Diagnosis of Challenges and Uncertainties for Implementation of Sustainable Aviation Fuel (SAF) in Colombia, and Recommendations to Move Forward

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Analysis

5. Conclusions

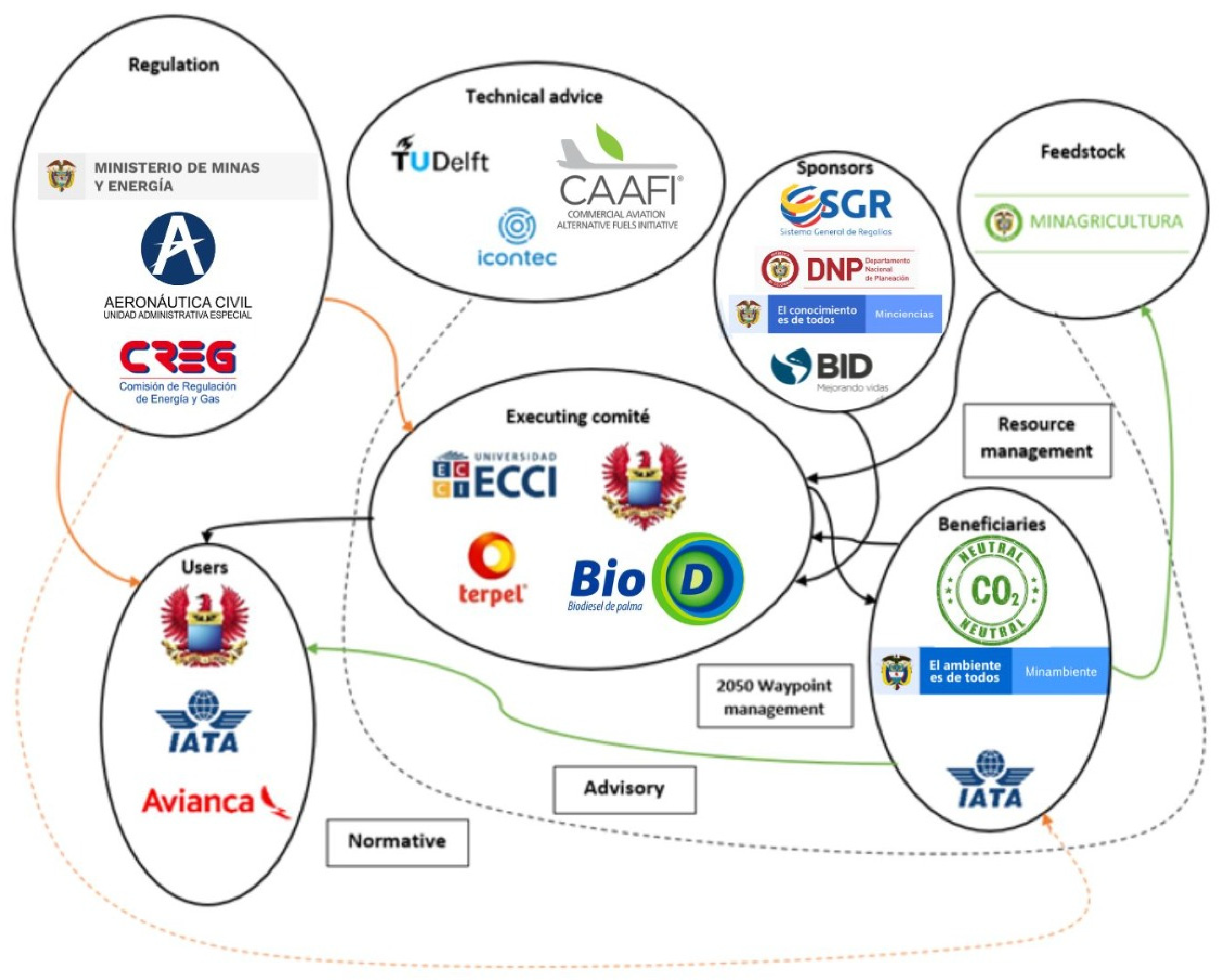

- With the fieldwork, 25 actors, four technologies, and the components of the transaction cost were identified, reaching the point of having the bases to define the regulatory framework as the most relevant component for viability. Moreover, as it is iterated and interacts with the key actors, the form and strategy to generate a value chain proposal is identified, which adjusts to the Colombian context.

- Among the challenges for the implementation of SAF in Colombia are guaranteeing sustainability from the selection of the feedstock, transformation, transportation, and final use, where the amount of energy involved and the impact of the carbon footprint throughout the life cycle and having indicators that align with the requirements of ICAO and certified by RSB Roundtable on Sustainable Biomaterials or ISCC, and failing that, possible integration with chains supply of foreign airlines.

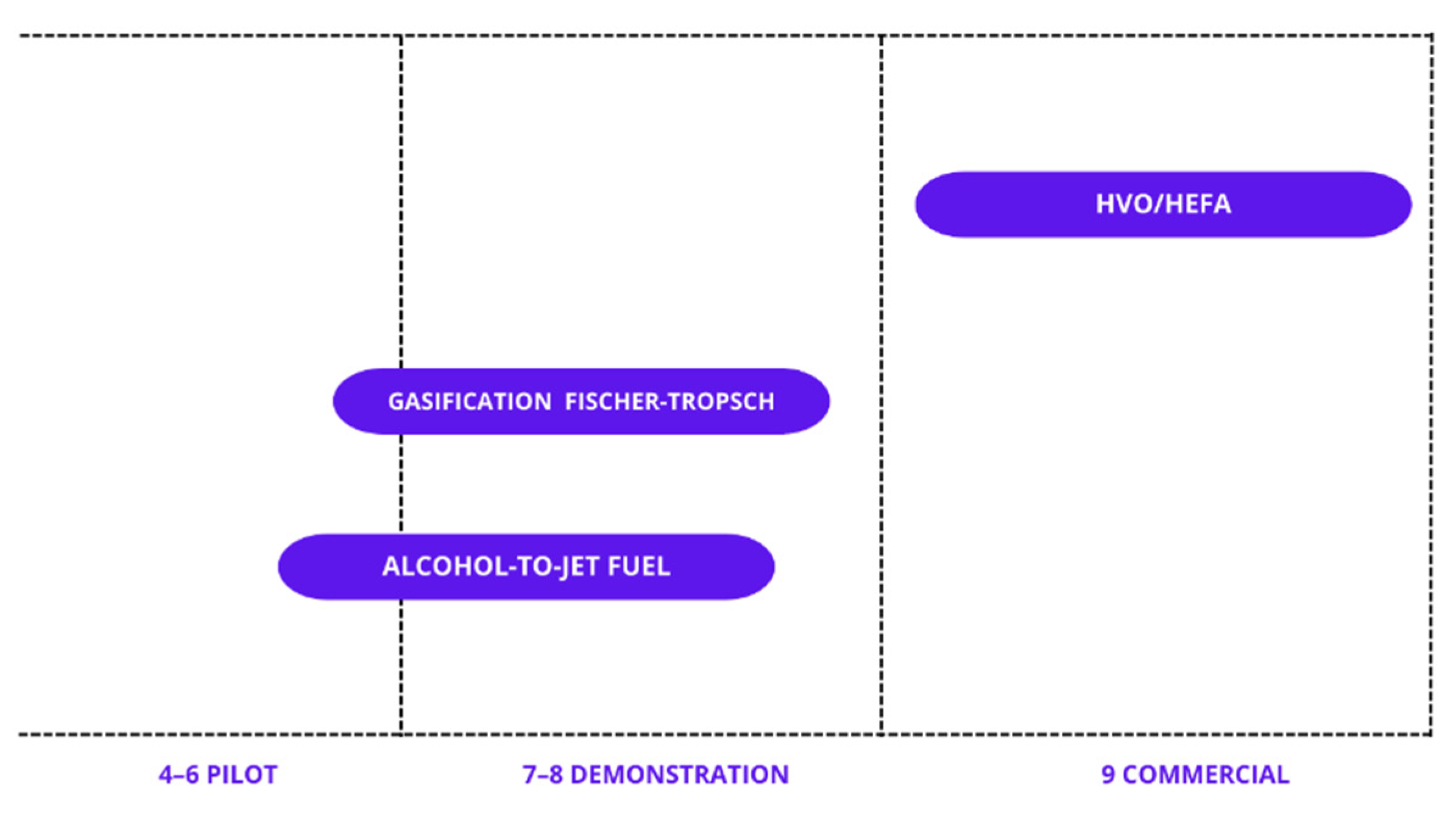

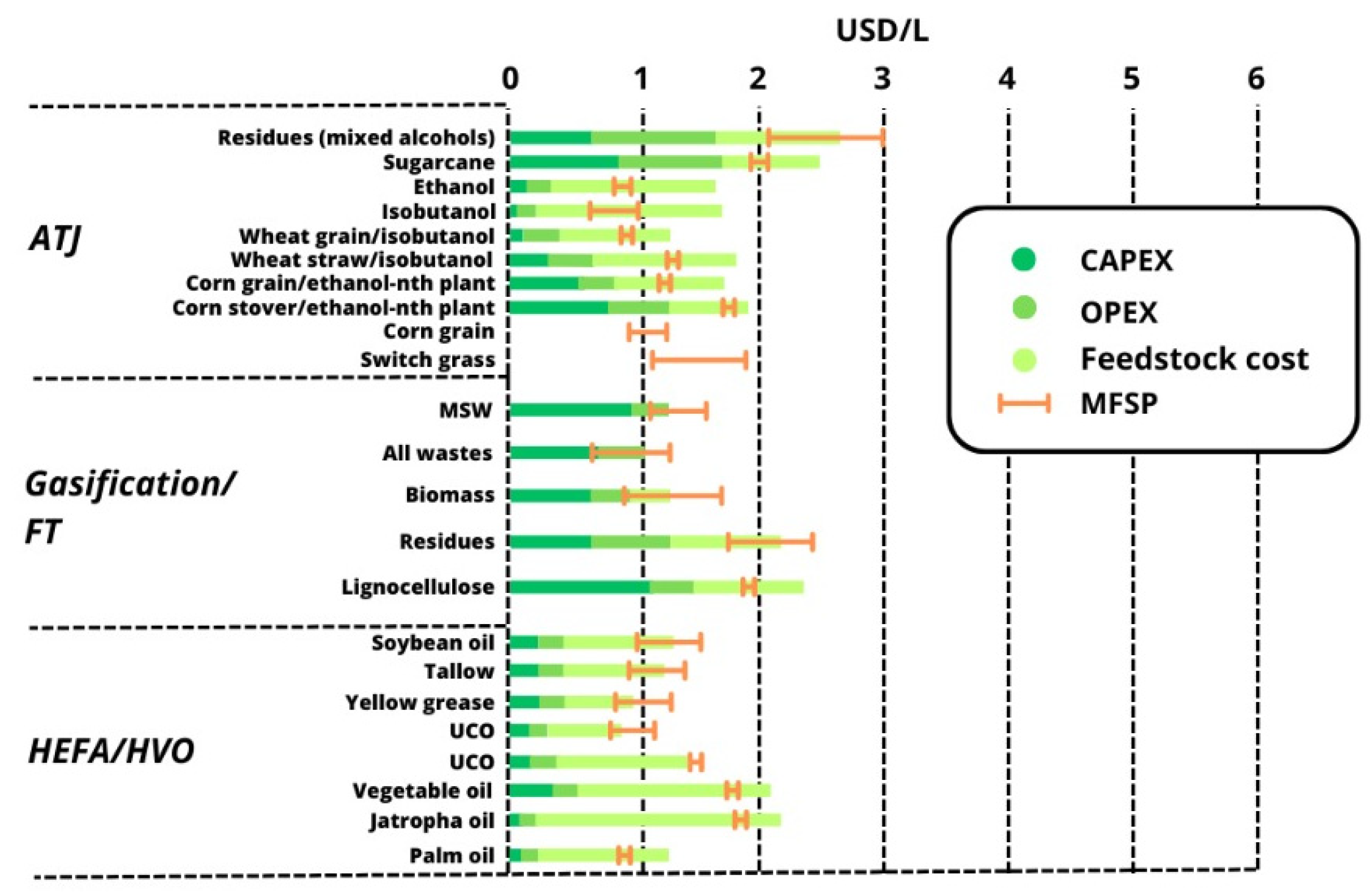

- The leading choice made in the optimal strategy predictions based on transaction costs was technology because, at the moment, in Colombia, neither HEFA with a TRL 9 nor Fischer–Tropsch with a TRL8 are a real option. However, the latter, together with Alcohol to Jet, generates a double environmental impact and is aligned with the National Circular Economy Strategy and the Colombia Carbon Neutral Strategy of the Ministry of the Environment because its raw material is organic waste and integrates sustainably into the aeronautical sector.

- The transaction cost is the decisive factor in Colombia by which to integrate SAF by clients, both at the state and private level (COLAF and IATA), where the regulatory framework plays a decisive role in the transformation of this factor, for which the policies of use, price, incentives, credits, and exemptions are part of the roadmap to turn SAF production technology in Colombia into a real option.

- An important aspect is that feedstock, even though they can be used within the research, must be certified by competent entities such as ISCC or RSB in order to be used on a large scale in such a large and demanding industry to ensure the quality and security of its inputs, especially palm oil.

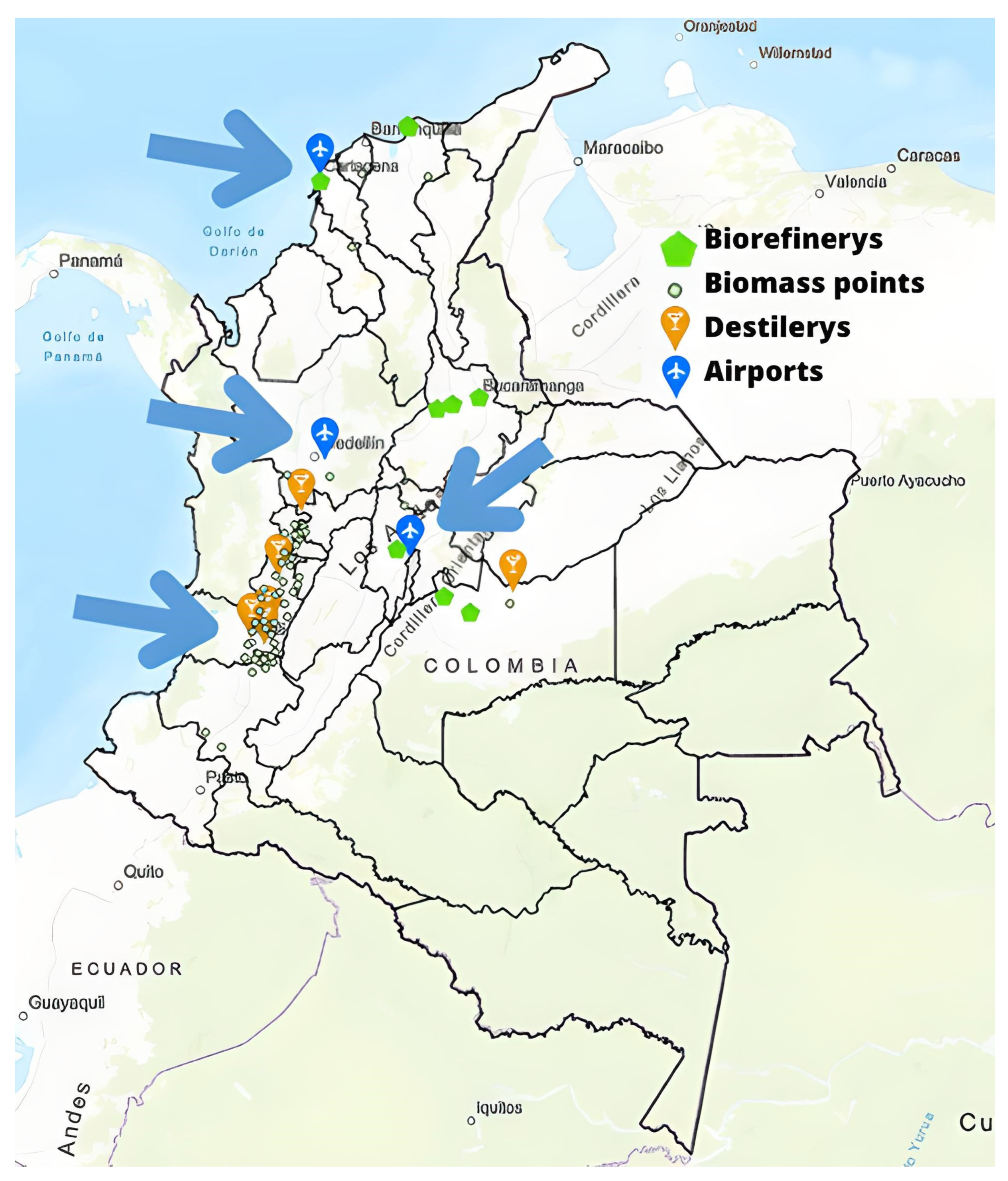

- At the moment, the gross production potential for lignocellulosic feedstock was calculated based on production. However, it is necessary to submit it to some economic and environmental evaluation filters to find the availability of this material to be used in SAF production, which will be the subject of the following article, and it is necessary to do fieldwork to determine the real availability of the types of biomasses mentioned in this article.

- The viability of the SAF implementation in Colombia, according to the ECOCANVAS tool, cannot be analyzed only from the economic point of view; it must also be analyzed under the environmental, legal, and social components, where the government is the leading actor with the management of framework regulation so that the flow of income that sustains the business generates the incentives, credits, and exemptions. On the social side, having gasification Fischer–Tropsch technology that transforms garbage and organic waste into SAF will have a positive impact, with new productive chains and the adoption of behavior patterns that will favor the implementation of this project.

- The book and claim system is a mechanism that allows for the certification and tracking of Sustainable Aviation Fuel production, enabling airlines and other aviation fuel users to support the development and use of SAF, even if they do not have direct access to a local producer. The above may be a strategy by which to make Colombia competitive in SAF implementation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Staples, M.D.; Malina, R.; Suresh, P.; Hileman, J.I.; Barrett, S.R.H. Aviation CO2 emissions reductions from the use of alternative jet fuels. Energy Policy 2018, 114, 342–354. [Google Scholar] [CrossRef]

- Wise, M.; Muratori, M.; Kyle, P. Biojet fuels and emissions mitigation in aviation: An integrated assessment modeling analysis. Transp. Res. D Transp. Environ. 2017, 52, 244–253. [Google Scholar] [CrossRef] [Green Version]

- International Civil Aviation Organization (ICAO). La OACI Acoge Con Satisfacción el Compromiso de la Industria Del Transporte Aéreo de Emisiones Netas Cero Para 2050. Available online: https://www.icao.int/Newsroom/Pages/ES/ICAO-welcomes-new-netzero-2050-air-industry-commitment.aspx (accessed on 5 August 2021).

- International Civil Aviation Organization (ICAO). Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA). 2018. Available online: https://www.icao.int/environmental-protection/CORSIA/Pages/default.aspx (accessed on 9 September 2021).

- Ministerio de Ambiente y Desarrollo Sostenible. Colombia Carbono Neutral’, Una Estrategia Para Combatir el Cambio Climático. Available online: https://www.minambiente.gov.co/index.php/noticias/5028-colombia-carbono-neutral-una-estrategia-para-combatir-el-cambio-climatico (accessed on 7 April 2021).

- Wang, W.-C.; Tao, L. Bio-jet fuel conversion technologies. Renew. Sustain. Energy Rev. 2016, 53, 801–822. [Google Scholar] [CrossRef] [Green Version]

- Uribe, J. Las Algas ya Son Combustible Para Aviones. Available online: http://www.eltiempo.com/archivo/documento/CMS-10803344 (accessed on 21 November 2011).

- Vidoz, N. Por Primera Vez, la Aerolínea Lufthansa Utilizará Biocombustible en Una Ruta Regular. 2011. Available online: http://www.energiverde.com/biocombustible/por-primera-vez-la-aerolinea-lufthansa-utilizara-biocombustible-en-una-ruta-regular (accessed on 15 October 2021).

- Vidoz, N. La Aerolínea KLM Realizará Pruebas Para Usar Aceite de Cocina Como Combustible. 2011. Available online: http://www.energiverde.com/biocombustible/la-aerolinea-klm-realizara-pruebas-para-usar-aceite-de-cocina-como-combustible (accessed on 15 October 2021).

- Vidoz, N. Air France Concluye Exitosamente su Primer Vuelo Utilizando Biocombustible. 2011. Available online: http://www.energiverde.com/biocombustible/air-france-concluye-exitosamente-su-primer-vuelo-utilizando-biocombustible (accessed on 15 October 2021).

- Admin. Primer Vuelo Comercial en America del Sur Con Biocombustibles. 2012. Available online: https://biodiesel.com.ar/6657/primer-vuelo-comercial-america-del-sur-con-biocombustibles (accessed on 2 February 2022).

- Mayorga, M.A.; Estrada, J.G.C.; Paez, J.A.B.; Lopez, C.; Lopez, M. Use of Biofuels in the Aeronautical Industry. Case of the Colombian Air Force. Tecciencia 2019, 14, 33–43. [Google Scholar] [CrossRef] [Green Version]

- SAF. Aviation Benefits Beyond Borders. 2011. Available online: https://aviationbenefits.org/environmental-efficiency/climate-action/sustainable-aviation-fuel/ (accessed on 25 February 2022).

- Smith, P.M.; Gaffney, M.J.; Shi, W.; Hoard, S.; Armendariz, I.I.; Mueller, D.W. Drivers and barriers to the adoption and diffusion of Sustainable Jet Fuel (SJF) in the U.S. Pacific Northwest. J. Air Transp. Manag. 2017, 58, 113–124. [Google Scholar] [CrossRef] [Green Version]

- Admin. Biojet, en 2015 Los Aviones Podrán Volar Con Biocombustibles en USA. 2011. Available online: https://biodiesel.com.ar/5238/biojet-en-2015-los-aviones-podran-volar-con-biocombustibles-en-usa (accessed on 5 December 2022).

- Martinez-Valencia, L.; Garcia-Perez, M.; Wolcott, M.P. Supply chain configuration of sustainable aviation fuel: Review, challenges, and pathways for including environmental and social benefits. Renew. Sustain. Energy Rev. 2021, 152, 111680. [Google Scholar] [CrossRef]

- Ministerio de Minas y Energía. Transición Energética: Un Legado Para el Presente y el Futuro de Colombia; Ministerio de Minas y Energía: Bogotá, Colombia, 2021.

- ASTM D4054-19; Standard Practice for Evaluation of New Aviation Turbine Fuels and Fuel Additives. ASTM International: Conshohocken, PA, USA, 2019. [CrossRef]

- ASTM D 7566-20c; Standard Specification for Aviation Turbine Fuel Containing Synthesized Hydrocarbons. ASTM International: Conshohocken, PA, USA, 2021.

- Sapp, M.; ASTM Approves New SAF Production Pathway Called Catalytic Hydrothermolysis Jet. Biofuels Digest. 2020. Available online: https://www.biofuelsdigest.com/bdigest/2020/02/19/astm-approves-new-saf-production-pathway-called-catalytic-hydrothermolysis-jet/ (accessed on 11 November 2021).

- Fedebiocombustible. Vademécum de lo Biocombustibles, un Compromiso con el Desarrollo Rural. 2023. Available online: www.fedebiocombustibles.com (accessed on 5 February 2023).

- Sicard, T.L.; Gallini, S. Los Biocombustibles en Colombia a Debate, (Memorias de Foro Biocombustibles en Colombia a Debate); Congreso de la República de Colombia: Bogotá, Colombia, 2008.

- Congreso de la Republica de Colombia. Ley 336 del 2021 Camara, Ley 229 del 2021 Senado; Congreso de la Republica de Colombia: Bogotá, Colombia, 2021.

- National Planning Department of Colombia. National Development Plan 2022–2026 Colombia World Power of Life, Colombia. 2023; p. 161. Available online: https://www.dnp.gov.co/plan-nacional-desarrollo/pnd-2022-2026/Paginas/default.aspx#:~:text=Para%20convertir%20a%20Colombia%20en%20una%20potencia%20mundial%20de%20la,el%20cambio%20clim%C3%A1tico%20y%20Convergencia (accessed on 6 May 2023).

- Jiang, C.; Yang, H. Carbon tax or sustainable aviation fuel quota. Energy Econ. 2021, 103, 105570. [Google Scholar] [CrossRef]

- Betancourt, M.A.M.; Santamaria, C.A.L.; Gómez, M.L.; Caranton, A.R.G. Experimental analysis of biodiesel synthesis from palm kernel oil: Empirical model and surface response variables. React. Kinet. Mech. Catal. 2020, 131, 297–317. [Google Scholar] [CrossRef]

- Gonzalez Caranton, A.R.; Silva Leal, V.; Bayona-Roa, C.; Betancourt, M.A.M.; Betancourt, C.; Cortina, D.; Acuña, N.J.; López, M. Experimental Investigation of the Mechanical and Thermal Behavior of a PT6A-61A Engine Using Mixtures of JETA-1 and Biodiesel. Energies 2021, 14, 3282. [Google Scholar] [CrossRef]

- GTalero; Bayona-Roa, C.; Silva, V.; Mayorga, M.; Pava, J.; Lopez, M. Biodiesel substitution in a J69 aeronautic turbine engine: An experimental assessment of the effects on energy efficiency, technical performance and emissions. Sustain. Energy Technol. Assess. 2020, 40, 100746. [Google Scholar] [CrossRef]

- Talero, G.; Bayona-Roa, C.; Muñoz, G.; Galindo, M.; Silva, V.; Pava, J.; Lopez, M. Experimental Methodology and Facility for the J69-Engine Performance and Emissions Evaluation Using Jet A1 and Biodiesel Blends. Energies 2019, 12, 4530. [Google Scholar] [CrossRef] [Green Version]

- Rodriguez, W.E.; Rodriguez, A.; Lopez, M.; Mayorga, A. Life Cycle Analysis of Biodiesel Blends for Aviation. Tecciencia 2019, 14, 53–59. [Google Scholar] [CrossRef] [Green Version]

- Durán Preciado, D.E. Aeropuertos de Colombia. 2013. Available online: https://www.sic.gov.co/recursos_user/documentos/promocion_competencia/Estudios_Economicos/Estudios_Economicos/Estudios_Mercado_Aeropuertos.pdf (accessed on 11 December 2022).

- Aeronáutica Civil. Services at Airports Airports in Charge of the Civil Aviation Authority of Colombia. 2022. Available online: https://www.aerocivil.gov.co/aeropuertos/Catalogo%20de%20servicios%20actualizado/Catalogo%20Ingles%202022.pdf (accessed on 10 February 2023).

- IATA. The Value of Air Transport in Colombia. 2019. Available online: https://www.iata.org/contentassets/bbff04f2b67140638dffb0b5cc5fc8e1/the-value-of-air-transport-in-colombia.pdf (accessed on 8 December 2022).

- Aeronautica Civil. Estadísticas de Las Actividades Aeronáuticas. 2022. Available online: https://www.aerocivil.gov.co/atencion/estadisticas-de-las-actividades-aeronauticas/bases-de-datos (accessed on 20 February 2023).

- Unidad Administrativa Especial de Aeronáutica Civil Colombia. Plan de Acción de Emisiones de CO2. Available online: https://www.icao.int/environmental-protection/pages/climatechange_actionplan.aspx (accessed on 29 August 2022).

- Congreso de Colombia. Acción Cimática. Bogotá. 2021, pp. 1–38. Available online: https://www.beltranpardo.com/wp-content/uploads/2021/12/LEY-2169-DEL-22-DE-DICIEMBRE-DE-2021.pdf (accessed on 29 August 2022).

- Pisupadti, S.V. Fuel Chemistry. In Encyclopedia of Physical Science and Technology; Elsevier: Amsterdam, The Netherlands, 2003; pp. 253–274. [Google Scholar] [CrossRef]

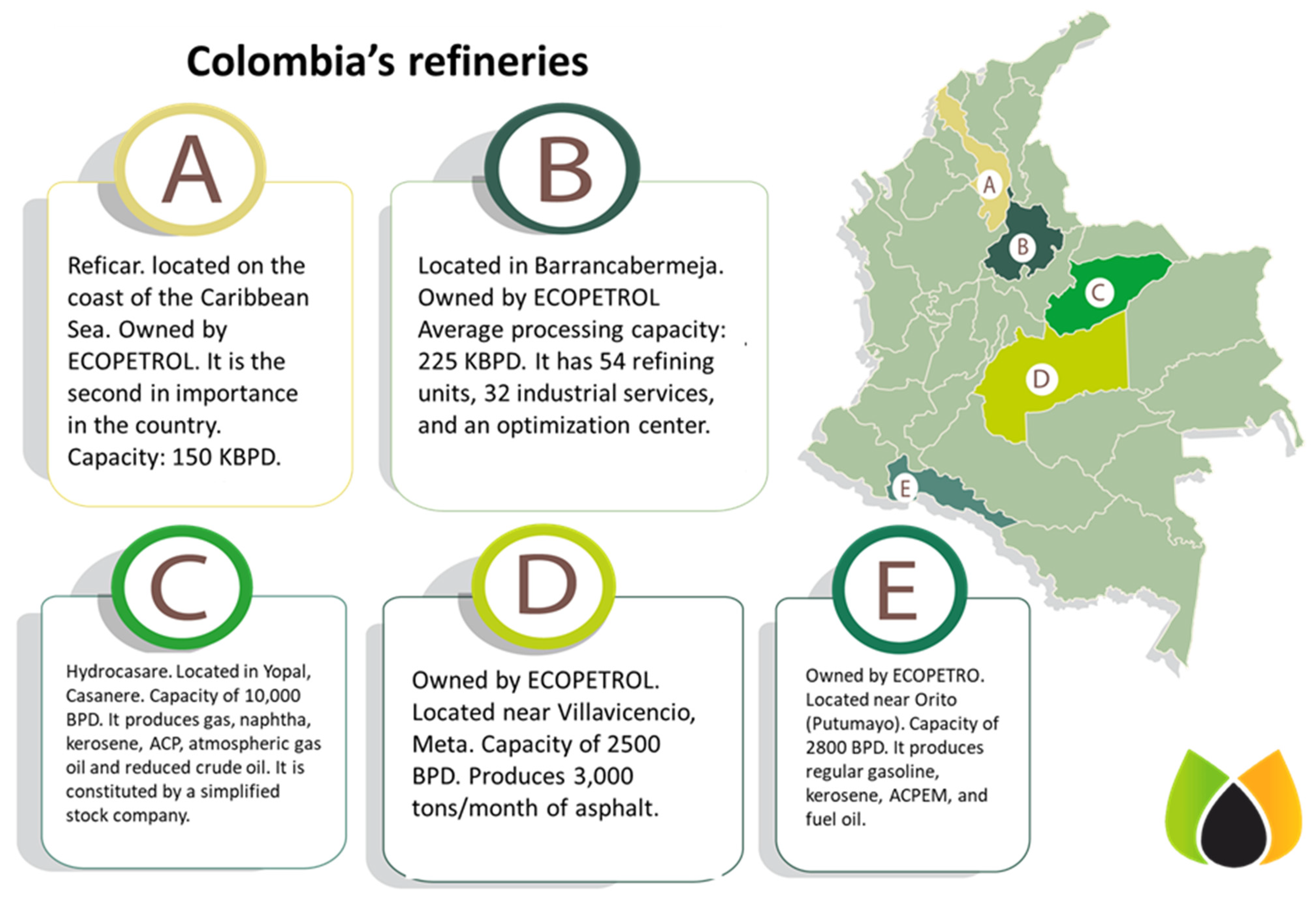

- Crudotransparente. Refinería del Meta, un Megaproyecto Que Quedó en el Papel—Crudo Transparente. 21 March 2021. Available online: https://crudotransparente.com/2021/03/24/refineria-del-meta-un-megaproyecto-que-quedo-en-el-papel/ (accessed on 11 February 2023).

- Unidad de Planeación Minero Energética. Plan Indicativo de Abastecimiento de Combustibles Líquidos. 2021. Available online: https://www1.upme.gov.co/Hidrocarburos/publicaciones/Plan_Indicativo_Abastecimiento_Combustibles_Liquidos_2021.pdf (accessed on 12 December 2022).

- Ecopetrol, S.A. Refinería de Barrancabermeja. 9 November 2014. Available online: https://nuevoportal.ecopetrol.com.co/wps/portal/ecopetrol-web/nuestra-empresa/quienes-somos/lo-que-hacemos/refinacion/complejo-barrancabermeja/ (accessed on 11 February 2023).

- Arrieta, A.; Janna, F.; Lopez, D.; Forero, C.; Herrera, B.; Alvarado, P.; Ceballos, C.; Giraldo, S.; Porras, J.; Mejia, A.; et al. Consultoría Técnica Para el Fortalecimiento y Mejoramiento de la Base de Datos de Factores de Emisión de los Combustibles Colombianos. Medellin. January 2016. Available online: http://www.upme.gov.co/calculadora_emisiones/aplicacion/Informe_Final_FECOC.pdf (accessed on 28 February 2023).

- Terpel. Informe de Gestión y Sostenibilidad. 2021. Available online: https://www.terpel.com/accionistas-e-inversionistas/gobierno-corporativo/asamblea-accionistas/informes-de-gestion (accessed on 28 February 2023).

- Abrantes, I.; Ferreira, A.F.; Silva, A.; Costa, M. Sustainable aviation fuels and imminent technologies—CO2 emissions evolution towards 2050. J. Clean. Prod. 2021, 313, 127937. [Google Scholar] [CrossRef]

- Ng, K.S.; Farooq, D.; Yang, A. Global biorenewable development strategies for sustainable aviation fuel production. Renew. Sustain. Energy Rev. 2021, 150, 111502. [Google Scholar] [CrossRef]

- IRENA. Reaching Zero with Renewables: Biojet Fuels; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2021; ISBN 978-92-9260-350-2. [Google Scholar]

- Ministerio de Minas y Energia. Atlas del Potencial Energético de la Biomasa Residual en Colombia; UPME: Bogotá, Colombia, 2010; ISBN 978-958-8504-59-9.

- Air Colombia Force; Tamara, J. Reunión SAF Colombia; Fuerza Aérea Colombiana: Bogotá, Colombia, 2022. [Google Scholar]

- FAC. Plan Estratégico FAC 2042. 2021. Available online: https://www.fac.mil.co/sites/default/files/2021-04/edaes.pdf (accessed on 20 July 2022).

- Ministerio de Medio Ambiente de Colombia. Estrategia Nacional de Economia Circular. 2021. Available online: https://www.minambiente.gov.co/asuntos-ambientales-sectorial-y-urbana/estrategia-nacional-de-economia-circular/ (accessed on 6 May 2023).

- Seber, G.; Escobar, N.; Valin, H.; Malina, R. Uncertainty in life cycle greenhouse gas emissions of sustainable aviation fuels from vegetable oils. Renew. Sustain. Energy Rev. 2022, 170, 112945. [Google Scholar] [CrossRef]

- RSB. Roundtable on Sustainable Biomaterials, The RSB Standard for Feedstock. 2022. Available online: https://rsb.org/the-rsb-standard/about-the-rsb-standard/ (accessed on 28 January 2023).

- ECOCANVAS. Bussines Model. 2012. Available online: https://www.circulareconomyclub.com/listings/ecocanvas-%C2%B7-circular-business-model-design/ (accessed on 20 September 2022).

- Fuerza Aerea Colombiana. Taller de Cocreación Biocombustible Aeronautico Colombia; Fuerza Aerea Colombiana: Bogotá, Colombia, 22 September 2021. [Google Scholar]

- Bland, D.J.; Osterwalder, A. Testing Business Ideas; John Wiley & Sons: Hoboken, NJ, USA, 2020; ISBN 9781119551423. [Google Scholar]

- ICAO. On Board a Sustainable Future; ICAO: Montreal, QC, Canada, 2016. [Google Scholar]

- IATA; ATAG. Waypoint 2050 Balancing Growth in Connectivity with a Comprehensive Global Air Transport Response to the Climate Emergency: A Vision of Net-Zero Aviation by Mid-Century. 2021. Available online: www.bluesky-d2d.com (accessed on 11 May 2023).

- Graterol, C. Taller de Cocreación Hoja de Ruta SAF Colombia; FEDEBIOCOMBUSTIBLE: Bogotá, Colombia, 2021. [Google Scholar]

- TU Delft—John Posada Duque Profesor y Asesor Tecnico. Taller de Cocreación Hoja de Ruta SAF Colombia; TU Delft: Delft, The Netherlands, 2021. [Google Scholar]

- Leon, S.A. Simulación de Tres Alternativas Para la Producción de Combustible Sostenible de Aviación (SAF) en Colombia; Universidad Nacional de Colombia: Bogotá, Colombia, 2023. [Google Scholar]

- Valero, M. Cadena de Suministros Para Aceite de Palma y Aceite de Cocina Usado en la Producción de Biocombustible Aeronáutico en Colombia; Universidad ECCI: Bogotá, Colombia, 2023. [Google Scholar]

- UPRA. EVA 2021. Available online: https://upra.gov.co/es-co/Paginas/eva_2021.aspx (accessed on 25 January 2023).

- Lopez, G.; Buriticá, C.; Ramirez, C.; Moreno, R.; Martinez, F.; Aldana, F. Los Recursos Distribuidos de Bioenergía en Colombia; Universidad Distrital Francisco José de Caldas: Bogotá, Colombia, 2020. [Google Scholar]

- Camenzind, D.A. Supply Chain Analysis for Sustainable Alternative Jet Fuel Production from Lipid Feedstocks in the U.S. Pacific Northwest. Ph.D. Dissertation, Washington State University, Washington, DC, USA, 2018. [Google Scholar]

- Monteiro, R.R.C.; dos Santos, I.A.; Arcanjo, M.R.A.; Cavalcante, C.L., Jr.; de Luna, F.M.T.; Fernandez-Lafuente, R.; Vieira, R.S. Production of Jet Biofuels by Catalytic Hydroprocessing of Esters and Fatty Acids: A Review. Catalysts 2022, 12, 237. [Google Scholar] [CrossRef]

- Romero, L.; Cortez, R.; Sánchez, L.; Piracoca, M.; Ayala, L.; Castro, Y.B. Proceso Integral de Obtención de Glicerol Como Subproducto de la Producción de Biodiésel, a Partir Del Aceite de Higuerilla (Integral Process of Obtaining Glycerol as a By-Product of Biodiesel Production from Castor Oil). 2012. Available online: http://webbook.nist.gov/cgi/cbook.cgi?Name=glycerine&Units=SI&cTP (accessed on 15 March 2023).

- Ayandiran, A.A.; Boahene, P.E.; Dalai, A.K.; Hu, Y. Hydroprocessing of oleic acid for production of jet fuel range hydrocarbons over Sn(1)-Fe(3)-Cu(13)/SiO2-Al2O3 catalyst: Process parameters optimization, kinetics, and thermodynamic study. Asia-Pac. J. Chem. Eng. 2021, 16, e2621. [Google Scholar] [CrossRef]

- Weitkamp, J. Catalytic Hydrocracking-Mechanisms and Versatility of the Process. ChemCatChem 2012, 4, 292–306. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Tan, C.-S. Supporting Information Production of Bio Jet-Fuel from Octadecane and Derivatives of Castor Oil Using a Bifunctional Catalyst Ni-Pd@Al-MCF in Pressurized CO2-Hexane-Water Solvent. Energy Fuels 2022, 36, 3119–3133. [Google Scholar] [CrossRef]

- Garcia, F.J.O.; Arroyo, J.A.M.; Sánchez, P.F.; Juárez, E.M.; Esquivel, J.M.D. Hydrocracking Kinetics of a Heavy Crude Oil on a Liquid Catalyst. Energy Fuels 2017, 31, 6794–6799. [Google Scholar] [CrossRef]

- Lu, M.; Liu, X.; Li, Y.; Nie, Y.; Lu, X.; Deng, D.; Ji, J. Hydrocracking of bio-alkanes over Pt/Al-MCM-41 mesoporous molecular sieves for bio-jet fuel production. J. Renew. Sustain. Energy 2016, 8, 053103. [Google Scholar] [CrossRef]

- Martinez-Hernandez, E.; Ramírez-Verduzco, L.F.; Amezcua-Allieri, M.A.; Aburto, J. Process simulation and techno-economic analysis of bio-jet fuel and green diesel production—Minimum selling prices. Chem. Eng. Res. Des. 2019, 146, 60–70. [Google Scholar] [CrossRef]

- Jiménez-Díaz, L.; Caballero, A.; Pérez-Hernández, N.; Segura, A. Microbial alkane production for jet fuel industry: Motivation, state of the art and perspectives. Microb. Biotechnol. 2017, 10, 103–124. [Google Scholar] [CrossRef]

- Geleynse, S.; Brandt, K.; Garcia-Perez, M.; Wolcott, M.; Zhang, X. The Alcohol-to-Jet Conversion Pathway for Drop-In Biofuels: Techno-Economic Evaluation. ChemSusChem 2018, 11, 3728–3741. [Google Scholar] [CrossRef]

- Pechstein, J.; Neuling, U.; Gebauer, J.; Kaltschmitt, M. Alcohol-to-Jet (AtJ). In Biokerosene: Status and Prospects; Springer: Berlin/Heidelberg, Germany, 2017; pp. 543–574. [Google Scholar] [CrossRef]

- Kumar, B.; Bhardwaj, N.; Agrawal, K.; Chaturvedi, V.; Verma, P. Current perspective on pretreatment technologies using lignocellulosic biomass: An emerging biorefinery concept. Fuel Process. Technol. 2020, 199, 106244. [Google Scholar] [CrossRef]

- Staples, M.D.; Malina, R.; Olcay, H.; Pearlson, M.N.; Hileman, J.I.; Boies, A.; Barrett, S.R. Lifecycle greenhouse gas footprint and minimum selling price of renewable diesel and jet fuel from fermentation and advanced fermentation production technologies. Energy Environ. Sci. 2014, 7, 1545–1554. [Google Scholar] [CrossRef]

- Frank, W.A.; Morales, G.V.; Okulik, N.B.; Sham, E.L. Producción Catalítica de Etileno: Síntesis del Catalizador y Propuesta Experimental; Facultad de Ingeniería del NDA: Santiago del Estero, Argentina, 3–4 October 2013. [Google Scholar]

- Agudelo, J.L.; Montes, C. Deshidratación Catalítica de Etanol a Etileno Sobre Hmor y hzsm-5 Modificada Con Hierro y Cobre modified with copper and iron. Ing. E Investig. 2005, 25, 22–26. [Google Scholar] [CrossRef]

- Campelo, J.M. Deshidratación de Alcoholes en Fase Gaseosa, Catalizada Por Sistemas Ortofosfato de Aluminio-Alumina; ProQuest LLC: Ann Arbor, MI, USA, 1997. [Google Scholar]

- Franco, O.; Espitia, H. Catalizadores de alumina y estudio cinetico de la deshidratación de etanol a etileno. Ing. E Investig. 1983, 7, 42–49. [Google Scholar] [CrossRef]

- Finiels, A.; Fajula, F.; Hulea, V. Nickel-based solid catalysts for ethylene oligomerization-a review. Catal. Sci. Technol. 2014, 4, 2412–2426. [Google Scholar] [CrossRef]

- Conrad, M.A. Support-Enhanced Thermal Oligomerization of Ethylene to Liquid Fuel Hydrocarbons. Ph.D. Dissertation, University Graduate School, West Lafayette, IN, USA, 2022. [Google Scholar]

- Ekbom, T. Förstudie För Biobaserat Flygbränsle För Stockholm-Arlanda Flygplats; Varmesfork: Stockholm, Sweden, 2009. [Google Scholar]

- Petersen, A.M.; Farzad, S.; Görgens, J.F. Techno-economic assessment of integrating methanol or Fischer-Tropsch synthesis in a South African sugar mill. Bioresour. Technol. 2015, 183, 141–152. [Google Scholar] [CrossRef] [PubMed]

- Swanson, R.M.; Platon, A.; Satrio, J.A.; Brown, R.C. Techno-economic analysis of biomass-to-liquids production based on gasification. Fuel 2010, 89 (Suppl. S1), S11–S19. [Google Scholar] [CrossRef] [Green Version]

- Bain, R.L. Material and Energy Balances for Methanol from Biomass Using Biomass Gasifiers. 1992. Available online: http://www.doe.gov/bridge/home.html (accessed on 15 March 2023).

- Schuster, G.; Löffler, G.; Weigl, K.; Hofbauer, H. Biomass steam gasification–An extensive parametric modeling study. Bioresour. Technol. 2001, 77, 71–79. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kreutz, T.G.; Larson, E.D.; Liu, G.; Williams, R.H. Fischer-Tropsch Fuels from Coal and Biomass. In Proceedings of the 25th Annual International Pittsburgh Coal Conference, Pittsburgh, PA, USA, 29 September–2 October 2008. [Google Scholar]

- Cheng, K.; Kang, J.; King, D.L.; Subramanian, V.; Zhou, C.; Zhang, Q.; Wang, Y. Advances in Catalysis for Syngas Conversion to Hydrocarbons. In Advances in Catalysis; Academic Press Inc.: Cambridge, MA, USA, 2017; pp. 125–208. [Google Scholar] [CrossRef]

- Shahriar, M.F.; Khanal, A. The current techno-economic, environmental, policy status and perspectives of sustainable aviation fuel (SAF). Fuel 2022, 325, 124905. [Google Scholar] [CrossRef]

- Martinez, J.; Gonzalez, A.; Lopez, M.; Mayorga, M. Evaluación del Comportamiento de Mezclas de Biocombustibles Colombianos en Turbinas Aeronáuticas; Universidad ECCI: Bogotá, Colombia, 2022. [Google Scholar]

- Capaz, R.S. Alternative Aviation Fuels in Brazil: Environmental Performance and Economic Feasibility. 2021. Available online: http://repository.tudelft.nl/ (accessed on 27 February 2023).

- Chevron Corporation. Aviation Fuels. 2007. Available online: http://www.chevron.com/productsservices/aviation/ (accessed on 14 March 2023).

- García, F.N.V. Biojet Fuel Production via Alternative Thermochemical Routes: Thermoeconomic, Life Cycle and Flight Performance Analysis; Universidad Politécnica de Madrid: Madrid, Spain, 2021. [Google Scholar] [CrossRef]

- CORSIA. Corsia Supporting Document Corsia Eligible Fuels-Life Cycle Assessment Methodology; International Civil Aviation Organization (ICAO): Montréal, QC, Canada, 2019. [Google Scholar]

- Csonka, S. Reunión de Acercamiento Entre FAC y CAAFI; CAAFI Commercial Aviation Alternative Fuels Initiative: Cambridge, MA, USA, 2021. [Google Scholar]

- Preciado, M. Reunión Hoja de Ruta SAF Colombia; ECOPETROL: Bogotá, Colombia, 2022. [Google Scholar]

- Cuellar Sanchez Monica. Entrevista; FEDEPALMA: Bogotá, Colombia, 2020. [Google Scholar]

- RSB. Agroicone Publish Study to Support Sustainable Transformation in Brazil with SAF. Available online: https://rsb.org/2021/05/19/rsb-agroicone-publish-study-to-support-sustainable-transformation-in-brazil-with-saf/ (accessed on 19 March 2021).

- Wang, Z.; Kamali, F.P.; Osseweijer, P.; Posada, J.A. Socioeconomic effects of aviation biofuel production in Brazil: A scenarios-based Input-Output analysis. J. Clean. Prod. 2019, 230, 1036–1050. [Google Scholar] [CrossRef]

- Kamali, F.P.; Borges, J.A.R.; Osseweijer, P.; Posada, J.A. Towards social sustainability: Screening potential social and governance issues for biojet fuel supply chains in Brazil. Renew. Sustain. Energy Rev. 2018, 92, 50–61. [Google Scholar] [CrossRef]

- Forrester, J.W. System dynamics, systems thinking, and soft OR. Syst. Dyn. Rev. 1994, 10, 245–256. [Google Scholar] [CrossRef]

| Year | Country | Company | Plane | Percentage of SAF Blend | Type of SAF | From | To | Ref |

|---|---|---|---|---|---|---|---|---|

| 2008 | United Kingdom | Virgin Atlantic Airlines | B746-400 | 20% | Coconut and babassu oil fuel | Seattle, Washington | Seattle, Washington | [6] |

| 2009 | United States | United Airlines | Boeing 737 | Jatropha and algae derived fuel | Houston | Chicago | [7] | |

| 2011 | Germany | Lufthansa | Airbus 321 | 50% | biofuel | Hamburg | Frankfurt | [8] |

| 2011 | Netherlands | KLM | Airbus | 50% | Recycling Frying oil fuel | Amsterdam | Paris | [9] |

| 2011 | France | Air France | Airbus A321 | 50% | cooking oil | Toulouse | Paris | [10] |

| 2012 | Chile | LAN Airlines; COPEC | Airbus A320 | cooking oil | Santiago | Concepcion | [11] | |

| 2013 | Colombia | LAN Colombia; TERPEL | Airbus A320 | 33% | Camelina oil | Bogotá | Cali | [12] |

| ASTM Reference 1 | Conversion Process | Abbreviation | Possible Feedstock | Mix Ratio by Volume | Marketing Proposals/Projects |

|---|---|---|---|---|---|

| ASTM D7566 Annex 1 | Fischer–Tropsch Hydroprocessed Synthesized Paraffinic Kerosene | FT | Coal, natural gas, biomass | 50% | Fulcrum Bioenergy, Red Rock Biofuels, SG Preston, Kaidi, Sasol, Shell, Syntroleum |

| ASTM D7566 Annex 2 | Paraffinic kerosene synthesized from hydroprocessed fatty acids and esters | HEFA | Bio-oils, animal fats, recycled oils | 50% | World Energy, Honeywell UOP, Neste Oil, Dynamic Fuels, EERC |

| ASTM D7566 Annex 3 | Isoparaffins synthesized from hydroprocessed fermented sugars | SIP | Biomass used for sugar production. | 10% | Amyris, Total |

| ASTM D7566 Annex 4 | Kerosene synthesized with aromatics derived from the alkylation of light aromatics from non-petroleum sources | FT-SKA | Coal, natural gas, biomass | 50% | Sasol |

| ASTM D7566 Annex 5 | Synthetic Paraffinic Kerosene Alcohol to Jet | ATJ-SPK | Biomass from the production of ethanol or isobutane | 50% | Gevo, Cobalt, Honeywell UOP, Lanzatech, Swedish Biofuels, Byogy |

| ASTM D7566 Annex 6 | Catalytic Hydrothermolysis Jet Fuel | CHJ | Triglycerides such as soybean oil, jatropha oil, camelina oil, carinated oil, and tung oil | 50% | Applied Research Associates (ARA) |

| ASTM D7566 Annex 7 | Paraffinic kerosene synthesized from hydrocarbon esters and fatty acids | HC-HEFA-SPK | Algae | 10% | IHI Corporation |

| ASTM D1655 Annex A1 | co-hydroprocessing of esters and fatty acids in a conventional oil refinery | Co-processed HEFA | Fats, oils, and fats (FOG) co-processed with petroleum | 5% | |

| ASTM D1655 Annex A1 | Fischer–Tropsch hydrocarbon co-hydroprocessing in a conventional oil company refinery | Co-processed FT | Fischer–Tropsch hydrocarbons co-processed with petroleum | 5% | Fulcrum |

| Year | Document | Theme | Observation | Reference |

|---|---|---|---|---|

| 2008 | CONPES 3510 | Policy Guidelines to promote sustainable biofuel production in Colombia | Policy aimed at promoting the sustainable production of biofuels in Colombia, taking advantage of the opportunities ofeconomic and social development offered by emerging markets. | [22] |

| 2008 | Decree 2328 | Promotion | Whereby the Intersectoral Commission for the Management of Biofuels is created | [21] |

| 2010 | Resolution 180,919 | The Action Plan is adopted to develop the PROURE | PROURE: Program for the Rational and Efficient Use of Energy and other forms of Unconventional Energy | [17] |

| 2021 | LAW 336 | To establish minimum measures to achieve carbon neutrality, climate resilience, and low-carbon development in the country | This commitment means progress in assigning responsibilities to key government actors to support the feasibility of an early phase of the SAF | [23] |

| 2022 | CONPES 4075 ENERGY TRANSITION POLICY | The Ministry of Mines and Energy, in 2023, will establish the sectoral roadmap for the consolidation of the use of first-generation biofuels | The definition, analysis, design, evaluation, and formulation of guidelines and regulations for the promotion of the alternative use of biofuels | [23] |

| 2023 | National Development Plan 2022–2026 (literal D) | More efficient modes of transport at the operational and energy level, Number 3; technological advancement of the transport sector and promotion of active mobility | The government will drive the development and use of SAF sustainable aviation fuels | [24] |

| Crop Type | Production 2021 | Residue Name | Residue Percentage | Residue/Year | Humidity |

|---|---|---|---|---|---|

| Sugarcane | 27,155,902 | Bud * | 55.00% | 14,935,746 | 68% |

| Bagasse | 45.00% | 12,220,156 | 41% | ||

| Sugarcane (panela) | 78,330,803 | Bud * | 64.00% | 50,131,714 | 71% |

| Bagasse | 36.00% | 28,199,089 | 41% | ||

| Rice | 1,963,653 | Chaff | 53.70% | 1,054,554 | 73% |

| Husk | 46.30% | 909,099 | 4% | ||

| Oil Palm | 1,725,835 | Shell | 15.00% | 258,875 | 17% |

| Fibers | 20.00% | 345,167 | 35% | ||

| Palm rachis * | 65.00% | 1,121,793 | 58% | ||

| Corn | 1,661,407 | Stubble | 59.00% | 980,230 | 32% |

| Cob | 23.00% | 382,124 | 27% | ||

| Basket | 18.00% | 299,053 | 6% | ||

| Coffee | 13,508 | Pulp * | 34.64% | 4679 | 80% |

| Cisco | 3.35% | 453 | 7% | ||

| Stems | 62.01% | 8377 | 26% |

| Technology | Operation | References |

|---|---|---|

| HEFA | General | [63,64] |

| Hydrolysis | [65] | |

| Deoxygenation | [66,67] | |

| Hydrocracking | [68,69,70,71] | |

| ATJ | General | [6,44,72,73,74] |

| Pretreatment y saccharification | [75] | |

| Fermentation | [76] | |

| dehydration | [77,78,79,80] | |

| oligomerization e hydrocracking | [81,82] | |

| FT | General | [83] |

| Gasification | [84,85,86,87] | |

| Fischer–Tropsch Reaction and Hydrocracking | [88,89] | |

| General | Validation | [90,91,92,93,94,95] |

| Factor | Analysis |

|---|---|

| Political |

|

| Economic |

|

| Social |

|

| Technology |

|

| Environmental |

|

| Legal |

|

| Feedstock | Production Ton/Year | SAF/Feedstock | SAF Production Potential Ton/Year | SAF Production Potential Gal/Year |

|---|---|---|---|---|

| Production of UCO | 8866.00 | 44.30% | 3927.64 | 1,284,372.89 |

| Production of palm oil | 87,604.79 | 43.70% | 38,283.30 | 12,518,981.36 |

| TOTAL | 13,803,354.26 | |||

| Demand Contribution | 2.76% |

| Technology | Feedstock Ton/Year | SAF/Feedstock | Production Potential of SAF Ton/Year | Production Potential Gal/Year |

|---|---|---|---|---|

| FT | 43,602,622.01 | 11.00% | 4,796,288.42 | 1,568,429,382.94 |

| ATJ | 67,248,486.04 | 7.60% | 5,110,884.94 | 1,671,305,269.15 |

| TOTAL | 3,239,734,652.09 | |||

| Demand Contribution | 647.95% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López Gómez, M.; Posada, J.; Silva, V.; Martínez, L.; Mayorga, A.; Álvarez, O. Diagnosis of Challenges and Uncertainties for Implementation of Sustainable Aviation Fuel (SAF) in Colombia, and Recommendations to Move Forward. Energies 2023, 16, 5667. https://doi.org/10.3390/en16155667

López Gómez M, Posada J, Silva V, Martínez L, Mayorga A, Álvarez O. Diagnosis of Challenges and Uncertainties for Implementation of Sustainable Aviation Fuel (SAF) in Colombia, and Recommendations to Move Forward. Energies. 2023; 16(15):5667. https://doi.org/10.3390/en16155667

Chicago/Turabian StyleLópez Gómez, Mauricio, John Posada, Vladimir Silva, Lina Martínez, Alejandro Mayorga, and Oscar Álvarez. 2023. "Diagnosis of Challenges and Uncertainties for Implementation of Sustainable Aviation Fuel (SAF) in Colombia, and Recommendations to Move Forward" Energies 16, no. 15: 5667. https://doi.org/10.3390/en16155667

APA StyleLópez Gómez, M., Posada, J., Silva, V., Martínez, L., Mayorga, A., & Álvarez, O. (2023). Diagnosis of Challenges and Uncertainties for Implementation of Sustainable Aviation Fuel (SAF) in Colombia, and Recommendations to Move Forward. Energies, 16(15), 5667. https://doi.org/10.3390/en16155667