Characterization, at Partial Loads, of the Combustion and Emissions of a Dual-Fuel Engine Burning Diesel and a Lean Gas Surrogate

Abstract

1. Introduction

2. Materials and Methods

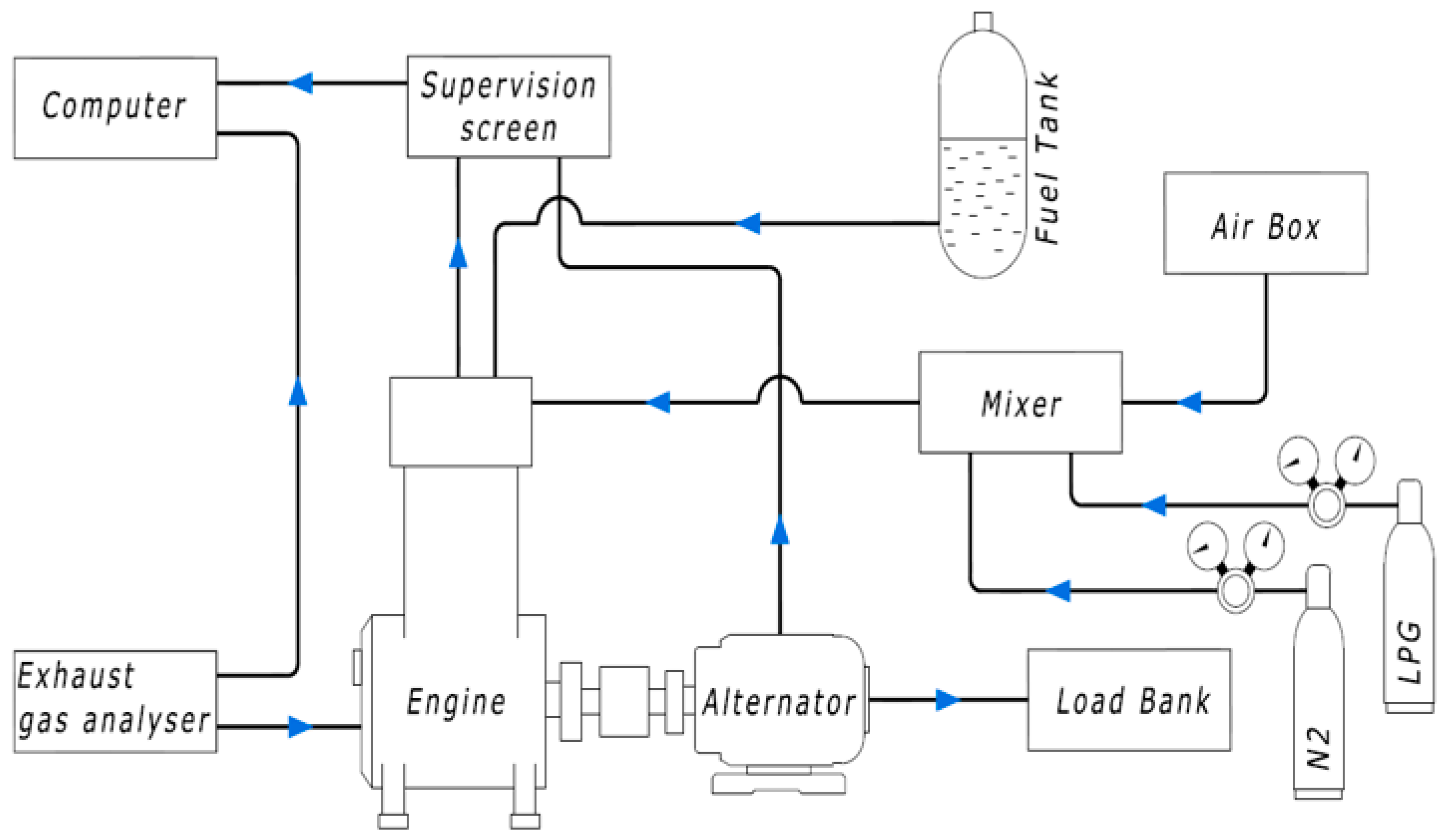

2.1. Experimental Device

2.2. Fuels Used

2.3. Test Procedure and Methods

3. Results and Discussion

3.1. The Combustion Parameters

3.1.1. Limit of Diesel Substitution

3.1.2. Cylinder Pressure and Heat Release

3.1.3. The Mean Indicated Pressure and the Coefficient of Variation

3.2. Performance Parameters

3.2.1. Fuel Consumption

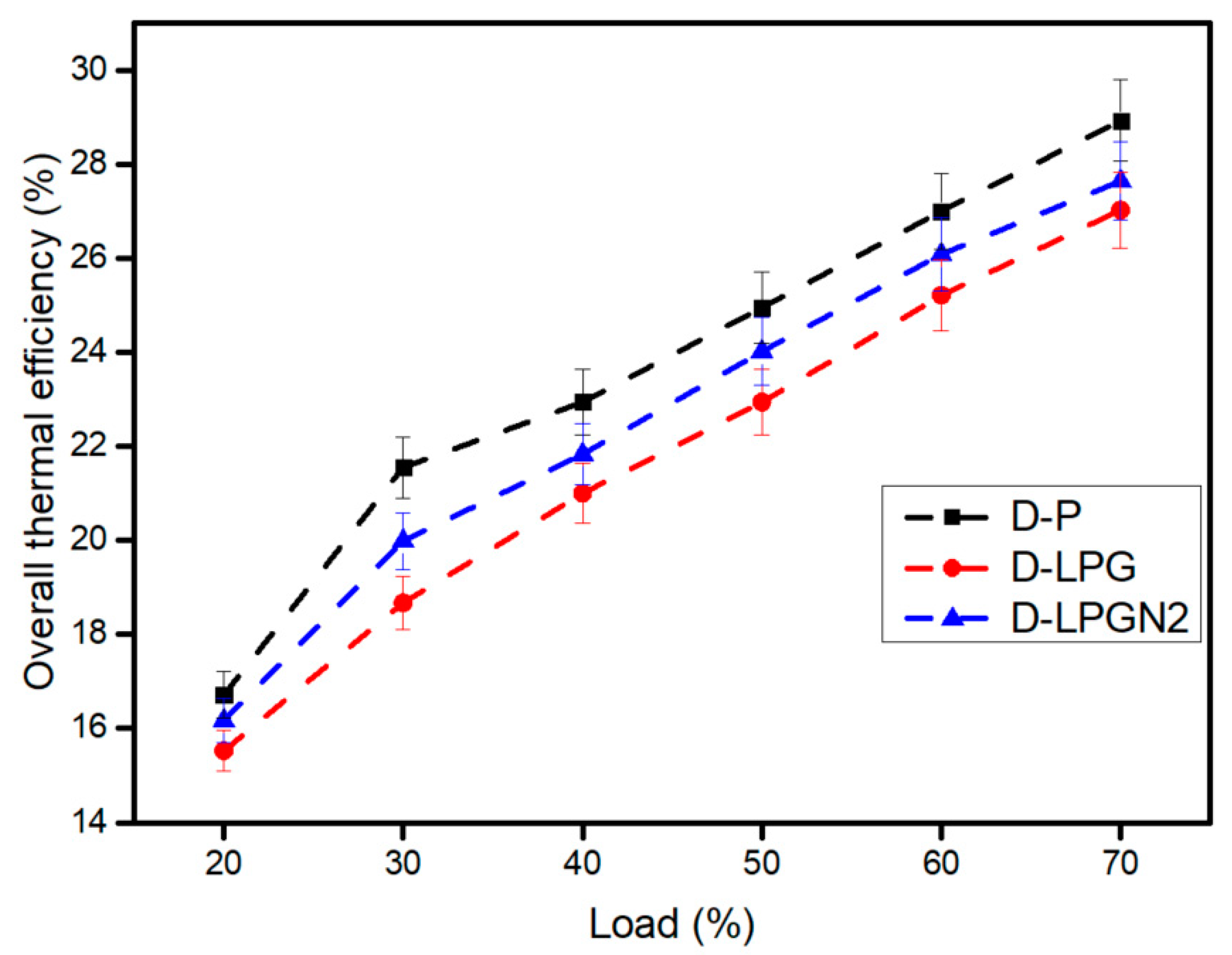

3.2.2. Brake-Specific Fuel Consumption (BSFC) and Thermal Efficiency (ηth)

4. Emissions

4.1. CO2 Emission

4.2. CO Emissions

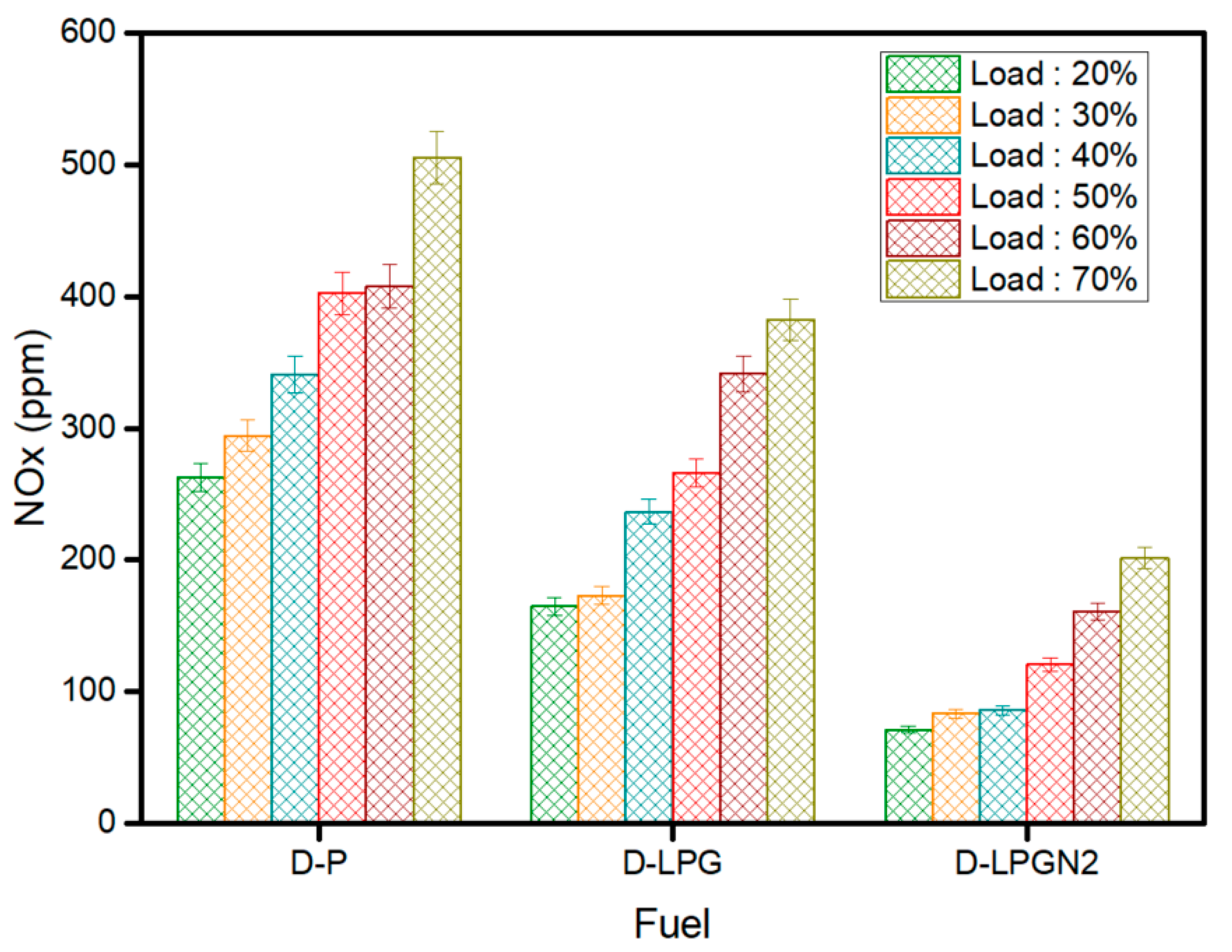

4.3. NOx Emissions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cozzi, L.; Gould, T.; Bouckart, S.; Crow, D.; Kim, T.-Y.; McGlade, C.; Olejarnik, P.; Wanner, B.; Wetzel, D. World Energy Outlook 2020; International Energy Agency: Paris, France, 2020; pp. 213–250.

- Ministère de l’Energie. Annuaire Statistique 2018: Energie; Ministère de l’Energie: Ouagadougou, Burkina Faso, 2019; p. 17. [Google Scholar]

- Institut National de la Statistique et de la Démographie. Annuaire Statistique 2018: Agriculture; Institut National de la Statistique et de la Démographie: Ouagadougou, Burkina Faso, 2019; p. 396. [Google Scholar]

- Barry, F.; Sawadogo, M.; Ouédraogo, I.W.; Bologo/Traoré, M.; Dogot, T. Geographical and Economic Assessment of Feedstock Availability for Biomass Gasification in Burkina Faso. Energy Convers. Manag. X 2021, 13, 100163. [Google Scholar] [CrossRef]

- IEA Bioenergy. Contribution of Bioenergy to the World’s Future Energy; International Energy Agency: Paris, France, 2007.

- Sheth, P.N.; Babu, B.V. Experimental Studies on Producer Gas Generation from Wood Waste in a Downdraft Biomass Gasifier. Bioresour. Technol. 2009, 100, 3127–3133. [Google Scholar] [CrossRef] [PubMed]

- Fajimi, L.I.; Oboirien, B.O.; Adams, T.A. Simulation Studies on the Co-Production of Syngas and Activated Carbon from Waste Tyre Gasification Using Different Reactor Configurations. Energy Convers. Manag. X 2021, 11, 100105. [Google Scholar] [CrossRef]

- Patel, M.; Zhang, X.; Kumar, A. Techno-Economic and Life Cycle Assessment on Lignocellulosic Biomass Thermochemical Conversion Technologies: A Review. Renew. Sustain. Energy Rev. 2016, 53, 1486–1499. [Google Scholar] [CrossRef]

- Parikh, P.P.; Bhave, A.G.; Kapse, D.V.; Shashikantha. Study of Thermal and Emission Performance of Small Gasifier-Dual-Fuel Engine Systems. Biomass 1989, 19, 75–97. [Google Scholar] [CrossRef]

- Bilcan, A. Contribution à l’Etude Du Cycle Termodynamique de Moteurs Fonctionnant En Dual-Fuel. Ph.D. Thesis, Université de Nantes, Nantes, France, 2003. [Google Scholar]

- Hagos, F.Y.; Aziz, A.R.A.; Sulaiman, S.A. Methane Enrichment of Syngas (H2/CO) in a Spark-Ignition Directinjection Engine: Combustion, Performance and Emissions Comparison with Syngas and Compressed Natural Gas. Energy 2015, 90, 2006–2015. [Google Scholar] [CrossRef]

- Singh, J.; Singh, S.; Mohapatra, S.K. Production of Syngas from Agricultural Residue as a Renewable Fuel and Its Sustainable Use in Dual-Fuel Compression Ignition Engine to Investigate Performance, Emission, and Noise Characteristics. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 41–55. [Google Scholar] [CrossRef]

- Das, S.; Kashyap, D.; Kalita, P.; Kulkarni, V.; Itaya, Y. Clean Gaseous Fuel Application in Diesel Engine: A Sustainable Option for Rural Electrification in India. Renew. Sustain. Energy Rev. 2020, 117, 109485. [Google Scholar] [CrossRef]

- Paykani, A.; Chehrmonavari, H.; Tsolakis, A.; Alger, T.; Northrop, W.F.; Reitz, R.D. Synthesis Gas as a Fuel for Internal Combustion Engines in Transportation. Prog. Energy Combust. Sci. 2022, 90, 100995. [Google Scholar] [CrossRef]

- Bhaduri, S.S. Experimental Studies on HCCI Combustion of Biomass Syngas Towards Tar Tolerant Operation. Ph.D. Thesis, University of Louvain, Ottignies-Louvain-la-Neuve, Belgium, 2015; p. 236. [Google Scholar]

- Aklouche, F.Z. Combustion Des Moteurs Diesel En Mode Dual-Fuel: Optimisation de l’Injection Du Combustible Pilote. Ph.D. Thesis, Université Bretagne Loire, Brest, France, 2018. [Google Scholar]

- Sahoo, B.B.; Sahoo, N.; Saha, U.K. Effect of Engine Parameters and Type of Gaseous Fuel on the Performance of Dual-Fuel Gas Diesel Engines—A Critical Review. Renew. Sustain. Energy Rev. 2009, 13, 1151–1184. [Google Scholar] [CrossRef]

- Shrivastava, V.; Jha, A.K.; Wamankar, A.K.; Murugan, S. Performance and Emission Studies of a CI Engine Coupled with Gasifier Running in Dual Fuel Mode. Procedia Eng. 2013, 51, 600–608. [Google Scholar] [CrossRef]

- Singh, R.N.; Singh, S.P.; Pathak, B.S. Investigations on Operation of CI Engine Using Producer Gas and Rice Bran Oil in Mixed Fuel Mode. Renew. Energy 2007, 32, 1565–1580. [Google Scholar] [CrossRef]

- Sadig, H.; Sulaiman, S.A.; Said, M.A. Effect of Producer Gas Staged Combustion on the Performance and Emissions of a Single Shaft Micro-Gas Turbine Running in a Dual Fuel Mode. J. Energy Inst. 2017, 90, 132–144. [Google Scholar] [CrossRef]

- Pradhan, A.; Baredar, P.; Kumar, A. Syngas as An Alternative Fuel Used in Internal Combustion Engines: A Review. J. Pure Appl. Sci. Technol. 2015, 5, 51–66. [Google Scholar]

- Bilcan, A.; Le Corre, O.; Tazerout, M.; Ramesh, A.; Ganesan, S. Characterization of the LPG–Diesel Dual Fuel Combustion; SAE Technical Paper 2001-28-0036; SAE International: Warrendale, PA, USA, 2001; pp. 249–258. [Google Scholar] [CrossRef]

- Garnier, C.; Bilcan, A.; Le Corre, O.; Rahmouni, C. Characterisation of a Syngas-Diesel Fuelled CI Engine; SAE Technical Paper 2005-01-1731; SAE International: Warrendale, PA, USA, 2005. [Google Scholar] [CrossRef]

- Qi, D.H.; Bae, C.; Feng, Y.M.; Jia, C.C.; Bian, Y.Z. Preparation, Characterization, Engine Combustion and Emission Characteristics of Rapeseed Oil Based Hybrid Fuels. Renew. Energy 2013, 60, 98–106. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, F.; Zhao, Y.; Li, D.; Lei, X. Study on Cycle-by-Cycle Variations in a Diesel Engine with Dimethyl Ether as Port Premixing Fuel. Appl. Energy 2015, 143, 58–70. [Google Scholar] [CrossRef]

- Rao, G.; Kumar, G.N.; Herbert, M. Effect of Injection Pressure on the Performance and Emission Characteristics of the CI Engine Using Vateria Indica Biodiesel. Int. J. Ambient Energy 2019, 40, 758–767. [Google Scholar] [CrossRef]

- Yomi, G.W. Analyse et Modélisation Des Cycles Thermodynamiques d’Un Moteur Diesel Fonctionnant Aux Huiles Végétales Intégrant Plusieurs Solutions d’Optimisation. Ph.D. Thesis, Université Joseph KI-ZERBO, Ouagadougou, Burkina Faso, 2020. [Google Scholar]

- Surawski, N.C.; Miljevic, B.; Bodisco, T.A.; Situ, R.; Brown, R.J.; Ristovski, Z.D. Performance and Gaseous and Particle Emissions from a Liquefied Petroleum Gas (LPG) Fumigated Compression Ignition Engine. Fuel 2014, 133, 17–25. [Google Scholar] [CrossRef]

- Saleh, H.E. Effect of Variation in LPG Composition on Emissions and Performance in a Dual Fuel Diesel Engine. Fuel 2008, 87, 3031–3039. [Google Scholar] [CrossRef]

- Poonia, M.P.; Ramesh, A.; Gaur, R.R. Effect of Intake Air Temperature and Pilot Fuel Quantity on the Combustion Characteristics of a Lpg Diesel Dual Fuel Engine; SAE Technical Paper 982455; SAE International: Warrendale, PA, USA, 1998. [Google Scholar] [CrossRef]

- Guan, C.; Cheung, C.S.; Ning, Z.; Wong, P.K.; Huang, Z. Comparison on the Effect of Using Diesel Fuel and Waste Cooking Oil Biodiesel as Pilot Fuels on the Combustion, Performance and Emissions of a LPG-Fumigated Compression-Ignition Engine. Appl. Therm. Eng. 2017, 125, 1260–1271. [Google Scholar] [CrossRef]

- Mustafi, N.N.; Raine, R.R.; Verhelst, S. Combustion and Emissions Characteristics of a Dual Fuel Engine Operated on Alternative Gaseous Fuels. Fuel 2013, 109, 669–678. [Google Scholar] [CrossRef]

- Papagiannakis, R.G.; Hountalas, D.T. Combustion and Exhaust Emission Characteristics of a Dual Fuel Compression Ignition Engine Operated with Pilot Diesel Fuel and Natural Gas. Energy Convers. Manag. 2004, 45, 2971–2987. [Google Scholar] [CrossRef]

- Tira, H.S.; Herreros, J.M.; Tsolakis, A.; Wyszynski, M.L. Characteristics of LPG-Diesel Dual Fuelled Engine Operated with Rapeseed Methyl Ester and Gas-to-Liquid Diesel Fuels. Energy 2012, 47, 620–629. [Google Scholar] [CrossRef]

- Dhole, A.E.; Yarasu, R.B.; Lata, D.B. Investigations on the Combustion Duration and Ignition Delay Period of a Dual Fuel Diesel Engine with Hydrogen and Producer Gas as Secondary Fuels. Appl. Therm. Eng. 2016, 107, 524–532. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; Holman, J.P., Ed.; McGraw-Hill Education: New York, NY, USA, 1988; Volume 53, ISBN 9788578110796. [Google Scholar]

- Biswas, S.; Kakati, D.; Chakraborti, P.; Banerjee, R. Assessing the Potential of Ethanol in the Transition of Biodiesel Combustion to RCCI Regimes under Varying Injection Phasing Strategies: A Performance-Emission-Stability and Tribological Perspective. Fuel 2021, 304, 121346. [Google Scholar] [CrossRef]

- Liu, J.; Wu, P.; Ji, Q.; Sun, P.; Wang, P.; Meng, Z.; Ma, H. Experimental Study on Effects of Pilot Injection Strategy on Combustion and Emission Characteristics of Diesel/Methanol Dual-Fuel Engine under Low Load. Energy 2022, 247, 123464. [Google Scholar] [CrossRef]

- Santoso, W.B.; Bakar, R.A.; Ariyono, S.; Cholis, N. Study of Cyclic Variability in Diesel-Hydrogen Dual Fuel Engine Combustion. Int. J. Mech. Mechatron. Eng. 2012, 12, 52–56. [Google Scholar]

- Goto, S.; Lee, D.; Shakal, J.; Harayama, N.; Honjyo, F.; Ueno, H. Performance and Emissions of an LPG Lean-Burn Engine for Heavy Duty Vehicles; SAE Technical Paper 1999-01-1513; SAE International: Warrendale, PA, USA, 1999; pp. 1055–1065. [Google Scholar] [CrossRef]

- Banapurmath, N.R.; Tewari, P.G. Comparative Performance Studies of a 4-Stroke CI Engine Operated on Dual Fuel Mode with Producer Gas and Honge Oil and Its Methyl Ester (HOME) with and without Carburetor. Renew. Energy 2009, 34, 1009–1015. [Google Scholar] [CrossRef]

- Sombatwong, P.; Thaiyasuit, P.; Pianthong, K. Effect of Pilot Fuel Quantity on the Performance and Emission of a Dual Producer Gas–Diesel Engine. Energy Procedia 2013, 34, 218–227. [Google Scholar] [CrossRef]

- Elnajjar, E.; Hamdan, M.O.; Selim, M.Y.E. Experimental Investigation of Dual Engine Performance Using Variable LPG Composition Fuel. Renew. Energy 2013, 56, 110–116. [Google Scholar] [CrossRef]

- Lal, S.; Mohapatra, S.K. The Effect of Compression Ratio on the Performance and Emission Characteristics of a Dual Fuel Diesel Engine Using Biomass Derived Producer Gas. Appl. Therm. Eng. 2017, 119, 63–72. [Google Scholar] [CrossRef]

- Singh, D.; Nishiie, T.; Tanvir, S.; Qiao, L. An Experimental and Kinetic Study of Syngas/Air Combustion at Elevated Temperatures and the Effect of Water Addition. Fuel 2012, 94, 448–456. [Google Scholar] [CrossRef]

- Malik, A.; Mohapatra, S.K. Biomass-Based Gasifiers for Internal Combustion (IC) Engines—A Review. Sadhana Acad. Proc. Eng. Sci. 2013, 38, 461–476. [Google Scholar] [CrossRef]

- Yaliwal, V.S.; Banapurmath, N.R.; Gireesh, N.M.; Hosmath, R.S.; Donateo, T.; Tewari, P.G. Effect of Nozzle and Combustion Chamber Geometry on the Performance of a Diesel Engine Operated on Dual Fuel Mode Using Renewable Fuels. Renew. Energy 2016, 93, 483–501. [Google Scholar] [CrossRef]

- Sharma, M.; Kaushal, R. Performance and Emission Analysis of a Dual Fuel Variable Compression Ratio (VCR) CI Engine Utilizing Producer Gas Derived from Walnut Shells. Energy 2020, 192, 116725. [Google Scholar] [CrossRef]

- Ramadhas, A.S.; Jayaraj, S.; Muraleedharan, C. Dual Fuel Mode Operation in Diesel Engines Using Renewable Fuels: Rubber Seed Oil and Coir-Pith Producer Gas. Renew. Energy 2008, 33, 2077–2083. [Google Scholar] [CrossRef]

- Aklouche, F.Z.; Loubar, K.; Bentebbiche, A.; Awad, S.; Tazerout, M. Experimental Investigation of the Equivalence Ratio Influence on Combustion, Performance and Exhaust Emissions of a Dual Fuel Diesel Engine Operating on Synthetic Biogas Fuel. Energy Convers. Manag. 2017, 152, 291–299. [Google Scholar] [CrossRef]

- Ashok, B.; Denis Ashok, S.; Ramesh Kumar, C. LPG Diesel Dual Fuel Engine—A Critical Review. Alex. Eng. J. 2015, 54, 105–126. [Google Scholar] [CrossRef]

- Kouremenos, D.A.; Rakopoulos, C.D.; Hountalas, D.T. Experimental Investigation of the Performance and Exhaust Emissions of a Swirl Chamber Diesel Engine Using JP-8 Aviation Fuel. Int. J. Energy Res. 1997, 21, 1173–1185. [Google Scholar] [CrossRef]

- Maurya, R.K.; Agarwal, A.K. Experimental Investigation of Cyclic Variations in HCCI Combustion Parameters for Gasoline like Fuels Using Statistical Methods. Appl. Energy 2013, 111, 310–323. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, Z.; Wei, L.; Zhang, J.; Law, C.K. Experimental and Modeling Study on Ignition Delays of Lean Mixtures of Methane, Hydrogen, Oxygen, and Argon at Elevated Pressures. Combust. Flame 2012, 159, 918–931. [Google Scholar] [CrossRef]

- Sayin, C.; Canakci, M. Effects of Injection Timing on the Engine Performance and Exhaust Emissions of a Dual-Fuel Diesel Engine. Energy Convers. Manag. 2009, 50, 203–213. [Google Scholar] [CrossRef]

- Ferguson, C.; Kirkpatrick, A. Internal Combustion Engines Applied Thermosciences, 3rd ed.; Wiley: Hoboken, NJ, USA, 2016; ISBN 978-0-471-35617-2. [Google Scholar]

- Zheng, M.; Reader, G.T.; Hawley, J.G. Diesel Engine Exhaust Gas Recirculation—A Review on Advanced and Novel Concepts. Energy Convers. Manag. 2004, 45, 883–900. [Google Scholar] [CrossRef]

- Lavoie, G.A.; Heywood, J.B.; Keck, J.C. Experimental and Theoretical Study of Nitric Oxide Formation in Internal Combustion Engines. Combust. Sci. Technol. 1970, 1, 313–326. [Google Scholar] [CrossRef]

| Model | Lister Petter (TR1) |

|---|---|

| Engine type | 4 stroke, direct injection (DI), compression ignition, single cylinder, naturally aspirated, air cooled |

| Displacement (cm3) | 773 |

| Power (kW) | 4 kW at 1500 rpm |

| Bore/Stroke (mm) | 98.42/101.6 |

| Geometrical compression ratio | 15.85:1 |

| Instrument | Manufacturer—Model | Resolution | Uncertainty |

|---|---|---|---|

| Pressure sensor | AVL/GH15D | 0.01 MPa | ±0.22% |

| Angular encoder | ROD426 | 0.1 °V | ±0.5% |

| LPG flow meter | BRONKHORST/F-201AV-50K | 0.03 kg/h | ±0.3% |

| Nitrogen flow meter | BRONKHORST/F-202AV-M10 | 0.01 kg/h | ±0.3% |

| Diesel flow measurement device | GRADUATED PIPETTE | 0.1 mL | ±10% |

| STOPWATCH | 0.1 s | ±1% |

| Gas | Range | Accuracy | Resolution |

|---|---|---|---|

| CO | 0–10,000 ppm | ±5% of reading (200…2000 ppm) ±10% of reading (rest of range) | 1 ppm |

| NO | 0–4000 ppm | ±5% of reading (100…1999.9 ppm) | 1 ppm |

| NO2 | 0–500 ppm | ±5 ppm (0…99.9 ppm) ±5% of reading (rest of range) | 0.1 ppm |

| CO2 | 0–50% Vol.% | (0…25 Vol.%) ±0.5 Vol.% | 0.01 Vol.% |

| Operating Mode | Fuel | Designation | Equivalence Ratio | Engine Settings |

|---|---|---|---|---|

| Conventional diesel | Neat diesel | D-P | 0.28 to 0.57 | Speed:1500 rpm Injection timing: 20 °CAD BTDC Load: 20%, 30%, 40%, 50%, 60%, 70% Diesel substitution rate: 0 to max |

| Dual-fuel | Pilot: Diesel Primary fuel: Liquefied petroleum gas | D–LPG | 0.35 to 0.59 | |

| Dual-fuel | Pilot: Diesel Primary fuel: Gas surrogate | D–LPGN2 | 0.25 to 0.52 |

| Load (%) | 20 | 30 | 40 | 50 | 60 | 70 | |

|---|---|---|---|---|---|---|---|

| Diesel Substitution (%) | D–LPG | 61.7 | 58.9 | 60.3 | 59.6 | 58.8 | 57.9 |

| D–LPGN2 | 65.2 | 63.5 | 62.3 | 61.6 | 60.8 | 59.8 |

| Pilot Fuel | Primary Fuel | Engine Type | Load (%) | Brake-Specific Fuel Consumption (kg/kWh) | Searcher |

|---|---|---|---|---|---|

| Diesel | Single cylinder diesel engine, DI, 1500 rpm, CR: 17.6 | 20 | 0.35 | [33] | |

| Diesel | Natural gas | Single cylinder diesel engine, DI 1500 rpm CR: 17.6 | 20 | 0.67 | [33] |

| Diesel | Single cylinder diesel engine, DI 1500 rpm CR: 17.6 | 60 | 0.4 | [33] | |

| Diesel | Natural gas | Single cylinder diesel engine, DI 1500 rpm CR: 17.6 | 60 | 0.63 | [33] |

| Diesel | Single cylinder, diesel engine, 1500 rpm CR: 18 | 80 | 0.282 | [49] | |

| Diesel | Producer gas | Single cylinder, diesel engine, 1500 rpm CR: 18 | 80 | 0.34 | [49] |

| Diesel | Single cylinder diesel engine, DI 1500 rpm CR: 18 | 80 | 0.282 | [42] | |

| Diesel | Syngas | Single cylinder diesel engine, DI 1500 rpm CR: 18 | 80 | 0.34 | [42] |

| Diesel | Syngas | Single cylinder variable compression ratio diesel engine, DI 1500 rpm CR: 14 | 40 | 0.71 | [44] |

| Diesel | Syngas | Single cylinder variable compression ratio diesel engine, DI 1500 rpm CR: 14 | 80 | 0.59 | [44] |

| Diesel | LPGN2 | Single cylinder diesel engine, DI 1500 rpm CR: 18.375 | 20 | 3.44 | Present work |

| Diesel | LPGN2 | Single cylinder diesel engine, DI 1500 rpm CR: 18.375 | 70 | 1.64 | Present work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diané, A.; Yomi, G.W.; Zongo, S.; Daho, T.; Jeanmart, H. Characterization, at Partial Loads, of the Combustion and Emissions of a Dual-Fuel Engine Burning Diesel and a Lean Gas Surrogate. Energies 2023, 16, 5587. https://doi.org/10.3390/en16155587

Diané A, Yomi GW, Zongo S, Daho T, Jeanmart H. Characterization, at Partial Loads, of the Combustion and Emissions of a Dual-Fuel Engine Burning Diesel and a Lean Gas Surrogate. Energies. 2023; 16(15):5587. https://doi.org/10.3390/en16155587

Chicago/Turabian StyleDiané, Ali, Gounkaou Woro Yomi, Sidiki Zongo, Tizane Daho, and Hervé Jeanmart. 2023. "Characterization, at Partial Loads, of the Combustion and Emissions of a Dual-Fuel Engine Burning Diesel and a Lean Gas Surrogate" Energies 16, no. 15: 5587. https://doi.org/10.3390/en16155587

APA StyleDiané, A., Yomi, G. W., Zongo, S., Daho, T., & Jeanmart, H. (2023). Characterization, at Partial Loads, of the Combustion and Emissions of a Dual-Fuel Engine Burning Diesel and a Lean Gas Surrogate. Energies, 16(15), 5587. https://doi.org/10.3390/en16155587