A Survey of Time-Series Prediction for Digitally Enabled Maintenance of Electrical Grids

Abstract

:1. Introduction

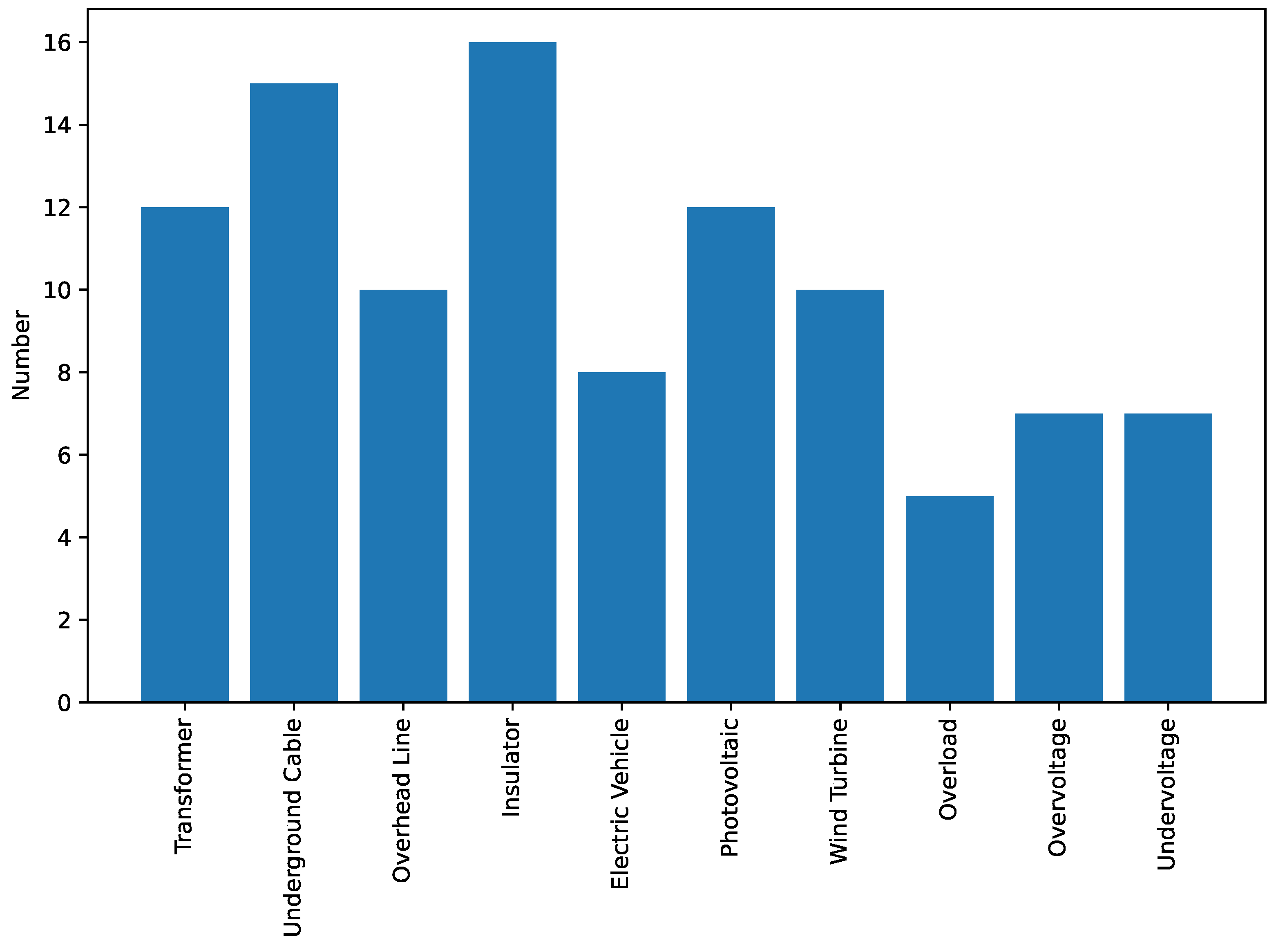

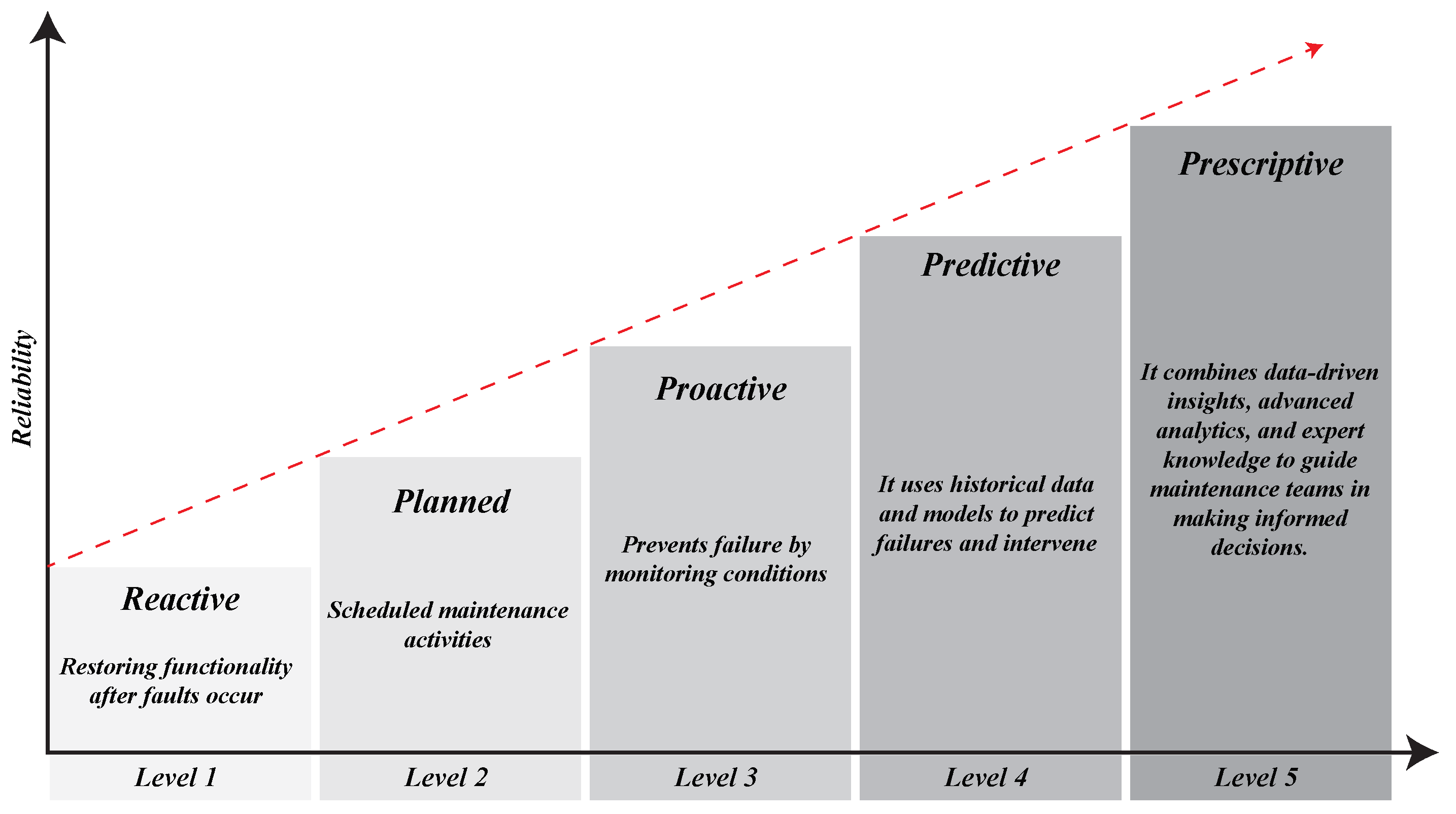

2. Electrical Grid Maintenance

2.1. Reactive Maintenance

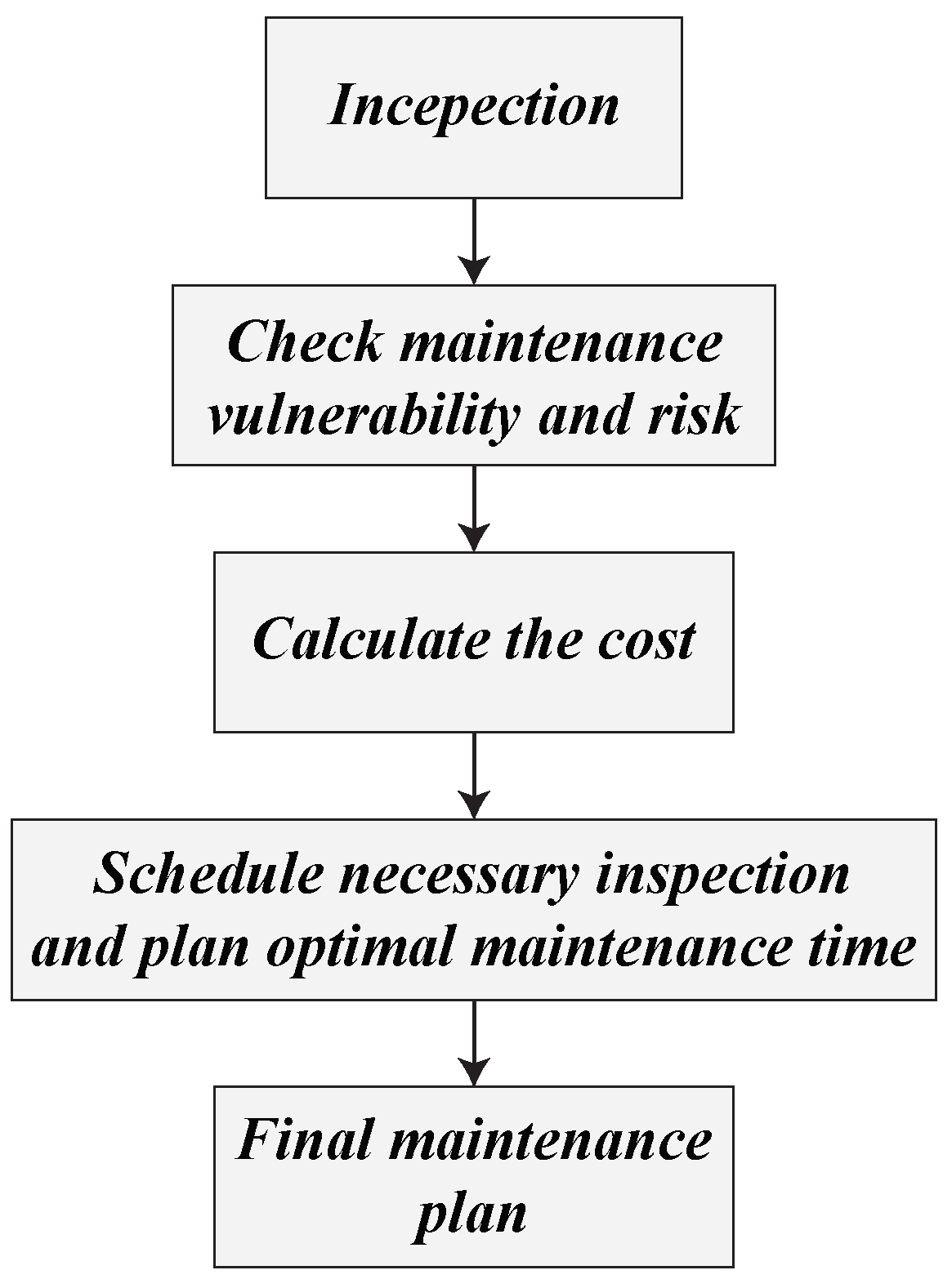

2.2. Planned Maintenance

2.2.1. Maintenance Routine Determination Based on Vulnerability

2.2.2. Maintenance Routine Determination Based on Risk

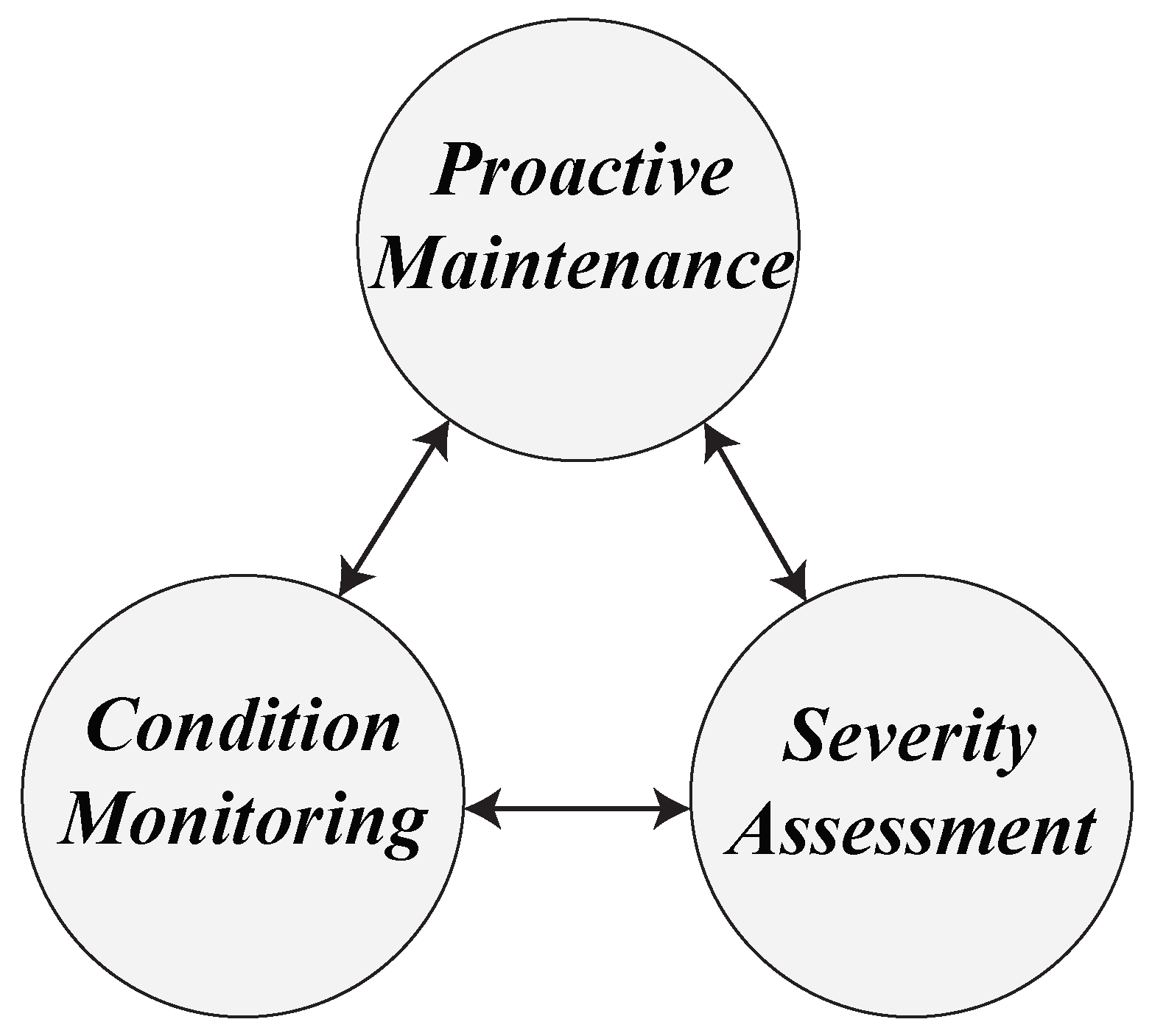

2.3. Proactive Maintenance

2.3.1. Condition Monitoring

2.3.2. Severity Assessment

2.4. Predictive Maintenance

2.4.1. Fault Prediction

2.4.2. Reliability Assessment

2.5. Prescriptive Maintenance

2.5.1. Non-Wires Alternatives

2.5.2. Distributed Energy Resources

3. Time-Series Forecasting Application for Maintenance

3.1. Data Collection

3.2. Underground Cables

3.2.1. Advantages and Limitations of Underground Cables

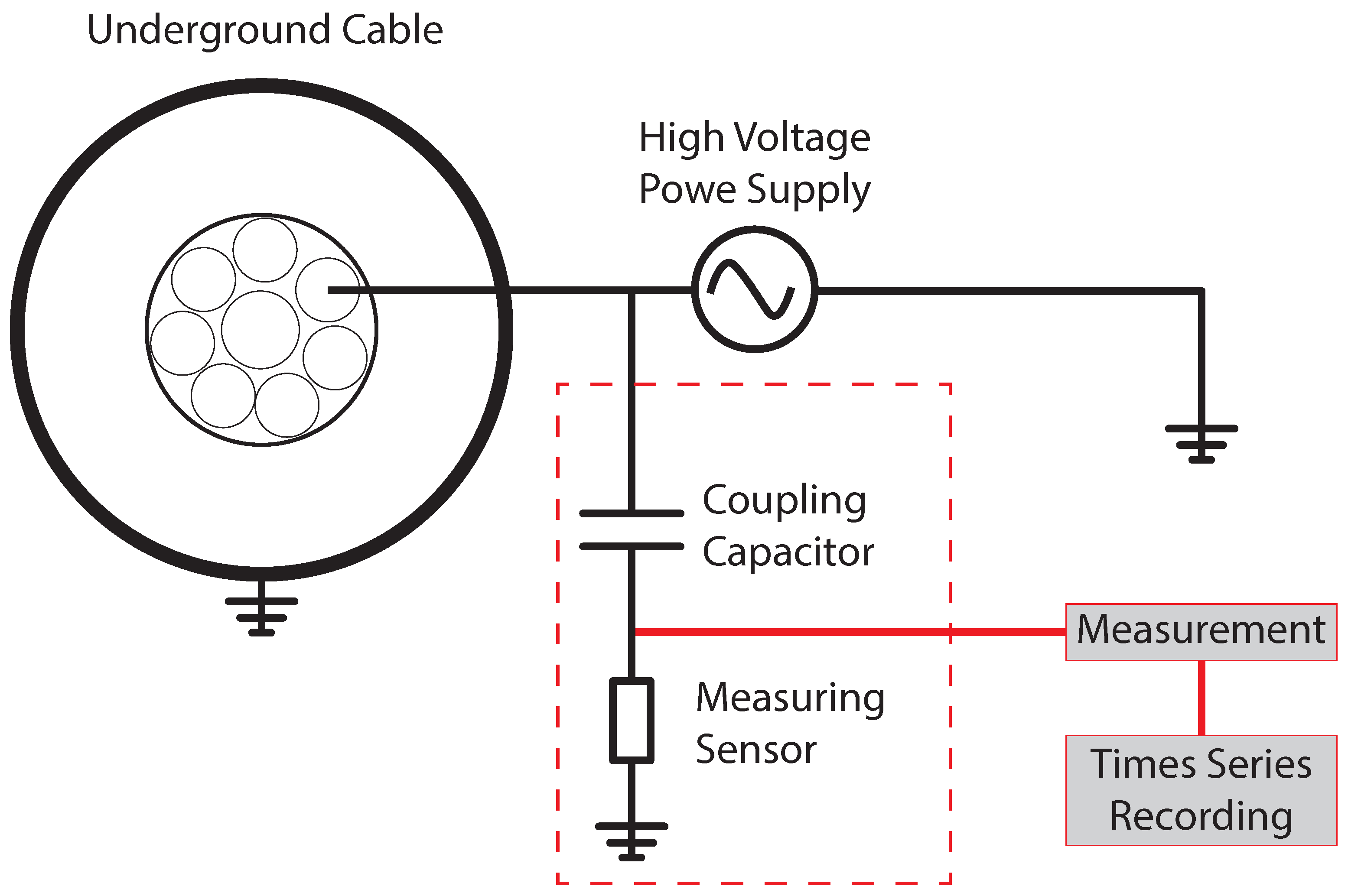

3.2.2. Partial Discharge Measuring Device

3.2.3. Environmental Condition

3.2.4. Approaches for Fault Prediction in Underground Cables

3.3. Insulators

3.3.1. Flashover

3.3.2. Leakage Current

3.3.3. Approaches for Fault Prediction in Insulators

3.4. Transformer

3.4.1. Faults in Transformers

3.4.2. Dissolved Gas Analysis Data

3.5. Overhead Line

4. Challenges, Advantages, and Limitations of Electrical Grid Maintenance

4.1. Model Selection

| Maintenance Level | Reactive | Planned | Proactive | Predictive | Prescriptive |

|---|---|---|---|---|---|

| Characteristics | Fixing after failure | Scheduled based on time or usage | Conduct with early sign of equipment deterioration | Conduct before equipment failure based on the prediction analysis | Predict the failure and recommend solution |

| Requirements | Quick response team and emergency equipment | Maintenance schedule and regular inspection | measuring device installment, communication link, and trend tracking | Real-time data collection, predictive tools, and machine learning | Advanced analytic and integration with operational system |

| Advantages | Minimal planning | Unplanned downtime reduction | Equipment lifetime enhancement and major failure risk reduction | Cost-effective and optimized maintenance schedule | Increased uptime and optimized resource allocation |

| Limitations | Increased overall maintenance cost, safety risks, and high downtime | Missed or unnecessary maintenance due to scheduling constraints | Initial investments and false alarms | Need accurate data, specialized expertise, and investment on predictive technology | Complex data analysis and incorrect or ineffective recommendations |

4.2. Grid Expansion Requirement

4.3. Ineffective Solutions

4.4. Data Availability

4.4.1. Measuring Device Installation

4.4.2. Grid Scalability

4.4.3. Cost and Return

4.4.4. Cyber Attacks

4.4.5. General Data Protection Regulation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ruschel, E.; Santos, E.A.P.; Loures, E.d.F.R. Industrial maintenance decision-making: A systematic literature review. J. Manuf. Syst. 2017, 45, 180–194. [Google Scholar]

- Muller, A.; Marquez, A.C.; Iung, B. On the concept of e-maintenance: Review and current research. Reliab. Eng. Syst. Saf. 2008, 93, 1165–1187. [Google Scholar]

- Luxhøj, J.T.; Riis, J.O.; Thorsteinsson, U. Trends and perspectives in industrial maintenance management. J. Manuf. Syst. 1997, 16, 437–453. [Google Scholar] [CrossRef]

- Bokrantz, J.; Skoogh, A.; Berlin, C.; Wuest, T.; Stahre, J. Smart Maintenance: A research agenda for industrial maintenance management. Int. J. Prod. Econ. 2020, 224, 107547. [Google Scholar]

- Leukel, J.; González, J.; Riekert, M. Adoption of machine learning technology for failure prediction in industrial maintenance: A systematic review. J. Manuf. Syst. 2021, 61, 87–96. [Google Scholar] [CrossRef]

- Shadi, M.R.; Mirshekali, H.; Dashti, R.; Ameli, M.T.; Shaker, H.R. A parameter-free approach for fault section detection on distribution networks employing gated recurrent unit. Energies 2021, 14, 6361. [Google Scholar] [CrossRef]

- Mirshekali, H.; Dashti, R.; Shaker, H.R. A novel fault location algorithm for electrical networks considering distributed line model and distributed generation resources. In Proceedings of the 2020 IEEE PES Innovative Smart Grid Technologies Europe (ISGT-Europe), The Hague, The Netherlands, 26–28 October 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 16–20. [Google Scholar]

- Shadi, M.R.; Ameli, M.T.; Azad, S. A real-time hierarchical framework for fault detection, classification, and location in power systems using PMUs data and deep learning. Int. J. Electr. Power Energy Syst. 2022, 134, 107399. [Google Scholar]

- Vincenti, H. Improving Maintenance Scheduling with Condition Monitoring on the Electric Distribution Grid: An Economic Analysis Comparing Corrective and Predictive Maintenance. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2022. [Google Scholar]

- Langdon, W.B. Scheduling planned maintenance of the national grid. In Proceedings of the Evolutionary Computing: AISB Workshop, Sheffield, UK, 3–4 April 1995; Selected Papers. Springer: Berlin/Heidelberg, Germany, 1995; pp. 132–153. [Google Scholar]

- Jung, C.M.; Ray, P.; Salkuti, S.R. Asset management and maintenance: A smart grid perspective. Int. J. Electr. Comput. Eng. (IJECE) 2019, 9, 3391–3398. [Google Scholar] [CrossRef]

- Langdon, W.B. Scheduling planned maintenance of the south wales region of the national grid. In Proceedings of the Evolutionary Computing: AISB International Workshop, Manchester, UK, 7–8 April 1997; Selected Papers. Springer: Berlin/Heidelberg, Germany, 1997; pp. 179–197. [Google Scholar]

- Burke, E.K.; Smith, A. A memetic algorithm to schedule planned maintenance for the national grid. J. Exp. Algorithmics (JEA) 1999, 4, 1-es. [Google Scholar]

- Wang, T.; Lu, P.; Cao, X.; Yang, X.; Wang, W.; Lv, H.; Feng, C.; Liu, T.; Li, S. Static security risk assessment of power grid under planned maintenance. In Proceedings of the 2019 IEEE 8th International Conference on Advanced Power System Automation and Protection (APAP), Xi’an, China, 21–24 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1809–1813. [Google Scholar]

- Elbouchikhi, E.; Zia, M.F.; Benbouzid, M.; El Hani, S. Overview of signal processing and machine learning for smart grid condition monitoring. Electronics 2021, 10, 2725. [Google Scholar]

- Wu, M.; Cao, H.; Cao, J.; Nguyen, H.L.; Gomes, J.B.; Krishnaswamy, S.P. An overview of state-of-the-art partial discharge analysis techniques for condition monitoring. IEEE Electr. Insul. Mag. 2015, 31, 22–35. [Google Scholar]

- Anijärv, T.E.; Shabbir, N.; Kütt, L.; Iqbal, M.N. Requirements to data acquisition and signal analysis for electrical grid condition monitoring. In Proceedings of the 2020 IEEE 61th International Scientific Conference on Power and Electrical Engineering of Riga Technical University (RTUCON), Riga, Latvia, 5–7 November 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6. [Google Scholar]

- Malik, H.; Fatema, N.; Iqbal, A. Intelligent Data-Analytics for Condition Monitoring: Smart Grid Applications; Academic Press: Cambridge, MA, USA, 2021. [Google Scholar]

- Fioravanti, R.; Kumar, K.; Nakata, S.; Chalamala, B.; Preger, Y. Predictive-maintenance practices: For operational safety of battery energy storage systems. IEEE Power Energy Mag. 2020, 18, 86–97. [Google Scholar] [CrossRef]

- Gorenstein, A.; Kalech, M. Predictive maintenance for critical infrastructure. Expert Syst. Appl. 2022, 210, 118413. [Google Scholar]

- Khoshafian, S.; Rostetter, C. Digital prescriptive maintenance. In BPM Everywhere: Internet of Things, Process of Everything; Future Strategies Inc.: Lighthouse Point, FL, USA, 2015; pp. 1–20. [Google Scholar]

- Liu, B.; Lin, J.; Zhang, L.; Kumar, U. A dynamic prescriptive maintenance model considering system aging and degradation. IEEE Access 2019, 7, 94931–94943. [Google Scholar] [CrossRef]

- Goby, N.; Brandt, T.; Neumann, D. Deep reinforcement learning with combinatorial actions spaces: An application to prescriptive maintenance. Comput. Ind. Eng. 2023, 179, 109165. [Google Scholar]

- Baidya, S.; Potdar, V.; Ray, P.P.; Nandi, C. Reviewing the opportunities, challenges, and future directions for the digitalization of energy. Energy Res. Soc. Sci. 2021, 81, 102243. [Google Scholar]

- De Dutta, S.; Prasad, R. Digitalization of global cities and the smart grid. Wirel. Pers. Commun. 2020, 113, 1385–1395. [Google Scholar] [CrossRef]

- Wilczek, P. Connecting the dots: Distribution grid investments to power the energy transition. In Proceedings of the 11th Solar & Storage Power System Integration Workshop (SIW 2021), Online, 28 September 2021; IET: London, UK, 2021; Volume 2021, pp. 1–18. [Google Scholar]

- Barai, G.R.; Krishnan, S.; Venkatesh, B. Smart metering and functionalities of smart meters in smart grid-a review. In Proceedings of the 2015 IEEE Electrical Power and Energy Conference (EPEC), London, ON, Canada, 26–28 October 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 138–145. [Google Scholar]

- Kumar, U.; Galar, D. Maintenance in the era of industry 4.0: Issues and challenges. In Quality, IT and Business Operations: Modeling and Optimization; Springer: Berlin/Heidelberg, Germany, 2018; pp. 231–250. [Google Scholar]

- Kalpakis, K.; Gada, D.; Puttagunta, V. Distance measures for effective clustering of ARIMA time-series. In Proceedings of the 2001 IEEE International Conference on Data Mining, San Jose, CA, USA, 29 November–2 December 2001; IEEE: Piscataway, NJ, USA, 2001; pp. 273–280. [Google Scholar]

- Dimri, T.; Ahmad, S.; Sharif, M. Time series analysis of climate variables using seasonal ARIMA approach. J. Earth Syst. Sci. 2020, 129, 1–16. [Google Scholar]

- Gardner, E.S., Jr. Exponential smoothing: The state of the art. J. Forecast. 1985, 4, 1–28. [Google Scholar]

- Shohan, M.J.A.; Faruque, M.O.; Foo, S.Y. Forecasting of electric load using a hybrid LSTM-neural prophet model. Energies 2022, 15, 2158. [Google Scholar]

- Delgado, I.; Fahim, M. Wind turbine data analysis and LSTM-based prediction in SCADA system. Energies 2020, 14, 125. [Google Scholar] [CrossRef]

- Zendehboudi, A.; Baseer, M.A.; Saidur, R. Application of support vector machine models for forecasting solar and wind energy resources: A review. J. Clean. Prod. 2018, 199, 272–285. [Google Scholar]

- Dashti, R.; Daisy, M.; Mirshekali, H.; Shaker, H.R.; Aliabadi, M.H. A survey of fault prediction and location methods in electrical energy distribution networks. Measurement 2021, 184, 109947. [Google Scholar]

- Badawi, M.; Ibrahim, S.A.; Mansour, D.E.A.; El-Faraskoury, A.A.; Ward, S.A.; Mahmoud, K.; Lehtonen, M.; Darwish, M.M. Reliable estimation for health index of transformer oil based on novel combined predictive maintenance techniques. IEEE Access 2022, 10, 25954–25972. [Google Scholar] [CrossRef]

- Fox, H.; Pillai, A.C.; Friedrich, D.; Collu, M.; Dawood, T.; Johanning, L. A review of predictive and prescriptive offshore wind farm operation and maintenance. Energies 2022, 15, 504. [Google Scholar]

- Shafiullah, M.; Abido, M.A. A review on distribution grid fault location techniques. Electr. Power Components Syst. 2017, 45, 807–824. [Google Scholar]

- Sopelsa Neto, N.F.; Stefenon, S.F.; Meyer, L.H.; Ovejero, R.G.; Leithardt, V.R.Q. Fault prediction based on leakage current in contaminated insulators using enhanced time series forecasting models. Sensors 2022, 22, 6121. [Google Scholar] [CrossRef]

- Mahmoud, M.A.; Md Nasir, N.R.; Gurunathan, M.; Raj, P.; Mostafa, S.A. The current state of the art in research on predictive maintenance in smart grid distribution network: Fault’s types, causes, and prediction methods—A systematic review. Energies 2021, 14, 5078. [Google Scholar]

- de Faria, H., Jr.; Costa, J.G.S.; Olivas, J.L.M. A review of monitoring methods for predictive maintenance of electric power transformers based on dissolved gas analysis. Renew. Sustain. Energy Rev. 2015, 46, 201–209. [Google Scholar]

- Gandhi, K.; Bansal, H.O. Smart Metering in electric power distribution system. In Proceedings of the 2013 International Conference on Control, Automation, Robotics and Embedded Systems (CARE), Jabalpur, India, 16–18 December 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 1–6. [Google Scholar]

- Contreras-Ocana, J.E.; Siddiqi, U.; Zhang, B. Non-wire alternatives to capacity expansion. In Proceedings of the 2018 IEEE Power & Energy Society General Meeting (PESGM), Portland, OR, USA, 5–10 August 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–5. [Google Scholar]

- Johns, A.; Jamali, S. Accurate fault location technique for power transmission lines. IEE Proc. Gener. Transm. Distrib. 1990, 137, 395–402. [Google Scholar] [CrossRef]

- Fang, S.; Mingze, Z.; Sheng, L.; Xiaoyu, W.; Haiyang, C. Fast detection method of insulator fault based on image processing technology. In Proceedings of the 2020 IEEE 5th Information Technology and Mechatronics Engineering Conference (ITOEC), Chongqing, China, 12–14 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 400–406. [Google Scholar]

- Senobari, R.K.; Sadeh, J.; Borsi, H. Frequency response analysis (FRA) of transformers as a tool for fault detection and location: A review. Electr. Power Syst. Res. 2018, 155, 172–183. [Google Scholar]

- Personal, E.; García, A.; Parejo, A.; Larios, D.F.; Biscarri, F.; León, C. A comparison of impedance-based fault location methods for power underground distribution systems. Energies 2016, 9, 1022. [Google Scholar] [CrossRef]

- Mirshekali, H.; Dashti, R.; Keshavarz, A.; Torabi, A.J.; Shaker, H.R. A novel fault location methodology for smart distribution networks. IEEE Trans. Smart Grid 2020, 12, 1277–1288. [Google Scholar]

- Mirshekali, H.; Dashti, R.; Shaker, H.R.; Samsami, R.; Torabi, A.J. Linear and nonlinear fault location in smart distribution network under line parameter uncertainty. IEEE Trans. Ind. Inform. 2021, 17, 8308–8318. [Google Scholar] [CrossRef]

- Mirshekali, H.; Dashti, R.; Handrup, K.; Shaker, H.R. Real fault location in a distribution network using smart feeder meter data. Energies 2021, 14, 3242. [Google Scholar] [CrossRef]

- Mirshekali, H.; Dashti, R.; Keshavarz, A.; Shaker, H.R. Machine learning-based fault location for smart distribution networks equipped with micro-PMU. Sensors 2022, 22, 945. [Google Scholar] [CrossRef]

- Vaish, R.; Dwivedi, U.; Tewari, S.; Tripathi, S.M. Machine learning applications in power system fault diagnosis: Research advancements and perspectives. Eng. Appl. Artif. Intell. 2021, 106, 104504. [Google Scholar]

- Mirshekali, H.; Keshavarz, A.; Dashti, R.; Hafezi, S.; Shaker, H.R. Deep learning-based fault location framework in power distribution grids employing convolutional neural network based on capsule network. Electr. Power Syst. Res. 2023, 223, 109529. [Google Scholar] [CrossRef]

- Mishra, D.P.; Ray, P. Fault detection, location and classification of a transmission line. Neural Comput. Appl. 2018, 30, 1377–1424. [Google Scholar]

- Shi, Q.; Liang, S.; Fei, W.; Shi, Y.; Shi, R. Study on Bayesian network parameters learning of power system component fault diagnosis based on particle swarm optimization. Int. J. Smart Grid Clean Energy 2013, 2, 132–137. [Google Scholar] [CrossRef]

- Barnish, T.J.; Muller, M.R.; Kasten, D.J. Motor maintenance: A survey of techniques and results. In 1997 ACEEE Summer Study on Energy Efficiency in Industry; American Council for an Energy-Efficient Economy: Washington, DC, USA, 1997. [Google Scholar]

- Yare, Y.; Venayagamoorthy, G.K. Optimal maintenance scheduling of generators using multiple swarms-MDPSO framework. Eng. Appl. Artif. Intell. 2010, 23, 895–910. [Google Scholar] [CrossRef]

- Reddy, S.S. Optimal scheduling of thermal-wind-solar power system with storage. Renew. Energy 2017, 101, 1357–1368. [Google Scholar]

- Ertekin, Ş.; Rudin, C.; McCormick, T.H. Reactive point processes: A new approach to predicting power failures in underground electrical systems. Ann. Appl. Stat. 2015, 9, 122–144. [Google Scholar] [CrossRef]

- Edwin, N.; Mjølnerød, H.; Gran, B. Data-driven and risk-based decision support for maintenance planning on electrical power grid systems. In Safety and Reliability–Safe Societies in a Changing World; CRC Press: Boca Raton, FL, USA, 2018; pp. 607–614. [Google Scholar]

- Perez-Canto, S.; Rubio-Romero, J.C. A model for the preventive maintenance scheduling of power plants including wind farms. Reliab. Eng. Syst. Saf. 2013, 119, 67–75. [Google Scholar] [CrossRef]

- Shahin, A.; Aminsabouri, N.; Kianfar, K. Developing a Decision Making Grid for determining proactive maintenance tactics: A case study in the steel industry. J. Manuf. Technol. Manag. 2018. [Google Scholar] [CrossRef]

- Wang, Q.; Bu, S.; He, Z. Achieving predictive and proactive maintenance for high-speed railway power equipment with LSTM-RNN. IEEE Trans. Ind. Inform. 2020, 16, 6509–6517. [Google Scholar]

- Chakkor, S.; Baghouri, M.; Abderrahmane, H. Real Time and Wireless Smart Faults Detection Device for Wind Turbines. Int. J. Comput. Sci. Telecommun. IJCST 2014, 5, 1–7. [Google Scholar]

- Joseph, J.; Krishnan, S.T. Development of severity and location indices based condition monitoring scheme for underground cables by impedance spectroscopy. IEEE Trans. Power Deliv. 2020, 36, 533–543. [Google Scholar] [CrossRef]

- Hegedűs, C.; Ciancarini, P.; Frankó, A.; Kancilija, A.; Moldován, I.; Papa, G.; Poklukar, Š.; Riccardi, M.; Sillitti, A.; Varga, P. Proactive maintenance of railway switches. In Proceedings of the 2018 5th International Conference on Control, Decision and Information Technologies (CoDIT), Thessaloniki, Greece, 10–13 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 725–730. [Google Scholar]

- Reder, W.; Flaten, D. Reliability centered maintenance for distribution underground systems. In Proceedings of the 2000 Power Engineering Society Summer Meeting (Cat. No. 00CH37134), Seattle, WA, USA, 16–20 July 2000; IEEE: Piscataway, NJ, USA, 2000; Volume 1, pp. 551–556. [Google Scholar]

- Yeddanapudi, S.R.K.; Li, Y.; McCalley, J.D.; Chowdhury, A.A.; Jewell, W.T. Risk-based allocation of distribution system maintenance resources. IEEE Trans. Power Syst. 2008, 23, 287–295. [Google Scholar] [CrossRef]

- Selvaraj, Y.; Selvaraj, C. Proactive maintenance of small wind turbines using IoT and machine learning models. Int. J. Green Energy 2022, 19, 463–475. [Google Scholar] [CrossRef]

- Ran, Y.; Zhou, X.; Lin, P.; Wen, Y.; Deng, R. A survey of predictive maintenance: Systems, purposes and approaches. arXiv 2019, arXiv:1912.07383. [Google Scholar]

- Ledari, S.A.; Mirzaie, M. Sheath induced voltage prediction of high voltage cable based on artificial neural network. Comput. Electr. Eng. 2020, 87, 106788. [Google Scholar] [CrossRef]

- Alazab, M.; Khan, S.; Krishnan, S.S.R.; Pham, Q.V.; Reddy, M.P.K.; Gadekallu, T.R. A multidirectional LSTM model for predicting the stability of a smart grid. IEEE Access 2020, 8, 85454–85463. [Google Scholar] [CrossRef]

- Mahdi, M.; Genc, V.I. Post-fault prediction of transient instabilities using stacked sparse autoencoder. Electr. Power Syst. Res. 2018, 164, 243–252. [Google Scholar] [CrossRef]

- Joyce, J.M. Kullback-leibler divergence. In International Encyclopedia of Statistical Science; Springer: Berlin/Heidelberg, Germany, 2011; pp. 720–722. [Google Scholar]

- Rahman, F.A.; Varuttamaseni, A.; Kintner-Meyer, M.; Lee, J.C. Application of fault tree analysis for customer reliability assessment of a distribution power system. Reliab. Eng. Syst. Saf. 2013, 111, 76–85. [Google Scholar]

- Goyal, A.; Aprilia, E.; Janssen, G.; Kim, Y.; Kumar, T.; Mueller, R.; Phan, D.; Raman, A.; Schuddebeurs, J.; Xiong, J.; et al. Asset health management using predictive and prescriptive analytics for the electric power grid. IBM J. Res. Dev. 2016, 60, 4:1–4:14. [Google Scholar] [CrossRef]

- Alberta, E.E. Non-Wires Alternatives Study; Navigant: Toronto, ON, Canada, 2020. [Google Scholar]

- Lorente, Q.; Villeneuve, E.; Merlo, C.; Boy, G.A.; Thermy, F. Development of a digital twin for collaborative decision-making, based on a multi-agent system: Application to prescriptive maintenance. In Proceedings of the INCOSE International Symposium, Virtual Event, 16–19 November 2021; Wiley Online Library: Hoboken, NJ, USA, 2022; Volume 32, pp. 109–117. [Google Scholar]

- Zhang, K.; Wang, B.; Liu, D.; Zhao, J.; Guo, Y.; Wu, Z. Prediction modeling of frequency response characteristic of power system based on historical data. In Proceedings of the 2020 IEEE/IAS Industrial and Commercial Power System Asia (I&CPS Asia), Weihai, China, 13–15 July 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1486–1490. [Google Scholar]

- Yang, J.; Xiang, Y.; Wang, Z.; Dai, J.; Wang, Y. Optimal investment decision of distribution network with investment ability and project correlation constraints. Front. Energy Res. 2021, 9, 728834. [Google Scholar]

- Reid, B.; Bourg, J.; Schmidt, D. Let’s Make a Deal: Non-Wires Alternatives for Traditional Transmission and Distribution? IEEE Power Energy Mag. 2022, 20, 23–31. [Google Scholar] [CrossRef]

- Wang, J.; Zhong, H.; Xia, Q.; Li, G.; Zhou, M. Sharing Non-wire Alternatives for Transmission Expansion Deferral. In Sharing Economy in Energy Markets: Modeling, Analysis and Mechanism Design; Springer: Berlin/Heidelberg, Germany, 2022; pp. 227–269. [Google Scholar]

- Strezoski, L. Distributed energy resource management systems—DERMS: State of the art and how to move forward. Wiley Interdiscip. Rev. Energy Environ. 2023, 12, e460. [Google Scholar]

- Deboever, J.; Peppanen, J.; Maitra, A.; Damato, G.; Taylor, J.; Patel, J. Energy storage as a non-wires alternative for deferring distribution capacity investments. In Proceedings of the 2018 IEEE/PES Transmission and Distribution Conference and Exposition (T&D), Denver, CO, USA, 16–19 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–5. [Google Scholar]

- Tabors, R.D. Transportation Electrification in a Grid With Increased Non-Wires Alternatives. IEEE Electrif. Mag. 2019, 7, 88–86. [Google Scholar] [CrossRef]

- Sun, L.; Vu, K.; Ntakou, E.; Farzan, F.; Mahani, K.; Masiello, R. A Practical Implementation of Non-Wires Alternatives in Low Voltage AC Networks. In Proceedings of the 2022 IEEE/PES Transmission and Distribution Conference and Exposition (T&D), New Orleans, LA, USA, 25–28 April 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–5. [Google Scholar]

- Contreras-Ocana, J.E.; Chen, Y.; Siddiqi, U.; Zhang, B. Non-wire alternatives: An additional value stream for distributed energy resources. IEEE Trans. Sustain. Energy 2019, 11, 1287–1299. [Google Scholar] [CrossRef]

- Andrianesis, P.; Caramanis, M.; Masiello, R.D.; Tabors, R.D.; Bahramirad, S. Locational marginal value of distributed energy resources as non-wires alternatives. IEEE Trans. Smart Grid 2019, 11, 270–280. [Google Scholar] [CrossRef]

- Laws, N.D.; Webber, M.E. Valuing Distributed Energy Resources for Non-Wires Alternatives. arXiv 2023, arXiv:2301.06636. [Google Scholar]

- Mar, A.; Pereira, P.; Martins, J.F. A survey on power grid faults and their origins: A contribution to improving power grid resilience. Energies 2019, 12, 4667. [Google Scholar] [CrossRef]

- Çelık, D.; Meral, M.E.; Waseem, M. A New Area Towards to Digitalization of Energy Systems: Enables, Challenges and Solutions. In Proceedings of the 2022 14th International Conference on Electronics, Computers and Artificial Intelligence (ECAI), Ploiesti, Romania, 30 June–1 July 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Torres, J.F.; Hadjout, D.; Sebaa, A.; Martínez-Álvarez, F.; Troncoso, A. Deep learning for time series forecasting: A survey. Big Data 2021, 9, 3–21. [Google Scholar] [CrossRef]

- Pompodakis, E.; Chrysochos, A.I.; Ahmed, A.; Alexiadis, M.C. Time-Series Temperature-Dependent Power Flow Considering Unbalanced Thermoelectric Equivalent Circuits for Underground LV and MV Cables. TechRxiv 2021. [Google Scholar] [CrossRef]

- Bonanno, R.; Lacavalla, M. A feasibility analysis aimed at defining an alert system for Distribution MV Underground Cables. In Proceedings of the 2020 AEIT International Annual Conference (AEIT), Catania, Italy, 23–25 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6. [Google Scholar]

- Chen, X.; Xu, Y.; Cao, X. Nonlinear time series analysis of partial discharges in electrical trees of XLPE cable insulation samples. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1455–1461. [Google Scholar] [CrossRef]

- Stefenon, S.F.; Ribeiro, M.H.D.M.; Nied, A.; Mariani, V.C.; dos Santos Coelho, L.; da Rocha, D.F.M.; Grebogi, R.B.; de Barros Ruano, A.E. Wavelet group method of data handling for fault prediction in electrical power insulators. Int. J. Electr. Power Energy Syst. 2020, 123, 106269. [Google Scholar] [CrossRef]

- Wang, X.; Li, Q.; Yang, R.; Li, C.; Zhang, Y. Diagnosis of solid insulation deterioration for power transformers with dissolved gas analysis-based time series correlation. IET Sci. Meas. Technol. 2015, 9, 393–399. [Google Scholar] [CrossRef]

- Zhan, J.; Chung, C.; Demeter, E. Time series modeling for dynamic thermal rating of overhead lines. IEEE Trans. Power Syst. 2016, 32, 2172–2182. [Google Scholar] [CrossRef]

- Li, P.; Zhao, N.; Zhou, D.; Cao, M.; Li, J.; Shi, X. Multivariable time series prediction for the icing process on overhead power transmission line. Sci. World J. 2014, 2014, 256815. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Lee, W.K.; Hou, Y.; Pong, P.W. Underground power cable detection and inspection technology based on magnetic field sensing at ground surface level. IEEE Trans. Magn. 2014, 50, 1–5. [Google Scholar] [CrossRef]

- Bak, C.L.; da Silva, F.F. High Voltage AC underground cable systems for power transmission–A review of the Danish experience: Part 2. Electr. Power Syst. Res. 2016, 140, 995–1004. [Google Scholar] [CrossRef]

- Menges, R.; Beyer, G. Underground cables versus overhead lines: Do cables increase social acceptance of grid development? Results of a Contingent Valuation survey in Germany. Int. J. Sustain. Energy Plan. Manag. 2014, 3, 33–48. [Google Scholar]

- Maggioli, E.; Leite, H.; Morais, C. A survey of the Portuguese MV underground cable failure. In Proceedings of the 2016 13th International Conference on the European Energy Market (EEM), Porto, Portugal, 6–9 June 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–5. [Google Scholar]

- Costello, S.; Chapman, D.; Rogers, C.; Metje, N. Underground asset location and condition assessment technologies. Tunn. Undergr. Space Technol. 2007, 22, 524–542. [Google Scholar] [CrossRef]

- Yin, X.; Wang, M. Science Mapping for Recent Research Regarding Urban Underground Infrastructure. Buildings 2022, 12, 2031. [Google Scholar] [CrossRef]

- Lauletta, J.L.; Sozer, Y.; De Abreu-Garcia, J.A. A novel sensing device for underground cable condition assessment. In Proceedings of the 2015 IEEE Electrical Insulation Conference (EIC), Seattle, WA, USA, 7–10 June 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 523–528. [Google Scholar]

- Mahar, V.; Yadav, D.S.; Koul, M.V. A Novel Sensing Device for Assessing Underground Cable Condition. Int. J. Food Nutr. Sci. 2022, 11, 484–490. [Google Scholar]

- Mortensen, L.K.; Shaker, H.R.; Veje, C.T. Relative fault vulnerability prediction for energy distribution networks. Appl. Energy 2022, 322, 119449. [Google Scholar] [CrossRef]

- Arikan, O.; Uydur, C.C.; Kumru, C.F. Prediction of dielectric parameters of an aged mv cable: A comparison of curve fitting, decision tree and artificial neural network methods. Electr. Power Syst. Res. 2022, 208, 107892. [Google Scholar] [CrossRef]

- Skydt, M.R.; Bang, M.; Shaker, H.R. A probabilistic sequence classification approach for early fault prediction in distribution grids using long short-term memory neural networks. Measurement 2021, 170, 108691. [Google Scholar] [CrossRef]

- Samet, H.; Tajdinian, M.; Khaleghian, S.; Ghanbari, T. A statistical-based criterion for incipient fault detection in underground power cables established on voltage waveform characteristics. Electr. Power Syst. Res. 2021, 197, 107303. [Google Scholar] [CrossRef]

- Spellman, C.; Young, H.; Haddad, A.; Rowlands, A.; Waters, R. Survey of polymeric insulator ageing factors. In Proceedings of the 1999 Eleventh International Symposium on High Voltage Engineering, London, UK, 23–27 August 1999; IET: London, UK, 1999; Volume 4, pp. 160–163. [Google Scholar]

- Mussina, D.; Irmanova, A.; Jamwal, P.K.; Bagheri, M. Multi-modal data fusion using deep neural network for condition monitoring of high voltage insulator. IEEE Access 2020, 8, 184486–184496. [Google Scholar] [CrossRef]

- Catterson, V.; Castellon, J.; Pilgrim, J.; Saha, T.K.; Ma, H.; Vakilian, M.; Moradnouri, A.; Gholami, M.; Sparling, B. The impact of smart grid technology on dielectrics and electrical insulation. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 3505–3512. [Google Scholar] [CrossRef]

- Miller, H.C. Surface flashover of insulators. IEEE Trans. Electr. Insul. 1989, 24, 765–786. [Google Scholar] [CrossRef]

- Miller, H.C. Flashover of insulators in vacuum: Review of the phenomena and techniques to improved holdoff voltage. IEEE Trans. Electr. Insul. 1993, 28, 512–527. [Google Scholar] [CrossRef]

- Zhao, C.; Mei, H.; Zhu, M.; Dai, H.; Wang, L.; Zhou, Z. Development of contamination flashover pre-warning system and analysis of operating experience. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2234–2241. [Google Scholar] [CrossRef]

- Cui, L.; Ramesh, M. Prediction of flashover voltage using electric field measurement on clean and polluted insulators. Int. J. Electr. Power Energy Syst. 2020, 116, 105574. [Google Scholar] [CrossRef]

- Salem, A.A.; Abd-Rahman, R.; Ahmad, H.; Kamarudin, M.; Jamal, N.; Othman, N.; Ishak, M. A new flashover prediction on outdoor polluted insulator using leakage current harmonic components. In Proceedings of the 2018 IEEE 7th International Conference on Power and Energy (PECon), Kuala Lumpur, Malaysia, 3–4 December 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 413–418. [Google Scholar]

- Seman, L.O.; Stefenon, S.F.; Mariani, V.C.; dos Santos Coelho, L. Ensemble learning methods using the Hodrick–Prescott filter for fault forecasting in insulators of the electrical power grids. Int. J. Electr. Power Energy Syst. 2023, 152, 109269. [Google Scholar] [CrossRef]

- Bessedik, S.A.; Hadi, H. Prediction of flashover voltage of insulators using least squares support vector machine with particle swarm optimisation. Electr. Power Syst. Res. 2013, 104, 87–92. [Google Scholar] [CrossRef]

- Gencoglu, M.T.; Uyar, M. Prediction of flashover voltage of insulators using least squares support vector machines. Expert Syst. Appl. 2009, 36, 10789–10798. [Google Scholar] [CrossRef]

- Nguyen, T.P.; Yeh, C.T.; Cho, M.Y.; Chang, C.L.; Chen, M.J. Convolutional neural network bidirectional long short-term memory to online classify the distribution insulator leakage currents. Electr. Power Syst. Res. 2022, 208, 107923. [Google Scholar] [CrossRef]

- Bueno-Barrachina, J.M.; Ye-Lin, Y.; Nieto-del Amor, F.; Fuster-Roig, V. Inception 1D-convolutional neural network for accurate prediction of electrical insulator leakage current from environmental data during its normal operation using long-term recording. Eng. Appl. Artif. Intell. 2023, 119, 105799. [Google Scholar] [CrossRef]

- Moreau, O.; Santos, G.; Guillot, Y. Computation of very fast transient overvoltages inside transformers resulting from switchings in power plants. In Proceedings of the 2005 International Conference on Power Systems Transients (IPST 2005), Montreal, QC, Canada, 19–23 June 2005. [Google Scholar]

- Shokrzadeh, S.; Ribberink, H.; Rishmawi, I.; Entchev, E. A simplified control algorithm for utilities to utilize plug-in electric vehicles to reduce distribution transformer overloading. Energy 2017, 133, 1121–1131. [Google Scholar] [CrossRef]

- Xing, M.; Ding, W.; Li, H.; Zhang, T. A Power Transformer Fault Prediction Method through Temporal Convolutional Network on Dissolved Gas Chromatography Data. Secur. Commun. Netw. 2022, 2022, 5357412. [Google Scholar] [CrossRef]

- Zhu, Y.L.; Zhao, W.Q.; Zhai, X.M.; Zhang, X.Q. A fault prediction approach for power transformer based on support vector machine. In Proceedings of the 2007 International Conference on Wavelet Analysis and Pattern Recognition, Beijing, China, 2–4 November 2007; IEEE: Piscataway, NJ, USA, 2007; Volume 4, pp. 1457–1461. [Google Scholar]

- Taha, I.B.; Mansour, D. Novel power transformer fault diagnosis using optimized machine learning methods. Intell. Autom. Soft Comput. 2021, 28, 739–752. [Google Scholar] [CrossRef]

- Belagoune, S.; Bali, N.; Bakdi, A.; Baadji, B.; Atif, K. Deep learning through LSTM classification and regression for transmission line fault detection, diagnosis and location in large-scale multi-machine power systems. Measurement 2021, 177, 109330. [Google Scholar] [CrossRef]

- Nicolaou, C.P.; Papadakis, A.P.; Razis, P.A.; Kyriacou, G.A.; Sahalos, J.N. Measurements and predictions of electric and magnetic fields from power lines. Electr. Power Syst. Res. 2011, 81, 1107–1116. [Google Scholar] [CrossRef]

- Yang, Y.; Harley, R.G.; Divan, D.; Habetler, T.G. Thermal modeling and real time overload capacity prediction of overhead power lines. In Proceedings of the 2009 IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Cargese, France, 31 August–3 September 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 1–7. [Google Scholar]

- Liu, X.; Zhang, P.; Deng, X.; Sun, D. Hierarchical overvoltage predictive control scheme for a DFIG-based wind farm. Electr. Power Syst. Res. 2023, 217, 109172. [Google Scholar] [CrossRef]

- Jung, Y.; Jung, J.; Kim, B.; Han, S. Long short-term memory recurrent neural network for modeling temporal patterns in long-term power forecasting for solar PV facilities: Case study of South Korea. J. Clean. Prod. 2020, 250, 119476. [Google Scholar] [CrossRef]

- Doucoure, B.; Agbossou, K.; Cardenas, A. Time series prediction using artificial wavelet neural network and multi-resolution analysis: Application to wind speed data. Renew. Energy 2016, 92, 202–211. [Google Scholar] [CrossRef]

- Zonta, T.; Da Costa, C.A.; da Rosa Righi, R.; de Lima, M.J.; da Trindade, E.S.; Li, G.P. Predictive maintenance in the Industry 4.0: A systematic literature review. Comput. Ind. Eng. 2020, 150, 106889. [Google Scholar] [CrossRef]

- Ferreira, L.L.; Albano, M.; Silva, J.; Martinho, D.; Marreiros, G.; Di Orio, G.; Maló, P.; Ferreira, H. A pilot for proactive maintenance in industry 4.0. In Proceedings of the 2017 IEEE 13th International Workshop on Factory Communication Systems (WFCS), Trondheim, Norway, 31 May–2 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–9. [Google Scholar]

- Hernández-Callejo, L. A comprehensive review of operation and control, maintenance and lifespan management, grid planning and design, and metering in smart grids. Energies 2019, 12, 1630. [Google Scholar] [CrossRef]

- Balaraman, S.; Kamaraj, N. Cascade BPN based transmission line overload prediction and preventive action by generation rescheduling. Neurocomputing 2012, 94, 1–12. [Google Scholar] [CrossRef]

- Yap, W.K.; Havas, L.; Overend, E.; Karri, V. Neural network-based active power curtailment for overvoltage prevention in low voltage feeders. Expert Syst. Appl. 2014, 41, 1063–1070. [Google Scholar] [CrossRef]

- Ye, R.; Huang, X.; Chen, Z.; Ji, Z. A hybrid charging management strategy for solving the under-voltage problem caused by large-scale EV fast charging. Sustain. Energy Grids Netw. 2021, 27, 100508. [Google Scholar] [CrossRef]

- Cicilio, P.; Glennon, D.; Mate, A.; Barnes, A.; Chalishazar, V.; Cotilla-Sanchez, E.; Vaagensmith, B.; Gentle, J.; Rieger, C.; Wies, R.; et al. Resilience in an evolving electrical grid. Energies 2021, 14, 694. [Google Scholar] [CrossRef]

- Ma, Z.; Clausen, A.; Lin, Y.; Jørgensen, B.N. An overview of digitalization for the building-to-grid ecosystem. Energy Inform. 2021, 4, 1–21. [Google Scholar] [CrossRef]

- Papadopoulos, P.; Skarvelis-Kazakos, S.; Grau, I.; Cipcigan, L.M.; Jenkins, N. Predicting electric vehicle impacts on residential distribution networks with distributed generation. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 1–5. [Google Scholar]

- Casals-Torrens, P.; González-Parada, A.; Bosch-Tous, R. Online PD detection on high voltage underground power cables by acoustic emission. Procedia Eng. 2012, 35, 22–30. [Google Scholar] [CrossRef]

- Mashad Nemati, H.; Sant’Anna, A.; Nowaczyk, S. Reliability evaluation of underground power cables with probabilistic models. In Proceedings of the The 11th International Conference on Data Mining (DMIN’15), Las Vegas, NV, USA, 27–30 July 2015; pp. 37–43. [Google Scholar]

- De Benedetti, M.; Leonardi, F.; Messina, F.; Santoro, C.; Vasilakos, A. Anomaly detection and predictive maintenance for photovoltaic systems. Neurocomputing 2018, 310, 59–68. [Google Scholar] [CrossRef]

- Yaseen, M.; Swathi, D.; Kumar, T.A. IoT based condition monitoring of generators and predictive maintenance. In Proceedings of the 2017 2nd International Conference on Communication and Electronics Systems (ICCES), Coimbatore, India, 19–20 October 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 725–729. [Google Scholar]

- Ghavami, A.; Kar, K.; Gupta, A. Decentralized charging of plug-in electric vehicles with distribution feeder overload control. IEEE Trans. Autom. Control 2016, 61, 3527–3532. [Google Scholar] [CrossRef]

- Yaslan, Y.; Bican, B. Empirical mode decomposition based denoising method with support vector regression for time series prediction: A case study for electricity load forecasting. Measurement 2017, 103, 52–61. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, H.; Xing, X. Scalability for smart infrastructure system in smart grid: A survey. Wirel. Pers. Commun. 2018, 99, 161–184. [Google Scholar] [CrossRef]

- Rodriguez-Calvo, A.; Cossent, R.; Frías, P. Scalability and replicability analysis of large-scale smart grid implementations: Approaches and proposals in Europe. Renew. Sustain. Energy Rev. 2018, 93, 1–15. [Google Scholar] [CrossRef]

- Houssainy, S.; Livingood, W. Optimal strategies for a cost-effective and reliable 100% renewable electric grid. J. Renew. Sustain. Energy 2021, 13, 066301. [Google Scholar] [CrossRef]

- Ma, R.; Chen, H.H.; Huang, Y.R.; Meng, W. Smart grid communication: Its challenges and opportunities. IEEE Trans. Smart Grid 2013, 4, 36–46. [Google Scholar] [CrossRef]

- Bobbio, A.; Bonanni, G.; Ciancamerla, E.; Clemente, R.; Iacomini, A.; Minichino, M.; Scarlatti, A.; Terruggia, R.; Zendri, E. Unavailability of critical SCADA communication links interconnecting a power grid and a Telco network. Reliab. Eng. Syst. Saf. 2010, 95, 1345–1357. [Google Scholar] [CrossRef]

- Martinez, J.; Ruiz, A.; Puelles, J.; Arechalde, I.; Miadzvetskaya, Y. Smart grid challenges through the lens of the european general data protection regulation. In Proceedings of the Advances in Information Systems Development: Information Systems Beyond, Toulon, France, 28–30 August 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 113–130. [Google Scholar]

- Fabiano, N. Internet of Things and the legal issues related to the data protection law according to the new European General Data Protection Regulation. Athens JL 2017, 3, 201. [Google Scholar] [CrossRef]

| References | [35] | [36] | [37] | [38] | [39] | [40] | [41] | This Paper |

|---|---|---|---|---|---|---|---|---|

| ReM | 🗸 | × | × | 🗸 | × | × | 🗸 | 🗸 |

| PlM | × | × | × | × | × | × | 🗸 | 🗸 |

| ProM | × | × | × | × | × | × | 🗸 | 🗸 |

| PredM | × | 🗸 | 🗸 | × | 🗸 | 🗸 | 🗸 | 🗸 |

| PresM | × | × | 🗸 | × | × | × | × | 🗸 |

| UCFP | × | × | × | 🗸 | × | × | × | 🗸 |

| IFP | 🗸 | × | × | × | 🗸 | × | × | 🗸 |

| OLFP | 🗸 | × | × | 🗸 | × | 🗸 | × | 🗸 |

| TFP | 🗸 | 🗸 | × | × | × | 🗸 | 🗸 | 🗸 |

| Underground Cable | Insulator | Overhead Line | Transformer |

|---|---|---|---|

|

|

|

|

| Reference | Method | Data | Maintenance Level | Advantages | Limitations |

|---|---|---|---|---|---|

| [144] | Probabilistic | Current | Prescriptive | Predicting EVs impact on residential load, Considering Different types of DGs and seasonal effects, providing re-schedule charging plan | No solution for high DG penetration, large-scale EV charging, and smart EV charging |

| [145] | Electrical and Electro-acoustic | Leakage Current | Proactive | Using acoustic sensors, enabling wide range of frequency, cost-effective | No predictive procedure, not available for HV cables, not detecting PD level |

| [146] | Probabilistic | Failure rate, Age, Length | Predictive | Prediction of underground cable failures, five models for failure estimation, piecewise constant model | Limited availability of age data, practical implementation, and long-term prediction |

| [147] | ANN | Solar radiance, Temperature | Predictive | predicting anomalies and faults in PV systems, power prediction | Not robust against different conditions and need available data and real-time monitoring |

| [148] | FFT | Vibration, Temperature | Proactive | IoT system, predicting abnormal conditions, using FFT algorithm | Need communication link, vulnerable to cyber attacks, needs additional technical resources for IoT system |

| [149] | Optimization | Power | Prescriptive | No need for infrastructure expansion, provide solution to minimized aggregate load, prevent overload | Accurate load prediction is needed, trade-off between charging efficiency and charging speed is not investigated |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirshekali, H.; Santos, A.Q.; Shaker, H.R. A Survey of Time-Series Prediction for Digitally Enabled Maintenance of Electrical Grids. Energies 2023, 16, 6332. https://doi.org/10.3390/en16176332

Mirshekali H, Santos AQ, Shaker HR. A Survey of Time-Series Prediction for Digitally Enabled Maintenance of Electrical Grids. Energies. 2023; 16(17):6332. https://doi.org/10.3390/en16176332

Chicago/Turabian StyleMirshekali, Hamid, Athila Q. Santos, and Hamid Reza Shaker. 2023. "A Survey of Time-Series Prediction for Digitally Enabled Maintenance of Electrical Grids" Energies 16, no. 17: 6332. https://doi.org/10.3390/en16176332

APA StyleMirshekali, H., Santos, A. Q., & Shaker, H. R. (2023). A Survey of Time-Series Prediction for Digitally Enabled Maintenance of Electrical Grids. Energies, 16(17), 6332. https://doi.org/10.3390/en16176332