A Review of Drive Cycles for Electrochemical Propulsion

Abstract

:1. Introduction

2. Review

2.1. Breakdown of Topics

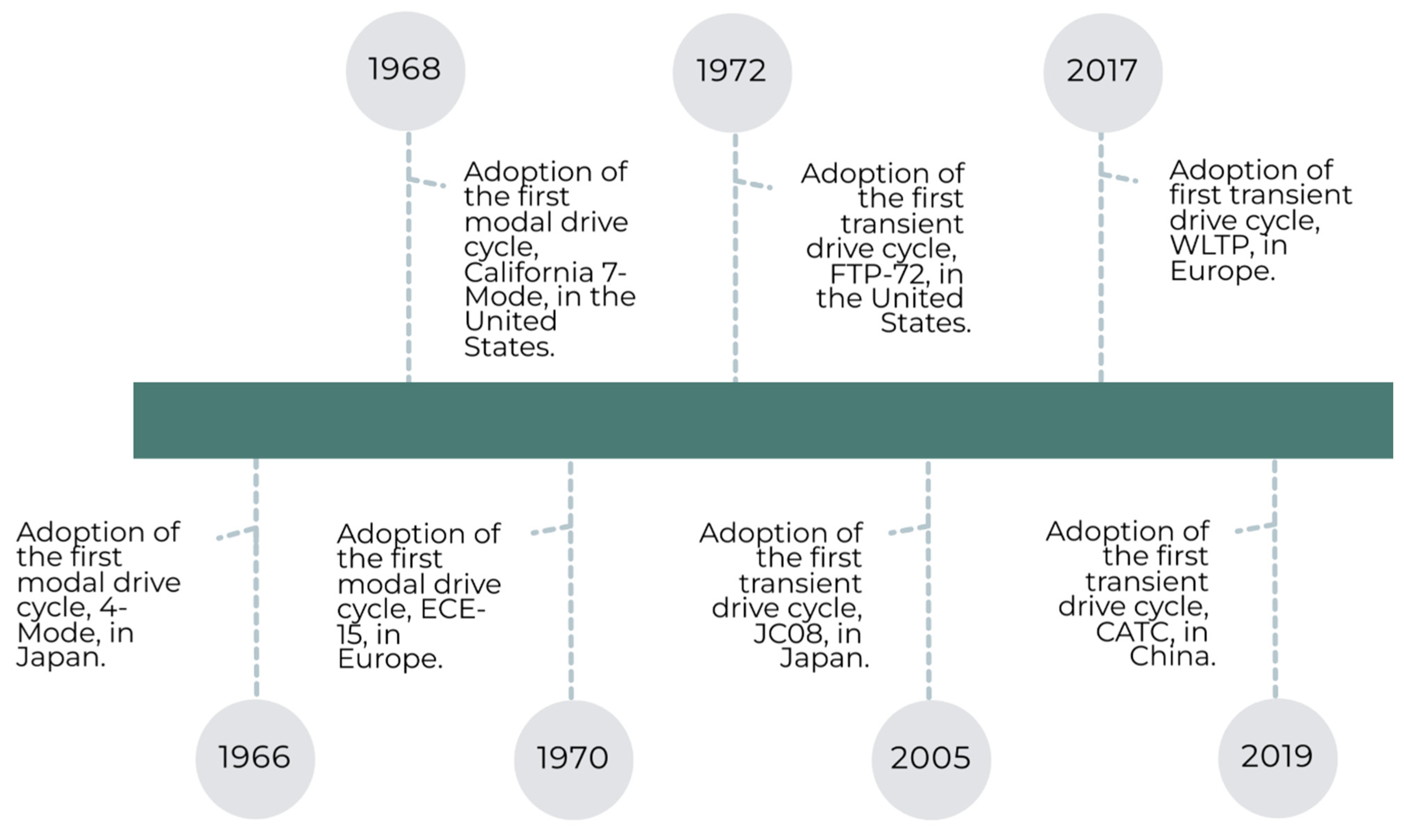

2.2. Drive Cycle Classification

2.3. Overview and History of Legislative Drive Cycles Sorted by Region and Vehicle Type

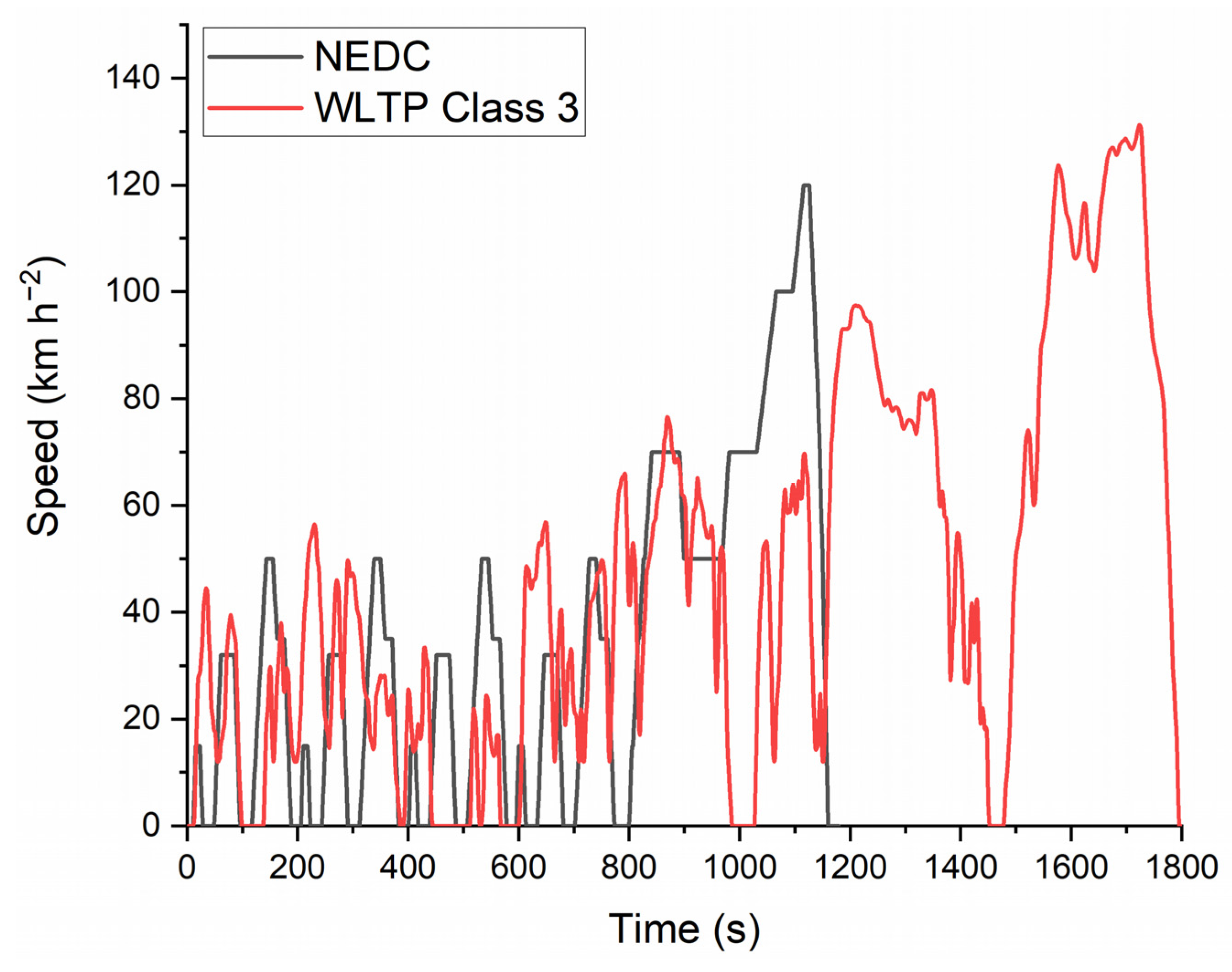

2.3.1. European Drive Cycles

2.3.2. American Drive Cycles

2.3.3. Japanese Drive Cycles

2.3.4. Chinese Drive Cycles

2.3.5. Worldwide Drive Cycles—Worldwide Harmonised Light Vehicle Test Procedure (WLTP)

2.3.6. Marine Cycles

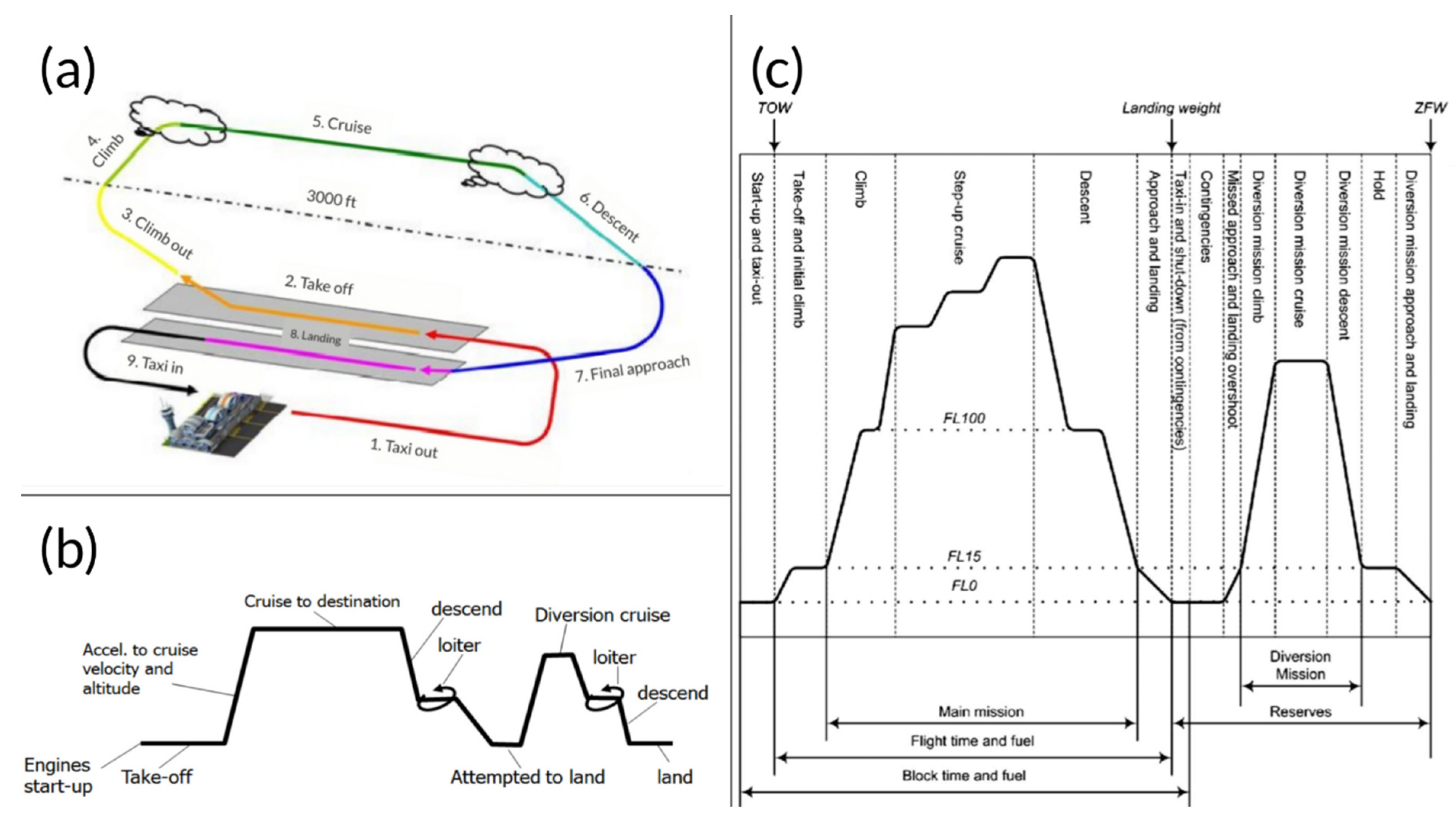

2.3.7. Aviation Mission Profile

2.4. Comparison of Legislative Drive Cycles

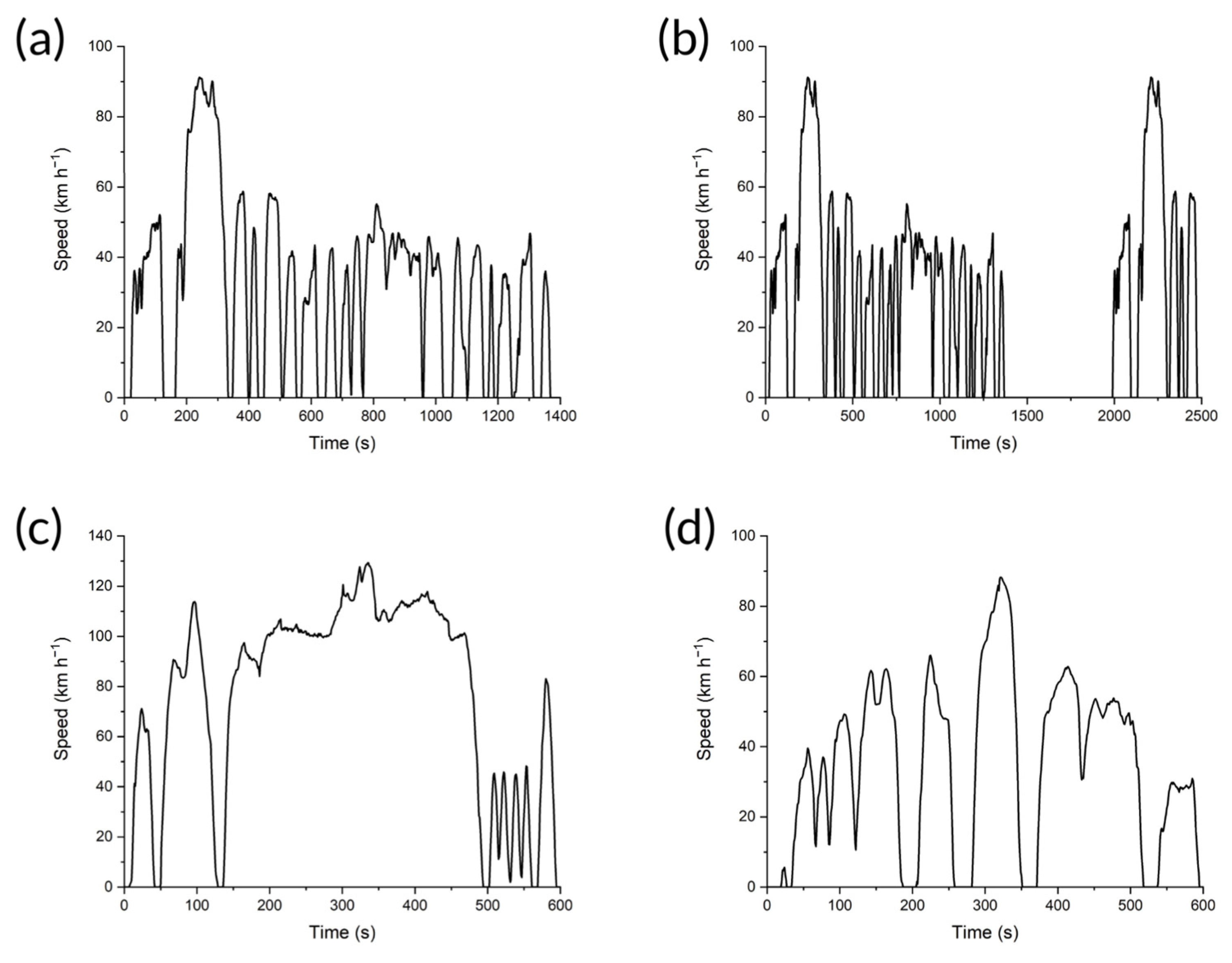

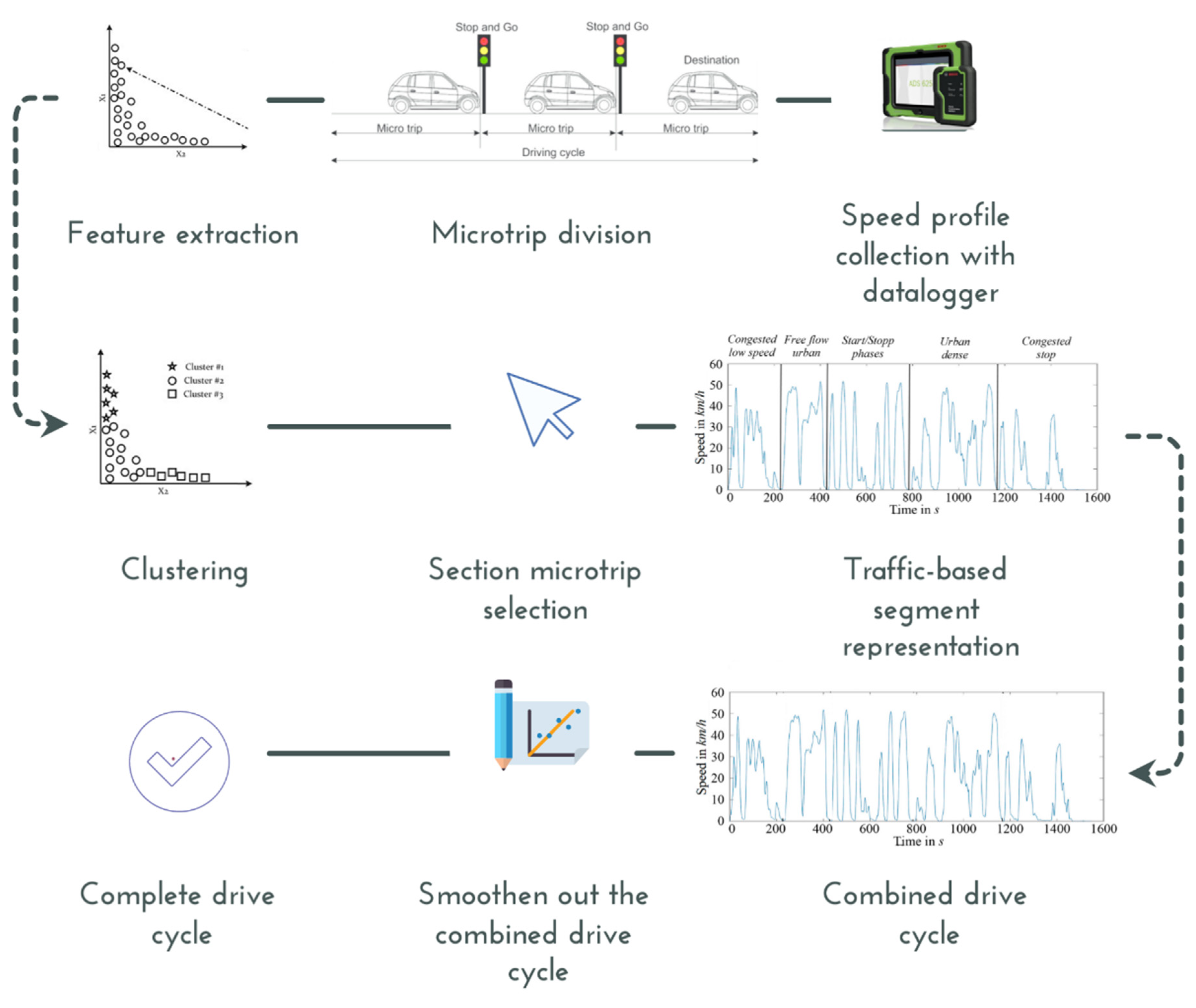

2.5. Transient Drive Cycle Developmental Procedure Using the Micro-Trip Method

2.6. Standardised Transient ‘Drive Cycle’ Testing Protocols for Electrochemical Device Testing

2.7. Drive Cycle to Power Cycle Conversion for Electrochemical Device and Vehicle Testing

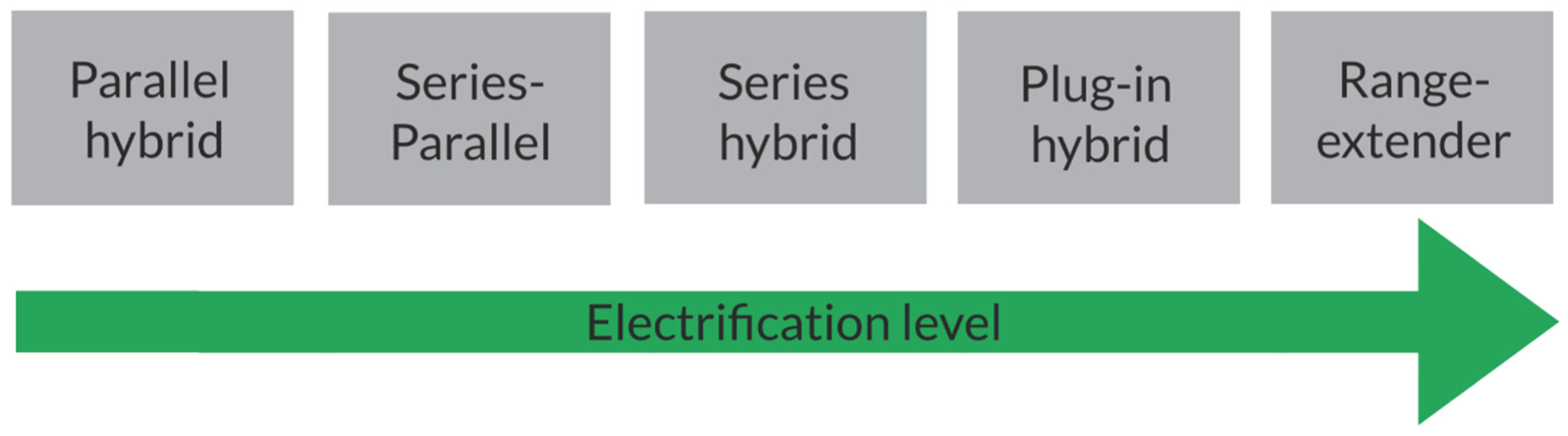

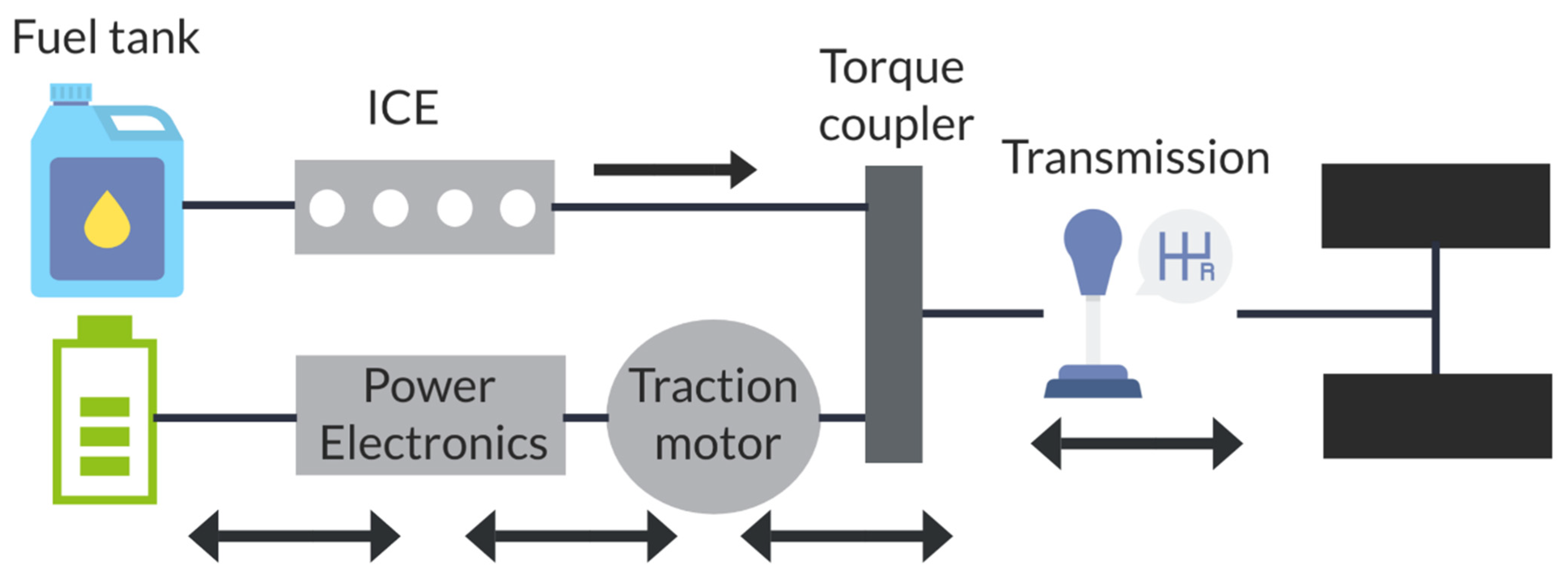

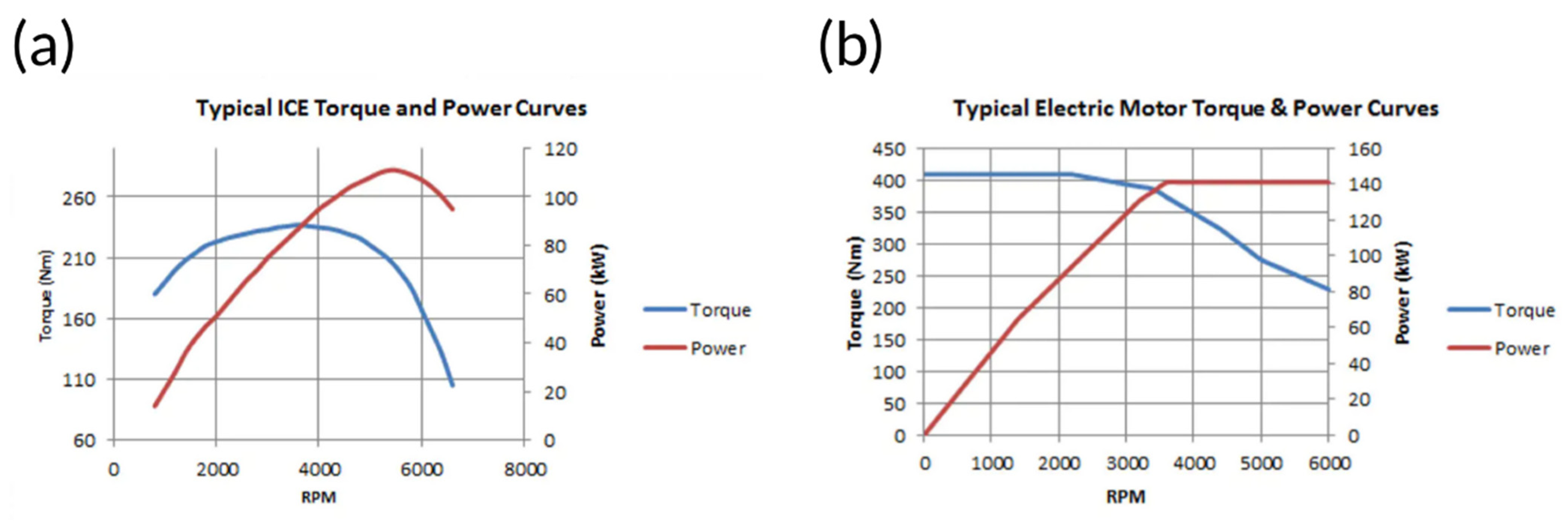

2.8. Using Power Cycles as a Sizing Tool for Electric and Hybrid Vehicles of Different Architectures

2.9. Drive Cycles and Duty Cycles for Different Propulsion Systems—Differences, Complications, and Accuracy

3. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barlow, T.; Latham, S.; Mccrae, I.; Boulter, P. A reference book of driving cycles for use in the measurement of road vehicle emissions. In TRL Published Project Report; TRL Limited: Berkshire, UK, 2009; p. 280. [Google Scholar]

- Esteves-Booth, A.; Muneer, T.; Kubie, J.; Kirby, H. A review of vehicular emission models and driving cycles. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2002, 216, 777–797. [Google Scholar] [CrossRef]

- Tutuianu, M.; Bonnel, P.; Ciuffo, B.; Haniu, T.; Ichikawa, N.; Marotta, A.; Pavlovic, J.; Steven, H. Development of the World-wide harmonized Light duty Test Cycle (WLTC) and a possible pathway for its introduction in the European legislation. Transp. Res. Part D Transp. Environ. 2015, 40, 61–75. [Google Scholar] [CrossRef]

- Singh, R.; Mittal, S. A Simplified Method to Form a Fuel Economy Test Cycle for Test Tracks/Autonomous Vehicles; SAE Technical Paper 2019-26-0343; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Nicolas, R.; The Different Driving Cycles. Car Engineer. 2013. Available online: https://www.car-engineer.com/the-different-driving-cycles/ (accessed on 31 August 2021).

- Son, J.; Park, M.; Won, K.; Kim, Y.; Son, S.; McGordon, A.; Jennings, P.; Birrell, S. Comparative Study between Korea and UK: Relationship between Driving Style and Real-World Fuel Consumption. Int. J. Automot. Technol. 2016, 17, 175–181. [Google Scholar] [CrossRef]

- Giakoumis, E.G. Driving and Engine Cycles; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Watson, H.C. Vehicle Driving Patterns and Measurement Methods for Energy and Emissions Assessment; Bureau of Transport Economics: Washington, DC, USA, 1978.

- Rahman, S.M.A.; Fattah, I.M.R.; Ong, H.C.; Ashik, F.R.; Hassan, M.M.; Murshed, M.T.; Imran, M.A.; Rahman, M.H.; Rahman, M.A.; Hasan, M.A.M.; et al. State-of-the-art of establishing test procedures for real driving gaseous emissions from light- and heavy-duty vehicles. Energies 2021, 14, 4195. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (EPA). Frequently Asked Questions. U.S. Department of Energy. Available online: https://www.fueleconomy.gov/feg/info.shtml#guzzler (accessed on 23 November 2021).

- Secretariat of the United Nations. Recueil des Traites. Treaty Ser. 1981, 1249, 20376–20402. [Google Scholar]

- Liu, Y.; Wu, Z.X.; Zhou, H.; Zheng, H.; Yu, N.; An, X.P.; Li, J.Y.; Li, M.L. Development of China Light-Duty Vehicle Test Cycle. Int. J. Automot. Technol. 2020, 21, 1233–1246. [Google Scholar] [CrossRef]

- Tsotridis, G.; Pilenga, A.; Marco, G.; De Malkow, T. EU Harmonised Test Protocols for PEMFC MEA Testing in Single Cell Configuration for Automotive Applications; European Comission: Brussels, Belgium, 2015. [Google Scholar] [CrossRef]

- DieselNet. ECE 15 + EUDC/NEDC. DieselNet. 2013. Available online: https://dieselnet.com/standards/cycles/ece_eudc.php (accessed on 1 September 2021).

- Jeong, N.T.; Yang, S.M.; Kim, K.S.; Wang, M.S.; Kim, H.S.; Suh, M.W. Urban Driving Cycle for Performance Evaluation of Electric Vehicles. Int. J. Automot. Technol. 2016, 17, 145–151. [Google Scholar] [CrossRef]

- Peng, J.; Jiang, J.; Ding, F.; Tan, H. Development of driving cycle construction for hybrid electric bus: A case study in Zhengzhou, China. Sustainability 2020, 12, 7188. [Google Scholar] [CrossRef]

- Samuel, S.; Austin, L.; Morrey, D. Automotive test drive cycles for emission measurement and real-world emission levels—A review. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2002, 216, 555–564. [Google Scholar] [CrossRef]

- Tong, H.Y.; Ng, K.W. Developing electric bus driving cycles with significant road gradient changes: A case study in Hong Kong. Sustain. Cities Soc. 2023, 98, 104819. [Google Scholar] [CrossRef]

- Fotouhi, A.; Montazeri-Gh, M. Tehran driving cycle development using the k-means clustering method. Sci. Iran. 2013, 20, 286–293. [Google Scholar]

- Launch UK. X-431 Euro Pro 5 LINK. Launch UK. 2022. Available online: https://www.launchtech.co.uk/oem-level-vehicle-diagnostics/X-431-Euro-Pro-5-LINK-with-Smartlink-VCi/ (accessed on 20 May 2022).

- The Council of the European Communities. Council Directive 70/220/EEC of 20 March 1970 on the Approximation of the Laws of the Member States Relating to Measures to Be Taken against Air Pollution by Gases from Positive-Ignition Engines of Motor Vehicles; The Council of the European Communities: Brussels, Belgium, 1970.

- WLTP Facts. From NEDC to WLTP: What Will Change? WLTP Facts. Available online: https://www.wltpfacts.eu/from-nedc-to-wltp-change/ (accessed on 1 September 2021).

- Shale-Hestor, T. What Are the NEDC Fuel Economy Tests? Auto Express. 2019. Available online: https://www.autoexpress.co.uk/car-news/107032/what-are-the-nedc-fuel-economy-tests (accessed on 4 November 2021).

- DieselNet. FTP-72 (UDDS). DieselNet. 2014. Available online: https://dieselnet.com/standards/cycles/ftp72.php (accessed on 24 November 2021).

- DieselNet. FTP-75. DieselNet. 2014. Available online: https://dieselnet.com/standards/cycles/ftp75.php (accessed on 1 September 2021).

- Karavalakis, G.; Short, D.; Hajbabaei, M.; Vu, D.; Villela, M.; Russell, R.; Durbin, T.; Asa-Awuku, A. Criteria Emissions, Particle Number Emissions, Size Distributions, and Black Carbon Measurements from PFI Gasoline Vehicles Fuelled with Different Ethanol and Butanol Blends; SAE Technical Paper 2013-01-1147; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Kuhlwein, J.; German, J.; Bandivadekar, A. Development of Test Cycle Conversion Factors among Worldwide Light-Duty Vehicle CO2 Emission Standards; The International Council on Clean Transportation—ICCT: Washington, DC, USA, 2014; p. 64. [Google Scholar]

- Mathworks. Drive Cycle Source; Mathworks: Natick, MA, USA, 2017. [Google Scholar]

- United States Environmental Protection Agency. PA EPA Adds Reality Driving Cycle to VEH. Certification Test. EPA. 1996. Available online: https://archive.epa.gov/epapages/newsroom_archive/newsreleases/8fe4d7d91eafa23d8525646b006991da.html (accessed on 1 September 2021).

- DieselNet. SFTP-US06. DieselNet. 2013. Available online: https://dieselnet.com/standards/cycles/ftp_us06.php (accessed on 1 September 2021).

- DieselNet. SFTP-SC03. DieselNet. 2013. Available online: https://dieselnet.com/standards/cycles/ftp_sc03.php (accessed on 1 September 2021).

- Earth Cars. EPA Fuel Economy Ratings—What’s Coming in 2008. Earth Cars. 2007. Available online: https://web.archive.org/web/20071008015835/http://www.earthcars.com/articles/article.htm?articleId=6 (accessed on 1 September 2021).

- DieselNet. EPA Highway Fuel Economy Test Cycle (HWFET). DieselNet. 2000. Available online: https://dieselnet.com/standards/cycles/hwfet.php (accessed on 1 September 2021).

- Transport Policy. Japan Light-Duty Emissions. TransportPolicy.net. 2018. Available online: https://www.transportpolicy.net/standard/japan-light-duty-emissions/ (accessed on 25 November 2021).

- GB/T 38146.1-2019; China Automotive Test Cycle—Part 1: Light-duty Vehicles. InterRegs International Regulations: Fareha, UK, 2021. Available online: https://www.interregs.com/catalogue/details/chn-38146119/gb-t-381461-2019/automotive-test-cycle-for-light-duty-vehicles/ (accessed on 6 September 2021).

- DieselNet. China Light-Duty Vehicle Test Cycle (CLTC). DieselNet. Available online: https://dieselnet.com/standards/cycles/cltc.php (accessed on 6 September 2021).

- Yu, H.; Liu, Y.; Li, J. Comparison of fuel consumption and emission characteristics of china VI coach under different test cycle. IOP Conf. Ser. Earth Environ. Sci. 2020, 431, 012062. [Google Scholar] [CrossRef]

- International Council on Clean Transportation. China’s Stage 6 Emission Standard for New Light-Duty Vehicles (Final Rule); International Council on Clean Transportation: Washington, DC, USA, 2017. [Google Scholar]

- Wang, X.; Fu, T.; Wang, C.; Ling, J. Fuel Consumption and Emissions at China Automotive Test Cycle for A Heavy Duty Vehicle based on Engine-in-the-loop Methodology. J. Phys. Conf. Ser. 2020, 1549, 022119. [Google Scholar] [CrossRef]

- X-Engineer. EV Design—Energy Consumption. X-Engineer. 2021. Available online: https://x-engineer.org/automotive-engineering/vehicle/electric-vehicles/ev-design-energy-consumption/ (accessed on 31 August 2021).

- EC. Commission Regulation (EU) 2018/1832 of 5 November 2018 amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) 2017/1151 for the purpose of improving the emission. Off. J. Eur. Union 2018, 1832, 301. [Google Scholar]

- German Association of the Automotive Industry. Global WLTP Roll-Out for More Realistic Results in Fuel Consumption. Verband der Automobilindustrie. 2020. Available online: https://www.vdik.de/wp-content/uploads/2020/02/WLTP_Questions-and-Answers-about-the-test-procedure.pdf (accessed on 1 September 2021).

- WLTP Facts. Transition Timeline: From NEDC to WLTP. WLTP Facts. Available online: https://www.wltpfacts.eu/ (accessed on 1 September 2021).

- DieselNet. Worldwide Harmonized Light Vehicles Test Cycle (WLTC). DieselNet. 2019. Available online: https://dieselnet.com/standards/cycles/wltp.php (accessed on 1 September 2021).

- Saxe, H.; Larsen, T. Air pollution from ships in three Danish ports. Atmos. Environ. 2004, 38, 4057–4067. [Google Scholar] [CrossRef]

- Shahiran, E.; Anida, I.; Norbakyah, J.; Salisa, A. Development of Penambang Boat Driving Cycle to Evaluate Energy Consumption and Emissions. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1068, 012008. [Google Scholar] [CrossRef]

- Surko, S.; Osborne, M. Operating speed profiles and the ship design cycle. Nav. Eng. J. 2005, 117, 79–85. [Google Scholar] [CrossRef]

- Winther, M.; Rypdal, K. EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019 Aviation; EMEP: Copenhagen, Denmark, 2019. [Google Scholar]

- Lyu, Y.; Liem, R.P. Flight performance analysis with data-driven mission parameterization: Mapping flight operational data to aircraft performance analysis. Transp. Eng. 2020, 2, 100035. [Google Scholar] [CrossRef]

- Dicks, A.L. PEM Fuel Cells: Applications; Elsevier Ltd.: Amsterdam, The Netherlands, 2012; Volume 4. [Google Scholar] [CrossRef]

- TUDelft. Aerospace Design and Systems Engineering Elements I; TUDelft: Delft, The Netherlands, 2017; p. 2017. [Google Scholar]

- Kyprianidis, K.G. Future Aero Engine Designs: An Evolving Vision. Available online: cdn.intechopen.com/pdfs/22893/InTech-Future_aero_engine_designs_an_evolving_vision.pdf (accessed on 23 January 2022).

- Drive Smart. Speed Limits by Country. Drive Smart. 2010. Available online: https://www.rhinocarhire.com/Drive-Smart-Blog/Speed-Limits-by-Country.aspx (accessed on 23 January 2022).

- Wang, H.; Zhang, X.; Ouyang, M. Energy consumption of electric vehicles based on real-world driving patterns: A case study of Beijing. Appl. Energy 2015, 157, 710–719. [Google Scholar] [CrossRef]

- Ahmadi, S.; Bathaee, S.; Hosseinpour, A.H. Improving fuel economy and performance of a fuel-cell hybrid electric vehicle (fuel-cell, battery, and ultra-capacitor) using optimized energy management strategy. Energy Convers. Manag. 2018, 160, 74–84. [Google Scholar] [CrossRef]

- Zhao, R.; Lorenz, R.D.; Jahns, T.M. Lithium-ion Battery Rate-of-Degradation Modeling for Real-Time Battery Degradation Control during EV Drive Cycle. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition, ECCE, Portland, OR, USA, 23–27 September 2018; pp. 2127–2134. [Google Scholar] [CrossRef]

- Wang, Y.; Moura, S.J.; Advani, S.G.; Prasad, A.K. Optimization of powerplant component size on board a fuel cell/battery hybrid bus for fuel economy and system durability. Int. J. Hydrogen Energy 2019, 44, 18283–18292. [Google Scholar] [CrossRef]

- Sun, Z.; Wen, Z.; Zhao, X.; Yang, Y.; Li, S. Real-world driving cycles adaptability of electric vehicles. World Electr. Veh. J. 2020, 11, 19. [Google Scholar] [CrossRef]

- Alves, J.; Baptista, P.; Gonçalves, G.; Duarte, G. Indirect methodologies to estimate energy use in vehicles: Application to battery electric vehicles. Energy Convers. Manag. 2016, 124, 116–129. [Google Scholar] [CrossRef]

- Janulin, M.; Vrublevskyi, O.; Prokhorenko, A. Energy Minimization in City Electric Vehicle using Optimized Multi-Speed Transmission. Int. J. Automot. Mech. Eng. 2022, 19, 9721–9733. [Google Scholar] [CrossRef]

- Pollet, B.G.; Staffell, I.; Shang, J.L. Current status of hybrid, battery and fuel cell electric vehicles: From electrochemistry to market prospects. Electrochim. Acta 2012, 84, 235–249. [Google Scholar] [CrossRef]

- Lanzarotto, D.; Marchesoni, M.; Passalacqua, M.; Prato, A.P.; Repetto, M. Overview of different hybrid vehicle architectures. IFAC-Pap. 2018, 51, 218–222. [Google Scholar] [CrossRef]

- Grammatico, S.; Balluchi, A.; Cosoli, E. A series-parallel hybrid electric powertrain for industrial vehicles. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, VPPC, Lille, France, 1–3 September 2010; pp. 1–5. [Google Scholar] [CrossRef]

- Wu, B.; Parkes, M.A.; Yufit, V.; De Benedetti, L.; Veismann, S.; Wirsching, C.; Vesper, F.; Martinez-Botas, R.F.; Marquis, A.J.; Offer, G.J.; et al. Design and testing of a 9.5 kWe proton exchange membrane fuel cell–supercapacitor passive hybrid system. Int. J. Hydrogen Energy 2014, 39, 7885–7896. [Google Scholar] [CrossRef]

- Kingston, L. BMW i8 Long-Term Test Review: Our Final Verdict. Car Mag. 2020. Available online: https://www.carmagazine.co.uk/car-reviews/long-term-tests/bmw/bmw-i8-2016-hybrid-long-term-test-review/ (accessed on 4 December 2021).

- Varga, B.O. Electric vehicles, primary energy sources and CO2 emissions: Romanian case study. Energy 2013, 49, 61–70. [Google Scholar] [CrossRef]

- Whitehead, J. Here’s Why Electric Cars Have Plenty of Grunt, Oomph and Torque; The Conversation: Melbourne, VIC, Australia, 2019. [Google Scholar]

- Meddour, A.; Rizoug, N.; Babin, A. The influence of driving cycle characteristics on motor optimisation for electric vehicles. In Proceedings of the 2022 30th Mediterranean Conference on Control and Automation, MED, Vouliagmeni, Greece, 28 June–1 July 2022; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2022; pp. 43–48. [Google Scholar] [CrossRef]

- Zhao, X.; Ma, J.; Wang, S.; Ye, Y.; Wu, Y.; Yu, M. Developing an electric vehicle urban driving cycle to study differences in energy consumption. Environ. Sci. Pollut. Res. 2019, 26, 13839–13853. [Google Scholar] [CrossRef]

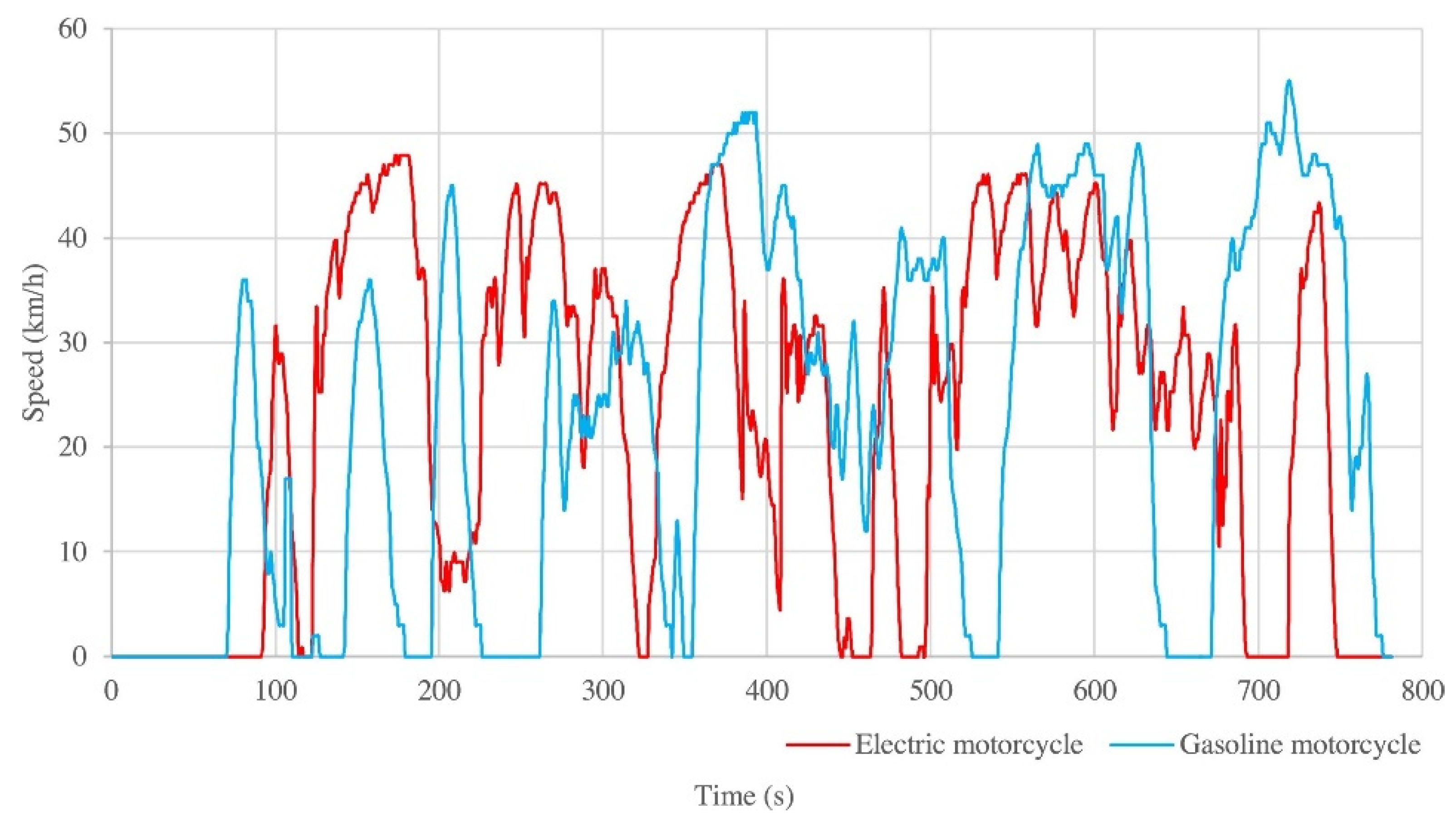

- Koossalapeerom, T.; Satiennam, T.; Satiennam, W.; Leelapatra, W.; Seedam, A.; Rakpukdee, T. Comparative study of real-world driving cycles, energy consumption, and CO2 emissions of electric and gasoline motorcycles driving in a congested urban corridor. Sustain. Cities Soc. 2019, 45, 619–627. [Google Scholar] [CrossRef]

- Borgia, F.; Samuel, S. Design of Drive Cycle for Electric Powertrain Testing. In SAE Technical Papers; SAE International: Warrendale, PA, USA, 2023. [Google Scholar] [CrossRef]

- Lawrence, C.; ElShatshat, R.; Salama, M.; Fraser, R. An efficient auxiliary system controller for Fuel Cell Electric Vehicle (FCEV). Energy 2016, 116, 417–428. [Google Scholar] [CrossRef]

| Stage | Definition |

|---|---|

| Taxi-out | Travelling on land from parking area to runway |

| Take-off | Transition stage from land propulsion to air propulsion; aircraft takes off from the runway |

| Climb | Aircraft ascends to a predetermined cruising altitude |

| Cruise | Aircraft flying at optimal level to proceed to destination prior to descent, usually the longest stage |

| Descent | Aircraft decreases in altitude in preparation for landing |

| Final Approach | Aircraft positioned to start landing onto the runway |

| Landing | Aircraft returns to land propulsion mode |

| Taxi-in | Travelling on land from runway to parking area |

| Drive Cycle Feature | Definition |

|---|---|

| Average speed | Sum of all speed data values divided by the number of data points (equal to the total duration if datalogging interval is 1 s) |

| Idle time percentage | Ratio of time stopped divided by total time (percentage) |

| Velocity variance | Sum of the speed at a given time minus the average velocity squared, divided the total number of data points |

| Energy | Sum of squared speed values |

| Maximum speed | Maximum speed value |

| Minimum speed | Minimum speed value |

| Difference between maximum speed and minimum speed | Minimum speed subtracted from maximum speed |

| Average acceleration or deceleration | Sum of all acceleration or deceleration values divided by the total number of data points |

| Acceleration variance | Sum of the acceleration values at a given time minus the average acceleration, squared, divided by the total number of data points |

| Average acceleration | Sum of all acceleration values divided by the number of data points |

| Average deceleration | Sum of all deceleration values divided by the number of data points |

| Percentage of cruising | Time travelling at a constant speed divided total time (percentage) |

| Maximum acceleration or deceleration | Maximum value of acceleration or deceleration |

| Minimum acceleration or deceleration | Minimum value of acceleration or deceleration |

| Total distance | Total distance travelled (can be obtained by integrating the speed vs. time graph) |

| Average square acceleration | Sum of acceleration squared divided by the number of data points |

| Relative acceleration | Sum of speed values multiplied by acceleration at a given time over the total distance |

| Relative deceleration | Sum of speed values multiplied by deceleration at a given time over the total distance |

| Percentage of time when absolute acceleration and deceleration >1.5 m s−2 | Time during which the acceleration >1.5 m s−2 divided by the total time (percentage) |

| Percentage of time when absolute velocity times acceleration is between 3 and 6 m2 s−3 | Time during which the absolute velocity is between 3 and 6 m2 s−3 divided by the total time (percentage) |

| Author | Parameters Compared | Drive Cycles Used | Conclusions or Takeaway |

|---|---|---|---|

| Jeong et al. [15] | Performance evaluation, acceleration | Non-legislated Gwacheong, Korea drive cycle | Higher acceleration of electric motors not accurately represented in conventional drive cycles |

| Meddour et al. [68] | Battery sizing, electric motor cost, electric motor loss | WLTP, FTP-75, Artemis 150, and Artemis Urban | Torque demands vary drastically between drive cycles, choosing an accurate drive cycle is important |

| Zhao et al. [69] | Range estimation, energy consumption | XA-EV-UDC, FTP-72, FTP-75, JC08, 10–15 Mode, NEDC, and ECE-15 | Using conventional drive cycles for range estimation and energy consumption can produce a relative error as high as 38.14% and 21.17%, respectively |

| Koossalapeerom et al. [70] | Time spent during acceleration and deceleration, time spent cruising, speed, energy consumption, EV vs. CV | Non-legislated EV and CV motorcycle drive cycle in Khon Kaen City, Thailand | The EV drive cycle has less time spent during acceleration and deceleration, suggesting higher cruising times. Energy consumption of EV drive cycle can be as high as eight times lower than that of CV drive cycle |

| Borgia et al. [71] | Acceleration, deceleration, range estimation, intermediate vs. harsh driving, overall drive cycle attributes, EV vs. hybrid vs. CV | SEVCI, SEVCH, WLTP, NEDC | Acceleration and deceleration times are less for the EV when compared to CV, regenerative braking and electric motor characteristics are the main cause. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.D.; Millichamp, J.; Suter, T.; Shearing, P.R.; Brett, D.J.L.; Robinson, J.B. A Review of Drive Cycles for Electrochemical Propulsion. Energies 2023, 16, 6552. https://doi.org/10.3390/en16186552

Yang JD, Millichamp J, Suter T, Shearing PR, Brett DJL, Robinson JB. A Review of Drive Cycles for Electrochemical Propulsion. Energies. 2023; 16(18):6552. https://doi.org/10.3390/en16186552

Chicago/Turabian StyleYang, Jia Di, Jason Millichamp, Theo Suter, Paul R. Shearing, Dan J. L. Brett, and James B. Robinson. 2023. "A Review of Drive Cycles for Electrochemical Propulsion" Energies 16, no. 18: 6552. https://doi.org/10.3390/en16186552

APA StyleYang, J. D., Millichamp, J., Suter, T., Shearing, P. R., Brett, D. J. L., & Robinson, J. B. (2023). A Review of Drive Cycles for Electrochemical Propulsion. Energies, 16(18), 6552. https://doi.org/10.3390/en16186552