A Comprehensive Review of Digital Twin Technology for Grid-Connected Microgrid Systems: State of the Art, Potential and Challenges Faced

Abstract

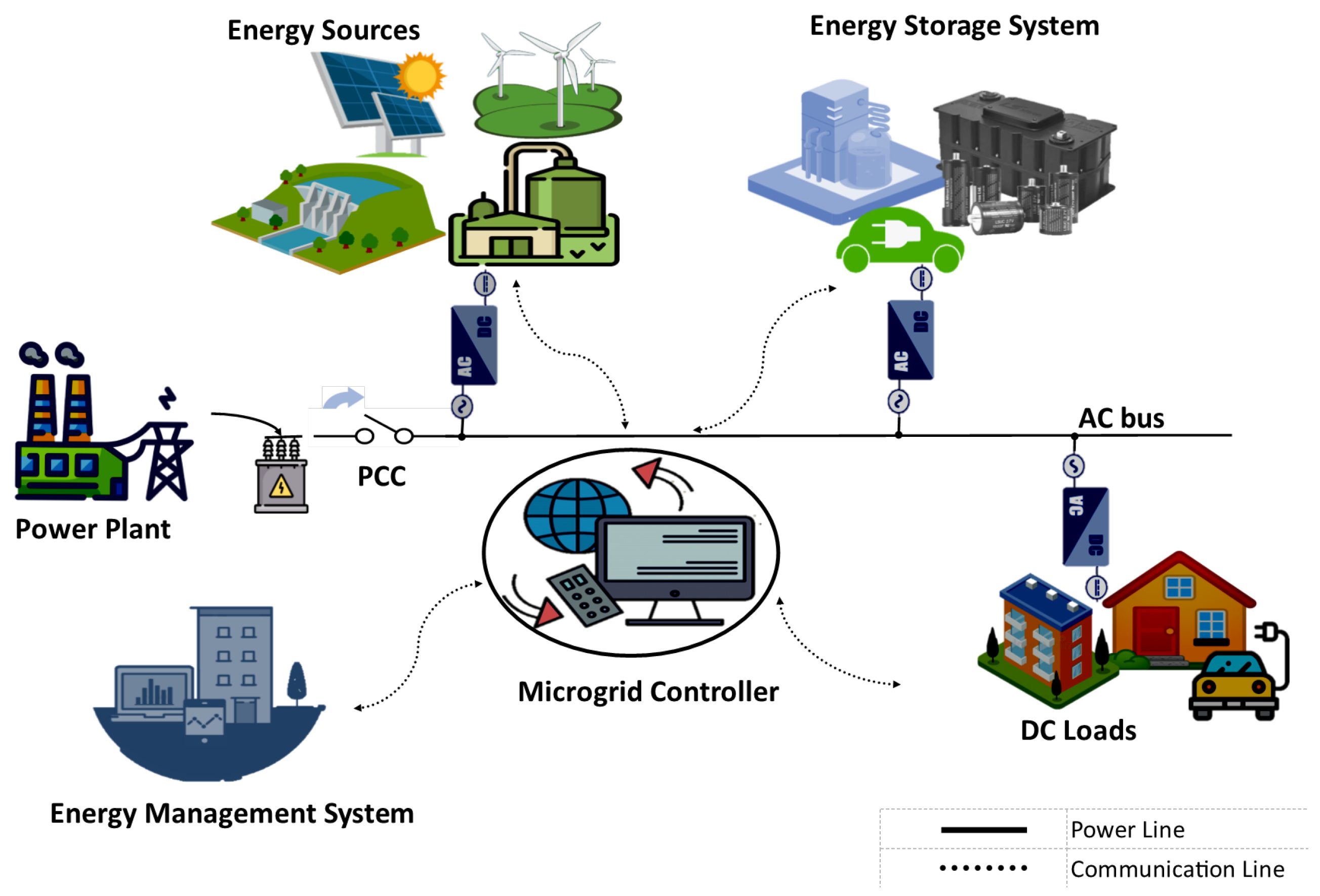

:1. Introduction

2. DT Development

2.1. DT Design Requirements

2.2. DT Enablers and Its Stages

3. DT Applications for MG Components

3.1. Solar Power

3.2. Wind Energy

3.3. Biogas Energy

3.4. Battery

3.5. Electric Vehicle

3.6. Power Converters

4. DT for EMS Operation

5. Challenges and Applications of MGDT

5.1. Challenges in Developing MGDT

5.2. Applications of MGDT

- Health Monitoring: The health monitoring of equipment used in the energy sector is very important as they face various wear and tear situations such as environmental conditions, thermal expansions, vibrations, etc. It is easier to keep industrial equipment running well if there is a primary awareness about its current state of health. Capturing system degradation, performance and ageing data of physical systems are essential requirements of health monitoring [27]. The MGDT can also be used to know the remaining utilised life of the electrical equipment so that the life expectancy can be known. High-fidelity DT models can estimate maintenance needs for power carriers, circuit breakers and other industrial equipment [22].

- Forecasting: Forecasting power availability in MGs will help maintain the supply–demand balance, which is the primary and basic user demand. With the uncertainty of RES, establishing effective predictors to determine the available power of MG is vital. Accurate estimates of available power will enable their participation in services like reactive power support, voltage regulation, etc., to ensure MG’s reliable and secure operation.

- Fault detection: Power grids are frequently prone to faults due to their complexity. Therefore, fault diagnosis is a crucial part of MGs. After a fault event occurs, it is crucial to detect the occurrence, determine the type of problem and prescribe the necessary measures. An efficient fault diagnostic system is required in which DT can help in developing such a model [22]. This will increase the MG dependability by reducing the system response time [81] and associated implications, such as loss of load, outage cost and system stress. A field-programmable gate array DT is used for real-time monitoring and fault diagnostic of power electronic transformer in [82].

- Control Management: The management through MGDT can be seen in two sections. First, the maintenance of optimal power flow [83] within the MGs. Second, as the DT is completely made out of available data, it is important to take good care of the data and do the best possible channelisation of those data. Exploiting the full capability of the mature simulation environment, the effectiveness of the suggested control strategies may be verified under various operating scenarios. Hence, the essential changes can be performed in advance [29].

- Decision Making: The MGDT will facilitate decision-making by supplying information such as the remaining life of equipment, equipment health, weather reports, scheduled power and available power. Information gathered by the MGDT model will aid operators in making judgements.

- Cyber security: Keeping sensitive information safe is very important in the modern era of widespread digitisation. As power grids have become increasingly dependent on digital means of communication and control, safeguarding information has become essential. A protective setting is crucial for MG’s trouble-free operation. Kandasamy et al. [84] created a virtual replica of a physical test-bed for cyber security research on smart grids to address its limitations.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sleiti, A.K.; Kapat, J.S.; Vesely, L. Digital twin in energy industry: Proposed robust digital twin for power plant and other complex capital-intensive large engineering systems. Energy Rep. 2022, 8, 3704–3726. [Google Scholar] [CrossRef]

- Hatziargyriou, N.; Sakis Meliopoulos, A. Distributed energy sources: Technical challenges. In Proceedings of the 2002 IEEE Power Engineering Society Winter Meeting. Conference Proceedings (Cat. No.02CH37309), New York, NY, USA, 27–31 January 2002; Volume 2, pp. 1017–1022. [Google Scholar] [CrossRef]

- Chandra, A.; Singh, G.K.; Pant, V. Protection of AC microgrid integrated with renewable energy sources—A research review and future trends. Electr. Power Syst. Res. 2021, 193, 107036. [Google Scholar] [CrossRef]

- Sbordone, D.; Bertini, I.; Di Pietra, B.; Falvo, M.C.; Genovese, A.; Martirano, L. Ev fast charging stations and energy storage technologies: A real implementation in the smart micro grid paradigm. Electr. Power Syst. 2015, 120, 96–108. [Google Scholar] [CrossRef]

- Khemmook, P.; Prompinit, K.; Surinkaew, T. Control of a microgrid using robust data-driven-based controllers of distributed electric vehicles. Electr. Power Syst. Res. 2022, 213, 108681. [Google Scholar] [CrossRef]

- Dragicevic, T.; Vasquez, J.C.; Guerrero, J.M.; Skrlec, D. Advanced lvdc electrical power architectures and microgrids: A step toward a new generation of power distribution networks. IEEE Electrif. Mag. 2014, 2, 54–65. [Google Scholar] [CrossRef] [Green Version]

- DOE. 2012 DOE Microgrid Workshop Summary Report (September 2012) Department of Energy; U.S. Department of Energy: Washington, DC, USA, 2012.

- Saeed, M.H.; Fangzong, W.; Kalwar, B.A.; Iqbal, S. A review on microgrids’ challenges & perspectives. IEEE Access 2021, 9, 166502–166517. [Google Scholar]

- Jamil, M.; Hussain, B.; Abu-Sara, M.; Boltryk, R.J.; Sharkh, S.M. Microgrid power electronic converters: State of the art and future challenges. In Proceedings of the 2009 44th International Universities Power Engineering Conference (UPEC), Glasgow, UK, 1–4 September 2009; pp. 1–5. [Google Scholar]

- Khavari, F.; Badri, A.; Zangeneh, A. Energy management in multi-microgrids considering point of common coupling constraint. Int. J. Electr. Power Energy Syst. 2020, 115, 105465. [Google Scholar] [CrossRef]

- Daneshi, H.; Khorashadi-Zadeh, H. Microgrid energy management system: A study of reliability and economic issues. In Proceedings of the 2012 IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012; pp. 1–5. [Google Scholar]

- Khodaei, A. Resiliency-oriented microgrid optimal scheduling. IEEE Trans. Smart Grid 2014, 5, 1584–1591. [Google Scholar] [CrossRef]

- He, J.; Li, Y.W.; Blaabjerg, F. Flexible microgrid power quality enhancement using adaptive hybrid voltage and current controller. IEEE Trans. Ind. Electron. 2013, 61, 2784–2794. [Google Scholar] [CrossRef]

- Hirsch, A.; Parag, Y.; Guerrero, J. Microgrids: A review of technologies, key drivers, and outstanding issues. Renew. Sustain. Energy Rev. 2018, 90, 402–411. [Google Scholar] [CrossRef]

- Gokhale, P.; Bhat, O.; Bhat, S. Introduction to iot, International Advanced Research Journal in Science. Eng. Technol. 2018, 5, 41–44. [Google Scholar]

- Hossein Motlagh, N.; Mohammadrezaei, M.; Hunt, J.; Zakeri, B. Internet of Things (IoT) and the Energy Sector. Energies 2020, 13, 494. [Google Scholar] [CrossRef] [Green Version]

- Nord, J.H.; Koohang, A.; Paliszkiewicz, J. The internet of things: Review and theoretical framework. Expert Syst. Appl. 2019, 133, 97–108. [Google Scholar] [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A survey on digital twin: Definitions, characteristics, applications, and design implications. IEEE Access 2019, 7, 167653–167671. [Google Scholar] [CrossRef]

- Minerva, R.; Lee, G.M.; Crespi, N. Digital twin in the iot context: A survey on technical features, scenarios, and architectural models. Proc. IEEE 2020, 108, 1785–1824. [Google Scholar] [CrossRef]

- Stark, R.; Fresemann, C.; Lindow, K. Development and operation of digital twins for technical systems and services. CIRP Ann. 2019, 68, 129–132. [Google Scholar] [CrossRef]

- Lopes, J.A.P.; Madureira, A.G.; Matos, M.; Bessa, R.J.; Monteiro, V.; Afonso, J.L.; Santos, S.F.; Catalão, J.P.; Antunes, C.H.; Magalhães, P. The future of power systems: Challenges, trends, and upcoming paradigms. Wiley Interdiscip. Rev. Energy Environ. 2020, 9, e368. [Google Scholar] [CrossRef]

- Palensky, P.; Cvetkovic, M.; Gusain, D.; Joseph, A. Digital twins and their use in future power systems. Digit. Twin 2021, 1, 4. [Google Scholar] [CrossRef]

- Zhou, M.; Yan, J.; Feng, D. Digital twin framework and its application to power grid online analysis. CSEE J. Power Energy Syst. 2019, 5, 391–398. [Google Scholar] [CrossRef]

- Andryushkevich, S.K.; Kovalyov, S.P.; Nefedov, E. Composition and application of power system digital twins based on ontological modeling. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; pp. 1536–1542. [Google Scholar] [CrossRef]

- Pan, H.; Dou, Z.; Cai, Y.; Li, W.; Lei, X.; Han, D. Digital twin and its application in power system. In Proceedings of the 2020 5th International Conference on Power and Renewable Energy (ICPRE), Shanghai, China, 12–14 September 2020; pp. 21–26. [Google Scholar]

- Madni, A.M.; Madni, C.C.; Lucero, S.D. Leveraging digital twin technology in model-based systems engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef] [Green Version]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital twin: Values, challenges and enablers from a modeling perspective. IEEE Access 2020, 8, 21980–22012. [Google Scholar] [CrossRef]

- Zhong, Y.; Zhang, W.; Ha, X.; Chen, Q.; Huang, J.; Yan, K. Innovative digital twin platform construction for smart grid system. In Proceedings of the 2021 IEEE 23rd Int Conf on High Performance Computing & Communications; 7th Int Conf on Data Science & Systems; 19th Int Conf on Smart City; 7th Int Conf on Dependability in Sensor, Cloud & Big Data Systems & Application (HPCC/DSS/SmartCity/DependSys), Haikou, China, 20–22 December 2021; pp. 1833–1838. [Google Scholar]

- Bazmohammadi, N.; Madary, A.; Vasquez, J.C.; Mohammadi, H.B.; Khan, B.; Wu, Y.; Guerrero, J.M. Microgrid digital twins: Concepts, applications, and future trends. IEEE Access 2022, 10, 2284–2302. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital twin in industry: State-of-the-art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Pargmann, H.; Euhausen, D.; Faber, R. Intelligent big data processing for wind farm monitoring and analysis based on cloud-technologies and digital twins: A quantitative approach. In Proceedings of the 2018 IEEE 3rd International Conference on Cloud Computing and Big Data Analysis (ICCCBDA), Chengdu, China, 20–22 April 2018; pp. 233–237. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, W.; Arendt, P.; Huang, H.-Z. Toward a Better Understanding of Model Validation Metrics. J. Mech. Des. 2011, 133, 071005. Available online: http://arxiv.org/abs/https://asmedigitalcollection.asme.org/mechanicaldesign/article-pdf/133/7/071005/5926232/071005_1.pdf (accessed on 6 July 2022). [CrossRef]

- Parisi, G.I.; Kemker, R.; Part, J.L.; Kanan, C.; Wermter, S. Continual lifelong learning with neural networks: A review. Neural Netw. 2019, 113, 54–71. [Google Scholar] [CrossRef]

- Bullich-Massague, E.; Díaz-González, F.; Aragüés-Peñalba, M.; Girbau-Llistuella, F.; Olivella-Rosell, P.; Sumper, A. Microgrid clustering architectures. Appl. Energy 2018, 212, 340–361. [Google Scholar] [CrossRef]

- Yoldaş, Y.; Önen, A.; Muyeen, S.; Vasilakos, A.V.; Alan, I. Enhancing smart grid with microgrids: Challenges and opportunities. Renew. Sustain. Energy Rev. 2017, 72, 205–214. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Development of a pss for smart grid energy distribution optimization based on digital twin. Procedia CIRP 2022, 107, 1138–1143. [Google Scholar] [CrossRef]

- Baboli, P.T.; Babazadeh, D.; Kumara Bowatte, D.R. Measurement-based modeling of smart grid dynamics: A digital twin approach. In Proceedings of the 2020 10th Smart Grid Conference (SGC), Kashan, Iran, 16–17 December 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Borth, M.; Verriet, J.; Muller, G. Digital twin strategies for sos 4 challenges and 4 architecture setups for digital twins of sos. In Proceedings of the 2019 14th annual conference system of systems engineering (SoSE), Anchorage, AK, USA, 19–22 May 2019; pp. 164–169. [Google Scholar]

- Danilczyk, W.; Sun, Y.L.; He, H. Smart grid anomaly detection using a deep learning digital twin. In Proceedings of the 2020 52nd North American Power Symposium (NAPS), Tempe, AZ, USA, 11–13 April 2021; pp. 1–6. [Google Scholar]

- Reports, S.I. Global Market Outlook for Solar Power 2018–2022. 2018. Available online: https://resources.solarbusinesshub.com/solar-industry-reports/item/global-market-outlook-2018-2022 (accessed on 6 July 2022).

- Smiley, K.; Qu, X.; Galoppo, T.; Harper, K.E.; Kucheria, A.; Acharya, M.; Tarzanin, F. Managing solar asset performance with connected analytics. ABB Rev. 2019, 2019, 34–41. [Google Scholar]

- Jain, P.; Poon, J.; Singh, J.P.; Spanos, C.; Sanders, S.R.; Panda, S.K. A digital twin approach for fault diagnosis in distributed photovoltaic systems. IEEE Trans. Power Electron. 2020, 35, 940–956. [Google Scholar] [CrossRef]

- Rana, M.; Rahman, A.; Jin, J. A data-driven approach for forecasting state level aggregated solar photovoltaic power production. In Proceedings of the 2020 International Joint Conference on Neural Networks (IJCNN), Glasgow, UK, 19–24 July 2020; pp. 1–8. [Google Scholar] [CrossRef]

- Shi, J.; Lee, W.-J.; Liu, Y.; Yang, Y.; Wang, P. Forecasting power output of photovoltaic systems based on weather classification and support vector machines. IEEE Trans. Ind. Appl. 2012, 48, 1064–1069. [Google Scholar] [CrossRef]

- Chen, H.; Yi, H.; Jiang, B.; Zhang, K.; Chen, Z. Data-driven detection of hot spots in photovoltaic energy systems. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 1731–1738. [Google Scholar] [CrossRef]

- Ciuriuc, A.; Rapha, J.I.; Guanche, R.; Domínguez-García, J.L. Digital tools for floating offshore wind turbines (FOWT): A state of the art. Energy Rep. 2022, 8, 1207–1228. [Google Scholar] [CrossRef]

- Li, Y.; Shen, X. A novel wind speed-sensing methodology for wind turbines based on digital twin technology. IEEE Trans. Instrum. Meas. 2022, 71, 1–13. [Google Scholar] [CrossRef]

- Moghadam, F.K.; Nejad, A.R. Online condition monitoring of floating wind turbines drivetrain by means of digital twin. Mech. Syst. Signal Process. 2022, 162, 108087. [Google Scholar] [CrossRef]

- Sivalingam, K.; Sepulveda, M.; Spring, M.; Davies, P. A Review and Methodology Development for Remaining Useful Life Prediction of Offshore Fixed and Floating Wind turbine Power Converter with Digital Twin Technology Perspective. In Proceedings of the 2018 2nd International Conference on Green Energy and Applications (ICGEA), Singapore, 24–26 March 2018; Voluem 2018, pp. 197–204. [Google Scholar] [CrossRef]

- Pimenta, F.; Pacheco, J.; Branco, C.; Teixeira, C.; Magalhães, F. Development of a digital twin of an onshore wind turbine using monitoring data. J. Phys. Conf. Ser. 2020, 1618, 022065. [Google Scholar] [CrossRef]

- Chiu, M.-C.; Wen, C.-Y.; Hsu, H.-W.; Wang, W.-C. Key wastes selection and prediction improvement for biogas production through hybrid machine learning methods. Sustain. Energy Technol. Assess. 2022, 52, 102223. [Google Scholar] [CrossRef]

- Shahsavar, M.M.; Akrami, M.; Gheibi, M.; Kavianpour, B. Constructing a smart framework for supplying the biogas energy in green buildings using an integration of response surface methodology, artificial intelligence and petri net modelling. Energy Convers. Manag. 2021, 248, 114794. [Google Scholar] [CrossRef]

- Spinti, J.P.; Smith, P.J.; Smith, S.T. Atikokan Digital Twin: Machine learning in a biomass energy system. Appl. Energy 2021, 310, 118436. [Google Scholar] [CrossRef]

- Elmaz, F.; Yücel, Ö.; Mutlu, A.Y. Predictive modeling of biomass gasification with machine learning-based regression methods. Energy 2020, 191, 116541. [Google Scholar] [CrossRef]

- Wang, Y.; Huntington, T.; Scown, C.D. Tree-based automated machine learning to predict biogas production for anaerobic co-digestion of organic waste. ACS Sustain. Chem. Eng. 2021, 9, 12990–13000. [Google Scholar] [CrossRef]

- Li, W.; Rentemeister, M.; Badeda, J.; Jöst, D.; Schulte, D.; Sauer, D.U. Digital twin for battery systems: Cloud battery management system with online state-of-charge and state-of-health estimation. J. Energy Storage 2020, 30, 101557. [Google Scholar] [CrossRef]

- Wu, B.; Widanage, W.D.; Yang, S.; Liu, X. Battery digital twins: Perspectives on the fusion of models, data and artificial intelligence for smart battery management systems. Energy AI 2020, 1, 100016. [Google Scholar] [CrossRef]

- Söderäng, E.; Hautala, S.; Mikulski, M.; Storm, X.; Niemi, S. Development of a Digital Twin for Real-Time Simulation of a Combustion Engine-Based Power Plant with Battery Storage and Grid Coupling. SSRN Electron. J. 2021, 266, 115793. [Google Scholar] [CrossRef]

- Bhatti, G.; Mohan, H.; Raja Singh, R. Towards the future of ssmart electric vehicles: Digital twin technology. Renew. Sustain. Energy Rev. 2021, 141, 110801. [Google Scholar] [CrossRef]

- Habib, A.A.; Hasan, M.K.; Mahmud, M.; Motakabber, S.; Ibrahimya, M.I.; Islam, S. A review: Energy storage system and balancing circuits for electric vehicle application. IET Power Electron. 2021, 14, 1–13. [Google Scholar] [CrossRef]

- Liu, W.; Placke, T.; Chau, K.T. Overview of batteries and battery management for electric vehicles. Energy Rep. 2022, 8, 4058–4084. [Google Scholar] [CrossRef]

- Merkle, L.; Segura, A.S.; Torben Grummel, J.; Lienkamp, M. Architecture of a digital twin for enabling digital services for battery systems. In Proceedings of the 2019 IEEE International Conference on Industrial Cyber Physical Systems (ICPS), Taipei, Taiwan, 6–9 May 2019; pp. 155–160. [Google Scholar] [CrossRef]

- Li, H.; Kaleem, M.B.; Chiu, I.-J.; Gao, D.; Peng, J. A digital twin model for the battery management systems of electric vehicles. In Proceedings of the 2021 IEEE 23rd Int Conf on High Performance Computing & Communications; 7th Int Conf on Data Science & Systems; 19th Int Conf on Smart City; 7th Int Conf on Dependability in Sensor, Cloud & Big Data Systems & Application (HPCC/DSS/SmartCity/DependSys), Haikou, China, 20–22 December 2021; pp. 1100–1107. [Google Scholar]

- Yu, G.; Ye, X.; Xia, X.; Chen, Y. Towards cognitive ev charging stations enabled by digital twin and parallel intelligence. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI), Beijing, China, 15 July–5 August 2021; pp. 290–293. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, H. Application of digital twin concept in condition monitoring for dc-dc converter. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 2199–2204. [Google Scholar] [CrossRef]

- Peng, Y.; Zhao, S.; Wang, H. A digital twin based estimation method for health indicators of dc–dc converters. IEEE Trans. Power Electron. 2021, 36, 2105–2118. [Google Scholar] [CrossRef]

- Rouzbehi, K.; Miranian, A.; Escaño, J.M.; Rakhshani, E. A Data-Driven Based Voltage Control Strategy for DC-DC Converters: Application to DC Microgrid. Electronics 2019, 8, 493. [Google Scholar] [CrossRef] [Green Version]

- Milton, M.; De La O, C.; Ginn, H.L.; Benigni, A. Controller-embeddable probabilistic real-time digital twins for power electronic converter diagnostics. IEEE Trans. Power Electron. 2020, 35, 9850–9864. [Google Scholar] [CrossRef]

- Wunderlich, A.; Santi, E. Digital Twin Models of Power Electronic Converters Using Dynamic Neural Networks. In Proceedings of the 2021 IEEE Applied Power Electronics Conference and Exposition (APEC), Phoenix, AZ, USA, 14–17 June 2021; pp. 2369–2376. [Google Scholar] [CrossRef]

- Cinar, S.; Cinar, S.O.; Wieczorek, N.; Sohoo, I.; Kuchta, K. Integration of Artificial Intelligence into Biogas Plant Operation. Processes 2021, 9, 85. [Google Scholar] [CrossRef]

- Planas, E.; Andreu, J.; Garate, J.; De Alegría, I.M.; Ibarra, E. AC and DC technology in microgrids: A review. Renew. Sustain. Energy Rev. 2015, 43, 726–749. [Google Scholar] [CrossRef]

- O’Dwyer, E.; Pan, I.; Charlesworth, R.; Butler, S.; Shah, N. Integration of an energy management tool and digital twin for coordination and control of multi-vector smart energy systems. Sustain. Cities Soc. 2020, 62, 102412. [Google Scholar] [CrossRef]

- Yu, W.; Patros, P.; Young, B.; Klinac, E.; Walmsley, T.G. Energy digital twin technology for industrial energy management: Classification, challenges and future. Renew. Sustain. Energy Rev. 2022, 161, 112407. [Google Scholar] [CrossRef]

- Onile, A.E.; Machlev, R.; Petlenkov, E.; Levron, Y.; Belikov, J. Uses of the digital twins concept for energy services, intelligent recommendation systems, and demand side management: A review. Energy Rep. 2021, 7, 997–1015. [Google Scholar] [CrossRef]

- You, M.; Wang, Q.; Sun, H.; Castro, I.; Jiang, J. Digital twins based day-ahead integrated energy system scheduling under load and renewable energy uncertainties. Appl. Energy 2022, 305, 117899. [Google Scholar] [CrossRef]

- Tan, R.; Shi, Y.; Fan, Y.; Zhu, W.; Wu, T. Energy saving technologies and best practices for 5g radio access network. IEEE Access 2022, 10, 51747–51756. [Google Scholar] [CrossRef]

- Teng, S.Y.; Touš, M.; Leong, W.D.; How, B.S.; Lam, H.L.; Máša, V. Recent advances on industrial data-driven energy savings: Digital twins and infrastructures. Renew. Sustain. Energy Rev. 2021, 135, 110208. [Google Scholar] [CrossRef]

- Granacher, J.; Nguyen, T.V.; Castro-Amoedo, R.; Maréchal, F. Overcoming decision paralysis—A digital twin for decision making in energy system design. Appl. Energy 2022, 306, 117954. [Google Scholar] [CrossRef]

- Chandak, S.; Rout, P. The implementation framework of a microgrid: A review. Int. J. Energy Res. 2021, 45, 3523–3547. [Google Scholar] [CrossRef]

- Debouza, M.; Al-Durra, A.; EL-Fouly, T.H.; Zeineldin, H.H. Survey on microgrids with flexible boundaries: Strategies, applications, and future trends. Electr. Power Syst. Res. 2022, 205, 107765. [Google Scholar] [CrossRef]

- Huang, J.; Zhao, L.; Wei, F.; Cao, B. The application of digital twin on power industry. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 647. [Google Scholar] [CrossRef]

- Xiong, J.; Ye, H.; Pei, W.; Kong, L.; Huo, Q.; Han, Y. A monitoring and diagnostics method based on FPGA-digital twin for power electronic transformer. Electr. Power Syst. Res. 2022, 210, 108111. [Google Scholar] [CrossRef]

- Park, H.-A.; Byeon, G.; Son, W.; Jo, H.-C.; Kim, J.; Kim, S. Digital Twin for Operation of Microgrid: Optimal Scheduling in Virtual Space of Digital Twin. Energies 2020, 13, 5504. [Google Scholar] [CrossRef]

- Kandasamy, N.K.; Venugopalan, S.; Wong, T.K.; Nicholas, L.J. EPICTWIN: An Electric Power Digital Twin for Cyber Security Testing, Research and Education. Comput. Electr. Eng. 2021, 101, 108061. [Google Scholar] [CrossRef]

- Magargle, R.; Johnson, L.; Mandloi, P.; Davoudabadi, P.; Kesarkar, O.; Krishnaswamy, S.; Batteh, J.; Pitchaikani, A. A simulation-based digital twin for model-driven health monitoring and predictive maintenance of an automotive braking system. In Proceedings of the 12th International Modelica Conference, Prague, Czech Republic, 15–17 May 2017; Linköping University Electronic Press: Linköping, Sweden, 2017; pp. 35–46. [Google Scholar]

- Peng, Y.; Zhang, X.; Song, Y.; Liu, D. A low cost flexible digital twin platform for spacecraft lithium-ion battery pack degradation assessment. In Proceedings of the 2019 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Auckland, New Zealand, 20–23 May 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Coraddu, A.; Oneto, L.; Baldi, F.; Cipollini, F.; Atlar, M.; Savio, S. Data-driven ship digital twin for estimating the speed loss caused by the marine fouling. Ocean. Eng. 2019, 186, 106063. [Google Scholar] [CrossRef]

- Ahmadi, A.; Nabipour, M.; Mohammadi-Ivatloo, B.; Amani, A.M.; Rho, S.; Piran, M.J. Long-term wind power forecasting using tree-based learning algorithms. IEEE Access 2020, 8, 151511–151522. [Google Scholar] [CrossRef]

- Eom, H.; Son, Y.; Choi, S. Feature-Selective Ensemble Learning-Based Long-Term Regional PV Generation Forecasting. IEEE Access 2020, 8, 54620–54630. [Google Scholar] [CrossRef]

- Alkhayat, G.; Mehmood, R. Energy and AI A review and taxonomy of wind and solar energy forecasting methods based on deep learning. Energy AI 2021, 4, 100060. [Google Scholar] [CrossRef]

- Santhosh, M.; Venkaiah, C.; Vinod Kumar, D. Current advances and approaches in wind speed and wind power forecasting for improved renewable energy integration: A review. Eng. Rep. 2020, 2, e12178. [Google Scholar] [CrossRef]

- Aghazadeh Ardebili, A.; Longo, A.; Ficarella, A. Digital Twin (DT) in Smart Energy Systems—Systematic Literature Review of DT as a growing solution for Energy Internet of the Things (EIoT). E3S Web Conf. 2021, 312, 09002. [Google Scholar] [CrossRef]

- Wang, J.; Ye, L.; Gao, R.X.; Li, C.; Zhang, L. Digital twin for rotating machinery fault diagnosis in smart manufacturing. Int. J. Prod. Res. 2019, 57, 3920–3934. [Google Scholar] [CrossRef]

- Orive, D.; Iriondo, N.; Burgos, A.; Saráchaga, I.; Álvarez, M.L.; Marcos, M. Fault injection in digital twin as a means to test the response to process faults at virtual commissioning. In Proceedings of the 2019 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; pp. 1230–1234. [Google Scholar] [CrossRef]

- Gao, F.; He, B. Power supply line selection decision system for new energy distribution network enterprises based on digital twinning. Energy Rep. 2021, 7, 760–771. [Google Scholar] [CrossRef]

- Danilczyk, W.; Sun, Y.; He, H. Angel: An intelligent digital twin framework for microgrid security. In Proceedings of the 2019 North American power symposium (NAPS), Wichita, KS, USA, 13–15 October 2019; pp. 1–6. [Google Scholar]

- Eckhart, M.; Ekelhart, A.; Weippl, E. Enhancing cyber situational awareness for cyber-physical systems through digital twins. In Proceedings of the 2019 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; pp. 1222–1225. [Google Scholar] [CrossRef]

- Atalay, M.; Angin, P. A digital twins approach to smart grid security testing and standardization. In Proceedings of the 2020 IEEE International Workshop on Metrology for Industry 4.0 & IoT, Roma, Italy, 3–5 June 2020; pp. 435–440. [Google Scholar]

- Qian, C.; Liu, X.; Ripley, C.; Qian, M.; Liang, F.; Yu, W. Digital twin—Cyber replica of physical things: Architecture, applications and future research directions. Future Internet 2022, 14, 64. [Google Scholar] [CrossRef]

| Application | References | Description |

|---|---|---|

| Microgrid Components: Energy sources | ||

| Solar power | [42,43,44], | Different conditions such as fault assessment, forecasting power production and prediction of hot spots in PV modules using ML and DT techniques are mentioned in these papers. |

| Wind Energy | [46,47,48,49,50] | DT of offshore and onshore wind turbines for predicting RUL of components, monitoring of health, wind speed sensing and online condition monitoring are studied. |

| Biogas Energy | [51,52,53,54,55,70] | Dynamic forecasting using DT and predictive analytics, optimised operation of biomass boiler and data-driven approaches for biogas output prediction on the largest data set are discussed. |

| Microgrid Components: Energy storage | ||

| Battery | [56,57,58,62] | These papers focus on the emergence of ML technologies for better control of battery, the development of DT for BMS on the cloud, the architecture of DT to know the life cycle of battery and the formation of power plant’s DT including battery storage. |

| EV | [59,60,61,62,63] | These papers discuss ESS cell voltage life, architecture for DT of BMS, battery voltage assessment using regression model, health monitoring of battery and infrastructure management of charging stations using an intelligent system. |

| Microgrid Components: Power Converter | ||

| [6,9,12,65,66,67,68,69,71,72] | A data-driven approach to determine the capability of the buck-converter, diagnosis of the open switch problem and monitoring and identification of the DC–DC converter is covered in these references. Further, in [72], the pathway of establishing real-time models of power electronic converters is discussed. | |

| Application Type | References | Description |

|---|---|---|

| Health Monitoring | [49,85,86,87] | In these works, the authors have discussed monitoring and predictive maintenance models by using physics-based DT or Data-Driven-based DT. |

| Forecasting | [88,89,90,91] | Using different techniques, such as physics-based, data-driven, hybrid, output power estimation of wind and solar systems can be found in these works. In [87], deep learning-based power output forecasting methods have been consolidated. |

| Fault-Detection | [42,92,93,94] | DT-based fault diagnostic methods for Distributed PV systems, rotating machinery and power converters have been studied. |

| Control Management | [23,59,72,83] | In these works, it has been explained that EMS forms an advanced management system that can operate MG environment with the best possible management of power flow on a physical level and can also manage information on a cyber level. |

| Decision Making | [23,75,78,95] | These papers discuss how decision-making procedures can be made easy with the help of DT technology. The predictive nature of DT helps speed up the decision-making process. |

| Cyber Security | [61,84,96,97,98,99] | The DT-based methods have been established for power system security which is needed to protect smart grids. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumari, N.; Sharma, A.; Tran, B.; Chilamkurti, N.; Alahakoon, D. A Comprehensive Review of Digital Twin Technology for Grid-Connected Microgrid Systems: State of the Art, Potential and Challenges Faced. Energies 2023, 16, 5525. https://doi.org/10.3390/en16145525

Kumari N, Sharma A, Tran B, Chilamkurti N, Alahakoon D. A Comprehensive Review of Digital Twin Technology for Grid-Connected Microgrid Systems: State of the Art, Potential and Challenges Faced. Energies. 2023; 16(14):5525. https://doi.org/10.3390/en16145525

Chicago/Turabian StyleKumari, Namita, Ankush Sharma, Binh Tran, Naveen Chilamkurti, and Damminda Alahakoon. 2023. "A Comprehensive Review of Digital Twin Technology for Grid-Connected Microgrid Systems: State of the Art, Potential and Challenges Faced" Energies 16, no. 14: 5525. https://doi.org/10.3390/en16145525

APA StyleKumari, N., Sharma, A., Tran, B., Chilamkurti, N., & Alahakoon, D. (2023). A Comprehensive Review of Digital Twin Technology for Grid-Connected Microgrid Systems: State of the Art, Potential and Challenges Faced. Energies, 16(14), 5525. https://doi.org/10.3390/en16145525