1. Introduction

About 50% of the total final energy consumption in the world can be attributed to the heat used in the residential and industrial sectors. With the rapid development of urbanization, the heating area of urban buildings in northern China increased from 5 billion m

2 to 15.6 billion m

2 from 2001 to 2020. In 2020, the urban heating energy consumption in northern China was 214 million tons of standard coal, accounting for 20.2% of the total building energy consumption [

1]. Heating is not only an energy consumption issue but is also a livelihood issue. In northern China, the average outdoor temperature in the heating season is relatively low. For example, the calculated outdoor temperature for heating in Zhangjiakou, Hebei, is −13.6 °C. In addition, space heating still relies on traditional energy sources, such as coal and natural gas, in northern China. The spatial distribution of the solar energy resources in China is highly consistent with traditional centralized heating areas, especially in the northern regions. Therefore, the development of solar heating in northern China not only has demand advantages but also resource advantages.

Solar-heating systems with storage are very common. The salt-gradient solar pond (SGSP) is one of these systems. Rghif et al. conducted extensive in-depth research to further improve the performance and efficiency of SGSP systems [

2,

3,

4,

5]. STS can effectively solve the mismatch between the supply of and demand for thermal energy in time and space, and the solar fraction and operational stability of solar-heating systems can be significantly improved. Thus, seasonal thermal storage technology has attracted increasing attention. Many researchers have conducted performance and operation strategy analyses.

A reasonable performance analysis of the system is premised on establishing a solar-heating system with STS. Tosatto et al. studied the environmental aspect and technical performance of large-scale thermal energy storage coupled with a heat pump in district-heating systems. The results showed that the integration of the heat pump proved to be effective at increasing the thermal storage efficiency by 6% (from 87%) compared to the reference case without a heat pump in the case of insulated-tank thermal storage, and by 16% (from 64%) in the case of an insulated shallow pit [

6]. Narula et al. present a new simulation method for modeling hourly energy flows in a district-heating system integrated with STS. Based on the validation with the measured values of Friedrichshafen and Marstal, the annual energy flow could be closely replicated, while large monthly differences between the simulations and measurements were reported [

7]. Ushamah et al. compared the performances of district-heating systems with STS under different climatic conditions and identified the best suitable solar thermal technology. The conclusion was that the zone with a continental semi-arid climate was the most suitable, with an STS efficiency of 61% and a solar fraction of 91% [

8]. Kim et al. evaluated the technology and economic performance of a hybrid renewable energy system with STS in South Korea using dynamic simulations and experimental results. The results showed that the proposed system reduced CO

2 emissions by up to 61% compared with a centralized heat-pump system, and enhanced primary energy savings by up to 73% compared with gas-fired boilers [

9]. Chu et al. assessed the technical and economic feasibility of a solar-assisted precinct-level heating system with STS for Australian cities, and the results demonstrated that the proposed system could achieve technical and economic targets in all five Australian cities considered with an optimal collector area and storage volume [

10]. Renaldi et al. established a validated simulation model to study the yearly performance of a solar district-heating system with STS in the UK. According to the study, solar collectors and the long-term storage size have a more significant influence on the techno-economic metrics than short-term storage [

11]. Zhang et al. experimentally investigated the dynamic thermal behaviors of a combined solar- and ground-source heat-pump (SGHP) system with a dual storage tank for a single-family house on typical days [

12].

The design of reasonable operation strategies is an important factor to realize the stable operation of the system, the efficient integration of all parts of the system, and the reduction in the system cost. Maragna et al. introduced a multi-source system and overall control strategies combining solar thermal collectors, borehole thermal energy storage, a heap pump, and a backup boiler. Monthly and typical-day system performances were also analyzed, and the results illustrated that the energy balance is sensitive to the choice of the parameter values used for the controls [

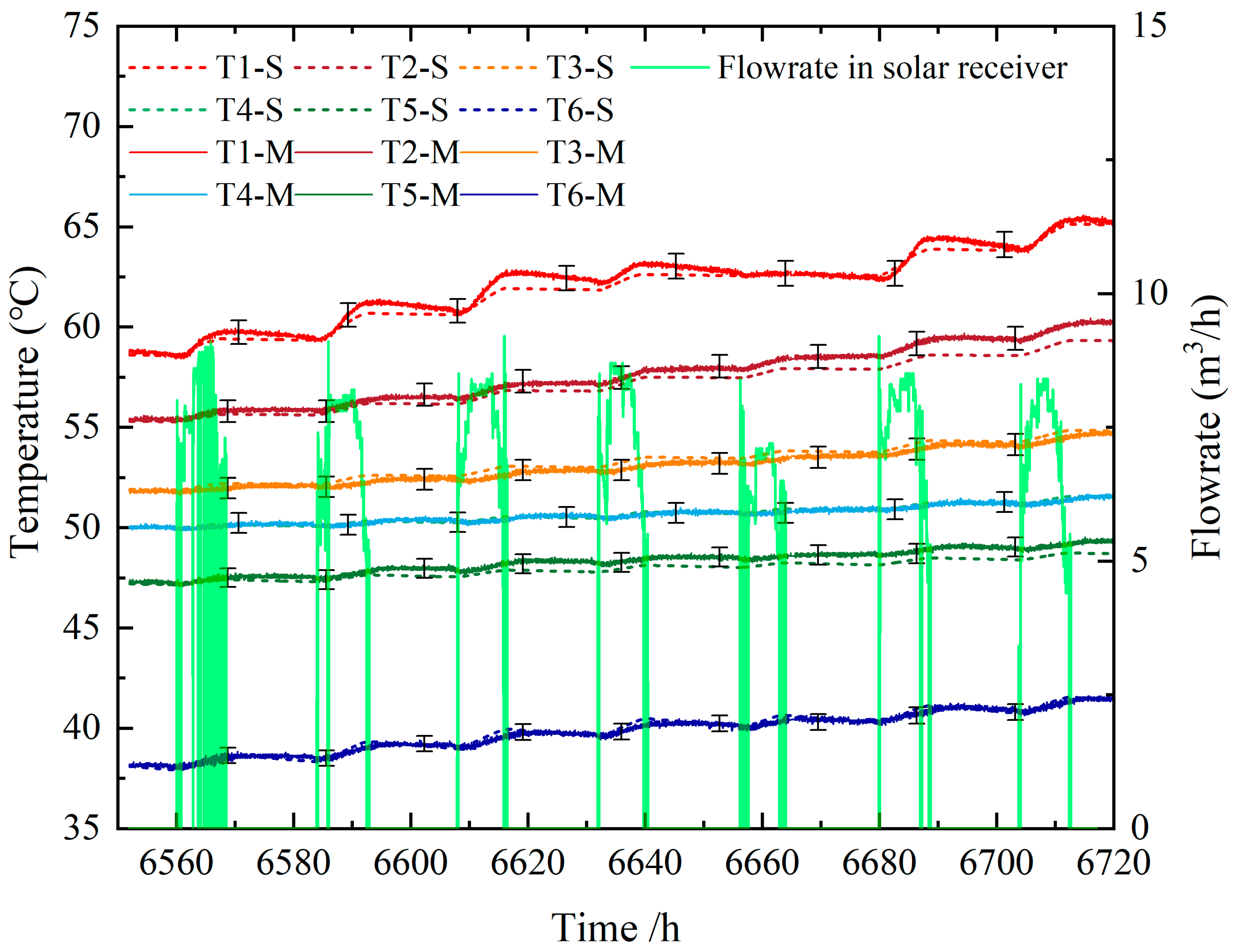

13]. Li et al. compared the influence of the control strategies of the solar-collection subsystem on the system performance in a non-heating system. Note that the control strategies were significant for improving the heat-collection performance of the solar receiver, and the stratification of the STS also had an impact on the collection efficiency of the receiver, especially at the end of the non-heating season [

14]. Villasmil et al. studied the performance of a solar-heating system with STS under the variation in solar-collector control strategies. The results showed that the required storage volume was minimized through the application of a low-flow controller, while the use of a high-flow controller and variable-flow controller led to increases of 42 and 8% in the storage volume, respectively [

15]. Wang et al. proposed a feedback control strategy for an integrated solar- and air-source heat-pump water-heating system, for which the temperature of the heat storage tank was compared with the set temperature curve to determine whether to use an air-source heat pump for auxiliary heating. The reliability of the control strategy was verified through a simulation and experimental research, and the operational efficiencies of the collector and air-source heat pump were significantly improved [

16]. Zhao et al. proposed a system operation control strategy and studied the annual operating performance of a solar-heating system with seasonal water-pool thermal storage in cold regions of China. The analysis revealed that the solar fraction of the system with the adjustment-operation strategy during the heating period can reach 78.5% [

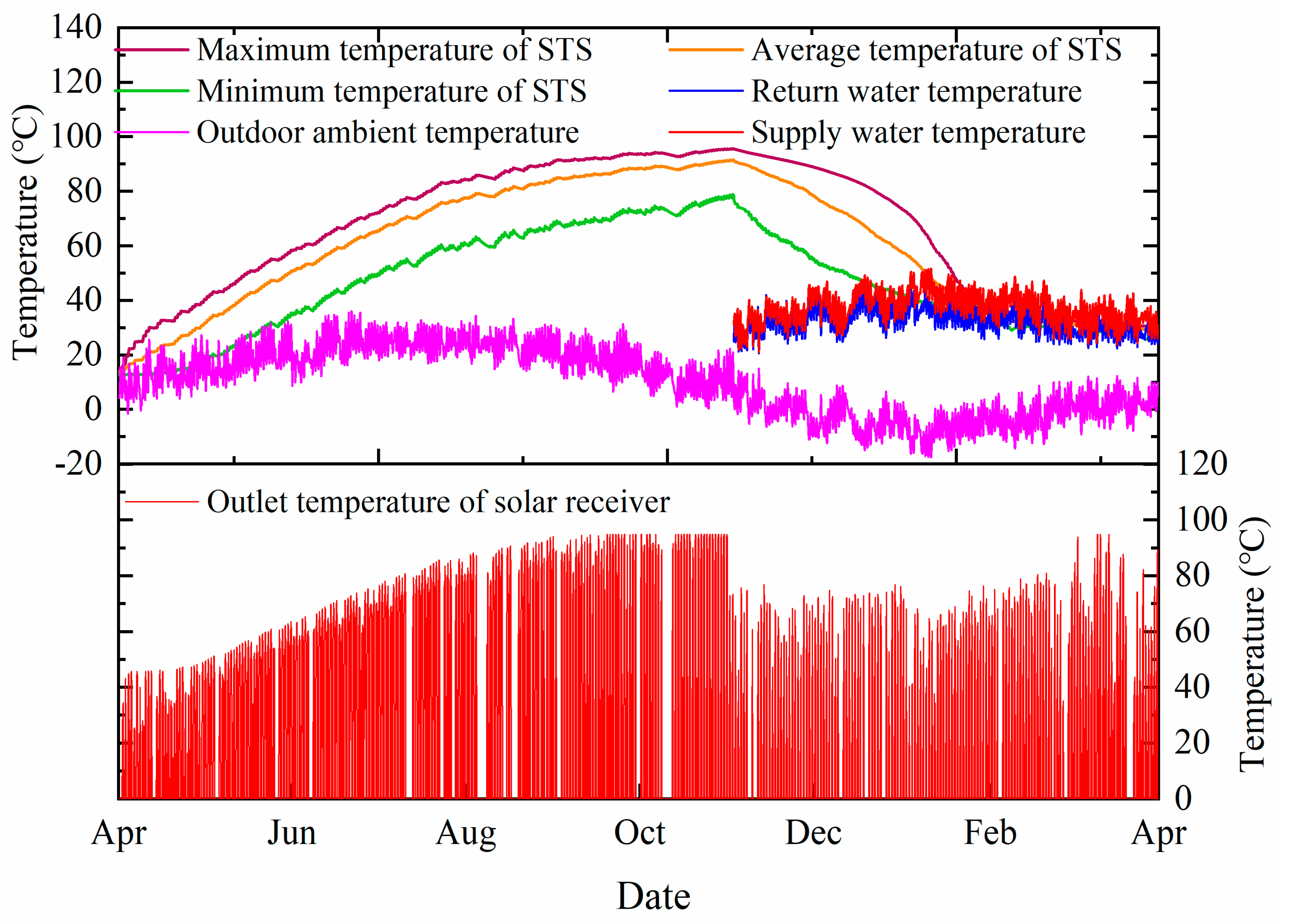

17].

As mentioned above, many scholars have conducted a lot of work concerning the performance assessment of solar-heating systems with STS, and most previous studies focused on techno-economic analyses based on the annual energy balance of the system, or operation strategy analyses aimed at the solar circuit or thermal storage circuit. However, due to the instability of solar radiation resources and the heat demand, it is necessary to balance the heat supply and demand throughout the year, and to analyze the dynamic response characteristics and heating quality on a minute timescale. Yet, related studies are still scarce.

To fill the gaps mentioned above, based on a pilot solar-heating system with STS in Huangdicheng, northern China, a dynamic performance evaluation and operation strategy study are presented in this paper. The main novelties of the present study can be clarified as follows:

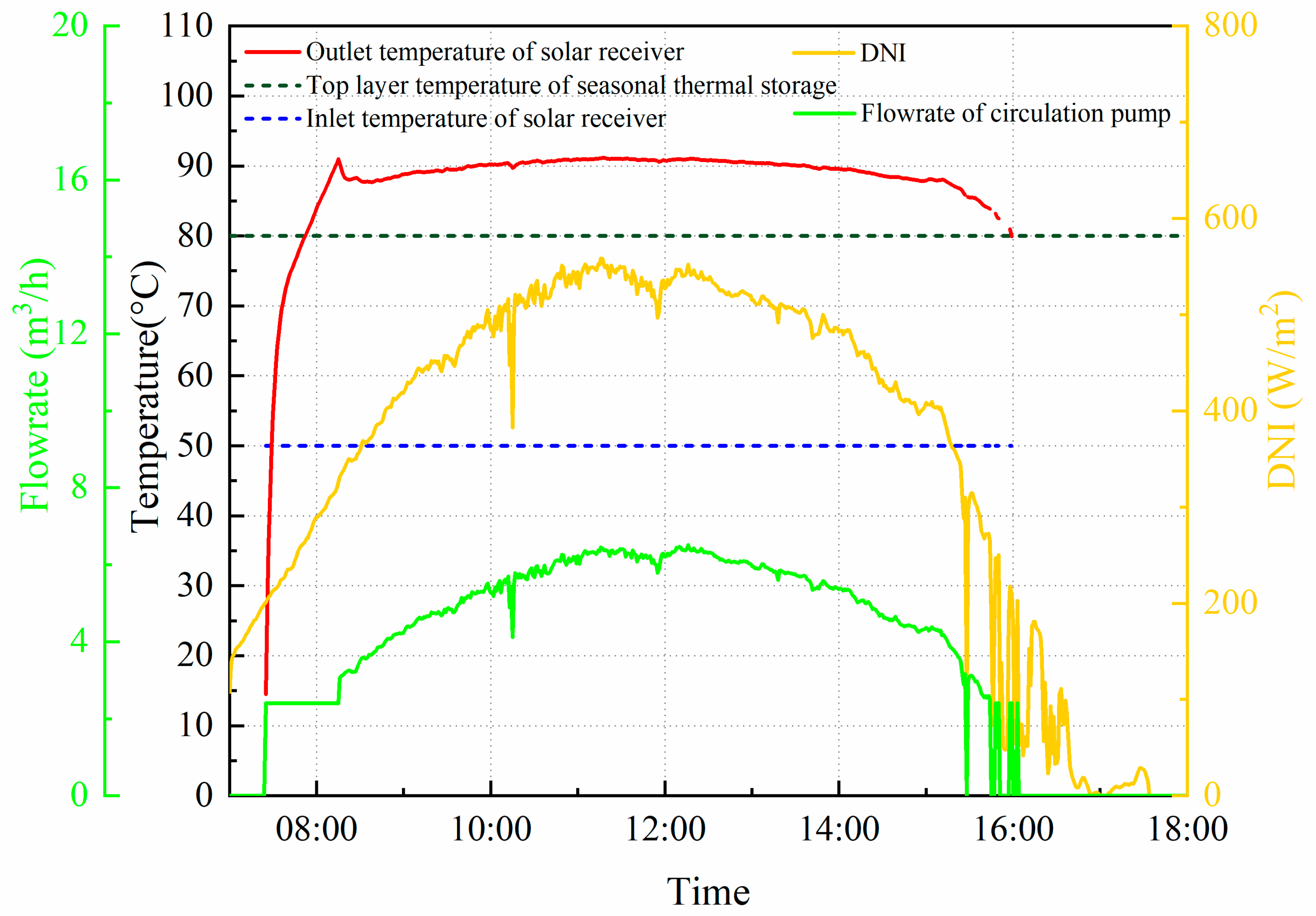

The system’s dynamical performance was analyzed with a dynamic simulated method in typical-day or typical-operation modes, and the switch mechanism between multiple operation modes was revealed on a minute timescale;

The system can reach a higher system performance with the proposed control strategies under different operation stages;

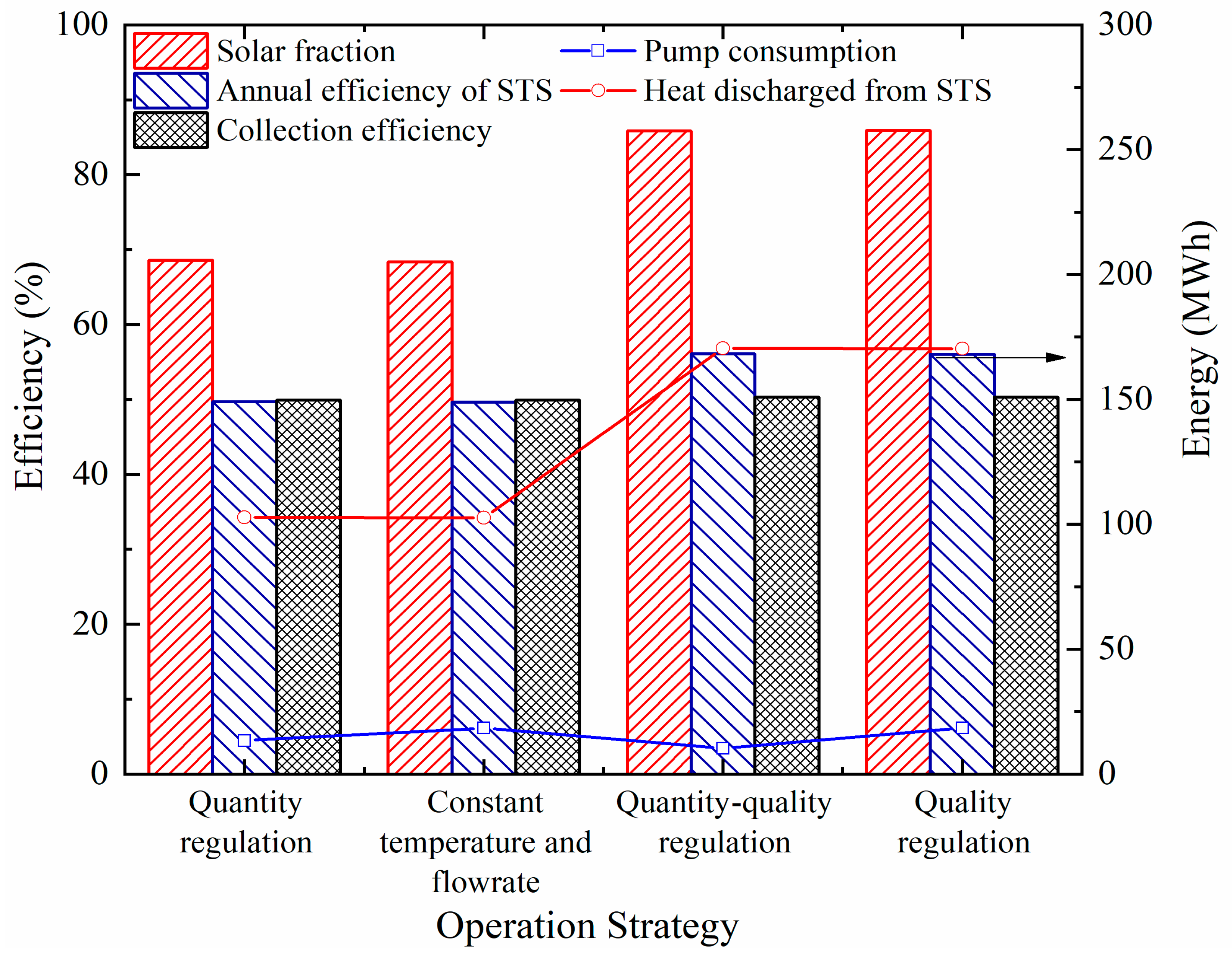

The impacts of different heating operation strategies on the system performance were quantified. The performance indicators included the collection efficiency, storage efficiency, solar fraction of the system, and consumption of the circulation pump on the heating side.

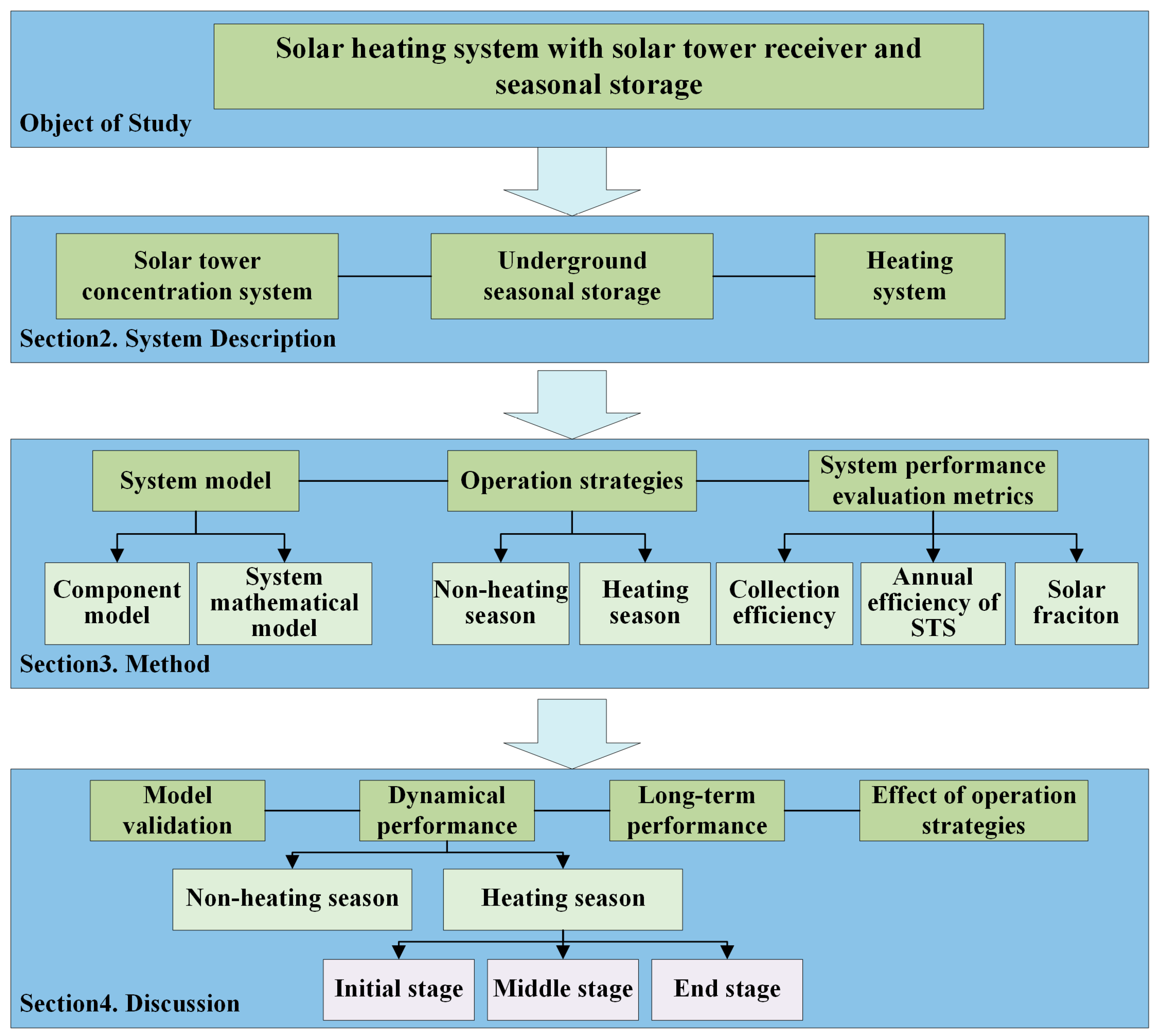

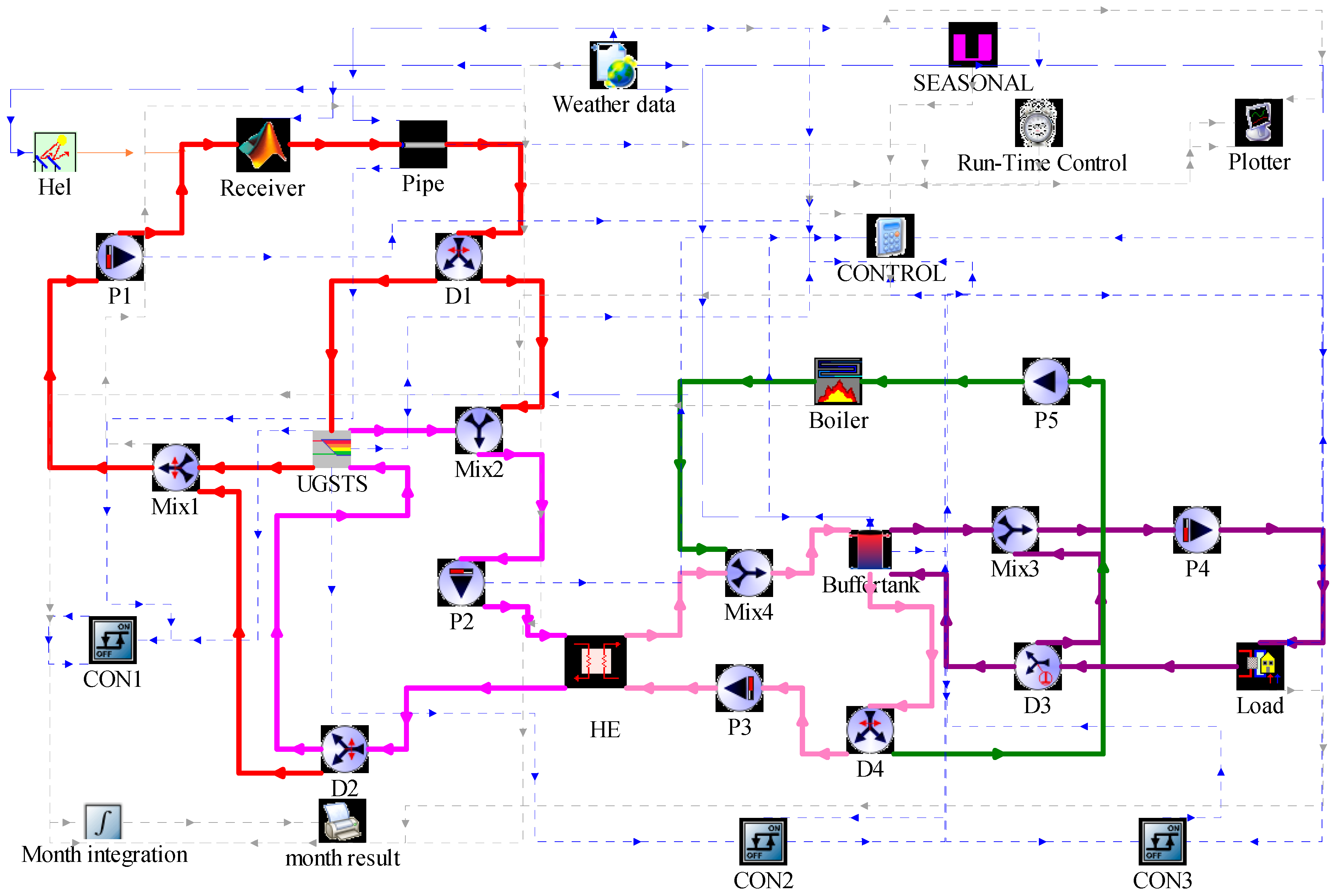

The frame structure of the study is presented in

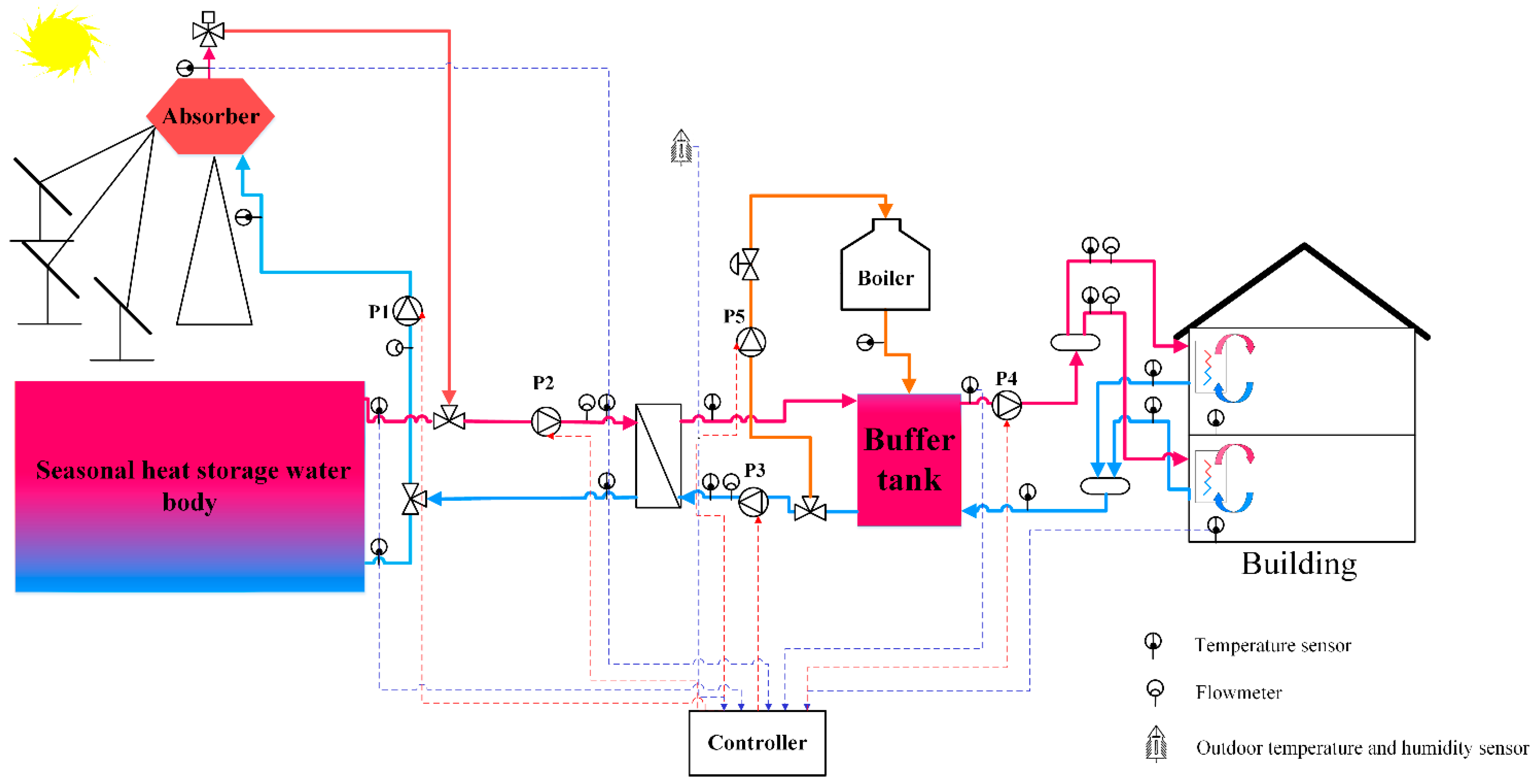

Figure 1. The concept of a pilot solar-heating system with a solar-tower receiver and STS is described in

Section 2.

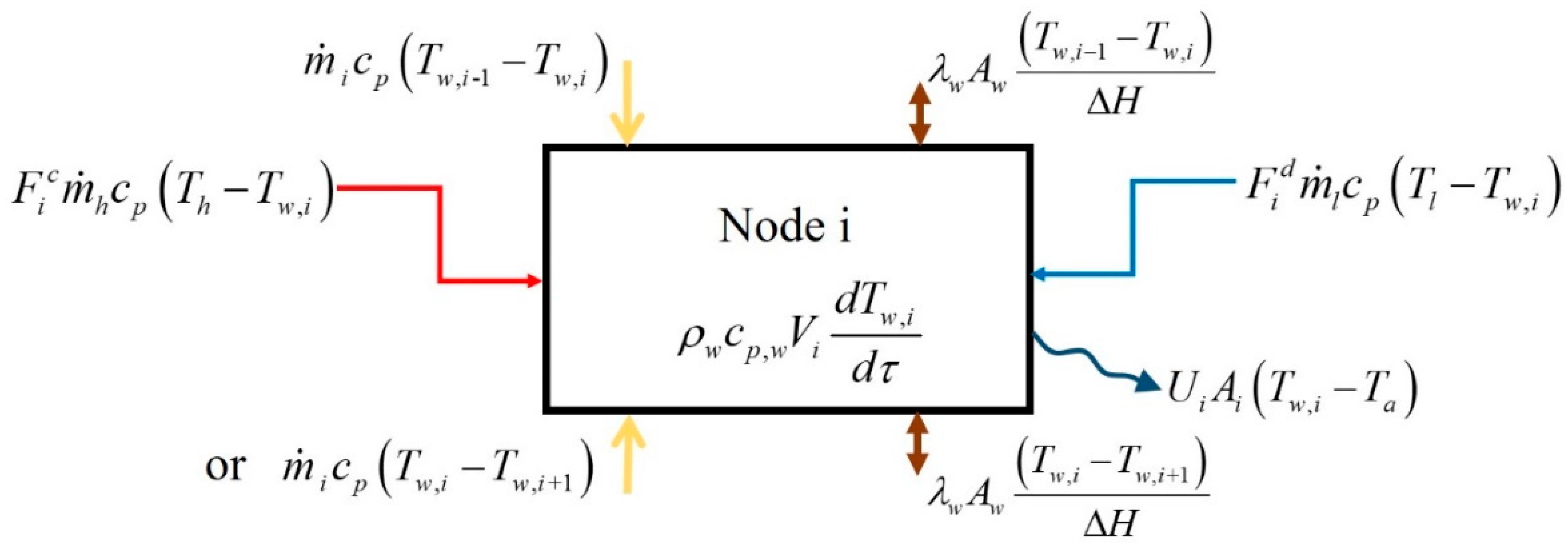

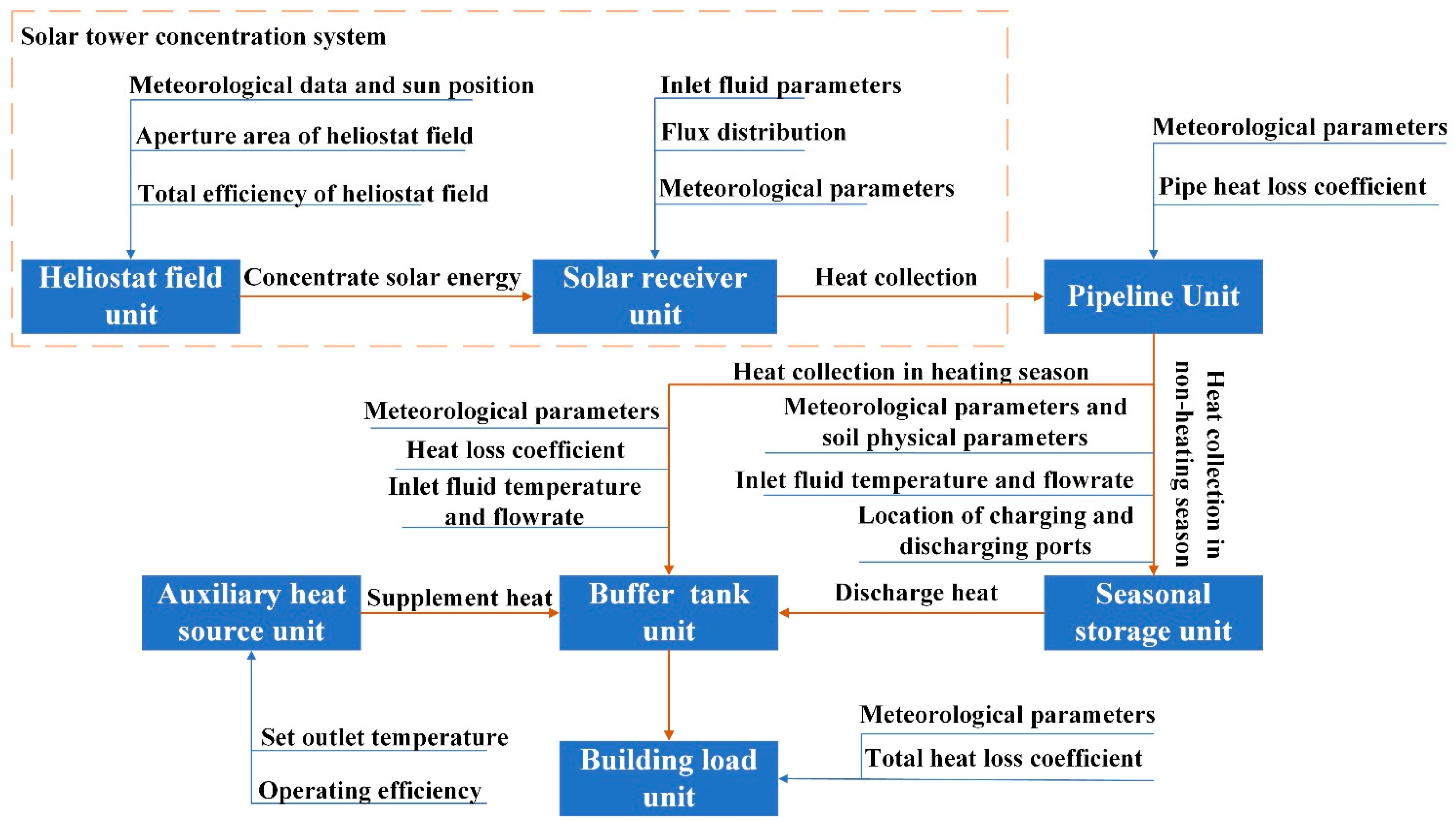

Section 3 shows the analysis methods, which include the system simulation method, operation strategies, and performance evaluation metrics.

Section 4 shows the validation of the system model, the assessment of the dynamic performance of the system in different operation modes, the long-term performance, and the analysis of the operation strategies. Finally, the main conclusions of our study are summarized in

Section 5.