Adsorption Air-Conditioning for Automotive Applications: A Critical Review

Abstract

:1. Introduction

- The impact of AC systems on fuel consumption and electric vehicle range. This section focuses on the impact of air-conditioning systems on fuel consumption and the range of electric vehicles. It examines the energy requirements of these systems and their implications for vehicle efficiency.

- The classification of air-conditioning systems for automotive applications. A comprehensive classification of air-conditioning systems used in automotive applications is presented in this section. It provides an overview of the different types of systems and their key characteristics.

- Vapour-compression (VC) systems. This section delves into the widely employed VC systems, discussing their working principles, innovative refrigerants, and efficiency. It highlights the advantages and drawbacks of this established technology.

- Thermally driven automotive air-conditioning systems. This section explores thermally driven air-conditioning systems, which offer improved energy efficiency and a reduced environmental impact.

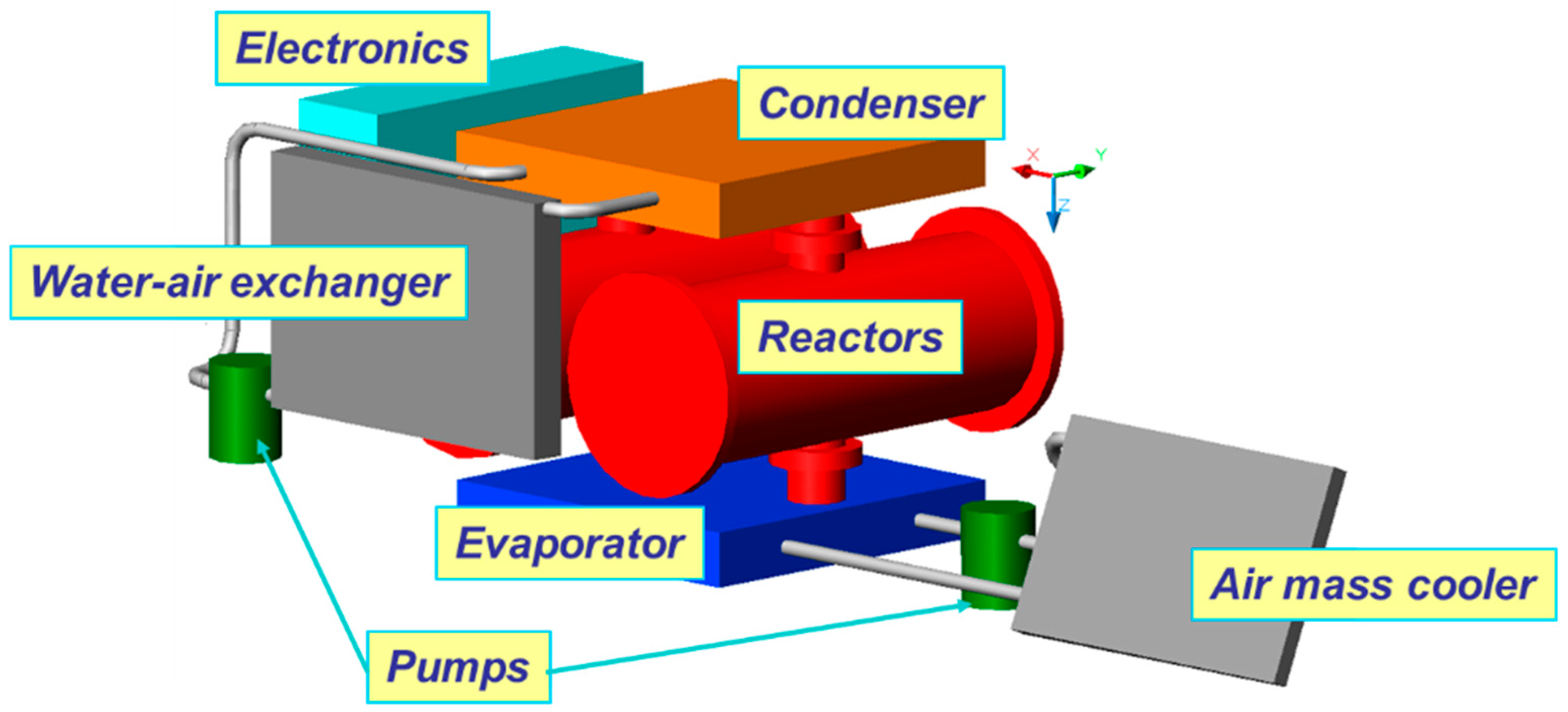

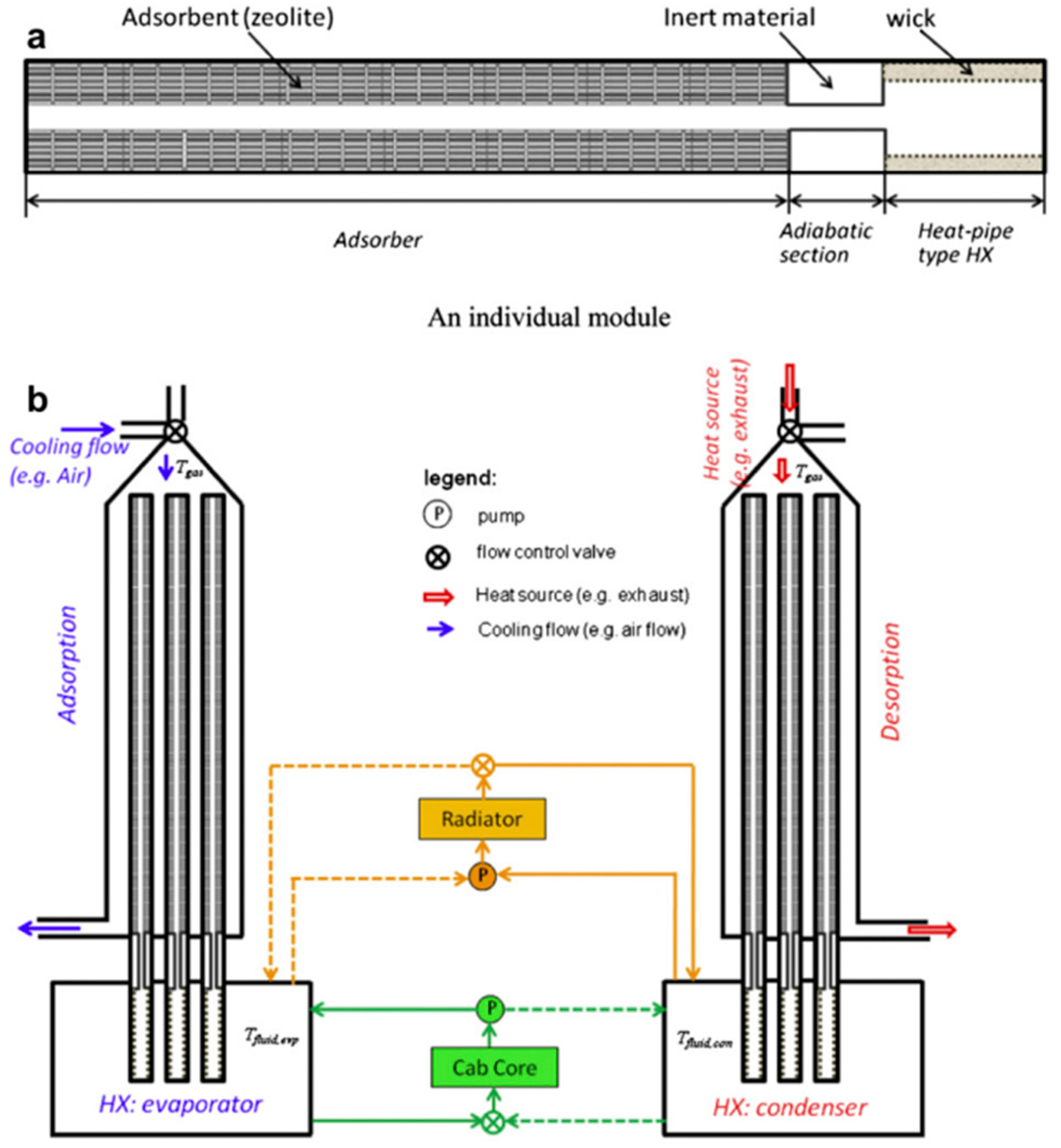

- Adsorption air conditioners. This section focuses on adsorption air conditioners. It presents all of the most updated and recent research works dealing with all of the main aspects of such technology including materials, components, system integration, etc.

- Limitations of adsorption air conditioners. While adsorption air conditioners show promise, this section addresses their limitations and challenges. Factors such as system complexity, regeneration requirements, and cost are discussed.

- The issue of electric vehicles—other active air-conditioning technologies. Given the unique requirements of electric vehicles, this section explores other active air-conditioning technologies tailored specifically for electric vehicle applications. It highlights innovations and advancements in this area.

2. The Impact of AC Systems on Fuel Consumption and Electric Vehicle Range

- Integration of waste heat recovery systems to utilize excess heat from the AC system and reduce the load on the engine [19].

3. Classification of Air-Conditioning Systems for Automotive Applications

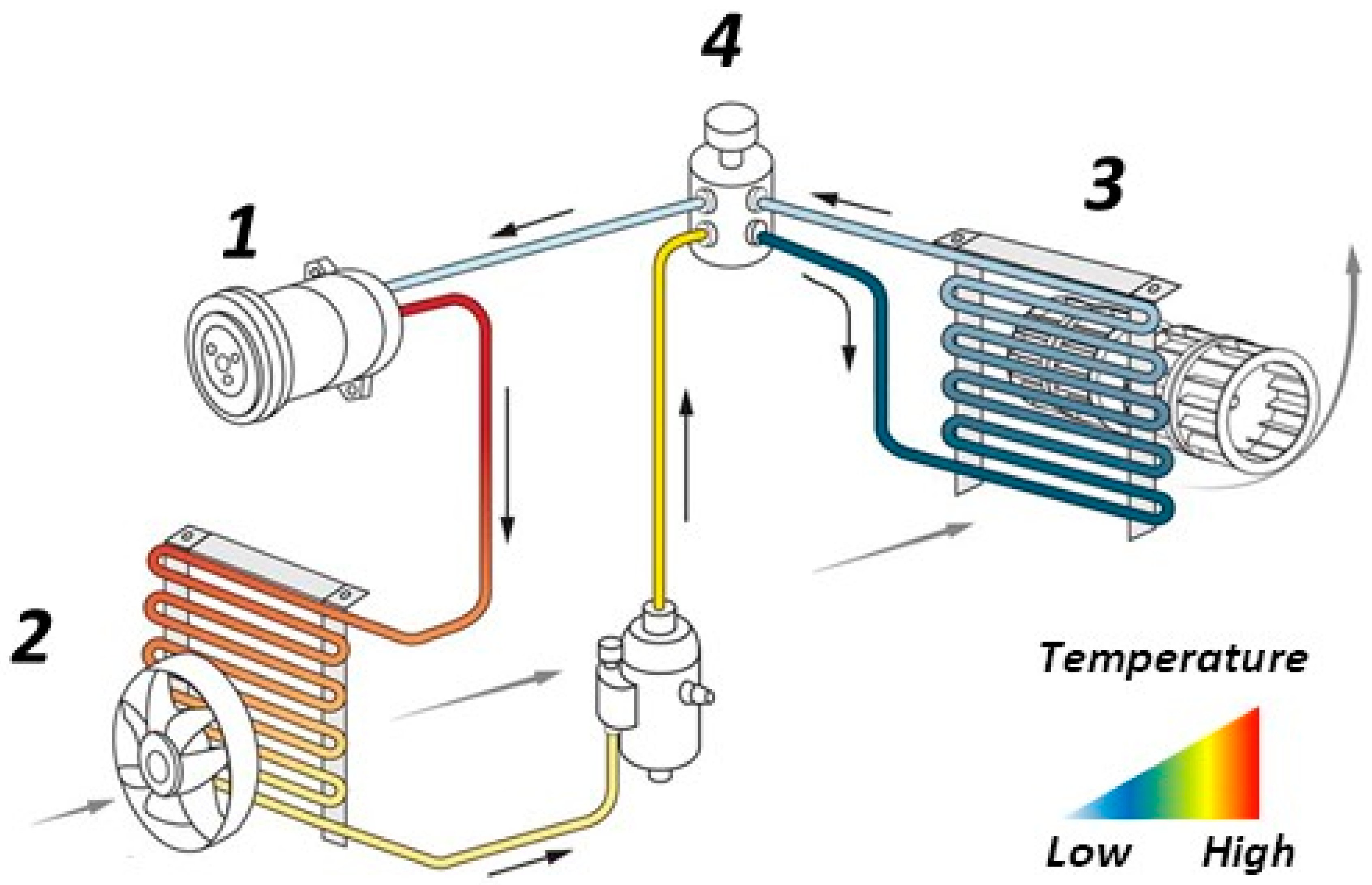

3.1. Vapour-Compression Systems

3.2. Thermally Driven Systems

- Adsorption systems;

- Absorption systems;

- Thermochemical systems;

- Ejector systems;

- Rankine systems;

- Steam jet coolers.

3.3. Electrically Driven Systems

3.4. Hybrid Systems

3.5. Climate Control Systems

4. Vapour-Compression Systems

5. Thermally Driven Automotive Air-Conditioning Systems

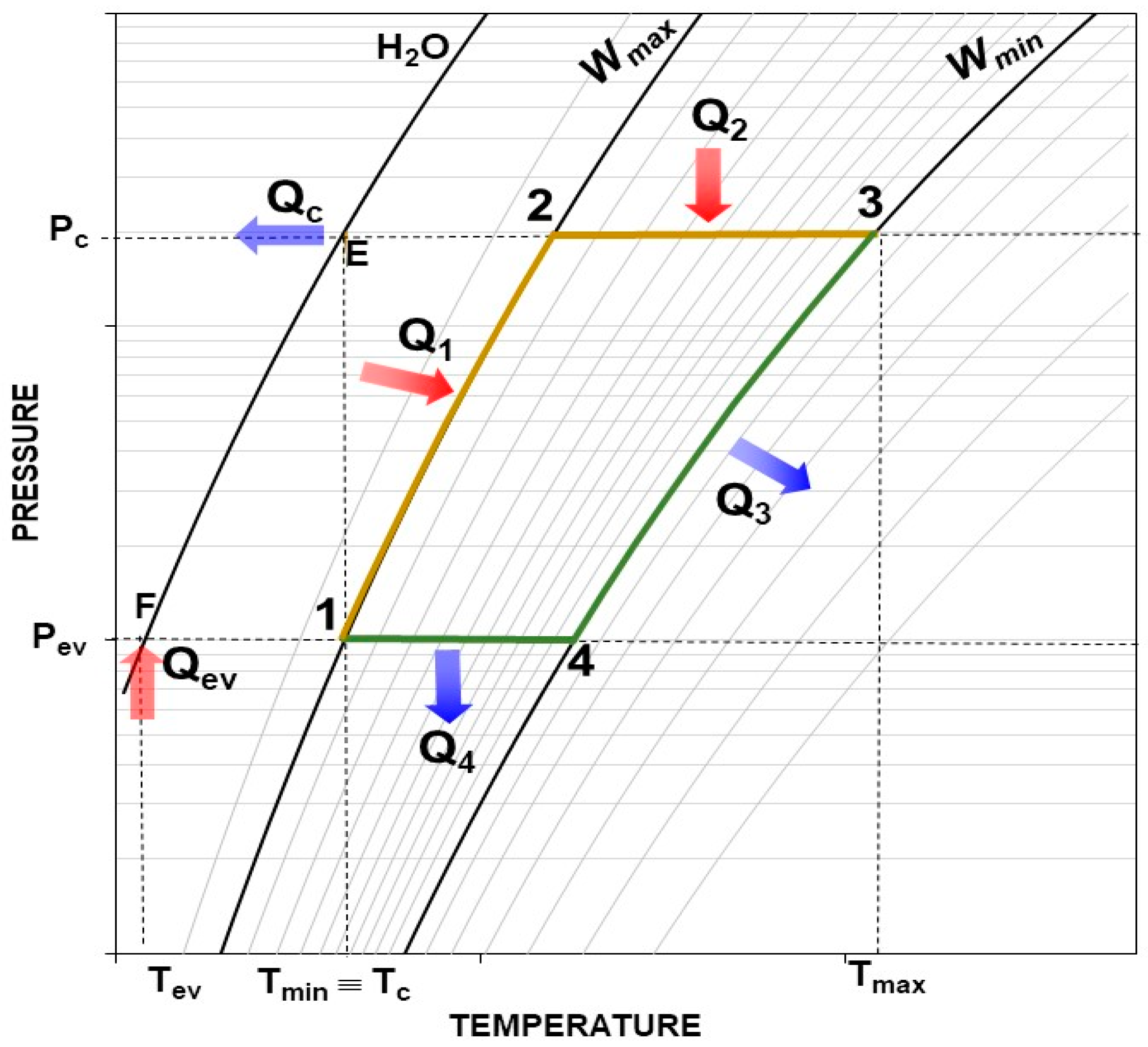

6. Adsorption Air Conditioners

- Adsorption: The cycle begins with an adsorber, which contains a solid adsorbent material, often activated carbon, zeolite, or silica gel. The adsorbent has a high affinity for the refrigerant vapour. At low temperatures, the adsorbent attracts and retains the refrigerant vapour molecules on its surface, effectively adsorbing the vapour and releasing heat.

- Desorption: The adsorbed vapour is then desorbed from the adsorbent material by raising its temperature. This is achieved by supplying heat from an external source, such as hot water or gas. The refrigerant vapour is released from the adsorbent surface, and the adsorbent material is regenerated.

- Condensation: The desorbed refrigerant vapour is then condensed into a liquid state by transferring heat to a cooling medium, such as air or water. This process releases additional heat, which has to be dissipated in the ambient.

- Expansion: The high-pressure liquid refrigerant is throttled through a valve, which reduces its pressure, and is transferred to the evaporator. This expansion process is different to the expansion valve in traditional refrigeration cycles.

- Evaporation: The low-pressure, low-temperature refrigerant liquid absorbs heat from the surrounding environment (such as air or water) and evaporates, turning into a vapour. This heat absorption cools down the environment, making it suitable for air-conditioning in vehicles or other applications.

- Adsorbent Regeneration: After the evaporation, the low-pressure refrigerant vapour returns to the adsorber, where it is adsorbed again by the adsorbent material. The adsorption process generates heat, which has to be dissipated (usually at the same temperature as the condensation heat) in the ambient. The cycle repeats as the adsorbent is regenerated and used for adsorption again.

- Greenhouse Gas Emissions: Adsorption systems use natural refrigerants or environmentally friendly alternatives, such as water, which have a significantly lower global warming potential compared to the refrigerants used in conventional systems. This results in reduced direct emissions of greenhouse gases, mitigating their contribution to climate change.

- Energy Consumption: Adsorption systems have the potential to achieve higher energy efficiency by utilizing waste heat. This reduces the overall energy consumption and reliance on fossil fuels, further minimizing their environmental impact.

- Resource Depletion: Adsorption systems employ adsorbent materials that can be sourced sustainably. Additionally, adsorbents can be regenerated and reused, reducing resource depletion and waste generation compared to conventional systems.

- Chemical and Toxic Substances: Adsorption systems generally involve the use of non-toxic adsorbent materials and do not require the use of harmful or ozone-depleting substances. This mitigates the potential environmental risks associated with leaks or accidental releases.

- The adsorption and desorption temperatures affect the COP significantly.

- The condensing temperature is less sensitive to the COP of a zeolite–water adsorption system than an activated carbon–methanol adsorption system.

- The system’s performance can be enhanced by optimizing the mass transfer within the adsorber, and an air-cooled condenser may be used.

- A well-designed evaporator can fuel the refrigeration capacity output.

- The use of adiabatic and cooling adsorption processes can provide additional refrigeration capacity for immediate space cooling.

- The adsorber can function as another regenerator if there is a refrigeration capacity deficit.

- Adsorption Capacity: A high adsorption capacity allows for a greater amount of refrigerant to be adsorbed onto the material’s surface, resulting in an improved cooling performance. Adsorbents with a higher adsorption capacity can achieve higher cooling capacities and better overall efficiency.

- Desorption Temperature: An ideal adsorbent material should have a desorption temperature that matches well with the available heat source.

- Thermal Conductivity: A higher thermal conductivity allows for better heat transfer between the refrigerant and the adsorbent, leading to faster adsorption and desorption rates. An improved heat transfer enhances the chiller’s overall efficiency and performance.

- Stability and Durability: Adsorption chillers operate through repeated cycles of adsorption and desorption, subjecting the material to temperature and pressure variations. An adsorbent material with excellent stability and durability can maintain its performance over an extended period, minimizing degradation and ensuring consistent efficiency.

7. Limitations of Adsorption Air Conditioners

- Capacity Density: One of the primary limitations of adsorption air conditioners is their lower cooling capacity density compared to that of standard systems. Adsorption technology relies on the desorption of water vapour from a solid material, and this process is slower and less efficient than the compression and expansion of refrigerant gases used in standard air conditioners. As a result, adsorption systems may struggle to provide adequate cooling performance, especially in extremely hot climates or under heavy load conditions, or they may result in bulk and heavy systems that could impact the integration process in small vehicles, even though the industry has made significant advancements to address this issue, such as compact and efficient evaporator designs [86], compact or innovative adsorber heat exchangers [87,88], the introduction of composite adsorbents [89,90], etc. The reported capacity density values for adsorption systems range from 70 to 110 W/kg (based on different studies [79,91,92]), while a typical VC system has an energy that is higher than 520 W/kg [92]. In terms of volumetric energy density, the reported values are lower than 27 W/m3 [79]. Also, the external piping and valves, whose size and weight increase with the capacity, contribute to reducing the capacity density. A solution for such an issue may be represented by the integration of heat pipe technology for heat exchange into high-power air conditioners [93]. However, there is a need for further improvement in the capacity density of adsorption systems. It is important to note that conventional terminologies, for example, the specific cooling power (SCP) based on dry mass, can be misleading. Instead, specific energy density based on the total mass or volume of the system should be used, and a fair comparison with conventional VC systems should be made when appropriate.

- Size and Weight: When comparing the size and weight of adsorption systems to compression-based systems for automotive applications, there are notable differences to consider. Adsorption systems tend to be bulkier and heavier than their compression counterparts. This is primarily due to the adsorbent material used in adsorption systems, which requires a larger exchanger surface area for efficient cooling [94]. As a result, adsorption systems often require larger components and additional space for the adsorption and desorption processes to take place effectively. This increased size and weight can pose challenges in automotive applications, where space and weight constraints are crucial considerations for vehicle design and performance. On the other hand, compression-based systems, such as mechanical vapour-compression (MVC) systems, have undergone significant miniaturization and optimization over the years [95]. They have been engineered to be more compact and lightweight, making them a preferred choice for automotive air-conditioning applications. These systems leverage the efficiency of compression and expansion cycles, which can be achieved with smaller components and less material. The size and weight limitations of adsorption systems can impact the overall design and performance of vehicles. They may require more space for installation and could add extra weight, potentially affecting fuel efficiency and vehicle handling. In contrast, compression systems offer more flexibility in terms of integration and can be designed to fit within the available space and weight restrictions of a vehicle. While efforts have been made to reduce the size and weight of adsorption systems through advancements in technology, they still tend to lag behind compression-based systems in this aspect. As a result, the size and weight considerations remain significant limitations for adsorption systems in automotive applications, where compactness and lightweight solutions are highly valued.

- Response Time: Adsorption air conditioners typically have a longer response time compared to standard systems. Adsorption and desorption processes take time to occur, resulting in a slower cooling performance when the system is first activated. This delay can be problematic in situations where quick cooling is necessary, such as when entering a hot vehicle or during short stops. Moreover, another property of the adsorbent materials that affects the response time is the adsorption kinetic. The adsorption kinetic in adsorption air conditioners is primarily determined by the properties of the adsorbent material, its shape, and its physical status. The adsorbent should have a large surface area and a strong adsorption affinity for the refrigerant being targeted. Additionally, the adsorbent should be able to maintain its structural integrity over many adsorption–desorption cycles to ensure that it provides long-term performance. In terms of adsorption kinetics, the rate at which the refrigerant (usually water) molecules are adsorbed onto the adsorbent material is a key factor in determining the overall efficiency, the cycle time, and the specific cooling capacity of adsorption air conditioners [96,97].

- Limited Operating Conditions: In automotive applications, closed-cycle adsorption systems face certain limitations in terms of their operating conditions when compared to VC systems. These limitations arise from the fundamental differences in the underlying principles of these two cooling technologies. VC systems allow for a wide range of operating conditions, including varying temperatures, making them adaptable to different environmental conditions and user preferences. The compressors in these systems can adjust their speed and capacity, providing the operator with precise control over cooling output. On the other hand, adsorption systems utilize the adsorption and desorption of a working substance that selectively adsorbs the adsorbate (water vapour) at low temperatures and desorbs it at higher temperatures; this process drives the cooling effect in the system. One of the limitations of adsorption systems in automotive applications is their dependence on specific operating conditions for efficient performance [98,99]. The adsorbent material used in the system has a limited range of temperatures at which it can effectively adsorb and desorb the adsorbate [100]. This restricts the operating temperature range of the system, limiting its adaptability to varying ambient temperatures and user preferences. Moreover, efficient adsorption systems often require high desorption temperatures to release the adsorbed refrigerant effectively. Achieving these high temperatures can be challenging in automotive applications, especially considering the limited temperature of waste heat sources available in some conditions such as start-up and idle operations.

- Reliability: When evaluating reliability, it has been reported that adsorption systems can effectively function for many years [101], while adsorbent materials are capable of thousands of cycles [102]. It is important to note, however, that the systems presented in the previous references are not suitable for automobile air-conditioning due to the harsh operational environment. Vibrations, sudden impacts, and high temperatures can all potentially damage the adsorber’s heat exchanger. Therefore, sintered or firmly coated adsorber heat exchangers may be preferable to the conventional wire-mesh packing method [103,104,105]. Also, exchangers that are made of plastic material, if well engineered, can represent an effective breakthrough for reliability and lifetime increase [106]. In addition, a high-temperature environment can negatively impact the adsorption process, which is highly dependent on the coolant temperature.

- Economic aspects: The production cost of adsorption air conditioners for automotive applications can vary depending on various factors, and it is generally higher than that of conventional systems. Recently, Al Hasni and Santori provided the average cost breakdown for an adsorption chiller [8]. They showed that, although adsorption chillers are more environmentally sustainable than other types of chillers, their price-performance trade-off makes it difficult for them to capture a significant share of the air conditioner system. The authors also highlighted that the emphasis in research so far has been on improving performance, without adequately considering whether this will lead to reduced manufacturing costs. To address this gap, they estimated the manufacturing cost and end-user price of silica gel adsorption chillers. The analysis is extended across different COP and SCP combinations and identifies a minimum annual selling volume of 14 units. The manufacturing process used for the production of adsorption air conditioners also plays a role in determining the cost. The cost of the process, such as batch production or continuous production, depends on the equipment needed, the level of automation, and the time it takes to complete the process. Their results assess the economic viability of adsorption chillers with advanced adsorption materials, such as metal–organic frameworks (MOFs) and advanced zeolites, which do not compete, for the moment, with silica gel chillers in cost; thus, future innovative adsorption materials should be compared to silica gel using the correlations they presented in their study.

- Non-technical aspects: The current development of adsorption systems is predominantly conducted through laboratory- or project-based research. However, for this technology to progress and gain acceptance on a wider scale, active involvement and support from the car manufacturing industry are crucial. In addition, authorities need to provide support and incentives to push new technologies forward. For instance, renewable energy technologies like solar PV and hybrid vehicles gained widespread acceptance through government incentives during their early introduction. Similarly, adsorption systems for automobile air-conditioning could benefit from similar support from authorities.

8. The Issue of Electric Vehicles—Other Active Air-Conditioning Technologies

8.1. Electric Compressor Systems

8.2. Thermal Storage Systems

8.3. Solar-Powered Ventilation

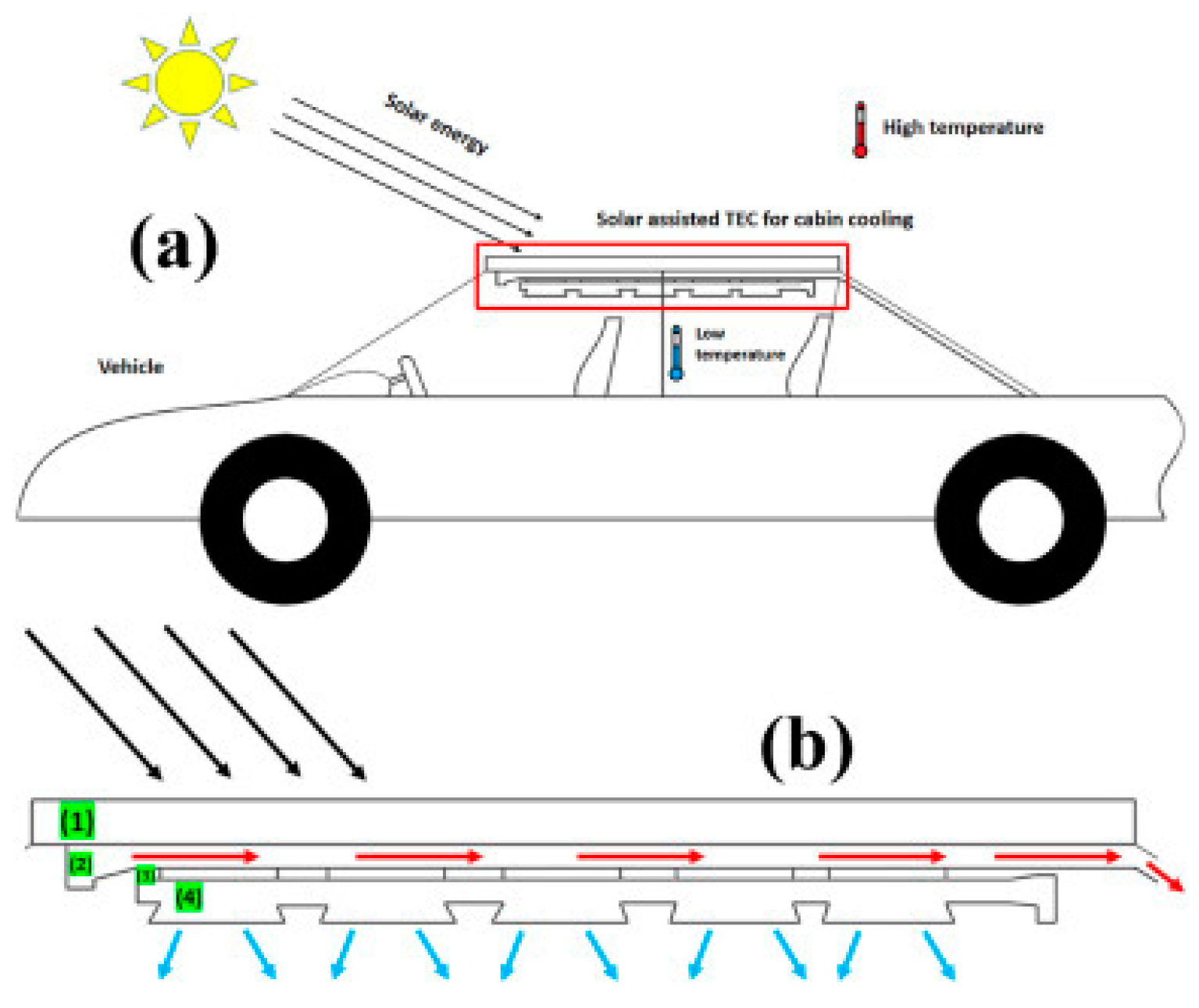

8.4. Thermoelectric Air Conditioners

- Compact Size: Thermoelectric devices are compact and have a low-profile design, making them suitable for integration into automotive AC systems without requiring significant space.

- Solid-State Operation: Thermoelectric devices have no moving parts, making them reliable, vibration-resistant, and maintenance-free.

- Rapid Response: Thermoelectric devices can quickly adjust the cooling or heating output, providing immediate comfort to the passengers.

- Zonal Control: Thermoelectric technology enables zonal control, allowing for different areas or seats within the vehicle to be cooled or heated individually based on passenger preferences.

- Environmentally Friendly: Thermoelectric technology does not use refrigerants or harmful gases, eliminating the environmental concerns that are associated with traditional VC systems.

- Reduced HVAC System Complexity: Thermoelectric devices can simplify the AC system design by eliminating the need for mechanical compressors, refrigerant lines, and complex control mechanisms.

- Limited Cooling Capacity: The cooling capacity of thermoelectric devices is typically lower compared to traditional VC systems, which may limit their application in larger vehicles or extremely hot climates.

- Efficiency at High-Temperature Differentials: The thermoelectric efficiency decreases as the temperature differential across the device increases. Optimizing the efficiency of thermoelectric devices at higher temperature differentials remains a challenge.

- Cost: The cost of thermoelectric devices, especially those with a high efficiency and cooling capacity, can be higher compared to that of traditional AC systems. However, advancements in materials and manufacturing processes are gradually reducing costs.

- Power Consumption: Thermoelectric devices require a significant amount of electrical power, which can impact the overall vehicle’s energy consumption and potentially reduce the driving range in electric vehicles.

8.5. Advanced Control Systems

8.6. Future Innovations

9. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vashisht, S.; Rakshit, D. Recent advances and sustainable solutions in automobile air conditioning systems. J. Clean. Prod. 2021, 329, 129754. [Google Scholar] [CrossRef]

- Kwon, J.Y.; Kim, J.K.; Lee, H.; Lee, D.; Ju, D.Y. A Comprehensive Overview of Basic Research on Human Thermal Management in Future Mobility: Considerations, Challenges, and Methods. Sustainability 2023, 15, 7335. [Google Scholar] [CrossRef]

- He, Z.; Ji, L.; Xing, Z. Experimental Investigation on the DLC Film Coating Technology in Scroll Compressors of Automobile Air Conditioning. Energies 2020, 13, 5103. [Google Scholar] [CrossRef]

- Chen, X.; Liang, K.; Li, Z.; Zhao, Y.; Xu, J.; Jiang, H. Experimental assessment of alternative low global warming potential refrigerants for automotive air conditioners application. Case Stud. Therm. Eng. 2020, 22, 100800. [Google Scholar] [CrossRef]

- Meng, Z.; Zhang, H.; Lei, M.; Qin, Y.; Qiu, J. Performance of low GWP R1234yf/R134a mixture as a replacement for R134a in automotive air conditioning systems. Int. J. Heat Mass Transf. 2018, 116, 362–370. [Google Scholar] [CrossRef]

- Zheng, W.; Chen, Y.; Hua, N.; Zhong, T.; Gong, Y. Comparative Performance of an Automotive Air Conditioning System Using Micro-channel Condensers with and Without Liquid-vapor Separation. Energy Procedia 2014, 61, 1646–1649. [Google Scholar] [CrossRef] [Green Version]

- Cola, F.; De Gennaro, M.; Perocchio, D.; Canuto, E.; Daniele, S.; Napoli, P.; Toscano Rivalta, G.; Chiavazzo, E.; Fasano, M.; Asinari, P. Integrated receivers with bottom subcooling for automotive air conditioning: Detailed experimental study of their filling capacity. Int. J. Refrig. 2016, 62, 72–84. [Google Scholar] [CrossRef] [Green Version]

- AL-Hasni, S.; Santori, G. The cost of manufacturing adsorption chillers. Therm. Sci. Eng. Prog. 2023, 39, 101685. [Google Scholar] [CrossRef]

- Shancita, I.; Masjuki, H.H.; Kalam, M.A.; Fattah, I.M.R.; Rashed, M.M.; Rashedul, H.K. A review on idling reduction strategies to improve fuel economy and reduce exhaust emissions of transport vehicles. Energy Convers. Manag. 2014, 88, 794–807. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, C.; Chen, X.; Zhang, C.; Chen, J. Annual energy consumption of electric vehicle air conditioning in China. Appl. Therm. Eng. 2017, 125, 567–574. [Google Scholar] [CrossRef]

- Huff, S.; West, B.; Thomas, J. Effects of Air Conditioner Use on Real-World Fuel Economy. SAE Tech. Pap. 2013, 2. [Google Scholar] [CrossRef]

- Emerging Technologies for Electric and Hybrid Vehicles; MDPI: Basel, Switzerland, 2018. [CrossRef] [Green Version]

- Guo, F.; Chen, Z.; Xiao, F.; Li, A.; Shi, J. Real-time energy performance benchmarking of electric vehicle air conditioning systems using adaptive neural network and Gaussian process regression. Appl. Therm. Eng. 2023, 222, 119931. [Google Scholar] [CrossRef]

- Farrington, R.; Rugh, J. Impact of Vehicle Air-Conditioning on Fuel Economy, Tailpipe Emissions, and Electric Vehicle Range Preprint Impact of Vehicle Air-Conditioning on Fuel Economy, Tailpipe Emissions, and Electric Vehicle Range. 2000. Available online: https://www.nrel.gov/docs/fy00osti/28960.pdf (accessed on 27 May 2023).

- Wang, F.; Wu, W.; Zhu, Q.; Li, K.; Zhang, H. Experimental study of electronic expansion valve opening on the performance of electric vehicle heat pump system at different compressor speeds. Int. J. Refrig. 2023, 149, 94–104. [Google Scholar] [CrossRef]

- Li, Z.; Liang, K.; Chen, X.; Zhu, Z.; Zhu, Z.; Jiang, H. A comprehensive numerical model of a vapour compression refrigeration system equipped with a variable displacement compressor. Appl. Therm. Eng. 2022, 204, 117967. [Google Scholar] [CrossRef]

- He, L.; Li, P.; Zhang, Y.; Jing, H.; Gu, Z. Control strategy analysis of multistage speed compressor for vehicle air conditioning based on particle swarm optimization. Case Stud. Therm. Eng. 2023, 47, 103033. [Google Scholar] [CrossRef]

- Li, G.; Tang, Z.; Zou, H.; Zhang, R. Experimental investigation of cooling performance of a CO2 heat pump system with an integrated accumulator heat exchanger for electric vehicles: Impact of refrigerant charge and valve opening. Appl. Therm. Eng. 2023, 224, 120077. [Google Scholar] [CrossRef]

- Zhang, Y.; Han, Y.; Yan, J.; Chen, R. Thermodynamic analysis of compound cycle system for automotive waste heat recovery and air conditioning refrigeration. Energy Convers. Manag. 2018, 168, 32–48. [Google Scholar] [CrossRef]

- Marshall, G.J.; Mahony, C.P.; Rhodes, M.J.; Daniewicz, S.R.; Tsolas, N.; Thompson, S.M. Thermal Management of Vehicle Cabins, External Surfaces, and Onboard Electronics: An Overview. Engineering 2019, 5, 954–969. [Google Scholar] [CrossRef]

- Bridge, D. 3D Thermal simulation of a vehicle cabin with a view to reducing air conditioning loads. In Institution of Mechanical Engineers—VTMS 10, Vehicle Thermal Management Systems Conference and Exhibition; WoodHead Publishing: Sawston, UK, 2011; pp. 583–597. [Google Scholar] [CrossRef]

- Bandi, P.; Manelil, N.P.; Maiya, M.P.; Tiwari, S.; Thangamani, A.; Tamalapakula, J.L. Influence of flow and thermal characteristics on thermal comfort inside an automobile cabin under the effect of solar radiation. Appl. Therm. Eng. 2022, 203, 117946. [Google Scholar] [CrossRef]

- Khayyam, H.; Abawajy, J.; Jazar, R.N. Intelligent energy management control of vehicle air conditioning system coupled with engine. Appl. Therm. Eng. 2012, 48, 211–224. [Google Scholar] [CrossRef]

- Khayyam, H. Adaptive intelligent control of vehicle air conditioning system. Appl. Therm. Eng. 2013, 51, 1154–1161. [Google Scholar] [CrossRef]

- Khayyam, H.; Nahavandi, S.; Hu, E.; Kouzani, A.; Chonka, A.; Abawajy, J.; Marano, V.; Davis, S. Intelligent energy management control of vehicle air conditioning via look-ahead system. Appl. Therm. Eng. 2011, 31, 3147–3160. [Google Scholar] [CrossRef]

- Peng, Q.; Du, Q. Progress in Heat Pump Air Conditioning Systems for Electric Vehicles—A Review. Energies 2016, 9, 240. [Google Scholar] [CrossRef] [Green Version]

- Basile, S. Cool: How Air Conditioning Changed Everything; Fordham University Press: New Your, NY, USA, 2014. [Google Scholar] [CrossRef]

- Zhang, N.; Dai, Y.; Feng, L.; Li, B. Study on environmentally friendly refrigerant R13I1/R152a as an alternative for R134a in automotive air conditioning system. Chin. J. Chem. Eng. 2022, 44, 292–299. [Google Scholar] [CrossRef]

- Cho, H.; Park, C. Experimental investigation of performance and exergy analysis of automotive air conditioning systems using refrigerant R1234yf at various compressor speeds. Appl. Therm. Eng. 2016, 101, 30–37. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Y.; Jia, S.; Zhang, X.; Huang, L. Experimental study of R744 heat pump system for electric vehicle application. Appl. Therm. Eng. 2021, 183, 116191. [Google Scholar] [CrossRef]

- Yadav, S.; Liu, J.; Kim, S.C. A comprehensive study on 21st-century refrigerants—R290 and R1234yf: A review. Int. J. Heat Mass Transf. 2022, 182, 121947. [Google Scholar] [CrossRef]

- Janković, Z.; Atienza, J.S.; Suárez, J.A.M. Thermodynamic and heat transfer analyses for R1234yf and R1234ze(E) as drop-in replacements for R134a in a small power refrigerating system. Appl. Therm. Eng. 2015, 80, 42–54. [Google Scholar] [CrossRef]

- Trane® Leverages Solstice® Technology to Drive Cooling and Heating Innovation. Available online: https://www.honeywell-refrigerants.com/europe/wp-content/uploads/2018/11/Solstice-ze-Trane-Case-Study_EN.pdf (accessed on 11 July 2023).

- El Abbadi, J.; Coquelet, C.; Valtz, A.; Houriez, C. Experimental measurements and modelling of vapour−liquid equilibria for four mixtures of 2,3,3,3−tetrafluoropropene (R1234yf) with 1,1,1,2−tetrafluoroethane (R134a) or 1,1−difluoroethane (R152a) or trans−1−chloro−3,3,3−trifluoropropene (R1233zd(E)) or 2−chloro−3,3,3−trifluoropropene (R1233xf). Int. J. Refrig. 2022, 140, 172–185. [Google Scholar] [CrossRef]

- Bell, I.H.; Domanski, P.A.; McLinden, M.O.; Linteris, G.T. The hunt for nonflammable refrigerant blends to replace R-134a. Int. J. Refrig. 2019, 104, 484–495. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, J.; Feng, X.; Chang, L.; Chen, Y.; Wang, X. The solutions to electric vehicle air conditioning systems: A review. Renew. Sustain. Energy Rev. 2018, 91, 443–463. [Google Scholar] [CrossRef]

- Boretti, A. Advances in hydrogen compression ignition internal combustion engines. Int. J. Hydrogen Energy 2011, 36, 12601–12606. [Google Scholar] [CrossRef]

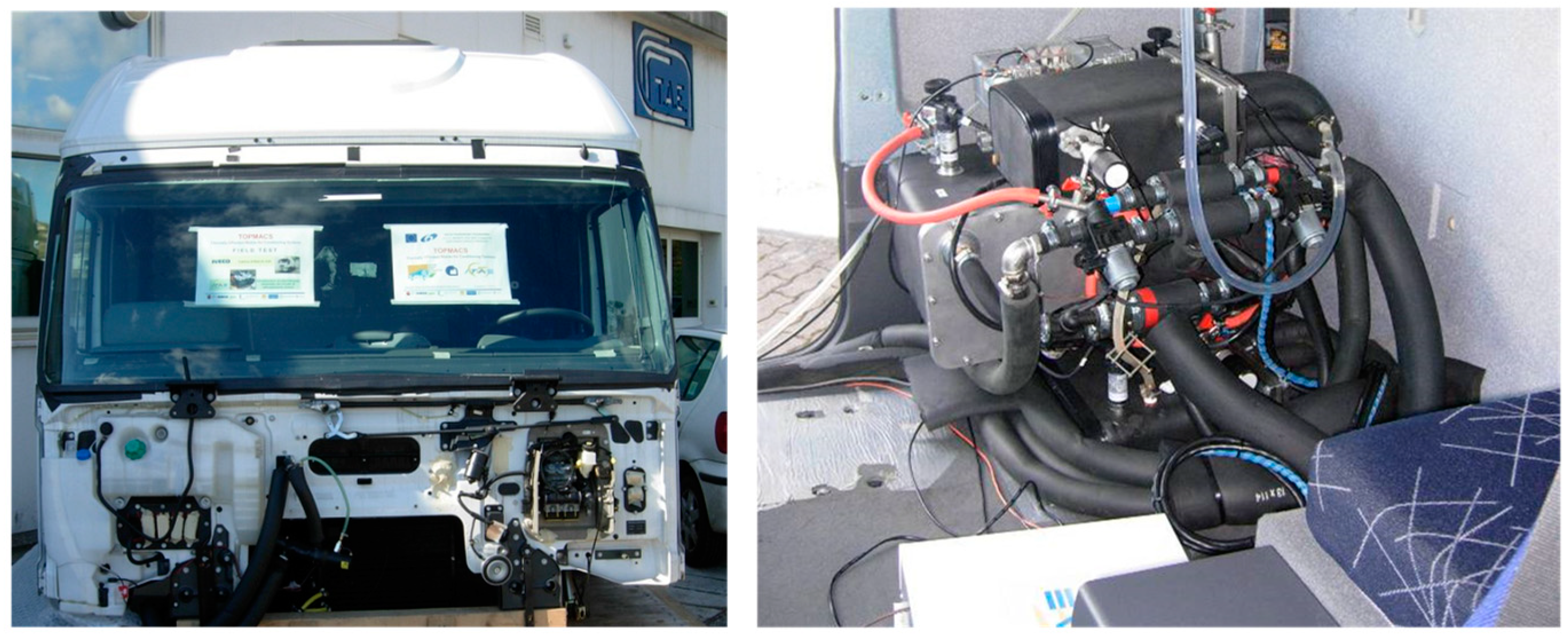

- Magnetto, D.; De Boer, R.; Vasta, S. TOPMACS: Thermally Operated Mobile Air Conditioning Systems. In Institution of Mechanical Engineers—VTMS 10, Vehicle Thermal Management Systems Conference and Exhibition; WoodHead Publishing: Sawston, UK, 2011; pp. 635–647. [Google Scholar] [CrossRef]

- Maeda, S.; Thu, K.; Maruyama, T.; Miyazaki, T. Critical Review on the Developments and Future Aspects of Adsorption Heat Pumps for Automobile Air Conditioning. Appl. Sci. 2018, 8, 2061. [Google Scholar] [CrossRef] [Green Version]

- Abdullah, M.O.; Tan, I.A.W.; Lim, L.S. Automobile adsorption air-conditioning system using oil palm biomass-based activated carbon: A review. Renew. Sustain. Energy Rev. 2011, 15, 2061–2072. [Google Scholar] [CrossRef]

- Frazzica, A.; Palomba, V.; Dawoud, B.; Gullì, G.; Brancato, V.; Sapienza, A.; Vasta, S.; Freni, A.; Costa, F.; Restuccia, G. Design, realization and testing of an adsorption refrigerator based on activated carbon/ethanol working pair. Appl. Energy 2016, 174, 15–24. [Google Scholar] [CrossRef]

- Ruthven, D.M. Principles of Adsorption and Adsorption Processes; Wiley: Hoboken, NJ, USA, 1984; p. 433. [Google Scholar]

- Sapienza, A.; Palomba, V.; Gullì, G.; Frazzica, A.; Vasta, S. A new management strategy based on the reallocation of ads-/desorption times: Experimental operation of a full-scale 3 beds adsorption chiller. Appl. Energy 2017, 205, 1081–1090. [Google Scholar] [CrossRef]

- Olkis, C.; AL-Hasni, S.; Brandani, S.; Vasta, S.; Santori, G. Solar powered adsorption desalination for Northern and Southern Europe. Energy 2021, 232, 120942. [Google Scholar] [CrossRef]

- Lombardo, W.; Sapienza, A.; Ottaviano, S.; Branchini, L.; De Pascale, A.; Vasta, S. A CCHP system based on ORC cogenerator and adsorption chiller experimental prototypes: Energy and economic analysis for NZEB applications. Appl. Therm. Eng. 2021, 183, 116119. [Google Scholar] [CrossRef]

- Palomba, V.; Wittstadt, U.; Bonanno, A.; Tanne, M.; Harborth, N.; Vasta, S. Components and design guidelines for solar cooling systems: The experience of ZEOSOL. Renew. Energy 2019, 141, 678–692. [Google Scholar] [CrossRef]

- Freni, A.; Maggio, G.; Vasta, S.; Santori, G.; Polonara, F.; Restuccia, G. Optimization of a solar-powered adsorptive ice-maker by a mathematical method. Sol. Energy 2008, 82, 965–976. [Google Scholar] [CrossRef] [Green Version]

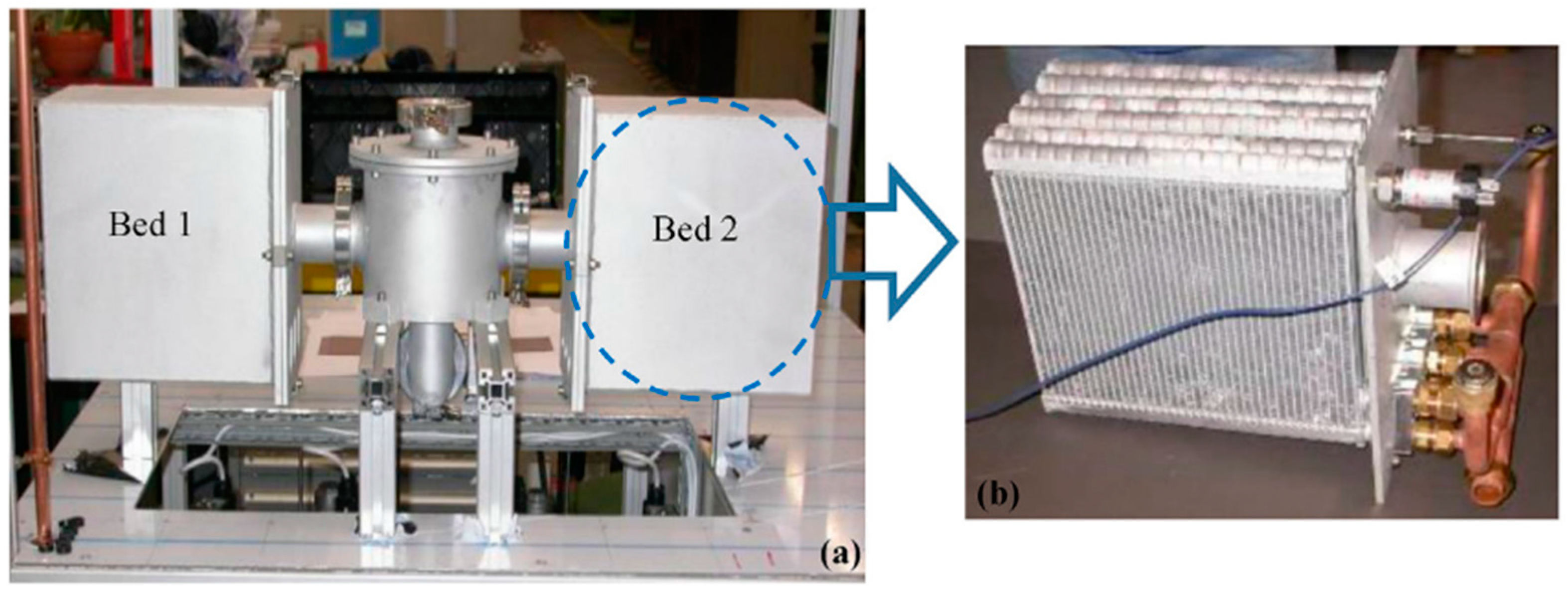

- Vasta, S.; Freni, A.; Sapienza, A.; Costa, F.; Restuccia, G. Development and lab-test of a mobile adsorption air-conditioner. Int. J. Refrig. 2012, 35, 701–708. [Google Scholar] [CrossRef]

- Palomba, V.; Aprile, M.; Motta, M.; Vasta, S. Study of sorption systems for application on low-emission fishing vessels. Energy 2017, 134, 554–565. [Google Scholar] [CrossRef]

- Aristov, Y. Concept of adsorbent optimal for adsorptive cooling/heating. Appl. Therm. Eng. 2014, 72, 166–175. [Google Scholar] [CrossRef]

- Zhong, Y.; Fang, T.; Wert, K.L. An adsorption air conditioning system to integrate with the recent development of emission control for heavy-duty vehicles. Energy 2011, 36, 4125–4135. [Google Scholar] [CrossRef]

- Sharafian, A.; Mehr, S.M.N.; Thimmaiah, P.C.; Huttema, W.; Bahrami, M. Effects of adsorbent mass and number of adsorber beds on the performance of a waste heat-driven adsorption cooling system for vehicle air conditioning applications. Energy 2016, 112, 481–493. [Google Scholar] [CrossRef]

- Sharafian, A.; McCague, C.; Bahrami, M. Impact of fin spacing on temperature distribution in adsorption cooling system for vehicle A/C applications. Int. J. Refrig. 2015, 51, 135–143. [Google Scholar] [CrossRef]

- Sharafian, A.; Bahrami, M. Assessment of adsorber bed designs in waste-heat driven adsorption cooling systems for vehicle air conditioning and refrigeration. Renew. Sustain. Energy Rev. 2014, 30, 440–451. [Google Scholar] [CrossRef]

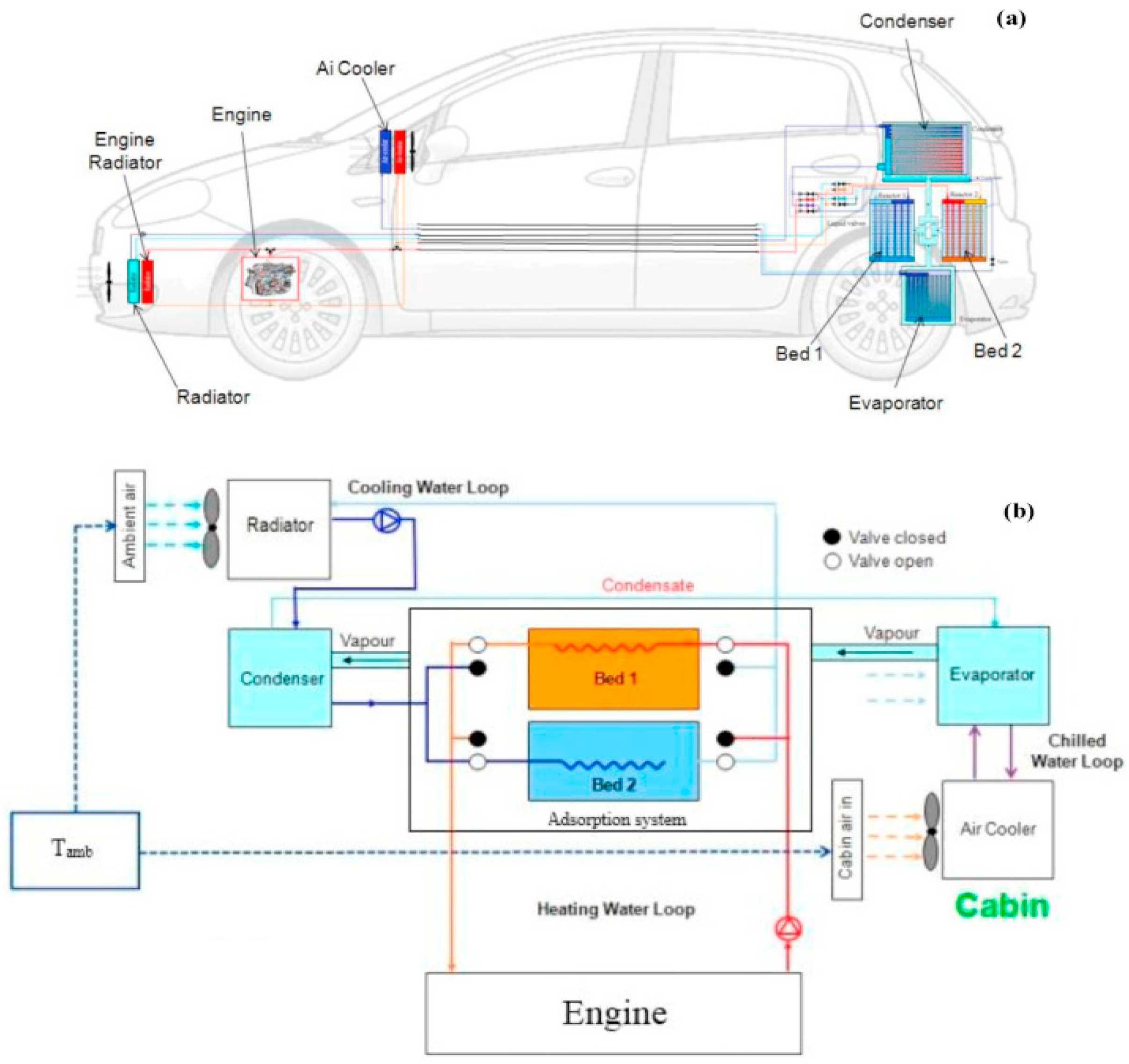

- Verde, M.; Harby, K.; de Boer, R.; Corberán, J.M. Performance evaluation of a waste-heat driven adsorption system for automotive air-conditioning: Part I—Modeling and experimental validation. Energy 2016, 116, 526–538. [Google Scholar] [CrossRef]

- Verde, M.; Harby, K.; de Boer, R.; Corberán, J.M. Performance evaluation of a waste-heat driven adsorption system for automotive air-conditioning: Part II—Performance optimization under different real driving conditions. Energy 2016, 115, 996–1009. [Google Scholar] [CrossRef]

- Verde, M.; Harby, K.; Corberán, J.M. Optimization of thermal design and geometrical parameters of a flat tube-fin adsorbent bed for automobile air-conditioning. Appl. Therm. Eng. 2017, 111, 489–502. [Google Scholar] [CrossRef] [Green Version]

- Tamainot-Telto, Z.; Metcalf, S.J.; Critoph, R.E. Novel compact sorption generators for car air conditioning. Int. J. Refrig. 2009, 32, 727–733. [Google Scholar] [CrossRef] [Green Version]

- Final Report Summary—TOPMACS (Thermally OPerated Mobile Air Conditioning Systems)|FP6|CORDIS|European Commission. Available online: https://cordis.europa.eu/project/id/12471/reporting (accessed on 1 June 2023).

- Golparvar, B.; Niazmand, H.; Sharafian, A.; Hosseini, A.A. Optimum fin spacing of finned tube adsorber bed heat exchangers in an exhaust gas-driven adsorption cooling system. Appl. Energy 2018, 232, 504–516. [Google Scholar] [CrossRef]

- Flannery, B.; Lattin, R.; Finckh, O.; Berresheim, H.; Monaghan, R.F.D. Development and experimental testing of a hybrid Stirling engine-adsorption chiller auxiliary power unit for heavy trucks. Appl. Therm. Eng. 2017, 112, 464–471. [Google Scholar] [CrossRef]

- Flannery, B.; Finckh, O.; Berresheim, H.; Monaghan, R.F.D. Refroidisseur à adsorption à moteur Stirling hybride pour des applications d’unités de puissance auxiliaire pour des camions. Int. J. Refrig. 2017, 76, 356–366. [Google Scholar] [CrossRef]

- Jiangzhou, S.; Wang, R.Z.; Lu, Y.Z.; Xu, Y.X.; Wu, J.Y. Experimental Investigations on Adsorption Air-Conditioner Used in Internal-Combustion Locomotive Driver-Cabin. Available online: www.elsevier.com/locate/apthermeng (accessed on 1 June 2023).

- He, Z.; Bai, Y.; Huang, H.; Li, J.; Kobayashi, N.; Osaka, Y.; Deng, L. Study on the performance of compact adsorption chiller with vapor valves. Appl. Therm. Eng. 2017, 126, 37–42. [Google Scholar] [CrossRef]

- Sharafian, A.; Dan, P.C.; Huttema, W.; Bahrami, M. Performance analysis of a novel expansion valve and control valves designed for a waste heat-driven two-adsorber bed adsorption cooling system. Appl. Therm. Eng. 2016, 100, 1119–1129. [Google Scholar] [CrossRef]

- Freni, A.; Maggio, G.; Sapienza, A.; Frazzica, A.; Restuccia, G.; Vasta, S. Comparative analysis of promising adsorbent/adsorbate pairs for adsorptive heat pumping, air conditioning and refrigeration. Appl. Therm. Eng. 2016, 104, 85–95. [Google Scholar] [CrossRef]

- Sharafian, A.; Mehr, S.M.N.; Huttema, W.; Bahrami, M. Effects of different adsorber bed designs on in-situ water uptake rate measurements of AQSOA FAM-Z02 for vehicle air conditioning applications. Appl. Therm. Eng. 2016, 98, 568–574. [Google Scholar] [CrossRef]

- Shi, B.; Al-Dadah, R.; Mahmoud, S.; Elsayed, A.; Elsayed, E. CPO-27(Ni) metal–organic framework based adsorption system for automotive air conditioning. Appl. Therm. Eng. 2016, 106, 325–333. [Google Scholar] [CrossRef]

- Wang, L.W.; Jiang, L.; Gao, J.; Gao, P.; Wang, R.Z. Analysis of resorption working pairs for air conditioners of electric vehicles. Appl. Energy 2017, 207, 594–603. [Google Scholar] [CrossRef]

- Vasta, S.; Palomba, V.; La Rosa, D.; Mittelbach, W. Adsorption-compression cascade cycles: An experimental study. Energy Convers. Manag. 2018, 156, 365–375. [Google Scholar] [CrossRef]

- Kiliç, M.; Anjrini, M. Comparative performance evaluation of the mechanical and adsorption hybrid cooling systems for the cascaded and the serial connected evaporators configurations. Case Stud. Therm. Eng. 2021, 28, 101489. [Google Scholar] [CrossRef]

- Koushaeian, M.; Duong, X.Q.; Park, M.Y.; Lee, W.S.; Kwon, O.K.; Shah, N.A.; Chung, J.D. Investigation of the cascade type of hybrid adsorption-vapor compression chiller. Case Stud. Therm. Eng. 2023, 47, 103037. [Google Scholar] [CrossRef]

- Roumpedakis, T.C.; Vasta, S.; Sapienza, A.; Kallis, G.; Karellas, S.; Wittstadt, U.; Tanne, M.; Harborth, N.; Sonnenfeld, U. Performance Results of a Solar Adsorption Cooling and Heating Unit. Energies 2020, 13, 1630. [Google Scholar] [CrossRef] [Green Version]

- Pan, Q.W.; Shan, H.; Liu, H.R.; Wang, R.Z. A vapor compression-adsorption thermal management system for electric vehicle: Concept and working fluid pairs. Energy Convers. Manag. 2021, 238, 114168. [Google Scholar] [CrossRef]

- Zhang, L.Z.; Wang, L. Performance estimation of an adsorption cooling system for automobile waste heat recovery. Appl. Therm. Eng. 1997, 17, 1127–1139. [Google Scholar] [CrossRef]

- Grisel, R.J.H.; Smeding, S.F.; de Boer, R. Waste heat driven silica gel/water adsorption cooling in trigeneration. Appl. Therm. Eng. 2010, 30, 1039–1046. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.C.; Xia, Z.Z.; Wu, J.Y. Design and performance prediction of a novel zeolite–water adsorption air conditioner. Energy Convers. Manag. 2006, 47, 590–610. [Google Scholar] [CrossRef]

- Wu, W.D.; Zhang, H.; Men, C.L. Performance of a modified zeolite 13X-water adsorptive cooling module powered by exhaust waste heat. Int. J. Therm. Sci. 2011, 50, 2042–2049. [Google Scholar] [CrossRef]

- Verde, M.; Cortés, L.; Corberán, J.M.; Sapienza, A.; Vasta, S.; Restuccia, G. Modelling of an adsorption system driven by engine waste heat for truck cabin A/C. Performance estimation for a standard driving cycle. Appl. Therm. Eng. 2010, 30, 1511–1522. [Google Scholar] [CrossRef] [Green Version]

- Suzuki, M. Application of adsorption cooling systems to automobiles. Heat Recovery Syst. CHP 1993, 13, 335–340. [Google Scholar] [CrossRef]

- Jiangzhou, S.; Wang, R.Z.; Lu, Y.Z.; Xu, Y.X.; Wu, J.Y. Experimental study on locomotive driver cabin adsorption air conditioning prototype machine. Energy Convers. Manag. 2005, 46, 1655–1665. [Google Scholar] [CrossRef]

- Wang, D.C.; Li, Y.H.; Li, D.; Xia, Y.Z.; Zhang, J.P. A review on adsorption refrigeration technology and adsorption deterioration in physical adsorption systems. Renew. Sustain. Energy Rev. 2010, 14, 344–353. [Google Scholar] [CrossRef]

- Jiangzhou, S.; Wang, R.Z.; Lu, Y.Z.; Xu, Y.X.; Wu, J.Y.; Li, Z.H. Locomotive driver cabin adsorption air-conditioner. Renew. Energy 2003, 28, 1659–1670. [Google Scholar] [CrossRef]

- Lu, Y.Z.; Wang, R.Z.; Jianzhou, S.; Xu, Y.X.; Wu, J.Y. Practical experiments on an adsorption air conditioner powered by exhausted heat from a diesel locomotive. Appl. Therm. Eng. 2004, 24, 1051–1059. [Google Scholar] [CrossRef]

- Prabakaran, P.; Karthikeyan, S. Algae biofuel: A futuristic, sustainable, renewable and green fuel for I.C. engines. Mater Today Proc. 2023. [Google Scholar] [CrossRef]

- Toppi, T.; Villa, T.; Vasta, S.; Mittelbach, W.; Freni, A. Testing of a Falling-Film Evaporator for Adsorption Chillers. Energies 2022, 15, 1709. [Google Scholar] [CrossRef]

- Gai, X.; Song, J.; Wang, L.; He, B. Numerical analysis of heat pipe-assisted finned adsorber with FAM-Z02/water pair for vehicle air conditioning. Appl. Therm. Eng. 2022, 213, 118715. [Google Scholar] [CrossRef]

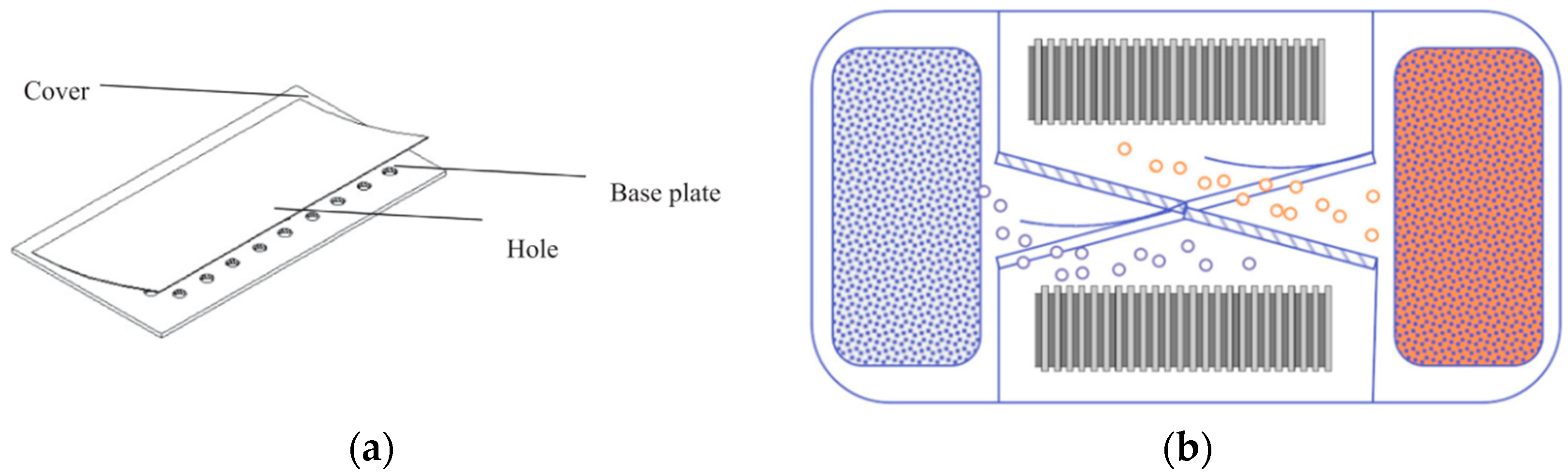

- Rogala, Z. Adsorption chiller using flat-tube adsorbers—Performance assessment and optimization. Appl. Therm. Eng. 2017, 121, 431–442. [Google Scholar] [CrossRef]

- Freni, A.; Russo, F.; Vasta, S.; Tokarev, M.; Aristov, Y.I.; Restuccia, G. An advanced solid sorption chiller using SWS-1L. Appl. Therm. Eng. 2007, 27, 2200–2204. [Google Scholar] [CrossRef]

- Freni, A.; Sapienza, A.; Glaznev, I.S.; Aristov, Y.I.; Restuccia, G. Experimental testing of a lab-scale adsorption chiller using a novel selective water sorbent ‘silica modified by calcium nitrate. Int. J. Refrig. 2012, 35, 518–524. [Google Scholar] [CrossRef]

- Jones, M.A.L.B.J. Automotive adsorption air conditioner powered by exhaust heat. Part 1: Conceptual and embodiment design. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2006, 220, 959–972. [Google Scholar] [CrossRef]

- Lambert, M.A.; Jones, B.J. Automotive adsorption air conditioner powered by exhaust heat. Part 2: Detailed design and analysis. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2006, 220, 973–989. [Google Scholar] [CrossRef]

- Vasta, S.; Palomba, V.; La Rosa, D.; Bonanno, A. Experimental assessment and numerical study of a pump-assisted loop heat pipe for high capacity thermal systems. Appl. Therm. Eng. 2020, 180, 115828. [Google Scholar] [CrossRef]

- Palomba, V.; Vasta, S.; Giacoppo, G.; Calabrese, L.; Gulli, G.; La Rosa, D.; Freni, A. Design of an Innovative Graphite Exchanger for Adsorption Heat Pumps and Chillers. Energy Procedia 2015, 81, 1030–1040. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Li, J. Development and analysis of a simple structured and economic miniature vapor compression refrigerator for cooling electronics in harsh environment. Appl. Therm. Eng. 2023, 223, 120047. [Google Scholar] [CrossRef]

- Tatlier, M.; Munz, G.; Fueldner, G.; Henninger, S.K. Effect of zeolite A coating thickness on adsorption kinetics for heat pump applications. Microporous Mesoporous Mater. 2014, 193, 115–121. [Google Scholar] [CrossRef]

- Schnabel, L.; Tatlier, M.; Schmidt, F.; Erdem-Şenatalar, A. Adsorption kinetics of zeolite coatings directly crystallized on metal supports for heat pump applications (adsorption kinetics of zeolite coatings). Appl. Therm. Eng. 2010, 30, 1409–1416. [Google Scholar] [CrossRef]

- Rezk, A.R.M.; Al-Dadah, R.K. Physical and operating conditions effects on silica gel/water adsorption chiller performance. Appl. Energy 2012, 89, 142–149. [Google Scholar] [CrossRef]

- Sapienza, A.; Santamaria, S.; Frazzica, A.; Freni, A. Influence of the management strategy and operating conditions on the performance of an adsorption chiller. Energy 2011, 36, 5532–5538. [Google Scholar] [CrossRef]

- Rouf, R.A.; Alam, K.C.A.; Khan, M.A.H. Effect of Operating Conditions on the Performance of Adsorption Solar Cooling Run by Solar Collectors. Procedia Eng. 2013, 56, 607–612. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Chua, H.T.; Ng, K.C. Experimental investigation of silica gel–water adsorption chillers with and without a passive heat recovery scheme. Int. J. Refrig. 2005, 28, 756–765. [Google Scholar] [CrossRef]

- Belding, W.A.; Delmas, M.P.F.; Holeman, W.D. Desiccant aging and its effects on desiccant cooling system performance. Appl. Therm. Eng. 1996, 16, 447–459. [Google Scholar] [CrossRef]

- Vasta, S.; Giacoppo, G.; Barbera, O.; Calabrese, L.; Bonaccorsi, L.; Freni, A. Innovative zeolite coatings on graphite plates for advanced adsorbers. Appl. Therm. Eng. 2014, 72, 153–159. [Google Scholar] [CrossRef]

- Do, J.; Cha, D.; Park, I.; Kwon, O.K.; Bae, J.; Park, J. Hydrothermal synthesis and application of adsorbent coating for adsorption chiller. Prog. Org. Coat. 2019, 128, 59–68. [Google Scholar] [CrossRef]

- McCague, C.; Huttema, W.; Fradin, A.; Bahrami, M. Lab-scale sorption chiller comparison of FAM-Z02 coating and pellets. Appl. Therm. Eng. 2020, 173, 115219. [Google Scholar] [CrossRef]

- Sapienza, A.; Brancato, V.; Aristov, Y.; Vasta, S. Plastic heat exchangers for adsorption cooling: Thermodynamic and dynamic performance. Appl. Therm. Eng. 2021, 188, 116622. [Google Scholar] [CrossRef]

- Sood, D.; Das, D.; Ali, S.F.; Rakshit, D. Numerical analysis of an automobile cabin thermal management using passive phase change material. Therm. Sci. Eng. Progress 2021, 25, 100870. [Google Scholar] [CrossRef]

- Vasta, S.; Palomba, V.; La Rosa, D.; Bonanno, A. Adsorption Cold Storage for Mobile Applications. Appl. Sci. 2020, 10, 2044. [Google Scholar] [CrossRef] [Green Version]

- Huang, K.D.; Tzeng, S.C.; Ma, W.P.; Wu, M.F. Intelligent solar-powered automobile-ventilation system. Appl. Energy 2005, 80, 141–154. [Google Scholar] [CrossRef]

- Al-Rawashdeh, H.; Hasan, A.O.; Al-Shakhanbeh, H.A.; Al-Dhaifallah, M.; Gomaa, M.R.; Rezk, H. Investigation of the Effect of Solar Ventilation on the Cabin Temperature of Vehicles Parked under the Sun. Sustainability 2021, 13, 13963. [Google Scholar] [CrossRef]

- Srivastava, R.S.; Kumar, A.; Thakur, H.; Vaish, R. Solar assisted thermoelectric cooling/heating system for vehicle cabin during parking: A numerical study. Renew. Energy 2022, 181, 384–403. [Google Scholar] [CrossRef]

- Ahmed, H.A.; Megahed, T.F.; Mori, S.; Nada, S.; Hassan, H. Performance investigation of new design thermoelectric air conditioning system for electric vehicles. Int. J. Therm. Sci. 2023, 191, 108356. [Google Scholar] [CrossRef]

- Kim, D.H.; Seo, S.; Kim, S.; Shin, S.; Son, K.; Jeon, S.J.; Han, S. Design and performance analyses of thermoelectric coolers and power generators for automobiles. Sustain. Energy Technol. Assess. 2022, 51, 101955. [Google Scholar] [CrossRef]

- Su, C.Q.; Wang, Z.Z.; Liu, X.; Xiong, X.; Jiang, T.; Wang, Y.P. Research on thermal comfort of commercial vehicle and economy of localized air conditioning system with thermoelectric coolers. Energy Rep. 2022, 8, 795–803. [Google Scholar] [CrossRef]

| N | Sigle | Name | Formula | Description | GWP |

|---|---|---|---|---|---|

| 1 | R134a [28] | 1,1,1,2-Tetrafluoroethane | F3C-CH2-F | The R134a has been widely used as a replacement for the ozone-depleting refrigerant R12 (CFC-12). It has a relatively low global warming potential (GWP) compared to previous refrigerants. The R134a offers good thermodynamic properties and is compatible with the materials that are commonly found in automotive AC systems. However, its GWP is relatively high, and efforts are being made to transition to lower GWP alternatives. | 1300 |

| 2 | R1234yf [29] | 2,3,3,3-Tetrafluoropropene | CH2=CF-CF3 | The R1234yf is a hydrofluoroolefin (HFO) refrigerant specifically designed as a low GWP alternative to the R134a. It has a significantly lower GWP and is being widely adopted in the automotive industry to reduce environmental impact. The R1234yf provides a similar cooling performance to the R134a and is compatible with existing AC system components. It has gained regulatory approval for use in many regions. | 4 |

| 3 | R744 [30] | Carbon Dioxide | CO2 | Carbon dioxide, or R744, is an environmentally friendly refrigerant with a GWP of 1. It is a natural refrigerant and has excellent thermodynamic properties. However, due to its high operating pressures, the R744 requires specialized AC system components, including high-pressure compressors and heat exchangers. R744 AC systems are commonly used in electric and hybrid vehicles. | 1 |

| 4 | R152a [28] | 1,1-Difluoroethane | C2H4F2 | The R152a is a hydrofluorocarbon (HFC) refrigerant that has a lower GWP than the R134a. It offers similar thermodynamic properties to the R134a and is compatible with existing AC system components. However, its use is less widespread compared to the R134a and R1234yf. | 124 |

| 5 | R290 [31] | Propane | CH3CH2CH3 | Propane, or R290, is a hydrocarbon refrigerant with a very low GWP. It is a natural refrigerant and has excellent thermodynamic properties. The R290 is flammable and requires specific safety measures during handling and use. Its application in automotive AC systems is limited due to safety concerns, but it has been explored in some specialized vehicle applications. | 3 |

| 6 | R1234ze [32] | Trans-1,3,3,3-Tetrafluoropropene | C3H2F4 | The R1234ze is an HFO refrigerant with a very low GWP. It is considered a potential replacement for the R134a and R1234yf. The R1234ze offers good energy efficiency and thermal properties, making it suitable for automotive AC systems. It is being actively researched and tested for its applicability in various cooling applications. It has zero ozone depletion potential (ODP = 0), a very low global warming potential that is even lower than CO2 [33], and it is classified by ANSI/ASHRAE as a class A2L refrigerant (lower flammability and lower toxicity). | <1 [33] |

| 7 | R152a/R1234yf Blends [34] | -- | -- | Blends of the R152a and R1234yf are being considered as potential alternatives to single-component refrigerants. These blends aim to combine the desirable characteristics of both refrigerants, such as a low GWP, good energy efficiency, and compatibility with existing AC system components. Research is ongoing to optimize the blend ratios and assess their performance in automotive AC applications. | |

| 8 | HFOs [35] | Hydrofluoroolefins (HFOs) with Ultra-Low GWPs | -- | HFOs continue to be an area of exploration for future refrigerants. Researchers are working on developing HFOs with ultra-low GWPs to further reduce the environmental impact of automotive AC systems. These HFOs aim to provide improved energy efficiency and thermodynamic properties while minimizing direct and indirect greenhouse gas emissions. | |

| 9 | R717, R600 [36] | Natural Refrigerants: Ammonia, Butane | -- | Natural refrigerants, such as ammonia (R717) and hydrocarbons (propane–R290, butane–R600), are gaining attention as environmentally friendly alternatives. These refrigerants have very low GWPs and are readily available. However, their adoption in automotive AC systems is limited due to safety concerns and the need for specialized components. Ongoing research is focused on enhancing the safety aspects and evaluating the feasibility of natural refrigerants in automotive applications. |

| From the Coolant | From the Exhaust | |

|---|---|---|

| Temperature | 80–90 °C | >400 °C |

| Pros |

|

|

| Cons |

|

|

| N | Type of Vehicle | Adsorbent | Refrigerant | Tsource | Tev | COP | SCP | Capacity | Heat Source | Reference |

|---|---|---|---|---|---|---|---|---|---|---|

| [°C] | [°C] | [W/kg] | [kW] | |||||||

| 1 | Car | Zeolite 13X | Water | 300–450 | 10 | 0.41 | 45 | n.a. | Exhaust | [75] |

| 2 | Car | AC | Ammonia | 90 | 20 | 0.22 | <800 | 1.6–2.0 | Coolant loop | [58] |

| 3 | Car | Silica Gel | Water | 90 | 12 | 0.61 | 205 | 3.6 | Coolant loop | [76] |

| 4 | Truck | Zeolite | Water | 250–300 | 10 | 0.38 | 26 | 45 | Exhaust | [77] |

| 5 | Truck | Zeolite 13X | Water | 0 | 1–16 | 0.4 | 180 | 0.01 | Exhaust | [78] |

| 6 | Truck | Zeolite | Water | 250 | 7–15 | 0.43 | n.a. | 2.0 | Exhaust | [51] |

| 7 | Truck | Zeolite | Water | 90 | 10 | 0.6 | n.a. | 5.0 | Coolant loop | [79] |

| 8 | Truck | Zeolite | Water | >400 | 11 | n.a | n.a. | 2.5 | Exhaust | [80] |

| 9 | Truck | Zeolite FAM Z02 | Water | 90 | 9 | 0.45 | 300–600 | 2.3 | Coolant loop | [48] |

| 10 | Train | Zeolite | Water | 230 | 18 | 0.38 | n.a. | 3.4 | Exhaust | [81] |

| 11 | Train | Zeolite | Water | 350–450 | 10 | 0.25 | 165 | 6.5–10.0 | Exhaust | [82] |

| 12 | Train | Zeolite | Water | 400 | 7 | 0.25 | n.a. | 5.0 | Exhaust | [83] |

| 13 | Train | Zeolite | Water | 200–250 | 18 | 0.21 | n.a. | 3.0–4.2 | Exhaust | [84] |

| 14 | Train | Zeolite | Water | 200–250 | 5 | 0.25 | n.a. | 2.8–4.0 | Exhaust | [63] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasta, S. Adsorption Air-Conditioning for Automotive Applications: A Critical Review. Energies 2023, 16, 5382. https://doi.org/10.3390/en16145382

Vasta S. Adsorption Air-Conditioning for Automotive Applications: A Critical Review. Energies. 2023; 16(14):5382. https://doi.org/10.3390/en16145382

Chicago/Turabian StyleVasta, Salvatore. 2023. "Adsorption Air-Conditioning for Automotive Applications: A Critical Review" Energies 16, no. 14: 5382. https://doi.org/10.3390/en16145382

APA StyleVasta, S. (2023). Adsorption Air-Conditioning for Automotive Applications: A Critical Review. Energies, 16(14), 5382. https://doi.org/10.3390/en16145382