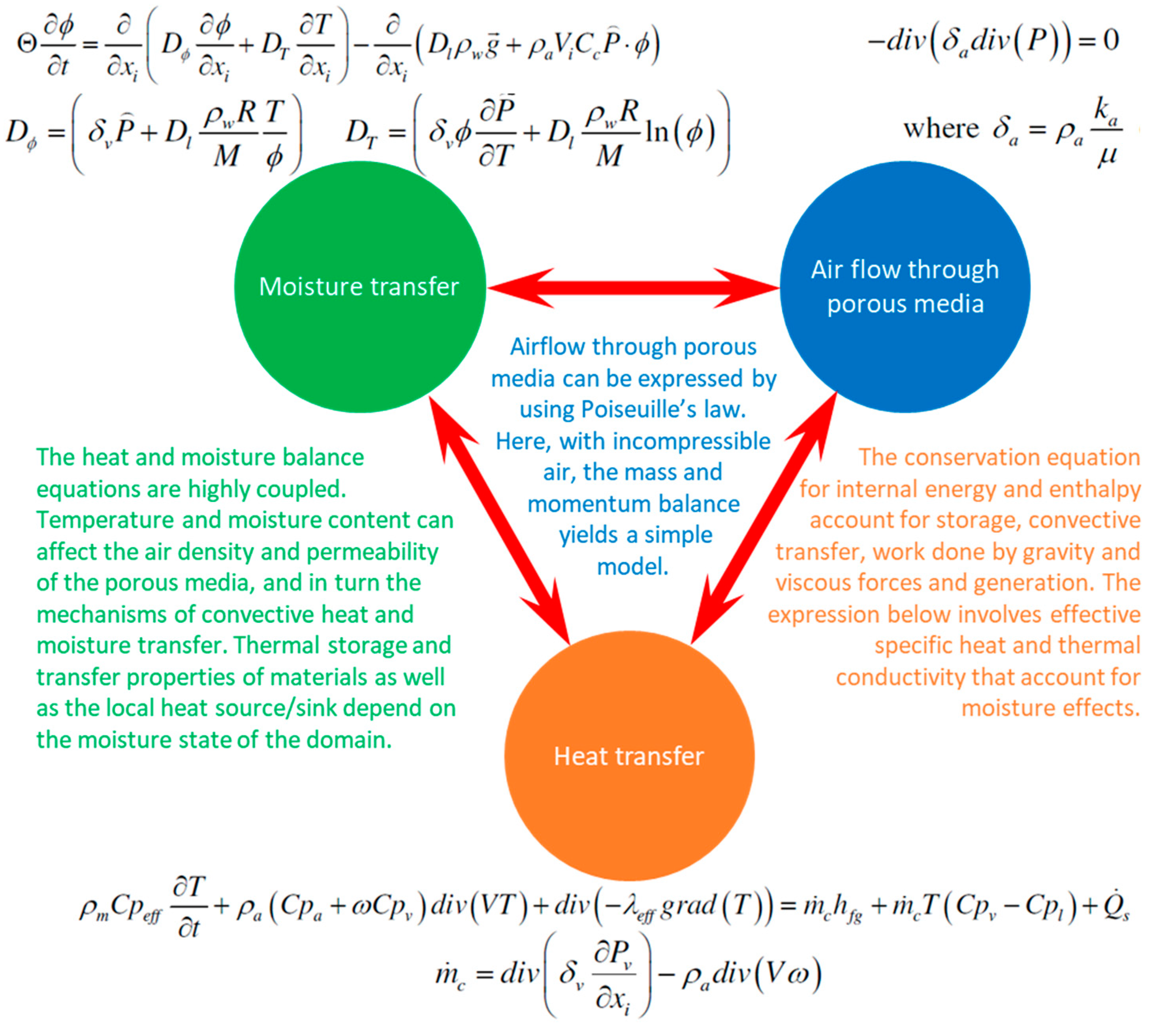

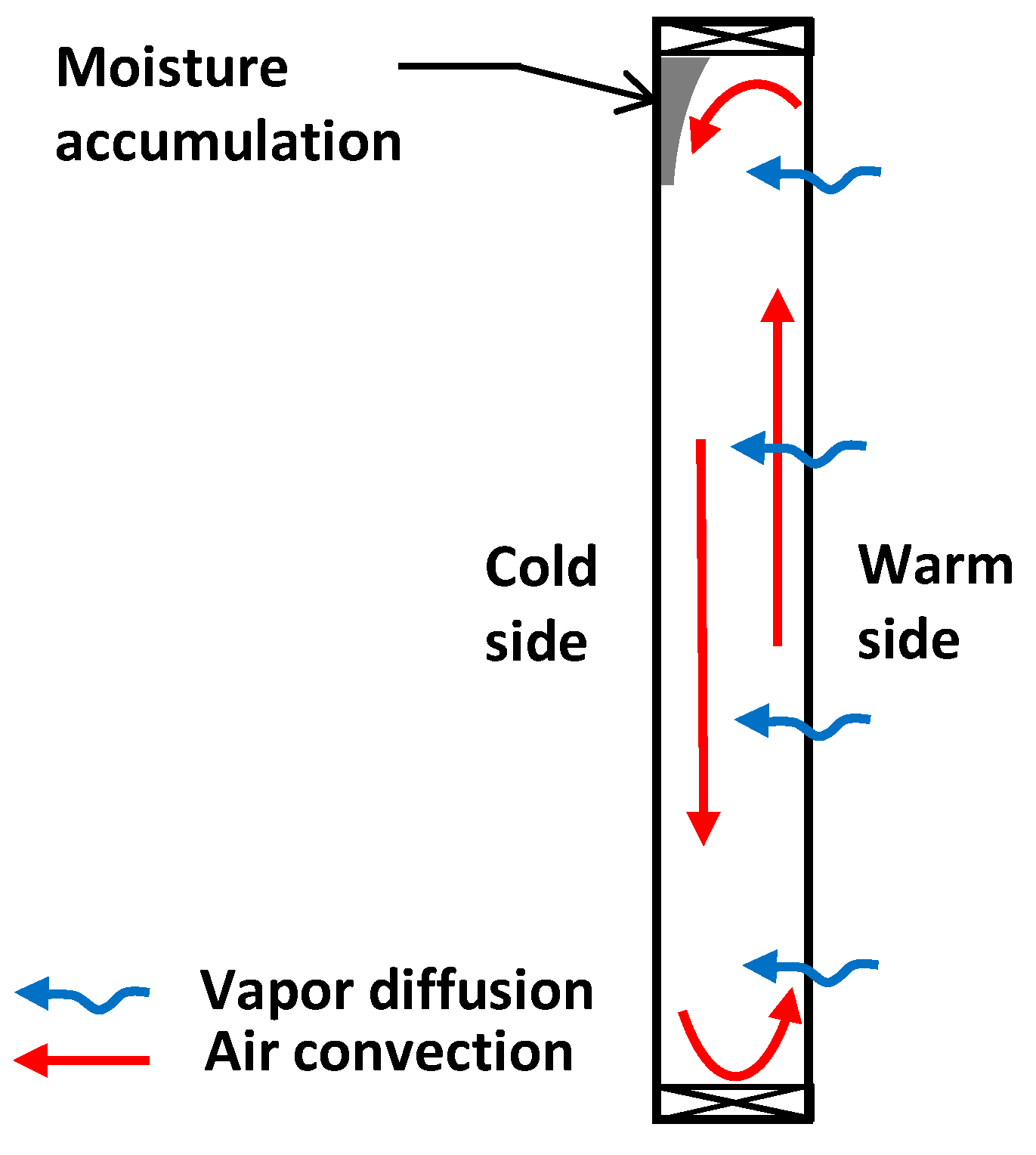

5.2. Interconnected Heat, Air, and Moisture Transfer

5.3. Whole Building Hygrothermal Analysis

5.4. Available Benchmarks

6. Discussion

6.1. Bottlenecks in LCAs Frameworks, Standards and Regulations

- In active technologies, the trade-off is mostly between energy-and-carbon-intensive manufacturing processes of the equipment (e.g., wind turbines, etc.) and zero carbon emission by their green power generation on the other hand, which is an ongoing source of debate and varies from case to case.

- In passive technologies (such as sustainable building materials), the argument is not focused on a particular life cycle stage and is extended to the entire life cycle. That said, in passive technologies, the trade-offs can be articulated as embodied vs. operational carbon emission, which is not limited to the manufacturing and use stage merely, compared to active technologies.

6.2. Application and Performance

6.3. Challenges

7. Conclusions

- increase production of diverse crop-based materials, including sustainable binders such as mycelium;

- upgrade from lab-scale to full-scale benches;

- ensure long-term performance measurements;

- categorize crop-based building materials with respect to their potential use;

- assess more completely and thoroughly their environmental impacts;

- improve their thermo-hygro-mechanical characteristics;

- define new standards and regulations;

- more complete databases and inventories, and hence characterizations are needed in the use of hybrid LCA to estimate the environmental impacts of modern crop-based building materials (see Appendix C).

- life cycle costing and social life cycle analysis have to be combined into a stand-alone more complete Life Cycle Sustainability Assessment (LCSA) (see Appendix B).

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Bio-Based Materials

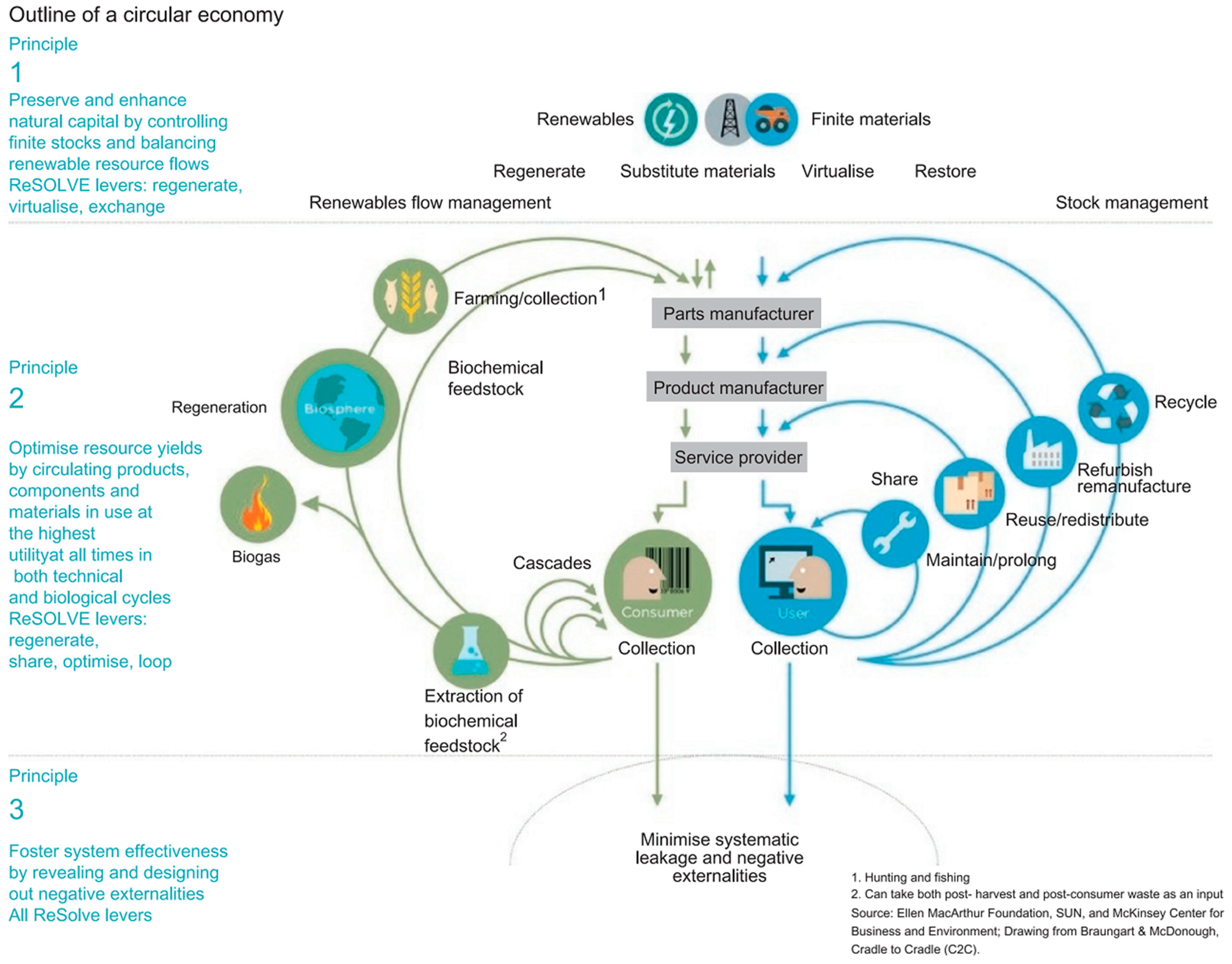

Appendix B. Environmental Impacts Assessment

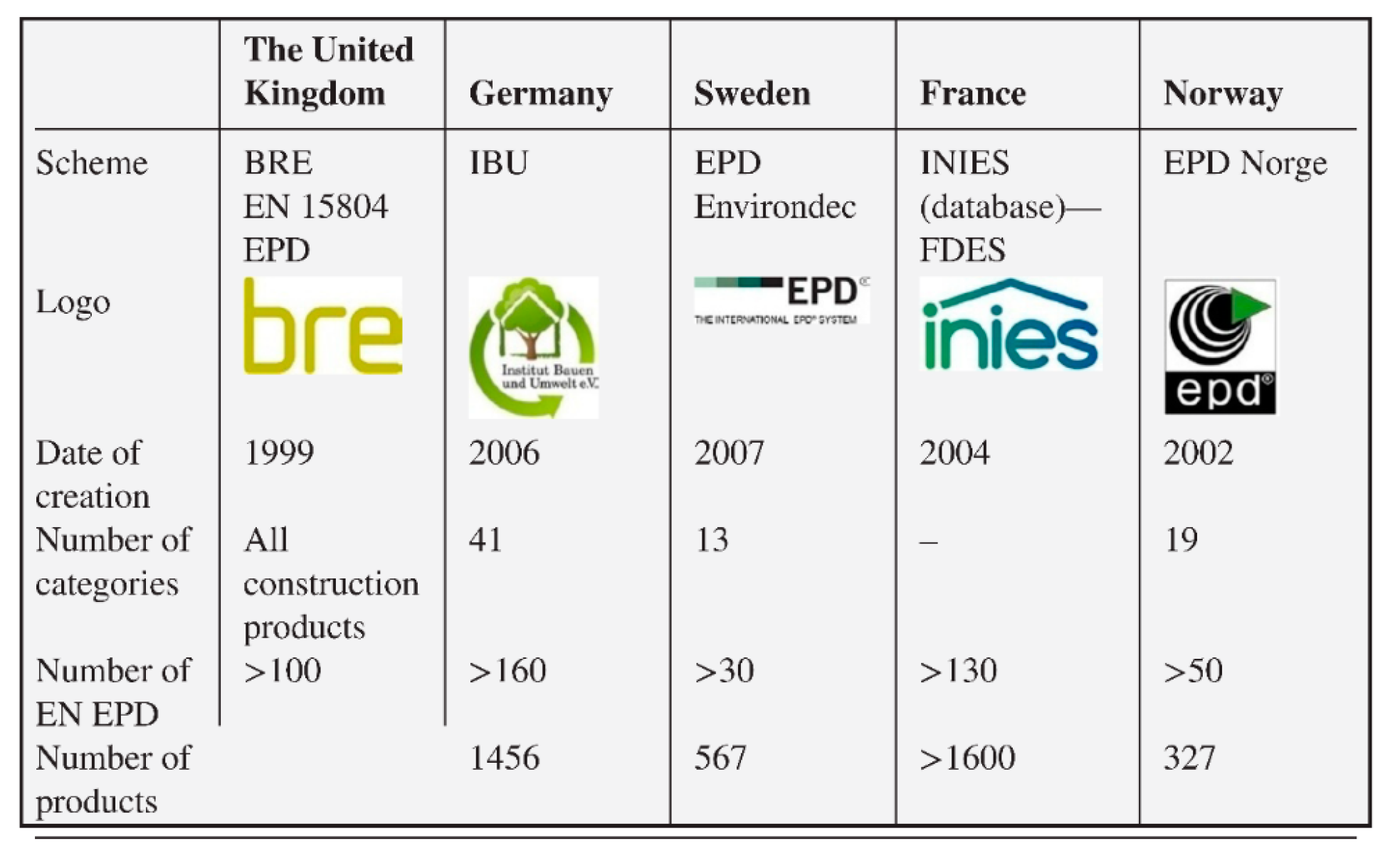

Appendix B.1. Standards, Frameworks, and Ecolabels

Appendix B.2. Life-Cycle Assessment Related Methods

Appendix C. Life-Cycle Assessment Methods

References

- Moussa, T.; Maalouf, C.; Ingrao, C.; Scrucca, F.; Costantine, G.; Asdrubali, F. Bio-based and recycled-waste materials in buildings: A study of energy performance of hemp-lime concrete and recycled-polyethylene terephthalate façades for office facilities in France and Italy. Sci. Technol. Built Environ. 2018, 24, 492–501. [Google Scholar] [CrossRef]

- Jones, D.; Brischke, C. Performance of BIO-Based Building Materials; Woodhead Publishing: Delhi, India, 2017. [Google Scholar]

- Beccali, M.; Cellura, M.; Fontana, M.; Longo, S.; Mistretta, M. Energy retrofit of a single-family house: Life cycle net energy saving and environmental benefits. Renew. Sustain. Energy Rev. 2013, 27, 283–293. [Google Scholar] [CrossRef]

- Lawrence, M. Reducing the environmental impact of construction by using renewable materials. J. Renew. Mater. 2015, 3, 163–174. [Google Scholar] [CrossRef] [Green Version]

- Cuéllar-Franca, R.M.; Azapagic, A. Environmental Impacts of the UK Residential Sector: Life Cycle Assessment of Houses. Build. Environ. 2012, 54, 86–99. [Google Scholar] [CrossRef]

- Joseph, P.; Tretsiakova-McNally, S. Sustainable non-metallic building materials. Sustainability 2010, 2, 400–427. [Google Scholar] [CrossRef] [Green Version]

- Dutil, Y.; Rousse, D.; Quesada, G. Sustainable buildings: An ever evolving target. Sustainability 2011, 3, 443–464. [Google Scholar] [CrossRef] [Green Version]

- Calkins, M. Materials for Sustainable Sites: A Complete Guide to the Evaluation, Selection, and Use of Sustainable Construction Materials; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Gorse, C.; Thomas, F.; Glew, D.; Shenton, D.M. Achieving Sustainability in New Build and Retrofit: Building Performance and Life Cycle Analysis. In Building Sustainable Futures; Springer: Berlin, Germany, 2016; pp. 183–207. [Google Scholar]

- Menet, J.-L.; Gruescu, I.-C. A comparative life cycle assessment of exterior walls constructed using natural insulation materials. Short Hyper Artic. En Ligne 2012, 1, 14. [Google Scholar]

- EN 15804:2012; European Committee for Standardization. Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. CEN-CENELEC Management Centre: Brussels, Belgium, 2012.

- Van Dam, J.E.G.; Bos, H.L. The Environmental Impact of Fibre Crops in Industrial Applications; Food and Agriculture Organization: Rome, Italy, 2004. [Google Scholar]

- Cherubini, F.; Guest, G.; Strømman, A.H. Bioenergy from forestry and changes in atmospheric CO2: Reconciling single stand and landscape level approaches. J. Environ. Manag. 2013, 129, 292–301. [Google Scholar] [CrossRef]

- Schulte, M.; Lewandowski, I.; Pude, R.; Wagner, M. Comparative life cycle assessment of bio-based insulation materials: Environmental and economic performances. GCB Bioenergy 2021, 13, 979–998. [Google Scholar] [CrossRef]

- Martin, M.; Røyne, F.; Ekvall, T.; Moberg, Å. Life cycle sustainability evaluations of bio-based value chains: Reviewing the indicators from a Swedish perspective. Sustainability 2018, 10, 547. [Google Scholar] [CrossRef] [Green Version]

- Berndes, G.; Ahlgren, S.; Börjesson, P.; Cowie, A.L. Bioenergy and land use change—State of the art. Wiley Interdiscip. Rev. Energy Environ. 2013, 2, 282–303. [Google Scholar] [CrossRef]

- Potrč, T.; Rebec, K.M.; Knez, F.; Kunič, R.; Legat, A. Environmental footprint of external thermal insulation composite systems with different insulation types. Energy Procedia 2016, 96, 312–322. [Google Scholar] [CrossRef] [Green Version]

- Escobar, N.; Laibach, N. Sustainability check for bio-based technologies: A review of process-based and life cycle approaches. Renew. Sustain. Energy Rev. 2021, 135, 110213. [Google Scholar] [CrossRef]

- Zamagni, A.; Guinée, J.; Heijungs, R.; Masoni, P.; Raggi, A. Lights and shadows in consequential LCA. Int. J. Life Cycle Assess. 2012, 17, 904–918. [Google Scholar] [CrossRef]

- Schmidt, J.H. System delimitation in agricultural consequential LCA. Int. J. Life Cycle Assess. 2008, 13, 350–364. [Google Scholar] [CrossRef]

- Escobar, N.; Ribal, J.; Clemente, G.; Sanjuán, N. Consequential LCA of two alternative systems for biodiesel consumption in Spain, considering uncertainty. J. Clean. Prod. 2014, 79, 61–73. [Google Scholar] [CrossRef]

- Lewandowski, I. Securing a sustainable biomass supply in a growing bioeconomy. Glob. Food Secur. 2015, 6, 34–42. [Google Scholar] [CrossRef]

- Rosegrant, M.W.; Ringler, C.; Zhu, T.; Tokgoz, S.; Bhandary, P. Water and food in the bioeconomy: Challenges and opportunities for development. Agric. Econ. 2013, 44, 139–150. [Google Scholar] [CrossRef]

- Escobar, N.; Haddad, S.; Boerner, J.; Britz, W. Land use mediated GHG emissions and spillovers from increased bioplastic consumption. Environ. Res. Lett. 2018, 13, 125005. [Google Scholar] [CrossRef]

- Nong, D.; Escobar, N.; Britz, W.; Börner, J. Long-term impacts of bio-based innovation in the chemical sector: A dynamic global perspective. J. Clean. Prod. 2020, 272, 122738. [Google Scholar] [CrossRef]

- Florentino, B.; Chanton, J.P.; Barlaz, M.A. Measurement of carbon storage in landfills from the biogenic carbon content of excavated waste samples. Waste Manag. 2013, 33, 2001–2005. [Google Scholar]

- Silva, D.A.L.; Lahr, F.A.R.; Pavan, A.L.R.; Saavedra, Y.M.B.; Crespo-Mendes, N.; Sousa, S.R.; Sanches, R.; Ometto, A.R. Do wood-based panels made with agro-industrial residues provide environmentally benign alternatives? An LCA case study of sugarcane bagasse addition to particle board manufacturing. Int. J. Life Cycle Assess. 2014, 19, 1767–1778. [Google Scholar] [CrossRef]

- Fieschi, M.; Pretato, U. Role of compostable tableware in food service and waste management. A life cycle assessment study. Waste Manag. 2018, 73, 14–25. [Google Scholar] [CrossRef]

- Garfí, M.; Flores, L.; Ferrer, I. Life cycle assessment of wastewater treatment systems for small communities: Activated sludge, constructed wetlands and high rate algal ponds. J. Clean. Prod. 2017, 161, 211–219. [Google Scholar] [CrossRef]

- Seghetta, M.; Tørring, D.; Bruhn, A.; Thomsen, M. Bioextraction potential of seaweed in Denmark—An instrument for circular nutrient management. Sci. Total Environ. 2016, 563, 513–529. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Asif, M.; Muneer, T.; Kelley, R. Life cycle assessment: A case study of a dwelling home in Scotland. Build. Environ. 2007, 42, 1391–1394. [Google Scholar] [CrossRef]

- Bowick, M.F. A Life Cycle Assessment Model of Canadian Residential Dwellings and Building Stocks. Ph.D. Dissertation, Ryerson University, Toronto, ON, Canada, 2011. [Google Scholar]

- Peñaloza, D.; Erlandsson, M.; Falk, A. Exploring the climate impact effects of increased use of bio-based materials in buildings. Constr. Build. Mater. 2016, 125, 219–226. [Google Scholar] [CrossRef] [Green Version]

- Hill, C.A. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: Hoboken, NJ, USA, 2007; Volume 5. [Google Scholar]

- Ding, T.; Xiao, J.; Tam, V.W. A closed-loop life cycle assessment of recycled aggregate concrete utilization in China. Waste Manag. 2016, 56, 367–375. [Google Scholar] [CrossRef]

- Giergiczny, Z.; Król, A.; Tałaj, M.; Wandoch, K. Performance of concrete with low CO2 emission. Energies 2020, 13, 4328. [Google Scholar] [CrossRef]

- Bumanis, G.; Vitola, L.; Pundiene, I.; Sinka, M.; Bajare, D. Gypsum, Geopolymers, and starch—Alternative binders for bio-based building materials: A review and life-cycle assessment. Sustainability 2020, 12, 5666. [Google Scholar] [CrossRef]

- Heinrich, L.A. Future opportunities for bio-based adhesives–advantages beyond renewability. Green Chem. 2019, 21, 1866–1888. [Google Scholar] [CrossRef] [Green Version]

- Pizzi, A. Recent developments in eco-efficient bio-based adhesives for wood bonding: Opportunities and issues. J. Adhes. Sci. Technol. 2006, 20, 829–846. [Google Scholar] [CrossRef]

- Segovia, F.; Blanchet, P.; Auclair, N.; Essoua, G.G.E. Thermo-mechanical properties of a wood fiber insulation board using a bio-based adhesive as a binder. Buildings 2020, 10, 152. [Google Scholar] [CrossRef]

- Ferreira, J.V.; Esteves, B.; Nunes, L.; Domingos, I. Life Cycle Assessment of Thermally Treated and Untreated Maritime Pine Boards: A Portuguese Case Study. In Proceedings of the European Conference on Wood Modification, Lisbon, Portugal, 10–12 March 2014. [Google Scholar]

- Elmasoudi, I.; Ibrahim, M.G.; Tokimatsu, K.; Elbeltagi, E. Environmental impact assessment model for buildings’ construction activities. Int. J. Constr. Manag. 2022, 22, 849–860. [Google Scholar] [CrossRef]

- The Architectural Review. Available online: www.architectural-review.com (accessed on 29 April 2023).

- Livne, A.; Wösten, H.A.B.; Pearlmutter, D.; Gal, E. Fungal Mycelium Bio-Composite Acts as a CO2-Sink Building Material with Low Embodied Energy. ACS Sustain. Chem. Eng. 2022, 10, 12099–12106. [Google Scholar] [CrossRef]

- Gérardin, P. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Ann. For. Sci. 2016, 73, 559–570. [Google Scholar] [CrossRef] [Green Version]

- Lecompte, T.; Levasseur, A.; Maxime, D. Lime and hemp concrete LCA: A dynamic approach of GHG emissions and capture. Acad. J. Civ. Eng. 2017, 35, 513–521. [Google Scholar]

- Wojnowska-Baryła, I.; Kulikowska, D.; Bernat, K. Effect of bio-based products on waste management. Sustainability 2020, 12, 2088. [Google Scholar] [CrossRef] [Green Version]

- Beigbeder, J.; Soccalingame, L.; Perrin, D.; Bénézet, J.-C.; Bergeret, A. How to manage biocomposites wastes end of life? A life cycle assessment approach (LCA) focused on polypropylene (PP)/wood flour and polylactic acid (PLA)/flax fibres biocomposites. Waste Manag. 2019, 83, 184–193. [Google Scholar] [CrossRef] [Green Version]

- Pittau, F.; Krause, F.; Lumia, G.; Habert, G. Fast-growing bio-based materials as an opportunity for storing carbon in exterior walls. Build. Environ. 2018, 129, 117–129. [Google Scholar] [CrossRef]

- Fouquet, M.; Levasseur, A.; Margni, M.; Lebert, A.; Lasvaux, S.; Souyri, B.; Buhé, C.; Woloszyn, M. Methodological challenges and developments in LCA of low energy buildings: Application to biogenic carbon and global warming assessment. Build. Environ. 2015, 90, 51–59. [Google Scholar] [CrossRef]

- Evrard, A.; De Herde, A. Hygrothermal performance of lime-hemp wall assemblies. J. Build. Phys. 2010, 34, 5–25. [Google Scholar] [CrossRef]

- de Bruijn, P.B.; Jeppsson, K.-H.; Sandin, K.; Nilsson, C. Mechanical properties of lime–hemp concrete containing shives and fibres. Biosyst. Eng. 2009, 103, 474–479. [Google Scholar] [CrossRef]

- Haik, R.; Peled, A.; Meir, I. The thermal performance of lime hemp concrete (LHC) with alternative binders. Energy Build. 2020, 210, 109740. [Google Scholar] [CrossRef]

- Rahim, M.; Douzane, O.; Tran Le, A.; Promis, G.; Laidoudi, B.; Crigny, A.; Dupre, B.; Langlet, T. Characterization of flax lime and hemp lime concretes: Hygric properties and moisture buffer capacity. Energy Build. 2015, 88, 91–99. [Google Scholar] [CrossRef]

- Rode, C.; Peuhkuri, R.; Time, B.; Svennberg, K.; Ojanen, T.; Mukhopadhyaya, P.; Kumaran, M.; Dean, S.W. Moisture Buffer Value of Building Materials. J. ASTM Int. 2007, 4. [Google Scholar] [CrossRef] [Green Version]

- Brischke, C.; Hanske, M. Durability of untreated and thermally modified reed (Phragmites australis) against brown, white and soft rot causing fungi. Ind. Crops Prod. 2016, 91, 49–55. [Google Scholar] [CrossRef]

- Hofmann, K.; Kreisel, H.; Kordon, K.; Preuss, F.; Kües, U.; Schauer, F. The key role of lignin decomposing fungi in the decay of roofs thatched with water reed. Mycol. Prog. 2016, 15, 35. [Google Scholar] [CrossRef]

- Wöhler-Geske, A.; Moschner, C.R.; Gellerich, A. Provenances and properties of thatching reed (Phragmites australis). Landbauforsch. Ger. 2016, 66, 1–10. [Google Scholar]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Abdou, A.; Budaiwi, I. The variation of thermal conductivity of fibrous insulation materials under different levels of moisture content. Constr. Build. Mater. 2013, 43, 533–544. [Google Scholar] [CrossRef]

- Patnaik, A.; Mvubu, M.; Muniyasamy, S.; Botha, A.; Anandjiwala, R. Thermal and sound insulation materials from waste wool and recycled polyester fibers and their biodegradation studies. Energy Build. 2015, 92, 161–169. [Google Scholar] [CrossRef]

- Korjenic, A.; Petránek, V.; Zach, J.; Hroudová, J. Development and performance evaluation of natural thermal-insulation materials composed of renewable resources. Energy Build. 2011, 43, 2518–2523. [Google Scholar] [CrossRef]

- Georgiev, G.P.; Theuerkorn, W.; Krus, M.; Kilian, R.; Grosskinsky, T. The potential role of cattail-reinforced clay plaster in sustainable building. Mires Peat 2014, 13, 1–13. [Google Scholar]

- Palumbo, M.; Formosa, J.; Lacasta, A. Thermal degradation and fire behaviour of thermal insulation materials based on food crop by-products. Constr. Build. Mater. 2015, 79, 34–39. [Google Scholar] [CrossRef] [Green Version]

- Sing, K.S. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Hansen, K.K. Sorption Isotherms. A Catalogue; Technical University of Denmark: Lyngby, Denmark, 1986. [Google Scholar]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015. 87, 1051–1069.

- Zhang, X.; Kuenzel, H.; Zillig, W.; Mitterer, C.; Zhang, X. A Fickian model for temperature-dependent sorption hysteresis in hygrothermal modeling of wood materials. Int. J. Heat Mass Transf. 2016, 100, 58–64. [Google Scholar] [CrossRef]

- Promis, G.; Douzane, O.; Le, A.T.; Langlet, T. Moisture hysteresis influence on mass transfer through bio-based building materials in dynamic state. Energy Build. 2018, 166, 450–459. [Google Scholar] [CrossRef]

- Promis, G.; Dutra, L.F.; Douzane, O.; Le, A.T.; Langlet, T. Temperature-dependent sorption models for mass transfer throughout bio-based building materials. Constr. Build. Mater. 2019, 197, 513–525. [Google Scholar] [CrossRef]

- Teasdale-St-Hilaire, A.; Derome, D. Comparison of experimental and numerical results of wood-frame wall assemblies wetted by simulated wind-driven rain infiltration. Energy Build. 2007, 39, 1131–1139. [Google Scholar] [CrossRef]

- Tariku, F.; Kumaran, K.; Fazio, P. Transient model for coupled heat, air and moisture transfer through multilayered porous media. Int. J. Heat Mass Transf. 2010, 53, 3035–3044. [Google Scholar] [CrossRef] [Green Version]

- Saber, H.H.; Maref, W.; Elmahdy, H.; Swinton, M.C.; Glazer, R. 3D heat and air transport model for predicting the thermal resistances of insulated wall assemblies. J. Build. Perform. Simul. 2012, 5, 75–91. [Google Scholar] [CrossRef]

- Elmahdy, A.H.; Maref, W.; Swinton, M.C.; Saber, H.H.; Glazer, R. Development of energy ratings for insulated wall assemblies. In Proceedings of the 2009 Building Envelope Symposium, San Diego, CA, USA, 26 October 2009; p. 2009. [Google Scholar]

- Rahim, M.; Douzane, O.; Le, A.T.; Promis, G.; Langlet, T. Experimental investigation of hygrothermal behavior of two bio-based building envelopes. Energy Build. 2017, 139, 608–615. [Google Scholar] [CrossRef]

- Slimani, Z.; Trabelsi, A.; Virgone, J.; Freire, R.Z. Study of the hygrothermal behavior of wood fiber insulation subjected to non-isothermal loading. Appl. Sci. 2019, 9, 2359. [Google Scholar] [CrossRef] [Green Version]

- Kessentini, R.; Klinkova, O.; Tawfiq, I.; Haddar, M. Transient hygro-thermo-mechanical stresses analysis in multi-layers bonded structure with coupled bidirectional model. Int. J. Mech. Sci. 2019, 150, 188–201. [Google Scholar] [CrossRef]

- Langmans, J.; Klein, R.; Roels, S. Numerical and experimental investigation of the hygrothermal response of timber frame walls with an exterior air barrier. J. Build. Phys. 2013, 36, 375–397. [Google Scholar] [CrossRef]

- Belleudy, C.; Woloszyn, M.; Chhay, M.; Cosnier, M. A 2D model for coupled heat, air, and moisture transfer through porous media in contact with air channels. Int. J. Heat Mass Transf. 2016, 95, 453–465. [Google Scholar] [CrossRef] [Green Version]

- Plathner, P.; Woloszyn, M. Interzonal air and moisture transport in a test house: Experiment and modelling. Build. Environ. 2002, 37, 189–199. [Google Scholar] [CrossRef]

- Holm, A.; Kuenzel, H.M.; Sedlbauer, K. The hygrothermal behaviour of rooms: Combining thermal building simulation and hygrothermal envelope calculation. In Proceedings of the Eighth International Ibpsa Conference, Eindhoven, The Netherlands, 11–14 August 2003. [Google Scholar]

- Holm, A.; Sedlbauer, K.; Künzel, H.M.; Radon, J. Berechnung des hygrothermischen Verhaltens von Räumen-Einfluss des Lüftungsverhaltens auf die Raumluftfeuchte. Tag. Für Das 2002, 11, 562–575. [Google Scholar]

- Künzel, H.M. Verfahren Zur Ein-Und Zweidimensionalen Berechnung Des Gekoppelten Wärme-Und Feuchtetransports in Bauteilen Mit einfachen Kennwerten; Universität Stuttgart: Stuttgart, Germany, 1994. [Google Scholar]

- Rode, C.; Sørensen, K.G. Whole Building Hygrothermal Simulation Model; ASHRAE Transactions: Washington, DC, USA, 2010. [Google Scholar]

- Hens, H. IEA-ECBCS Annex 41 Whole building heat, air and moisture response. In Proceedings of the Nordic Building Physics Conference, Copenhagen, Denmark, 16–18 June 2008. [Google Scholar]

- Hens, H. IEA Annex 14: Condensation and energy. J. Therm. Insul. 1992, 15, 261–273. [Google Scholar] [CrossRef]

- Hens, H. IEA Annex 24: Heat, air and moisture transfer through new and retrofitted insulated envelope parts (Hamtie). Final. Rep. 1996, 1, 56. [Google Scholar]

- Annex, I.E. Integral Building Envelope Performance Assessment; International Energy Agency: Paris, France, 2003. [Google Scholar]

- Rode, C.; Woloszyn, M. Whole-building hygrothermal modeling in IEA Annex 41. In Thermal Performance of the Exterior Envelopes of Whole Buildings: Buildings X. 2007; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Peachtree Corners, Georgia, 2008. [Google Scholar]

- Kumaran, K.; Sanders, C. IEA Annex 41, Final Report, Volume 3. Whole Building Heat, Air, Moisture Response-Boundary Conditions and Whole Building HAM Analysis; International Energy Agency: Paris, France, 2008. [Google Scholar]

- Burrows, J.; Gallagher, J.F. NRC-IRC web site provides extensive building science information. Home Build. Mag. 2009, 22, 10. [Google Scholar]

- Maref, W.; Lacasse, M.; Kumaran, M.; Swinton, M.C. Benchmarking of the advanced hygrothermal model-hygIRC with mid-scale experiments,” eSim. In Proceedings of the eSim 2002 Proceedings, University of Concordia, Montreal, QC, Canada, 12 September 2002. [Google Scholar]

- Elmahdy, A. Heating Transmission and R-value of Fenestration Using IRC Hot Box: Procedure and uncertainty analysis. ASHRAE Trans. 1992, 1, 838–845. [Google Scholar]

- Sathre, R.; González-García, S. Life cycle assessment (LCA) of wood-based building materials. In Eco-Efficient Construction and Building Materials; Elsevier: Amsterdam, The Netherlands, 2014; pp. 311–337. [Google Scholar]

- Marcelino-Sadaba, S.; Kinuthia, J.; Oti, J.; Meneses, A.S. Challenges in Life Cycle Assessment (LCA) of stabilised clay-based construction materials. Appl. Clay Sci. 2017, 144, 121–130. [Google Scholar] [CrossRef]

- Bilec, M.; Ries, R.; Matthews, H.S.; Sharrard, A.L. Example of a hybrid life-cycle assessment of construction processes. J. Infrastruct. Syst. 2006, 12, 207–215. [Google Scholar] [CrossRef] [Green Version]

- Säynäjoki, A.; Heinonen, J.; Junnonen, J.-M.; Junnila, S. Input–output and process LCAs in the building sector: Are the results compatible with each other? Carbon Manag. 2017, 8, 155–166. [Google Scholar] [CrossRef]

- Treloar, G.J.; Love, P.E.D.; Faniran, O.O.; Iyer-Raniga, U. A hybrid life cycle assessment method for construction. Constr. Manag. Econ. 2000, 18, 5–9. [Google Scholar] [CrossRef]

- Lokesh, K.; Matharu, A.S.; Kookos, I.K.; Ladakis, D.; Koutinas, A.; Morone, P.; Clark, J. Hybridised sustainability metrics for use in life cycle assessment of bio-based products: Resource efficiency and circularity. Green Chem. 2020, 22, 803–813. [Google Scholar] [CrossRef] [Green Version]

- Sherwood, J.; Clabeaux, R.; Carbajales-Dale, M. An extended environmental input–output lifecycle assessment model to study the urban food–energy–water nexus. Environ. Res. Lett. 2017, 12, 105003. [Google Scholar] [CrossRef]

- Hollberg, A.; Ruth, J. LCA in architectural design—A parametric approach. Int. J. Life Cycle Assess. 2016, 21, 943–960. [Google Scholar] [CrossRef] [Green Version]

- Sahoo, K.; Bergman, R.; Alanya-Rosenbaum, S.; Gu, H.; Liang, S. Life cycle assessment of forest-based products: A review. Sustainability 2019, 11, 4722. [Google Scholar] [CrossRef] [Green Version]

- Correa, J.P.; Montalvo-Navarrete, J.M.; Hidalgo-Salazar, M.A. Carbon footprint considerations for biocomposite materials for sustainable products: A review. J. Clean. Prod. 2019, 208, 785–794. [Google Scholar] [CrossRef]

- Canada Hemp Foods Ltd. Available online: www.canadahempfoods.com (accessed on 29 April 2023).

- Northern Alberta Development Council. Available online: nadc.ca (accessed on 29 April 2023).

- Building Design and Construction. Available online: www.bdcnetwork.com (accessed on 29 April 2023).

- Bader, C.; Costa, J.; Nic Lee, N.; Smith, R.; Ri, R.; Weaver, J.C.; Oxman, N. Computational methods for the characterization of Apis mellifera comb architecture. Commun. Biol. 2022, 5, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Inamura, C.; Stern, M.; Lizardo, D.; Houk, P.; Oxman, N. Additive manufacturing of transparent glass structures. 3d Print. Addit. Manuf. 2018, 5, 269–283. [Google Scholar] [CrossRef]

- Kayser, M.; Cai, L.; Falcone, S.; Bader, C.; Inglessis, N.; Darweesh, B.; Oxman, N. FIBERBOTS: An autonomous swarm-based robotic system for digital fabrication of fiber-based composites. Constr. Robot. 2018, 2, 67–79. [Google Scholar] [CrossRef]

- Oxam. Available online: https://oxman.com/projects (accessed on 29 April 2023).

- ISO 14020:2006; International Organization for Standardization. Environmental Labels and Declarations—General Principles. ISO: Geneva, Switzerland, 2006.

- ISO 14024:2018; International Organization for Standardization. Environmental Labels and Declarations—Type I Environmental Labeling—Principles and Procedures. ISO: Geneva, Switzerland, 2018.

- ISO 14021:2016; International Organization for Standardization. Environmental Labels and Declarations—Self-Declared Environmental Claims (Type II Environmental Labelling). ISO: Geneva, Switzerland, 2016.

- ISO 14025:2020; International Organization for Standardization. Environmental Labels and Declarations—Type III Environmental Declarations—Principles and Procedures. ISO: Geneva, Switzerland, 2020.

- Available online: www.environdec.com (accessed on 10 May 2020).

- ISO 14040:2006; International Organization for Standardization.Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; International Organization for Standardization. Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Luo, L.; van der Voet, E.; Huppes, G.; de Haes, H.A.U. Allocation issues in LCA methodology: A case study of corn stover-based fuel ethanol. Int. J. Life Cycle Assess. 2009, 14, 529–539. [Google Scholar] [CrossRef]

- Tao, L.; Tan, E.C.D.; McCormick, R.; Zhang, M.; Aden, A.; He, X.; Zigler, B.T. Techno-economic analysis and life-cycle assessment of cellulosic isobutanol and comparison with cellulosic ethanol and n-butanol. Biofuels Bioprod. Biorefining 2014, 8, 30–48. [Google Scholar] [CrossRef]

- Cambero, C.; Sowlati, T. Assessment and optimization of forest biomass supply chains from economic, social and environmental perspectives–A review of literature. Renew. Sustain. Energy Rev. 2014, 36, 62–73. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Schau, E.M.; Lehmann, A.; Traverso, M. Towards life cycle sustainability assessment. Sustainability 2010, 2, 3309–3322. [Google Scholar] [CrossRef] [Green Version]

- Guinée, J.B.; Cucurachi, S.; Henriksson, P.J.G.; Heijungs, R. Digesting the alphabet soup of LCA. Int. J. Life Cycle Assess. 2018, 23, 1507–1511. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zamagni, A.; Pesonen, H.-L.; Swarr, T. From LCA to Life Cycle Sustainability Assessment: Concept, practice and future directions. Int. J. Life Cycle Assess. 2013, 18, 1637–1641. [Google Scholar] [CrossRef] [Green Version]

| Building Life Cycle Information | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A 1–3 | A 4–5 | B 1–7 | C 1–4 | ||||||||||

| Product stage | Construction Process stage | Use stage | End of life stage | ||||||||||

| A1 | A2 | A3 | A4 | A5 | B1 | B2 | B3 | B4 | B5 | C1 | C2 | C3 | C4 |

| Raw material supply | Transpor | Manufacturing | Transport | Construction Installation Process | Use | Maintanance (incl. transport) | Repair (incl. transport) | Replacement (incl. transport) | Refurbishment (incl. transport) | De-construction /Demolition | Transport | Waste processing | Disposal |

| Scenario | Scenario | Scenario | Scenario | Scenario | Scenario | Scenario | Scenario | Scenario | Scenario | Scenario | |||

| B6 | Operational energy use | ||||||||||||

| Scenario | |||||||||||||

| B7 | Operational water use | ||||||||||||

| Scenario | |||||||||||||

| Author | Field of Study | Method or Application |

|---|---|---|

| Bilec et al. [96] | LCA | Process & Input-Output methods |

| Säynäjoki et al. [97] | LCA | Hybrid method |

| Treloar et al. [98] | LCA | A hybrid method in the construction industry |

| Bowick [32] | LCA | Canadian residential dwellings LCA database |

| Lokesh et al. [99] | LCA | Non-aggregated hybrid LCA of circular crop-based building material |

| Sherwood et al. [100] | LCA | Techno-economic approach for using LCA |

| Author | Field of Study | Application |

|---|---|---|

| Hollberg and Ruth [101] | LCA | LCA in architectural design |

| Escobar and laibach [18] | Sustainability review | Circular and sustainable utilization of crop-based materials |

| Van dam and Bos [12] | Environmental impacts | Fiber crops usage in industrial applications |

| Schulte et al. [14] | LCA comparative assessment | Crop-based insulation materials |

| Berndes et al. [16] | Crop-based energy | LUC (land use change) |

| Escobar et al. [24] | Environmental impacts of bio-plastics | LUC-rooted GHG emissions |

| Escobar et al. [21] | Consequential LCA | Bio-fuels |

| Martin et al. [15] | LCA | LCA in crop-based value chains |

| Florentino et al. [26] | Landfilling | Biogenic carbon measurement |

| Silva et al. [27] | LCA | Environmental tradeoffs in agglomerates of wood-based and crop-based residues |

| Fieschi and Pretato [28] | LCA | Waste management |

| Sahoo et al. [102] | LCA | LCA of wood-based products |

| Peñaloza et al. [33] | LCA | Effect of increasing crop-based content in building materials |

| Ding et al. [35] | LCA | Closed loop LCA on recycled aggregate concrete |

| Gorse et al. [9] | LCA | Building sustainability |

| Potrč et al. [17] | LCA | Insulation environmental footprints |

| Giergiczny et al. [36] | LCA | Low CO2 emission concretes |

| Bumanis et al. [37] | LCA | LCA and review of alternative binders for crop-based concretes |

| Correa et al. [103] | Carbon footprint | Bio-composite materials |

| Elmasoudi et al. [42] | Environmental impact assessment | Environmental assessment of construction activities |

| Pittau et al. [49] | Embodied carbon assessment | Carbon sequestration effect in fast-growing crop-based material |

| Asif et al. [31] | LCA | Emission of different constructing building materials |

| www.architectural-review.com [43] | Current status of regulation and crop-based material production in France | |

| Wojnowska-Baryła et al. [47] | Waste management | End-of-life scenarios: Effect of crop-based materials on the waste management |

| Beigbeder et al. [48] | End of life | End-of-life scenarios of crop-based composites |

| Fouquet et al. [50] | LCA | Biogenic carbon in low-energy buildings |

| Lecompte et al. [46] | LCA | GHG emission and uptake of lime hemp concrete |

| Author | Field of Study | Application and Details |

|---|---|---|

| Jones and Brischke [2] | Crop-based building material | A comprehensive review of crop-based materials, their environmental impacts, and corresponding hygrothermal properties |

| Heinrich [38] | Gluing | Bio-based adhesives |

| Pizzi [39] | Gluing | Bio-based wood-binders |

| Segovia et al. [40] | Gluing | Bio-based wood-binders |

| Gérardin [45] | Wood preservation | Chemical modification of wood preservatives |

| Rode et al. [55] | Hygrothermal properties | Moisture buffer of building materials |

| [51] | Hygrothermal properties | Transient hygrothermal performance of lime hemp walls |

| Author | Material | Field of Study | Application and Details |

|---|---|---|---|

| Evrard and Herde [51] | LHC | Hygrothermal properties | Transient hygrothermal performance of lime hemp walls |

| De Bruijn et al. [52] | LHC | Mechanical properties | Mechanical strength of lime hemp walls |

| Haik et al. [53] | LHC | Thermal performance | The effect of alternative binders on the thermal performance of LHC |

| Rahim et al. [54] | FLC & LHC | Hygric Properties | FLC and LHC characterization |

| Brischke and Hanske [56] | Reed | Hygromechanical properties | Moisture absorption and durability of thermally modified reed |

| Hofmann et al. [57] | Reed | Durability | Growth of fungi on reed decay in roof thatching |

| Wöhler-Geske et al. [58] | Reed | Hygric properties and durability | Water absorption and durability of thatching reed |

| Joshi et al. [59] | Wool | Environmental performance | Comparison between wool and glass fiber in terms of environmental performance |

| Abdou et al. [60] | Wool | Hygrothermal properties | Thermal and hygric properties co-dependence in wool |

| Putnaik et al. [61] | Wool | Acoustic and thermal properties | Acoustic and thermal insulation of wool |

| Korjenic et al. [62] | Vegetal pith | Hygric properties | Hygroscopicity analysis of vegetal pith as insulation material |

| Palumbo et al. [64] | pith | Thermal properties and durability | Thermal property of the pith extracted from corn aggregate |

| Author | Field of Study | Application and Details |

|---|---|---|

| Sing [65] | Hygroscopicity | Classification of sorption isotherms |

| Hansen [66] | Hygroscopicity | A catalogue containing sorption and desorption isotherm equations for different building materials |

| Zhang et al. [68] | HM simulation | Modeling temperature-dependent hysteresis phenomena in |

| Promis et al. [69] | HM simulation | Moisture hysteresis analysis in hemp and rape straw |

| Promis et al. [70] | Hygrothermal and mechanical simulation | Simultaneous mechanical and hygrothermal loading and its analysis |

| Teasdale-St-Hilaire and Derome [71] | HAM simulation | Analyzing the Convection effect in insulation materials as well as the wetting process of rain infiltration |

| Tariku et al. [72] | HAM simulation | Heat air and moisture non-linear formulation and analysis |

| Saber et al. [73] | HAM simulation | Inclusion of windows in the wall models and further analysis of air leakage in the wall |

| Elmahdy et al. [74] | Energy rating experimentation | Benchmarking energy rating in different sets of wall assemblies |

| Rahim et al. [75] | HM experimentation | Experimental characterization of a hygrothermal balance of hemp and rape straw |

| Slimani et al. [76] | HM simulation | Developing two diffusive models for heat and moisture transfer |

| Kessentini et al. [77] | Hygrothermal and mechanical simulation | Evaluation of simultaneous mechanical load and concentration gradient |

| Langmans et al. [78] | HAM simulation | Inclusion of natural convection in the HAM simulation |

| Belleudy et al. [79] | HAM simulation | Describing different physics and solutions for the inclusion of air channels in wall assembly models |

| Plathner and Woloszyn [80] | Whole building simulation | Air-borne moisture transfer analysis in a multi-zone model of a test house |

| Holm et al. [82] | Whole building HM simulation | Introduction of the WUFI+ model |

| Holm et al. [81] | Whole building HM simulation | Combining thermal building simulation and hygrothermal envelope calculation |

| Rode and Sørensen [84] | Whole building HM simulation | Thermal and hygric transient model accounting for building envelope and indoor condition |

| Hens [86] | IEA Annex 24 | Heat, air, and moisture transport in insulated envelope parts |

| Hens [87] (1996) | IEA Annex 32 | Integral building performance assessment |

| Hens [85] (2009) | IEA Annex 41 | Whole building heat air and moisture transport model |

| Author or Project | Coordinator | Field of Study | Application and Details |

|---|---|---|---|

| NORDTEST project | Rode et al. [55] | Standardizing document | Standardizing moisture buffer of building materials |

| Lacasse et al. [92] | NRC-IRC | Benchmarking | Benchmarking of the hygIRC model |

| Elmahdy [93] | NRC-IRC | Benchmarking | Benchmarking the heat transfer of the fenestration system |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Motamedi, S.; Rousse, D.R.; Promis, G. The Evolution of Crop-Based Materials in the Built Environment: A Review of the Applications, Performance, and Challenges. Energies 2023, 16, 5252. https://doi.org/10.3390/en16145252

Motamedi S, Rousse DR, Promis G. The Evolution of Crop-Based Materials in the Built Environment: A Review of the Applications, Performance, and Challenges. Energies. 2023; 16(14):5252. https://doi.org/10.3390/en16145252

Chicago/Turabian StyleMotamedi, Sina, Daniel R. Rousse, and Geoffrey Promis. 2023. "The Evolution of Crop-Based Materials in the Built Environment: A Review of the Applications, Performance, and Challenges" Energies 16, no. 14: 5252. https://doi.org/10.3390/en16145252

APA StyleMotamedi, S., Rousse, D. R., & Promis, G. (2023). The Evolution of Crop-Based Materials in the Built Environment: A Review of the Applications, Performance, and Challenges. Energies, 16(14), 5252. https://doi.org/10.3390/en16145252