1. Introduction

Wood-plastic composites (WPCs) are produced by combining a polymeric matrix with wood particles, with this matrix potentially composed of either virgin or post-consumer polymers [

1]. These composites find extensive application across various sectors, such as construction, furniture manufacturing, transportation, technology, and other areas [

2].

Polymeric-origin composites are manufactured from at least two components: a matrix, usually taking the form of a polymeric phase, and a reinforcing or filling agent. These components do not homogeneously mix, resulting in a well-defined interface between phases. Full fusion into a solid solution does not occur, resulting in a clear demarcation between the matrix and the reinforcement. In many cases, the production of a composite aims to achieve specific characteristics and properties that would not be feasible to attain individually for each component. The primary function of the matrix is to transfer stress to the reinforcing agent. These reinforcements can take the form of particulate, lamellar, or fibrous materials (continuous or discontinuous). The interface, in turn, is identified as the interface region between the matrix and the reinforcing agent, marking a discontinuity of limited dimensions within the material where properties experience a sudden alteration from one phase to the other [

3]. In various situations, to facilitate the incorporation of loads into thermoplastic polymers, it becomes necessary to resort to compatibility agents, also recognized as coupling agents [

4]. Additionally, it is possible to use residues from wood and plastic consumption, further contributing to the sustainability of the manufacturing process [

5].

The manufacturing process of wood-plastic composites encompasses the combination of polymeric matrices, such as polypropylene (PP), polyethylene (PE), and polyvinyl chloride (PVC), together with lignocellulosic material, which can be fragmented into wood chips or particles. These proportions can vary between 30% and 70%, as mentioned in [

6]. The subsequent blend undergoes stages in equipment such as extruders and injectors, which are responsible for producing both the composites and their respective artifacts [

7]. The extrusion procedure that combines wood and plastic results in a material that retains its original appearance but presents superior attributes such as enhanced robustness, increased flexibility, and greater resistance to climatic adversities. These qualities, stemming from the properties of the employed plastics, lead to reduced maintenance needs and extended durability, as pointed out by [

8].

Plastics can be classified into two categories: thermoplastics and thermosetting, delineated by their preparation process and thermal response. Thermoplastics exhibit the ability to soften and flow when heated, allowing for molding according to the desired shape. This transition characterizes a reversible physical change. In contrast, thermosetting polymers emerge from polymerization that leads to the formation of cross-links between chains, rendering them permanently rigid, a phenomenon known as curing. Consequently, they become impervious to subsequent melting, insoluble, and not amenable to recycling [

9].

The growing demand for plastic products is driven by the application, convenience, durability, and versatility these materials offer society and current consumption patterns. However, it is regrettable that the inadequate disposal of these products is resulting in significant and, in some cases, irreversible damage to the environment [

10]. Improper plastic disposal leads to adverse impacts on the environment and human health, resulting in soil, freshwater, and ocean contamination. Furthermore, the increasing ingestion of plastic nanoparticles by humans and other species through food and drinking water raises uncertainties about their overall effects. Improper plastic disposal has a devastating impact on natural ecosystems and contributes to climate change, as carbon dioxide emissions increase annually due to the growing production and incineration of plastic waste [

11].

Pollution by plastics is particularly concerning on a global scale in aquatic environments. Due to the low density of plastics, they tend to float, disperse, and slowly accumulate, persisting in the environment for prolonged periods. This highlights the urgency of developing and implementing more sustainable approaches to plastic production, use, and lifecycle management [

11]. Furthermore, it is crucial to explore options that promote circular economy models, avoiding significant negative social and environmental impacts [

12].

The circular economy aims to transform traditional systems of production and consumption, often linear in nature, leading to the depletion of natural resources and excessive waste generation. The goal is to establish more sustainable and closed-loop systems where materials are continuously reused. In the realm of plastics, the circular economy seeks to reduce the reliance on virgin raw materials, which often require intensive extraction of natural resources and have a significant environmental impact. Instead, the focus is on reusing and recycling existing plastics, creating a continuous cycle of use. In the context of plastic recycling, the circular economy not only reduces the environmental impact associated with plastics but also brings about economic benefits. This includes resource conservation and the potential for job creation in the recycling and reuse industries. By embracing the principles of the circular economy, societies can pave the way for a more sustainable management of plastics, effectively addressing both environmental and economic concerns [

11].

Given this scenario, the use of post-consumer plastics in the production of new materials through recycling emerges as an essential measure to mitigate the environmental impact of polymeric waste. Creating new materials from these residues can replace conventional materials like wood and steel. Plastic waste recycling can be performed through mechanical, chemical, or energetic means. Mechanical recycling, in particular, not only reduces the impacts of improper disposal and landfilling but also decreases the consumption of fossil or natural raw materials used in the production of virgin polymers [

2,

12,

13]. Creating new materials from waste aligns with the trend of the circular economy, which seeks to reduce the extraction of natural and energy resources, minimize waste generation, and optimize the use of existing materials [

13].

In this context, this study aims to conduct a systematic review using the PRISMA methodology to assess recent research on wood-plastic composites produced from post-consumer plastics. In this context, this study aims to conduct a systematic review using the PRISMA methodology to assess recent research on wood-plastic composites produced from post-consumer plastics.

The following questions will be addressed:

What are the commonly used post-consumer plastics as substitutes for virgin plastics in composites?

What are the percentage compositions of wood and plastic in these composites?

Which shaping processes are commonly employed in their manufacturing?

What is the mechanical behavior of these composites?

Can the thermal behavior of composites produced from recycled plastics influence thermal comfort and impact energy efficiency when used in construction materials?

What are the recommended ideal compositions of post-consumer plastics and plant-based fillers for composite production, as suggested by the authors?

Are these composites considered sustainable products by the authors?

By comprehending the findings of these recent studies, valuable insights can be gained into the feasibility, challenges, and opportunities of applying plastic waste to composites used in construction, thereby contributing to a more sustainable and conscientious approach to waste management and material production.

2. Methodology

Initially, an exploratory analysis (

Figure 1) was conducted to find relevant articles using the keywords “composites”, “wood-plastic”, and “recycling” on the Google Scholar database, without limitation of the publication year. This exploratory search identified 5770 articles. Based on the recurrence analysis of some articles found in this search, the databases to be consulted in this review were selected, along with the definition of the objective and keywords to obtain specific articles related to the topic of interest.

The chosen databases were Science Direct, Periódicos CAPES, Scielo, and the search was conducted in English. To expand the number of relevant articles on the topic, the defined keywords were “wood plastic composites”, “WPC”, “Polymer”, “recycled”, “waste”, “construction”, and “sustainability.”

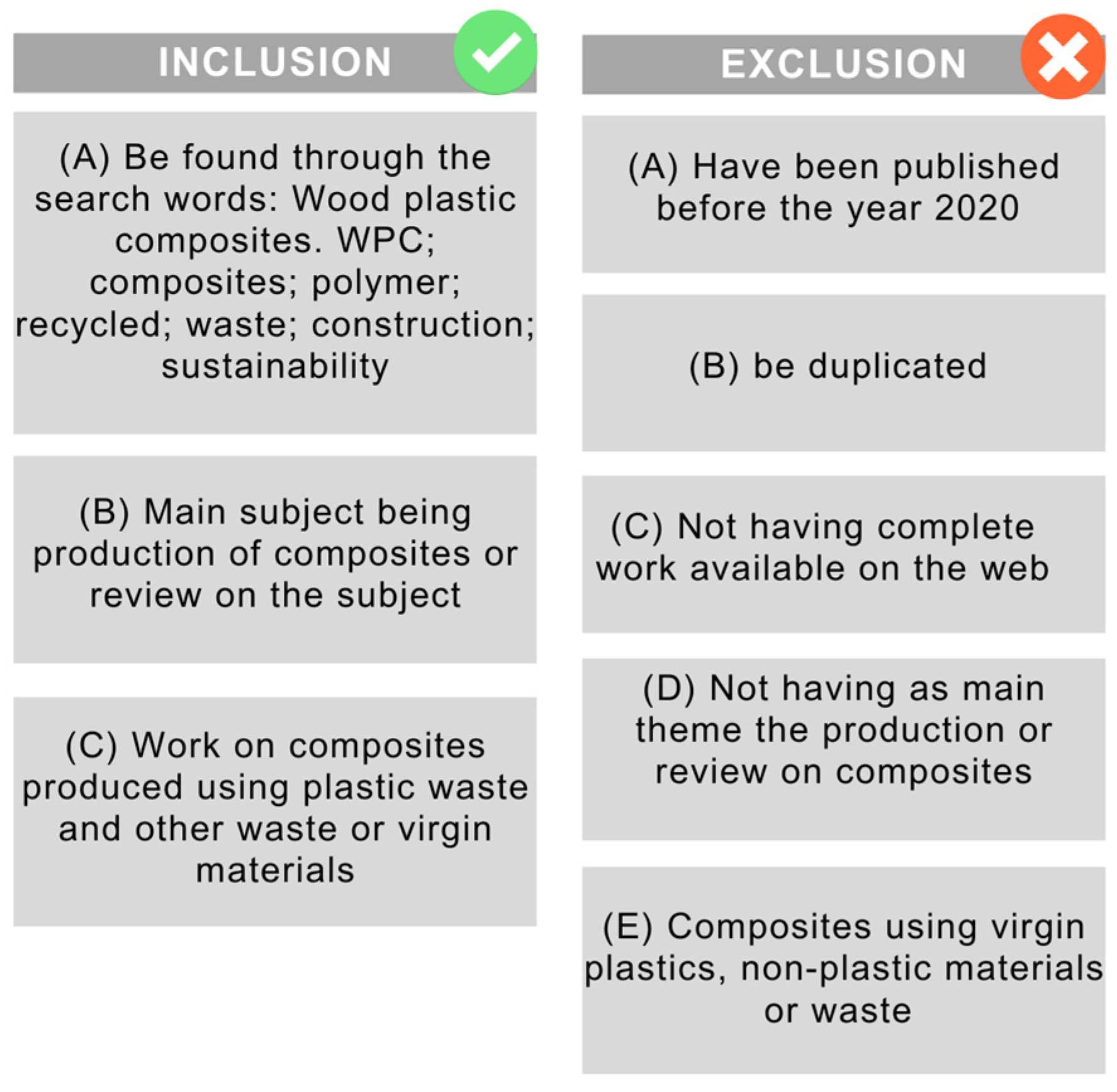

Inclusion and exclusion criteria were defined to evaluate the articles found in the established research databases. The inclusion criteria stipulate that the works must be published on the web and fully accessible in open-access scientific databases. Additionally, they must be recent works published from the year 2020 onwards and address the production of wood-plastic composites using plastic waste as a raw material.

Regarding the exclusion criteria (

Figure 2), works that were not fully available on the web, duplicated works, those published before 2020, or those that did not have the production of wood-plastic composites as their central theme were discarded. Works that did not use plastic waste as part of the raw material in the production of wood-plastic composites were also excluded.

Evaluation of the Results Determined from the Application of Inclusion and Exclusion Criteria

In the search for papers in the databases “CAPES”, “Science Direct”, and “Scielo”, using the defined keywords “wood plastic composites”, “WPC”, “Polymer”, “recycled”, “waste”, “construction” and “sustainability”, a total of 3111 papers were found. Out of these, 3109 were from the Science Direct database, 2 were from CAPES, and none were from Scielo. Applying the first exclusion criterion “A—publication period”, 2998 papers were removed because they were published before 2020. Regarding the exclusion criterion “B—duplicate”, no papers were removed. Moving on to the exclusion criterion “C—incomplete papers not available on the web”, 10 papers were removed. From the remaining 112 papers, with the application of the exclusion criterion “D—papers not primarily focused on the production or review of composites”, 47 papers were removed. Using the final set of 55 papers, the last exclusion criterion was applied, “E—Composites using virgin plastics, materials, or non-plastic waste”, resulting in 15 papers (

Table 1) included in the systematic review (

Figure 3).

When analyzing the excluded papers based on the exclusion criterion “E—Composites using virgin plastics, materials, or non-plastic waste”, a prevalence of studies exploring the incorporation of wood waste (19 papers) was observed, many of which used a polymer matrix derived from virgin plastics. Recurring materials such as biopolymers (7 papers) were also identified, where the original raw material was replaced with biopolymers to enhance the sustainability of the produced composites. Additionally, papers addressing the use of various types of waste (6 papers) were found, including electronic waste, glass waste, and others. Studies investigating different materials in composite production (5 papers), such as carbon fibers, metals, glass, and concrete, among others, were also observed. Finally, papers investigating agricultural waste (3 papers), such as bamboo fiber and corn waste, stood out as an alternative for composite production.

Figure 4 provides a visualization of the materials and waste frequently used in studies related to composites that were excluded as they did not involve waste plastic-based composites.

Based on the keywords of the 112 pre-selected articles, after applying exclusion criteria “B” and “C”, as well as removing duplicates and unavailable papers, a keyword co-occurrence map was generated using VOSviewer software version 1.6.19. However, it is observed that the identified words have little relevance to the researched keywords and study objectives (

Figure 5).

After the selection and application of the exclusion criterion “D—Papers not primarily focused on the production or review of composites”, where papers not centered on composites were excluded, another keyword co-occurrence map was generated for the most frequent keywords and authors in the pre-selected papers (55 papers), as shown in

Figure 6. The prevailing words, with at least one occurrence, were “recycling”, “sustainability”, “plastic waste”, “polymer composites”, “composites”, “wood-plastic composites”, “mechanical properties”, and “thermal properties.”

When comparing the most frequent keywords in the selected papers based on exclusion criteria “B” and “C” to those selected based on exclusion criterion “D”, it can be observed that the words present in the articles after exclusion criterion “D” are directly related to the objectives of this study and the keywords used for the paper search, such as “recycling”, “sustainability”, “plastic waste”, “polymer composites”, “composites”, and “wood-plastic composites”.

3. Results and Discussion

3.1. What Are the Main Post-Consumer Plastics Commonly Used as Substitutes for Virgin Plastics in the Production of these Composites?

Analyzing the studies in the systematic review found that different types of post-consumer plastics were used as waste in the evaluated experiments. Among the most prevalent typologies, polypropylene (PP) was highlighted in five studies [

14,

15,

16,

19,

22], and high-density polyethylene (HDPE) in another five studies [

16,

19,

20,

21,

22]. Additionally, polyethylene terephthalate (PET) was used in a specific study [

24]. In addition to these specific categories, other types of plastic waste were also addressed in a single study [

23], as shown in

Figure 5. These results highlight the diversity of post-consumer plastics employed in the analyzed research, indicating that the use of plastic waste in composites is not limited to a single type of plastic, emphasizing the importance of considering a wide range of plastic waste to explore effective recycling and reuse strategies (

Figure 7).

Each type of plastic waste possesses distinct characteristics that contribute to its specific application. HDPE stands out for its chemical resistance, while LDPE has favorable electrical properties. PVC is recognized for its excellent chemical resistance, and PP is valued for its good heat resistance. ABS, on the other hand, excels in exceptional abrasion and chemical resistance, as well as its ease of molding and machining. Regarding PS, its good mechanical properties and thermal insulation make it a common choice in food and pharmaceutical packaging applications. In addition to these mentioned plastics, others such as PBS, PC, PES, PET, PF, PHBV, PLA, PPC, and UPE have also been used as matrices in wood-plastic composites (WPCs), demonstrating significant improvements in the mechanical and thermophysical properties of the composite materials [

26].

The analyzed studies revealed common points in the use of plastic waste in composites. Firstly, there is a preference for recycled polypropylene (r-PP) and recycled high-density polyethylene (r-HDPE), demonstrating an environmental concern for reusing post-consumer materials. Additionally, plant-based fillers, such as crushed wood waste, pine nut shells, corn husks, hemp fibers, and wood chips, were incorporated to improve mechanical properties and reduce reliance on virgin materials.

3.2. What Are the Percentage Compositions of Wood and Plastic Employed in These Composites?

The studies reviewed showed a wide variation in the use of wood and plastic in composite compositions. In one study, the composites contained WPC residues with approximately 45% HDPE and additives, while the crushed recycled wood fiber represented about 50% of the composition [

23]. Another study had composite formulations ranging from 5% to 35% recycled polypropylene powder, while the wood content ranged from 60% to 85% by weight of the total mixture [

17]. Recycled PP ranging from 30% to 100% in cycles 1, 3, and 6, combined with variations of 40% to 70% wood flour, were used in another study [

18]. Additionally, composites were evaluated with 5% to 10% recycled PETE, compared with 43% to 45% wood fiber and 45% to 50% polymethyl methacrylate [

24]. Furthermore, four different plastic/fiber weight ratios ranging from 0% to 100% were considered in a study [

25]. The composites in another study ranged from 20% to 55%, while the wood content varied from 40% to 60% [

16]. Finally, variations from 0% to 100% of polypropylene and wood about the total weight of the composite were analyzed in other studies [

14]. The maximum and minimum variations in the percentage of plastic and wood can be visualized in

Figure 8.

The possibility of integrating a wide variety of materials is evident, encompassing diverse polymeric matrices, including both recycled and virgin options, as well as various fillers and residues. Composites offer an exceptionally flexible platform for incorporating multiple constituents, encompassing different materials, recycled and virgin polymeric matrices, as well as a range of fillers and residues.

3.3. What Shaping Processes Are Commonly Employed in the Manufacturing of These Composites?

Shaping methods play a crucial role in composite production, allowing materials to be molded and formed. Several studies have used different shaping methods to manufacture their composites. One study employed the extrusion method, which involves melting the components in an extruder and passing the material through a die to produce the desired shape [

16,

17,

22,

23]. Another study used injection and vulcanization methods, which involve injection of the molten material into a mold and subsequently curing it to achieve the desired properties [

15,

18]. A study opted for hot molding, which involves heating and shaping the composite material in a mold [

21]. Another study utilized the compression method, which involves applying pressure to compact the composite material in a mold [

14,

25]. The main shaping methods used can be visualized in

Figure 9.

Among the shaping methods used in the production of composites, extrusion, injection, vulcanization, hot molding, and compression are commonly employed, with extrusion being the most prioritized shaping method. These shaping methods offer different approaches to composite production, allowing control over the resulting materials’ shape, properties, and performance. The variety of shaping methods also highlights the versatility of the application of these composites in different industrial sectors.

In addition to choosing the ideal method of shaping for material production, the quality of the shaping process plays a fundamental role in composite manufacturing, directly influencing a series of key characteristics of the final product. A well-executed shaping process is essential to ensure uniform distribution of components, eliminate unwanted air bubbles, and create solid interfaces between different phases. These aspects hold paramount importance, as the uniform distribution of fillers and other additives directly impacts the mechanical properties such as strength, rigidity, and toughness of the resulting composite. Moreover, proper shaping also helps minimize potential defects that could lead to weak points in the material, affecting its durability and performance over time. Therefore, careful attention to the shaping method not only ensures the structural integrity of the composite but also significantly influences the crucial mechanical and functional attributes for its success in specific applications.

3.4. What Is the Mechanical Behavior of These Composites?

Among the studies analyzed, some evaluated the tensile and flexural strengths of composites manufactured from recycled plastics. When comparing these studies (

Figure 10), it is observed that the composites produced exhibit variation in results due to the different fillers, matrices, and shaping methods used. For the tensile tests, the minimum values range from 15.70 MPa [

23] to 38.55 MPa [

25], while the maximum values range from 32.00 MPa [

23] to 44.39 MPa [

25]. In the flexural tests, the minimum values range from 6.17 MPa [

14] to 34.83 MPa [

15], and the maximum values range from 17.96 MPa [

14] to 47.84 MPa [

15].

Studies have highlighted the importance of incorporating an interfacial compatibilizer to enhance the mechanical properties, particularly tensile and flexural strength, of wood-plastic composites (WPCs) [

15,

23]. Without the use of compatibilizers, WPCs exhibit a tensile strength ranging from 15.70 MPa to 27.0 MPa [

23]. However, by incorporating an interfacial compatibilizer at a 5% weight ratio, the tensile strength can be increased to a range of 19.0 MPa to 32.0 MPa [

23]. Furthermore, the addition of the MAPE compatibilizer leads to an improvement in flexural strength, increasing it from a range of 17.0 MPa to 27.0 MPa to 32.0 MPa compared with compatibilized WPCs [

23].

In another study, the addition of a compatibilizer to biomass/plastic composites, even when different agricultural residues are used as fillers, resulted in an increase in tensile strength from 36.80 MPa to 47.84 MPa and from 34.83 MPa to 43.06 MPa [

15]. Another study demonstrated that composites with chemically treated fillers exhibited significantly higher tensile strength than those with untreated fillers [

22]. Moreover, finer particle sizes showed higher tensile strength than coarser ones. However, the presence of coarse particles had a negative impact on the flexural strength of the composites.

Therefore, the main factors identified by the authors as potential influencers on the strength of the composites are the use of compatibilizers and the particle size of the raw materials. From the review, it is evident that the use of a compatibilizer improves the flexural properties of the composites and contributes to improved interfacial bonding between the matrix and fillers, aiding in stress transfer and consequently increasing strength.

In addition to the previously addressed aspects, it is important to recognize that the strength of composites is influenced by a range of other crucial factors. While compatibilizers and the particle size of raw materials play a significant role in enhancing mechanical properties, there are other variables that also play an essential part.

The selection of matrix and filler materials has a substantial impact on the strength of composites. Carefully choosing polymers and fillers with intrinsic strength properties can directly contribute to overall composite strength improvement. Additionally, the uniform and efficient distribution of fillers within the matrix is crucial to ensuring stress is evenly distributed, avoiding weak points and potential failures.

The manufacturing process also plays a vital role in determining composite strength. Factors like temperature profile, pressure, curing time, and mixing techniques can directly impact the final properties of the composite material. An improper process can result in poor dispersion and adhesion between the matrix and fillers, leading to reduced strength.

Furthermore, environmental influence and composite usage conditions also play a relevant role in long-term strength. Exposure to adverse weather conditions, such as humidity, temperature variations, and UV radiation, can affect material durability and, consequently, its mechanical strength.

In summary, the strength of composites is a complex interplay of various factors, including material selection, filler distribution/dispersion, manufacturing process, and environmental conditions. Therefore, a comprehensive approach that considers all these aspects is essential to achieving composites with optimized mechanical strength and long-term durability.

3.5. Can the Thermal Behavior of Composites Produced from Recycled Plastic Influence Thermal Comfort in Environments and Impact the Energy Efficiency of Buildings?

The results obtained by the studies demonstrate that the addition of plastic waste provided degradation temperatures above 250 °C in the degradation phase corresponding to the polymer matrix, reaching up to 600 °C, indicating good heat resistance [

15,

20,

21,

24,

25] (

Figure 11).

The results show that construction materials using recycled plastic composites can be a viable option to promote energy efficiency in buildings. When plastic composites are applied to the building envelope, they have the potential to increase the time interval during which the temperature is maintained and reduce the decrement factor of the buildings [

19], thus improving their thermal efficiency performance.

Therefore, the studies show that composites made from plastic waste have low thermal degradation, allowing them to withstand high temperatures in use environments, making them suitable for applications in the construction industry. The variation in plastic waste used in the studies shows the possibility of adjusting the thermal properties of the composites according to the specific needs of each application in the construction industry. This analysis highlights the importance of studying and understanding the thermal properties of plastic composites in the construction sector, enabling the proper selection of materials and improving the thermal performance of buildings, contributing to energy efficiency and sustainability in the construction industry.

However, in addition to the results and approaches of the examined studies, other factors play influential roles in the use of recycled plastic composites in construction. This encompasses the need to assess resistance to ultraviolet radiation (UV), which is crucial for situations involving prolonged exposure to solar radiation in outdoor applications.

Furthermore, evaluating fire resistance is also essential. Fire resistance is a critical aspect to consider when incorporating plastic composite materials into buildings. Ensuring that these materials possess fire-retardant properties and resistance is essential for occupant safety and compliance with building standards and regulations. Therefore, when assessing and selecting recycled plastic composites for construction use, it is necessary not only to consider thermal properties but also to take into account fire resistance and UV radiation resistance in order to ensure the durability, safety, and efficiency of the materials under various environmental conditions.

3.6. What Are the Ideal Compositions of Post-Consumer Plastics and Plant-Based Fillers Recommended by the Authors for Composite Production?

Some authors indicate ideal compositions for the produced composites, as shown in

Table 2. It can be observed that the considered optimal compositions may vary depending on the study and the desired properties of the composite. On average, authors who mentioned ideal compositions recommend using around 40% to 45% plant-based fillers and a plastic variation of 50% to 60%.

The main compositions included approximately 45% HDPE and 50% wood fiber, variations of 5% to 35% recycled polypropylene powder, and 60% to 85% weight of wood. Other compositions ranged from 30% to 100% recycled PP combined with 40% to 70% wood flour, 5% to 10% recycled PET with 43% to 45% wood fiber, and 45% to 50% polymethyl methacrylate, as well as variations from 0% to 100% plastic and wood fiber.

Beyond the main components, the quest for the ideal composition in recycled wood-plastic composites involves considerations that extend beyond the proportions of the matrix and filler. The quality of the raw materials used and the pre-treatment process play a pivotal role in achieving the desired properties in the composites. A thoughtful selection of plastic and wood waste sources, as well as an assessment of their purity, particle size distribution, and physical characteristics, are decisive factors for the success of the composite. Furthermore, appropriate pre-treatment, such as cleaning, grinding, and particle homogenization, directly influences interfacial adhesion and phase distribution, impacting the final mechanical and thermal properties of the end material.

Technological parameters during the production process also play a critical role. Factors like screw profile, temperature profile, screw speed, and feed rate affect the fusion, mixing, and shaping of components, directly shaping the final characteristics of the composite. A profound understanding of these parameters and their optimization is essential to ensuring that the material attains the desired properties and maintains its stability over time. Moreover, when determining the ideal composition, it is imperative to consider the specifics of the final application. Mechanical, thermal, impact strength, and environmental degradation properties vary according to the intended application. Understanding the specific demands of the construction industry and the requirements of the environment in which the composite will be used guides the selection of the most suitable composition to meet these needs.

Authors addressing optimal compositions in their research typically recommend specific ranges of proportions, such as incorporating approximately 40% to 45% wood fiber and varying plastic content between 50% and 60%. However, these values can vary based on the characteristics of the source materials, application objectives, and desired properties. Ultimately, a meticulous and comprehensive analysis of all these factors is essential to producing recycled composites that effectively and efficiently fulfill the specific requirements of the construction industry, thereby contributing to the sustainability and quality of the sector.

3.7. Are These Composites Considered by the Authors as Sustainable Products?

Several positive environmental impacts are mentioned in the studies on the use of plastic waste in the production of WPCs, as shown in

Table 3. No study indicated any negative environmental impact associated with the production of the composites. One study emphasizes that the moderate incorporation of waste in WPC formulations offers an easy and cost-effective method to recycle end-of-life products, resulting in high-performance composites, increasing production efficiency, minimizing waste, and aligning with the circular economy [

23]. Another study highlights that the use of recycled wood fiber waste and recycled polypropylene as raw materials significantly reduces the consumption of fossil-based materials in the WPC manufacturing process, contributing to environmental impact reduction [

17]. Other studies consider WPC a sustainable material as it reduces dependence on natural resources and promotes conscious production practices [

18,

22]. Another study emphasizes that producing composites using hot molding in a single step recovers plastic waste, replaces wood-based panels, and reduces the consumption of non-renewable energy [

21]. Another study highlights the reduction of waste disposal, contributing to a more sustainable environment [

25]. Another study emphasizes that using industrial waste in composite manufacturing results in a more sustainable production process, reducing toxic emissions and production costs [

16]. One study points out that using waste in panel manufacturing helps address material scarcity, reduces environmental problems, and alleviates pressure on forest resources while creating job opportunities [

14].

In terms of sustainability, the use of wood-plastic composites in construction, derived from post-consumer plastics rather than virgin plastics, contributes to reducing environmental impacts such as decreasing the amount of plastic waste in landfills and reducing the extraction of natural resources for obtaining virgin raw materials. The incorporation of plant-based fillers, such as crushed wood waste, pinecone shells, corn straw, hemp fibers, and wood chips, provides a sustainable alternative to the reliance on virgin materials. This practice contributes to minimizing the extraction of natural resources, preserves forests, and promotes the utilization of agricultural and forest waste. In terms of the product’s life cycle, wood-plastic composites made from post-consumer plastics have advantages over conventional materials. The use of these composites contributes to closing the life cycle of plastics, enabling their recycling and reintegration into the production chain. This reduces the need to produce new plastics, saving energy, water, and other natural resources. In addition to the aspects addressed by the authors, the sustainability of these composites extends beyond their initial production. Studying the durability of these materials over time is crucial, taking into account factors such as aging, degradation, exposure to adverse weather conditions, and repeated loading cycles. Understanding how these composites perform in a real construction environment is essential to assessing their longevity and performance over the years.

Moreover, evaluating the durability of these composites under practical conditions provides valuable insights to enhance formulation and manufacturing processes. By comprehending how the composites interact with environmental elements and maintain their mechanical and structural properties over time, adjustments in material design and composition can be made, ensuring greater strength and durability. This proactive approach not only extends the lifespan of products but also contributes to reducing the need for frequent replacements, resulting in lower resource consumption and reduced waste disposal.

The recyclability of wood-plastic composites after the end of their useful life cycle is a crucial consideration for environmental sustainability. As these materials reach the end of their life as construction components, they should be capable of being efficiently recycled and reintegrated into the production chain, avoiding waste accumulation in landfills or improper disposal. Therefore, research into how to recycle these composites efficiently and sustainably is fundamental to maximizing their potential for closing the lifecycle loop and minimizing environmental impact. Investing in appropriate recycling technologies and methods for wood-plastic composites is a crucial step in establishing a complete and circular solution. This necessitates identifying processes that effectively separate the composite components, such as plastic and organic matter, so that they can be recycled and reused effectively. Additionally, raising awareness and educating stakeholders in the production chain and end consumers about the importance of recycling these materials is essential.

Studying the aspects of durability and recyclability complements the sustainability approach of these composites, providing a holistic view of their environmental impact throughout the entire lifecycle. This assists in making informed decisions about their use in the construction industry and contributes to a more comprehensive and responsible approach to energy efficiency and sustainability in construction. By considering not only the initial production but also the lifespan and end-of-life fate of these composites, we can ensure that these materials significantly contribute to reducing environmental impact and promoting a more sustainable construction sector.

4. Conclusions

With the application of exclusion criteria “A”, “B”, and “C”, a total of 112 articles were retained, found using the defined keywords “wood plastic composites”, “WPC”, “polymer”, “recycled”, “waste”, “construction”, and “sustainability”. However, only 15 of these articles specifically discussed the addition of plastic waste as a raw material. This suggests that polymer composites are still primarily manufactured using virgin polymers, and there is a restricted body of research focused on the utilization of plastic waste in their production.

When analyzing the excluded articles based on the exclusion criterion “E—Composites using virgin plastics, materials, or non-plastic waste”, a significant prevalence of studies (around 34% of the articles) exploring the incorporation of wood waste was observed. Many of these studies employed a polymer matrix derived from virgin plastics. Additionally, recurring materials such as biopolymers (approximately 12% of the articles) were also identified, where the original raw material was replaced by biopolymers to enhance the sustainability of the composites. Interestingly, articles addressing the utilization of various types of waste (about 10% of the articles), including electronic waste, glass waste, and others, were found. Studies investigating diverse materials in composite production (approximately 9% of the articles), such as carbon fibers, metals, glass, and concrete, among others, were also observed. Lastly, articles investigating agricultural waste (about 5% of the articles), like bamboo fibers and corn waste, stood out as promising alternatives for composite production. These findings indicate that the incorporation of various types of waste as fillers in composites has been extensively studied, aiming to find sustainable disposal solutions for these materials while simultaneously enhancing the characteristics of the resulting composites.

After reviewing the 15 studies, it can be concluded that the use of post-consumer plastics, such as polypropylene and high-density polyethylene, combined with plant-based fillers is adopted to enhance mechanical properties and reduce dependence on virgin materials for both the polymer matrix and fillers. The optimal composition and shaping process may vary based on desired composite characteristics, providing flexibility to adjust filler quantities and material additions. The studies identified that the incorporation of compatibilizers and control of raw material particle size play significant roles in composite strength. Composites derived from plastic waste exhibit low thermal degradation, making them suitable for construction applications and capable of withstanding high temperatures when other factors are properly considered, such as exposure to weather and fire resistance. The diversity of plastic waste investigated demonstrates the ability to tailor the thermal properties of composites to specific application demands. The ease of processing, molding, and installing recycled plastic composites can influence construction efficiency.

From an environmental perspective, as indicated by the evaluated works, the adoption of these composites contributes to closing the plastic life cycle by enabling recycling and reintroduction into the production chain. They also offer opportunities for creating lightweight, durable, and high-performance products in the construction sector. Incorporating post-consumer wood-plastic composites in civil construction generates positive environmental impacts, including waste reduction, reduction of plastic pollution, promotion of recycling, decreased natural resource exploitation, and the production of more sustainable items. These materials find versatile applications, spanning coatings, flooring, windows, doors, panels, and structures, contributing to the construction of more efficient and sustainable buildings.

However, beyond the results and approaches of the examined studies, other factors play influential roles in the use of recycled plastic composites in construction. This encompasses the need to evaluate resistance to ultraviolet (UV) radiation, crucial for situations involving prolonged solar exposure in outdoor applications. Fire resistance, which is of utmost importance to ensure occupant safety and compliance with regulatory standards, and the ability to absorb moisture, which affects the long-term durability and dimensional stability of the composite, also represent highly relevant considerations. Mechanical properties, such as strength, rigidity, and impact resistance, play a comprehensive role in overall performance in construction applications. Long-term stability, considering factors like creep and fatigue, is essential to guaranteeing the durability of structural components and needs careful evaluation. In terms of sustainability, evaluation goes beyond the production cycle; assessing the durability and recyclability of this composite is crucial for waste reduction after use. The production and utilization costs of recycled plastic composites in construction projects also directly impact their widespread adoption as energy-efficient materials. Evaluating these factors is essential to obtaining a comprehensive understanding of the potential and limitations of recycled plastic composites in promoting energy efficiency and sustainability in the construction industry.