A New Method for Comprehensive and Quantitative Characterization of Shale Microfractures: A Case Study of the Lacustrine Shale in the Yuanba Area, Northern Sichuan Basin

Abstract

:1. Introduction

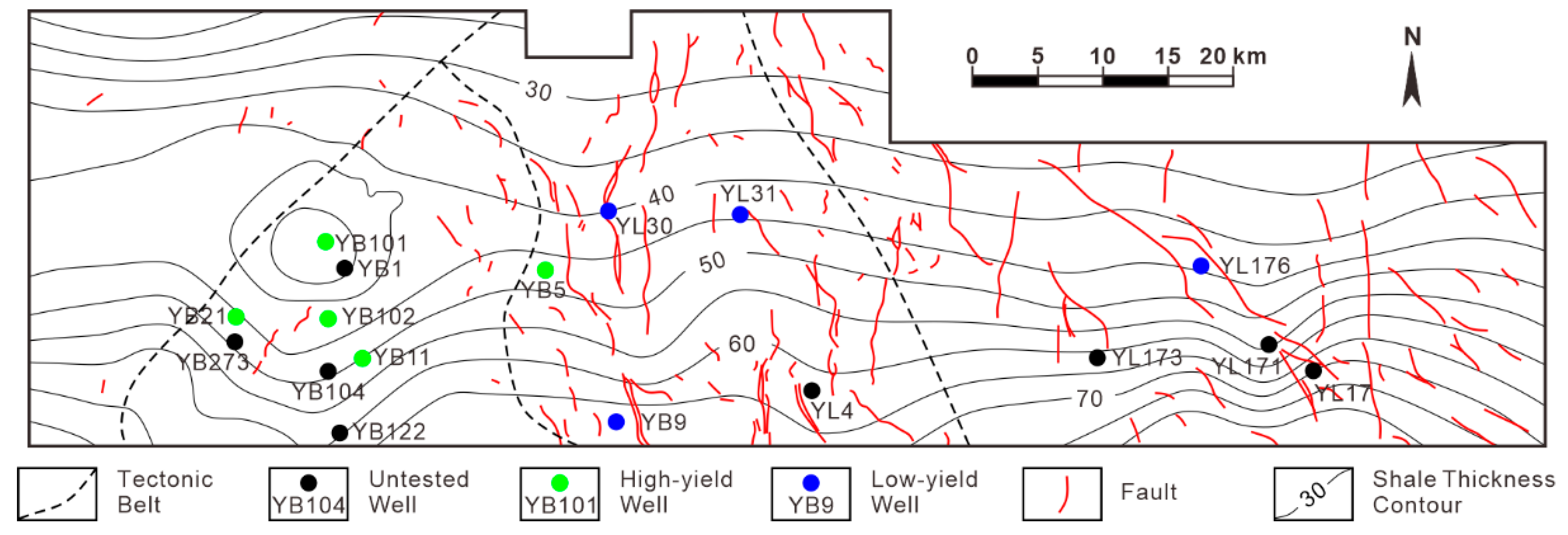

2. Geologic Background

3. Sampling and Methodology

4. Results

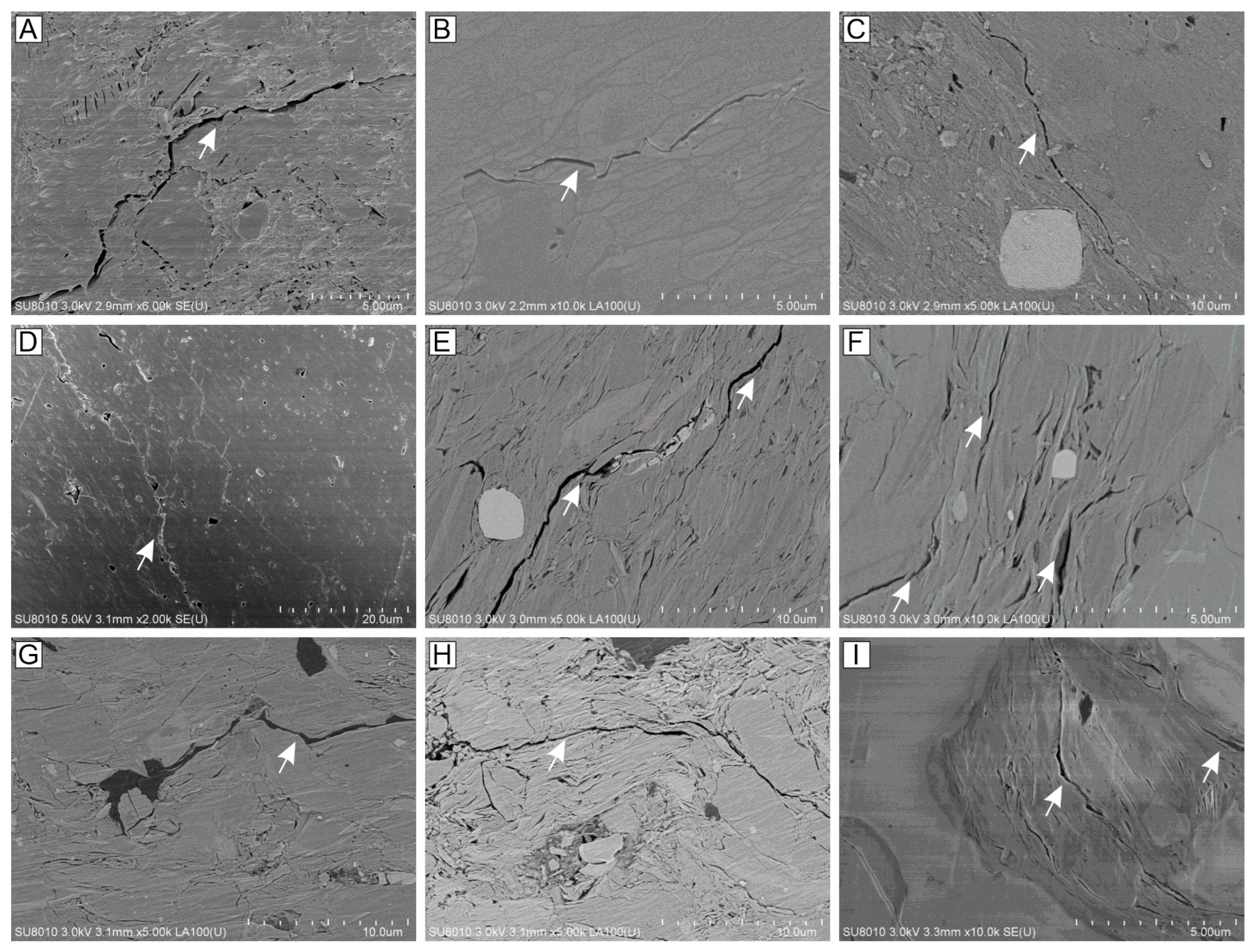

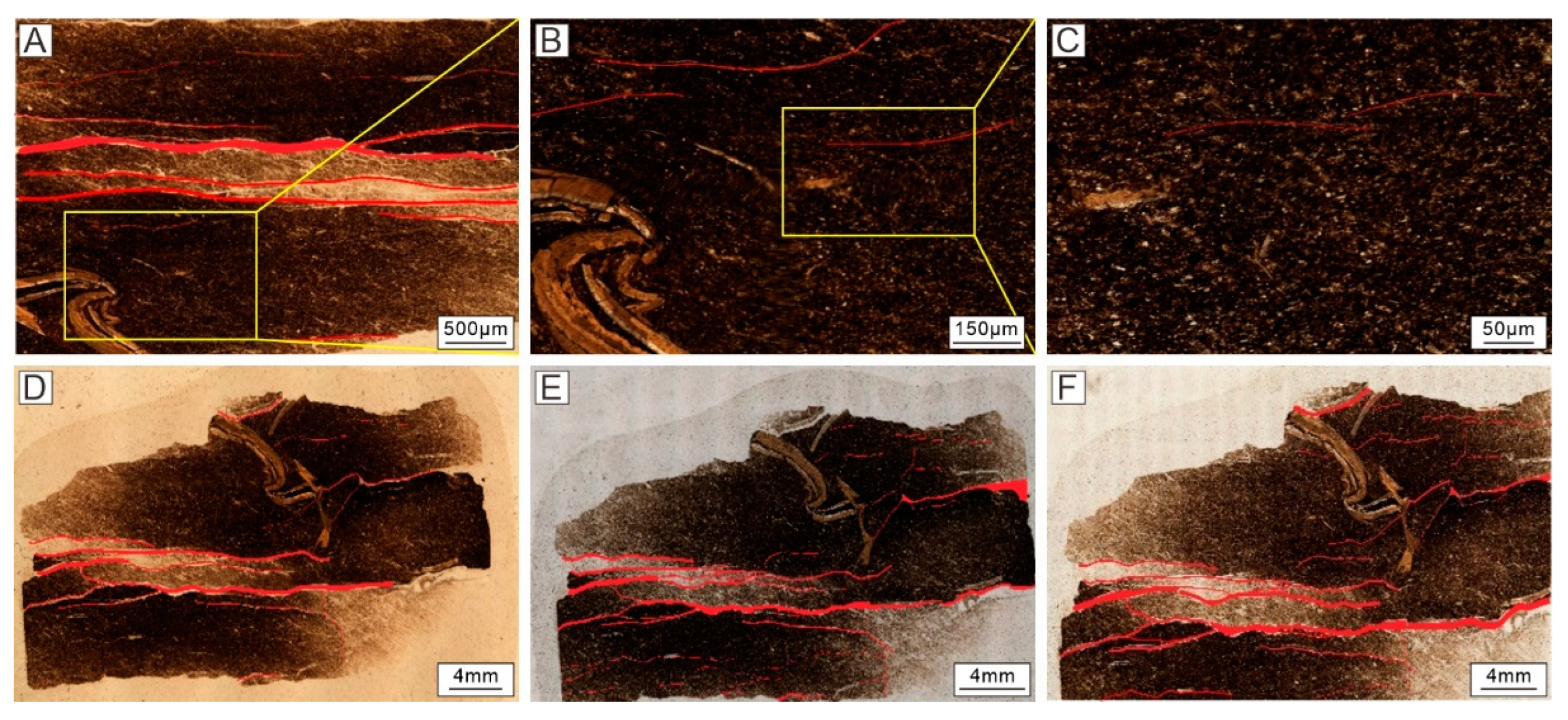

4.1. Morphology of Microfractures

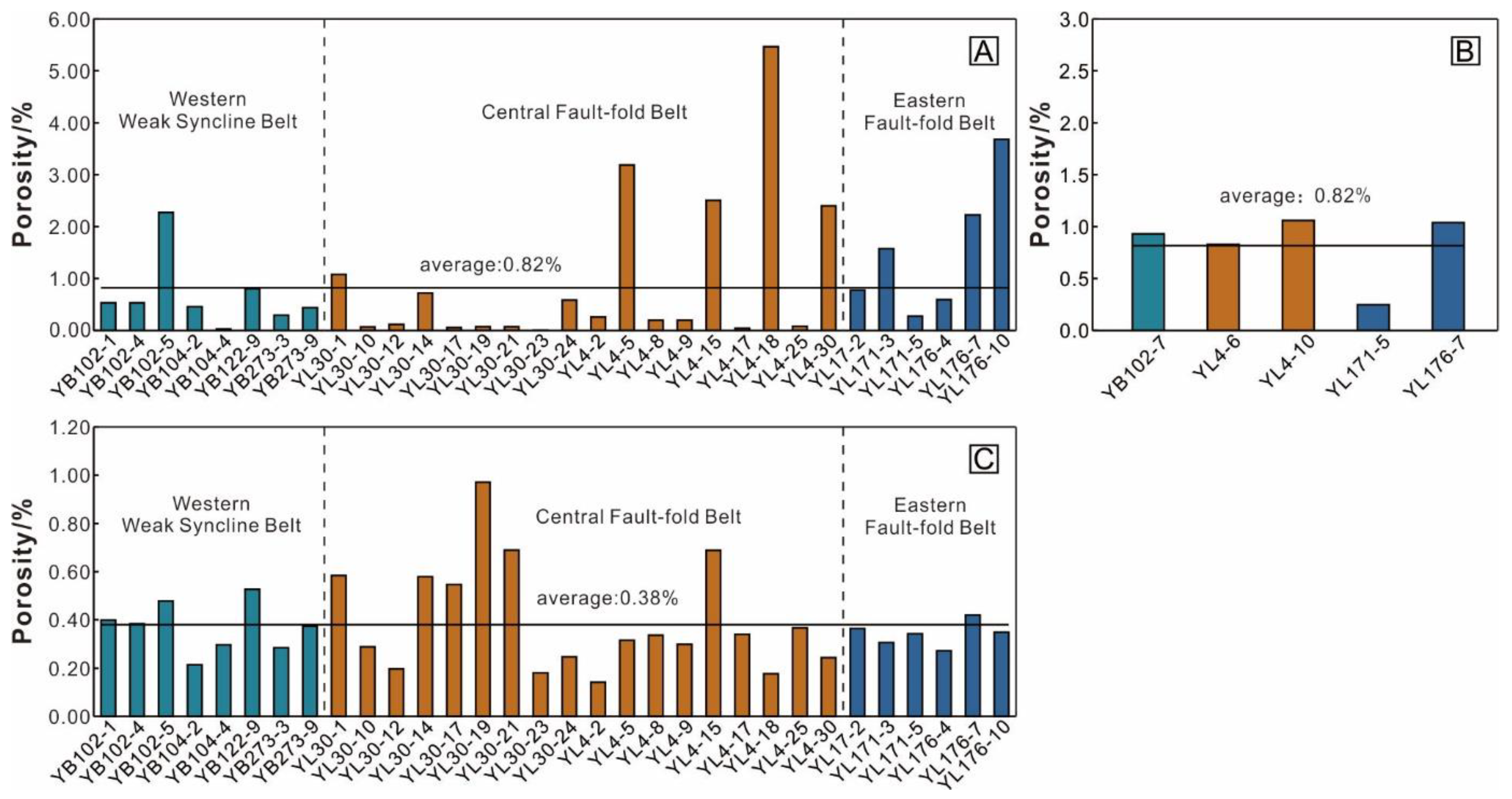

4.2. Quantitative Evaluation of Shale Microfractures

4.3. Total Porosity of Shale

5. Discussion

5.1. Performance of Comprehensive Quantitative Characterization of Shale Microfractures via RTS and SEM Observations

5.2. Differences and Causes of Percentage of Microfracture Porosity to Total Porosity

5.3. Shale Gas Enrichment and Favorable Exploration Area

6. Conclusions

- (1)

- The widths of the microfractures identified using the RTS observation, CT scanning, and SEM techniques are mainly 10–40 μm, 2–10 μm, and 100–400 nm, respectively. The combination of the RTS observation and SEM techniques can be used to comprehensively and quantitatively characterize the microfractures of different scales in shale.

- (2)

- The RTS observations mainly identify fractures with widths greater than 10 μm, while SEM mainly identifies fractures with widths of less than 10 μm. Based on the combined characterization method of RTS observations and SEM, we found that the microfractures in the J1z4 in the Yuanba area account for 21.09% of the total porosity, indicating that the shale in the Yuanba area is dominated by pore-type reservoirs and has the potential to yield stable shale gas production.

- (3)

- Some of the shales adjacent to faults and fold belts have relatively well developed microfractures, resulting in the percentage of microfracture porosity to the total porosity approaching or exceeding 50%, which may lead to the loss of shale gas. The weak tectonic deformation areas in the central–southern part of the western weak syncline belt and the southwestern part of the eastern fault-fold belt in the Yuanba area are the favorable enrichment areas for shale gas in the J1z4.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anders, M.H.; Laubach, S.E.; Scholz, C.H. Microfractures: A review. J. Struct. Geol. 2014, 69, 377–394. [Google Scholar]

- Gale, J.F.W.; Laubach, S.E.; Olson, J.E.; Eichhuble, P.; Fall, A. Natural fractures in shale: A review and new observations. AAPG Bull. 2014, 98, 2165–2216. [Google Scholar] [CrossRef]

- Slatt, R.M.; O’Brien, N.R. Pore types in the Barnett and Woodford gas shales: Contribution to understanding gas storage and migration pathways in fine-grained rocks. AAPG Bull. 2011, 95, 2017–2030. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Haghshenas, B.; Ghanizadeh, A.; Qanbari, F.; Williams-Kovacs, J.D.; Riazi, N.; Debuhr, C.; Deglint, H.J. Nanopores to megafractures: Current challenges and methods for shale gas reservoir and hydraulic fracture characterization. J. Nat. Gas Sci. Eng. 2016, 31, 612–657. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, D.D.; Jiang, Z.X.; Song, Y.; Luo, Q.; Wang, X. Mechanism for the formation of natural fractures and their effects on shale oil accumulation in Junggar Basin, NW China. Int. J. Coal Geol. 2022, 254, 103973. [Google Scholar] [CrossRef]

- Zhang, X.J.; He, J.H.; Deng, H.C.; Fu, M.Y.; Xiang, Z.H.; Peng, X.F.; Gluyas, J.G.; Li, R.X. Controls of interlayers on the development and distribution of natural fractures in lacustrine shale reservoirs: A case study of the Da’anzhai member in the Fuling area in the eastern Sichuan Basin. J. Pet. Sci. Eng. 2022, 208, 109224. [Google Scholar] [CrossRef]

- Gou, Q.Y.; Xu, S.; Hao, F.; Yang, F.; Zhang, B.Q.; Shu, Z.G.; Zhang, A.H.; Wang, Y.X.; Lu, Y.B.; Cheng, X.; et al. Full-scale pores and micro-fractures characterization using FE-SEM, gas adsorption, nano-CT and micro-CT: A case study of the Silurian Longmaxi Formation shale in the Fuling area, Sichuan Basin, China. Fuel 2019, 253, 167–179. [Google Scholar] [CrossRef]

- Li, W.H.; Ying, J.F.; Huang, Y.R.; Wang, M. Quantitative characterization of microfractures in the Cretaceous tight reservoirs from the Liuhe Basin. Energy Rep. 2021, 7, 5795–5803. [Google Scholar] [CrossRef]

- Ougier-Simonin, A.; Renard, F.; Boehm, C.; Vidal-Gilbert, S. Microfracturing and microporosity in shales. Earth-Sci. Rev. 2016, 162, 198–226. [Google Scholar] [CrossRef] [Green Version]

- Yang, F.; Ning, Z.F.; Wang, Q.; Zhang, R.; Krooss, B.M. Pore structure characteristics of lower Silurian shales in the southern Sichuan Basin, China: Insights to pore development and gas storage mechanism. Int. J. Coal Geol. 2016, 156, 12–24. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhao, J.Z.; Er, C.; Wang, R.; Wei, Z.K.; Shen, W.X. Study on types and features of the pore in Mesozoic and Upper Palaeozoic shales in Ordos Basin. J. Xi’an Shiyou Univ. (Nat. Sci. Ed.) 2014, 29, 14–19. (In Chinese) [Google Scholar]

- Vega, B.; Ross, C.M.; Kovscek, A.R. Imaging-based characterization of calcite-filled fractures and porosity in shales. SPE J. 2015, 20, 810–823. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reeds, R.M.; Willis, J.J.; Willis, K.M.; Cantin, J.J.R. Scanning-electron-microscope petrographic evidence for distinguishing organic matter pores associated with depositional organic matter versus migrated organic matter in mudrocks. GCAGS J. 2014, 3, 51–60. [Google Scholar]

- Tiwari, P.; Deo, M.; Lin, C.L.; Miller, J.D. Characterization of oil shale pore structure before and after pyrolysis by using X-ray micro CT. Fuel 2013, 107, 547–554. [Google Scholar] [CrossRef]

- Ramandi, H.L.; Mostaghimi, P.; Armstrong, R.T.; Saadatfar, M.; Pinczewski, W.V. Porosity and permeability characterization of coal—A micro-computed tomography study. Int. J. Coal Geol. 2016, 154, 57–68. [Google Scholar] [CrossRef]

- Jiang, S.; Xu, Z.Y.; Feng, Y.L.; Zhang, J.C.; Cai, D.S.; Chen, L.; Wu, Y.; Zhou, D.S.; Bao, S.J.; Long, S.X. Geologic characteristics of hydrocarbon-bearing marine, transitional and lacustrine shales in China. J. Asian Earth Sci. 2016, 115, 404–418. [Google Scholar] [CrossRef]

- Jiang, S.; Peng, Y.M.; Gao, B.; Zhang, J.C.; Cai, D.S.; Xue, G.; Bao, S.J.; Xu, Z.Y.; Tang, X.L.; Dahdah, N. Geology and shale gas resource potentials in the Sichuan Basin, China. Energy Explor. Exploit. 2016, 34, 689–710. [Google Scholar] [CrossRef] [Green Version]

- Potter, C.J. Paleozoic shale gas resources in the Sichuan Basin, China. AAPG Bull. 2018, 102, 987–1009. [Google Scholar] [CrossRef]

- Ma, X.H.; Xie, J.; Yong, R.; Zhu, Y.Q. Geological characteristics and high production control factors of shale gas reservoirs in Silurian Longmaxi Formation, southern Sichuan Basin, SW China. Pet. Explor. Dev. 2020, 47, 901–915. [Google Scholar] [CrossRef]

- Li, Y.J.; Feng, Y.Y.; Liu, H.; Zhang, L.H.; Zhao, S.X. Geological characteristics and resource potential of lacustrine shale gas in the Sichuan Basin, SW China. Pet. Explor. Dev. 2013, 40, 454–460. [Google Scholar] [CrossRef]

- Wang, X.Y.; Jin, Z.K.; Zhao, J.H.; Zhu, Y.X.; Hu, Z.Q.; Liu, G.X.; Jiang, T.; Wang, H.; Li, S.; Shi, S.T. Depositional environment and organic matter accumulation of Lower Jurassic nonmarine fine-grained deposits in the Yuanba Area, Sichuan Basin, SW China. Mar. Pet. Geol. 2020, 116, 104352. [Google Scholar] [CrossRef]

- Fathy, D.; Wagreich, M.; Fathi, E.; Ahmed, M.S.; Leila, M.; Sami, M. Maastrichtian Anoxia and Its Influence on Organic Matter and Trace Metal Patterns in the Southern Tethys Realm of Egypt during Greenhouse Variability. ACS Omega 2023, 8, 19603–19612. [Google Scholar] [CrossRef] [PubMed]

- Fishman, N.S.; Hackley, P.C.; Lowers, H.A.; Hill, R.J.; Egenhoff, S.O.; Eberl, D.D.; Blum, A.E. The nature of porosity in organic-rich mudstones of the Upper Jurassic Kimmeridge Clay Formation, North Sea, offshore United Kingdom. Int. J. Coal Geol. 2012, 103, 32–50. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, J.C.; Wang, X.Z.; Yu, B.S.; Ding, W.L.; Xiong, J.Y.; Yang, Y.T.; Wang, L.; Yang, C. Shale characteristics in the southeastern Ordos Basin, China: Implications for hydrocarbon accumulation conditions and the potential of continental shales. Int. J. Coal Geol. 2014, 128–129, 32–46. [Google Scholar] [CrossRef]

- Xu, Q.; Liu, B.; Ma, Y.; Song, X.; Wang, Y.; Chen, Z. Geological and geochemical characterization of lacustrine shale: A case study of the Jurassic Da’anzhai member shale in the central Sichuan Basin, southwest China. J. Nat. Gas Sci. Eng. 2017, 47, 124–139. [Google Scholar] [CrossRef]

- Chen, L.; Jiang, Z.X.; Liu, Q.X.; Jiang, S.; Liu, K.Y.; Tan, J.Q.; Gao, F.L. Mechanism of shale gas occurrence: Insights from comparative study on pore structures of marine and lacustrine shales. Mar. Pet. Geol. 2019, 104, 200–216. [Google Scholar] [CrossRef]

- Zhou, D.H.; Jiao, F.Z.; Guo, X.S.; Guo, T.L.; Wei, Z.H. Geologic analysis of Middle-Lower Jurassic shale reservoirs in Yuanba area, northeastern Sichuan Basin. Pet. Geol. Exp. 2013, 35, 596–600, 656, (In Chinese with English Abstract). [Google Scholar]

- Li, L.; Li, P.P.; Zhang, Z.C.; Hao, J.Y.; Xiao, J.L.; Zou, H.Y. Quantitative characterization of microscopic pore structure of shale in Da’anzhai Member in Yuanba area, northern Sichuan Basin. Sci. Technol. Eng. 2020, 20, 8923–8932, (In Chinese with English Abstract). [Google Scholar]

- Zhou, D.H.; Sun, C.X.; Liu, Z.B.; Nie, H.K. Geological characteristics of continental shale gas reservoir in the Jurassic Da’anzhai member in the northeastern Sichuan Basin. China Pet. Explor. 2020, 25, 32–42, (In Chinese with English Abstract). [Google Scholar]

- Li, P.P.; Hao, F.; Guo, X.S.; Zou, H.Y.; Yu, X.Y.; Wang, G.W. Processes involved in the origin and accumulation of hydrocarbon gases in the Yuanba gas field, Sichuan Basin, Southwest China. Mar. Pet. Geol. 2015, 59, 150–165. [Google Scholar] [CrossRef]

- Liu, Z.B.; Liu, G.X.; Hu, Z.Q.; Feng, D.J.; Zhu, T.; Bian, R.K.; Jiang, T.; Jin, Z.G. Lithofacies types and assemblage features of continental shale strata and their implications for shale gas exploration: A case study of the Middle and Lower Jurassic strata in the Sichuan Basin. Nat. Gas Ind. B 2020, 7, 358–369. [Google Scholar] [CrossRef]

- Yang, R.; He, S.; Li, T.Y.; Yang, X.Y.; Hu, Q.H. Origin of over-pressure in clastic rocks in Yuanba area, northeast Sichuan Basin, China. J. Nat. Gas Sci. Eng. 2016, 30, 90–105. [Google Scholar] [CrossRef]

- Li, Q.W.; Liu, Z.B.; Chen, F.R.; Liu, G.X.; Zhang, D.W.; Li, P.; Wang, P.F. Geochemical Characteristics and Organic Matter Provenance of Shale in the Jurassic Da’anzhai Member, Northeastern Sichuan Basin. Front. Earth Sci. 2022, 10, 860477. [Google Scholar] [CrossRef]

- Zheng, R.C.; Guo, C.L.; Liang, X.W.; Chang, H.L.; Lu, B.X. Characteristics and evaluation of reservoir spaces of shale gas (oil) in Da’anzhai member of Ziliujing Formation in Sichuan Basin. Lithol. Reserv. 2016, 28, 16–29, (In Chinese with English Abstract). [Google Scholar]

- Lai, J.; Li, D.; Wang, G.; Xiao, C.W.; Hao, X.L.; Luo, Q.Y.; Lai, L.B.; Qin, Z.Q. Earth stress and reservoir quality evaluation in high and steep structure: The Lower Cretaceous in the Kuqa Depression, Tarim Basin, China. Mar. Pet. Geol. 2019, 101, 43–54. [Google Scholar] [CrossRef]

- Zeng, L.B.; Jiang, J.W.; Yang, Y.L. Fractures in the low porosity and ultra-low permeability glutenite reservoirs: A case study of the late Eocene Hetaoyuan formation in the Anpeng oilfield, Nanxiang Basin, China. Mar. Pet. Geol. 2010, 27, 1642–1650. [Google Scholar] [CrossRef]

- Tang, X.L.; Jiang, Z.X.; Jiang, S.; Li, Z. Heterogeneous nanoporosity of the Silurian Longmaxi Formation shale gas reservoir in the Sichuan Basin using the QEMSCAN, FIB-SEM, and nano-CT methods. Mar. Pet. Geol. 2016, 78, 99–109. [Google Scholar] [CrossRef]

- Yang, F.; Ning, Z.; Wang, Q.; Liu, H. Pore structure of Cambrian shales from the Sichuan Basin in China and implications to gas storage. Mar. Pet. Geol. 2016, 70, 14–26. [Google Scholar] [CrossRef]

- Wang, P.F.; Jiang, Z.X.; Yin, L.S.; Chen, L.; Li, Z.; Zhang, C.; Li, T.W.; Huang, P. Lithofacies classification and its effect on pore structure of the Cambrian marine shale in the Upper Yangtze Platform, South China: Evidence from FE-SEM and gas adsorption analysis. J. Pet. Sci. Eng. 2017, 156, 307–321. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Li, X.Q.; Wei, Q.; Gao, W.J.; Liang, W.L.; Wang, Z.; Wang, F.Y. Quantitative characterization of pore-fracture system of organic-rich marine-continental shale reservoirs: A case study of the Upper Permian Longtan Formation, Southern Sichuan Basin, China. Fuel 2017, 200, 272–281. [Google Scholar] [CrossRef]

- Adeyilola, A.; Nordeng, S.; Onwumelu, C.; Nwachukwu, F.; Gentzis, T. Geochemical, petrographic and petrophysical characterization of the Lower Bakken shale, Divide County, North Dakota. Int. J. Coal Geol. 2020, 224, 103477. [Google Scholar] [CrossRef]

- Heriawan, M.N.; Koike, K. Coal quality related to microfractures identified by CT image analysis. Int. J. Coal Geol. 2015, 140, 97–110. [Google Scholar] [CrossRef]

- Gou, Q.Y.; Hao, F.; Yang, F.; Wang, Y.X.; Lu, Y.B.; Zhang, A.H.; Cheng, X.; Qing, J.W.; Gao, M.T. Study on characterization of micro-fracture of shale based on, micro-CT. Acta Geol. Sin. 2019, 93, 2372–2382, (In Chinese with English Abstract). [Google Scholar]

- Ge, J.; Zhao, W.C.; Wang, T.T.; Cai, T.T.; Cong, Z.C.; Bai, Y.J.; Gu, H.P. Study on Micro-nano pore characteristics and classification of tight sandstone reservoir based on Q-cluster. Geofluids 2022, 2022, 3218636. [Google Scholar] [CrossRef]

- Dewers, T.A.; Jason, H.; Russ, E.; Luca, D. Three-dimensional pore networks and transport properties of a shale gas formation determined from focused ion beam serial imaging. Gas Coal Technol. 2012, 5, 229–248. [Google Scholar] [CrossRef]

- Curtis, M.E.; Cardott, B.J.; Sondergeld, C.H.; Rai, C.S. Development of organic porosity in the Woodford Shale with increasing thermal maturity. Int. J. Coal Geol. 2012, 103, 26–31. [Google Scholar] [CrossRef]

- Jin, L.X.; Mathur, R.; Rother, G.; Cole, D.; Bazilevskaya, E.; Williams, J.; Carone, A.; Brantley, S. Evolution of porosity and geochemistry in Marcellus Formation black shale during weathering. Chem. Geol. 2013, 356, 50–63. [Google Scholar] [CrossRef]

- Keller, L.M.; Schuetz, P.; Erni, R.; Rossell, M.D.; Lucas, F.; Gasser, P.; Holzer, L. Characterization of multi-scale microstructural features in Opalinus Clay. Microporous Mesoporous Mater. 2013, 170, 83–94. [Google Scholar] [CrossRef]

- Bai, B.J.; Elgmati, M.; Zhang, H.; Wei, M.Z. Rock characterization of Fayetteville shale gas plays. Fuel 2013, 105, 645–652. [Google Scholar] [CrossRef]

- Wang, H.; He, Z.L.; Zhang, Y.G.; Su, K.; Wang, R.Y. Quantitative identification of microfractures in the marine shale reservoir of the Wufeng-Longmaxi Formation using water immersion tests and image characterization. Interpretation 2018, 6, 23–30. [Google Scholar] [CrossRef]

- Long, P.Y.; Zhang, J.C.; Tang, X.; Nie, H.K.; Liu, Z.J.; Han, S.B.; Zhu, L.L. Feature of muddy shale fissure and its effect for shale gas exploration and development. Nat. Gas Geosci. 2011, 22, 525–532. (In Chinese) [Google Scholar]

- Wu, S.T.; Zhai, X.F.; Yang, Z.; Bale, H.; Hong, Y.L.; Cui, J.W.; Pan, S.Q.; Lin, S.H. Characterization of fracture formation in organic-rich shales—An experimental and real time study of the Permian Lucaogou Formation, Junggar Basin, northwestern China. Mar. Pet. Geol. 2019, 107, 397–406. [Google Scholar] [CrossRef]

- Dong, H.M.; Sun, J.M.; Zhu, J.J.; Lin, Z.Z.; Cui, L.K.; Yan, W.C.; Xiong, Z. Quantitative characterization and characteristic analysis of pore structure of shale-gas reservoir in the Sichuan Basin, China. Interpretation 2019, 7, 23–32. [Google Scholar] [CrossRef]

- Liu, Z.B.; Hu, Z.Q.; Liu, G.X.; Liu, Z.J.; Liu, H.T.; Hao, J.Y.; Wang, P.W.; Li, P. Pore characteristics and controlling factors of continental shale reservoirs in the Lower Jurassic Ziliujing Formation, northeastern Sichuan Basin. Oil Gas Geol. 2021, 42, 136–145, (In Chinese with English Abstract). [Google Scholar]

- Ma, K.; Zhang, B.; Wen, S.Y.; Lin, X.Y.; Wang, Y.; Yang, K. Quantitative Characterization and Controlling Factors of Shallow Shale Reservoir in Taiyang Anticline, Zhaotong Area, China. Minerals 2022, 12, 998. [Google Scholar] [CrossRef]

- Sun, Y.; Zhai, C.; Xu, J.Z.; Cong, Y.Z.; Qin, L.; Zhao, C. Characterization and evolution of the full size range of pores and fractures in rocks under freeze-thaw conditions using nuclear magnetic resonance and three-dimensional X-ray microscopy. Eng. Geol. 2020, 271, 105616. [Google Scholar] [CrossRef]

- Watkins, H.; Butler, R.W.H.; Bond, C.E.; Healy, D. Influence of structural position on fracture networks in the Torridon Group, Achnashellach fold and thrust belt, NW Scotland. J. Struct. Geol. 2015, 74, 64–80. [Google Scholar] [CrossRef] [Green Version]

- Wei, X.L.; Zhang, Y.X.; Zhang, S.; Zhang, J.C.; Shi, M. A study on the morphology of natural microfractures in marine and continental transitional shale based on scanning electron microscopy image. Micron 2021, 148, 103105. [Google Scholar] [CrossRef]

- Guo, X.S.; Hu, D.F.; Li, Y.P.; Wei, Z.H.; Wei, X.F.; Liu, Z.J. Geological factors controlling shale gas enrichment and high production in Fuling shale gas field. Pet. Explor. Dev. 2017, 44, 513–523. [Google Scholar] [CrossRef]

- Wang, X.Z.; Liang, Q.S.; Gao, C.; Xue, P.; Yin, J.T.; Hao, S.Y. Hydrocarbon accumulation model influenced by “three elements (source-storage-preservation)” in lacustrine shale reservoir-A case study of Chang 7 shale in Yan’an area, Ordos Basin. Front. Earth Sci. 2022, 10, 1012607. [Google Scholar] [CrossRef]

- Fathy, D.; El-Balkiemy, A.F.; Makled, W.A.; Hosny, A.M. Organic geochemical signals of Paleozoic rocks in the southern Tethys, Siwa basin, Egypt: Implications for source rock characterization and petroleum system. Phys. Chem. Earth Parts A/B/C 2023, 130, 103393. [Google Scholar] [CrossRef]

- Liu, W.W.; Zhang, K.; Li, Q.W.; Yu, Z.H.; Cheng, S.H.; Liu, J.Y.; Liu, P.; Han, F.L.; Tang, L.Y.; Li, Z.W.; et al. Quantitative characterization for the micronanopore structures of terrestrial shales with different lithofacies types: A case study of the Jurassic Lianggaoshan Formation in the southeastern Sichuan Basin of the Yangtze region. Geofluids 2021, 1416303. [Google Scholar] [CrossRef]

- Curtis, J.B. Fractured shale-gas systems. AAPG Bull. 2002, 86, 1921–1938. [Google Scholar]

- Yao, J.; Ding, Y.; Sun, H.; Fan, D.Y.; Wang, M.; Jia, C.Q. Productivity Analysis of Fractured Horizontal Wells in Tight Gas Reservoirs Using a Gas–Water Two-Phase Flow Model with Consideration of a Threshold Pressure Gradient. Energy Fuels 2023, 37, 8190–8198. [Google Scholar] [CrossRef]

- Panahi, H.; Kobchenko, M.; Meakin, P.; Dysthe, D.K.; Renard, F. Fluid expulsion and microfracturing during the pyrolysis of an organic rich shale. Fuel 2019, 235, 1–16. [Google Scholar] [CrossRef]

- Zeng, Y.J.; Du, S.H.; Zhang, X.; Zhang, B.P.; Liu, H.L. The crucial geometric distinctions of microfractures as the indispensable transportation channels in hydrocarbon-rich shale reservoir. Energy Rep. 2020, 6, 2056–2065. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Li, Q.; Li, L.; Zou, H. A New Method for Comprehensive and Quantitative Characterization of Shale Microfractures: A Case Study of the Lacustrine Shale in the Yuanba Area, Northern Sichuan Basin. Energies 2023, 16, 5685. https://doi.org/10.3390/en16155685

Li P, Li Q, Li L, Zou H. A New Method for Comprehensive and Quantitative Characterization of Shale Microfractures: A Case Study of the Lacustrine Shale in the Yuanba Area, Northern Sichuan Basin. Energies. 2023; 16(15):5685. https://doi.org/10.3390/en16155685

Chicago/Turabian StyleLi, Pingping, Qianshen Li, Lei Li, and Huayao Zou. 2023. "A New Method for Comprehensive and Quantitative Characterization of Shale Microfractures: A Case Study of the Lacustrine Shale in the Yuanba Area, Northern Sichuan Basin" Energies 16, no. 15: 5685. https://doi.org/10.3390/en16155685