In Situ Combustion: A Comprehensive Review of the Current State of Knowledge

Abstract

1. Introduction

2. Forward and Reverse Combustion

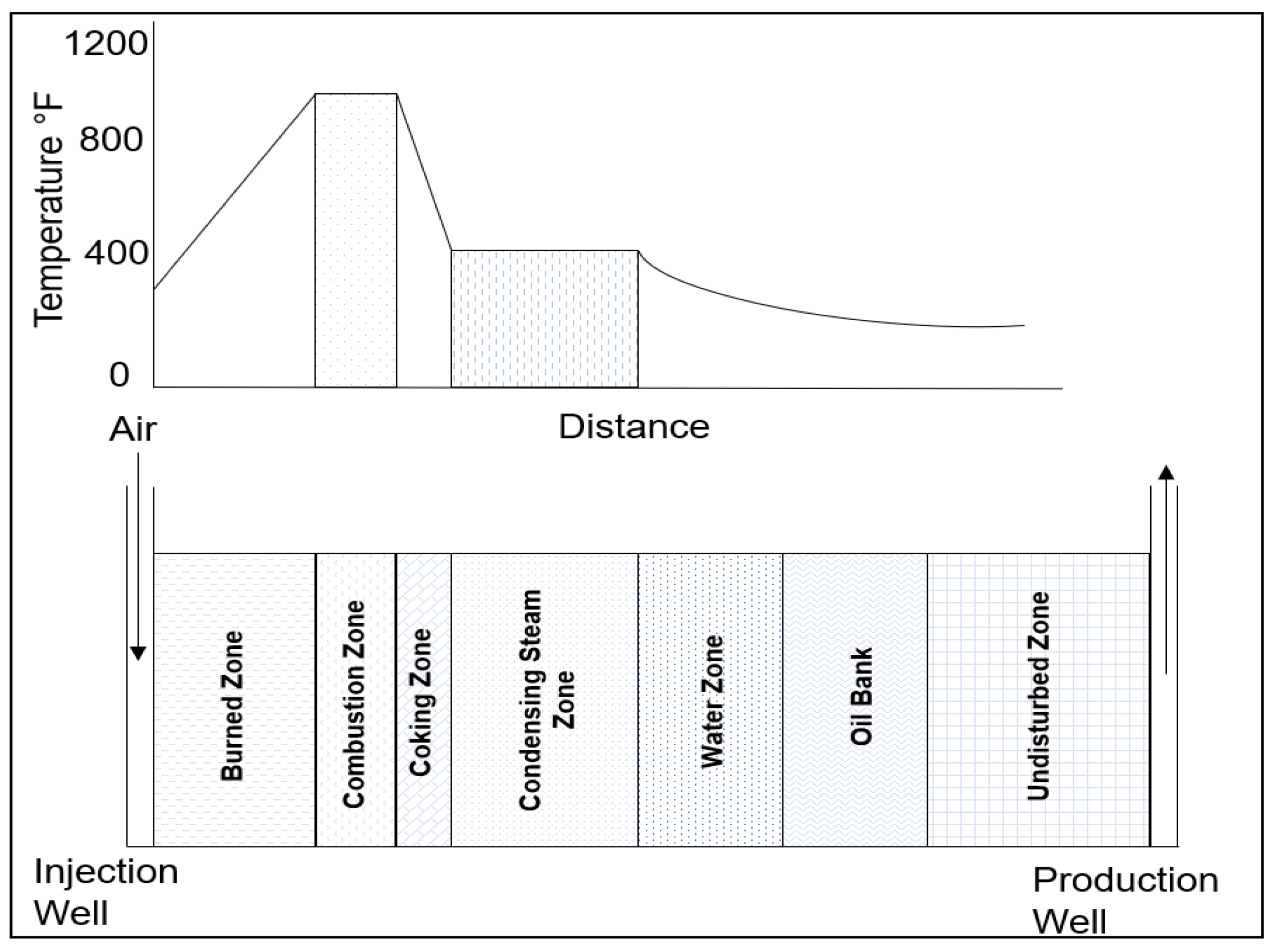

2.1. Dry Forward Combustion

2.2. Wet Forward Combustion

2.3. Reverse Combustion

- 1.

- The need for high-cost tubulars that can withstand the high temperatures of the produced fluids. Also, reverse combustion generally requires more oxygen than forward combustion; therefore, the costs will be higher.

- 2.

- Some deposits of unburned heavy hydrocarbons will remain in the reservoir. Eventually, these materials will tend to react, and the process will shift to forward combustion.

3. Other ISC Approaches

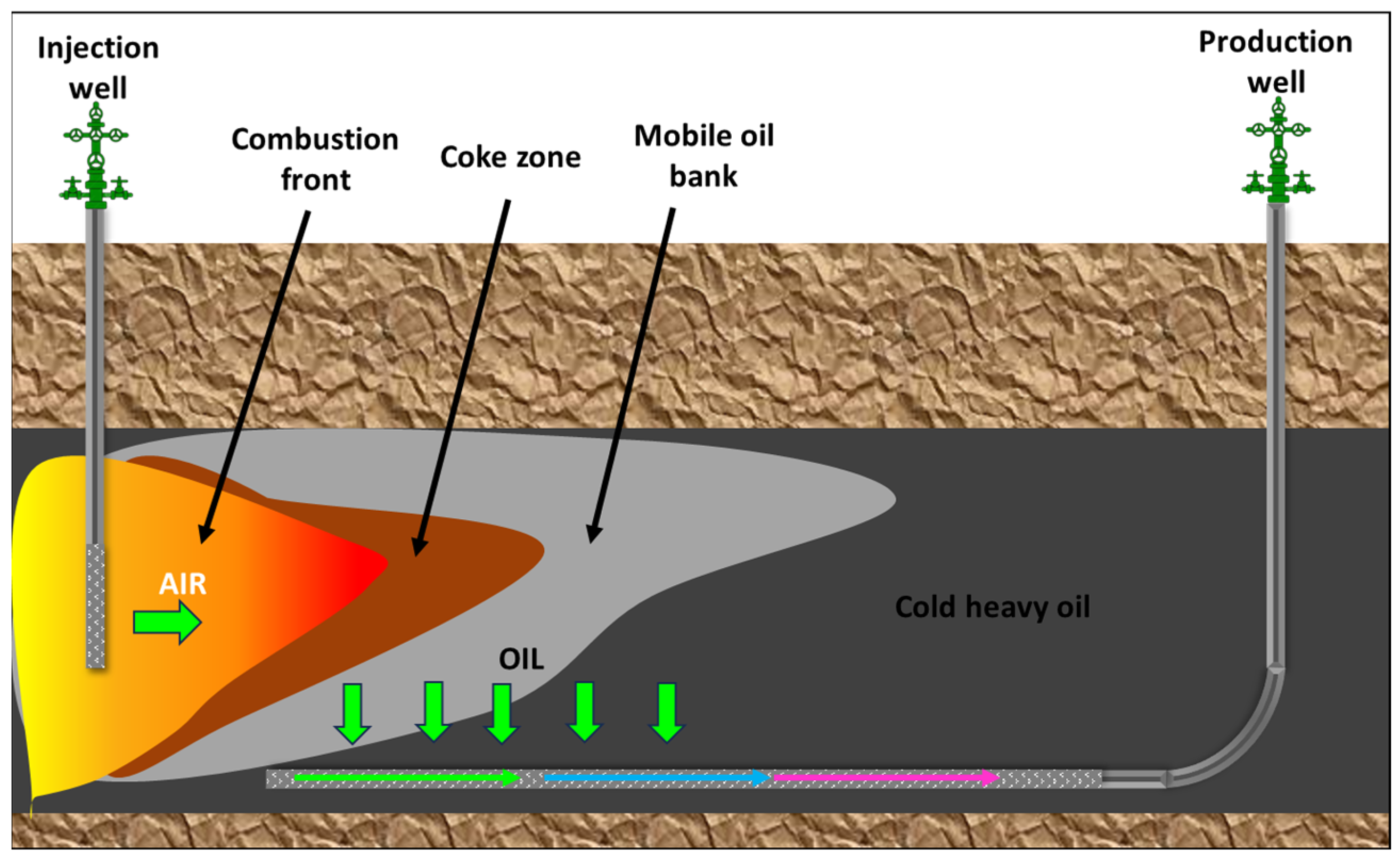

3.1. Toe-to-Heel Air Injection (THAI)

3.2. THAI-CAPRI

3.3. High-Pressure Air Injection (HPAI)

3.4. Combustion Override Split-Production Horizontal Well (COSH)

3.5. Comparison

4. Kinetics

- 1.

- To evaluate the reactivity of the oil.

- 2.

- To determine the conditions required to achieve ignition and whether self-ignition will occur in the reservoir upon air injection.

- 3.

- To gain insight into the nature of fuel formed and its impact on combustion.

- 4.

- To establish parameter values for the kinetic (reaction rate) models used in the numerical simulation of ISC processes.

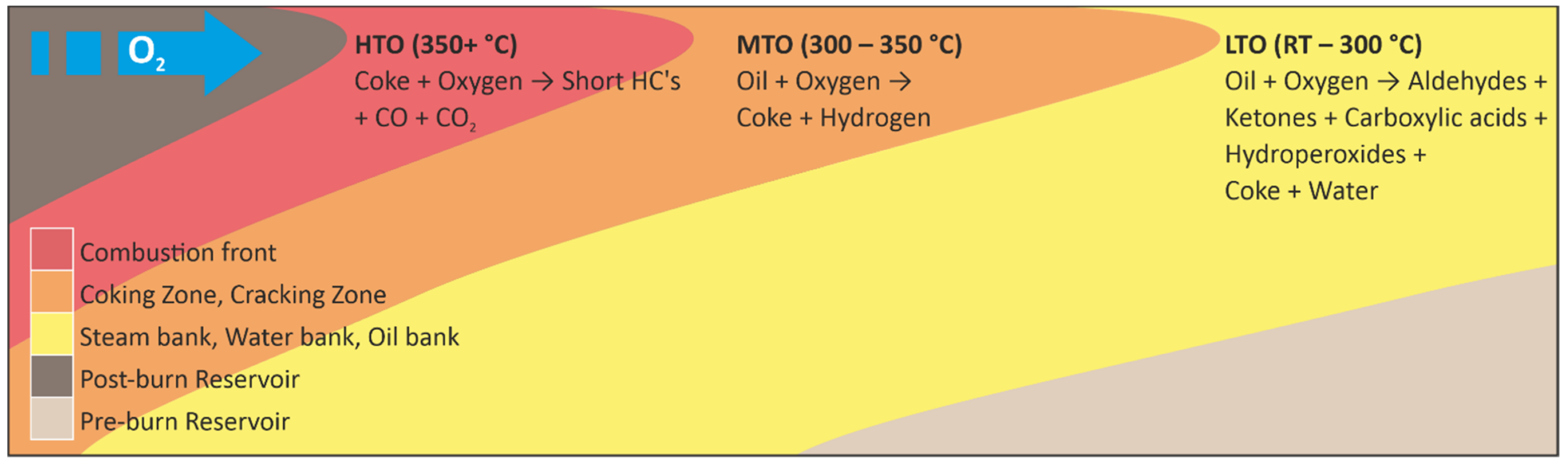

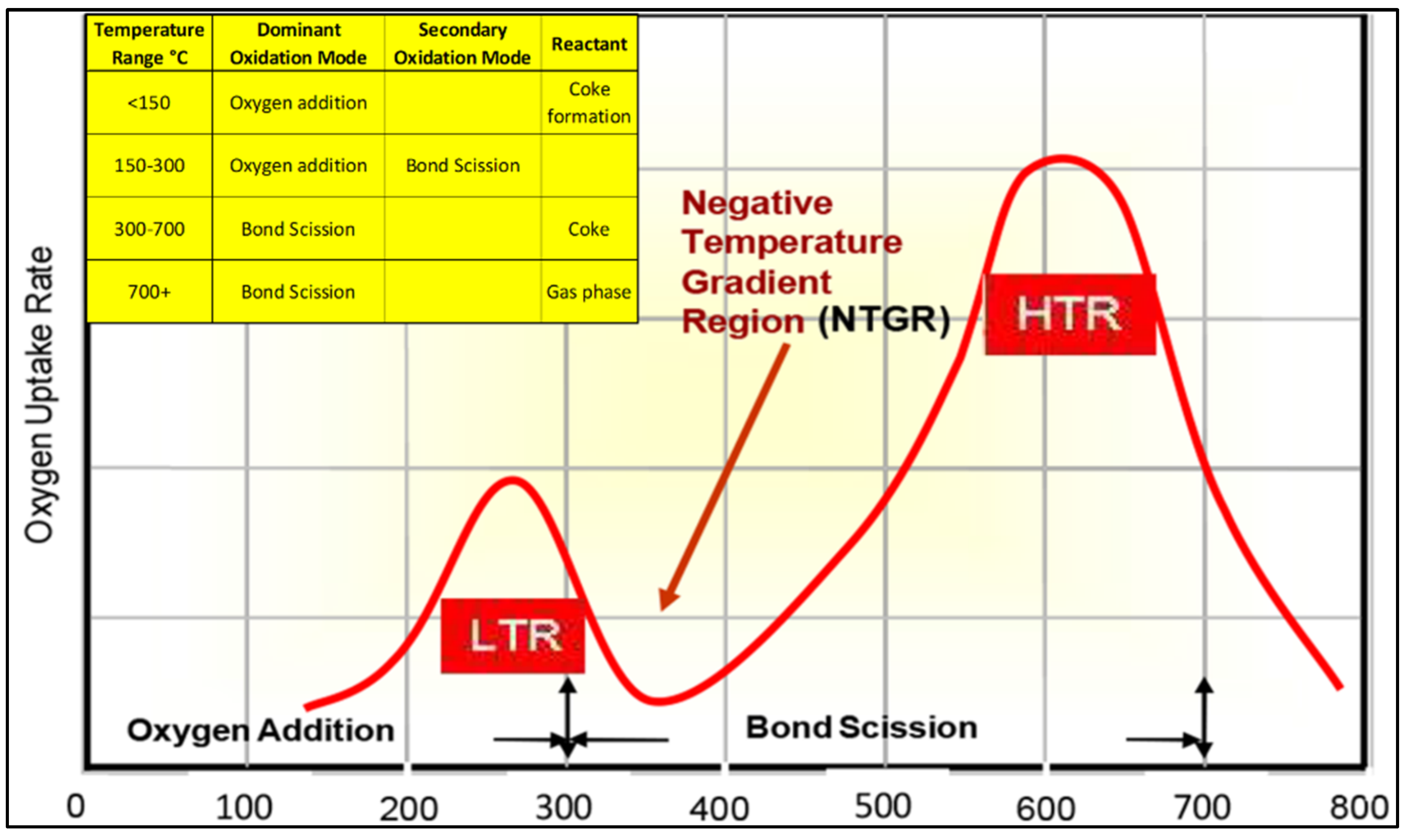

4.1. Low-Temperature Oxidation (LTO) Reactions

4.2. Medium-Temperature Oxidation Reactions

4.3. High-Temperature Oxidation Reactions (HTO)

5. Experiments

- 1.

- To gain a deeper understanding of the oxidation patterns and heat release characteristics of both the oil and the oil/rock systems.

- 2.

- To determine the kinetic parameters associated with the relevant chemical reactions.

- 3.

- To gain an insight into the anticipated recovery performance of the combustion process when implemented in a specific reservoir.

5.1. Qualitative Tests

5.2. Quantitative Tests—Ramped-Temperature Oxidation Test (RTO)

5.3. Combustion Performance Tests (Combustion Tube Tests)

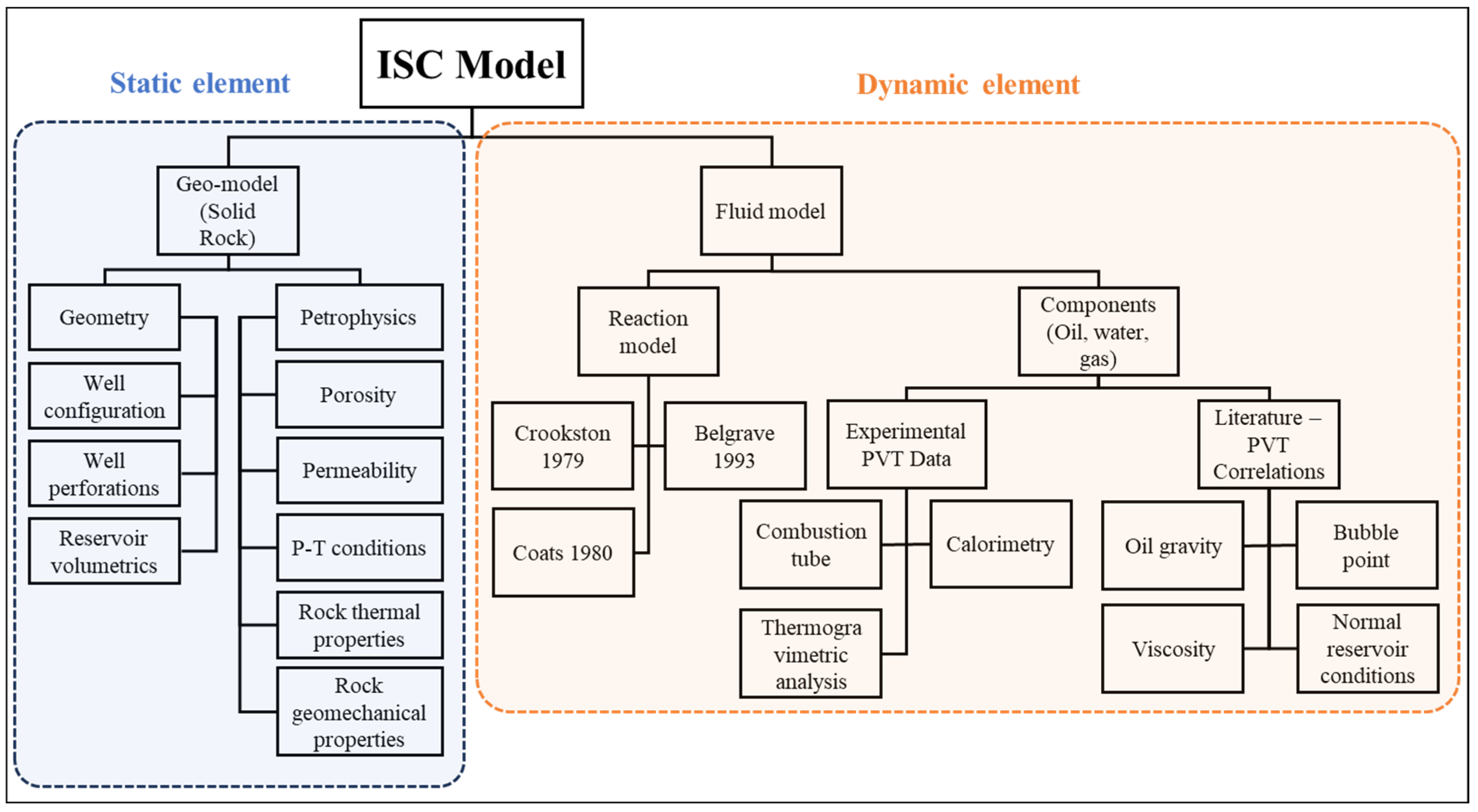

6. Simulation Coupling

Challenges in ISC Simulations

7. Pilots and Field Experience

7.1. Suplacu de Barcau, Romania

7.2. Santhal and Balol Projects

7.3. Bellevue Project

7.4. Whitesands Project Pilot—First THAI Pilot near Conklin, AB, Canada

7.5. Kerrobert

7.6. China

8. Criteria for Selecting ISC

9. Future Work

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moore, R.G.; Laureshen, C.J.; Ursenbach, M.G.; Mehta, S.A.; Belgrave, J.D.M. A Canadian Perspective On In Situ Combustion. J. Can. Pet. Technol. 1999, 38, 1–8. [Google Scholar] [CrossRef]

- Gutierrez, D.; Skoreyko, F.; Moore, R.G.; Mehta, S.A.; Ursenbach, M.G. The Challenge of Predicting Field Performance of Air Injection Projects Based on Laboratory and Numerical Modelling. J. Can. Pet. Technol. 2009, 48, 23–33. [Google Scholar] [CrossRef]

- Brigham, W.; Castanier, L.M. Chapter 16 In-situ Combustion. In Petroleum Engineering Handbook, Volume V: Reservoir Engineering and Petrophysics; Holstein, E.D., Ed.; Society of Petroleum Engineers: Richardson, TX, USA, 2007; Volume V, pp. 1367–1398. [Google Scholar]

- Sarathi, P.S. In-Situ Combustion Handbook—Principles and Practices; Office of Scientific and Technical Information (OSTI): Tulsa, OK, USA, 1999. [Google Scholar]

- Wolcott, E.R. Method of Increasing the Yield of Oil Wells. U.S. Patent 1,457,479, 5 June 1923. [Google Scholar]

- Howard, F.A. Method of Operating Oil Wells. Patent US1473348A, 6 November 1923. [Google Scholar]

- Kuhn, C.S.; Koch, R.L. In-Situ Combustion newest method of increasing oil recovery. Oil Gas J. 1953, 92, 113. [Google Scholar]

- Grant, B.F.; Szasz, S.E. Development of an Underground Heat Wave for Oil Recovery. J. Pet. Technol. 1954, 6, 23–33. [Google Scholar] [CrossRef]

- Chu, C. A Study of Fireflood Field Projects (includes associated paper 6504). J. Pet. Technol. 1977, 29, 111–120. [Google Scholar] [CrossRef]

- Cheih, C. State-of-the-Art Review of Fireflood Field Projects (includes associated papers 10901 and 10918). J. Pet. Technol. 1982, 34, 19–36. [Google Scholar] [CrossRef]

- Mills, R.V.A. The Paraffin Problems in Oil Wells. In U.S. Bureau of Mines Report of Investigation; Government Printing Office: Washington, DC, USA, 1923. [Google Scholar]

- Sheinman, A.B.; Dubroval, K.K.; Charuigin, M.M.; Zaks, S.L.; Zinchenka, K.E. Gasification of Crude Oil in Reservoir Sands. Pet. Eng. 1938, 1, 27–30. [Google Scholar]

- Panait-Patica, A.; Serban, D.; Ilie, N. Suplacu de Barcau Field—A Case History of a Successfull In-Situ Combustion Exploitation. In Proceedings of the SPE Europec/EAGE Annual Conference and Exhibition, Vienna, Austria, 12–15 June 2006. [Google Scholar]

- Guo, K.; Li, H.; Yu, Z. In-Situ heavy and extra-heavy oil recovery: A review. Fuel 2016, 185, 886–902. [Google Scholar] [CrossRef]

- Turta, A. Chapter 18-In Situ Combustion. In Enhanced Oil Recovery Field Case Studies; Sheng, J.J., Ed.; Gulf Professional Publishing: Boston, MI, USA, 2013; pp. 447–541. [Google Scholar]

- Castanier, L.M.; Brigham, W.E. Upgrading of crude oil via in situ combustion. J. Pet. Sci. Eng. 2003, 39, 125–136. [Google Scholar] [CrossRef]

- Xia, T.X.; Greaves, M.; Turta, A.T.; Ayasse, C. THAI—A ‘short-distance displacement’ in situ combustion process for the recovery and upgrading of heavy oil. Chem. Eng. Res. Des. 2003, 81, 295–304. [Google Scholar] [CrossRef]

- Gates, I.D.; Chakrabarty, N.; Moore, R.G.; Mehta, S.A.; Zalewski, E.; Pereira, P. In-situ upgrading of Llancanelo heavy oil using in situ combustion and a downhole catalyst bed. J. Can. Pet. Technol. 2008, 47, 23–31. [Google Scholar] [CrossRef] [PubMed]

- Kapadia, P.R.; Kallos, M.S.; Gates, I.D. Potential for hydrogen generation from in situ combustion of Athabasca bitumen. Fuel 2011, 90, 2254–2265. [Google Scholar] [CrossRef]

- Kapadia, P.R.; Wang, J.; Kallos, M.S.; Gates, I.D. Practical process design for in situ gasification of bitumen. Appl. Energy 2013, 107, 281–296. [Google Scholar] [CrossRef]

- Kapadia, P.R.; Kallos, M.S.; Gates, I.D. A review of pyrolysis, aquathermolysis, and oxidation of Athabasca bitumen. Fuel Process. Technol. 2015, 131, 270–289. [Google Scholar] [CrossRef]

- Hart, A.; Wood, J.; Greaves, M. Laboratory investigation of CAPRI catalytic THAI-add-on process for heavy oil production and in situ upgrading. J. Anal. Appl. Pyrolysis 2017, 128, 18–26. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Hu, Z.; Xu, B.; Li, Y.; Pu, W.; Zhao, J. A review of in situ upgrading technology for heavy crude oil. Petroleum 2021, 7, 117–122. [Google Scholar] [CrossRef]

- Storey, B.M.; Worden, R.H.; McNamara, D.D. The Geoscience of In-Situ Combustion and High-Pressure Air Injection. Geosciences 2022, 12, 340. [Google Scholar] [CrossRef]

- Hajdo, L.E.; Hallam, R.J.; Vorndran, L.D.L. Hydrogen Generation During In-Situ Combustion. In Proceedings of the Society of Petroleum Engineers-SPE California Regional Meeting, CRM 1985, London, UK, 18–20 September 1985; pp. 675–689. [Google Scholar]

- Davis, A.P.; Michaelides, E.E. Geothermal power production from abandoned oil wells. Energy 2009, 34, 866–872. [Google Scholar] [CrossRef]

- Cinar, M. Creating enhanced geothermal systems in depleted oil reservoirs via in situ combustion. In Proceedings of the Thirty-Eigth Workshop on Geothermal Reservoir Enginerring, Stanford, CA, USA, 11–13 February 2013. [Google Scholar]

- Cheng, W.-L.; Li, T.-T.; Nian, Y.-L.; Xie, K. Evaluation of working fluids for geothermal power generation from abandoned oil wells. Appl. Energy 2014, 118, 238–245. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, K.; Liu, C.; Mgijimi, M.B. Geothermal power production from abandoned oil reservoirs using in situ combustion technology. Energies 2019, 12, 4476. [Google Scholar] [CrossRef]

- Ramey, H.J. In-Situ Combustion. In Proceedings of the 8th World Petroleum Conference, Moscow, Russia, 13 June 1971. [Google Scholar]

- Turta, A.T. Conventional ISC. 2022. Available online: https://insitucombustion.ca/#conventional (accessed on 15 May 2023).

- Stosur, J.J. Chapter 34-In Situ Combustion Method for Oil Recovery State of the art and Potential. In The Future Supply of Nature-Made Petroleum and Gas; Meyer, R.F., Barnea, J., Grenon, M., Eds.; Elesver: Amsterdam, The Netherlands, 1977; pp. 611–623. [Google Scholar]

- Greaves, M.; Saghr, A.M.; Xia, T.X.; Turta, A.T.; Ayasse, C. THAI-New air injection technology for heavy oil recovery and in situ upgrading. J. Can. Pet. Technol. 2001, 40, 38–47. [Google Scholar] [CrossRef]

- Greaves, M.; Turta, A.T. Oilfield In-Situ Combustion Process. U.S. Patent US5626191A, 6 May 1997. [Google Scholar]

- Ayasse, C.; Bloomer, C.; Lyngberg, E.; Boddy, W.; Donnelly, J.; Greaves, M. First Field Pilot of the THAI Process. In Proceedings of the 6th Canadian International Petroleum Conference (56th Annual Technical Meeting), Calgary, AB, Canada, 7–9 June 2005. [Google Scholar]

- Perkins, G. Mathematical modelling of in situ combustion and gasification. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 232, 56–73. [Google Scholar] [CrossRef]

- Weissman, J.G.; Kessler, R.V.; Sawicki, R.A.; Belgrave, J.D.M.; Laureshen, C.J.; Mehta, S.A.; Moore, R.G.; Ursenbach, M.G. Down-hole catalytic upgrading of heavy crude oil. Energy Fuels 1996, 10, 883–889. [Google Scholar] [CrossRef]

- Speight, J.G. Thermal methods of recovery. In Heavy Oil Production Processes; Elsevier Science & Technology: Saint Louis, MO, USA, 2013; pp. 93–130. [Google Scholar]

- Yannimaras, D.V.; Tiffin, D.L. Screening of Oils for In-Situ Combustion at Reservoir Conditions by Accelerating-Rate Calorimetry. SPE Reserv. Eng. 1995, 10, 36–39. [Google Scholar] [CrossRef]

- Fassihi, M.R.; Yannimaras, D.V.; Kumar, V.K. Estimation of Recovery Factor in Light-Oil Air-Injection Projects. SPE Reserv. Eng. 1997, 12, 173–178. [Google Scholar] [CrossRef]

- Moore, R.G.; Laureshen, C.J.; Ursenbach, M.G.; Mehta, S.A.; Belgrave, J.D.M. Combustion/Oxidation Behavior of Athabasca Oil Sands Bitumen. SPE Reserv. Eval. Eng. 1999, 2, 565–571. [Google Scholar] [CrossRef]

- Turta, A.T.; Chattopadhyay, S.K.; Bhattacharya, R.N.; Condrachi, A.; Hanson, W. Current status of commercial in situ combustion projects worldwide. J. Can. Pet. Technol. 2007, 46, 8–14. [Google Scholar] [CrossRef]

- Montes, A.R.; Gutierrez, D.; Moore, R.G.; Mehta, S.A.; Ursenbach, M.G. Is High-Pressure Air Injection (HPAI) Simply a Flue-Gas Flood? J. Can. Pet. Technol. 2010, 49, 56–63. [Google Scholar] [CrossRef]

- Gutiérrez, D.; Moore, R.G.; Ursenbach, M.G.; Mehta, S.A. The ABCs of in-situ-combustion simulations: From laboratory experiments to field scale. In Proceedings of the Canadian Unconventional Resources Conference, Calgary, AB, Canada, 7 March 2012; pp. 256–267. [Google Scholar]

- Kisman, K.E.; Lau, E.C. A New Combustion Process Utilizing Horizontal Wells And Gravity Drainage. J. Can. Pet. Technol. 1994, 33, 39–45. [Google Scholar] [CrossRef]

- Wei, W. In-Situ Combustion for Heavy Oil: Toe-to-Heel Air Injection; University of Calgary: Calgary, AB, Canada, 2020. [Google Scholar]

- Dabbous, M.K.; Fulton, P.F. Low-Temperature-Oxidation Reaction Kinetics and Effects on the In-Situ Combustion Process. Soc. Pet. Eng. J. 1974, 14, 253–262. [Google Scholar] [CrossRef]

- Ranjbar, M. Improvement of medium and light oil recovery with thermocatalytic in situ combustion. J. Can. Pet. Technol. 1995, 34, 25–30. [Google Scholar] [CrossRef]

- Adagülü, G.D.; Akkutlu, I.Y. Influence of in situ fuel deposition on air injection and combustion processes. J. Can. Pet. Technol. 2007, 46, 54–61. [Google Scholar] [CrossRef]

- Gargar, N.K.; Mailybaev, A.A.; Marchesin, D.; Bruining, H. Compositional effects in light/medium oil recovery by air injection: Vaporization vs. combustion. J. Porous Media 2014, 17, 937–952. [Google Scholar] [CrossRef]

- Yuan, C.; Sadikov, K.; Varfolomeev, M.; Khaliullin, R.; Pu, W.; Al-Muntaser, A.; Saeed Mehrabi-Kalajahi, S. Low-temperature combustion behavior of crude oils in porous media under air flow condition for in-situ combustion (ISC) process. Fuel 2020, 259, 116293. [Google Scholar] [CrossRef]

- Belgrave, J.D.M.; Moore, R.G.; Ursenbach, M.G.; Bennion, D.W. A Comprehensive Approach to In-Situ Combustion Modeling. SPE Adv. Technol. Ser. 1993, 1, 98–107. [Google Scholar] [CrossRef]

- Butler, R.M. Thermal Recovery of Oil and Bitumen; Prentice Hall Inc.: Old Tappan, NJ, USA, 1991. [Google Scholar]

- Alexander, J.D.; Martin, W.L.; Dew, J.N. Factors Affecting Fuel Availability and Composition During In Situ Combustion. J. Pet. Technol. 1962, 14, 1154–1164. [Google Scholar] [CrossRef]

- Moore, R.G.; Laureshen, C.J.; Belgrave, J.D.M.; Ursenbach, M.G.; Mehta, S.A. In-Situ Combustion in Canadian heavy oil reservoirs. Fuel 1995, 74, 1169–1175. [Google Scholar] [CrossRef]

- Turta, A.T.; Greaves, M.; Grabowski, J. Comprehensive Assessment of Toe-To-Heel Air Injection (THAI) Process. In Guidelines for Development of Future Generations of In-Situ Combustion Processes; A T EOR Consulting Inc.: Calgary, AB, Canada, 2018. [Google Scholar]

- Moore, R.G. New Strategies For In Situ Combustion. J. Can. Pet. Technol. 1993, 32, 11–13. [Google Scholar] [CrossRef]

- Moschopedis, S.E.; Speight, J.G. Oxidation of petroleum fractions. Fuel 1973, 52, 83. [Google Scholar] [CrossRef]

- Moschopedis, S.E.; Speight, J.G. Oxidation of a bitumen. Fuel 1975, 54, 210–212. [Google Scholar] [CrossRef]

- Adegbesan, K.O. Kinetic Study of Low Temperature Oxidation of Athabasca Bitumen; University of Calgary: Calgary, AB, Canada, 1982. [Google Scholar]

- Al-Saadoon, F.T. Experimental and Statistical Study of Residual Oil Saturation after Gas, Water, and Steam Drive, and Fuel Availability for the In-Situ Combustion Process; U.S. Department of Energy: Washington, DC, USA, 1970. [Google Scholar]

- Dechaux, J.C.; Delfosse, L. The negative temperature coefficient in the C2 to C13 hydrocarbon oxidation. I. Morphological results. Combust. Flame 1979, 34, 161–168. [Google Scholar] [CrossRef]

- Alizadeh, A. A Robust Kinetic Model for Computer Modelling of In Situ Combustion Processes in Athabasca Oil Sands. Ph.D. Thesis, University of Calgary, Calgary, AB, Canada, 2020. [Google Scholar]

- Sur, S. In-Situ Combustion Myths and Facts. SPE Reserv. Eval. Eng. 2022, 26, 180–189. [Google Scholar] [CrossRef]

- Alamatsaz, A. Experimental Investigation of In Situ Combustion for Heavy Oils at Low Air Flux. Ph.D. Thesis, University of Calgary, Calgary, AB, Canada, 2014. [Google Scholar]

- Moore, R.G.; Belgrave, J.D.M.; Mehta, S.A.; Ursenbach, M.G.; Laureshen, C.J.; Xi, K. Some Insights Into the Low-Temperature and High-Temperature In-Situ Combustion Kinetics. In Proceedings of the SPE/DOE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 21–24 April 1992. [Google Scholar]

- Gutierrez, D.; Mallory, D.G. New Insights into the Understanding of In-Situ Combustion: Important Considerations When Modeling the Process. SPE Reserv. Eval. Eng. 2022, 26, 122–138. [Google Scholar] [CrossRef]

- Abu-Khamsin, S.A.; Brigham, W.E.; Ramey, H.J. Reaction Kinetics of Fuel Formation for In-Situ Combustion. SPE Reserv. Eng. 1988, 3, 1308–1316. [Google Scholar] [CrossRef]

- Belgrave, J.D.M. An Experimental and Numerical Investigation of In-Situ Combustion Tube Tests. Ph.D. Thesis, University of Calgary, Calgary, AB, Canada, 1987. [Google Scholar]

- Hayashitani, M.; Bennion, D.W.; Donnelly, J.K.; Moore, R.G. Thermal Cracking Models For Athabasca Oil Sands. In Proceedings of the SPE Annual Fall Technical Conference and Exhibition, Houston, TX, USA, 16–18 October 1978. [Google Scholar]

- Moore, R.G.; Ursenbach, M.G.; Laureshen, C.J.; Belgrave, J.D.M.; Mehta, S.A. Ramped Temperature Oxidation Analysis of Athabasca Oil Sands Bitumen. J. Can. Pet. Technol. 1999, 38, 13. [Google Scholar] [CrossRef]

- Belgrave, J.D.M.; Moore, R.G.; Bennion, D.W. The thermal behavior of vertically-operated near-adiabatic in-situ combustion tubes. J. Pet. Sci. Eng. 1990, 5, 51–65. [Google Scholar] [CrossRef]

- Sharma, J.; Dean, J.; Aljaberi, F.; Altememee, N. In-Situ Combustion in Bellevue field in Louisiana – History, current state and future strategies. Fuel 2021, 284, 118992. [Google Scholar] [CrossRef]

- Gutierrez, D.; Mallory, D.; Moore, R.G.; Mehta, S.A.; Ursenbach, M.G.; Bernal, A. New Insights into the Understanding of In-Situ Combustion: The Nature of the Fuel and the Role of Operating Pressure. SPE J. 2022, 37, 3579–3597. [Google Scholar] [CrossRef]

- Gutiérrez, D.; Mallory, D.; Moore, G.; Mehta, R.; Ursenbach, M.; Bernal, A. New Paradigm in the Understanding of In Situ Combustion: The Nature of the Fuel and the Important Role of Vapor Phase Combustion. In Proceedings of the SPE Improved Oil Recovery Conference, Online, 25–29 April 2022. [Google Scholar]

- Aleksandrov, D.; Kudryavtsev, P.; Hascakir, B. Variations in in-situ combustion performance due to fracture orientation. J. Pet. Sci. Eng. 2017, 154, 488–494. [Google Scholar] [CrossRef]

- Ismail, N.B.; Hascakir, B. Impact of asphaltenes and clay interaction on in-situ combustion performance. Fuel 2020, 268, 117358. [Google Scholar] [CrossRef]

- Tzanco, E.T.; Moore, R.G.; Belgrave, J.D.M.; Ursenbach, M.G. Laboratory Combustion Behaviour of Countess B Light Oil. J. Can. Pet. Technol. 1991, 30, 43–51. [Google Scholar] [CrossRef]

- Çınar, M.; Hasçakir, B.; Castanier, L.M.; Kovscek, A.R. Predictability of Crude Oil In-Situ Combustion by the Isoconversional Kinetic Approach. SPE J. 2011, 16, 537–547. [Google Scholar] [CrossRef]

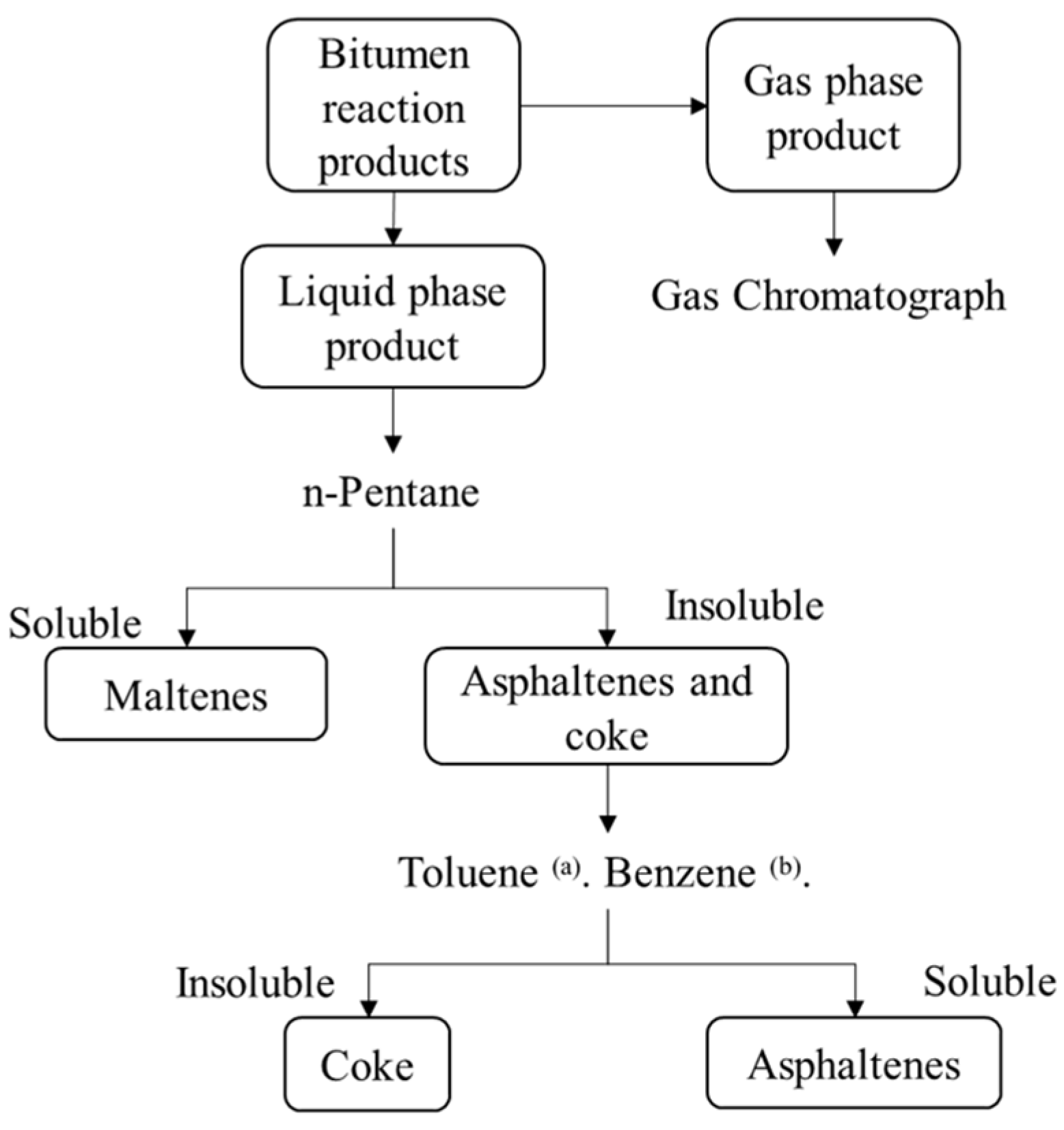

- Hascakir, B.; Ross, C.M.; Castanier, L.M.; Kovscek, A.R. Fuel Formation and Conversion During In-Situ Combustion of Crude Oil. SPE J. 2013, 18, 1217–1228. [Google Scholar]

- Coates, R.; Lorimer, S.; Ivory, J. Experimental and Numerical Simulations of a Novel Top Down In-Situ Combustion Process. In Proceedings of the SPE International Heavy Oil Symposium, Calgary, AB, Canada, 19–21 June 1995; pp. 487–498. [Google Scholar] [CrossRef]

- Coates, R.; Zhao, L.L. Numerical Evaluation of THAI Process. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 12–14 June 2001. [Google Scholar]

- Rahnema, H.; Barrufet, M.A.; Mamora, D. Self-Sustained CAGD Combustion Front Development; Experimental and Numerical Observations. Proc. SPE Symp. Improv. Oil Recovery 2012, 2, 1612–1623. [Google Scholar]

- Jia, N.; Moore, R.G.; Mehta, S.A.; Ursenbach, M.G. Kinetic modelling of thermal cracking and low temperature oxidation reactions. J. Can. Pet. Technol. 2006, 45, 21–28. [Google Scholar] [CrossRef]

- Ado, M.R. Impacts of Kinetics Scheme Used To Simulate Toe-to-Heel Air Injection (THAI) in Situ Combustion Method for Heavy Oil Upgrading and Production. ACS Omega 2020, 5, 1938–1948. [Google Scholar] [CrossRef] [PubMed]

- Rojas, A.A.; Yuan, C.; Emelianov, D.A.; Saifullin, E.R.; Mehrabi-Kalajahi, S.; Varfolomeev, M.A.; Sudakov, V.A.; Lotfullin, B.R.; Shevchenko, D.V.; Ganiev, B.G.; et al. A 3-Step Reaction Model for Numerical Simulation of In-Situ Combustion. In Proceedings of the InSPE Russian Petroleum Technology Conference, Online, 12–15 October 2021. [Google Scholar]

- Yang, M.; Harding, T.G.; Chen, Z. An Improved Kinetics Model for in Situ Combustion of Pre-Steamed Oil Sands. Energy Fuels 2017, 31, 3546–3556. [Google Scholar] [CrossRef]

- Turta, A.; Sierra, R.; Islam, M.; Singhal, A. Athabasca Toe-to-Heel Air Injection Pilot: Evaluation of the Spontaneous Ignition Based on Apparent Atomic Hydrogen-Carbon Ratio Variation. SPE Reserv. Eval. Eng. 2023, 26, 139–151. [Google Scholar] [CrossRef]

- Freitag, N.P.; Exelby, D.R. A SARA-Based model for simulating the pyrolysis reactions that occur in high-temperature EOR processes. J. Can. Pet. Technol. 2006, 45, 38–44. [Google Scholar] [CrossRef]

- Sequera, B.; Moore, R.G.; Mehta, S.A.; Ursenbach, M.G. Numerical Simulation of In-Situ Combustion Experiments Operated Under Low Temperature Conditions. J. Can. Pet. Technol. 2010, 49, 55–64. [Google Scholar] [CrossRef]

- Ahmadi, M. Hybrid of in-situ combustion and steam-based heavy oil recovery. In Sustainable In-Situ Heavy Oil and Bitumen Recovery; Elsevier: Amsterdam, The Netherlands, 2023; pp. 327–357. [Google Scholar]

- Computer Modelling Group Ltd. CMG Technologies (STARS User Manual); CMG: Calgary, AB, Canada, 2021. [Google Scholar]

- Phillips, C.R.; Haidar, N.I.; Poon, Y.C. Kinetic models for the thermal cracking of Athabasca bitumen: The effect of the sand matrix. Fuel 1985, 64, 678–691. [Google Scholar] [CrossRef]

- Fazlyeva, R.; Rezvani, H.; Askarova, A.; Khalilnezhad, A.; Cheremisin, A.; Riazi, M. Chapter 5-In situ combustion. Therm. Methods 2023, 1, 155–215. [Google Scholar] [CrossRef]

- Nissen, A.; Zhu, Z.; Kovscek, A.; Castanier, L.; Gerritsen, M. Upscaling Kinetics for Field-Scale In-Situ-Combustion Simulation. SPE Reserv. Eval. Eng. 2015, 18, 158–170. [Google Scholar] [CrossRef]

- Zhu, Z.; Bazargan, M.; Lapene, A.; Gerritsen, M.; Castanier, L.; Kovscek, A. Upscaling for Field-Scale In-Situ Combustion Simulation. In Proceedings of the Society of Petroleum Engineers Western North American Regional Meeting, Anchorage, AK, USA, 7–11 May 2011; pp. 344–357. [Google Scholar]

- Kumar, M. Simulation of Laboratory In-Situ Combustion Data and Effect of Process Variations. In Proceedings of the Ninth SPE Symposium on Reservoir Simulation, San Antonio, TX, USA, 1–4 February 1987. [Google Scholar]

- Ado, M.R. A detailed approach to up-scaling of the Toe-to-Heel Air Injection (THAI) In-Situ Combustion enhanced heavy oil recovery process. J. Pet. Sci. Eng. 2020, 187, 106740. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, C.; Chen, Y.; Gong, Y.; Song, Y.; Tang, J. In-Situ Combustion Simulation from Laboratory to Field Scale. Geofluids 2021, 2021, 8153583. [Google Scholar] [CrossRef]

- Ado, M.R.; Greaves, M.; Rigby, S.P. Dynamic Simulation of the Toe-to-Heel Air Injection Heavy Oil Recovery Process. Energy Fuels 2017, 31, 1276–1284. [Google Scholar]

- Zhu, Z.; Liu, Y.; Liu, C.; Kovscek, A.R. In-Situ Combustion Frontal Stability Analysis. SPE J. 2021, 26, 2271–2286. [Google Scholar] [CrossRef]

- Gadelle, C.P.; Burger, J.G.; Bardon, C.P.; Machedon, V.; Carcoana, A.; Petcovici, V. Heavy-Oil Recovery by In-Situ Combustion - Two Field Cases in Rumania. J. Pet. Technol. 1981, 33, 2057–2066. [Google Scholar]

- Branoiu, G.; Dinu, F.; Stoicescu, M.; Ghetiu, I.; Stoianovici, D. Half a century of continuous oil production by in-situ combustion in Romania – case study Suplacu de Barcau field. In Proceedings of the MATEC Web of Conferences 343, Sibiu, Romania, 2–4 June 2021; pp. 1–14. [Google Scholar]

- Welch, P.A.; Verney, M.J.; Best, B.P.; Feick, W.P. Whitesands In situ Partnership—Evaluation of Heavy Oil Reserves Based on Forecast Prices and Costs Kerrobert Property; McDaniel & Associates Consultants Ltd.: Calgary, AB, Canada, 2014. [Google Scholar]

- Dayal, H.S.; Bhushan, B.V.; Mitra, S.; Sinha, S.K.; Sur, S. In-Situ Combustion Opportunities and Anxieties. In Proceedings of the SPE Oil and Gas India Conference and Exhibition, Mumbai, India, 20–22 January 2010. [Google Scholar]

- Roychaudhury, S.; Sur, S.; Sinha, S.K. Experience with In Situ Combustion Pilot in Presence of Edge Water; UNITAR: Houston, TX, USA, 1995. [Google Scholar]

- Turta, A.T.; Singhal, A.; Sierra, R.; Greaves, M.; Islam, M. Evaluation of the First Field Piloting of the THAI Process: Athabasca Pilot. In Proceedings of the SPE Canadian Energy Technology Conference, Calgary, AB, Canada, 16 March 2023. [Google Scholar]

- Wei, W.; Wang, J.; Afshordi, S.; Gates, I.D. Detailed analysis of Toe-to-Heel Air Injection for heavy oil production. J. Pet. Sci. Eng. 2020, 186, 106704. [Google Scholar] [CrossRef]

- Yao, J.; Li, G.; Wu, J. Application of In-situ combustion for heavy oil production in China: A Review. J. Oil Gas Petrochem. Sci. 2018, 1, 69–72. [Google Scholar] [CrossRef]

- Teng, L.; Song, H.; Zhang, S.; Wu, F.; Xu, D.; Gong, Y.; Jiang, Z.; Gao, H.; Wang, C.; Zhong, L. Investigation on In-Situ Combustion in D66, a Multilayered Heavy Oil Reservoir, Liaohe Oilfield. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 17 October 2017. [Google Scholar]

- Wang, L.; Liu, D.; Zhang, H.; Long, H.; Wu, X.; Hao, R.; Liu, J.; Gao, F. The Research and Application of In-Situ Combustion with Gravity Technology in Thermal Developed Heavy Oil Reservoir. In Proceedings of the SPE Latin America and Caribbean Heavy and Extra Heavy Oil Conference, Lima, Peru, 19–20 October 2016. [Google Scholar]

- Liu, Y.; Huang, H.; Xu, X.; Liu, Q.; Han, D.; Cheng, H.; Wu, D.; Yan, H. Novel geochemical proxies derived from 1D simulation of Liaohe oil sand bitumen to monitor in-situ combustion process. J. Anal. Appl. Pyrolysis 2020, 148, 104811. [Google Scholar] [CrossRef]

- Ang, Y.; He, J.; Liao, G.; Wang, Z. Overview on the development history of combustion drive and its application prospect in China. Acta Pet. Sin. 2012, 33, 909–914. [Google Scholar]

- Taber, J.J.; Martin, F.D.; Seright, R.S. EOR Screening Criteria Revisited— Part 1: Introduction to Screening Criteria and Enhanced Recovery Field Projects. SPE Reserv. Eng. 1997, 12, 189–198. [Google Scholar] [CrossRef]

- Ado, M.R. Improving heavy oil production rates in THAI process using wells configured in a staggered line drive (SLD) instead of in a direct line drive (DLD) configuration: Detailed simulation investigations. J. Pet. Explor. Prod. Technol. 2021, 11, 4117–4130. [Google Scholar] [CrossRef]

- Ado, M.R. Improving oil recovery rates in THAI in situ combustion process using pure oxygen. Upstream Oil Gas Technol. 2021, 6, 100032. [Google Scholar] [CrossRef]

- Zamora, V.; Jonathan, A. In-Situ Combustion Simulation for A Heavy Oil Naturally Fractured Reservoir; University of Calgary: Calgary, AB, Canada, 2019. [Google Scholar]

- Pope, C.; Ismail, N.B.; Hascakir, B. Catalytic Impact of Clays During In-Situ Combustion. In Proceedings of the SPE Improved Oil Recovery Conference, Online, 31 August 2020. [Google Scholar]

- Zhang, X.; Wang, J.; Wang, L.; Li, Z.; Hu, W.; Dai, Y.; Kou, Y.; Lei, S.; Li, Q.; Zhang, W.; et al. Catalytic capacity evolution of montmorillonite in in-situ combustion of heavy oil. Fuel 2023, 333, 126621. [Google Scholar] [CrossRef]

- Minakov, A.V.; Meshkova, V.D.; Guzey, D.V.; Pryazhnikov, M.I. Recent Advances in the Study of In Situ Combustion for Enhanced Oil Recovery. Energies 2023, 16, 4266. [Google Scholar] [CrossRef]

- Anbari, H.; Robinson, J.P.; Greaves, M.; Rigby, S.P. Field performance and numerical simulation study on the toe to heel air injection (THAI) process in a heavy oil reservoir with bottom water. J. Pet. Sci. Eng. 2023, 220, 111202. [Google Scholar] [CrossRef]

- Song, P.; Li, Y.; Yin, Z.; Yuan, Q. Hydrogen Generation from Heavy Oils via In-situ Combustion Gasification. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 22–25 May 2023. [Google Scholar]

- Harding, T. Methods to Enhance Success of Field Application of In-Situ Combustion for Heavy Oil Recovery. SPE Reserv. Eval. Eng. 2023, 26, 190–197. [Google Scholar] [CrossRef]

- Yang, M.; Yang, M. Numerical Modelling of Hybrid Steam and Combustion Recovery Process for Oil Sands. In Proceedings of the SPE Reservoir Simulation Conference, Galveston, TX, USA, 10–11 April 2019. [Google Scholar]

- Ado, M.R. Electrically-enhanced THAI in situ combustion technology for upgrading and production of heavy oil. J. Pet. Explor. Prod. Technol. 2022, 12, 3373–3386. [Google Scholar] [CrossRef]

- Afanasev, P.; Smirnov, A.; Ulyanova, A.; Popov, E.; Cheremisin, A. Experimental Study of Catalytically Enhanced Cyclic Steam-Air Stimulation for In Situ Hydrogen Generation and Heavy Oil Upgrading. Catalysts 2023, 13, 1172. [Google Scholar] [CrossRef]

- Ado, M.R.; Greaves, M.; Rigby, S.P. Simulation of catalytic upgrading in CAPRI, an add-on process to novel in-situ combustion, THAI. Pet. Res. 2022, 7, 297–307. [Google Scholar] [CrossRef]

- Lopeman, T.; Anbari, H.; Leeke, G.; Wood, J. Numerical Modeling of Toe-to-Heel Air Injection and Its Catalytic Variant (CAPRI) under Varying Steam Conditions. Energy Fuels 2023, 37, 237–250. [Google Scholar] [CrossRef] [PubMed]

| ISC Mechanism | Definition | Applied to | Advantages | Disadvantages |

|---|---|---|---|---|

| Dry Forward Combustion | Most popular version of ISC. The combustion front is generated in situ. Same propagation direction of injected air and combustion front. | Heavy oil reservoirs. | The combustion provides the formation with a complete burning of formation, leaving the formation hydrocarbon-free. | Limit viscosity reduction to recover hydrocarbons. Low heat is transferred from the combustion front to the downstream zones. |

| Wet Forward Combustion | Combination of forward combustion and waterflooding. Addition of water or steam in the process. | Thin reservoirs. | Increases process efficiency. Improved heat transfer. Improved sweep efficiency. | Simultaneous co-injection of both water and gas can be challenging. |

| Reverse | The combustion front is initiated at the production well and moves backward against the airflow. | Reservoirs with low effective permeability. | A significant amount of cracking occurs. | Less upgraded oil is recovered. Spontaneous ignition near the injection well. |

| ISC Mechanism | Definition | Applied to | Advantages | Disadvantages |

|---|---|---|---|---|

| THAI | Combines a vertical air injector + horizontal production well. | Lower pressure, quality, thinner, and deeper than SAGD-fit reservoirs. | Up to 80% of the OOIP recovery. Oil upgrading up to 10° API. Fewer surface facilities. More controllable process than ISC. Negligible water use and less greenhouse gas emissions [33]. | Challenging to control the combustion front movement and complexities associated with heterogeneities. |

| HPAI | Air is injected into the reservoir at high temperature and pressure. Oxygen reacts with the hydrocarbons to improve mobility. | Light oils in deep, thin, high-pressure reservoirs with low permeability. | More reactions and more oxygen utilization, High mobility ratios. Possible high recovery factor, low air and energy requirements [24,43]. | Possible air breakthrough at the production well. |

| CAPRI | A variant of the THAI process. In situ refinery-type catalyst on the surface of the production well. | For in situ upgrading of fluids, the economic viability needs to be assessed. | Further upgrades the hydrocarbon in situ. | Possible production of heavy metals and sulphur |

| COSH | Utilizing gravity drainage as a driving mechanism. Incorporating multiple vertical injector wells in the upper region of the reservoir. The combustion front by oxygen injection propagates towards the production well beneath the injection wells. | Thick reservoirs. | Performance expected to be similar to that of SAGD. | The effectiveness has not been definitively proven. Uncertainties persist, highlighting the need for additional studies. |

| Temperature Region | Low-Temperature Reactions | Medium Temperature Reactions (Negative Temperature Gradient Region) | High-Temperature Reactions |

|---|---|---|---|

| Dominant oxidation mode | Oxygen-addition reactions | No oxidation. Thermal cracking and pyrolysis take place. | Bond-scission reactions (combustion reactions) |

| Reaction | hydrocarbons + oxygen → oxygenated species + coke + water | hydrocarbons → HC (liquid/solid) + HC (gas) + hydrogen | coke + oxygen → short-chain HCs + CO + CO2 + water + energy |

| Temperature | <300 °C | 280–350 °C | 380–800 °C |

| Description | Oxygen dissolves in the oil, producing partially oxygenated hydrocarbons, further polymerizing and promoting the formation of emulsions and asphaltenes. LTO reactions also promote the formation of some of the fuel (oxygenated hydrocarbon) needed further in the process. | Endothermic and homogeneous (gas-gas) reactions. Most of the coke (fuel) is produced here. | These heterogeneous (gas–solid/gas–liquid) reactions occur at the combustion front. Oxygen reacts with unoxidized oil, coke, and oxygenated compounds to produce COx, water, and energy. |

| Type of Test | Description | Test Name | Advantages | Limitations |

|---|---|---|---|---|

| Qualitative tests | Used for screening purposes. Qualitatively estimate kinetic parameters of oxidation reactions. | TGA, DTA, DSC, PDSC, ARC | They are simple, quick, and inexpensive to perform. | They do not provide any insight into the recovery performance. Not very realistic as only one reaction model is assumed. |

| Quantitative tests | These studies replicate the flow conditions in the reservoir and determine the oxidation kinetics parameters. A reactor cell containing oil and sand is heated, the air is flown, and the residual oil and effluent gases are analyzed to determine the parameters that could be used in thermal reservoir simulators to predict field performance. | RTO | Useful for understanding and determining oxidation regimes (oxygen addition vs. bond scission). | Does not reflect the same kinetic behavior observed during combustion tube tests due to peroxidation. |

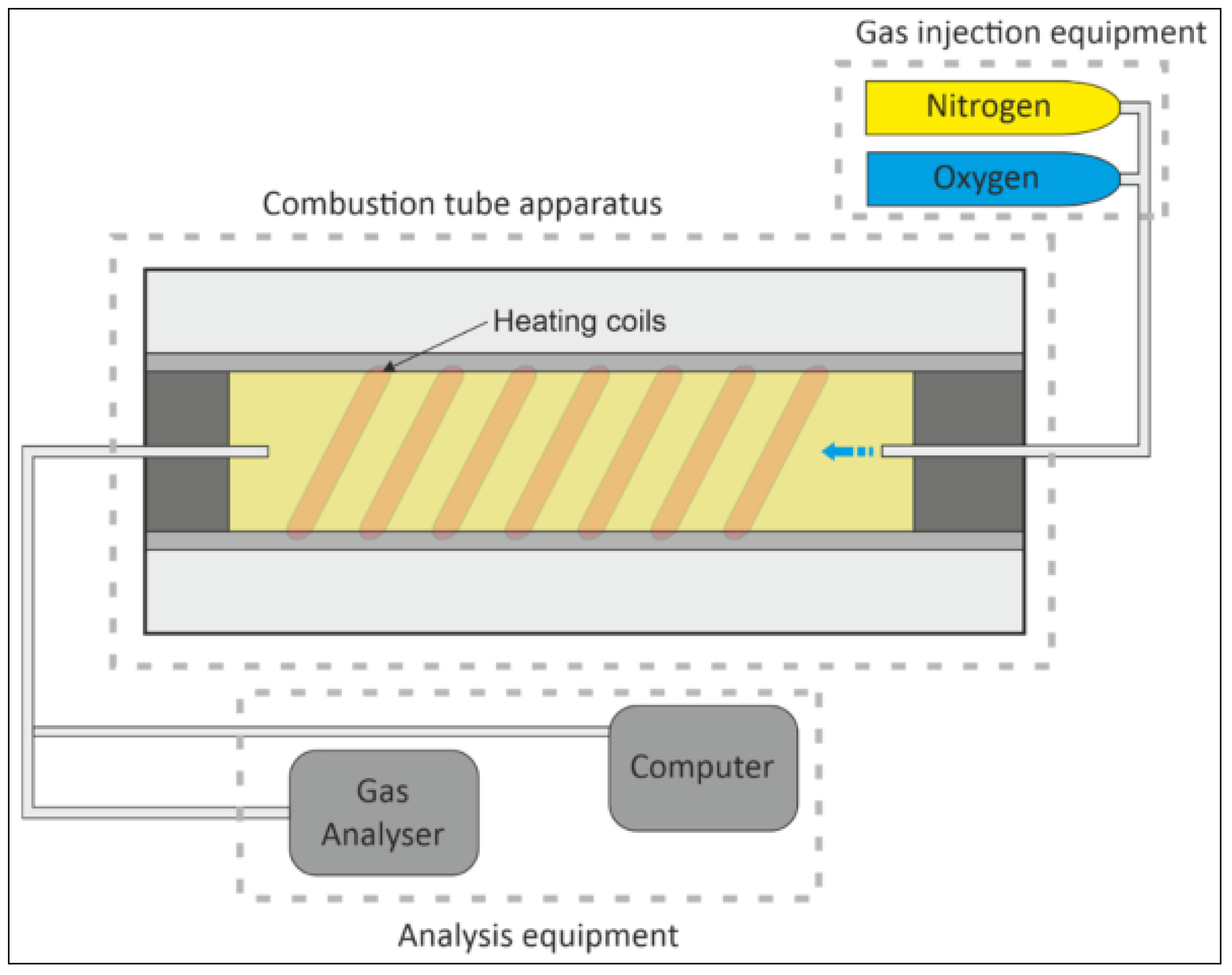

| Combustion performance studies | Physical setup aimed at simulating and observing the advancement of a real combustion front within a reactor cell. Provides an understanding of the parameters affecting the combustion. | Combustion tube tests | Useful for understanding combustion parameters (air and fuel requirements, air-fuel ratio) | Scaled experiments; upscaling is not a straightforward process. |

| Reference | [3] | [9] | [42] | [15] | [114] | [4] |

|---|---|---|---|---|---|---|

| Formation characteristics | The matrix/oil system is reactive enough to sustain combustion. Swelling clays may be a problem. | Relatively uniform sandstone reservoir | No presence of bottom water | High porosity sand/sandstone | Low clay content, low in minerals that promote increased fuel formation, such as pyrite, calcite, and siderite. Extensive fractures and strong water drive should be avoided at all costs. | |

| Reservoir depth | There is no depth limit as long as the reservoir contains the air injected. | >150 m (500 ft). | <3500 m (11,500 ft). Current field projects’ average depth is approximately 1070 m (3500 ft). | 90–3800 m (300–12,500 ft) | ||

| Reservoir thickness | The reservoir has to be at least 4 m (15 ft) in thickness to avoid excessive heat losses. | >3 m (10 ft) | >3 m (10 ft) | >3 m (10 ft) | 1.5–15 m (5–50 ft) | |

| Transmissibility | Air injectivity is favorable when the transmissibility is greater than 5 md m/cp. | 16 md m/cp | >20 md ft/cp | >20 md ft/cp | ||

| Permeability | >100 mD | >100 mD | Average permeability > 50 mD | Not critical | ||

| Porosity and oil saturation | The product, ϕSo, should be more than 0.08 for combustion to be economically successful. | ϕ > 22%. The product, ϕSo, should be more than 0.13. Oil saturation greater than 50 percent. | ϕ > 18%. The product ϕSo should be more than 0.07 | Oil saturation greater than 50% | ϕ > 18%. The product ϕSo should be more than 0.09 | |

| Oil gravity and viscosity | Viscosity has to be low enough to allow air injection and resulting oil production at the design rate. | 24° API or less. μo < 1000 cp | μo < 1000 cp (no need for CSS preheating)μo > 2000 cp (CSS becomes necessary) | μo: 60–10,000 cp | 10–16° API. μo < 5000 cp | μo < 5000 cp. Oil gravity 10–40° API |

| Oil characteristics | The oil has to be readily oxidizable, as determined by laboratory experiments. | Some asphaltic components | Low asphaltic, low heavy metal content. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antolinez, J.D.; Miri, R.; Nouri, A. In Situ Combustion: A Comprehensive Review of the Current State of Knowledge. Energies 2023, 16, 6306. https://doi.org/10.3390/en16176306

Antolinez JD, Miri R, Nouri A. In Situ Combustion: A Comprehensive Review of the Current State of Knowledge. Energies. 2023; 16(17):6306. https://doi.org/10.3390/en16176306

Chicago/Turabian StyleAntolinez, Juan D., Rahman Miri, and Alireza Nouri. 2023. "In Situ Combustion: A Comprehensive Review of the Current State of Knowledge" Energies 16, no. 17: 6306. https://doi.org/10.3390/en16176306

APA StyleAntolinez, J. D., Miri, R., & Nouri, A. (2023). In Situ Combustion: A Comprehensive Review of the Current State of Knowledge. Energies, 16(17), 6306. https://doi.org/10.3390/en16176306