An Updated Review of Solar Cooling Systems Driven by Photovoltaic–Thermal Collectors

Abstract

:1. Introduction

2. Photovoltaic–Thermal Collectors

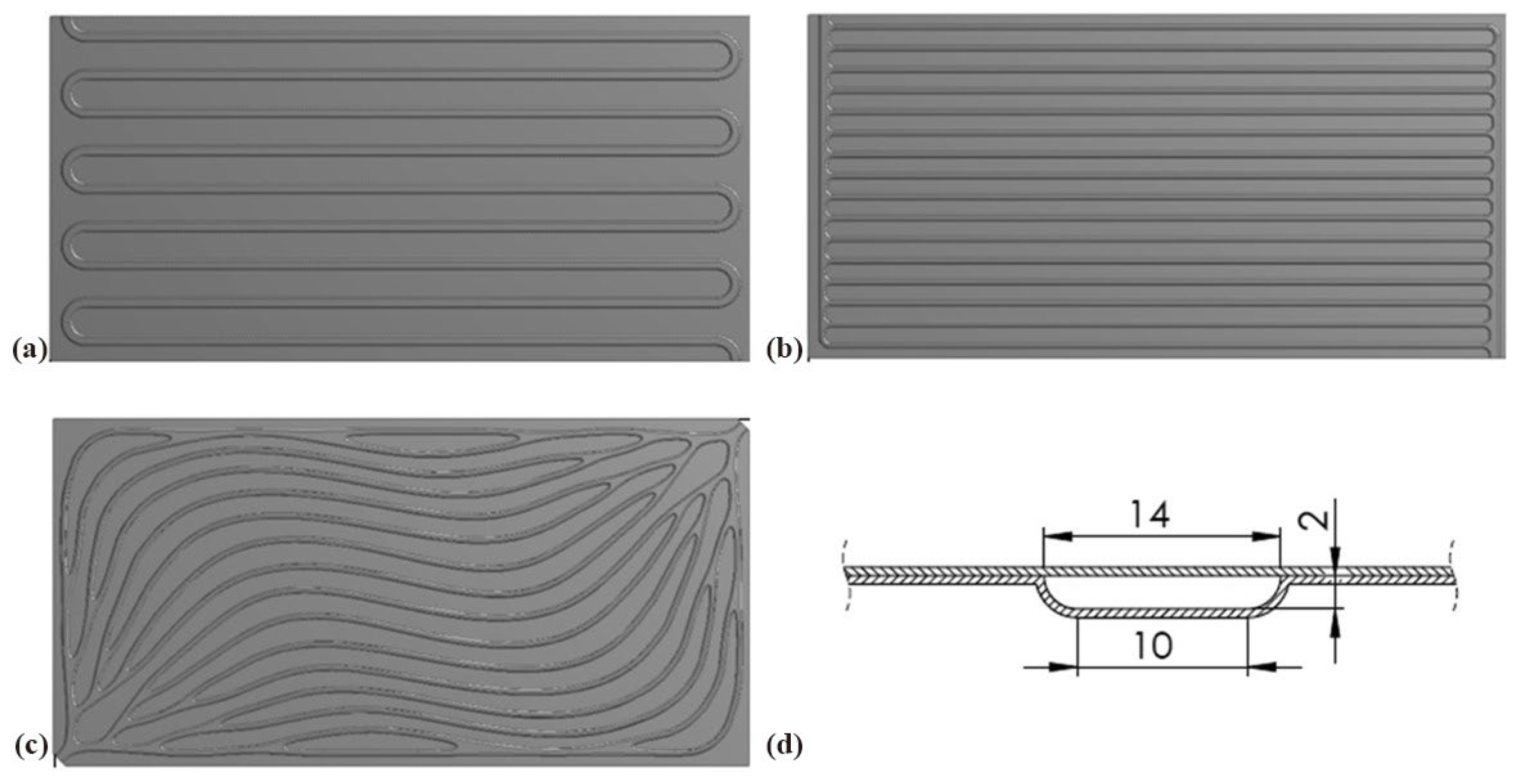

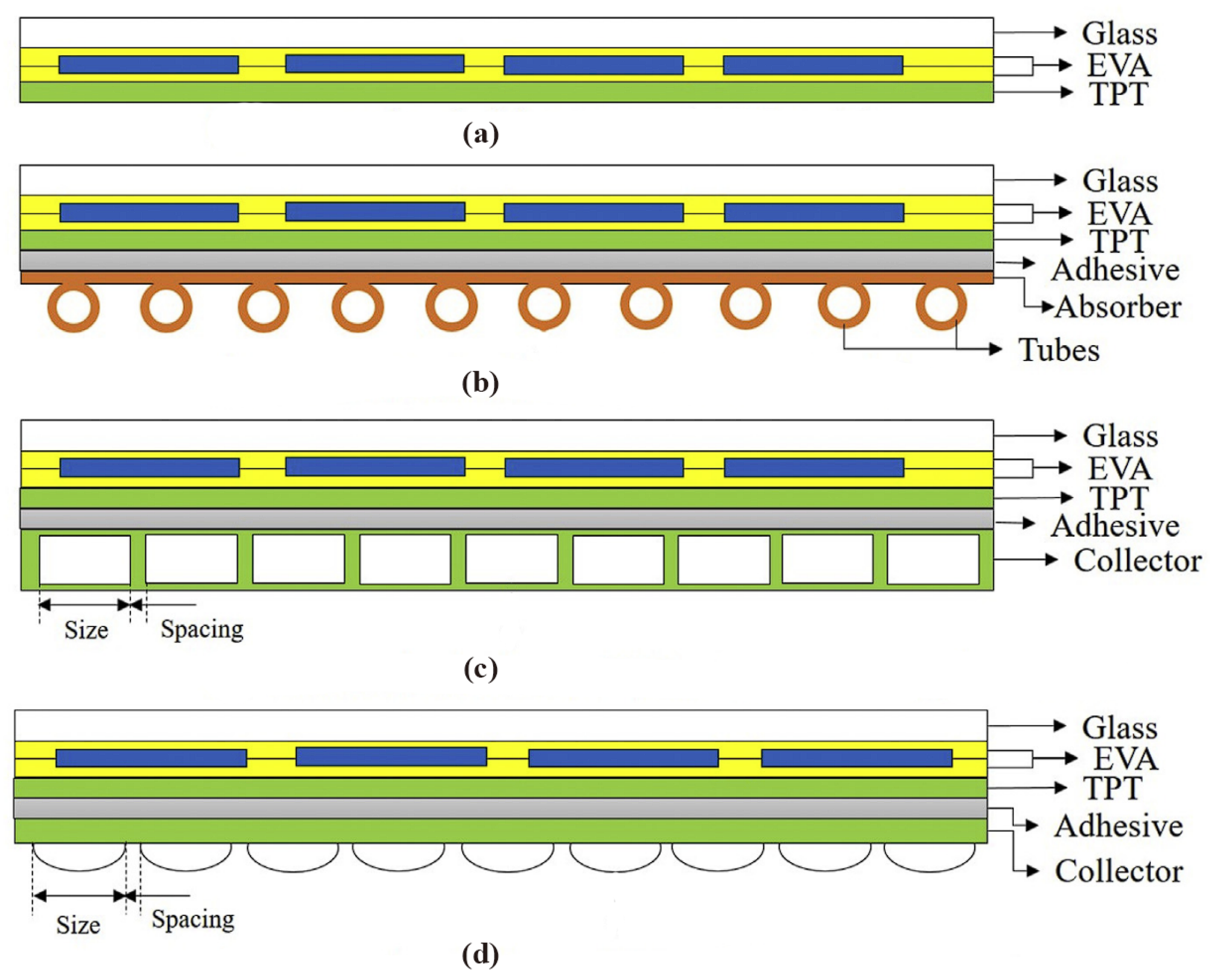

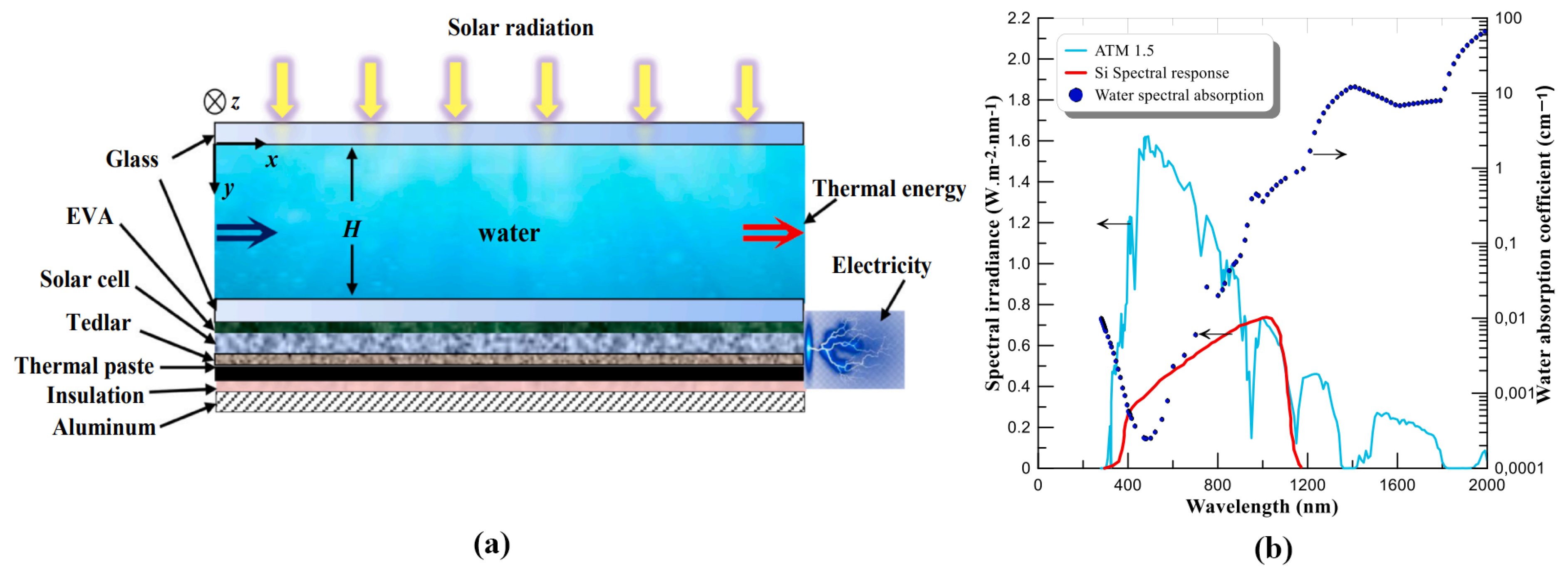

2.1. Photovoltaic–Thermal Collectors with Innovative Heat Exchange Structure

2.2. Photovoltaic–Thermal Collectors with Nanofluids

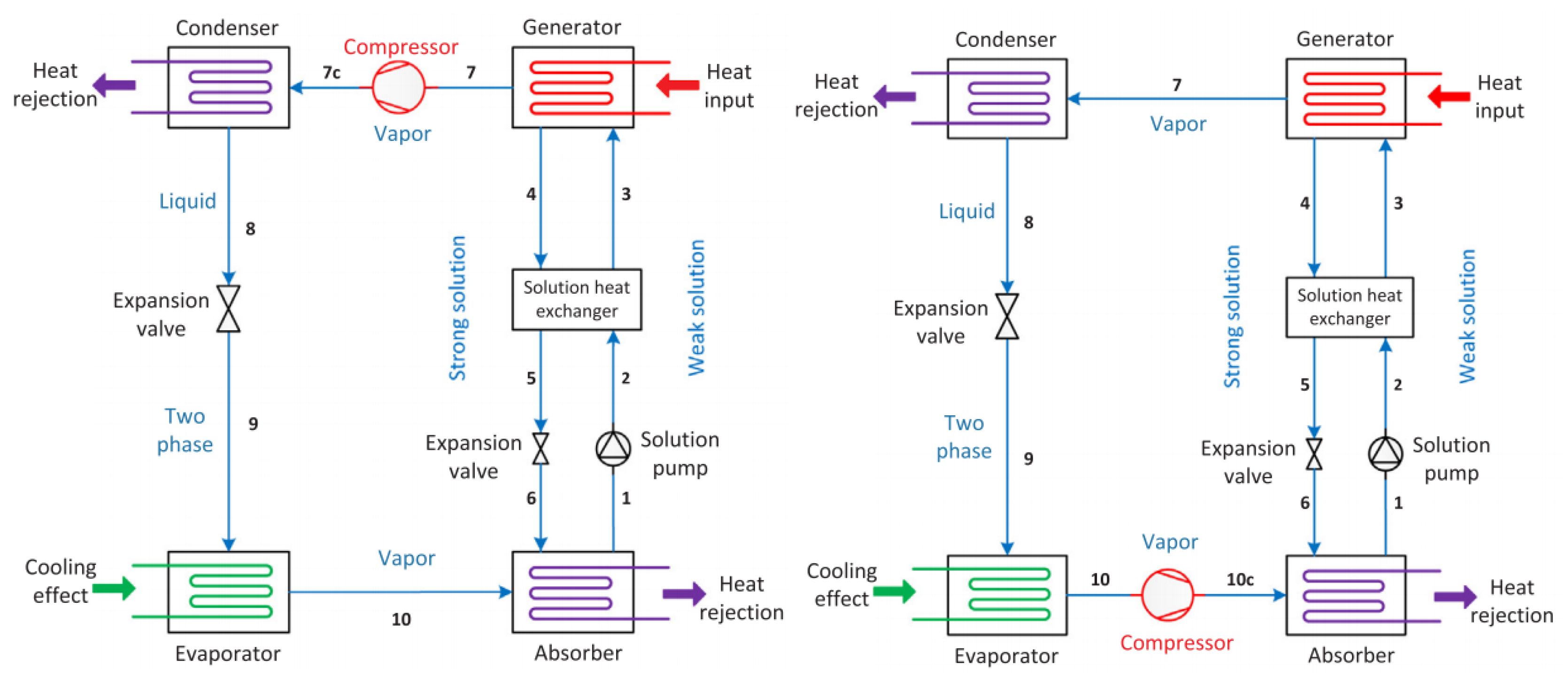

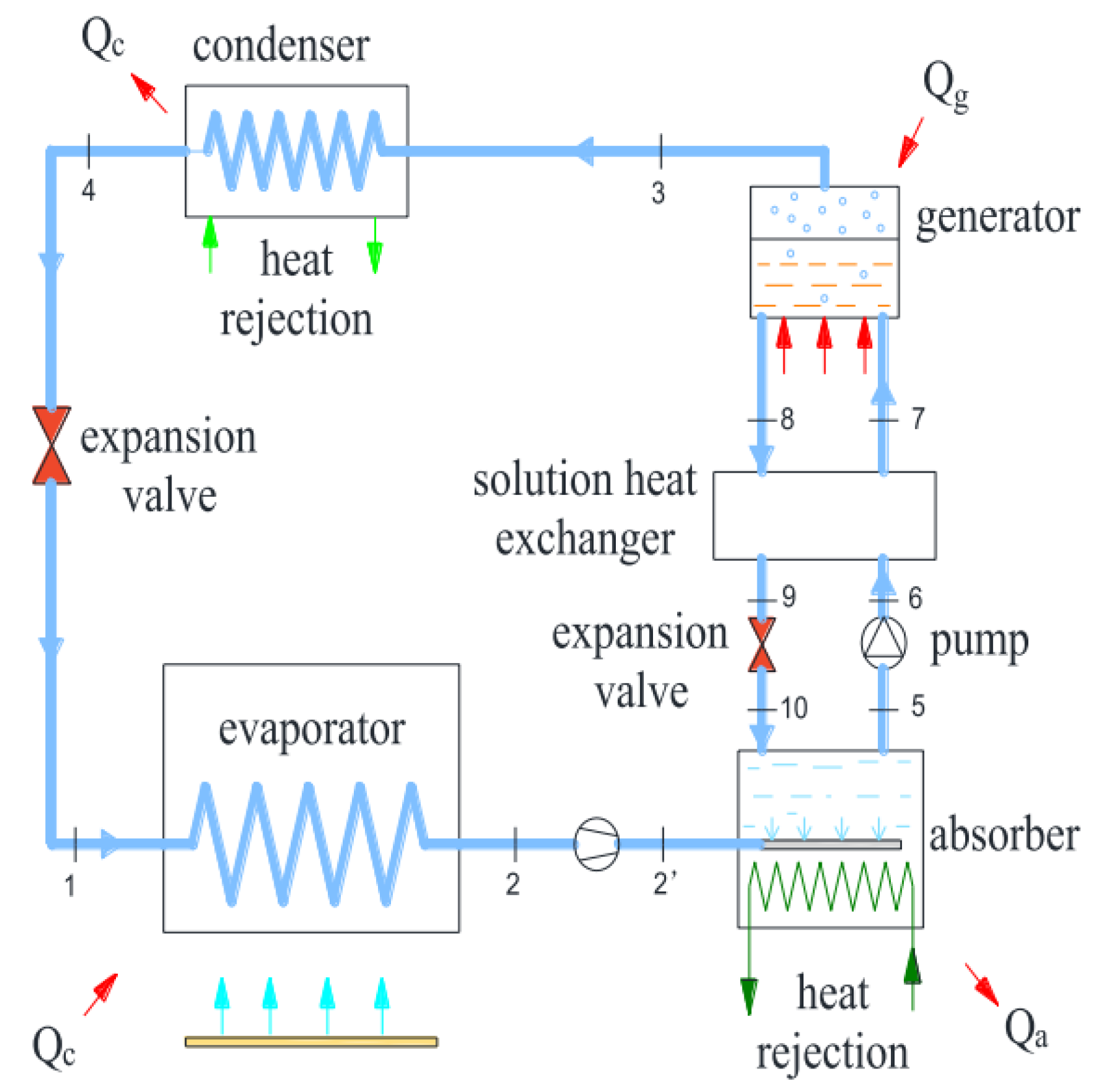

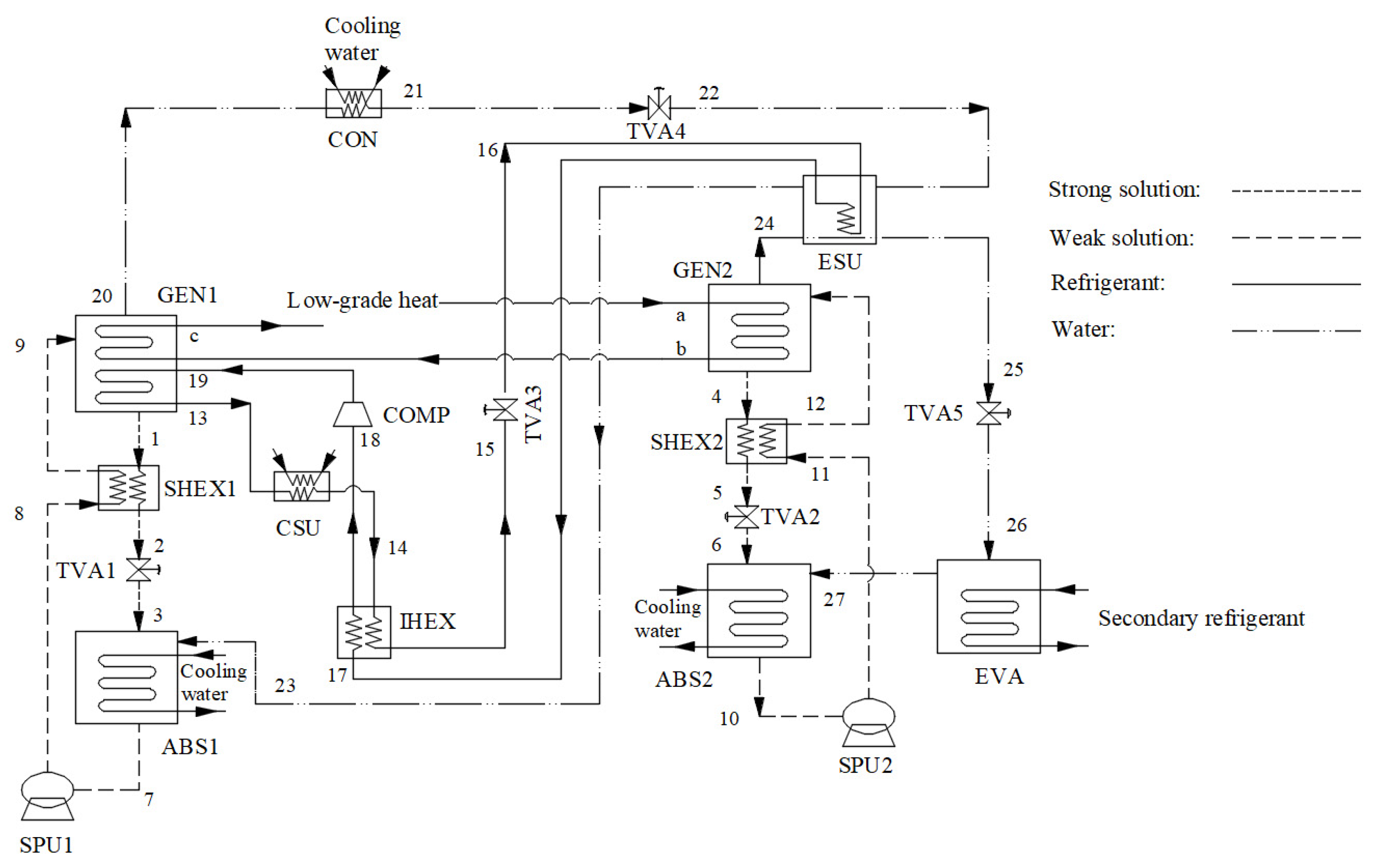

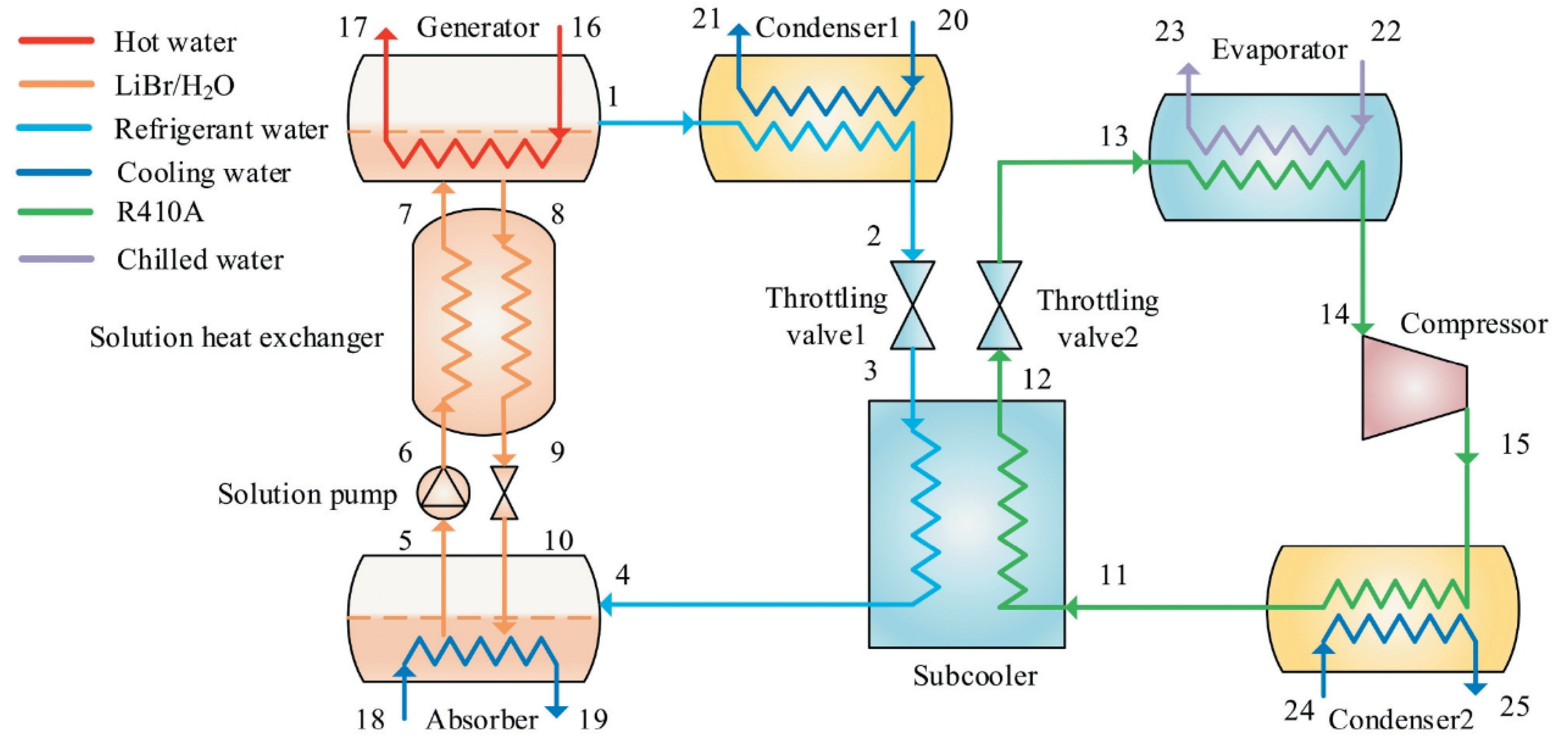

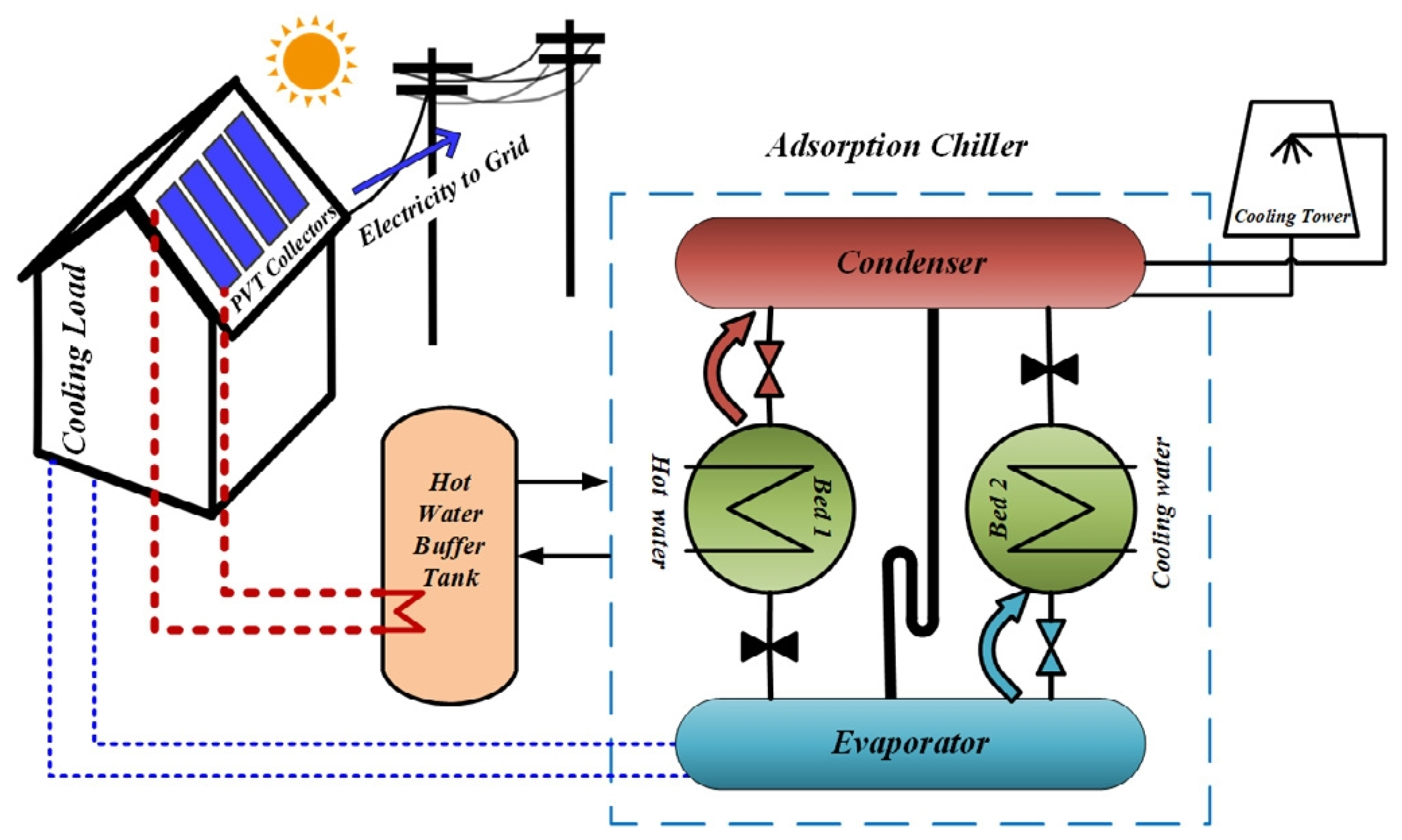

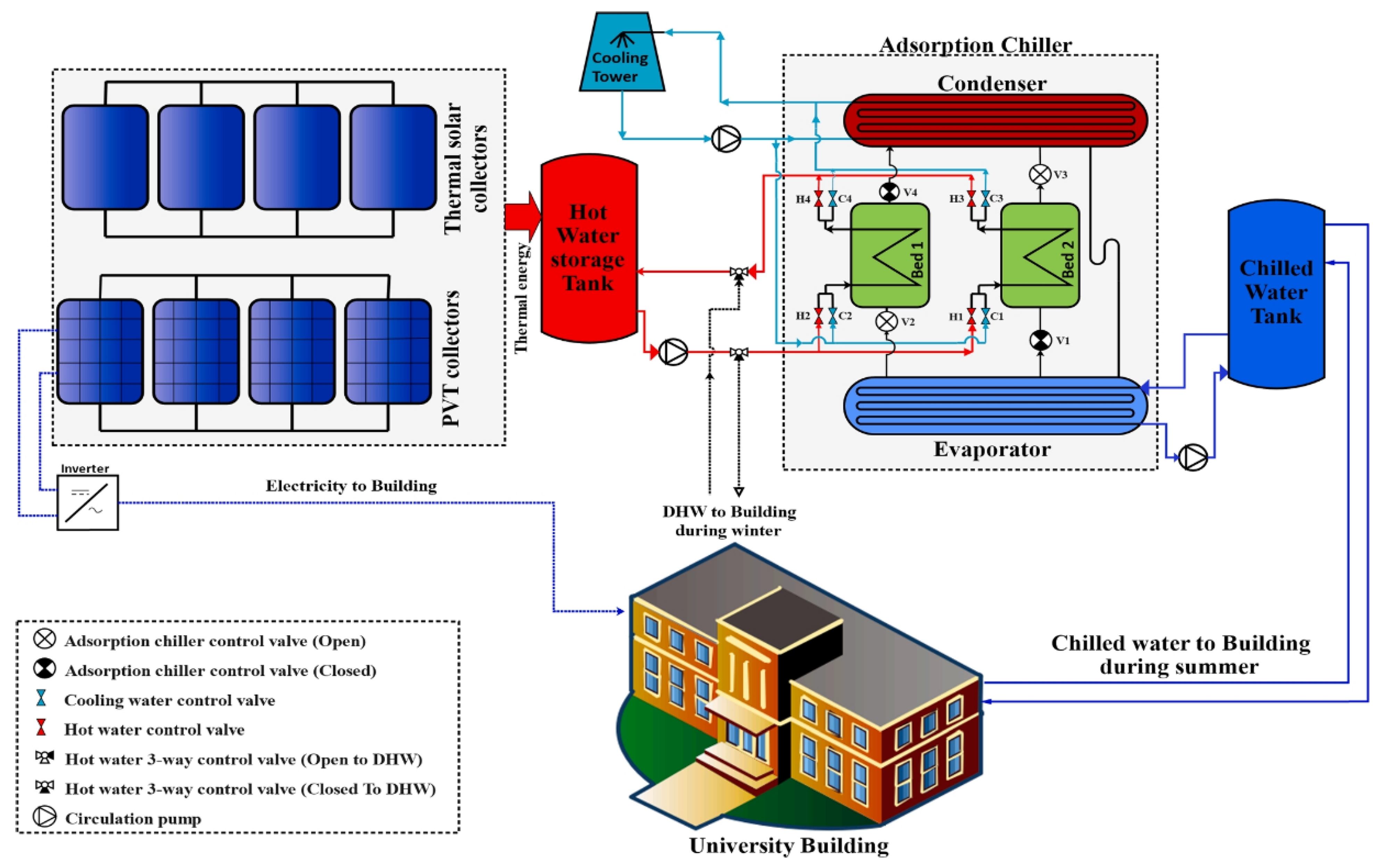

3. Thermally Driven Cooling Systems Utilizing Low Temperature Heat Sources

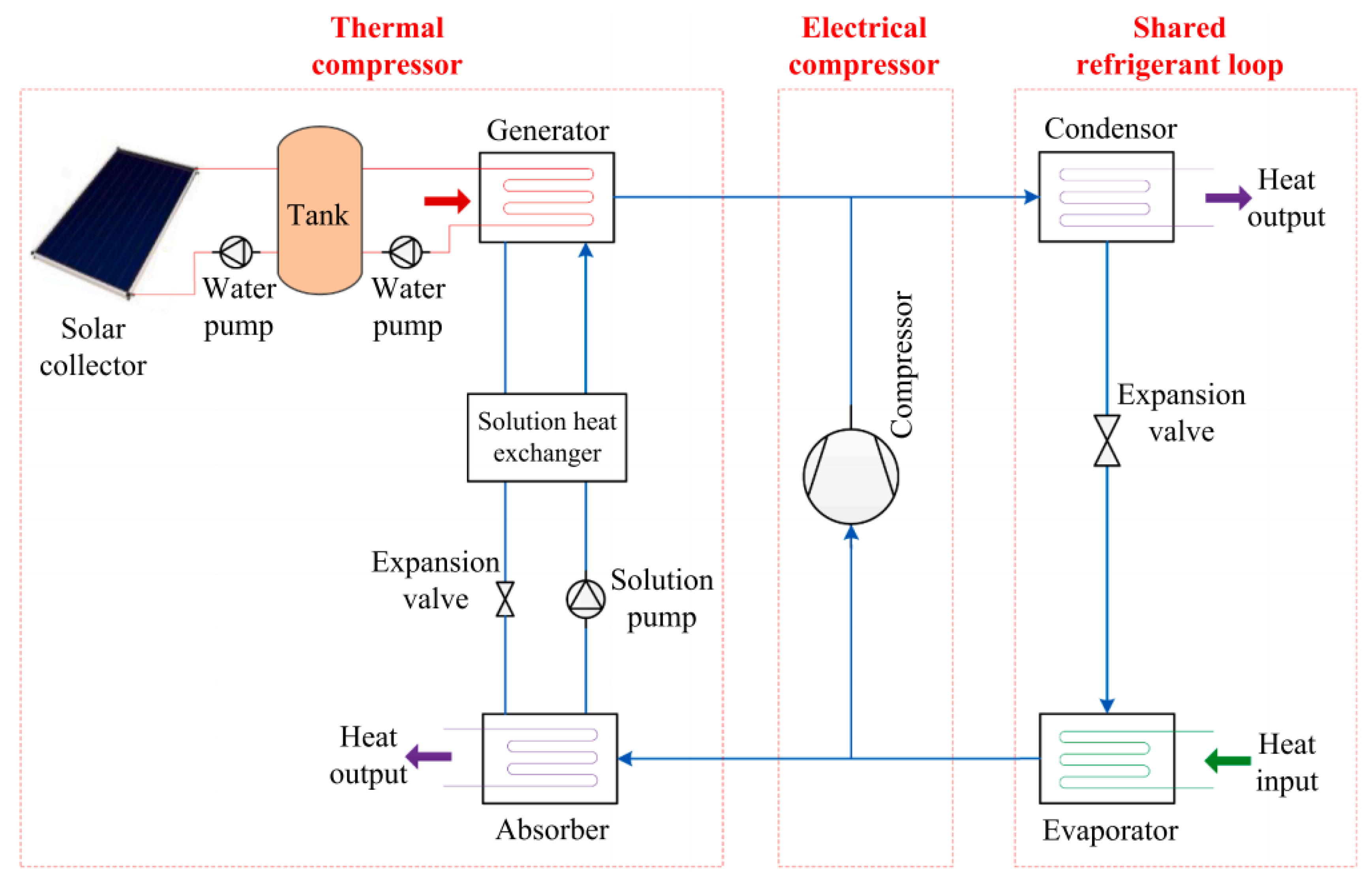

4. Solar Cooling Systems Driven by Photovoltaic–Thermal Collectors

5. Primary Concerns and Challenges

5.1. Photovoltaic–Thermal Collectors

5.1.1. Photovoltaic–Thermal Collectors with Innovative Heat Exchange Structure

5.1.2. Photovoltaic–Thermal Collectors with Nanofluids

5.2. Thermally Driven Cooling Systems Utilizing Low-Temperature Heat Sources

5.3. Solar Cooling Systems Driven by Photovoltaic–Thermal Collectors

6. Recommendations and Future Outlook

- Since electrical energy is a high-grade energy source and the energy output of PVT collectors is primarily determined by PV generation, the goal of PVT collector modifications should be to increase the thermal energy output as much as possible while not sacrificing electrical energy output. Additionally, when the PVT collector is employed to drive a thermally driven cooling system, the performance improvement in the modified PVT collectors for the overall cooling system is ultimately reflected in the electrical energy savings.

- Since the solar cooling layout driven by PVT collectors usually serves as the distributed system and the collector installation area is limited by building roof size, the cooling demand is inevitably met with the aid of the power grid. Thereby, the combination of the heat-driven process and the vapor compression one in the entire cycle is necessary. In this regard, the mass and energy coupling of the heat-driven process and the vapor compression one is beneficial to reduce the complexity of thermally driven hybrid chillers. Taking into account the coordination of the PV and thermal efficiencies, the heat source’s working temperature of the refrigeration cycle must come down to below 60 °C. Furthermore, the refrigeration cycle with the flexible allocation of heat consumption in a certain cooling demand is favorable from the economic viewpoint, e.g., through the time-of-use electricity price, to enhance the profitability.

- There is an urgent need to develop the prototype and exactly analyze the operation characteristic by means of experiment. The system design and operation optimization should be carried out based on the experiment data. Additionally, the cost of PVT collectors should be considered exactly in the assessment of system potential in order to avoid overestimation.

7. Conclusions

- The utilization of a coolant with high thermal conductivity and the proposed heat sink structure resulted in a more uniform temperature distribution of the PVT collector and the maintenance of a stable electrical energy conversion efficiency, with a thermal efficiency improvement of 12.2–68.5%. Although certain designs lead to an increase in pressure drop, this does not have a large impact on the electrical efficiency of the PVT collector in the range of operating conditions studied.

- The hybrid nanofluid used, due to its higher thermal conductivity, can transfer heat from the PV module more efficiently, which helps the PVT to achieve higher electrical and thermal outputs. In the reviewed literature, PVT systems with nanofluids have displayed improvements in electrical efficiency of 1.9–11% and thermal efficiency by 1.9–22.02%, compared to conventional PV systems and water-based PVT systems, respectively.

- The lower limit of the driving temperature of the novel thermally driven cooling system has been extended by 4–20 °C, depending on the type of thermally driven cooling system under study, which was mainly achieved using thermal and mechanical two-stage compression or cascade cooling. Here, the lower limit of the driving temperature of the adsorption cycle was extended by 20 °C, reaching 40–50 °C. In contrast, the lower limit of the driving temperature of the absorption cycle was extended by 4 °C, reaching 70 °C.

- Solar cooling systems are mainly PVT-driven adsorption cooling systems and PVT-driven absorption systems. The adsorptive system driven by PVT collectors has a maximum power production of 81.7 kWh per day, a maximum COP of 2.1, and a minimum payback period of 8.45 years. The absorption system driven by the PVT system, on the other hand, achieves a better cooling performance, with a maximum COP of 0.615 and annual electricity cost savings of CNY 109,080, and with a minimum payback period of 9.3 years.

- The improved economic features and adaptability to solar radiation of absorption–subcooled compression cooling systems make their further development in solar cooling systems more promising.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sur, A.; Das, R.K. Review on solar adsorption refrigeration cycle. Int. J. Mech. Eng. Technol. 2010, 1, 190–226. [Google Scholar]

- Ritchie, H.; Roser, M.; Rosado, P. Energy. Available online: https://ourworldindata.org/energy (accessed on 1 March 2022).

- Browne, M.C.; Norton, B.; McCormack, S.J. Heat retention of a photovoltaic/thermal collector with PCM. Sol. Energy 2016, 133, 533–548. [Google Scholar] [CrossRef] [Green Version]

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Singh, I.; Singh, D.; Singh, M. Thermal Modeling and Performance Evaluation of Photovoltaic Thermal (PV/T) Systems: A Parametric Study. Int. J. Green Energy 2019, 16, 483–489. [Google Scholar] [CrossRef]

- Hocine, H.; Touafek, K.; Kerrour, F. Theoretical and experimental study of new configuration of PVT collector. J. Sol. Energy Eng. 2016, 139, 021012. [Google Scholar] [CrossRef]

- Beccali, M.; Finocchiaro, P.; Nocke, B. Energy and economic assessment of desiccant cooling systems coupled with single glazed air and hybrid PV/thermal solar collectors for applications in hot and humid climate. Sol. Energy 2009, 83, 1828–1846. [Google Scholar] [CrossRef]

- Calise, F.; d’Accadia, M.D.; Vanoli, L. Design and dynamic simulation of a novel solar trigeneration system based on hybrid photovoltaic/thermal collectors (PVT). Energy Convers. Manag. 2012, 60, 214–225. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Palombo, A. Solar heating and cooling systems by absorption and adsorption chillers driven by stationary and concentrating photovoltaic/thermal solar collectors: Modelling and simulation. Renew. Sustain. Energy Rev. 2018, 81, 1112–1146. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.A.; Kazem, H.A.; Chaichan, M.T.; Sopian, K. The Impact of Climatic Conditions on PV/PVT Outcomes. In Photovoltaic/Thermal (PV/T) Systems: Principles, Design, and Applications; Springer International Publishing: Cham, Switzerland, 2019; pp. 173–222. [Google Scholar]

- Boumaaraf, B.; Boumaaraf, H.; Slimani, M.E.-A.; Tchoketch-Kebir, S.; Ait-Cheikh, M.S.; Touafek, K. Performance evaluation of a locally modified PV module to a PV/T solar collector under climatic conditions of semi-arid region. Math. Comput. Simul. 2020, 167, 135–154. [Google Scholar] [CrossRef]

- Ma, X.; Qiu, T.; Lv, J.; Shi, Q.; Meng, D. Performance investigation of an iron scrap filled tube-plate PV/T system. Energy Sustain. Dev. 2020, 58, 196–208. [Google Scholar] [CrossRef]

- Kazem, H.A.; Al-Waeli, A.H.A.; Chaichan, M.T.; Al-Waeli, K.H.; Al-Aasam, A.B.; Sopian, K. Evaluation and comparison of different flow configurations PVT systems in Oman: A numerical and experimental investigation. Sol. Energy 2020, 208, 58–88. [Google Scholar] [CrossRef]

- Misha, S.; Abdullah, A.L.; Tamaldin, N.; Rosli, M.A.M.; Sachit, F.A. Simulation CFD and experimental investigation of PVT water system under natural Malaysian weather conditions. Energy Rep. 2020, 6, 28–44. [Google Scholar] [CrossRef]

- Kianifard, S.; Zamen, M.; Nejad, A.A. Modeling, designing and fabrication of a novel PV/T cooling system using half pipe. J. Clean. Prod. 2020, 253, 119972. [Google Scholar] [CrossRef]

- Hissouf, M.; Feddaoui, M.; Najim, M.; Charef, A. Performance of a photovoltaic–thermal solar collector using two types of working fluids at different fluid channels geometry. Renew. Energy 2020, 162, 1723–1734. [Google Scholar] [CrossRef]

- Poredos, P.; Tomc, U.; Petelin, N.; Vidrih, B.; Flisar, U.; Kitanovski, A. Numerical and experimental investigation of the energy and exergy performance of solar thermal, photovoltaic and photovoltaic–thermal modules based on roll-bond heat exchangers. Energy Convers. Manag. 2020, 210, 112674. [Google Scholar] [CrossRef]

- Pang, W.; Zhang, Y.; Duck, B.C.; Yu, H.; Song, X.; Yan, H. Cross sectional geometries effect on the energy efficiency of a photovoltaic thermal module: Numerical simulation and experimental validation. Energy 2020, 209, 118439. [Google Scholar] [CrossRef]

- Shahsavar, A.; Jha, P.; Arici, M.; Nizetic, S.; Ma, Z. Energetic and exergetic performances of a nanofluid-based photovoltaic/thermal system equipped with a sheet-and-grooved serpentine tube collector: Indoor experimental tests. Sol. Energy 2021, 225, 918–933. [Google Scholar] [CrossRef]

- Ramdani, H.; Ould-Lahoucine, C. Study on the overall energy and exergy performances of a novel water-based hybrid photovoltaic–thermal solar collector. Energy Convers. Manag. 2020, 222, 113238. [Google Scholar] [CrossRef]

- Maadi, S.R.; Sabzali, H.; Kolahan, A.; Wood, D. Improving the performance of PV/T systems by using conical-leaf inserts in the coolant tubes. Sol. Energy 2020, 212, 84–100. [Google Scholar] [CrossRef]

- Maadi, S.R.; Navegi, A.; Solomin, E.; Ahn, H.S.; Wongwises, S.; Mahian, O. Performance improvement of a photovoltaic–thermal system using a wavy-strip insert with and without nanofluid. Energy 2021, 234, 121190. [Google Scholar] [CrossRef]

- Kalateh, M.R.; Kianifar, A.; Sardarabadi, M. Energy, exergy, and entropy generation analyses of a water-based photovoltaic thermal system, equipped with clockwise counter-clockwise twisted tapes: An indoor experimental study. Appl. Therm. Eng. 2022, 215, 118906. [Google Scholar] [CrossRef]

- Ould-Lahoucine, C.; Ramdani, H.; Zied, D. Energy and exergy performances of a TiO2-water nanofluid-based hybrid photovoltaic/thermal collector and a proposed new method to determine the optimal height of the rectangular cooling channel. Sol. Energy 2021, 221, 292–306. [Google Scholar] [CrossRef]

- Menon, G.S.; Murali, S.; Elias, J.; Delfiya, D.A.; Alfiya, P.; Samuel, M.P. Experimental investigations on unglazed photovoltaic–thermal (PVT) system using water and nanofluid cooling medium. Renew. Energy 2022, 188, 986–996. [Google Scholar] [CrossRef]

- Shahsavar, A.; Jha, P.; Arici, M.; Kefayati, G. A comparative experimental investigation of energetic and exergetic performances of water/magnetite nanofluid-based photovoltaic/thermal system equipped with finned and unfinned collectors. Energy 2021, 220, 119714. [Google Scholar] [CrossRef]

- Hissouf, M.; Feddaoui, M.; Najim, M.; Charef, A. Numerical study of a covered Photovoltaic–thermal Collector (PVT) enhancement using nanofluids. Sol. Energy 2020, 199, 115–127. [Google Scholar] [CrossRef]

- Jia, Y.; Ran, F.; Zhu, C.; Fang, G. Numerical analysis of photovoltaic–thermal collector using nanofluid as a coolant. Sol. Energy 2020, 196, 625–636. [Google Scholar] [CrossRef]

- Alsalame, H.A.M.; Lee, J.H.; Lee, G.H. Performance Evaluation of a Photovoltaic Thermal (PVT) system using nanofluids. Energies 2021, 14, 301. [Google Scholar] [CrossRef]

- Moravej, M.; Noghrehabadi, A.; Esmaeilinasab, A.; Khajehpour, E. The effect of SiO2 nanoparticle on the performance of photovoltaic thermal system: Experimental and Theoretical approach. J. Heat Mass Transf. Res. 2020, 7, 11–24. [Google Scholar]

- Gelis, K.; Celik, A.N.; Ozbek, K.; Ozyurt, O. Experimental investigation into efficiency of SiO2/water-based nanofluids in photovoltaic thermal systems using response surface methodology. Sol. Energy 2022, 235, 229–241. [Google Scholar] [CrossRef]

- Sreekumar, S.; Shah, N.; Mondol, J.D.; Hewitt, N.; Chakrabarti, S. Numerical investigation and feasibility study on MXene/water nanofluid based photovoltaic/thermal system. Clean. Energy Syst. 2022, 2, 100010. [Google Scholar] [CrossRef]

- Rahmanian, S.; Hamzavi, A. Effects of pump power on performance analysis of photovoltaic thermal system using CNT nanofluid. Sol. Energy 2020, 201, 787–797. [Google Scholar] [CrossRef]

- Karaaslan, I.; Menlik, T. Numerical study of a photovoltaic thermal (PV/T) system using mono and hybrid nanofluid. Sol. Energy 2021, 224, 1260–1270. [Google Scholar] [CrossRef]

- Hooshmandzade, N.; Motevali, A.; Seyedi, S.R.M.; Biparva, P. Influence of single and hybrid water-based nanofluids on performance of microgrid photovoltaic/thermal system. Appl. Energy 2021, 304, 117769. [Google Scholar] [CrossRef]

- Kazemian, A.; Salari, A.; Ma, T.; Lu, H. Application of hybrid nanofluids in a novel combined photovoltaic/thermal and solar collector system. Sol. Energy 2022, 239, 102–116. [Google Scholar] [CrossRef]

- Adun, H.; Adedeji, M.; Ruwa, T.; Senol, M.; Kavaz, D.; Dagbasi, M. Energy, exergy, economic, environmental (4E) approach to assessing the performance of a photovoltaic–thermal system using a novel ternary nanofluid. Sustain. Energy Technol. Assess. 2022, 50, 101804. [Google Scholar] [CrossRef]

- Rubbi, F.; Habib, K.; Saidur, R.; Aslfattahi, N.; Yahya, S.M.; Das, L. Performance optimization of a hybrid PV/T solar system using Soybean oil/MXene nanofluids as a new class of heat transfer fluids. Sol. Energy 2020, 208, 124–138. [Google Scholar] [CrossRef]

- Samylingam, L.; Aslfattahi, N.; Saidur, R.; Yahya, S.M.; Afzal, A.; Arifutzzaman, A.; Tan, K.H.; Kadirgama, K. Thermal and energy performance improvement of hybrid PV/T system by using olein palm oil with MXene as a new class of heat transfer fluid. Sol. Energy Mater. Sol. Cells 2020, 218, 110754. [Google Scholar] [CrossRef]

- Wu, W.; Leung, M.; Ding, Z.; Huang, H.; Bai, Y.; Deng, L. Comparative analysis of conventional and low-GWP refrigerants with ionic liquid used for compression-assisted absorption cooling cycles. Appl. Therm. Eng. 2020, 172, 115145. [Google Scholar] [CrossRef]

- Wu, W.; Leung, M. Transient and seasonal performance evaluation of a novel flexible heat pump for solar cooling. Energy Convers. Manag. 2020, 223, 113269. [Google Scholar] [CrossRef]

- Sun, Y.; Di, G.; Wang, J.; Wang, X.; Wu, W. Performance analysis of R1234yf/ionic liquid working fluids for single-effect and compression-assisted absorption refrigeration systems. Int. J. Refrig. 2020, 109, 25–36. [Google Scholar] [CrossRef]

- He, Y.; Jiang, Y.; Fan, Y.; Chen, G.; Tang, L. Utilization of ultra-low temperature heat by a novel cascade refrigeration system with environmentally-friendly refrigerants. Renew. Energy 2020, 157, 204–213. [Google Scholar] [CrossRef]

- Nikbakhti, R.; Wang, X.; Chan, A. Performance optimization of an integrated adsorption-absorption cooling system driven by low-grade thermal energy. Appl. Therm. Eng. 2021, 193, 117035. [Google Scholar] [CrossRef]

- Nikbakhti, R.; Iranmanesh, A. Potential application of a novel integrated adsorption–absorption refrigeration system powered with solar energy in Australia. Appl. Therm. Eng. 2021, 194, 117114. [Google Scholar] [CrossRef]

- Zeng, J.; Li, Z.; Peng, Z. Advanced exergy analysis of solar absorption-subcooled compression hybrid cooling system. Int. J. Green Energy 2022, 19, 219–241. [Google Scholar] [CrossRef]

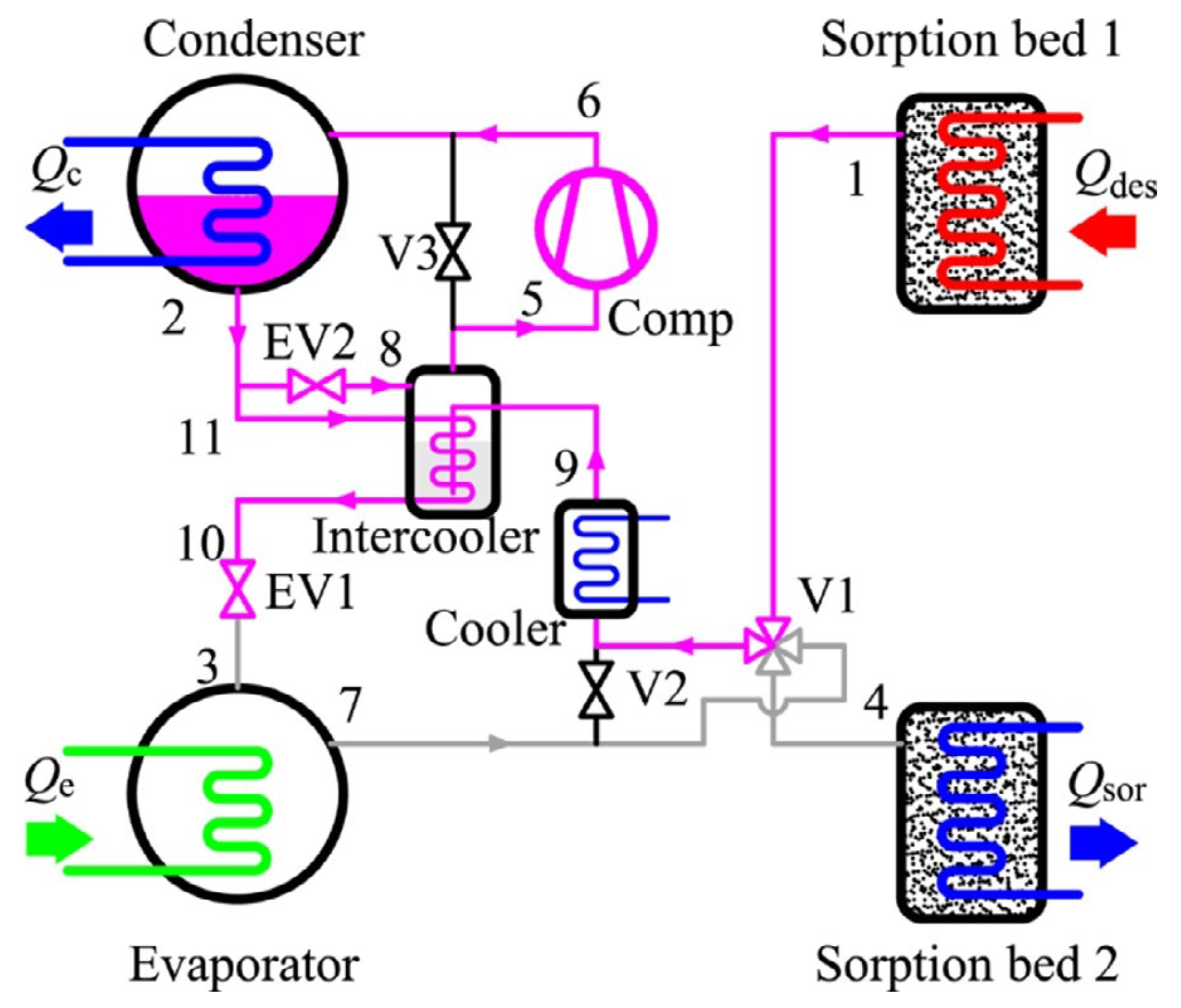

- Gao, P.; Wang, L.; Zhu, F. A novel hybrid solid sorption-compression refrigeration technology for refrigerated transportation and storage. Int. J. Refrig. 2021, 122, 1–10. [Google Scholar] [CrossRef]

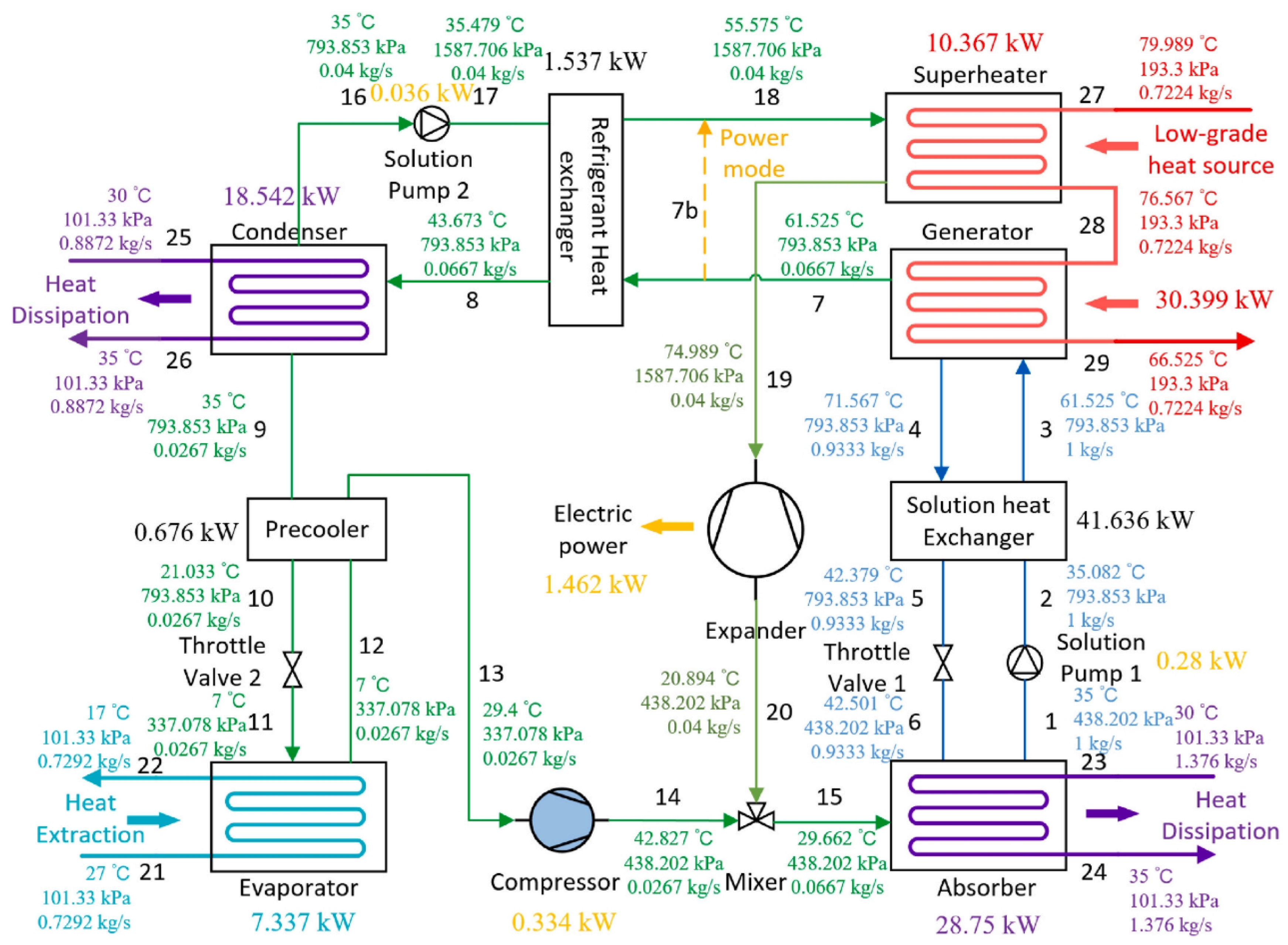

- Zhang, X.; Cai, L.; Chen, T.; Zhang, X. Performance analysis of a novel compression-assisted absorption power and refrigeration system with selected 1, 1-difluoroethane/ionic liquid. J. Clean. Prod. 2022, 340, 130856. [Google Scholar] [CrossRef]

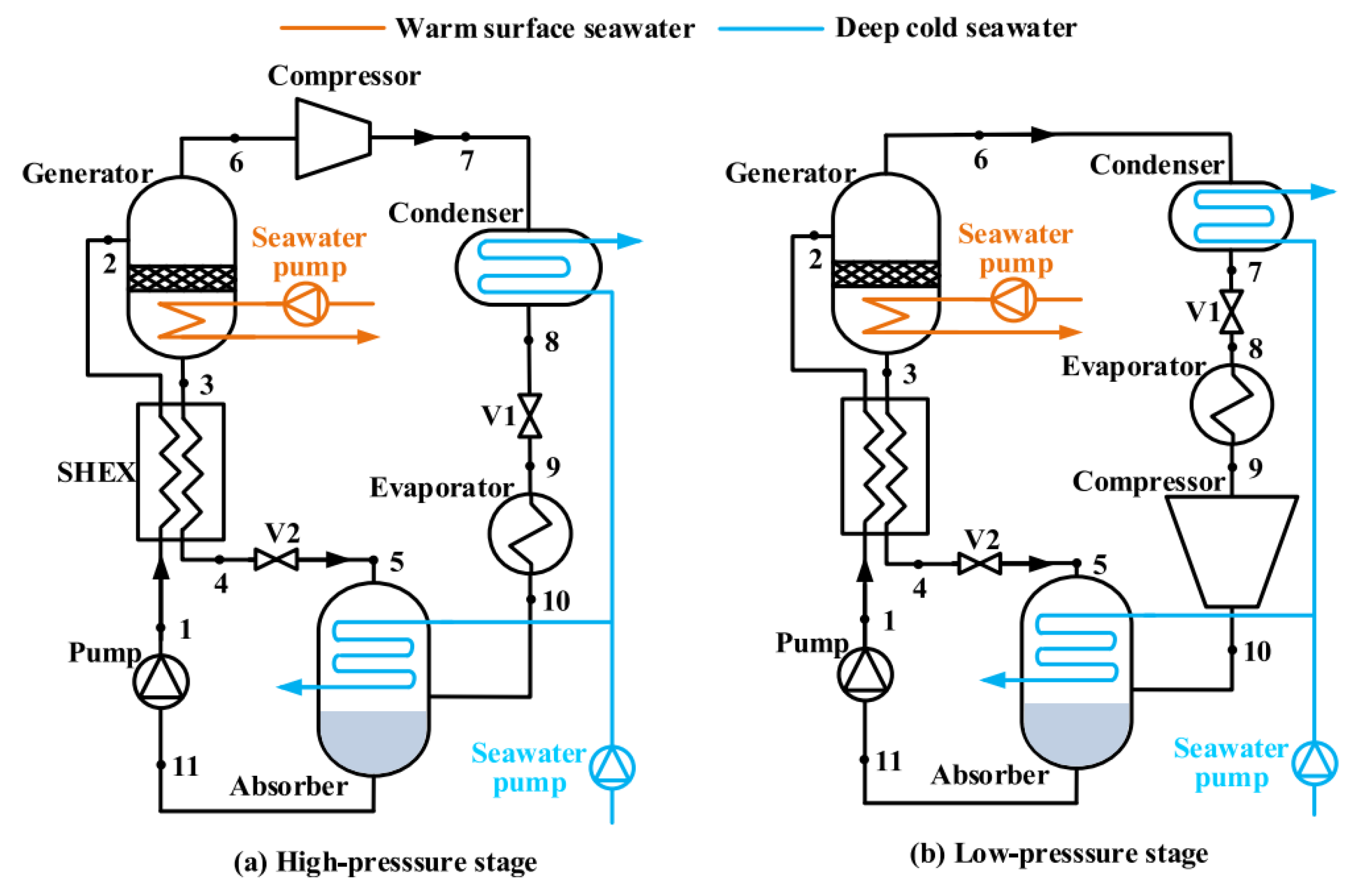

- Hu, Z.; Wan, Y.; Zhang, C.; Chen, Y. Compression-assisted absorption refrigeration using ocean thermal energy. Renew. Energy 2022, 186, 755–768. [Google Scholar] [CrossRef]

- Huang, C.; Li, Z.; Ye, Z.; Wang, R. Thermodynamic study of carbon dioxide transcritical refrigeration cycle with dedicated subcooling and cascade recooling. Int. J. Refrig. 2022, 137, 80–90. [Google Scholar] [CrossRef]

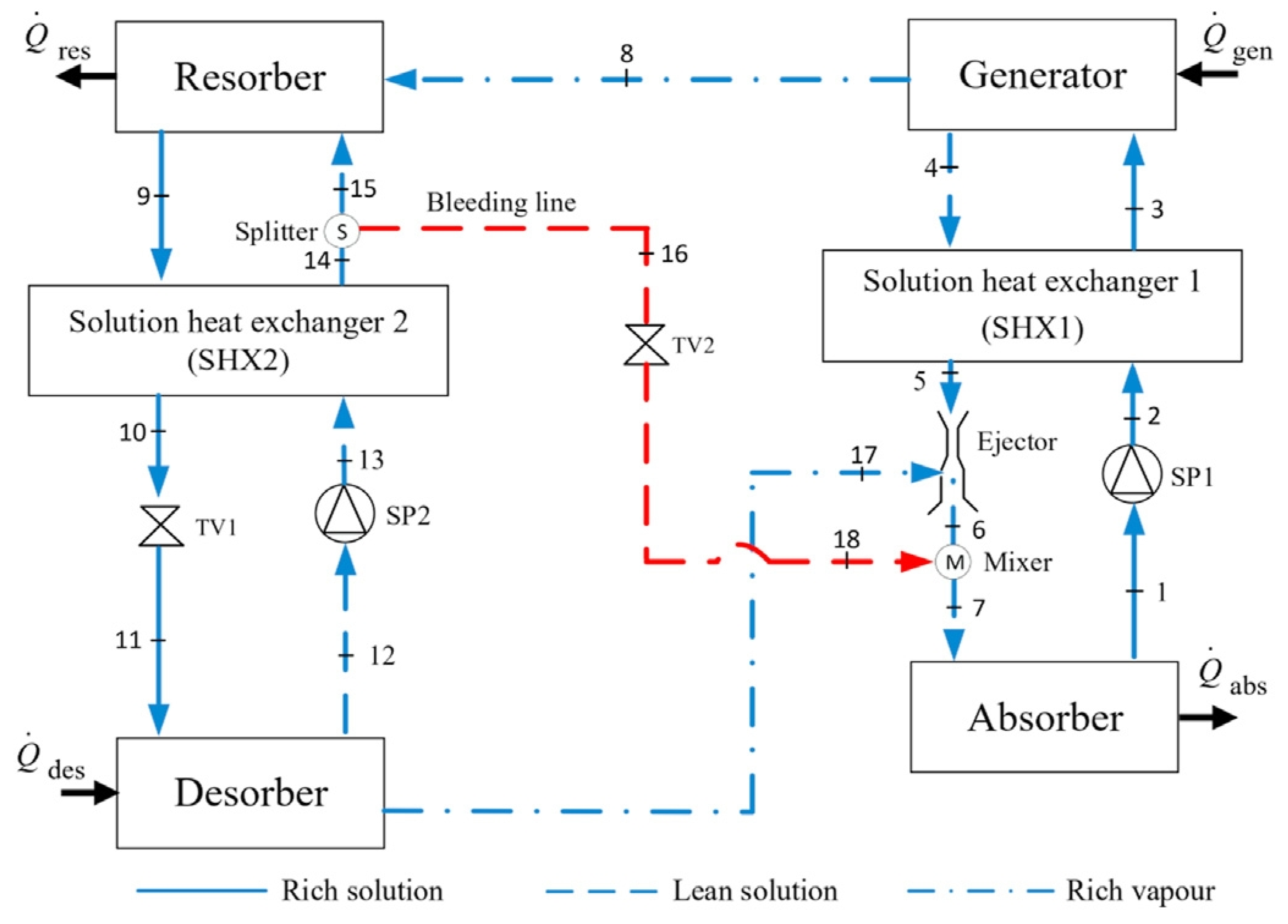

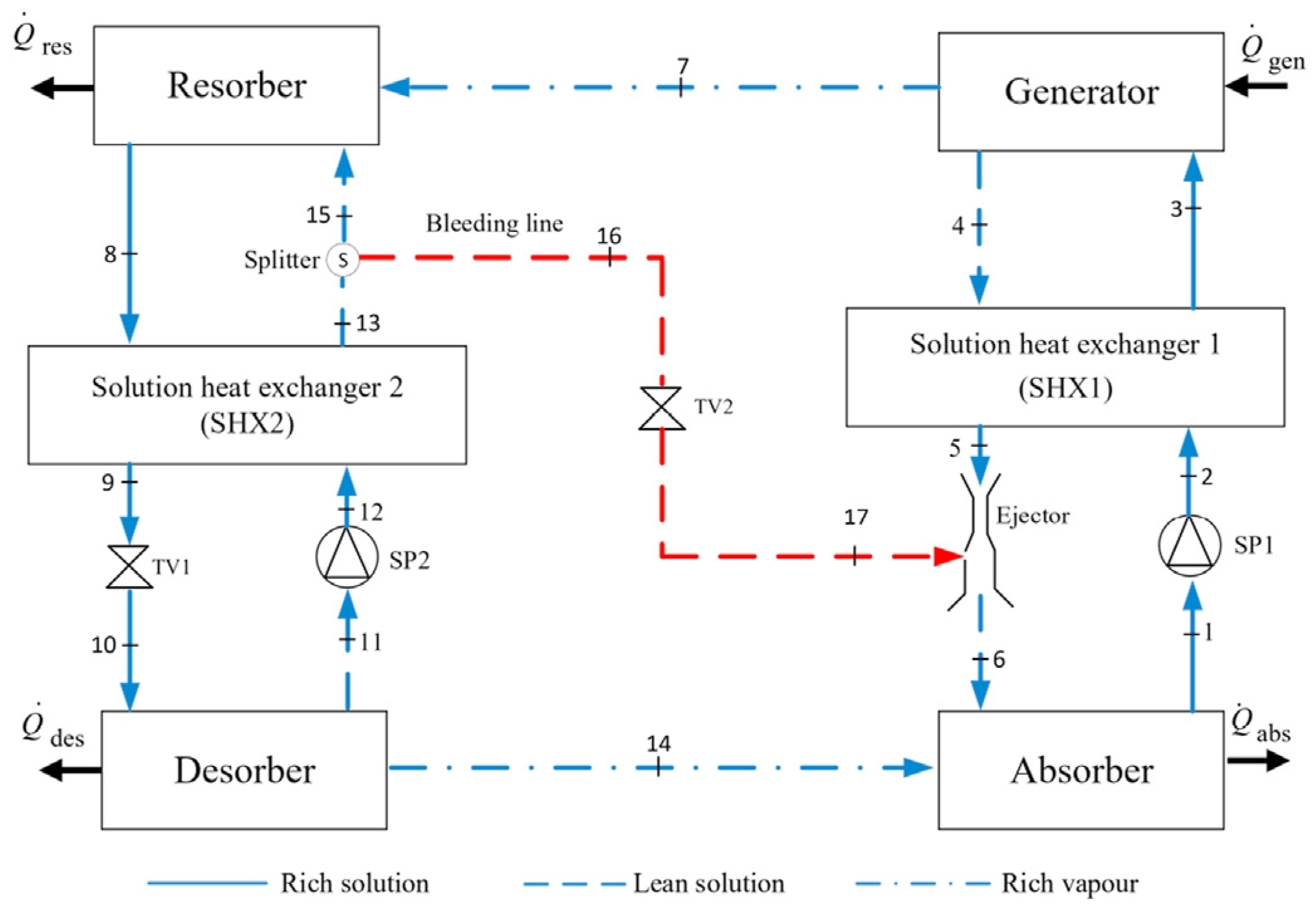

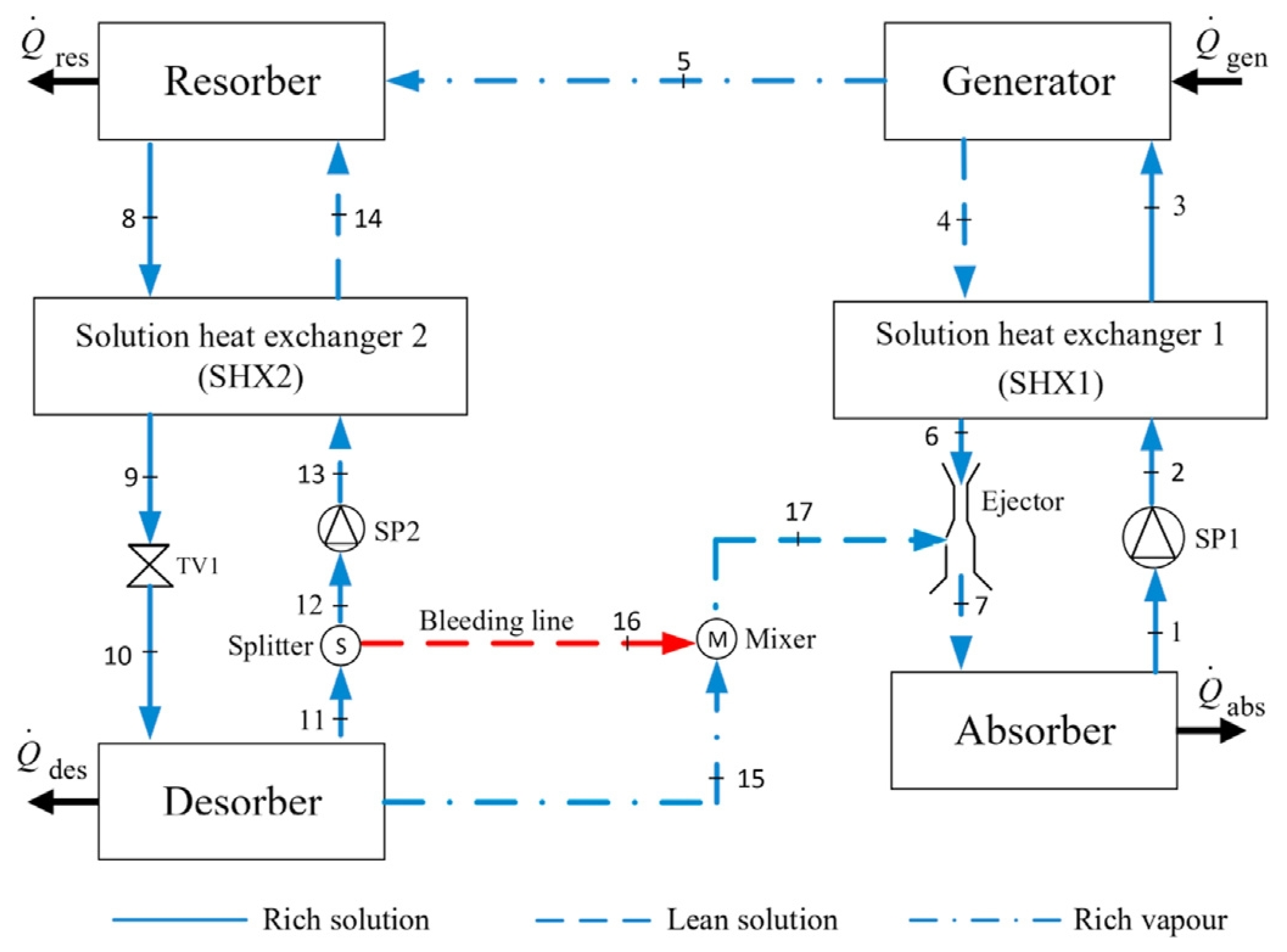

- Kumar, A.; Modi, A. Thermodynamic analysis of novel ejector-assisted vapour absorption-resorption refrigeration systems. Energy 2022, 244, 123154. [Google Scholar] [CrossRef]

- Hassan, A.A.; Elwardany, A.E.; Ookawara, S.; El-Sharkawy, I.I. Performance investigation of integrated PVT/adsorption cooling system under the climate conditions of Middle East. Energy Rep. 2020, 6, 168–173. [Google Scholar] [CrossRef]

- Hassan, A.A.; Elwardany, A.E.; Ookawara, S.; El-Sharkawy, I.I. Performance investigation of a solar-powered adsorption-based trigeneration system for cooling, electricity, and domestic hot water production. Appl. Therm. Eng. 2021, 199, 117553. [Google Scholar] [CrossRef]

- Hassan, A.A.; Elwardany, A.E.; Ookawara, S.; Sekiguchi, H.; Hassan, H. Energy, exergy, economic and environmental (4E) assessment of hybrid solar system powering adsorption-parallel/series ORC multigeneration system. Process Saf. Environ. Prot. 2022, 164, 761–780. [Google Scholar] [CrossRef]

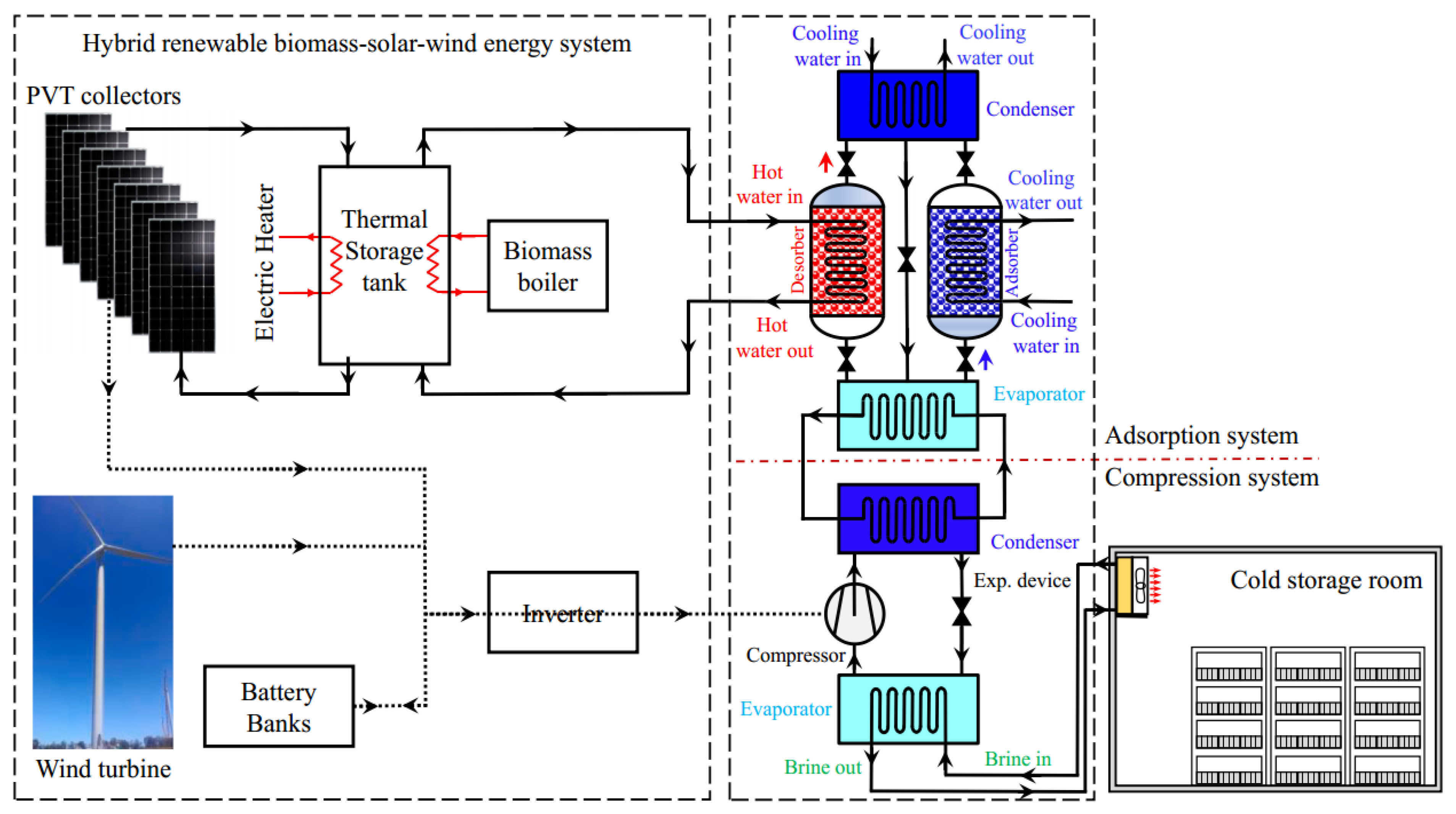

- Gado, M.G.; Nada, S.; Ookawara, S.; Hassan, H. Energy management of standalone cascaded adsorption-compression refrigeration system using hybrid biomass-solar-wind energies. Energy Convers. Manag. 2022, 258, 115387. [Google Scholar] [CrossRef]

- Gado, M.G.; Ookawara, S.; Nada, S.; Hassan, H. Renewable energy-based cascade adsorption-compression refrigeration system: Energy, exergy, exergoeconomic and enviroeconomic perspectives. Energy 2022, 253, 124127. [Google Scholar] [CrossRef]

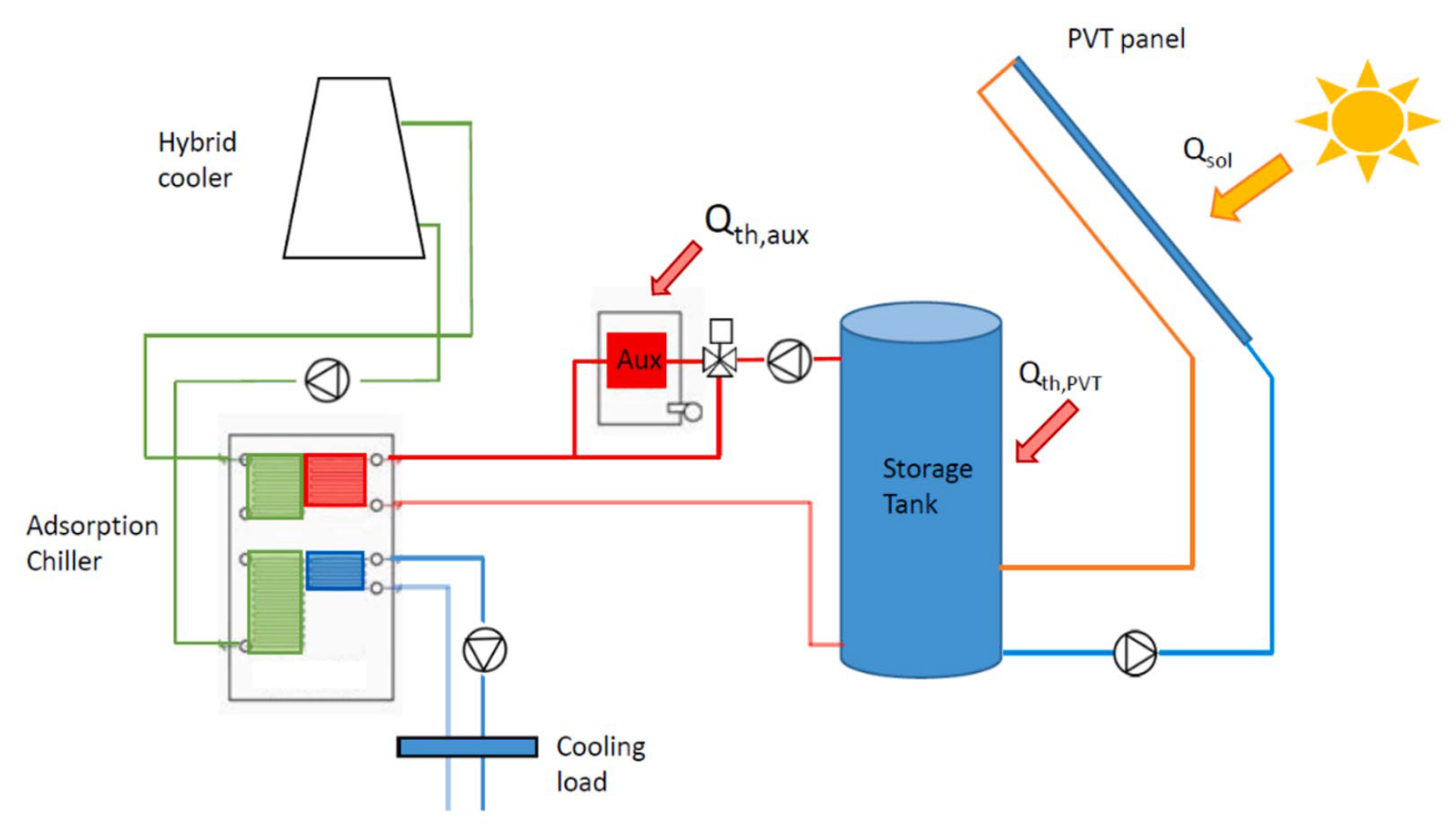

- Aneli, S.; Gagliano, A.; Tina, G.M.; Ilis, G.G.; Demir, H. Effectiveness and constraints of using PV/Thermal collectors for heat-driven chillers. Appl. Therm. Eng. 2022, 210, 118330. [Google Scholar] [CrossRef]

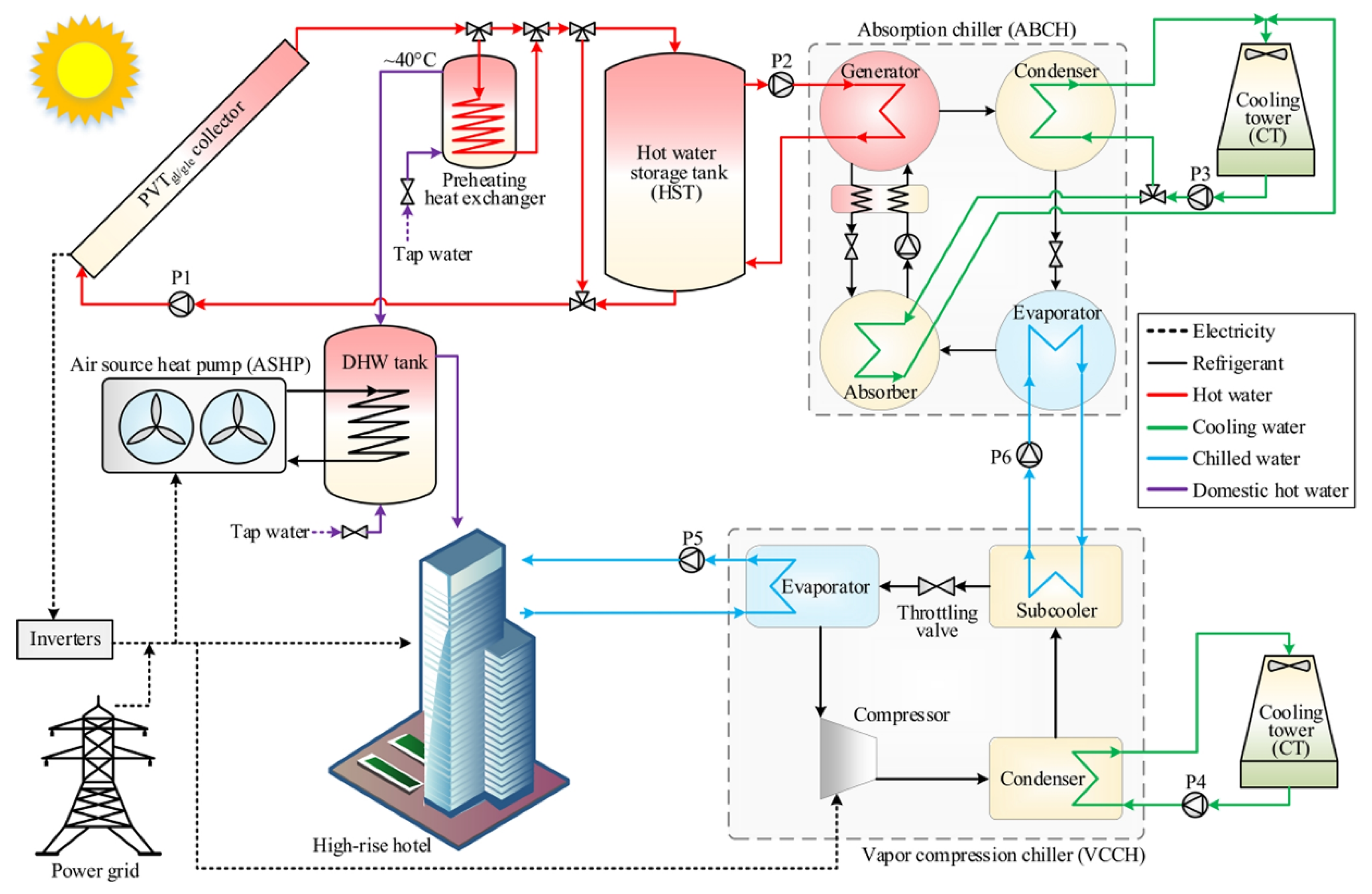

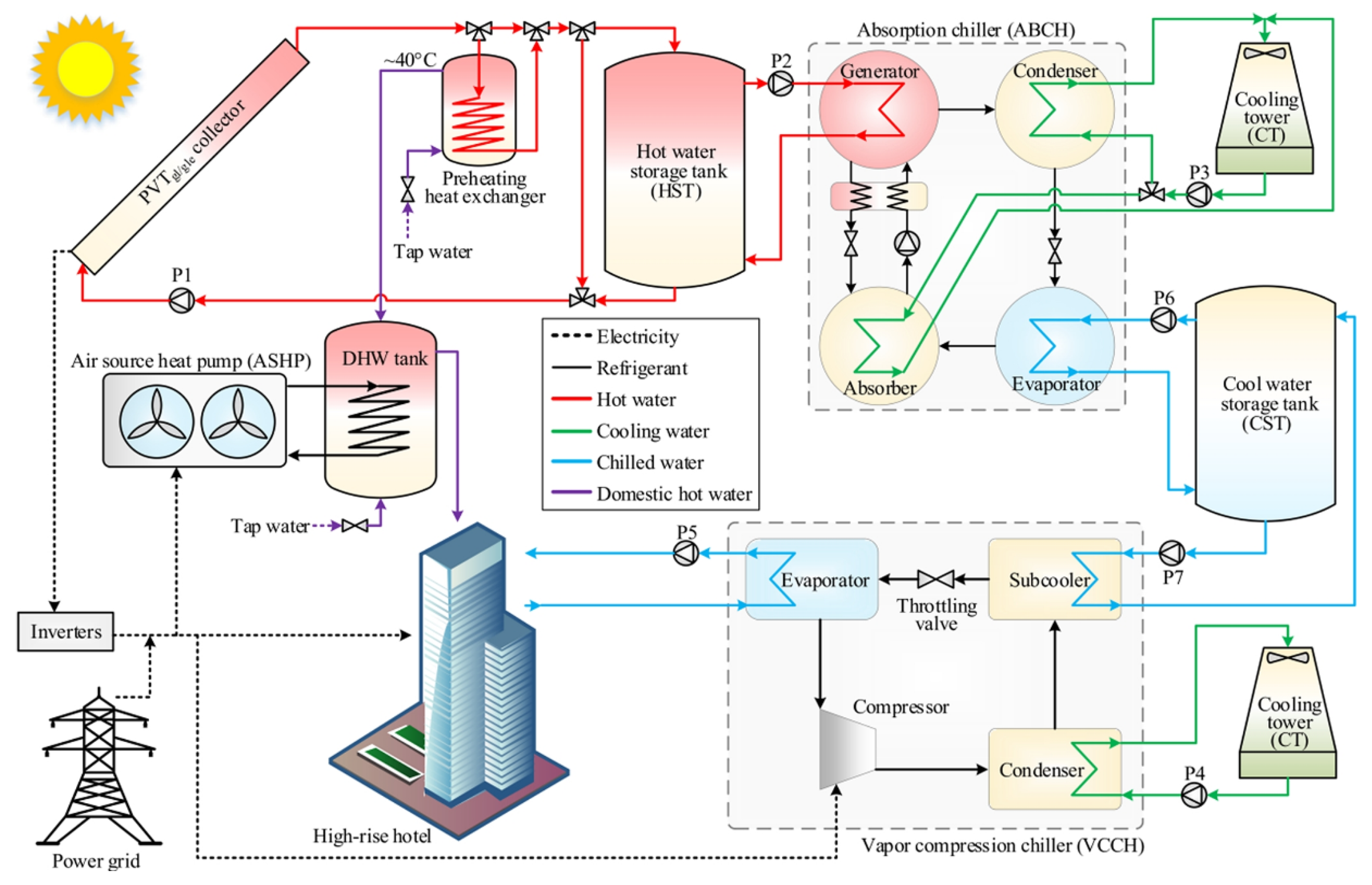

- Li, Z.; Chen, H.; Xu, Y.; Ooi, K.T. Comprehensive evaluation of low-grade solar trigeneration system by photovoltaic-thermal collectors. Energy Convers. Manag. 2020, 215, 112895. [Google Scholar] [CrossRef]

- Chen, H.; Li, Z.; Xu, Y. Assessment and parametric analysis of solar trigeneration system integrating photovoltaic thermal collectors with thermal energy storage under time-of-use electricity pricing. Sol. Energy 2020, 206, 875–899. [Google Scholar] [CrossRef]

| Ref. | N/E | Flow Channel Type | Cross-Sectional Shape/Insert Type | Efficiency | Working Fluid | Flow Rate | Key Findings | ||

|---|---|---|---|---|---|---|---|---|---|

| Electrical | Thermal | Total | |||||||

| [11] | N | Serpentine | Circle | 7% | 61% | 79.43% | Water | - |

|

| [12] | N | Sheet-and-plain | Circle | 15.5% | 49.1% | - | Water | 240 L/h |

|

| [13] | N and E | Direct, Spiral, Web | Circle | 7.1% for direct-PVT, 8.5% for web-PVT, 9.1% for spiral-PVT | 9.8% for direct-PVT, 19.4% for web-PVT, 26% for spiral-PVT | - | Water | 40 kg/h |

|

| [14] | N and E | A new dual oscillating | Circle | 11.71% | 59.6% | - | Water | 2–6 L/min |

|

| [15] | N | Serpentine | Half-circle | 12.6% | 71% | - | Water | 0.5–4 L/min |

|

| [16] | N | Sheet-and-plain | Circle, half-circle and square | - | - | - | Water, Ethanol–water | 0–0.06 kg/s |

|

| [17] | N and E | Serial, parallel and bionic. | Roll-bond | 14.5% | 33.5% | - | Water | 0.5, 0.25, 0.125, 0.0625 m/s |

|

| [18] | N and E | Sheet-and-plain | Rectangle andarch | 16.03% for conventional PV, 16.98% for arch-PVT, 16.52% for rectangle-PVT | 39.81% for arch-PVT 35.39% for rectangle-PVT | 54.83% for arch-PVT 50.83% for rectangle-PVT | Water | 75 kg/(m2·h) |

|

| [19] | E | Serpentine | Grooved | 12.38% | 50.88% | 83.47% | Fe3O4–water | 10–40 kg/h |

|

| [20] | N | Channel | Rectangular | 11.7–12.3% | - | 0.87 | Water | 0.0003–0.0007 (m/s) |

|

| [21] | N | Sheet-and-plain | Conical-leaf inserts | 13.1–14.1% | 55.1–69.4% | - | Water | - |

|

| [22] | N | Sheet-and-plain | Wavy inserts | 12.86% | 65.95% | - | Al2O3–water | - |

|

| [23] | E | Sheet-and-plain | The twisted tapes (clockwise and counter-clockwise) | 12.51% | 67.49% | - | Water | 0.019–0.036 kg/s |

|

| Ref. | N/E | Flow Channel Type | Base Fluid | Nanoparticle Type | Nanoparticle Fraction | Particle Size (nm) | Flow Rate | Key Findings |

|---|---|---|---|---|---|---|---|---|

| [24] | N | Rectangular channel | Water | TiO2 | 0, 0.2, 4.127 wt. % | - | - |

|

| [25] | E | Serpentine | Water | CuO | 0.05 wt. % | <50 | 0.067 kg/s |

|

| [26] | E | Finned serpentine tube | Water | magnetite | 0–2 wt. % | 13 | 20–80 kg/h |

|

| [27] | N | Sheet and tubes | Water | Cu, Al2O3 | 2 vol% | 10 | 0–0.012 kg/s |

|

| [28] | N | Sheet and tubes | Water | TiO2, Al2O3 | 0, 3, 6 vol% | 21 | 0.0005, 0.001, 0.01, 0.03 kg/s |

|

| [29] | N and E | Sheet and tubes | Water | CuO, Al2O3 | 0.5 wt. % | - | 0.05 kg/s |

|

| [30] | N and E | Sheet and tubes | Water | SiO2 | 1, 3 wt. % | 11–14, 60–70 | 40, 50, 70 L/h |

|

| [31] | N and E | Cooler blocks | Water | SiO2 | 0.1, 0.2, 0.3 vol% | 13–23 | 0.55–1.65 L/min |

|

| [32] | N | Sheet and tubes | Water | MXene (Ti3C2) | 0.01, 0.1, 0.2 wt. % | - | 30–90 kg/h |

|

| [33] | N | Sheet and tubes | Water | Multiwalled carbon nanotube (CNT) | 0–0.1 vol% | 30 | 25–400 L/h |

|

| [34] | N | Serpentine | Water | CuO, CuO + Fe | 2 vol% | - | 0.02–0.08 m/s |

|

| [35] | E | Sheet and tubes | Water | SiO2, Al2O3, SiO2 + Al2O3 | 0.1–0.5 wt. % | - | 3 L/min |

|

| [36] | N | Sheet and tubes | Water | MWCNT-Al2O3, MWCNT-SiC, Gr-Al2O3,Gr-SiC | 2 vol% | - | 30–70 kg/h |

|

| [37] | N | Sheet and tubes | Water | Al2O3 + ZnO + Fe3O4 | 0.4–1.3 vol% | Average of 90 | 0.008–0.1 kg/s |

|

| [38] | N | Serpentine | Soybean oil | MXene (Ti3C2) | 0.025–0.125 wt. % | Lateral size of 1–10 µm, thickness 1 nm | 0.01–0.07 kg/s |

|

| [39] | N | Serpentine | Olein palm oil | MXene (Ti3C2) | 0.01, 0.03, 0.05, 0.08, 0.1, 0.2 wt. % | - | 0.01–0.07 kg/s |

|

| Ref | N/E | Operating Temperature (°C) | COP | Working Pairs | Heat Source Temperature (°C) | Cooling Cycle Categories | Key Findings | |

|---|---|---|---|---|---|---|---|---|

| Tc | Te | |||||||

| [40] | N | 30 | 5 | 0.670 | R32/[HMIM][Tf2N] | 70 | Thermal and mechanical compression |

|

| [41] | N | 25 | 7 | Seasonal COP is 8.9 | NH3/LiNO3 | 70–90 | Thermal and mechanical compression |

|

| [42] | N | 30 | 5 | 0.35 | R1234yf/Ionic liquid | 62–70 | Thermal and mechanical compression |

|

| [43] | N | 35 | 7 | COPnet is 0.311–0.567 | LiBr/H2O for VAS R1234yf, and R1234ze(E) for VCS | 45–60 | Cascade layout |

|

| [44] | N | - | - | 0.4 | silica gel/H2O for adsorption LiBr/H2O for absorption | 50 | Cascade layout |

|

| [45] | N | - | - | 0.37 | silica gel/H2O for adsorption LiBr/H2O for absorption | 60 | Cascade layout |

|

| [46] | N | 40 | 4 | - | LiBr/H2O for absorption R410a for compression | 80 | Cascade layout |

|

| [47] | N | 40 | −25 | 7 | SrCl2-NH3 | 60 | Thermal and mechanical compression |

|

| [48] | N | 35 | 7 | 0.205–0.376 | R152a/[HMIM]Tf2N | 70 | Thermal and mechanical compression + kalina |

|

| [49] | N | - | - | - | LiBr/H2O | 25–45 | Thermal and mechanical compression |

|

| [50] | N | - | - | 0.47 | CO2 R1234yf LiBr/H2O | 69 | Cascade layout |

|

| [51] | N | 25 | −5 | 0.62 | - | 70 | VAR |

|

| Ref. | N/E | COP | Working Pairs | Key Findings |

|---|---|---|---|---|

| [52] | N | 0.42–0.43 | silica gel/H2O |

|

| [53] | N | 0.28–0.384 | silica gel/H2O |

|

| [54] | N | 0.41 | silica gel/H2O |

|

| [55] | N | 1.8–2.1 | silica gel/H2O |

|

| [56] | N | 0.122–0.124 | silica gel/H2O |

|

| [57] | N | 0.6–0.7 | silica gel/H2O |

|

| [58] | N | 0.615 | LiBr/H2O R410a |

|

| [59] | N | - | LiBr/H2O NH3 |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiao, C.; Li, Z. An Updated Review of Solar Cooling Systems Driven by Photovoltaic–Thermal Collectors. Energies 2023, 16, 5331. https://doi.org/10.3390/en16145331

Jiao C, Li Z. An Updated Review of Solar Cooling Systems Driven by Photovoltaic–Thermal Collectors. Energies. 2023; 16(14):5331. https://doi.org/10.3390/en16145331

Chicago/Turabian StyleJiao, Cong, and Zeyu Li. 2023. "An Updated Review of Solar Cooling Systems Driven by Photovoltaic–Thermal Collectors" Energies 16, no. 14: 5331. https://doi.org/10.3390/en16145331

APA StyleJiao, C., & Li, Z. (2023). An Updated Review of Solar Cooling Systems Driven by Photovoltaic–Thermal Collectors. Energies, 16(14), 5331. https://doi.org/10.3390/en16145331