Research Development and Critical Problems Existing in Strata Movement and Its Control

Abstract

:1. Introduction

2. Development History of Strata Movement and Control

3. Movement Law of the Overlying Strata in the Stope

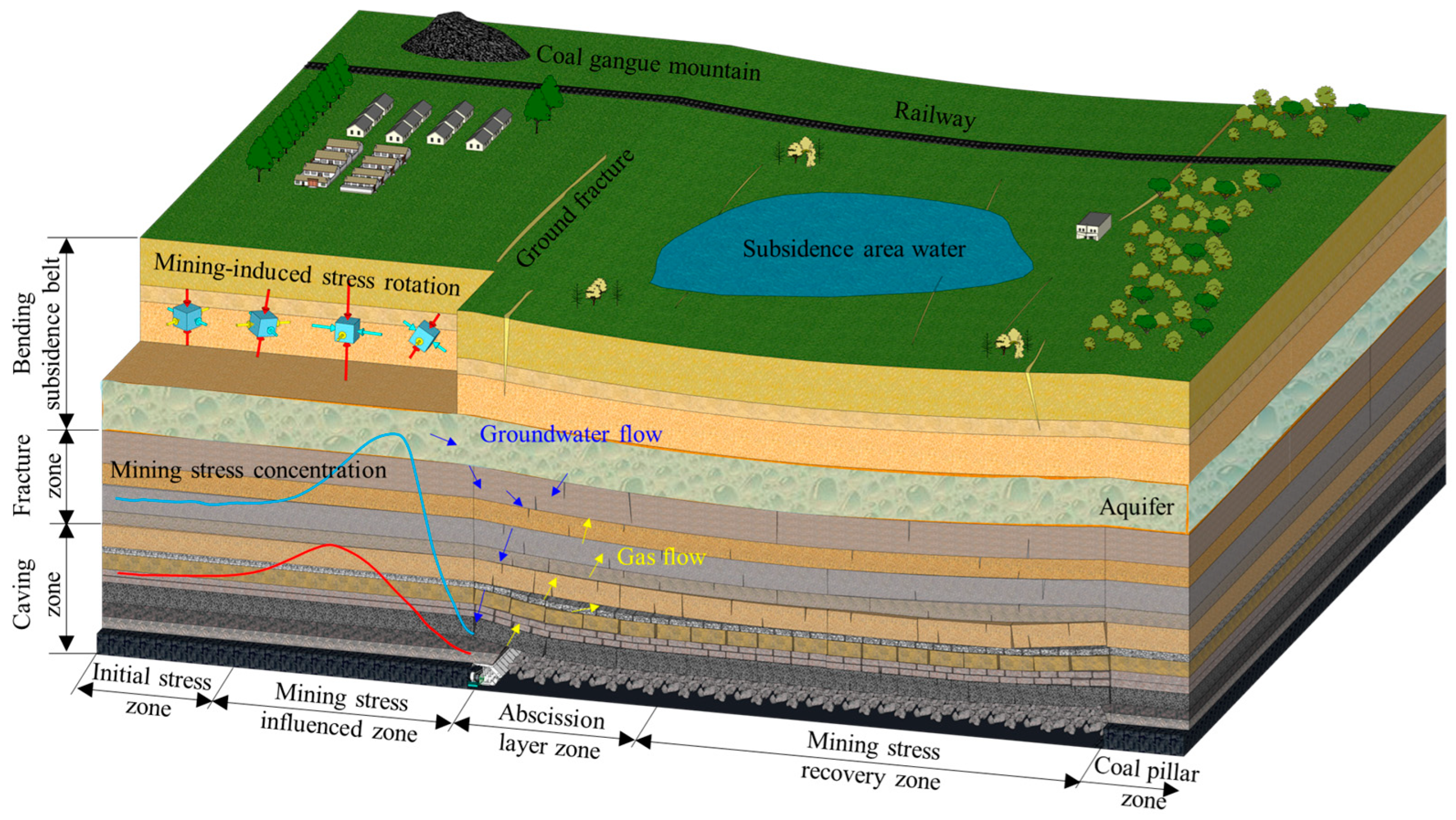

3.1. Longitudinal Partition Characteristics

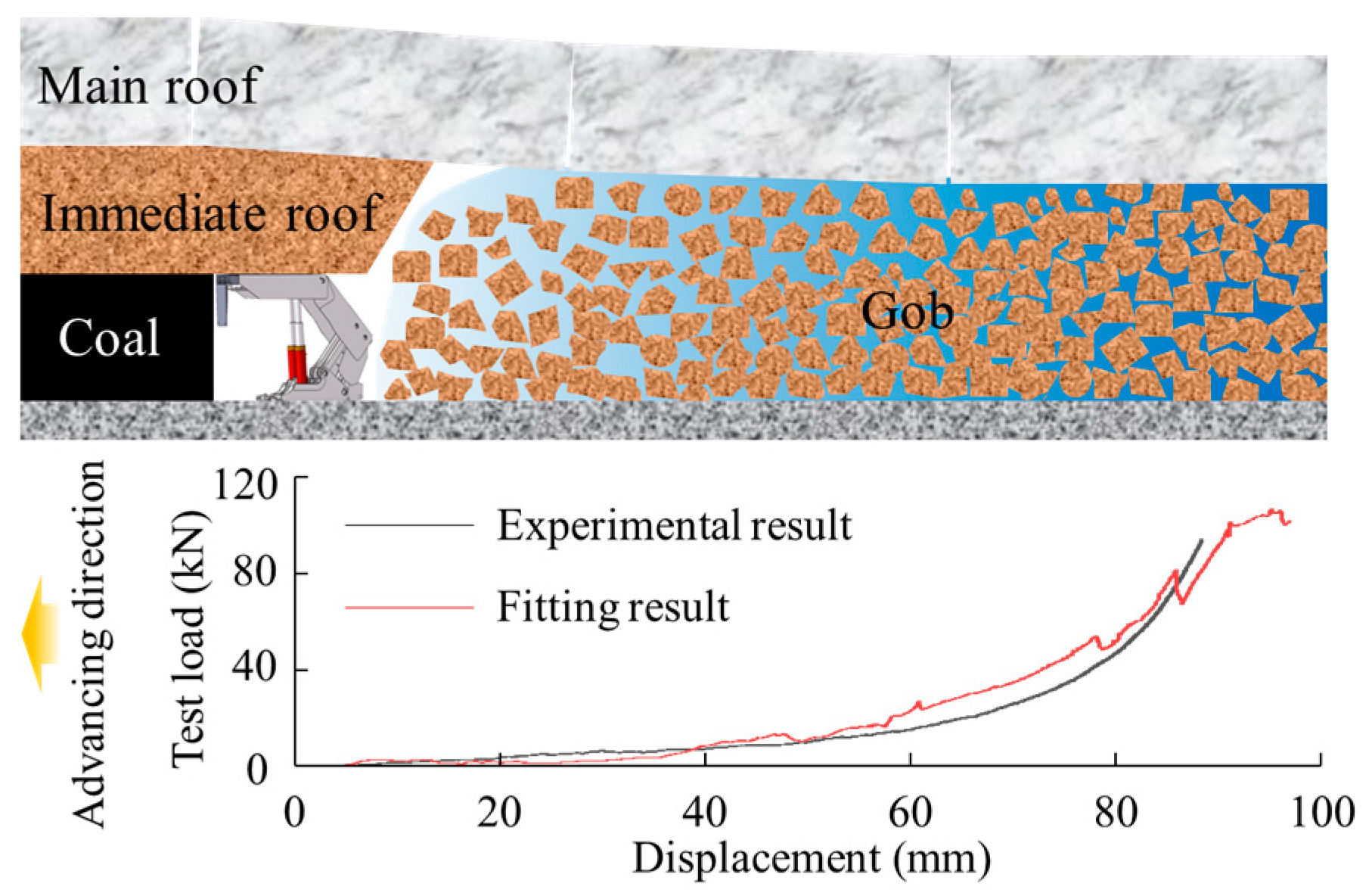

3.1.1. Caving Zone

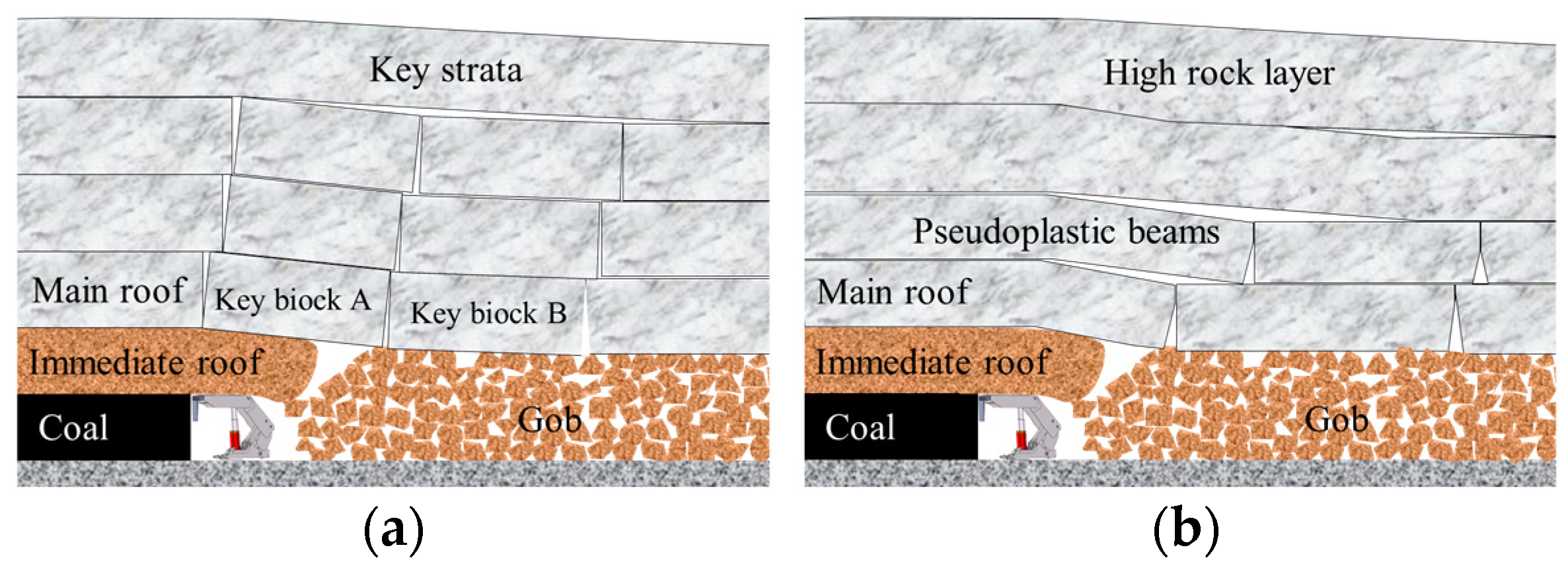

3.1.2. Fracture Zone

3.1.3. Bending Subsidence Belt

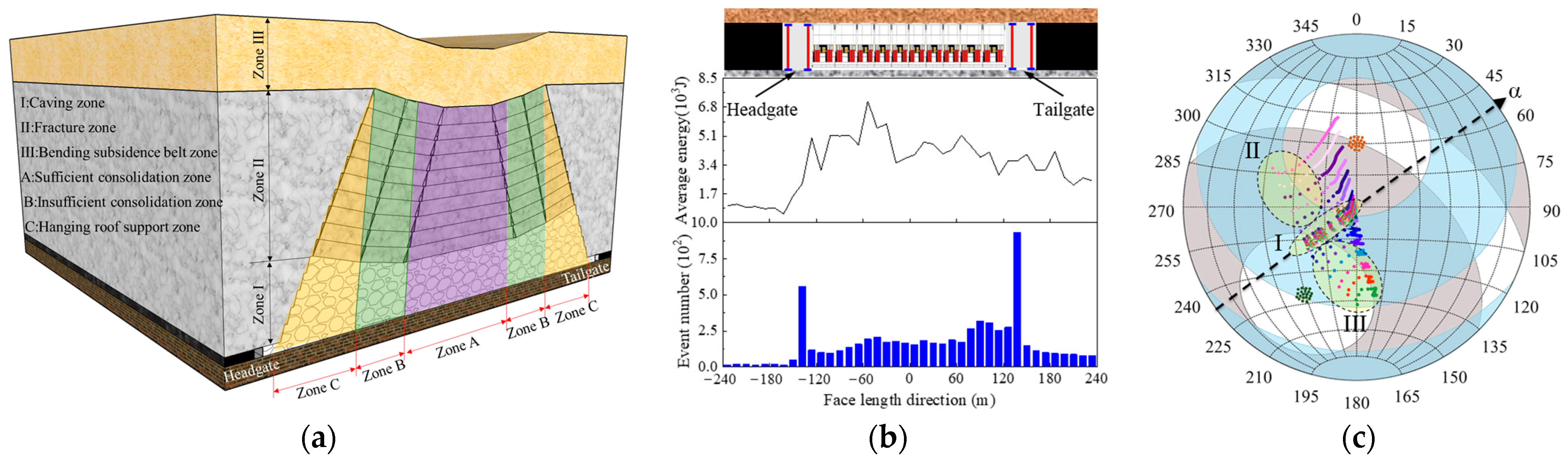

3.2. Horizontal Partition Characteristics

3.2.1. Toward Zoning Characteristics

3.2.2. Tendency Partition Characteristics

4. Influence of Strata Movement on Mining Safety and Environment

5. Relationship between Mining Support and Surrounding Rock

6. Application and Control Methods of Strata Movement

6.1. Application Methods of Strata Movement

6.2. Methods of Controlling Strata Movement

7. Key issues Discussion on Strata Movement

7.1. Full Process Description

7.2. Unified Field Theory

7.3. Complex and Difficult-to-Mine Coal Seam

7.3.1. Steeply Inclined Stope

7.3.2. Deep Longwall Panel with Thin Bedrock

7.4. Stiffness Theory for the Surrounding Rock Support System in Large Space Mining Panels

7.5. Intelligent Control Methods and Technologies for Strata Movement

8. Conclusions

- (1)

- Longwall mining causes discontinuous and large strata deformation. Mining pressure and surface subsidence are the visual forms of near-field and far-field strata movement. The relationships between mine pressure, strata movement, and surface subsidence in the stope are established based on the key stratum theory. The strata movement is divided longitudinally into the caving zone, the fracture zone, and the bending subsidence belt according to the different degrees of mining disturbance, and it is divided into the original rock stress area, the advance abutment pressure concentration area, the strong mining delamination area, and the re-compaction area according to the duration of the disturbance to the sequence of mining The tendency of strata movement is divided into the fully compacted zone, the non-fully compacted zone and the coal pillar support zone according to the different support conditions.

- (2)

- Considering the broken block occlusion pattern in the caving zone, structural models, such as the cantilever beam, voussoir beam, and transferring beam, are formed to guide the ground control. The structural balance method, dynamic load method, binary criterion method, and three-factor coupling method are proposed for the support selection. The concern in the fractured zone is the mining fracture, especially the delamination fracture development characteristics, which forms the O-ring theory. A gas extraction technology, key stratum water protection mining technology, and overburden separation grouting filling technology are proposed. The variation principle is utilized to demonstrate the subsidence surface in key stratum at the fracture zone, which provides a guidance for the key stratum water isolation capacity evaluation and delamination space determination. The coupling subsidence characteristics of the surface and the main key stratum are focused on the bending subsidence belt, and a hyperbolic-like model is proposed.

- (3)

- Strata movement leads to the mining stress concentration and mining stress rotation phenomena. Mining stress concentration drives the static destruction of roof caving, rib spalling, and water–sand inrush. The overlapped drive of stress concentration and roof dynamic load on the dynamic failure of the surrounding rock results in the sudden release of strain energy, causing weighting over great extent, rock bursts, coal and gas outbursts, and other dynamic disasters. The asymmetric distribution characteristics of the mining stress rotation trajectory cause the phenomenon of partitioning of the surrounding rock stability, which explains the causes of the asymmetric distribution of microseismic activity in the stope. Aiming at various disasters caused by strata movement, pre-cracking blasting, hydraulic fracturing, supercritical CO2 fracturing, and filling mining are proposed for the roof strata to avoid the emergence of uncontrollable strata movement patterns. The enhancement method of surrounding rock stability based on the goal of optimizing the mining stress rotation trajectory is established.

- (4)

- The proposed theory of beams and plates raises the analysis of strata position to a quantitative level, but the process of strata movement still remains at a qualitative level, and a cross-examination of mechanical theory and dynamic analysis methods is needed to realize a quantitative analysis of the whole process of strata movement. The visualization of strata movement is the basis for its quantitative analysis. Accurate rock movement measurements will result in a better correlation between rock movement and mine pressure behavior. It is important to determine the relationship between the supports and the surrounding rock and implement differentiated management for areas with high damage risk to the surrounding rock at the working face, which has an important effect on improving the stability of the surrounding rock. The key strata theory realizes a synergetic analysis of mine pressure, strata movement, and surface subsidence in the stope, but does not reveal the driving principle of strata movement on the process of mine pressure generation and surface subsidence in the stope. A unified field theory of strata movement should be established to realize the common perception of the positional field, displacement field, stress field, energy field, and fracture field of strata movement. The applicability of the traditional beam and plate theory in the strata movement of complex and difficult coal seams has yet to be investigated, and it should be clarified as soon as possible in order to realize the the scientific mining of complex and difficult coal seams.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, G.F.; Ren, S.H.; Pang, Y.H.; Qu, S.J.; Zheng, Z.D. Development achievements of China’s coal industry during the 13th Five-Year Plan period and implementation path of “dual carbon” targe. Coal Sci. Technol. 2021, 49, 1–8. [Google Scholar]

- Peng, S.S. Longwall Mining; Mining Engineering West Virginia University: Morgantown, WV, USA, 2006. [Google Scholar]

- Qian, M.G. Review of the theory and practice of strata control around longwall face in recent 20 years. J. China Univ. Min. Technol. 2000, 29, 1–4. [Google Scholar]

- Zhang, D.S.; Zhang, W.; Ma, L.Q.; Wang, X.F.; Fan, G.W. Developments and prospects of detecting mining-induced fractures in overlying strata by radon. J. China Univ. Min. Technol. 2016, 45, 1082–1097. [Google Scholar]

- Li, Q.S.; Li, X.B.; Xu, J.L.; Xu, Z.H.; Zhang, C. Research advances in mining fractures evolution law of rock strata and ecological treatment technology. Coal Sci. Technol. 2022, 50, 28–47. [Google Scholar] [CrossRef]

- Cao, Z.G.; Ju, J.F.; Xu, J.L. Distribution. model of water-conducted fracture main channel and its flow characteristics. J. China Coal Soc. 2019, 44, 3719–3728. [Google Scholar]

- Peng, S.P.; Bi, Y.L. Strategic consideration and core technology about environmental ecological restoration in coal mine areas in the Yellow River Basin of China. J. China Coal Soc. 2020, 45, 1211–1221. [Google Scholar]

- Wu, Q.; An, Y.H.; Liu, W.G.; Zhang, C.F.; LI, J.J. Water-soil environment issuesandits controlling technology in Shendong mining field. Coal Geol. Explor. 2005, 33, 54–58. [Google Scholar]

- Xie, H.P.; Gao, F.; Zhou, H.W.; Cheng, H.M.; Zhou, F.B. On theoretical and modeling approach to mining-enhanced permeability for simul-taneous exploitation of coal and gas. J. China Coal Soc. 2013, 38, 1101–1108. [Google Scholar]

- Yuan, L. Strategic thinking of simultaneous exploitation of coal and gas in deep mining. J. China Coal Soc. 2016, 41, 1–6. [Google Scholar]

- Wang, J.C.; Wang, Z.H. Propagating mechanism of top-coal fracture in longwall top-coal caving mining. J. China Coal Soc. 2018, 43, 2376–2388. [Google Scholar]

- Yang, S.L.; Wang, Z.H.; Jiang, W.; Yang, J.H. Advancing rate effect on rock and coal failure format in high-intensity mining face. J. China Coal Soc. 2016, 41, 586–594. [Google Scholar]

- Yuan, L.; Jiang, Y.D.; He, X.Q.; Dou, L.M.; Zhao, Y.X.; Zhao, X.S.; Wang, K.; Yu, Q.; Lu, X.M.; Li, H.C. Research progress of precise risk accurate identification and monitoring early warning on typical dynamic disasters in coal mine. J. China Coal Soc. 2018, 43, 306–318. [Google Scholar]

- Wang, S.M.; Du, L.; Song, S.J. Influence of mining ground fissures on soil erodibility in Northern Shaanxi coal mining area of Yellow River Basin. J. China Coal Soc. 2021, 46, 3027–3038. [Google Scholar]

- Guo, W.B.; Bai, E.H.; Zhao, G.B. Current status and progress on overburden and surface damage and prevention technology of high-intensity mining. J. China Coal Soc. 2020, 45, 509–523. [Google Scholar]

- Qian, M.G.; Xu, J.L. Behaviors of strata movement in coal mining. J. China Coal Soc. 2019, 44, 973–984. [Google Scholar]

- Wang, J.C. Sustainable coal mining based on mining ground control. J. Min. Strat. Control. Eng. 2019, 1, 013505. [Google Scholar]

- Qian, M.G.; Xu, J.L.; Miao, X.X. Green technique in coal mining. J. China Univ. Min. Technol. 2003, 32, 343–348. [Google Scholar]

- Qian, M.G. On sustainable coal mining in China. J. China Coal Soc. 2010, 35, 529–534. [Google Scholar]

- Wang, J.C.; Liu, F.; Wang, L. Sustainable coal mining and mining sciences. J. China Coal Soc. 2016, 41, 2651–2660. [Google Scholar]

- Allet, J.L. Discrete modeling for natural objects. Math. Geol. 1997, 29, 199–219. [Google Scholar]

- Yuan, L.; Zhang, P.S. Development status and prospect of geological guarantee technology for precise coalmining. J. China Coal Soc. 2019, 44, 2277–2284. [Google Scholar]

- Qian, M.G. A study of the behaviour of overlying strata in longwall mining and its application to strata control. In Proceedings of the Symposium on Strata Mechanics; Elsevier Scientific Publishing Company: Amsterdam, The Netherlands, 1982; pp. 13–17. [Google Scholar]

- Song, Z.Q.; Hao, J.; Shi, Y.K.; Tang, J.Q.; Liu, J.K. An overview of con notation and development of practical ground pressure contorl theory. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 2019, 38, 1–15. [Google Scholar]

- Qian, M.G.; Miao, X.X.; Xu, J.L. Theoretical study of key stratum in ground control. J. China Coal Soc. 1996, 6, 2–7. [Google Scholar]

- Wang, J.C.; Yang, S.L.; Yang, B.G.; Li, Y.; Wang, Z.H.; Yang, Y.; Ma, Y.Y. Roof subregional fracturing and support resistance distribution in deep longwall face with ultra-large length. J. China Coal Soc. 2019, 44, 54–63. [Google Scholar]

- Yang, S.L.; Wang, J.C.; Li, L.H. Analysis of deformation and fracture characteristics of key strata based on the medium thick plate theory. J. China Coal Soc. 2020, 45, 2718–2727. [Google Scholar]

- Wang, J.C.; Wang, Z.H.; Tang, Y.S.; Li, M.; Chang, K.L.; Gong, H.; Xu, G.L. Experimental study on mining-induced dynamic impact effect of main roofs in deeply buried thick coal seams with weakly consolidated thin bed rock. Chin. J. Rock Mech. Eng. 2021, 40, 2377–2391. [Google Scholar]

- Peng, S.S. Topical areas of research needs in ground control—A state of the art review on coal mine ground control. Int. J. Min. Sci. Technol. 2015, 25, 1–6. [Google Scholar] [CrossRef]

- Liang, B.; Wang, B.F.; Jiang, L.G.; Li, G.; Li, C.Y. Broken expand properties of caving rock in shallow buried goaf. J. China Univ. Min. Technol. 2016, 45, 475–482. [Google Scholar]

- Zhang, J.W.; Wang, H.L.; Chen, S.J.; Li, Y.L. Compressive deformation characteristics of large-size crushed rock. J. China Coal Soc. 2018, 43, 1000–1007. [Google Scholar]

- Dong, S.N. Some key scientific problems on water hazards frequently happened in China’s coal mines. J. China Coal Soc. 2010, 35, 66–71. [Google Scholar]

- Lin, B.Q.; Li, Q.Z.; Zhou, Y. Research advances about multi-field evolution of coupled thermodynamic disasters in coal mine goaf. J. China Coal Soc. 2021, 46, 1715–1726. [Google Scholar]

- Xu, J.L.; Ju, J.F. Structural morphology of key stratum and its influence on strata behaviors in fully mechanized face with super large mining height. Chin. J. Rock Mech. Eng. 2011, 30, 1547–1556. [Google Scholar]

- Yan, S.H.; Yin, X.W.; Xu, H.J.; Xu, G.; Liu, Q.M.; Yu, L. Roof structure of short cantilever-articulated rock beam and calculation of support resistance in full-mechanized face with large mining height. J. China Coal Soc. 2011, 36, 1816–1820. [Google Scholar]

- Yu, B.; Gao, R.; Meng, X.B.; Kuang, T.J. Near-far strata structure instability and associate strata behaviors in large space and corresponding control technology. Chin. J. Rock Mech. Eng. 2018, 37, 1134–1145. [Google Scholar]

- Wu, Y.P.; Yun, D.F.; Xie, P.S.; Wang, H.W.; Lang, D.; Hu, B.S. Progress, practice and scientific issues in steeply dipping coal seams fully-mechanized mining. J. China Coal Soc. 2020, 45, 24–34. [Google Scholar]

- Huang, Q.X. Ground pressure behavior and definition of shallow seams. Chin. J. Rock Mech. Eng. 2002, 21, 1174–1177. [Google Scholar]

- Jia, X.R.; Zhai, Y.D. The review of ground pressure theory of thin slab in coal mining and its application. Ground Press. Strat. Control. 1999, 3, 22–25+238. [Google Scholar]

- Qian, M.G.; Xu, J.L. Study on the “O-shape” circle distribution characteristics of mining-induced fractures in the overlying strata. J. China Coal Soc. 1998, 23, 466–469. [Google Scholar]

- Yuan, L.; Guo, H.; Shen, B.T.; Qu, Q.D.; Xue, J.H. Circular overlying zone at longwall panel for efficient methane capture of mutiple coal seams with low permeability. J. China Coal Soc. 2011, 36, 357–365. [Google Scholar]

- Wu, Q.; Xu, H.; Zhao, Y.W.; Cui, J.Q. Dynamic visualization and prediction for water bursting on coal roof based on “three maps method”. J. China Coal Soc. 2016, 41, 2968–2974. [Google Scholar]

- Li, S.G.; Lin, H.F.; Zhao, P.X.; Xiao, P.; Pan, H.Y. Dynamic evolution of mining fissure elliptic paraboloid zone and extraction coal and gas. J. China Coal Soc. 2014, 39, 1455–1462. [Google Scholar]

- Lai, X.P.; Zhang, X.D.; Shan, P.F.; Cui, F.; Liu, B.W.; Bai, R. Study on development law of water-conducting fractures in overlying strata of three soft coal seam mining under thick loose layers. J. Rock Mech. Eng. 2021, 40, 1739–1750. [Google Scholar]

- Li, H.Y.; Wang, W.H.; Qi, Q.X.; Zhang, L. Study on fissure development rule of overlying strata influenced by mining based on fractal theory. J. China Coal Soc. 2014, 39, 1023–1030. [Google Scholar]

- Xu, J.L.; Qian, M.G.; Zhu, W.B. Study on influences of primary key stratum on surface dynamic subsidence. J. Rock Mech. Eng. 2005, 24, 787–791. [Google Scholar]

- Wang, J.Z.; Chang, Z.Q.; Chen, Y. Study on mining degree and patterns of ground subsidence in condition of mining under thick unconsolidated layers. J. China Coal Soc. 2003, 28, 230–234. [Google Scholar]

- Xie, G.X. Mechanical characteristics of fully mechanized top-coal caving face and surrounding rock stress shell. J. China Coal Soc. 2005, 30, 309–313. [Google Scholar]

- Zhang, M.; Jiang, F.X.; Chen, G.Y.; Jiao, Z.H.; Hu, H.; Chen, B.B. A stope stress transfer model based on the motion state of thick and hard rock strata and its application. J. Rock Mech. Eng. 2020, 39, 1396–1407. [Google Scholar]

- Wang, Z.H.; Tang, Y.S.; Li, H.; Yang, Y.C.; Li, J.L.; Wang, Z.F. Distribution and influence factors of support resistance in longwall panel with large face length of a kilometer-deep coal mine. J. Min. Saf. Eng. 2023, 40, 1–10. [Google Scholar]

- Song, G.J.; Li, H.M. Study on influence factors of roof fall at fully mechanized sublevel caving face in Buertai coal mine. J. Min. Saf. Eng. 2018, 35, 1170–1176. [Google Scholar]

- Yang, S.L.; Wang, Z.H.; Kong, D.Z.; Cheng, Z.B.; Song, G.F. Overlying strata failure process and support resistance determination in large mining height face. J. Min. Saf. Eng. 2016, 33, 199–207. [Google Scholar]

- Yang, S.L.; Kong, D.Z. Flexible reinforcement mechanism and its application in the control of spalling at large mining height coal face. J. China Coal Soc. 2015, 40, 1361–1367. [Google Scholar]

- Zhang, J.; Yang, T.; Suo, Y.L.; Liu, D.; Zhou, F.W. Roof water-inrush disaster forecast based on the model of aquiclude instability. J. China Coal Soc. 2017, 42, 2718–2724. [Google Scholar]

- Dong, S.N.; Liu, Z.X.; Wang, H. Research status and prospection on the mechanism of dynamic sand inrush at weakly cemented strata in working face with thick bedrock. J. China Coal Soc. 2022, 47, 274–285. [Google Scholar]

- Guo, W.B.; Zhao, G.B.; Yang, W.Q.; Jiao, Y.H.; Ma, Z.B.; Chen, X.M. Deformation characteristics of high-rise structures due to coal mining and their precise grouting reinforcement mechanisms. J. China Coal Soc. 2022, 47, 1908–1920. [Google Scholar]

- Bi, Y.L.; Zou, H.; Peng, C.; Shi, L.M. Effects of mining subsidence on soil water movement in sandy area. J. China Coal Soc. 2014, 39, 490–496. [Google Scholar]

- Duncan Fama, M.E.; Pender, M.J. Analysis of the hollow inclusion method for measuring in situ rock stress. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1980, 17, 137–146. [Google Scholar] [CrossRef]

- Hamdi, P.; Stead, D.; Elmo, D.; Toyra, J. Use of an integrated finite/discrete element method-discrete fracture network approach to characterize surface subsidence associated with sub-level caving. Int. J. Rock Mech. Min. Sci. 2018, 103, 55–67. [Google Scholar] [CrossRef]

- Luo, X.; Hatherly, P. Application of microseismic monitoring to characterize geotechnical conditions in longwall mining. Explor. Geophys. 1998, 29, 489–493. [Google Scholar] [CrossRef]

- Gibowicz, S.J.; Kiko, A. An Introduction to Mining Seismology; Academic Press: New York, NY, USA, 1994. [Google Scholar]

- Amadei, B.; Stephansson, O. Rock Stress and Its Measurement; Centek Publishers: Stockholm, Sweden, 1997; pp. 134–142. [Google Scholar]

- Xu, W.Q.; Wang, E.Y.; Shen, R.X.; Wang, S.J.; Hou, E.K.; Gao, Q.Q. On the application of sensing device in mining stress monitoring. J. Min. Saf. Eng. 2016, 33, 1123–1129. [Google Scholar]

- Li, Y.; Qiao, L.; Sun, X.S. Analysis of some factors affecting precision in in-situ stress measurement with method of csiro cells. Chin. J. Rock Mech. Eng. 2006, 25, 2140–2144. [Google Scholar]

- Pang, Y.H.; Wang, G.F.; Li, B.B. Stress path effect and instability process analysis of overlying strata in deep stopes. Chin. J. Rock Mech. Eng. 2020, 39, 682–694. [Google Scholar]

- Leake, M.R.; Conrad, W.J.; Westman, E.C.; Afrouz, S.G.; Molka, R.J. Microseismic monitoring and analysis of induced seismicity source mechanisms in a retreating room and pillar coal mine in the United Eastern States. Undergr. Space 2017, 2, 115–124. [Google Scholar] [CrossRef]

- Bisrat, S.; Deshon, H.R.; Rowe, C. Microseismic swarm activity in the new Madrid seismic zone. Bull. Seismol. Soc. Am. 2012, 102, 1167–1178. [Google Scholar] [CrossRef]

- Debasis, D.; Akshay, K.; Rajat, P.S.R. Forecasting shield pressures at a longwall face using artificial neural net-works. Geotech. Geol. Eng. 2006, 24, 1021–1037. [Google Scholar]

- Coal in India 2019; Australian Government Department of Industry: Sydney, Australia, 2019.

- Peng, S.S. Longwall Mining, 3rd ed.; Taylor & Francis Group: London, UK, 2020. [Google Scholar]

- Prusek, S.; Plonka, M.; Walentek, A. Applying the ground reaction curve concept to the assessment of shield support performance in longwall faces. Arab. J. Geosci. 2016, 9, 167. [Google Scholar] [CrossRef]

- Medhurst, T.P. Practical considerations in longwall support behaviour and ground response. In Proceedings of the Australasian Institute of Mining and Metallurgy Publication Series, Brisbane, Australia, 6–28 April 2005; Volume 2, pp. 49–57. [Google Scholar]

- Khayrutdinov, M.M.; Golik, V.I.; Aleksakhin, A.V.; Trushina, E.V.; Lazareva, N.V.; Aleksakhina, Y.V. Proposal of an Algorithm for Choice of a Development System for Operational and Environmental Safety in Mining. Resources 2022, 11, 88. [Google Scholar] [CrossRef]

- Adigamov, A.E.; Yudenkov, A.V. Stress-strain behavior model of disturbed rock mass with regard to anisotropy and discontinuities. Min. Inf. Anal. Bull. 2021, 8, 93–103. [Google Scholar] [CrossRef]

- Rybak, J.M.; Kongar-Syuryun, C.; Tyulyaeva, Y.; Khayrutdinov, A.M.; Akinshin, I. Geomechanical substantiation of parameters of technology for mining salt deposits with a backfill. Min. Sci. 2021, 28, 19–32. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.; Ubysz, A.; Faradzhov, V. Models and algorithms of choice of development technology of deposits when selecting the composition of the backfilling mixture. IOP Conf. Series Earth Environ. Sci. 2021, 684, 012008. [Google Scholar] [CrossRef]

- Wang, G.F.; Hu, X.P.; Liu, X.H.; Yu, X.; Liu, W.C.; Lv, Y.; Zheng, Z. Adaptability analysis of four-leg hydraulic support for underhand working face with large mining height of kilometer deep mine. J. China Coal Soc. 2020, 45, 865–875. [Google Scholar]

- Zhang, J.W.; Cheng, D.L.; Yang, Y.C.; Wei, W.J.; Li, Z.L.; Song, Z.Y. Numerical and theoretical investigations of the effect of the gangue-coal density ratio on the drawing mechanism in longwall top-coal caving. Int. J. Coal Sci. Technol. 2022, 9, 31. [Google Scholar] [CrossRef]

- Wang, J.C. Engineering practice and theoretical progress of top-coal caving mining technology in China. J. China Coal Soc. 2018, 43, 43–51. [Google Scholar]

- Gu, D.Z. Theory framework and technological system of coal mine underground reservoir. J. China Coal Soc. 2015, 40, 239–246. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, Y.; Wang, Z.; Sun, W.; Wang, W.; Yang, H. Research Development and Critical Problems Existing in Strata Movement and Its Control. Energies 2023, 16, 6065. https://doi.org/10.3390/en16166065

Tang Y, Wang Z, Sun W, Wang W, Yang H. Research Development and Critical Problems Existing in Strata Movement and Its Control. Energies. 2023; 16(16):6065. https://doi.org/10.3390/en16166065

Chicago/Turabian StyleTang, Yuesong, Zhaohui Wang, Wenchao Sun, Wei Wang, and Haixiao Yang. 2023. "Research Development and Critical Problems Existing in Strata Movement and Its Control" Energies 16, no. 16: 6065. https://doi.org/10.3390/en16166065