Research on the Effect of Fire Thermal Energy on the Microstructure and Properties Mechanical of Fiber-Reinforced Cement Mortars

Abstract

:1. Introduction

2. Materials and Methods

2.1. Cement Mortar

- CEM I, CEM II (without additive): reference mortar;

- CEM II 1, CEM II 2, CEM II 3 (with additive): mortar with the addition of fibers in the amount of 0.5% of the weight of the cement.

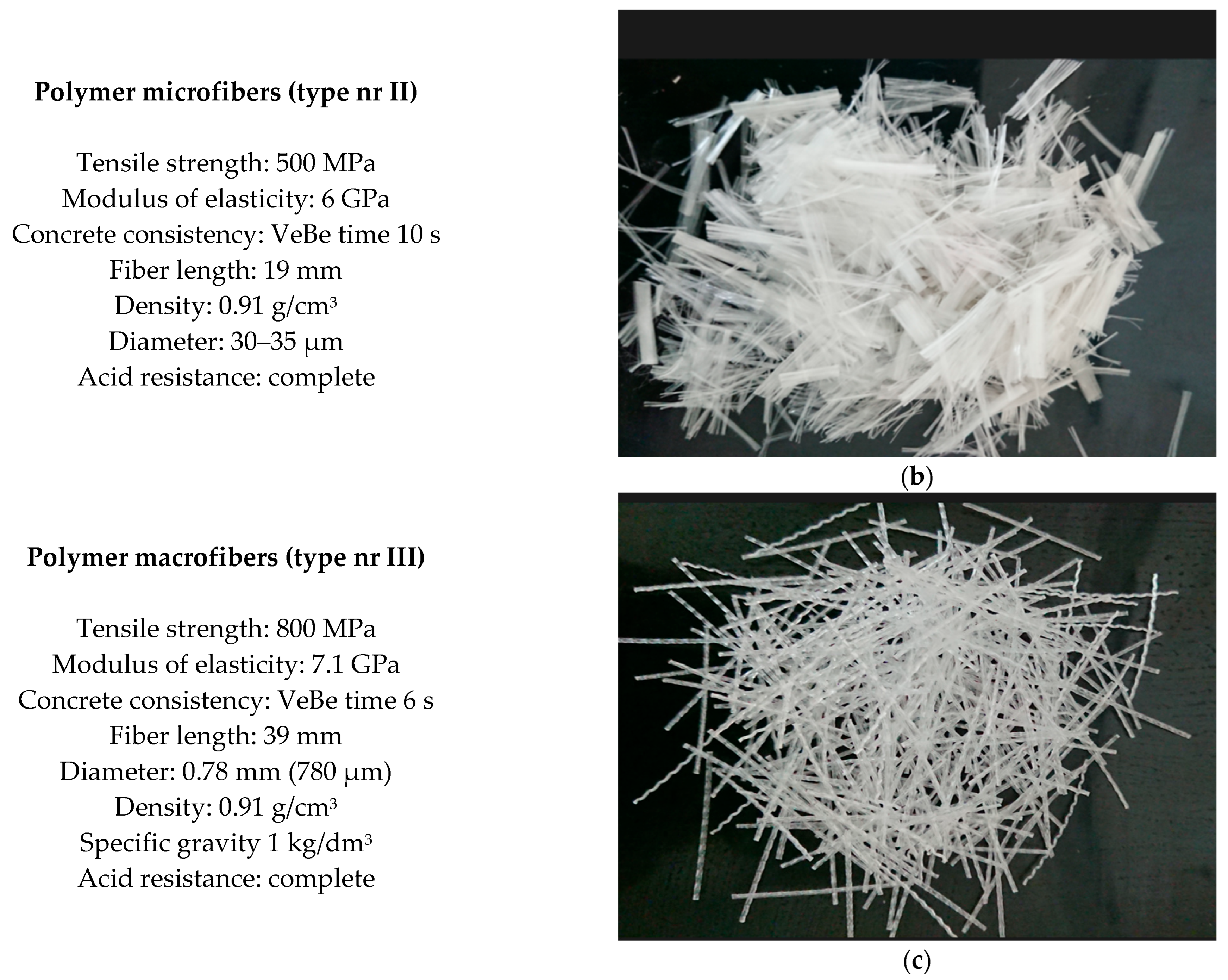

2.2. Fibers

2.3. Methodology of Testing

2.4. Statistical Methods

3. Results and Discussion

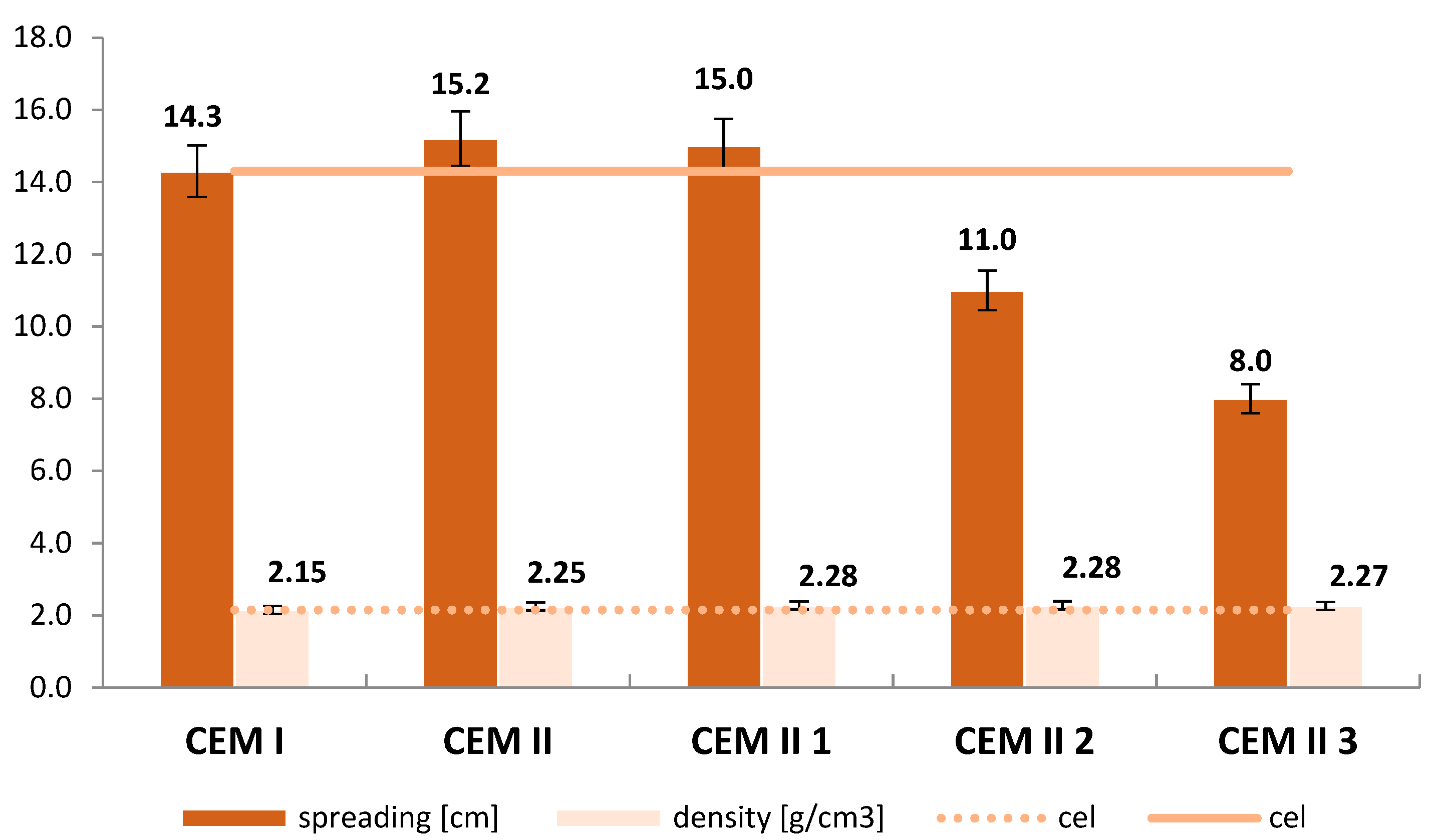

3.1. Consistency

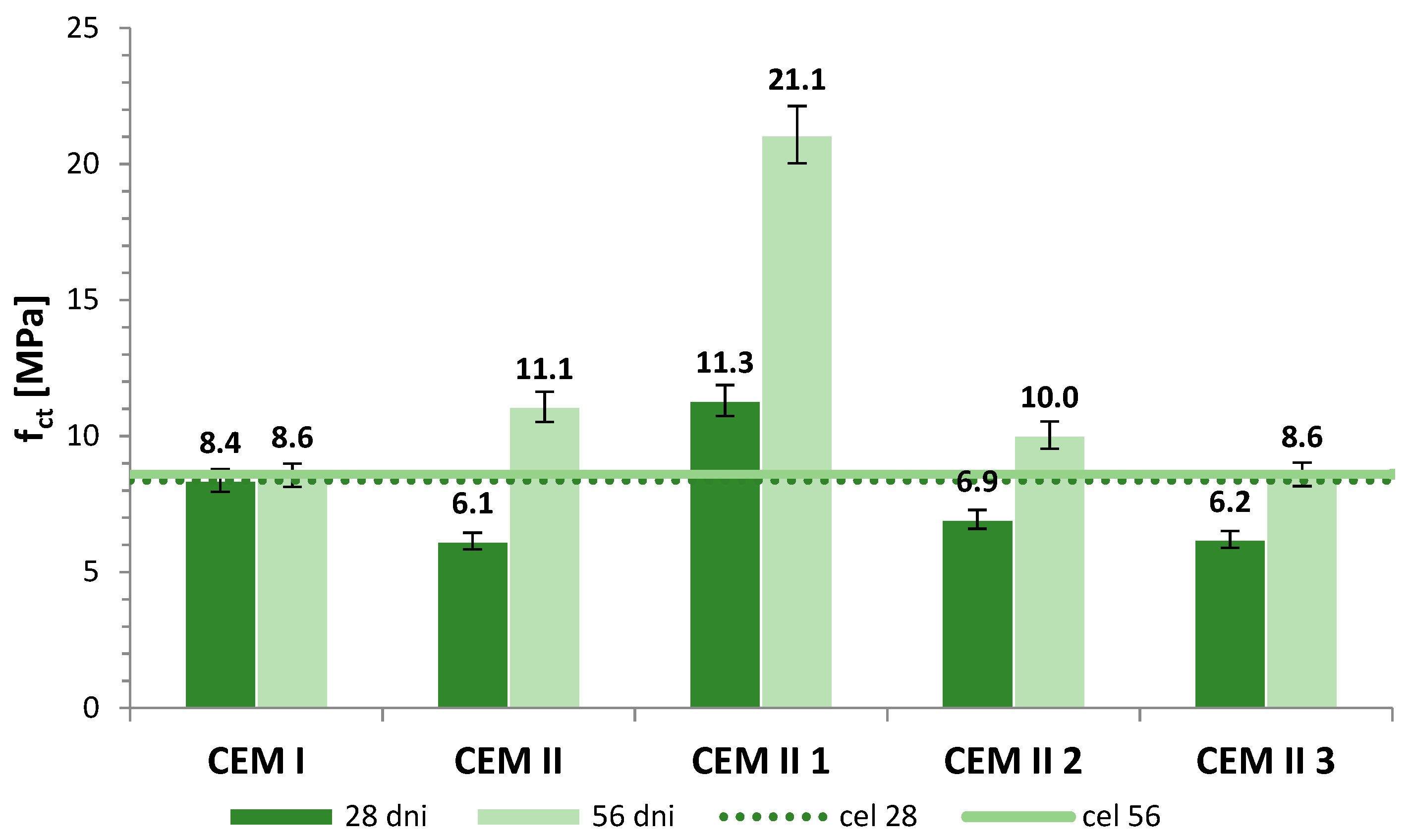

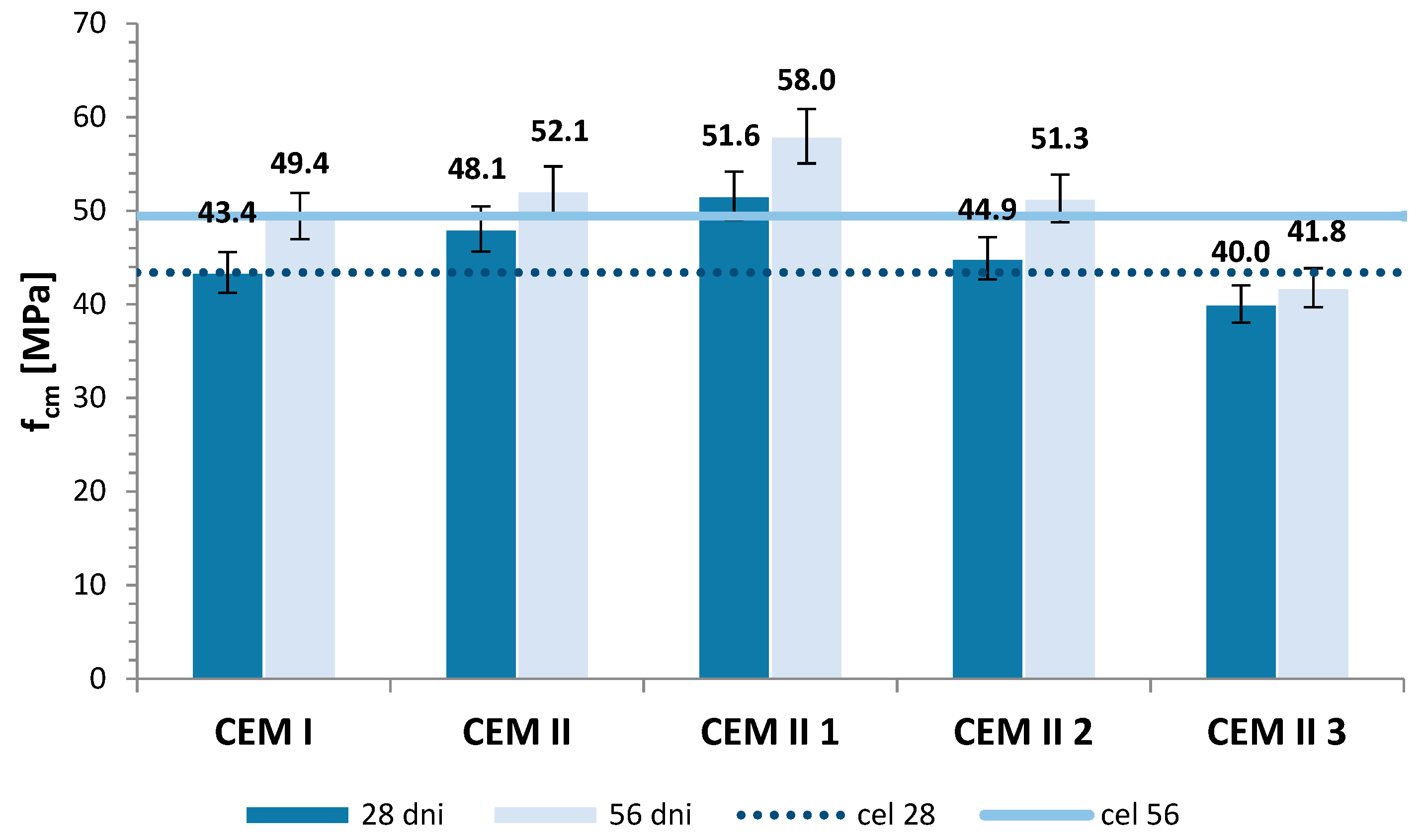

3.2. Compressive and Bending Strength

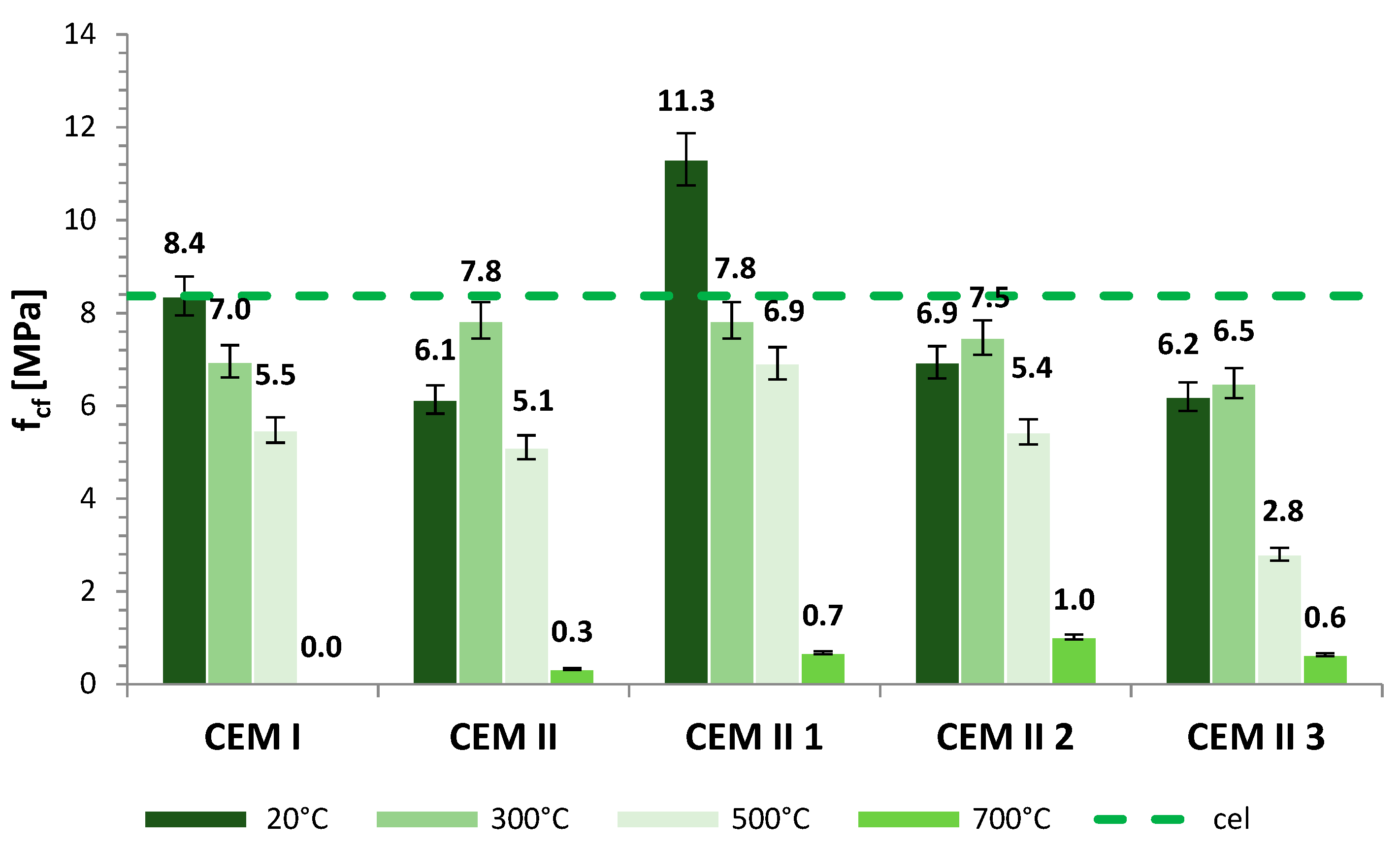

3.3. Influence of High Temperature on Strength

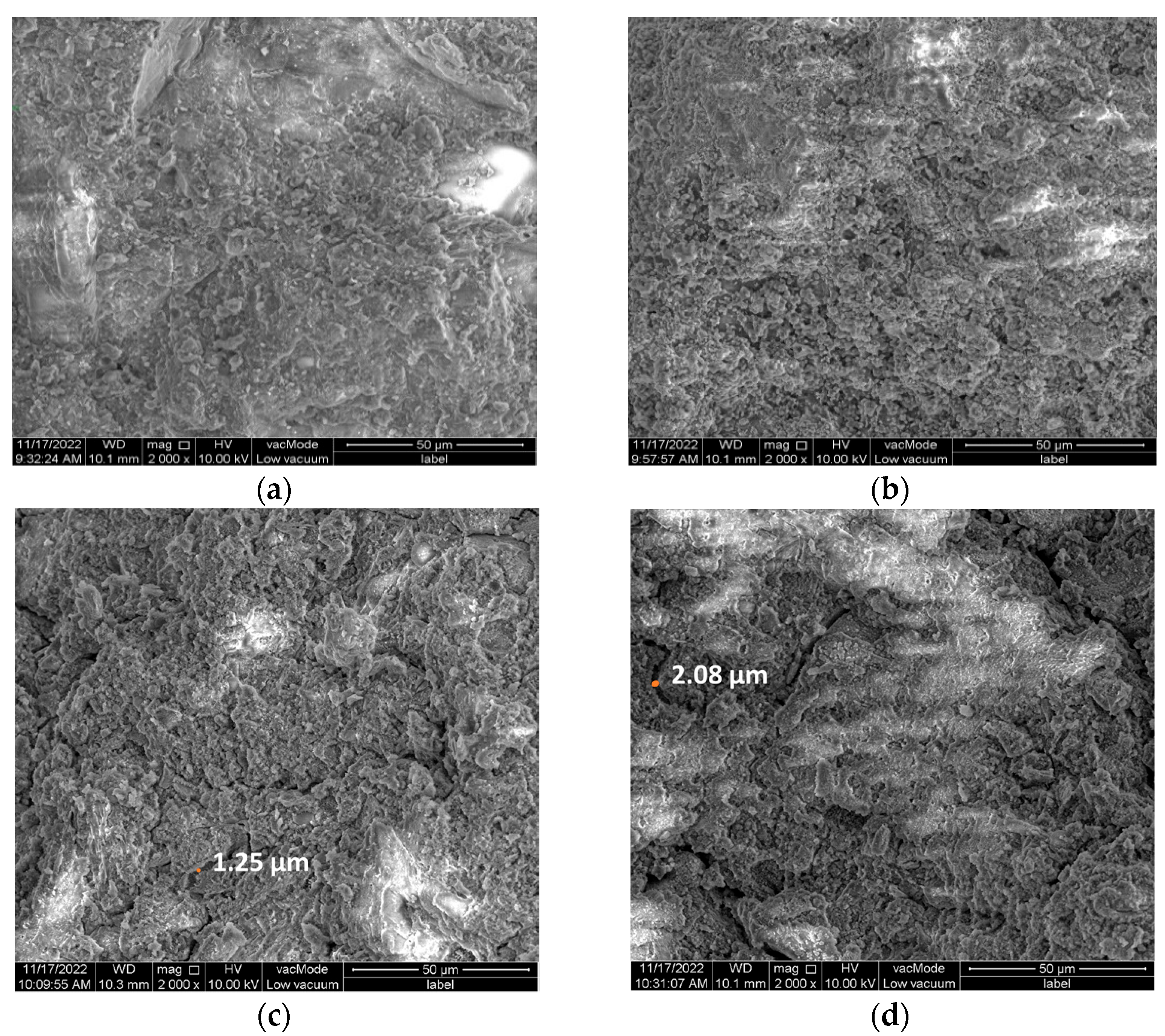

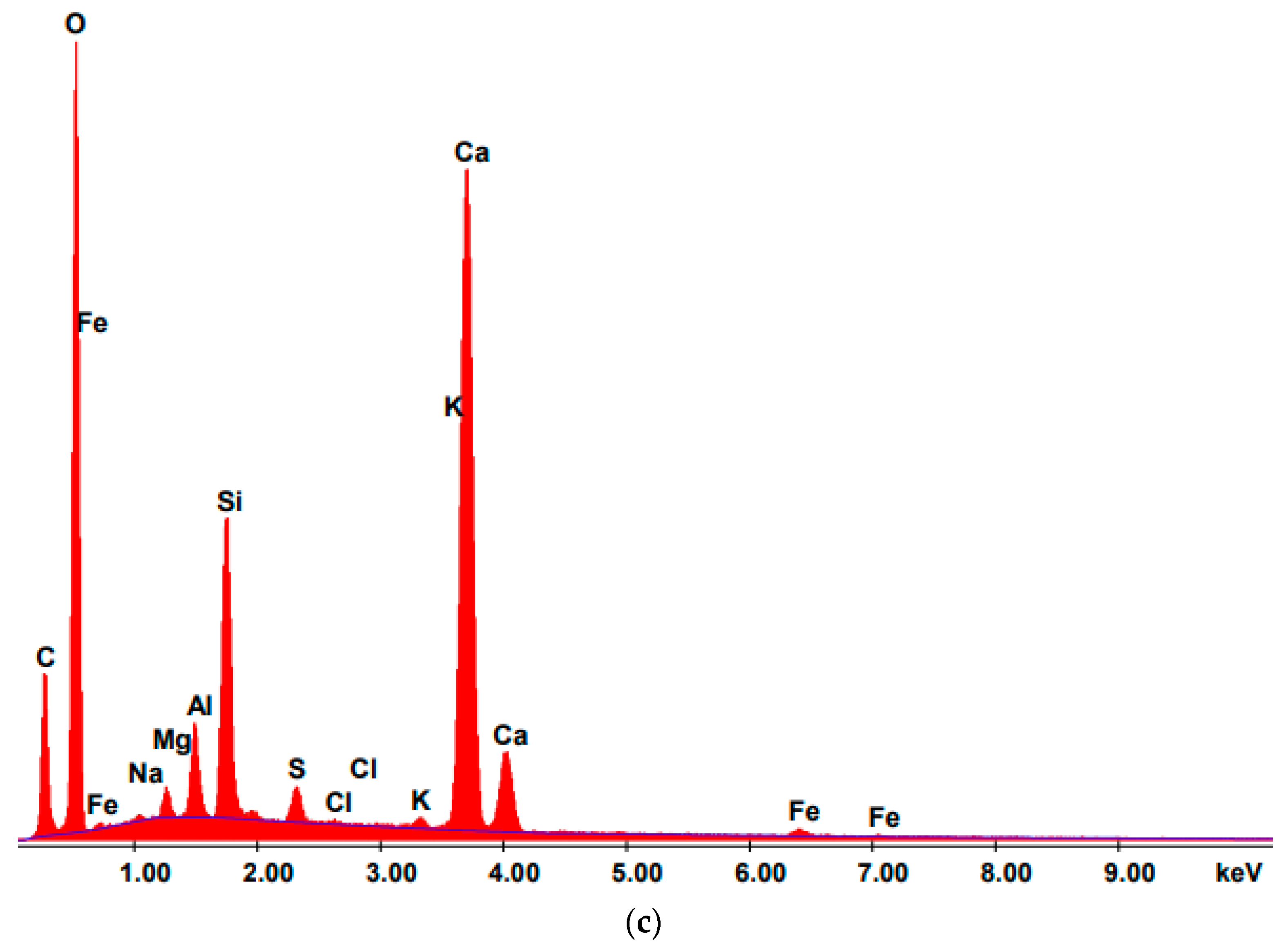

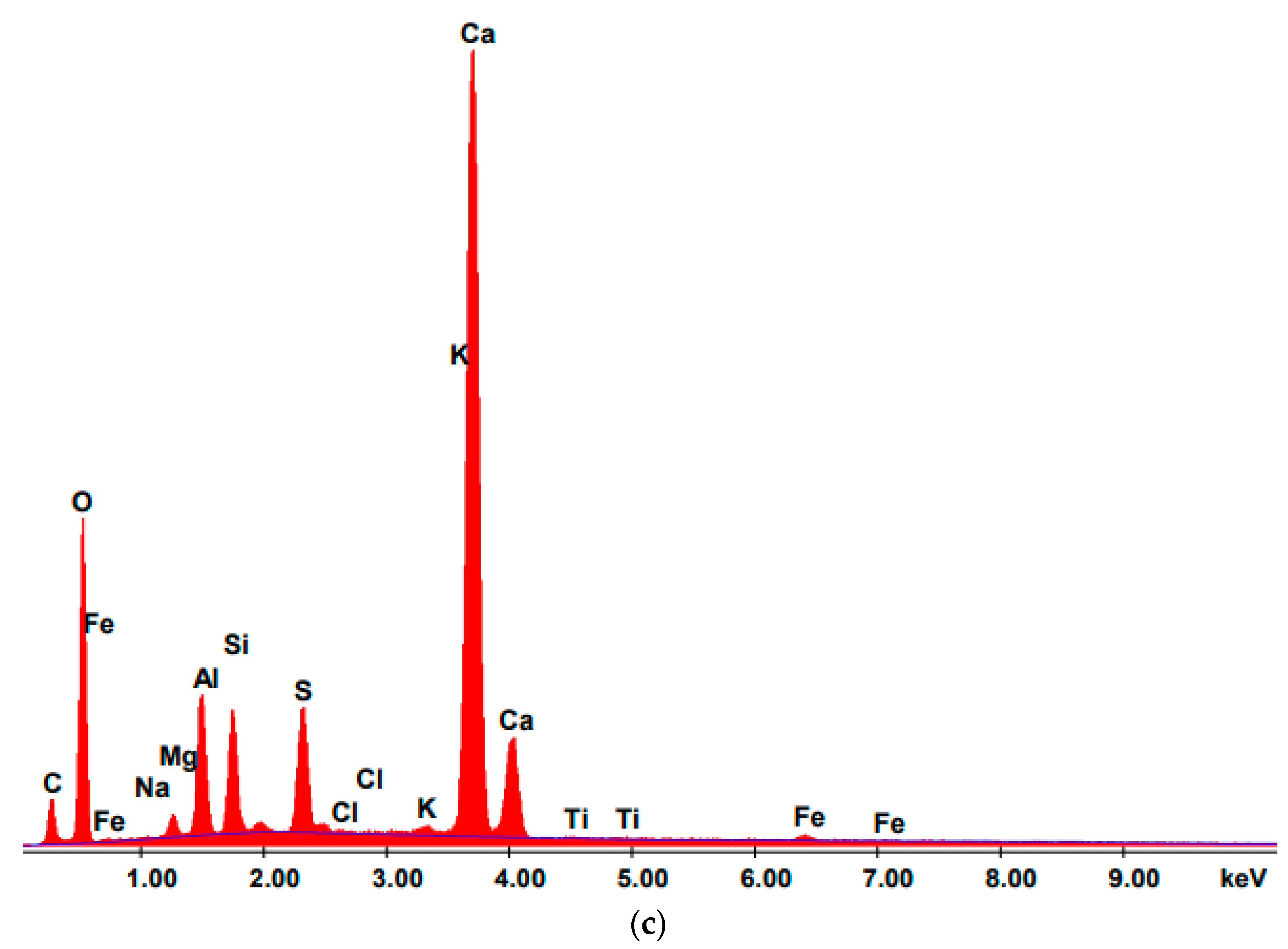

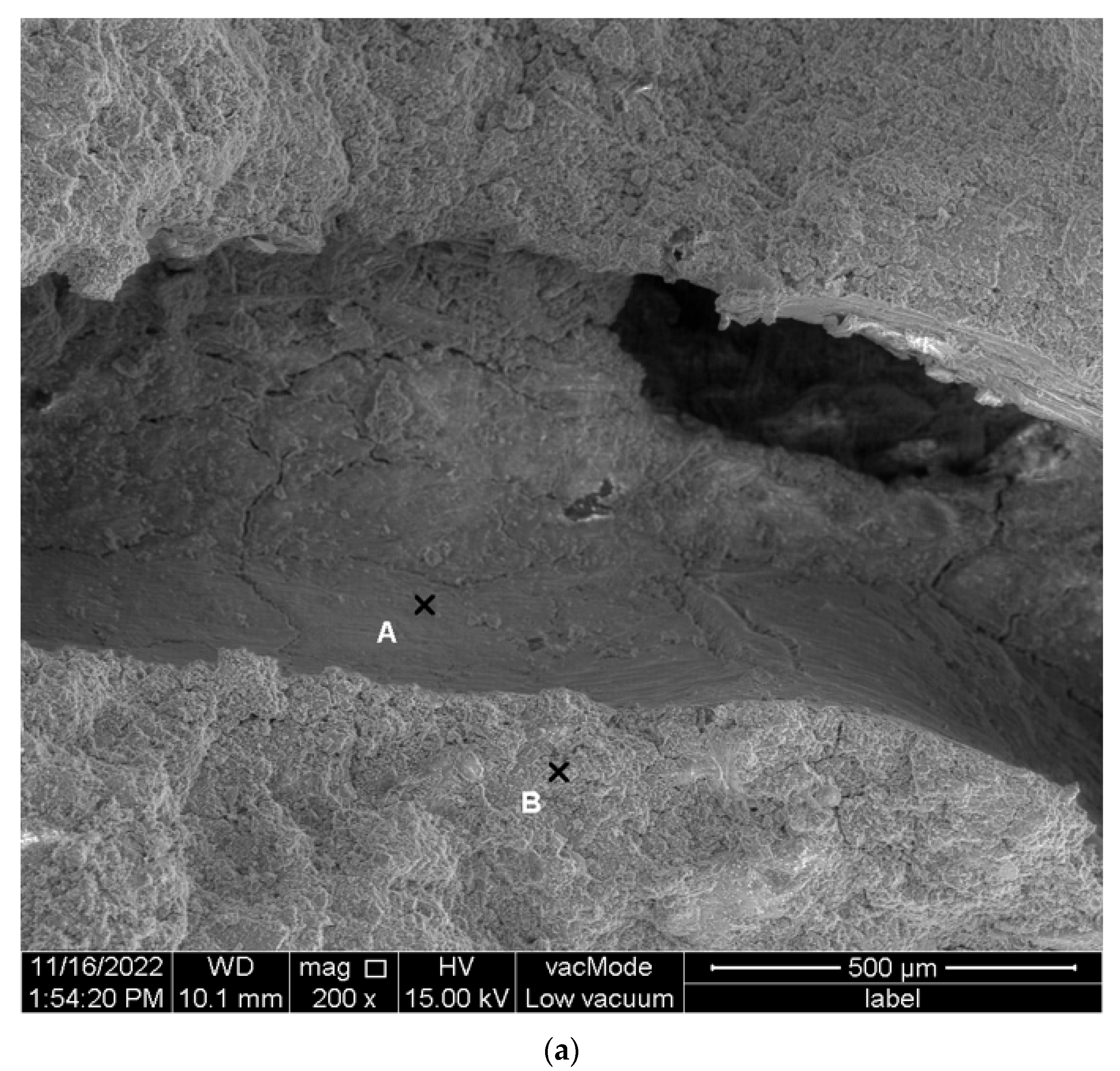

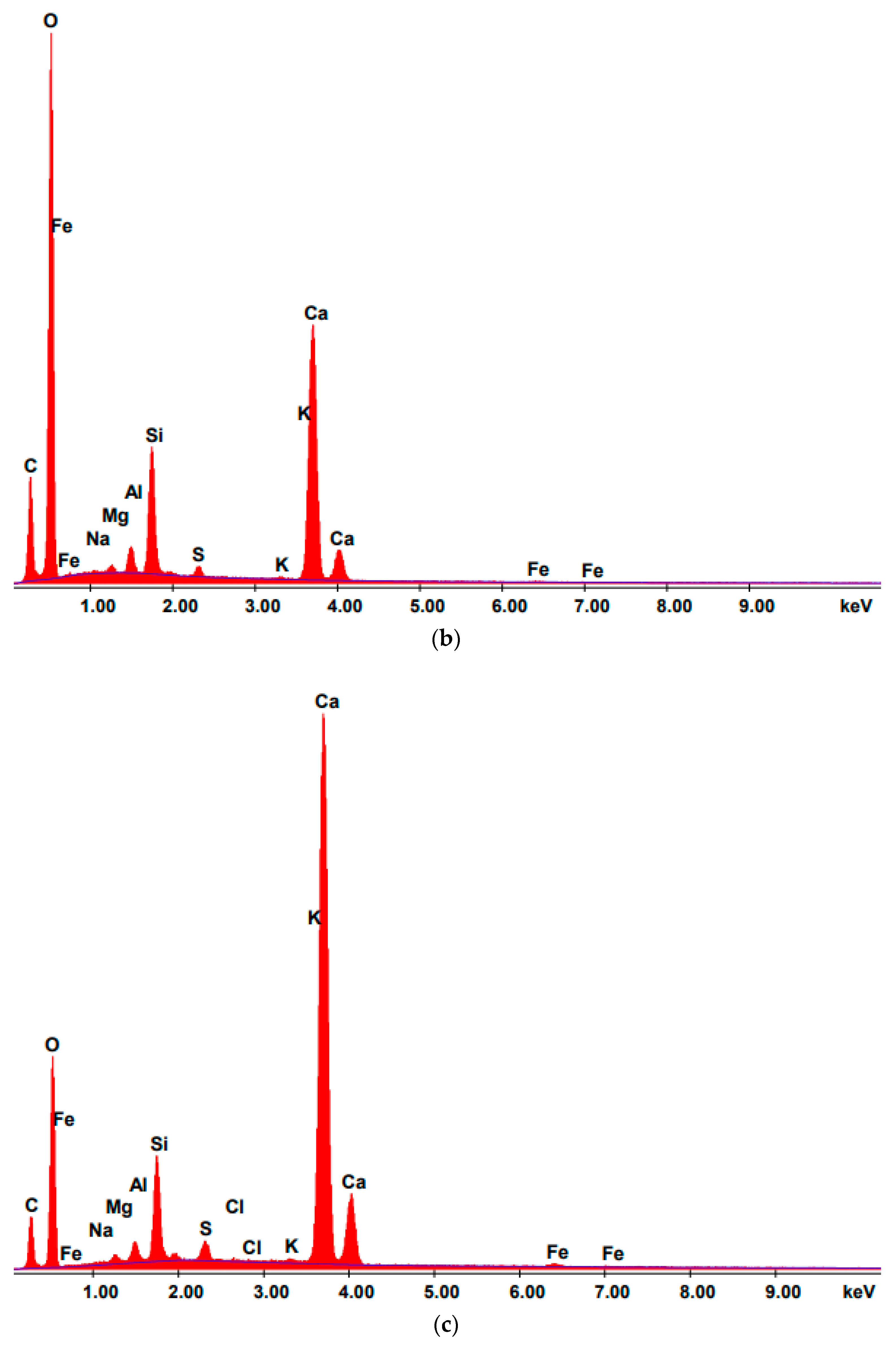

3.4. Test Results of the Structure and Composition of the Samples

4. Conclusions

- The tests of fresh cement mortar showed that the introduction of PPF fibers had a significant effect on consistency. However, much smaller differences occur in the density of the mixture. The results in this area are varied and depend on the type, length and shape of the fibres.

- In all cases tested as part of the strength tests, the samples after 56 days of maturation obtained higher strength. These differences were particularly large for type I fiber and amounted to about 80% for bending strength and 13% for compression in relation to tests carried out after 28 days of maturation.

- It has been shown that the shape and type of PPF fibers have a significant impact on strength at normal temperatures of 20 °C. Type I fibers have the highest strength (higher than reference samples) and type III fibers have the lowest strength. These differences are quite significant.

- Similar to I, during the tests at elevated temperatures, the highest residual strength was shown by type I fibers. Importantly, the addition of fibers of all types resulted in a decrease in the strength decrease both during compression and bending. In general, it can be stated that the addition of PPF fibers has a positive effect on the residual strength of mortars.

- Spalling of samples with PPF fibers was not observed during annealing. This confirms the previous results of studies widely described in the literature.

- The obtained results of the EDS analyses (oxide compositions) are characterized by a large dispersion of the obtained values. It is difficult to clearly indicate the effect of high temperatures on the formation of mortar cracking.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Environment Agency. EEA-Eionet Strategy 2021–2030; European Environment Agency: Copenhagen, Denmark, 2021. [Google Scholar]

- Banthia, N.; Zanotti, C.; Sappakittipakorn, M. Sustainable fiber reinforced concrete for repair applications. Constr. Build. Mater. 2014, 67, 405–412. [Google Scholar] [CrossRef]

- Kulesza, M.; Dębski, D.; Fangrat, J.; Michalak, J. Effect of redispersible polymer powders on selected mechanical properties of thin-bed cementitious mortars. Cem. Wapno Beton 2020, 2020, 168–177. [Google Scholar] [CrossRef]

- Liu, F.; Ding, W.; Qiao, Y. An experimental investigation on the integral waterproofing capacity of polypropylene fiber concrete with fly ash and slag powder. Constr. Build. Mater. 2019, 212, 675–686. [Google Scholar] [CrossRef]

- Sabet, F.A.; Libre, N.A.; Shekarchi, M. Mechanical and durability properties of self consolidating high performance concrete incorporating natural zeolite, silica fume and fly ash. Constr. Build. Mater. 2013, 44, 175–184. [Google Scholar] [CrossRef]

- Rudnicki, T.; Wołoszka, P. The use of technology whitetopping in the aspect of implementation of repairs of flexible pavements. Bull. Mil. Univ. Technol. 2016, 65, 3. [Google Scholar] [CrossRef]

- Limbachiya, M.; Meddah, M.S.; Ouchagour, Y. Use of recycled concrete aggregate in fly-ash concrete. Constr. Build. Mater. 2012, 27, 439–449. [Google Scholar] [CrossRef]

- Klimek, B.; Szulej, J.; Ogrodnik, P. The effect of replacing sand with aggregate from sanitary ceramic waste on the durability of stucco mortars. Clean Technol. Environ. Policy 2020, 22, 1929–1941. [Google Scholar] [CrossRef]

- Kadela, M.; Kukiełka, A. Influence of foaming agent content in fresh concrete on elasticity modulus of hard foam concrete. In Brittle Matrix Composites 11, Proceedings of the 11th International Symposium on Brittle Matrix Composites BMC 2015, Warsaw, Poland, 28–30 September 2015; Institute of Fundamental Technological Research PAS: Warsaw, Poland, 2015; pp. 489–496. [Google Scholar]

- Rudnicki, T.; Jurczak, R. Recycling of a Concrete Pavement after over 80 Years in Service. Materials 2020, 13, 2262. [Google Scholar] [CrossRef]

- Osborne, G.J. Durability of Portland blast-furnace slag cement concrete. Cem. Concr. Compos. 1999, 21, 11–21. [Google Scholar] [CrossRef]

- De Domenico, D.; Faleschini, F.; Pellegrino, C.; Ricciardi, G. Structural behavior of RC beams containing EAF slag as recycled aggregate: Numerical versus experimental results. Constr. Build. Mater. 2018, 171, 321–337. [Google Scholar] [CrossRef]

- Ogrodnik, P.; Zegardło, B.; Radzikowska, M. Use of post-production sanitary ceramic waste as a filler in cement composites of high chemical resistance. Przem. Chem. 2017, 96, 1100–1104. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Hansu, O.; Etli, S.; Alhassan, M. Mechanical and fracture characteristics of self-compacting concretes containing different percentage of plastic waste powder. Constr. Build. Mater. 2017, 140, 562–569. [Google Scholar] [CrossRef]

- Asokan, P.; Osmani, M.; Price, A.D.F. Improvement of the mechanical properties of glass fibre reinforced plastic waste powder filled concrete. Constr. Build. Mater. 2010, 24, 448–460. [Google Scholar] [CrossRef]

- Jackowski, M.; Małek, M.; Życiński, W.; Łasica, W.; Owczarek, M. Characterization of new recycled polymers shots addition for the mechanical strength of concrete. Mater. Tehnol. 2020, 54, 355–358. [Google Scholar] [CrossRef]

- Hama, S.M.; Hilal, N.N. Fresh properties of self-compacting concrete with plastic waste as partial replacement of sand. Int. J. Sustain. Built Environ. 2017, 6, 299–308. [Google Scholar] [CrossRef]

- Choi, Y.W.; Moon, D.J.; Chumg, J.S.; Cho, S.K. Effects of waste PET bottles aggregate on the properties of concrete. Cem. Concr. Compos. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibers in concrete: A review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Kim, S.B.; Yi, N.H.; Kim, H.Y.; Kim, J.H.J.; Song, Y.C. Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cem. Concr. Res. 2010, 32, 232–240. [Google Scholar] [CrossRef]

- Szcześniak, A.; Stolarski, A. Dynamic Relaxation Method for Load Capacity Analysis of Reinforced Concrete Elements. Appl. Sci. 2018, 8, 396. [Google Scholar] [CrossRef]

- Jiang, C.; Huang, S.; Zhu, Y.; Lin, Y.; Chen, D. Effect of polypropylene and basalt fiber on the behavior of mortars for repair applications. Adv. Mater. Sci. Eng. 2016, 2016, 14–16. [Google Scholar] [CrossRef]

- Padalu, P.K.V.R.; Singh, Y.; Das, S. Efficacy of basalt fibre reinforced cement mortar composite for out-of-plane strengthening of unreinforced masonry. Constr. Build. Mater. 2018, 191, 1172–1190. [Google Scholar] [CrossRef]

- Lignola, G.P.; Caggegi, C.; Ceroni, F.; de Santis, S.; Krajewski, P.; Lourenço, P.B.; Morganti, M.; Papanicolaou, C.; Pellegrino, C.; Prota, A.; et al. Performance assessment of basalt FRCM for retrofit applications on masonry. Compos. Part B Eng. 2017, 128, 1–18. [Google Scholar] [CrossRef]

- Simoes, T.; Costa, H.; Dias-da-Costa, D.; Júlio, E. Influence of type and dosage of micro-fibres on the physical properties of fibre reinforced mortar matrixes. Constr. Build. Mater. 2018, 187, 1277–1285. [Google Scholar] [CrossRef]

- Li, L.G.; Zhuo, H.X.; Zhu, J.; Kwan, A.K.H. Packing density of mortar containing polypropylene, carbon or basalt fibres under dry and wet conditions. Powder Technol. 2019, 342, 433–440. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Łagód, G.; Fic, S.; Jarosz-Hadam, M. Effect of polysiloxanes on roughness and durability of basalt fibres-reinforced cement mortar. Polymers 2018, 10, 420. [Google Scholar] [CrossRef] [PubMed]

- Atiyeh, M.; Aydin, E. Carbon-Fiber Enriched Cement-Based Composites for Better Sustainability. Materials 2020, 13, 1899. [Google Scholar] [CrossRef] [PubMed]

- Song, P.S.; Hwang, S.; Sheu, B.C. Strength properties of nylon- and polypropylene fibre reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. The effects of silica fume and polypropylene fibres on the impact resistance and mechanical properties of concrete. Constr. Build. Mater. 2010, 24, 927–933. [Google Scholar] [CrossRef]

- Karahan, O.; Atis, C.D. The durability properties of polypropylene fiber reinforced fly ash concrete. Mater. Des. 2011, 32, 1044–1049. [Google Scholar] [CrossRef]

- Habib, A.; Begum, R.; Alam, M.M. Mechanical Properties of Synthetic Fibers Reinforced Mortars. Int. J. Sci. Eng.Res. 2013, 4, 923–927, ISSN 2229-5518. [Google Scholar]

- Ponikiewski, T.; Szwabowski, J. Influence of the Type of Fibers on the Workability of Mortars; Publishing House of the Cracow University of Technology: Krakow, Poland, 2003; pp. 364–371. [Google Scholar]

- Ezerskiy, V.; Lelusz, M. Influence of anti-frost admixtures and cement class on the strength of cement mortars. Civ. Environ. Eng. 2010, 1, 111–116. [Google Scholar] [CrossRef]

- Drzymała, T.; Zegardło, T.; Jackiewicz-Rek, W.; Sowiński, D. The Effect of High Temperatures on the Flexural Strength of Cement Mortar Modified by the Addition of Polypropylene Fibres. Saf. Fire Technol. 2018, 51, 26–39. [Google Scholar] [CrossRef]

- EN-197-1:2011; Cement—Part 1: Composition, Requirements and Conformity Criteria for Common Cements. BSI: London, UK, 2011.

- PN-B-19707:2023-05; Cement—Special Cement—Composition, Requirements and Compliance Criteria. PKN: Warszawa, Polska, 2023.

- EN 196-1:2016-07; Cement Test Methods—Part 1: Determination of Strength. BSI: London, UK, 2016.

- Parameters of Pure Cement CEM I 42.5 R. Available online: https://ozarow.com.pl/p-cem-i-42-5-r-luz-cement-czysty (accessed on 8 August 2023).

- Size Distribution of Standard Sand Grains. Available online: https://kwarcmix.pl/ (accessed on 7 August 2023).

- EN 14889-2:2007; Concrete Fibers—Part 2: Polymer Fibers—Definitions, Requirements and Compliance. BSI: London, UK, 2007.

- Data from the Fiber Manufacturer. Available online: https://wigolen.com.pl/kategoria/wlokna-polipropylenowe/ (accessed on 7 August 2023).

- EN 1015-3:2000; Test Methods for Mortars for Masonry—Determination of the Consistency of Fresh Mortar (Using Flow Table). BSI: London, UK, 2000.

- EN 1015-6:2000; Test Methods for Mortars for Masonry—Determination of Bulk Density of Fresh Mortar. BSI: London, UK, 2000.

- Powęzka, A.; Ogrodnik, P.; Szulej, J.; Pecio, M. Glass cullet as additive to new sustainable composites based on alumina binder. Energies 2021, 14, 3423. [Google Scholar] [CrossRef]

- EN 1363-1:2020-07; Fire Resistance Tests—Part 1: General Requirements. BSI: London, UK, 2020.

- Powęzka, A.; Szulej, J.; Ogrodnik, P. Reuse of Heat Resistant Glass Cullet in Cement Composites Subjected to Thermal Load. Materials 2020, 13, 4434. [Google Scholar] [CrossRef] [PubMed]

- Win, T.T.; Jongvivatsakul, P.; Jirawattanasomkul, T.; Prasittisopin, L.; Likitlersuang, S. Use of polypropylene fibers extracted from recycled surgical face masks in cement mortar. Constr. Build. Mater. 2023, 391, 131845. [Google Scholar] [CrossRef]

- Chen, H.; Huang, X.; He, R.; Zhou, Z.; Fu, C.; Wang, J. Mechanical properties of polypropylene fiber cement mortar under different loading speeds. Sustainability 2021, 13, 3697. [Google Scholar] [CrossRef]

- Feng, H.; Gao, D.Y.; Yuan, J. The mechanical properties of polypropylene fiber reinforced polymer modified cement mortar. Appl. Mech. Mater. 2013, 438–439, 283–289. [Google Scholar] [CrossRef]

- Ogrodnik, P.; Szulej, J. The impact of aeration of concrete based on ceramic aggregate, exposed to high temperatures, on its strength parameters. Constr. Build. Mater. 2017, 157, 909–916. [Google Scholar] [CrossRef]

- Jean-Christophe Mindeguia Pierre Pimienta Albert Noumowé Mulumba Kanema Temperature, pore pressure and mass variation of concrete subjected to high temperature—Experimental and numerical discussion on spalling risk. Cem. Concr. Res. 2010, 40, 477–487. [CrossRef]

- Kalifa, P.; Chene, G.; Galle, C. High-temperature behaviour of HPC with polypropylene fibres: From spalling to microstructure. Cem. Concr. Res. 2001, 31, 1487–1499. [Google Scholar] [CrossRef]

- Nuaklong, P.; Boonchoo, N.; Jongvivatsakul, P.; Charinpanitkul, T. Hybrid effect of carbon nanotubes and polypropylene fibers on mechanical properties and fire resistance of cement mortar. Constr. Build. Mater. 2021, 275, 122189. [Google Scholar] [CrossRef]

- Boqiao, Y.Y.; Zhuge, W.Y.; Zhuge, Y.; Huang, Z. Properties of hybrid basalt-polypropylene fiber reinforced mortar at different temperatures. Constr. Build. Mater. 2022, 346, 128433. [Google Scholar] [CrossRef]

| Parameters | Standard Requirements PN-EN 197-1 | Average Values Achieved |

|---|---|---|

| Compressive strength, MPa | ||

| after 2 days | ≥20 | 28.6 |

| after 28 days | ≥42.5 ≤ 62.5 | 58.2 |

| Loss on ignition, % | ≤5.0 | 2.88 |

| The residue is insoluble, % | ≤5.0 | 0.83 |

| Sulphate content SO3, % | ≤4.0 | 2.65 |

| Chloride content Cl−, % | ≤0.10 | 0.04 |

| Start of setting time, min | ≤10 | 197 |

| Consistency, mm | ≤10 | 0.1 |

| Specific surface, cm2/g | no requirements | 3802 |

| Alkali content Na2Oeq | no requirements | 0.67 |

| Square mesh side dimension, mm | 2.00 | 1.60 | 1.00 | 0.50 | 0.16 | 0.08 |

| Total sieve residue, % | 0 | 7 ± 5 | 33 ± 5 | 67 ± 5 | 87 ± 5 | 99 ± 1 |

| Specification | Mass of Concrete Ingredients, g | |||

|---|---|---|---|---|

| Aggregate | Water | Cement | Fibers | |

| CEM I, CEM II | 1350 | 225 | 450 | - |

| CEM II 1, CEM II 2, CEM II 3 | 1350 | 225 | 405 | 41 |

| Variable | Descriptive Statistics (Mortars with Fiber) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Valid N | Mean | Median | Mode | Minimum | Maximum | Variance | Standard Deviation | Standard Error | Skewness | Standard Error Skewness | Kurtosis | Standard Error Kurtosis | |

| Flexural 20 °C | 25 | 7.8 | 7.0 | 6.57 | 5.4 | 12.7 | 4.290 | 2.071 | 0.414 | 1.055 | 0.464 | 0.188 | 0.902 |

| Flexural 300 °C | 25 | 7.3 | 7.1 | 6.81 | 6.1 | 9.4 | 0.626 | 0.791 | 0.158 | 0.725 | 0.464 | 0.284 | 0.902 |

| Flexural 500 °C | 25 | 5.2 | 5.4 | 5.40 | 2.3 | 7.3 | 1.935 | 1.391 | 0.278 | −0.694 | 0.464 | −0.026 | 0.902 |

| Flexural 700 °C | 25 | 0.5 | 0.5 | 0.001 | 0.0 | 1.2 | 0.148 | 0.385 | 0.077 | 0.168 | 0.464 | −0.830 | 0.902 |

| Compressive 20 °C | 25 | 45.6 | 45.0 | 50.94 | 39.1 | 53.4 | 17.565 | 4.191 | 0.838 | 0.295 | 0.464 | −1.096 | 0.902 |

| Compressive 300 °C | 25 | 43.3 | 42.5 | 0.001 | 34.1 | 53.1 | 28.976 | 5.383 | 1.077 | 0.414 | 0.464 | −0.685 | 0.902 |

| Compressive 500 °C | 25 | 29.6 | 26.9 | 0.001 | 20.9 | 40.3 | 33.531 | 5.791 | 1.158 | 0.582 | 0.464 | −0.872 | 0.902 |

| Compressive 700 °C | 25 | 13.0 | 13.1 | 14.06 | 7.5 | 18.4 | 10.206 | 3.195 | 0.639 | −0.023 | 0.464 | −0.914 | 0.902 |

| Temperature | Measurement Site | CaO | SiO2 | Al2O5 | Fe2O3 |

|---|---|---|---|---|---|

| 20 °C | fiber site | 41.54 | 26.68 | 5.85 | 1.52 |

| binder | 51.36 | 17.62 | 5.54 | 2.00 | |

| 300 °C | fiber site | 59.71 | 4.25 | 1.10 | 0.41 |

| binder | 63.59 | 4.41 | 1.95 | 0.55 | |

| 500 °C | fiber site | 65.54 | 10.75 | 2.66 | 0.76 |

| binder | 63.75 | 7.60 | 9.33 | 1.64 | |

| 700 °C | fiber site | 47.77 | 17.53 | 4.02 | 0.65 |

| binder | 62.39 | 11.90 | 2.98 | 1.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogrodnik, P.; Rutkowska, G.; Powęzka, A.; Żółtowski, M.; Szulej, J.; Wiśniewski, K.; Howorus, P. Research on the Effect of Fire Thermal Energy on the Microstructure and Properties Mechanical of Fiber-Reinforced Cement Mortars. Energies 2023, 16, 6450. https://doi.org/10.3390/en16186450

Ogrodnik P, Rutkowska G, Powęzka A, Żółtowski M, Szulej J, Wiśniewski K, Howorus P. Research on the Effect of Fire Thermal Energy on the Microstructure and Properties Mechanical of Fiber-Reinforced Cement Mortars. Energies. 2023; 16(18):6450. https://doi.org/10.3390/en16186450

Chicago/Turabian StyleOgrodnik, Paweł, Gabriela Rutkowska, Aleksandra Powęzka, Mariusz Żółtowski, Jacek Szulej, Krzysztof Wiśniewski, and Patryk Howorus. 2023. "Research on the Effect of Fire Thermal Energy on the Microstructure and Properties Mechanical of Fiber-Reinforced Cement Mortars" Energies 16, no. 18: 6450. https://doi.org/10.3390/en16186450

APA StyleOgrodnik, P., Rutkowska, G., Powęzka, A., Żółtowski, M., Szulej, J., Wiśniewski, K., & Howorus, P. (2023). Research on the Effect of Fire Thermal Energy on the Microstructure and Properties Mechanical of Fiber-Reinforced Cement Mortars. Energies, 16(18), 6450. https://doi.org/10.3390/en16186450