Abstract

Concerns about the depletion of petroleum reserves and rising pollution led researchers to search for alternate and environmentally compatible fuels for compression ignition engines. As an excellent alternative fuel additive to biodiesel–diesel blends, higher alcohol exhibits outstanding fuel properties (such as high energy content and cetane number) and can operate in diesel engines without requiring engine changes. This study focuses on investigating the ternary blends comprising higher alcohols, namely 1-heptanol and n-octanol, in hybrid biodiesel (animal fat oil–rice bran oil–cottonseed oil) and diesel on compression ignition engine characteristics. The performance, combustion, and emissions of a diesel engine fuelled with mono (D100), binary (B20), and ternary fuel blends (B20H10, B20H20, B20O10, and B20O20) were analysed at a constant engine speed of 1500 rpm. The test fuels met the American Society for Testing and Materials standards for fuel properties and exhibited stable behaviour during testing. Experimental results showed that at 100% load, the least brake-specific fuel consumptions for diesel fuel, B20, B20H10, B20H20, B20O10, and B20O20 were 254.1 g/kWh, 302.14 g/kWh, 281.25 g/kWh, 310.94 g/kWh, 292.8 g/kWh, and 313.80 g/kWh, respectively. Meanwhile, the maximum brake thermal efficiency values were obtained as 38.65%, 37.01%, 37.76%, 36.84%, 37.12%, and 36.38%, respectively. At 100% load, the peak heat release rates for diesel, B20, B20H10, B20H20, B20O10, and B20O20 were found to be 64.65 J/deg, 59.07 J/deg, 62.34 J/deg, 56.12 J/deg, 57.95 J/deg, and 51.9 J/deg, respectively. The addition of 1-heptanol and n-octanol as oxygenated additives into the ternary blend resulted in decreased carbon monoxide and unburned hydrocarbon emissions while increasing carbon dioxide and nitrous oxide emissions compared to diesel fuel. Overall, the study concludes that ternary blends with 1-heptanol and n-octanol as additives improve performance and combustion behaviour and reduce exhaust emissions compared to binary blends.

1. Introduction

Energy has become a crucial topic in both the global economy and human life, with its advancement and usage significantly impacting the sustainability of the human community [1]. Unfortunately, the escalating demand for conventional diesel fuel is rapidly depleting the world’s finite petroleum reserves [2,3]. Diesel engines, being highly efficient powertrains, play a vital role in powering various sectors of the global economy, including industry, agriculture, and transportation [4,5]. However, the utilization of fossil fuels in these engines releases substantial amounts of hazardous pollutants like soot and nitrogen oxides (NOx) [6]. Consequently, the pressing issues of climate change, acid rain, global warming, and increased greenhouse gas emissions have prompted governments and stakeholders to tighten pollution regulations, driving the academic community to seek long-term solutions for securing future energy supplies [7].

In response, researchers have conducted numerous studies on alternative fuels over the last few decades. Among these options, biodiesel is derived from a range of sources, including both edible and non-edible oilseeds. Edible oilseeds, such as rice bran oil, soybean, linseed, rapeseed, sunflower, safflower, peanut, cashew nut, and coconut, serve as viable feedstocks for biodiesel production [8]. Additionally, biodiesel can also be obtained from waste cooking oil and animal fat, like meat tallow [9,10]. In the case of non-edible oilseeds, feedstocks such as mahua, neem, cottonseed, Karanja, and jatropha can be utilized to produce biodiesel [11]. These diverse sources provide ample options for the production of biodiesel to meet various energy needs for traditional diesel fuel in the energy mix [5]. Transportation uses a lot of fossil fuels, mostly in internal combustion engines. Diesel engines are preferred for their combustion efficiency, dependability, cost-effectiveness, and flexibility [12]. Due to their widespread use, harmful exhaust gas emissions have increased. Vehicle and engine use in cities are rising, causing environmental degradation [2,4]. Vehicles emit large volumes of unburned hydrocarbons (HCs), carbon monoxide (CO), and NOx in densely populated cities [1]. Pollutants harm humans and the environment [13]. As a result, experts throughout the world are searching for options to reduce pollution and achieve energy independence [14].

In general, biodiesel has a greater cetane number than conventional diesel fuel, resulting in a shorter ignition delay period, implying that the engine starts quickly and runs smoothly [10,15,16,17]. Biodiesel is a beneficial fuel as it possesses a higher flash point and cetane number than diesel [15]. Butanol proportions of more than 10% in a biodiesel blend reduce the cetane number and increase the water content [16]. Alcohols (n-propanol, n-butanol, n-pentanol, n-hexanol, n-heptanol, n-octanol, and so on) contribute to next-generation biofuels possessing excellent fuel characteristics, resulting in reduced CO and NOx emissions and ignition delay with n-butanol addition to mahua biodiesel [17]. Several researchers [18,19,20] reported that biodiesels frequently have lower cetane numbers (CNs) than the minimal limitations established in standards such as EN 14, 214 (minimum 51) and ASTM D6751 (minimum 47). This lower CN can be due to biodiesels’ greater quantities of unsaturated fatty acids. Lower CN causes an increase in ignition delay and NOx emissions [18]. When compared to regular diesel fuel, biodiesel with alcohols reduces NOx emissions and improves the combustion properties [19]. The inclusion of pyrogallol enhances the cetane number in Moringa oleifera biodiesel, improving BTE and lowering NOx emissions [20]. Much research has explored how biodiesel affects diesel engine combustion and emissions. Yesilyurt et al. [21] examined the effects of biodiesel with diesel fuel at various fractions. Biodiesel increased exhaust gas temperature, NOx, and carbon dioxide (CO2) while decreasing brake thermal efficiency, CO, and smoke emissions. The authors [22,23] examined diesel engine performance and emissions using biodiesel/diesel blends with different biodiesel fractions. B100 had the lowest torque [24]. Due to biodiesel’s oxygenation, blends produced more NOx and less CO and smoke. Ge et al. [25] compared diesel and canola oil biodiesel emissions. Biodiesel had decreased peak pressure, thermal efficiency, CO, and PM emissions but higher NOx emissions [26,27]. Further, biodiesel to diesel fuel increases brake-specific fuel consumption (BSFC), NOx emissions, HC emissions, CO emissions, CO2 emissions [28,29], and particulate matter (PM) emissions [30,31]. Due to decreasing energy content, brake thermal efficiency (BTE) has changed to a certain limit [32]. Biodiesel’s high viscosity, poor low-temperature behaviour, and low volatility reduce combustion efficiency and quality, especially at low temperatures. Biodiesel’s low volatility and high viscosity also affect fuel atomization during injection [33,34].

Biodiesels have poor low-temperature characteristics, causing crystalline formations and fatty acid solidification [12]. Blending biodiesels with alcohols of different chain lengths can solve these concerns. Alcohols contain more oxygen than biodiesel and diesel fuel, which can ameliorate their drawbacks. Biomass fermentation produces liquid biofuels including methanol, ethanol, and butanol. They are essential spark ignition and compression ignition (CI) engine fuel alternatives [35,36]. Cheaper and more environmentally friendly than other methods are alcohol fermentation [37]. Alcohols have been extensively researched as engine fuels in recent decades. This adoption reduces air pollution and promotes renewable energy [19]. Methanol and ethanol have been extensively studied for biodiesel production in micro-reactors [38]. Methanol and ethanol are mixed with diesel fuel, biodiesel, or biodiesel/diesel fuel mixes to run the diesel engines [39,40,41]. NOx emissions are decreased when ethanol is added to a biodiesel–diesel blend [39]. Blends of biodiesel, diesel, and ethanol lower the levels of NOx, CO, HC, and smoke opacity [40]. However, CO2 emissions are increased. The thermal efficiency of diesel fuel tends to be improved by the addition of methanol and ethanol, although higher NOx emissions are a trade-off [41]. The major drawbacks of lower alcohols (ethanol and methanol) are low cetane number and flash point and difficulty in handling and storage [19]. To limit the disadvantages of lower alcohols, the higher alcohols with biodiesel–diesel blends are of significant relevance.

Alcohol-treated fuels reduce engine torque, CO, and smoke emissions while increasing BSFC. Oxygen-rich alcohols improve premixed and diffusive combustion [26]. Recent research has concentrated on higher alcohols, rather than lower chain alcohols, as diesel fuel substitutes in terms of combustion. Higher alcohols (alcohols with long chains of molecules), like C4–C8 and C4–C20 alcohols, are receiving more attention because they have more benefits than lower alcohols [42]. Higher alcohols are better diesel alternatives since they have similar physicochemical features [43]. Higher alcohols are long-chain alcohols with molecular weights and carbon atoms over three such as butanol, pentanol, hexanol, heptanol, octanol, decanol, and phytol [44]. Higher alcohols offer promising capabilities for diesel engines such as higher energy content, the ability to mix well with diesel (without any phase separation), superior density, lubricity, better ignition, less corrosion due to less water content, safer handling, and a broad range of flash points [45,46]. CI engines benefit from higher alcohols with long-chain carbon atoms. Higher alcohols have more diesel engine potential than lower alcohols [26]. Heptanol has a longer carbon chain structure, making it a better diesel engine fuel [21,47,48]. Heptanol has an increased cetane number and calorific value. Its decreased latent heat of vaporization hinders cold-start operations [6]. Across all load levels, heptanol in diesel fuel reduces CO and HC emissions but increases CO2 and NOx emissions in a single-cylinder diesel engine [21]. Nour et al. [40] evaluated the performance of a single-cylinder diesel engine operating at various loads and speeds while using heptanol at a volume ratio of 10% to 50% [49]. Alcohols and their blends with diesel can run at lower fuel-to-air ratios due to the oxygen in their structure [5]. They also have a higher octane rating, leading to a delayed ignition that produces more premixed combustion and less soot and smoke [44]. Most studies on higher alcohol diesel blends have focused on combustion studies, while fuel properties of higher alcohol diesel blends have received less attention [47,49,50]. Beta oxidation reversal, expanding the 1-butanol route, rerouting branched-chain amino acid biosynthesis, and microorganisms like Escherichia coli and Clostridium species can create octanol isomers [51,52]. n-octanol’s fuel properties including cetane number, calorific value, lower vapour pressure, and flash point outperform those of other higher alcohols (<C8), making it appropriate for biodiesels. Due to its 0.08 mm Hg vapour pressure, n-octanol is safe to store, handle, and transport [53]. Directly fuelling a diesel engine with biodiesel and alcohol causes combustion difficulties, rendering it unsuitable. Researchers have investigated binary mixtures such as diesel–biodiesel, biodiesel–alcohol, and diesel–alcohol. Recently, ternary blends of biodiesel–alcohol–diesel have been studied to minimize diesel fuel use. Ternary fuels possess a tendency to enhance performance features and minimize exhaust pollutants [46,54]. Recent investigations have studied higher alcohols in ternary fuels [52,55,56,57]. Higher-alcohol-based decanol was added to neem biodiesel and diesel to enhance engine performance and reduce emission characteristics without engine modification [55]. Ternary blends (mustard seed oil biodiesel, diesel, and alcohol: butanol and pentanol) showed improved performance in reducing emissions without compromising performance with brake power and torque [56]. Calophyllum inophyllum biodiesel, diesel, and additives (nanoparticles, alcohols, and antioxidants) forming ternary blends showed improved performances in diesel engines [57]. Not much research effort has been made with the use of higher alcohols (1-heptanol and n-octanol), biodiesel, and diesel as ternary blends to evaluate engine combustion, performance, and emission characteristics.

Motivation, Novelty, and Objective of the Study

According to the literature review, there is a significant research gap regarding the performance, combustion behaviour, and environmental characteristics of diesel engines running on 1-heptanol and n-octanol blends, especially at low mixing proportions of up to a 20% volume. To the best of the author’s knowledge, there is limited research on 1-heptanol and n-octanol-blended hybrid biodiesel (animal fat oil–rice bran oil–cottonseed oil)–diesel fuel blends in CI engines to assess performance, emissions, and combustion characteristics at different engine loads (25%, 50%, 75%, and full load) and a fixed engine speed of 1500 rpm. This experimental study is unique in that it bridges the research gap by thoroughly evaluating engine performance indicators (BSFC and BTE), combustion characteristics (in-cylinder pressure and net heat release rate), and exhaust emissions (CO, CO2, HC, and NOx emissions). The research adopted a single-cylinder, four-stroke, water-cooled, common rail direct injection (CRDI) computerized diesel engine that ran on diesel fuel, pure hybrid oil biodiesel, diesel/hybrid oil biodiesel, diesel/hybrid oil biodiesel/1-heptanol blends and diesel/hybrid biodiesel/n-octanol blends. Lower amounts of 1-heptanol and n-octanol were used in this study for a variety of reasons. For starters, a modest quantity of 1-heptanol (10% and 20% by volume) and n-octanol (10% and 20% by volume) can be blended with diesel/biodiesel without requiring engine modifications, saving money on engine and component modifications. Secondly, 1-heptanol and n-octanol have a lower manufacturing capacity and a greater cost than regular diesel fuel. As a result, the emphasis was on assessing lower concentrations of 1-heptanol and n-octanol. The results of the 1-heptanol and n-octanol blends were compared to those of higher alcohol blends, and thorough explanations were offered. Overall, this study fills a research gap and provides valuable insights into the performance, emissions, and combustion characteristics of diesel engines fuelled by 1-heptanol and n-octanol blends, particularly at lower mixing proportions, adding to existing knowledge on alternative diesel fuel options.

2. Materials and Methods

2.1. Preparations of the Fuels

Ternary fuel samples were prepared using the splash blending method, incorporating conventional diesel fuel (D100) as a reference. To prepare binary blend B20 and ternary blends B20H10, B20H20, B20O10, and B20O20, the volume percentages of 1-heptanol and n-octanol were increased from 10% to 20%. The properties of higher alcohols are presented in Table 1. The binary and ternary blends were selected after conducting pilot experiments at the research laboratory. Magnetic stirring was employed to ensure blend quality. The fuel samples were stored in sealed bottles under laboratory conditions for one week at 27 °C without phase separation as shown in Figure 1.

Table 1.

The properties of hybrid biodiesel, mineral diesel fuel, and higher alcohols.

Figure 1.

The physical appearance of diesel fuel, HBO, binary blends, and ternary blends.

2.2. Testing of the Fuels

The high-quality hybrid biodiesel derived from ternary oils (TOs) of animal fat–rice bran–cottonseed was produced by employing a single-stage transesterification method (SSTM) in a laboratory-scale biodiesel processor in the Biofuel Laboratory of the Department of Mechanical Engineering at Visvesvaraya Technological University in Mysuru, Karnataka, India. Prior to the SSTM, animal fat–rice bran–cottonseed oils were mixed to produce TOs. The SSTM was undertaken by employing esterified TOS in the presence of NaOH as an alkali catalyst. The physicochemical properties of the hybrid biodiesel, mineral diesel fuel, and higher alcohols are presented in Table 1.

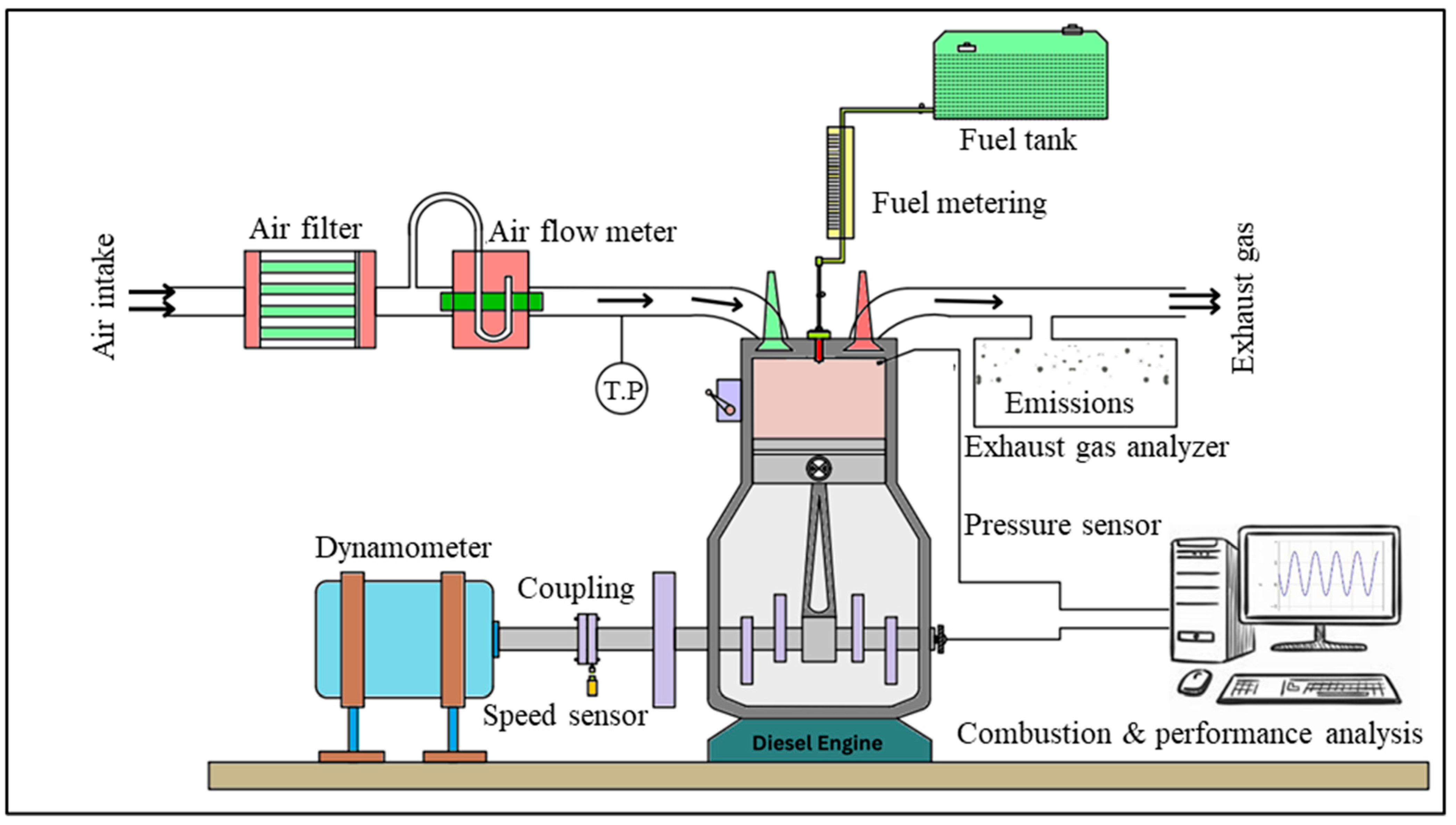

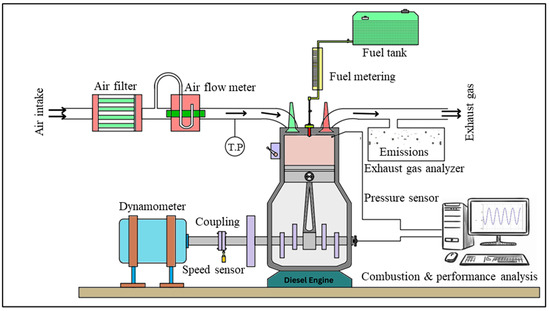

2.3. Test Engine and Facilities

The engine performance, exhaust gas emissions, and combustion characteristics of the prepared fuel blends were evaluated at the Biodiesel Research and Demonstration Centre, located at Vidyavardhaka College of Engineering in Mysuru, Karnataka, India. The testing was conducted on an engine test rig using a single-cylinder, four-stroke, naturally aspirated, water-cooled computerized engine. This engine had a bore of 87.5 mm, a stroke of 110 mm, and a capacity of 661 cc. The overall dimension of an engine is W 2000 × D 2500 × H 1500 mm. Detailed technical specifications of the engine can be found in Table 2. The experimental set-up and measurement system are depicted in Figure 2, while a photograph of the test rig is provided in Figure 3.

Table 2.

Technical specifications of the test engine.

Figure 2.

Schematic diagram of the experimental setup and measurement system.

Figure 3.

Test rig for binary and ternary blend fuels.

Cylinder pressure (CP) and net heat release rate (NHRR) measurements are used to determine the combustion characteristics of a CI engine running on various fuel types. A typical injection timing of 23° before the top dead centre (TDC) was used for experiments.

Table 3 provides a brief overview of integrated sensors and transmitters. It includes key details like measurement range, manufacturer, and relative uncertainty for each component. It further provides insights into equipment capabilities and precision in the experimental setup. Table 4 summarizes the AVL exhaust gas analyser specifications, a crucial tool in the test rig. It outlines measurements, resolutions, and descriptions of parameters assessed: CO, HC, CO2, NOx, and lambda. In addition, it concisely presents the analyser’s capabilities, enhancing the comprehension of its role in the experiment.

Table 3.

Specifications of Sensors and Transmitters in the Test Rig.

Table 4.

Specifications of AVL Exhaust Gas Analyser.

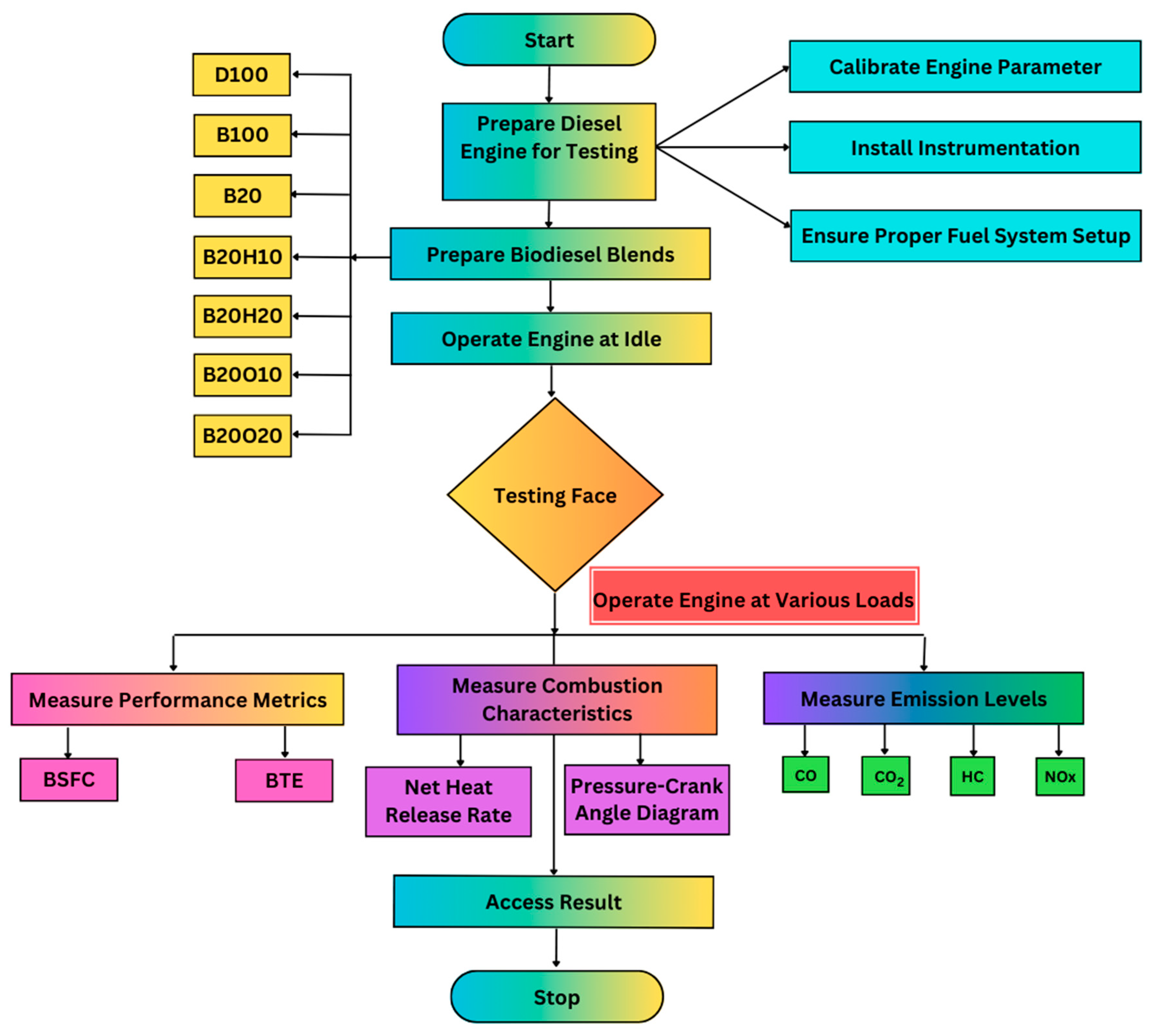

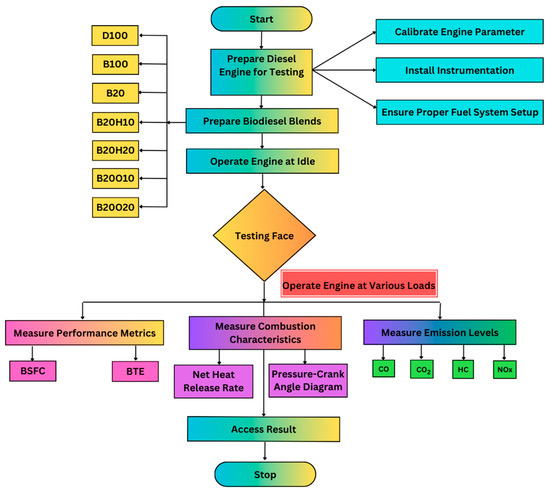

2.4. Experimental Procedures

In order to establish steady conditions, the process begins with a 15 min engine warm-up, utilizing just 100% diesel fuel. After achieving consistent conditions across all tested fuels, trials occurred within a temperature range of 25–27 °C and a humidity range of 55–60%. Diesel fuel was used as the reference. Engine performance, emissions, and combustion were evaluated under different loads (25%, 50%, 75%, and 100%) at a steady speed of 1500 rpm. The CP data were meticulously collected for each working cycle, spanning a 720° crank angle with precise 1° intervals for all loads. Averaged pressures for tested fuels were derived from a minimum of 25 cycles, using adept filtering. The “Engine Soft” software enabled comprehensive engine assessment, with each test conducted thrice for accuracy. Data were collected on an assortment of parameters, including current, voltage, temperatures, pressures, air and fuel mass flow rates, and the composition of exhaust gases. The same approach described above is used to test the binary (B20) and ternary blends (B20H10, B20H20, B20O10, and B20O20). After each fuel blend test, the fuel line was cleansed with pure diesel. Key variables such as brake power, thermal efficiency, fuel consumption, and combustion characteristics were computed using an in-depth analysis of the collected data. Throughout, strict adherence to safety protocols ensured the reliability and legitimacy of outcomes. The methodology employed to perform experiments and analysis is illustrated in Figure 4.

Figure 4.

Methodology of the present work.

2.5. Error and Uncertainty Analysis

Generally, experimental measurements carry inherent errors and uncertainties [62]. Within this research, the error associated with the measured parameters originates from the random error anticipated by the analytical technique [63]. It was quantified using Equation (1).

The uncertainty linked with computational parameters is derived based on the root mean square principle [64]. In this context, the uncertainty for the computational parameters can be expressed using Equations (2) and (3).

where R is a function dependent on independent variables from . Let u1, u2, …, un be uncertainties associated with these independent variables, while UR stands for the resulting uncertainty.

The detailed measurement range and precision of the instruments employed in this research are summarized in Table 5. Uncertainty analysis is carried out to know the accuracy obtained from the experiments. Each set of experiments is repeated thrice and recorded the response measurement data. The resulting uncertainty corresponding to each factor is presented in Table 5.

Table 5.

Experimental uncertainty of various measuring units.

The total uncertainty derived from the experiments can be computed using Equation (4).

The overall uncertainty in experiments was found to be ±3.752%. The reproducibility of results is indicated by the less than 5% uncertainty related to experiments and equipment.

3. Results and Discussion

The study analyses the engine performance, exhaust emissions, and combustion behaviour of different fuel samples in a diesel engine. The tested fuels include diesel, B20, B20H10, B20H20, B20O10, and B20O20. The experiments were conducted at varying engine loads (25%, 50%, 75%, and full load) while maintaining a constant engine speed of 1500 rpm. Comparisons between binary and ternary biodiesel–diesel blends and conventional diesel were made when 1-heptanol and n-octanol were added to diesel fuel, as well as their effects.

3.1. Combustion Analysis

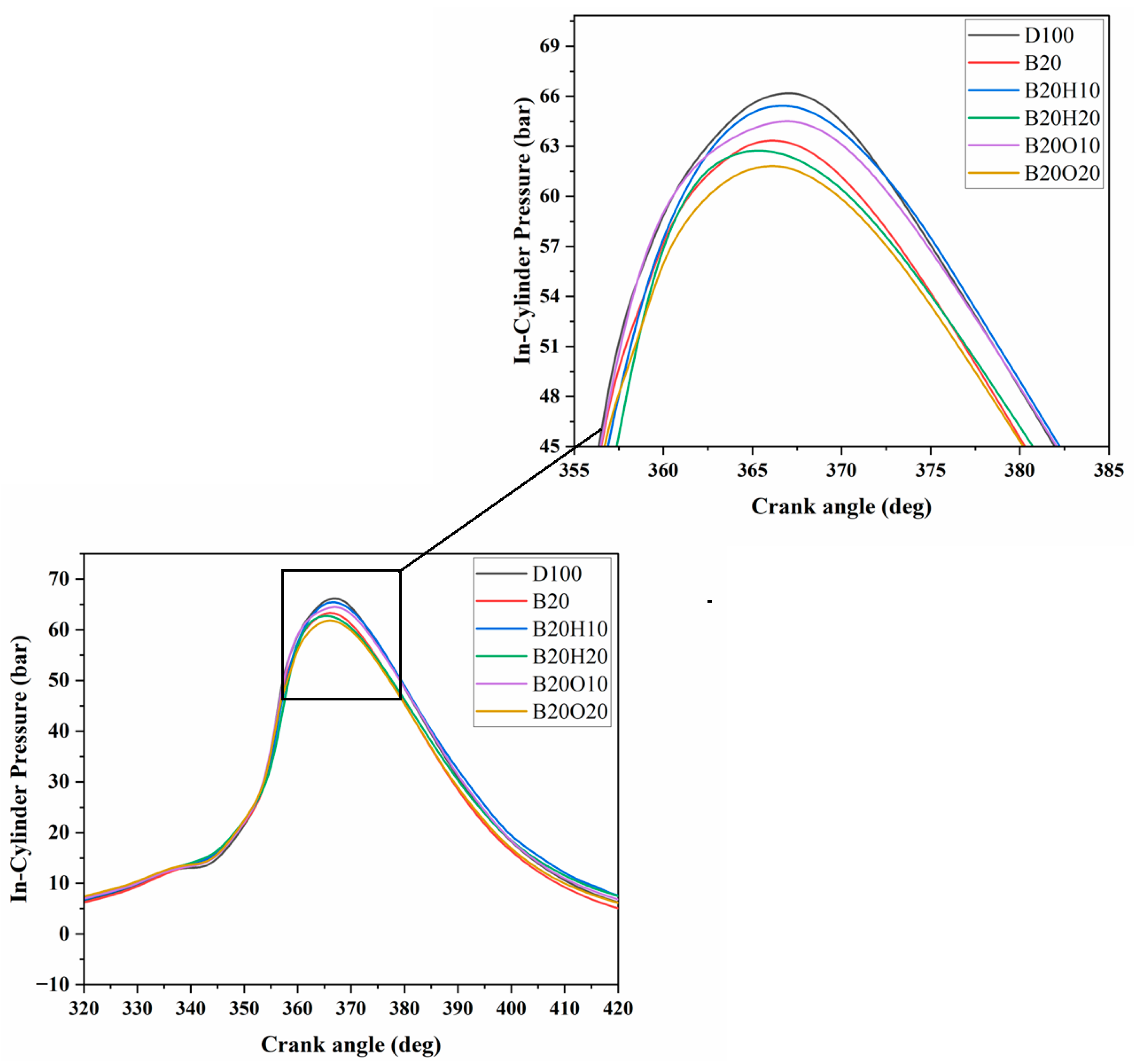

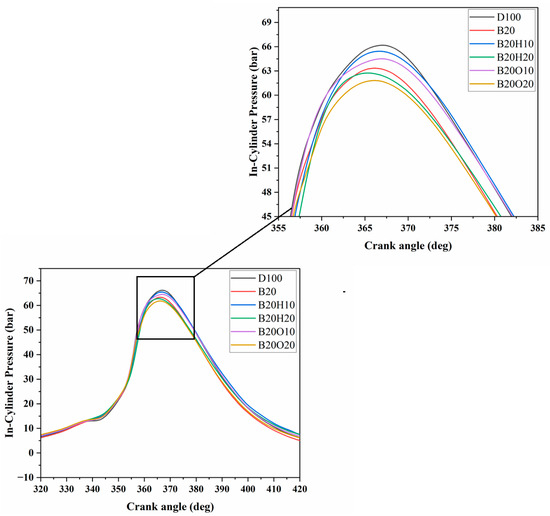

3.1.1. In-Cylinder Pressure

CP was examined in order to comprehend the mechanism underlying the combustion of the composite biodiesel in ICEs. The amount of fuel used during uncontrolled combustion has a negative effect on the CP. Figure 5 shows the trends of the pressure in the cylinder changes for different fuel samples when the engine is run at full load. At 100% engine load, the highest pressure in the cylinders was 66.18 bar for diesel fuel, 63.34 bar for B20, 65.42 bar for B20H10, 62.73 bar for B20H20, 64.51 bar for B20O10, and 61.82 bar for B20O20. At the TDC, when the crank angle was between 5° and 8°, these highest pressures were observed. The highest peak CP was achieved with diesel fuel (DF), and this can be attributed to its superior calorific value and efficient fuel atomization. Diesel fuel consistently displayed the highest in-cylinder pressure profiles in all engine load situations because of its higher calorific value (42.54 MJ/kg) and superior fuel atomization characteristics (Table 1). The trends of the peak in-cylinder gas pressure at the lower alcohol fractions slightly decreased when 10% of 1-heptanol and n-octanol was added to the diesel/biodiesel fuel blend. This may be due to 1-heptanol having a lower auto-ignition temperature than n-octanol (270 °C), as shown in Table 1.

Figure 5.

Peak in-cylinder pressure variation with engine load for different fuel samples (1500 rpm).

However, increasing the percentage to 20% in the diesel/biodiesel fuel blend led to a reduction in CP. These combustion trends are mainly due to the difference in energy and oxygen contents in 1-heptanol (14.13%) and n-octanol (15.7%), as shown in Table 1. The position of the in-cylinder peak pressure indicates the speed at which this energy is released. It is essential to mention that the rate of energy released depends on the presence of oxygen in the fuel structure (which accelerates combustion), viscosity (which affects fuel atomization and vaporization), and latent heat (which directly affects the ignition delay and combustion cooling). Combining these factors can explain the behaviour of CP for B20H10 and B20O10 compared to D100 and ternary blends of higher proportions of fuel blends. The binary blend of biodiesel/diesel (B20) exhibits lower CP compared to B20H10 and B20O10 and higher CP than B20H20 and B20O20, likely because the high-quality hybrid biodiesel blend with mineral diesel fuel is not significantly affected by CP. Similar trends were observed by Ramesh et al. [65] who studied a diesel engine powered by Calophyllum Inophyllum methyl ester and its blends with diesel fuel and hexanol. They found that increasing alcohol content reduced peak pressures, and their observations were ascribed to the higher latent heat of evaporation and relative specific temperatures of hexanol. Kumar et al. [66] investigated the effects of adding 30% higher-order alcohols to diesel fuel in a diesel engine. They ranked peak CP as follows: Isobutanol > n-pentanol > n-hexanol > n-octanol > ultra-low sulfur diesel fuel. Nanthagopal et al. [67]. discovered that blending n-octanol with Calophyllum Inophyllum biodiesel increased peak in-cylinder gas pressures by raising oxygen content, enhancing combustion efficiency. Emiroğlu and Şen [68] observed that alcohol-blended diesel fuels had higher and earlier peak CP, resulting in a shortened ignition delay interval.

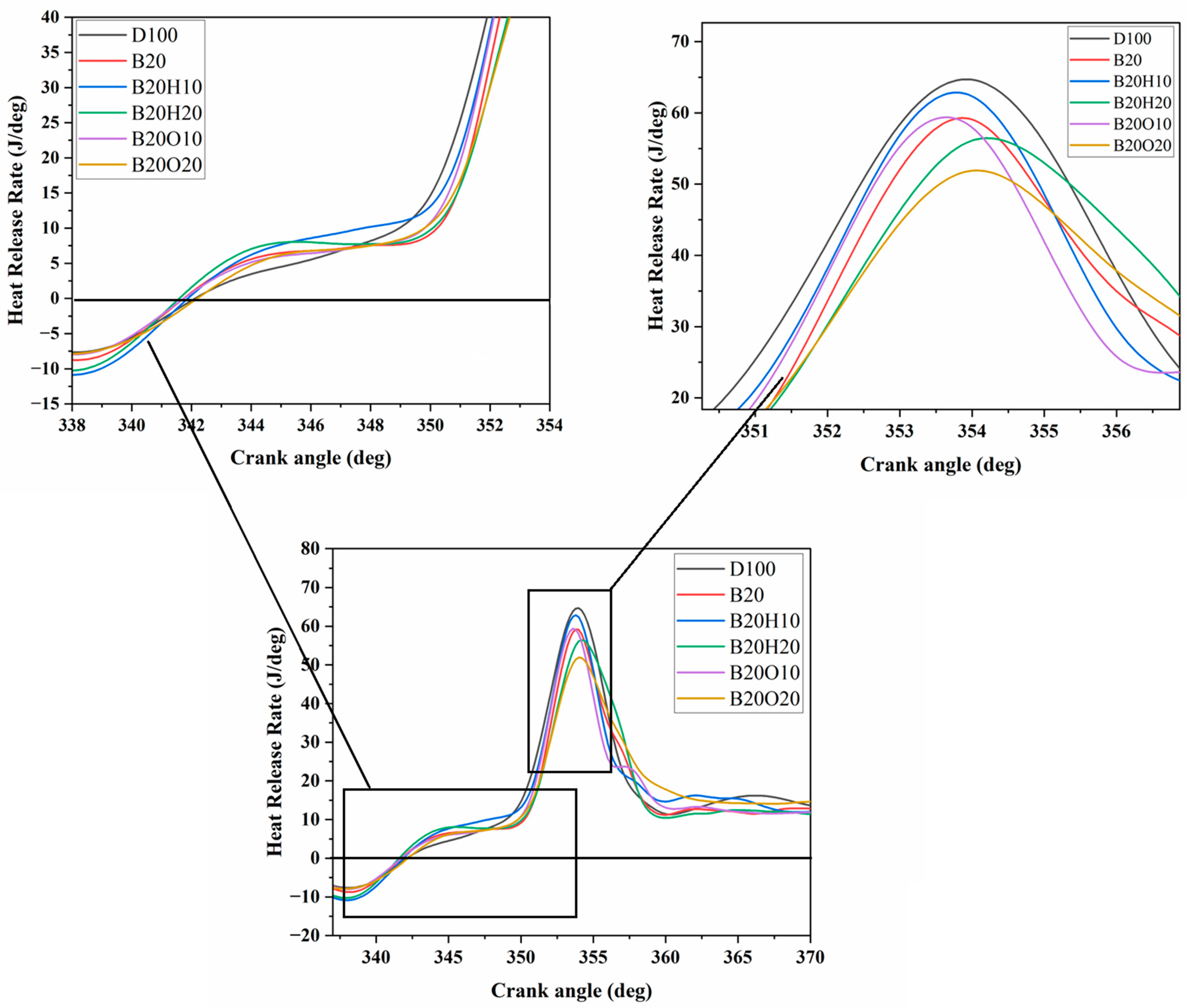

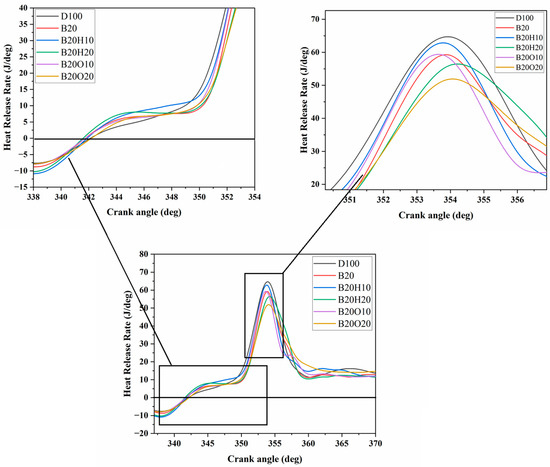

3.1.2. Net Heat Release Rate

Figure 6 illustrates the NHRR at full engine load. The NHRR test was influenced by the test fuels’ calorific value, volatile matter, cetane number, oxygen concentration, viscosity, density, and length of fuel injection [69]. Conventional diesel fuel consistently exhibited the highest peak heat release rate among all fuel samples at various engine loads. This can be attributed to its superior energy content and better fuel atomization characteristics. The highest NHRR values for D100, B20, B20H10, B20H20, B20O10, and B20O20 fuels at maximum engine load were estimated to be 64.65 J/deg, 59.07 J/deg, 62.34 J/deg, 56.12 J/deg, 57.95 J/deg, and 51.9 J/deg, respectively, and the corresponding graphs are displayed in Figure 6. A lower (10%) amount of 1-heptanol and n-octanol in the diesel/biodiesel blend gradually improves some parameters, such as fuel atomization and blending capabilities. Notably, 1-heptanol (39.92 MJ/kg) and n-octanol (38.53 MJ/kg) have higher calorific values than hybrid biodiesel. Because of its lower blending percentage with diesel and specific physicochemical properties, such as cetane number, viscosity, and density, the hybrid biodiesel blend (B20) has lower net heat release rates than unmodified diesel fuel and also low percentage blends of 1-heptanol and n-octanol mixtures (B20H10 and B20O10). However, there is no substantial improvement in heat release rate statistics when the diesel engine is fuelled with higher percentages (20%) of n-octanol to the diesel/biodiesel blend fuels (B20O20). This is mostly due to decreases in net heat release rate (51.9 J/deg) caused by excess oxygen in the structure lowering the temperature inside the cylinder, as well as the previously noted less excellent fuel qualities.

Figure 6.

The net heat release rate against crank angle at 100% load (1500 rpm).

Qi et al. [70] stated that heptanol and octanol blends show improved premixed-phase combustion compared to D100 despite their lower oxygen content. Longer ignition delays due to higher viscosities and lower cetane numbers lead to more fuel accumulation, resulting in enhanced combustion performance. Ağbulut et al. [71] remarked that an excessive amount of oxygen content in n-octanol promotes the enhancement of the combustion reaction. These findings align with studies conducted by various researchers [68,72,73]. However, Nour et al. [19] observed that the C7 and C8 types of alcohols have higher viscosities than diesel, impacting combustion efficiency negatively. Poorer fuel atomization and insufficient fuel/air mixing caused more fuel to burn in the mixing control phase and less fuel to burn in the premixed phase, which might have resulted in incomplete oxidation prior to the exhaust valve opening.

3.2. Engine Performance

Direct injection with a water-cooled diesel engine of a compression ratio of 17:5:1 (CR) at a stable speed of about 1500 rpm employing diesel (D100), binary blends of biodiesel/diesel (B20), ternary blends of diesel/biodiesel/1-heptanol (B20H10 and B20H20), and diesel/biodiesel/n-octanol (B20O10 and B20O20) blends was used for engine performance analysis. The engine power through BTE and BSFC was analysed and discussed.

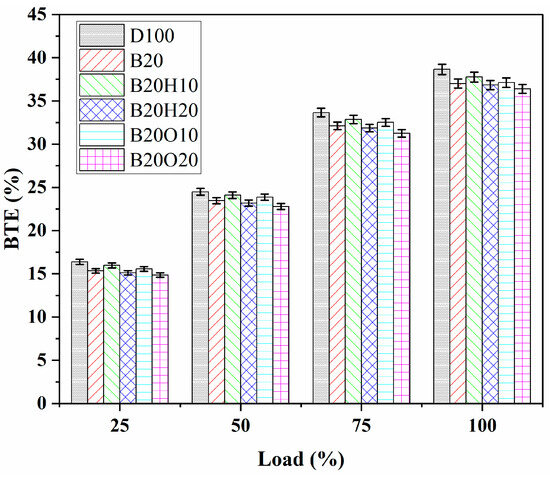

3.2.1. Brake Thermal Efficiency (BTE)

BTE is a crucial parameter that assesses the combustion quality of an engine; it is the ratio of brake power output to fuel energy consumption [74]. The brake thermal efficiency of diesel engines is the efficiency of converting the chemical energy of fuel into mechanical energy [65]. The BTE was estimated by using Equation (5).

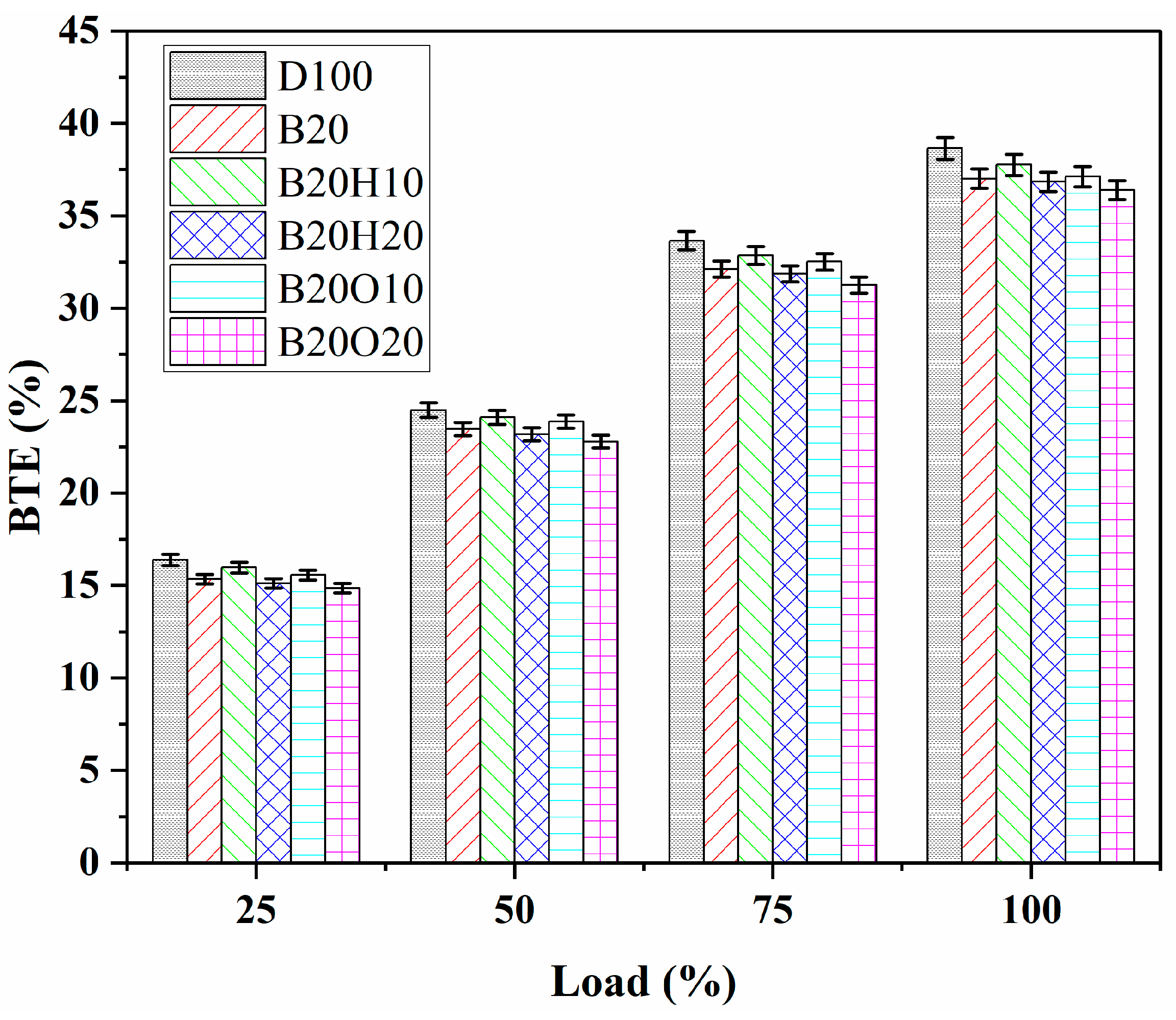

The terms QLHV, Pe, and mfuel depict the lower heat value of a fuel, effective engine power, and mass fuel consumption, respectively. Figure 7 illustrates the variation in BTE with engine load at a constant speed of 1500 rpm for diesel fuel and binary and ternary mixtures. At the maximum load, the BTE values for diesel fuel, B20, B20H10, B20H20, B20O10, and B20O20 were 38.65%, 37.01%, 37.76%, 36.84%, 37.12%, and 36.38%, respectively. According to the findings of other researchers [19,28,59], as the engine load increases, there is a fractional increase in BTE for all fuel samples following a direct proportionality between BTE and engine load. The decline in BTE for diesel/biodiesel and ternary blends of 1-heptanol and n-octanol is due to their reduced energy content and unfavourable combustion characteristics. Table 1 highlights that diesel fuel has a higher heating value (42.54 MJ/kg) than biodiesel (38.91 MJ/kg), 1-heptanol (39.92 MJ/kg), and n-octanol (38.53 MJ/kg). The improvement of fuel atomization and the air/fuel combination, which impacts BTE, is significantly influenced by changes in viscosity, surface tension, and density.

Figure 7.

BTE variation with engine load for higher alcohol and biodiesel blends.

At all engine loads, diesel fuel has a higher BTE than binary and ternary blends due to their comparable calorific values, with B20H10 following in close second. The injection of the biodiesel/diesel blend (B20) has equivalent combustion chamber effects, with B20O20 having the lowest BTE (36.38%) across all engine loads. Compared to octanol, the blended fuel with a lower percentage of heptanol has a higher BTE (37.76%) owing to its lower heating value. The distinction from n-octanol can be attributed to the fuel samples’ calorific value and oxygen content. When more 1-heptanol and n-octanol are added to the diesel/biodiesel blend fuels (B20H20 and B20O20), the BTE values are lower compared to the lower percentage of higher chain alcohol in B20H10 and B20O10. The slightly higher enthalpy of evaporation (see Table 1) in heptanol (574 kJ/kg) compared to octanol (270 kJ/kg) may contribute to achieving the highest BTE. Various parameters like density, viscosity, and flash point also play a role in achieving good combustion efficiency, which improves the BTE. Ibrahim [36] detected that adding 20% (by volume) butanol to the B50 fuel blend caused the peak thermal efficiency to drop from 30.7% to 29.4%. Similarly, Candan et al. [75] reported that BTE levels were typically decreased while running a diesel engine with a diesel/methanol blend (DMB) and attributed their findings to the alcohol’s calorific value of the DMB. On the other hand, Yesilyurt et al. [56] maintained that 1-butanol and n-pentanol-infused fuel samples exhibited allowable alterations in BTE values, indicating the potential of these higher alcohols as oxygenated fuel additives in CI engines. In contrast, Wei et al. [76] reported that the addition of n-pentanol to diesel fuel showed no significant difference in BTE values. Enhancing BTE on second-hand engines can be carried out in a number of ways. Jianqin Fu [77] for instance, demonstrated that increasing the compression ratio of a liquefied methane engine improved engine torque and thermal efficiency. Additionally, Silitonga [74] revealed similar outcomes for BTE with the addition of bioethanol to diesel fuel and biodiesel. They mentioned that the lower energy content of the alcohol-added blends led to lower BSFC and, consequently, lower BTE.

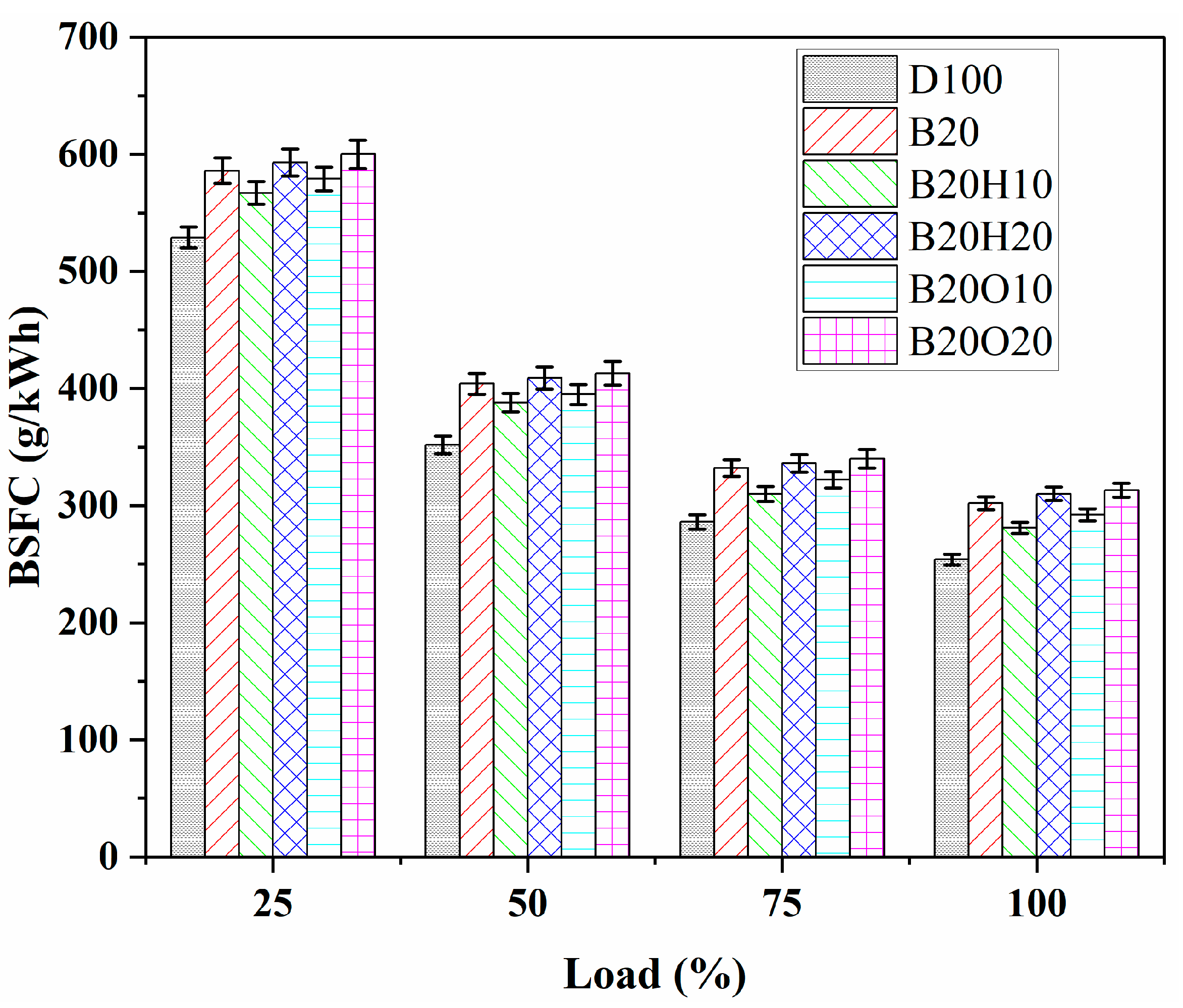

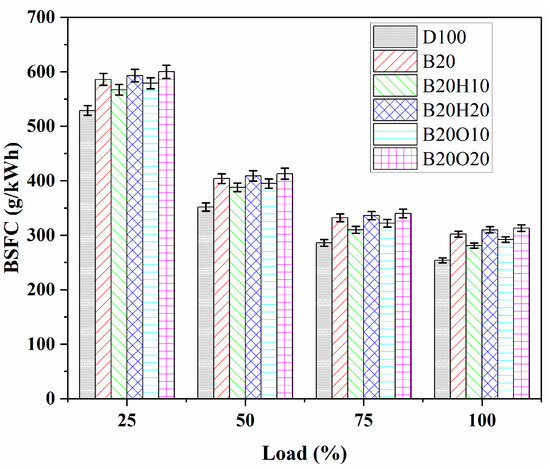

3.2.2. Break-Specific Fuel Consumption (BSFC)

BSFC measures the fuel needed to produce 1 kW of power per hour in internal combustion engines (ICEs). It is related to effective engine power and mass fuel consumption, and, interestingly, it has an inverse relationship with BTE for the fuels used [78]. BSFC plays a crucial role in fuel selection for engine evaluation. Figure 8 illustrates the results of BSFC for all tested fuel samples at varying engine loads. At 100% engine load, the BSFC values were 254.1 g/kWh for diesel fuel, 302.14 g/kWh for B20, 281.25 g/kWh for B20H10, 310.94 g/kWh for B20H20, 292.8 g/kWh for B20O10, and 313.80 g/kWh for B20O20. The BSFC decreases with increasing engine loads. Diesel fuel exhibits a lower BSFC compared to binary blends and ternary blends of 1-heptanol and n-octanol due to its higher energy content and BTE (Figure 7).

Figure 8.

BSFC across engine load for different binary and ternary blends.

The heptanol-blended fuel shows a lower BSFC than the octanol-blended fuel due to its higher viscosity. Heptanol has a viscosity of 5.75 mm2/s, while octanol has a viscosity of 7.59 mm2/s (refer to Table 1). This higher viscosity negatively impacts fuel atomization and fuel/air mixing, resulting in sub-optimal fuel fractions burned in the premixed phase and increased fuel burned in the mixing control phase. Moreover, fuels with higher proportions of 1-heptanol and n-octanol (B20H20 and B20O20) exhibit higher BSFC values compared to B20H10 and B20O10. The lowest BSFC may have been achieved because heptanol (574 kJ/kg) has a larger enthalpy of evaporation than octanol (315 kJ/kg) (see Table 1). The latent heat of evaporation, calorific value, viscosity, and density are some of the variables that affect how well an engine performs and how fuel burns. Alcohols (heptanol at 175 °C and octanol at 195 °C) vapourize more quietly than diesel fuel (180 °C to 360 °C) due to attained boiling temperatures. During the experiments, the engine loads led to an excess of fuel being injected into the combustion chamber due to the increased mixing ratio in the fuel blends. This resulted in the highest observed BSFC when the engine was fuelled with B20H20 (310.94 g/kWh) and B20O20 (313.80 g/kWh), while the lowest BSFC was recorded in pure diesel fuel (254.1 g/kWh) under the same loads. The peak BSFC values for all tested fuels occurred at 25% engine load, with a slight reduction beyond this under engine loads of 50%, 75%, and 100% compared to other tested fuels. Atmanli et al. [79] found that fuel blends with a lower energy content of higher alcohols and biodiesel led to increased BSFC in their experimental research. Diesel engines consumed more fuel with blends containing higher alcohols to compensate for the brake power loss. In another study, Atmanli et al. [80] investigated diesel fuel, vegetable oil, and n-butanol blends in a diesel engine and revealed the significant impact of cetane number on BSFC. Lower cetane numbers in fuel blends with higher alcohols caused delayed combustion and increased BSFC. Rahimi et al. [81] provided reasons for increased BSFC, attributing it to lower cetane numbers in fuel blends with alcohol and the influence of water content derived from the nature of alcohol. Yilmaz [82] observed that BSFC values increased with higher concentrations of C-1 alcohol (methanol) and C-2 alcohol (ethanol) in the blend. The researcher suggested improving fuel vapourization at higher engine loads and increasing air temperature before the suction process to address the issues. Sayin and Canakci [83] suggested that the increase in BSFC with rising engine loads is due to engine power increasing at a higher ratio than the consumed fuel. Similar findings and explanations have been reported by other researchers [67,68].

3.3. Exhaust Emissions

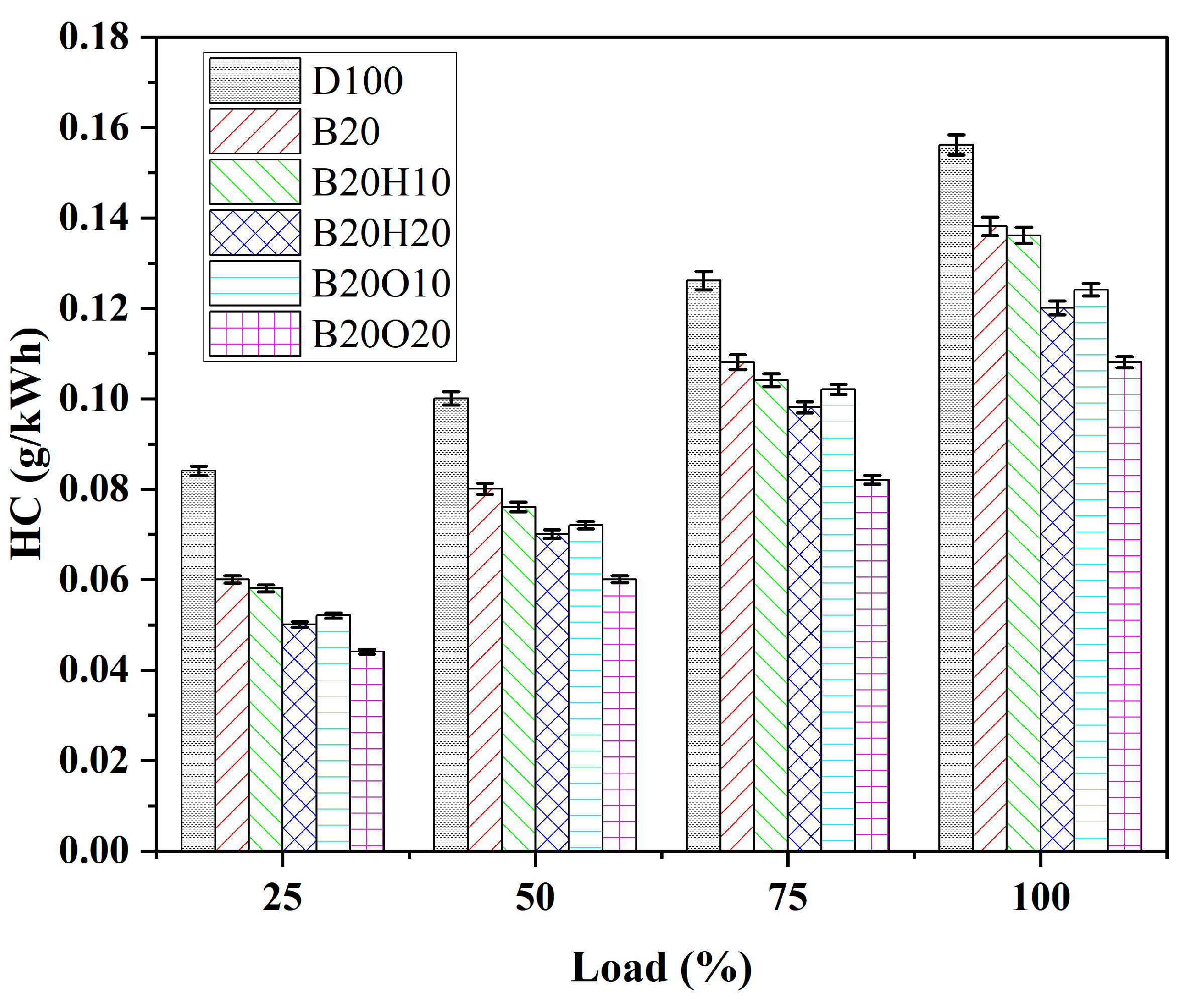

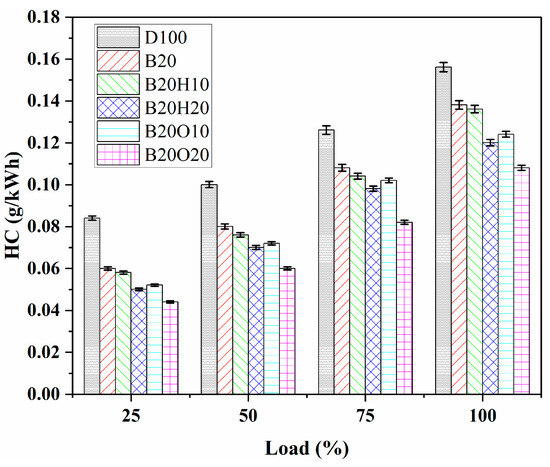

3.3.1. HC Emission

Unburned hydrocarbon (HC) emissions in internal combustion engines are influenced by critical combustion parameters such as air–fuel ratio, fuel spray characteristics, fuel properties, and engine operating conditions [84]. Figure 9 illustrates the HC emissions of various tested fuel samples with engine load variation, investigating advanced combustion characteristics. The graph shows a consistent trend of increasing HC emissions for all fuels as the engine load rises from 25% to 100%. Conventional diesel fuel, lacking native oxygen content in its atomic structure, exhibited the highest HC emissions at all engine loads due to its high efficiency, absence of oxygen molecules, and higher carbon content. In contrast, the ternary blend of n-octanol showcased lower HC emissions than diesel fuel for all loads. However, the proportion of n-octanol in the blend influenced the HC emission levels, with higher n-octanol percentages leading to overlean mixtures and increased oxygen content. Introducing 1-heptanol to biodiesel/diesel blends resulted in decreased HC emissions compared to pure diesel fuel; yet, they remained higher than those of the n-octanol-blended ternary fuel.

Figure 9.

HC emission variation with engine load for different fuel samples.

The maximum unburned HC emissions were recorded for different fuel samples: D100, B20, B20H10, B20H20, B20O10, and B20O20, with values of 0.156 g/kWh, 0.138 g/kWh, 0.136 g/kWh, 0.12 g/kWh, 0.124 g/kWh, and 0.108 g/kWh, respectively. These findings align with prior investigations involving various higher alcohols, where their presence in the fuel samples facilitated specific reactions within the combustion chamber due to increased temperatures, impacting HC emissions. In conclusion, HC emissions were substantially higher for all tested fuels compared to B20O20 fuel, which comprised 20% n-octanol, 20% biodiesel, and 60% diesel fuel. However, they showed slightly lower HC emissions than traditional diesel fuel at nearly all engine loads (refer to Figure 9). These findings highlight the potential benefits of certain fuel blends for reducing HC emissions and improving overall engine efficiency. Deep et al. [85] also observed a comparable trend when blending 1-octanol with diesel in volumes ranging from 10% to 40%. In a study by Mahalingam et al. [86], the addition of 10% and 20% pentanol to neat biodiesel resulted in a decrease in HC emissions of 2.1% and 3.6%, respectively, compared to B100 at all engine loads. Similarly, Babu et al. [87] found that a blend of 85% biodiesel, 5% diesel fuel, and 10% n-pentanol exhibited the lowest HC emissions among other ternary blends. At 100% load, this blend released 74 ppm, which was 39.4% lower than diesel fuel emissions.

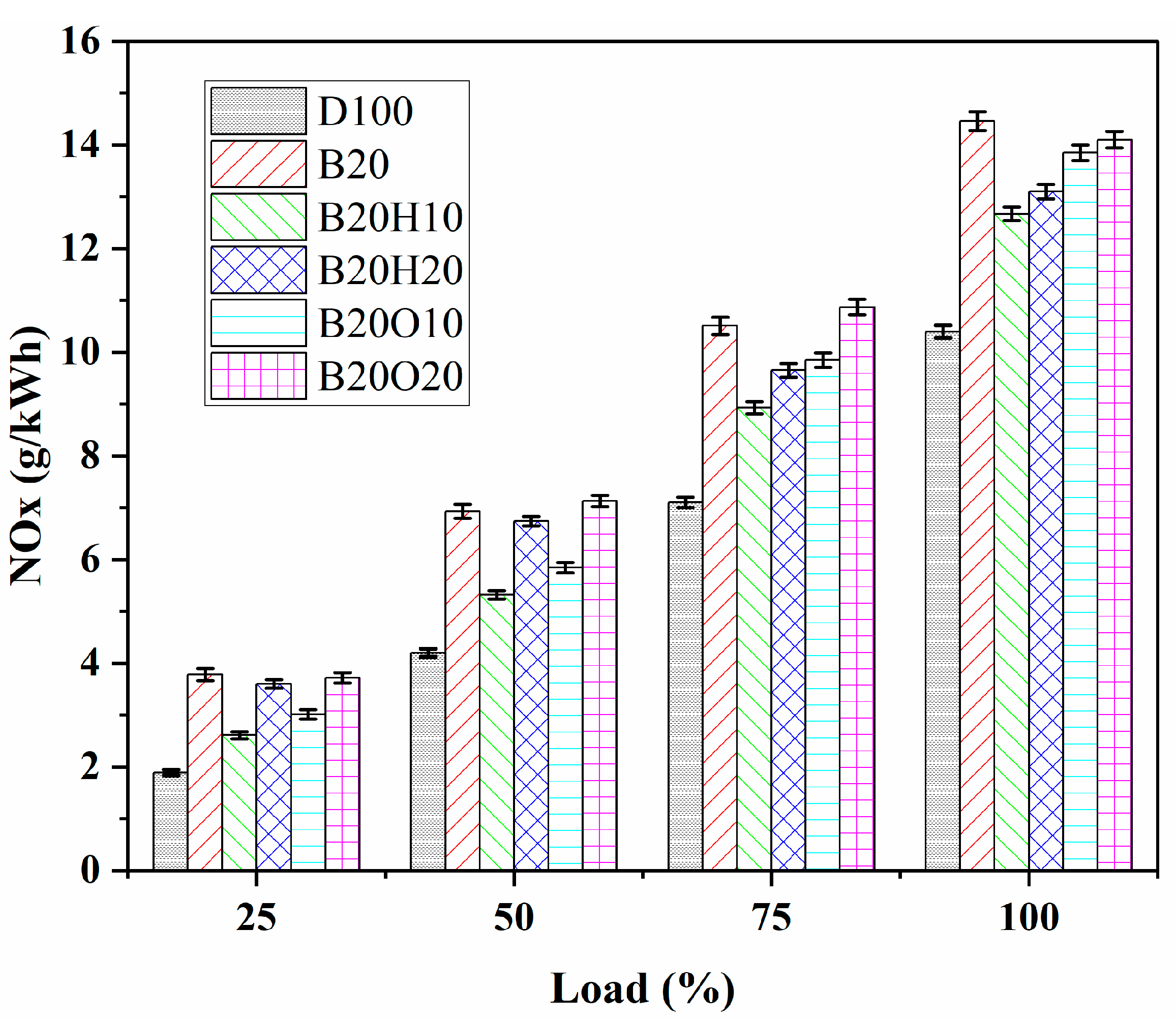

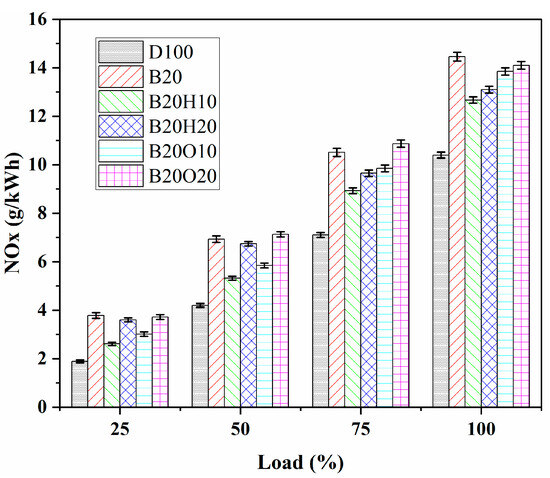

3.3.2. NOx Emission

The term oxides of nitrogen refer to NOx, including many different nitrogen compounds, such as nitrogen monoxide (NO), nitrogen dioxide (NO2), nitrous oxide (N2O), dinitrogen dioxide (N2O2), dinitrogen trioxide (N2O3), dinitrogen tetroxide (N2O4), and dinitrogen pentoxide (N2O5). However, it is widely recognized that more than 90% of NOx emitted from a CI engine consists of NO gas [88]. The air/fuel ratio, compression ratio, temperature, fuel injection pressure, engine speed, and load are few factors that affect the formation of NO [71]. Diesel fuel has lower NOx emissions because of combustion efficiency indices like a higher combustion chamber temperature, a faster flame, better thermal efficiency, and fewer oxygen molecules, as well as a higher energy content [89].

Figure 10 depicts the variations in brake-specific NOx emissions for diesel fuel and binary and ternary fuel blends at different engine loads. Unmodified diesel fuel showed the lowest NOx emission levels among all fuel samples and engine loads. The addition of n-octanol to the biodiesel/diesel fuel blend (B20O20) increased NOx emission values due to the higher oxygen content in the blends. This led to weaker combustion conditions at lower combustion chamber temperatures, inhibiting NOx formation that requires higher temperatures for nitrogen and oxygen molecules to react. At 100% load, NOx emissions for D100, B20, B20H10, B20H20, B20O10, and B20O20 were recorded as 10.4 g/kWh, 13.68 g/kWh, 12.67 g/kWh, 13.1 g/kWh, 13.85 g/kWh, and 14.1 g/kWh, respectively. Notably, the ternary blend of 1-heptanol/biodiesel/diesel (B20H10) exhibited the lowest NOx emission levels among the fuel blends. A fuel with a low cetane number results in a longer ignition delay period, leading to a higher end temperature of combustion and increased in-cylinder gas pressure. Although the NOx emissions for (B20H10) were still higher than those of diesel fuel, at full engine load, the NOx emission of (B20H10) increased by 21.8% compared to diesel fuel.

Figure 10.

NOx emission variation with engine load for different fuel samples.

Nour et al. [19] observed reduced NOx emissions for all tested blends under various conditions. The lowest NOx concentration was achieved when blending butanol, octanol, and heptanol with diesel fuel. Nanthagopal et al. [67] found that fuel samples with added alcohol (hexanol and decanol) exhibited improved oxygen content, leading to decreased NOx emissions with pure biodiesel and increased emissions with diesel fuel. Balamurugan et al. [90] conducted experiments with diesel fuel containing 4% and 8% n-propanol and n-butanol, resulting in decreased operating temperatures and subsequently reduced NOx emissions than diesel fuel. Nanthagopal et al. [91] found that using higher alcohols like butanol and pentanol with Calophyllum inophyllum biodiesel in CI engines reduced NOx emissions due to the high latent heat of alcohols in the blend. Soloiu et al. [92] reported that using oxygenated fuels like alcohol or fatty acid methyl ester helped reduce emissions due to a lower carbon-to-oxygen ratio and relative A/F ratio.

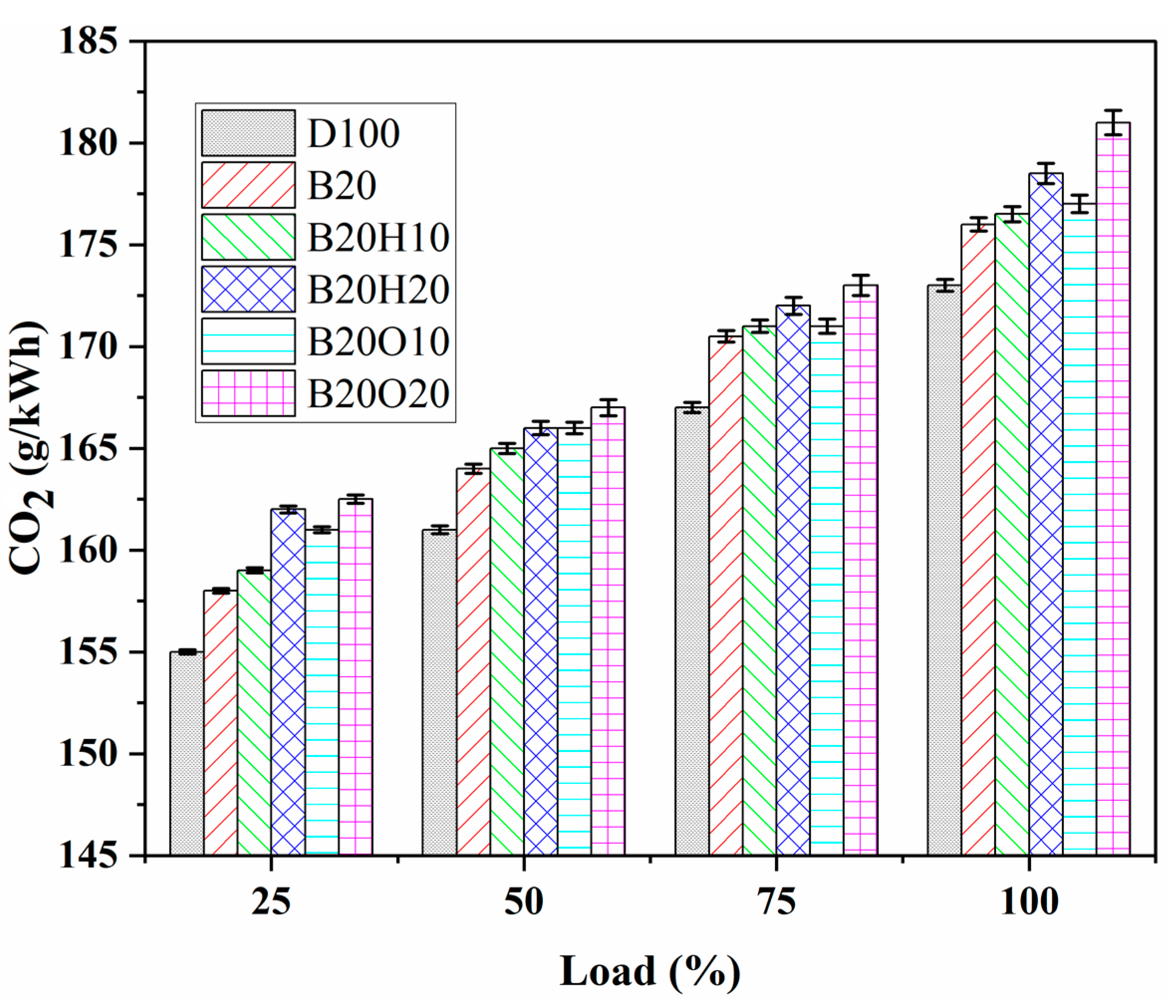

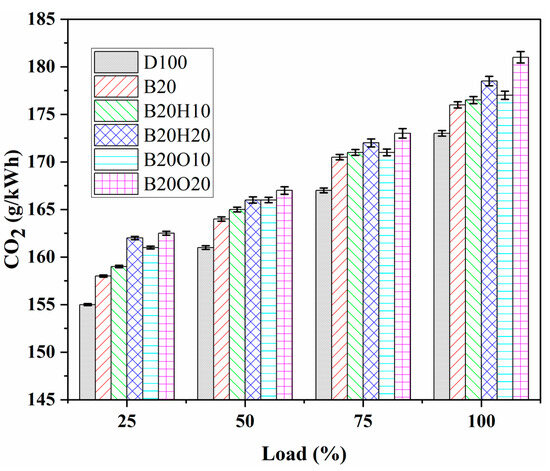

3.3.3. CO2 Emission

Higher oxygen content supports complete combustion leading to increased CO2 emissions. The presence of oxygen atoms promotes complete reactions and raises CO2 emissions in the exhaust. The hydroxyl radical OH, an essential oxidizing agent, converts CO to CO2 gas when sufficient oxygen is available [91]. Figure 11 illustrates the variation in CO2 emission values in g/kWh with engine load at a constant speed of 1500 rpm. As engine load increases, CO2 emissions also rise significantly, resulting in reduced BTE in the tested fuel samples. The B20O20 fuel blend exhibited the highest mean CO2 emissions at 181.11 g/kWh among the tested fuels owing to its native oxygen atoms that readily react with CO to produce CO2 gas, significantly influencing the generation of CO2. The CO2 emissions for D100, B20, B20H10, B20H20, B20O10, and B20O20 were recorded as 173.23 g/kWh, 176.17 g/kWh, 176.51 g/kWh, 178.53 g/kWh, 177.04 g/kWh, and 181.11 g/kWh, respectively. Blends containing higher alcohols (1-heptanol and n-octanol) showed similar CO2 emissions, with a difference of approximately 7 to 8%.

Figure 11.

CO2 emission variation with engine load for different fuel samples.

Therefore, the addition of alcohol resulted in reduced CO2 emissions than the B20 blend. 1-Heptanol, with oxygen molecules in its chemical bonds, readily reacts with CO molecules to form CO2. This has a big effect on how CO2 emissions are made. Baseline diesel fuel, with a higher calorific value and lower kinematic viscosity (refer to Table 1), improves atomization and BTE, resulting in reduced CO2 emissions. The characteristic of lower-percentage alcohols, with inherent oxygen molecules, also significantly impacts CO2 emissions in exhaust gases. Babu et al. [87] found that CI engines running on used frying oil biodiesel/alcohol/diesel fuel blends released more CO2 emissions than diesel and biodiesel blends as a result of the complete combustion process. Ramesh et al. [65] used hexanol as oxygenated long-chain alcohol in Calophyllum Inophyllum methyl ester/DF blends at various concentrations, resulting in CO gas reacting with the inherent oxygen molecules of hexanol and leading to CO2 emissions. Akar et al. [93] used butanol/biodiesel/diesel fuel blends and concluded that 1-heptanol-infused fuel blends could be preferred as a significant fuel additive to combat global warming over neat biodiesel fuel.

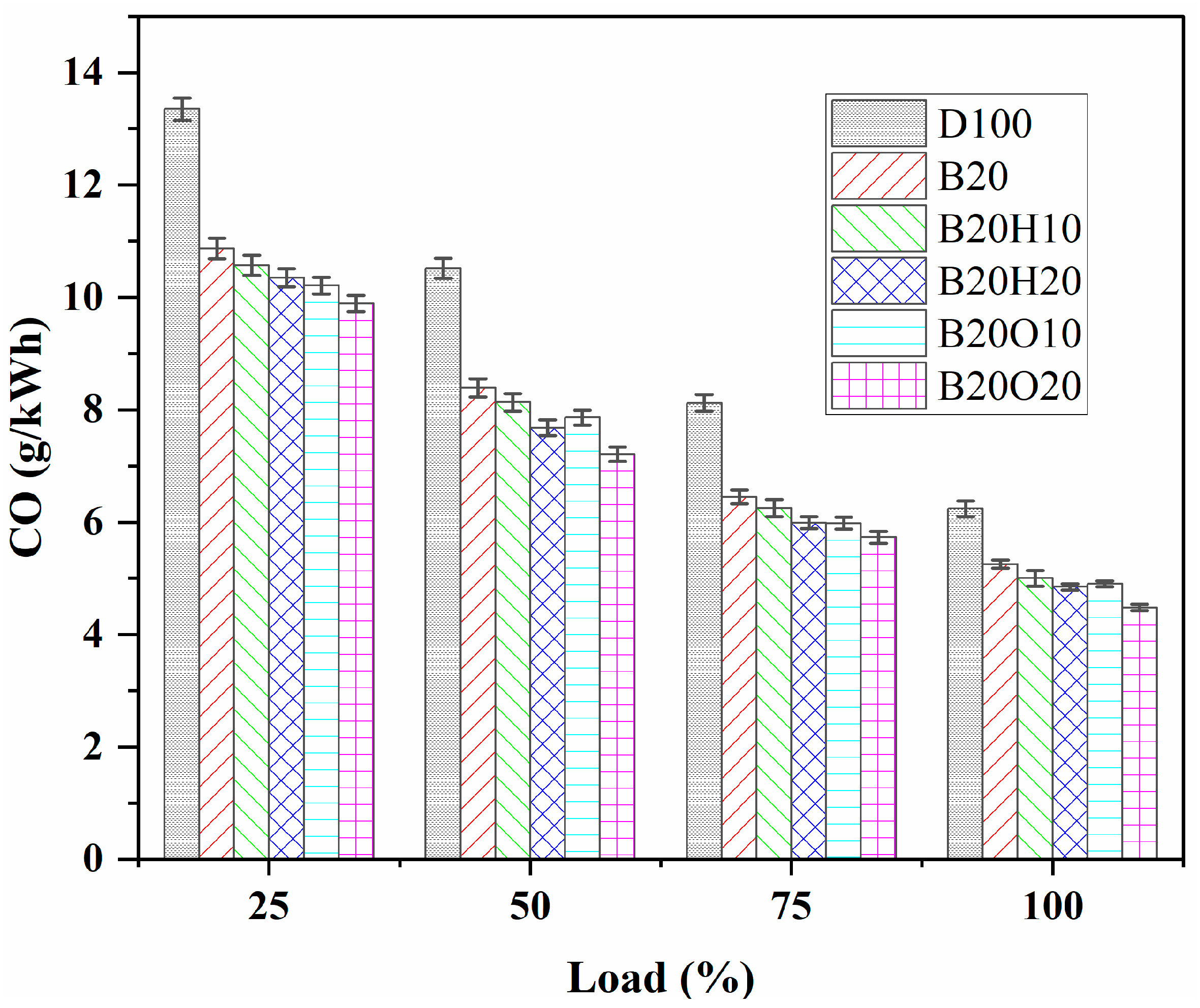

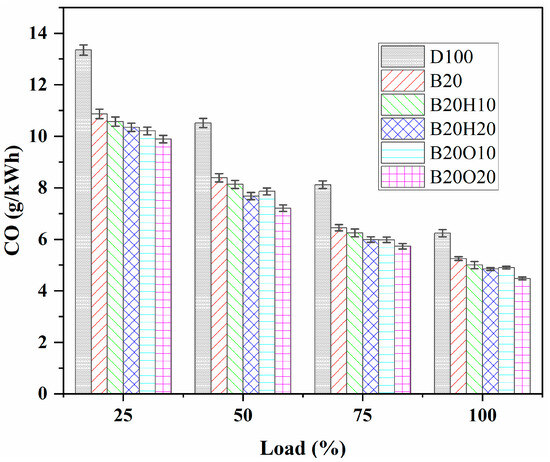

3.3.4. CO Emission

The engine cylinder’s incomplete combustion leads to CO emissions. Long-term combustion and a deficiency of oxygen molecules result in CO emissions. CO is particularly hazardous to humans because it is colourless and odourless [43]. At low engine loads, insufficient air/fuel mixtures result in greater CO emissions. Blends containing fewer carbon atoms, such as heptanol and octanol, are projected to provide lower CO emissions. At the maximum engine load, B20 and B20O20 exhibited CO emissions of 5.25 g/kWh and 4.48 g/kWh, respectively. Figure 12 demonstrates that incorporating higher alcohols into ternary blends of heptanol and octanol significantly reduced CO emissions beyond the B20 blend. The lowest CO emissions measured for D100, B20, B20H10, B20H20, B20O10, and B20O20 were 6.24 g/kWh, 5.25 g/kWh, 5.01 g/kWh, 4.85 g/kWh, 4.91 g/kWh, and 4.48 g/kWh, respectively, at full load. Alcohol addition reduces CO emissions at all engine speeds compared to diesel and B20 blends. The inclusion of alcohol reduces CO emissions at all engine speeds compared to diesel and B20 blends. Ternary blends of 1-heptanol (B20H10 and B20H20) exhibited 19.71% and 22.27% lower CO emissions than pure diesel oil at full load. Similarly, ternary blends of n-octanol (B20O10 and B20O20) showed 21.31% and 28.2% lower CO emissions than pure diesel oil at full load.

Figure 12.

CO emission variation with engine load for different fuel samples.

The increased oxygen content of n-octanol can be attributed to this phenomenon. Notably, the octanol addition to the blend exhibited superior abilities in lowering CO emissions. Additionally, less CO was formed due to the reduced number of carbon atoms in the chemical bond of alcohols (see Table 1). Similar findings were reported by the vast majority of researchers [21,80,81]. Akar et al. [89] discovered that combining butanol with flaxseed oil biodiesel/diesel fuel lowered CO emissions when compared to normal diesel fuel. Ramesh et al. [65] indicated that the addition of hexanol to B50 fuel to formulate ternary blends reduced CO emissions more than pure biodiesel fuel, but only when the hexanol level was equal to or more than 30% by weight. Li et al. [94] monitored lower CO emissions using (diesel + biodiesel + pentanol) blends. Additionally, Nanthagopal et al. [67] noted that infusing higher-order alcohol (decanol) increased the total oxygen concentration inside the cylinder, resulting in decreased CO emissions. In contrast, Randazzo and Sodré [95] claimed the opposite view: there is a direct correlation between the ethanol proportion in the B20 fuel mix and the steady increase in CO emissions. Wei et al. [76] also demonstrated that adding higher alcohols to mineral diesel fuel resulted in higher CO emissions, with a noticeable impact, particularly at low engine loads.

4. Conclusions

In this experimental study, the influence of binary and ternary blends of diesel/biodiesel with higher alcohols (1-heptanol and n-octanol) on compression ignition engine performance, combustion characteristics, and exhaust emissions was investigated. Tests were conducted at various engine loads, and results were compared with unmodified diesel fuel and B20 blend. Key findings are as follows:

- The introduction of lower percentages of 1-heptanol and n-octanol in the diesel/biodiesel fuel blend resulted in higher peak in-cylinder gas pressure compared to the binary blend. However, increasing the percentage to 20% in the diesel/biodiesel fuel blend led to a reduction in CP.

- The low percentage of heptanol in the diesel/biodiesel provided the highest heat released per cycle at all tested conditions compared to that of the low percentage of octanol fuel blends and B20. Additionally, Heptanol/diesel blends showed the highest combustion efficiency among the tested fuels.

- Diesel fuel demonstrated higher BTE owing to its superior heating value. The introduction of lower percentages of 1-heptanol and n-octanol in the blend resulted in higher BTE compared to binary blends but decreased with higher proportions of these alcohols. The BTE decrease followed the sequence B20O20 < B20H20 < B20 < B20O10 < B20H10. B20O20 experienced the smallest BTE decrease compared to diesel.

- Diesel fuel exhibited a lower BSFC compared to binary blends and ternary blends of 1-heptanol and n-octanol due to its higher energy content and better thermal efficiency. Fuels with higher proportions of 1-heptanol and n-octanol (B20H20 and B20O20) displayed higher BSFC values compared to B20H10 and B20O10. The lower BSFC may be attributed to the higher enthalpy of evaporation in heptanol (574 kJ/kg) compared to octanol (315 kJ/kg). Various factors, including the latent heat of evaporation, calorific value, viscosity, and density, influenced engine performance and combustion characteristics.

- Ternary blends with n-octanol showed lower HC emissions than diesel fuel at all loads. However, the amount of n-octanol in the blend affected HC levels, with higher percentages leading to overlean mixtures and increased oxygen content. Adding 1-heptanol to biodiesel/diesel blends reduced HC emissions compared to pure diesel but remained higher than n-octanol-blended fuel. The maximum HC emissions were in the order of D100 > B20 > B20H10 > B20O10 > B20H20 > B20O20.

- Diesel fuel resulted in the lowest NOx emissions at all loads. The addition of n-octanol to biodiesel/diesel fuel (B20O20) increased NOx emissions due to higher oxygen content, resulting in weaker combustion conditions. The ternary blend B20H10 showed the lowest NOx emissions. However, it still had higher NOx emissions than diesel fuel, increasing by 21.8% at full load. The maximum NOx emissions are in the order of B20 > B20O20 > B20H20 > B20O10 > B20H10 > D100.

- The B20O20 fuel blend had the highest CO2 emissions at 181.11 g/kWh due to its native oxygen atoms readily reacting with CO to form CO2. CO2 emissions for other blends ranged from 173.23 g/kWh to 181.11 g/kWh. Blends with higher alcohols showed similar CO2 emissions, with a difference of around 7 to 8%. The addition of alcohol reduced CO2 emissions compared to the B20 blend, with 1-heptanol playing a significant role in CO2 formation. The maximum CO2 emissions were in the order of B20O20 > B20H20 > B20O10 > B20H10 > B20 > D100.

- CO emissions were reduced significantly more with the addition of alcohol than diesel and B20 blends. Ternary blends of 1-heptanol (B20H10 and B20H20) exhibited 19.71% and 22.27% lower CO emissions than pure diesel oil at full load. Similarly, ternary blends of n-octanol (B20O10 and B20O20) showed 21.31% and 28.2% lower CO emissions than pure diesel oil at full load. The higher oxygen content of n-octanol contributed to this effect, and alcohols’ fewer carbon atoms in the chemical bond resulted in less CO formation. The least CO emissions were in the order of B20O20 < B20O10 < B20H20 < B20H10 < B20 < D100.

- The obtained results with ternary blends ensure an alternate promising next-generation ecofriendly fuel to run in diesel engines without significant modifications. The detailed insights could help to prepare ternary blends at an industrial scale. This research work can be extended in the following directions: 1. Higher alcohols, such as hexanol and decanal, can be investigated as fuel additives for diesel engines. 2. Engine parameters such as injection timing, injection pressure, compression ratio, and engine speed can be altered and analysed for better performance, combustion, and emission characteristics.

Author Contributions

Conceptualization, G.T. and S.B.P.; methodology, O.D.S., O.D., A.E., A.B.S. and M.P.G.C.; software, A.B.S. and M.P.G.C.; validation, G.T., S.B.P., A.B.S., O.D.S., O.D., A.E. and M.P.G.C.; formal analysis, G.T. and S.B.P.; investigation, G.T., S.B.P. and A.B.S.; resources, M.P.G.C.; data curation, G.T., S.B.P., A.B.S. and M.P.G.C.; writing—original draft preparation, G.T., S.B.P., A.B.S. and M.P.G.C.; writing—review and editing, G.T., S.B.P., A.B.S., M.P.G.C., O.D.S., O.D. and A.E.; supervision, S.B.P. and M.P.G.C.; funding acquisition, G.T., S.B.P., M.P.G.C., O.D. and A.E. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by The Vision Group of Science and Technology (VGST) grant funded by The Government of Karnataka, India. (GRD no. 349).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| ASTM | American Society for Testing and Materials |

| B100 | 100% Biodiesel fuel |

| D100/DF | Reference diesel fuel |

| B20 | Diesel (80%) + Biodiesel (20%) by vol. |

| B20H10 | Diesel (70%) + Biodiesel (20%) + 1-heptanol (10%) by vol. |

| B20H20 | Diesel (60%) + Biodiesel (20%) + 1-heptanol (20%) by vol. |

| B20O10 | Diesel (70%) + Biodiesel (20%) + n-octanol (10%) by vol. |

| B20O20 | Diesel (60%) + Biodiesel (20%) + n-octanol (20%) by vol. |

| CN | Cetane number |

| NaOH | Sodium hydroxide |

| HHV | Higher heating value |

| VCR | Variable compression ratio |

| CA, θ | Crank angle |

| NOx | Nitrogen oxides |

| HC | Unburnt hydrocarbons |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| PM | Particulate matter |

| BSFC | Brake-specific fuel consumption |

| BTE | Brake thermal efficiency |

| C4–C8 | Carbon chain length |

| CI | Compression-ignition |

| CRDI | Common rail direct injection |

| VCR | Variable compression ratio |

| HBO | Hybrid biodiesel oil |

| CHO | Crude hybrid oil |

| CP | Cylinder Pressure |

| DF | Diesel fuel |

| ICEs | Internal combustion engines |

| TDC | Top dead centre |

| NHRR | Net heat release rate |

| CR | Compression ratio |

| NO | Nitrogen monoxide |

| NO2 | Nitrogen dioxide |

| N2O2 | Dinitrogen dioxide |

| N2O3 | Dinitrogen trioxide |

| N2O4 | Dinitrogen tetroxide |

| N2O5 | Dinitrogen pentoxide |

| OS | Oxidation stability |

References

- Hajjari, M.; Tabatabaei, M.; Aghbashlo, M.; Ghanavati, H. A review on the prospects of sustainable biodiesel production: A global scenario with an emphasis on waste-oil biodiesel utilization. Renew. Sustain. Energy Rev. 2017, 72, 445–464. [Google Scholar] [CrossRef]

- Beretta, G.P. World energy consumption and resources: An outlook for the rest of the century. Int. J. Environ. Technol. Manag. 2007, 7, 99–112. [Google Scholar] [CrossRef]

- Verma, P.; Sharma, M.P. Review of process parameters for biodiesel production from different feedstocks. Renew. Sustain. Energy Rev. 2016, 62, 1063–1071. [Google Scholar] [CrossRef]

- De Almeida D’Agosto, M. Energy sources for transportation. In Transportation, Energy Use and Environmental Impacts; Elsevier: Amsterdam, The Netherlands, 2019; pp. 177–225. [Google Scholar] [CrossRef]

- Kumar Kadian, A.; Khan, M.; Sharma, R.P.; Mozammil hasnain, S.M. Performance enhancement and emissions mitigation of DI-CI engine fuelled with ternary blends of jatropha biodiesel-diesel-heptanol. Mater. Sci. Energy Technol. 2022, 5, 145–154. [Google Scholar] [CrossRef]

- EL-Seesy, A.I.; Kosaka, H.; Hassan, H.; Sato, S. Combustion and emission characteristics of a common rail diesel engine and RCEM fueled by n-heptanol-diesel blends and carbon nanomaterial additives. Energy Convers. Manag. 2019, 196, 370–394. [Google Scholar] [CrossRef]

- Sarma, C.J.; Sharma, P.; Bora, B.J.; Bora, D.K.; Senthilkumar, N.; Balakrishnan, D.; Ayesh, A.I. Improving the combustion and emission performance of a diesel engine powered with mahua biodiesel and TiO2 nanoparticles additive. Alex. Eng. J. 2023, 72, 387–398. [Google Scholar] [CrossRef]

- Gupta, J.; Agarwal, M.; Dalai, A.K. Intensified transesterification of mixture of edible and nonedible oils in reverse flow helical coil reactor for biodiesel production. Renew. Energy 2019, 134, 509–525. [Google Scholar] [CrossRef]

- Da Silva Guabiroba, R.C.; da Silva, R.M.; da Silva César, A.; da Silva, M.A.V. Value chain analysis of waste cooking oil for biodiesel production: Study case of one oil collection company in Rio de Janeiro—Brazil. J. Clean. Prod. 2017, 142, 3928–3937. [Google Scholar] [CrossRef]

- Adewale, P.; Dumont, M.J.; Ngadi, M. Recent trends of biodiesel production from animal fat wastes and associated production techniques. Renew. Sustain. Energy Rev. 2015, 45, 574–588. [Google Scholar] [CrossRef]

- Ayoob, A.K.; Fadhil, A.B. Valorization of waste tires in the synthesis of an effective carbon based catalyst for biodiesel production from a mixture of non-edible oils. Fuel 2020, 264, 116754. [Google Scholar] [CrossRef]

- Mahmudul, H.M.; Hagos, F.Y.; Mamat, R.; Adam, A.A.; Ishak, W.F.W.; Alenezi, R. Production, characterization and performance of biodiesel as an alternative fuel in diesel engines—A review. Renew. Sustain. Energy Rev. 2017, 72, 497–509. [Google Scholar] [CrossRef]

- Aljaafari, A.; Fattah, I.M.R.; Jahirul, M.I.; Gu, Y.; Mahlia, T.M.I.; Islam, M.A.; Islam, M.S. Biodiesel emissions: A state-of-the-art review on health and environmental impacts. Energies 2022, 15, 6854. [Google Scholar] [CrossRef]

- Goga, G.; Chauhan, B.S.; Mahla, S.K.; Cho, H.M. Performance and emission characteristics of diesel engine fueled with rice bran biodiesel and n-butanol. Energy Rep. 2019, 5, 78–83. [Google Scholar] [CrossRef]

- Samuel, O.D.; Gulum, M. Mechanical and corrosion properties of brass exposed to waste sunflower oil biodiesel-diesel fuel blends. Chem. Eng. Commun. 2019, 206, 682–694. [Google Scholar] [CrossRef]

- Rodríguez-Fernández, J.; Hernández, J.J.; Calle-Asensio, A.; Ramos, Á.; Barba, J. Selection of blends of diesel fuel and advanced biofuels based on their physical and thermochemical properties. Energies 2019, 12, 2034. [Google Scholar] [CrossRef]

- Elumalai, P.V.; Parthasarathy, M.; Lalvani, J.S.C.I.J.; Mehboob, H.; Samuel, O.D.; Enweremadu, C.C.; Saleel, C.A.; Afzal, A. Effect of injection timing in reducing the harmful pollutants emitted from CI engine using N-butanol antioxidant blended eco-friendly Mahua biodiesel. Energy Rep. 2021, 7, 6205–6221. [Google Scholar] [CrossRef]

- Emiroğlu, A.O.; Keskin, A.; Şen, M. Experimental investigation of the effects of turkey rendering fat biodiesel on combustion, performance and exhaust emissions of a diesel engine. Fuel 2017, 216, 266–273. [Google Scholar] [CrossRef]

- Nour, M.; Attia, A.M.A.; Nada, S.A. Combustion, performance and emission analysis of diesel engine fuelled by higher alcohols (butanol, octanol and heptanol)/diesel blends. Energy Convers. Manag. 2019, 185, 313–329. [Google Scholar] [CrossRef]

- Karthickeyan, V. Effect of cetane enhancer on Moringa oleifera biodiesel in a thermal coated direct injection diesel engine. Fuel 2018, 235, 538–550. [Google Scholar] [CrossRef]

- Yesilyurt, M.K. A detailed investigation on the performance, combustion, and exhaust emission characteristics of a diesel engine running on the blend of diesel fuel, biodiesel and 1-heptanol (C7 alcohol) as a next-generation higher alcohol. Fuel 2020, 275, 117893. [Google Scholar] [CrossRef]

- Tripathi, S.; Subramanian, K.A. Experimental investigation of utilization of Soya soap stock based acid oil biodiesel in an automotive compression ignition engine. Appl. Energy 2017, 198, 332–346. [Google Scholar] [CrossRef]

- Shelke, P.S.; Sakhare, N.M.; Lahane, S. Investigation of Combustion Characteristics of a Cottonseed Biodiesel Fuelled Diesel Engine. Procedia Technol. 2016, 25, 1049–1055. [Google Scholar] [CrossRef]

- Gürü, M.; Artukoǧlu, B.D.; Keskin, A.; Koca, A. Biodiesel production from waste animal fat and improvement of its characteristics by synthesized nickel and magnesium additive. Energy Convers. Manag. 2009, 50, 498–502. [Google Scholar] [CrossRef]

- Ge, J.C.; Kim, H.; Yoon, S.; Choi, N. Reducing volatile organic compound emissions from diesel engines using canola oil biodiesel fuel and blends. Fuel 2018, 218, 266–274. [Google Scholar] [CrossRef]

- Yesilyurt, M.K. The effects of the fuel injection pressure on the performance and emission characteristics of a diesel engine fuelled with waste cooking oil biodiesel-diesel blends. Renew. Energy 2019, 132, 649–666. [Google Scholar] [CrossRef]

- Santhoshkumar, A.; Thangarasu, V.; Anand, R. Performance, combustion, and emission characteristics of DI diesel engine using mahua biodiesel. In Advanced Biofuels Applications, Technologies and Environmental Sustainability; Woodhead Publishing Series in Energy; Woodhead Publishing: Sawston, UK, 2019; pp. 291–327. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Cho, H.M.; Lim, H.C. A study on the performance and emission of a diesel engine fueled with Karanja biodiesel and its blends. Energy 2013, 56, 1–7. [Google Scholar] [CrossRef]

- Altaie, M.A.H.; Janius, R.B.; Rashid, U.; Taufiq-Yap, Y.H.; Yunus, R.; Zakaria, R.; Adam, N.M. Performance and exhaust emission characteristics of direct-injection diesel engine fueled with enriched biodiesel. Energy Convers. Manag. 2015, 106, 365–372. [Google Scholar] [CrossRef]

- Bueno, A.V.; Pereira, M.P.B.; de Oliveira Pontes, J.V.; de Luna, F.M.T.; Cavalcante, C.L. Performance and emissions characteristics of castor oil biodiesel fuel blends. Appl. Therm. Eng. 2017, 125, 559–566. [Google Scholar] [CrossRef]

- Nabi, M.N.; Zare, A.; Hossain, F.M.; Ristovski, Z.D.; Brown, R.J. Reductions in diesel emissions including PM and PN emissions with diesel-biodiesel blends. J. Clean. Prod. 2017, 166, 860–868. [Google Scholar] [CrossRef]

- Cheikh, K.; Sary, A.; Khaled, L.; Abdelkrim, L.; Mohand, T. Experimental assessment of performance and emissions maps for biodiesel fueled compression ignition engine. Appl. Energy 2016, 161, 320–329. [Google Scholar] [CrossRef]

- Bari, S.; Saad, I. Optimization of vane numbers through simulation and experiment, and investigation of the effect on the performance and emissions of a CI (compression ignition) engine run with biodiesel. Energy 2015, 79, 248–263. [Google Scholar] [CrossRef]

- Gülüm, M.; Bilgin, A. A comprehensive study on measurement and prediction of viscosity of biodiesel-diesel-alcohol ternary blends. Energy 2018, 148, 341–361. [Google Scholar] [CrossRef]

- Zaharin, M.S.M.; Abdullah, N.R.; Najafi, G.; Sharudin, H.; Yusaf, T. Effects of physicochemical properties of biodiesel fuel blends with alcohol on diesel engine performance and exhaust emissions: A review. Renew. Sustain. Energy Rev. 2017, 79, 475–493. [Google Scholar] [CrossRef]

- Ibrahim, A. Performance and combustion characteristics of a diesel engine fuelled by butanol–biodiesel–diesel blends. Appl. Therm. Eng. 2016, 103, 651–659. [Google Scholar] [CrossRef]

- Pereira, L.G.; Dias, M.O.S.; Mariano, A.P.; Maciel Filho, R.; Bonomi, A. Economic and environmental assessment of n-butanol production in an integrated first and second generation sugarcane biorefinery: Fermentative versus catalytic routes. Appl. Energy 2015, 160, 120–131. [Google Scholar] [CrossRef]

- Tiwari, A.; Rajesh, V.M.; Yadav, S. Biodiesel production in micro-reactors: A review. Energy Sustain. Dev. 2018, 43, 143–161. [Google Scholar] [CrossRef]

- Tse, H.; Leung, C.W.; Cheung, C.S. Investigation on the combustion characteristics and particulate emissions from a diesel engine fueled with diesel-biodiesel-ethanol blends. Energy 2015, 83, 343–350. [Google Scholar] [CrossRef]

- Khoobbakht, G.; Najafi, G.; Karimi, M.; Akram, A. Optimization of operating factors and blended levels of diesel, biodiesel and ethanol fuels to minimize exhaust emissions of diesel engine using response surface methodology. Appl. Therm. Eng. 2016, 99, 1006–1017. [Google Scholar] [CrossRef]

- Jamrozik, A. The effect of the alcohol content in the fuel mixture on the performance and emissions of a direct injection diesel engine fueled with diesel-methanol and diesel-ethanol blends. Energy Convers. Manag. 2017, 148, 461–476. [Google Scholar] [CrossRef]

- Atmanli, A.; Yilmaz, N. A comparative analysis of n-butanol/diesel and 1-pentanol/diesel blends in a compression ignition engine. Fuel 2018, 234, 161–169. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Aydin, M. Experimental investigation on the performance, combustion and exhaust emission characteristics of a compression-ignition engine fueled with cottonseed oil biodiesel/diethyl ether/diesel fuel blends. Energy Convers. Manag. 2019, 205, 112355. [Google Scholar] [CrossRef]

- Rajesh Kumar, B.; Saravanan, S.; Rana, D.; Anish, V.; Nagendran, A. Effect of a sustainable biofuel—N-octanol—on the combustion, performance and emissions of a di diesel engine under naturally aspirated and exhaust gas recirculation (EGR) modes. Energy Convers. Manag. 2016, 118, 275–286. [Google Scholar] [CrossRef]

- Doǧan, O. The influence of n-butanol/diesel fuel blends utilization on a small diesel engine performance and emissions. Fuel 2011, 90, 2467–2472. [Google Scholar] [CrossRef]

- Campos-Fernández, J.; Arnal, J.M.; Gómez, J.; Dorado, M.P. A comparison of performance of higher alcohols/diesel fuel blends in a diesel engine. Appl. Energy 2012, 95, 267–275. [Google Scholar] [CrossRef]

- EL-Seesy, A.I.; Kayatas, Z.; Hawi, M.; Kosaka, H.; He, Z. Combustion and emission characteristics of a rapid compression-expansion machine operated with N-heptanol-methyl oleate biodiesel blends. Renew. Energy 2020, 147, 2064–2076. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, N.; Wang, X. Densities and viscosities for binary mixtures of dimethyl carbonate with 1-heptanol, 1-octanol, 1-nonanol, and 1-decanol. J. Chem. Thermodyn. 2021, 157, 106404. [Google Scholar] [CrossRef]

- Nour, M.; Nada, S.; Li, X. Experimental study on the combustion performance of a stationary CIDI engine fueled with 1-heptanol-diesel mixtures. Fuel 2021, 312, 122902. [Google Scholar] [CrossRef]

- Li, J.; Deng, X.; Zhao, W.; Wang, D. A comparative study for the n-butanol/n-octanol and n-butanol/ di-n-butylether fueled dual-fuel engines with different injection timings. Fuel 2023, 338, 127339. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Saravanan, B.; Somasundaram, P.; Jegadheesan, C.; Chaturvedi, B.; Sharma, S.; Patni, G. A novel study on the effect lemon peel oil as a fuel in CRDI engine at various injection strategies. Energy Convers. Manag. 2018, 172, 517–528. [Google Scholar] [CrossRef]

- Karthickeyan, V.; Ashok, B.; Nanthagopal, K.; Thiyagarajan, S.; Geo, V.E. Investigation of novel Pistacia khinjuk biodiesel in DI diesel engine with post combustion capture system. Appl. Therm. Eng. 2019, 159, 113969. [Google Scholar] [CrossRef]

- Bharti, A.; Banerjee, T. Reactive force field simulation studies on the combustion behavior of n-octanol. Fuel Process. Technol. 2016, 152, 132–139. [Google Scholar] [CrossRef]

- Yusri, I.M.; Mamat, R.; Akasyah, M.K.; Jamlos, M.F.; Yusop, A.F. Evaluation of engine combustion and exhaust emissions characteristics using diesel/butanol blended fuel. Appl. Therm. Eng. 2019, 156, 209–219. [Google Scholar] [CrossRef]

- Devarajan, Y.; Munuswamy, D.; Nagappan, B.; Choubey, G. Study on the effect on combining long-chain additive with neat bio-diesel fueled engine to examine its ignition characteristics. Fuel 2020, 279, 118400. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Eryilmaz, T.; Arslan, M. A comparative analysis of the engine performance, exhaust emissions and combustion behaviors of a compression ignition engine fuelled with biodiesel/diesel/1-butanol (C4 alcohol) and biodiesel/diesel/n-pentanol (C5 alcohol) fuel blends. Energy 2018, 165, 1332–1351. [Google Scholar] [CrossRef]

- Vigneshwar, V.; Krishnan, S.Y.; Kishna, R.S.; Srinath, R.; Ashok, B.; Nanthagopal, K. Comprehensive review of Calophyllum inophyllum as a feasible alternate energy for CI engine applications. Renew. Sustain. Energy Rev. 2019, 115, 109397. [Google Scholar] [CrossRef]

- Khan, M.M.; Kumar Kadian, A.; Sharma, R.P. Investigation of high fuel injection pressure variation on compression ignition engines powered by jatropha oil methyl ester-heptanol-diesel blends. Alex. Eng. J. 2023, 65, 675–688. [Google Scholar] [CrossRef]

- Yesilyurt, M.K. The examination of a compression-ignition engine powered by peanut oil biodiesel and diesel fuel in terms of energetic and exergetic performance parameters. Fuel 2020, 278, 118319. [Google Scholar] [CrossRef]

- EL-Seesy, A.I.; He, Z.; Kosaka, H. Combustion and emission characteristics of a common rail diesel engine run with n-heptanol-methyl oleate mixtures. Energy 2021, 214, 118972. [Google Scholar] [CrossRef]

- Yesilyurt, M.K.; Cakmak, A. An extensive investigation of utilization of a C8 type long-chain alcohol as a sustainable next-generation biofuel and diesel fuel blends in a CI engine—The effects of alcohol infusion ratio on the performance, exhaust emissions, and combustion characteristics. Fuel 2021, 305, 121453. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Xie, G.; Li, J.; Xu, W.; Jiang, F.; Huang, Y.; Tan, D. Investigation on the combustion and emission characteristics of diesel engine fueled with diesel/methanol/n-butanol blends. Fuel 2022, 314, 123088. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Li, J.; Lv, J.; Wang, S.; Zhong, Y.; Dong, R.; Gao, S.; Cao, C.; Tan, D. Investigation on combustion, performance and emission characteristics of a diesel engine fueled with diesel/alcohol/n-butanol blended fuels. Fuel 2022, 320, 123975. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Dong, R.; Zou, Z.; Gao, S.; Tan, D. Performance, combustion and emission characteristics investigations on a diesel engine fueled with diesel/ethanol/n-butanol blends. Energy 2022, 249, 123733. [Google Scholar] [CrossRef]

- Ramesh, A.; Ashok, B.; Nanthagopal, K.; Pathy, M.R.; Tambare, A.; Mali, P.; Phuke, P.; Patil, S.; Subbarao, R. Influence of hexanol as additive with Calophyllum Inophyllum biodiesel for CI engine applications. Fuel 2019, 249, 472–485. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R.; Kumar, M. Experimental investigations of oxidation stability of biodiesel produced from Prunus armeniaca oil (apricot oil) and effect of various antioxidants on stability, engine performance and emissions. Fuel 2018, 216, 861–869. [Google Scholar] [CrossRef]

- Nanthagopal, K.; Ashok, B.; Saravanan, B.; Pathy, M.R.; Sahil, G.; Ramesh, A.; Nabi, M.N.; Rasul, M.G. Study on decanol and Calophyllum Inophyllum biodiesel as ternary blends in CI engine. Fuel 2019, 239, 862–873. [Google Scholar] [CrossRef]

- Emiroğlu, A.O.; Şen, M. Combustion, performance and emission characteristics of various alcohol blends in a single cylinder diesel engine. Fuel 2018, 212, 34–40. [Google Scholar] [CrossRef]

- Awad, O.I.; Ali, O.M.; Mamat, R.; Abdullah, A.A.; Najafi, G.; Kamarulzaman, M.K.; Yusri, I.M.; Noor, M.M. Using fusel oil as a blend in gasoline to improve SI engine efficiencies: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 69, 1232–1242. [Google Scholar] [CrossRef]

- Qi, D.H.; Chen, H.; Geng, L.M.; Bian, Y.Z.H.; Ren, X.C.H. Performance and combustion characteristics of biodiesel–diesel–methanol blend fuelled engine. Appl. Energy 2010, 87, 1679–1686. [Google Scholar] [CrossRef]

- Ağbulut, Ü.; Sarıdemir, S.; Karagöz, M. Experimental investigation of fusel oil (isoamyl alcohol) and diesel blends in a CI engine. Fuel 2020, 267, 117042. [Google Scholar] [CrossRef]

- Huang, Z.; Lu, H.; Jiang, D.; Zeng, K.; Liu, B.; Zhang, J.; Wang, X. Combustion behaviors of a compression-ignition engine fuelled with diesel/methanol blends under various fuel delivery advance angles. Bioresour. Technol. 2004, 95, 331–341. [Google Scholar] [CrossRef]

- Tutak, W.; Lukács, K.; Szwaja, S.; Bereczky, Á. Alcohol–diesel fuel combustion in the compression ignition engine. Fuel 2015, 154, 196–206. [Google Scholar] [CrossRef]

- Silitonga, A.S.; Masjuki, H.H.; Ong, H.C.; Sebayang, A.H.; Dharma, S.; Kusumo, F.; Siswantoro, J.; Milano, J.; Daud, K.; Mahlia, T.M.I.; et al. Evaluation of the engine performance and exhaust emissions of biodiesel-bioethanol-diesel blends using kernel-based extreme learning machine. Energy 2018, 159, 1075–1087. [Google Scholar] [CrossRef]

- Candan, F.; Ciniviz, M.; Ors, I. Effect of cetane improver addition into diesel fuel: Methanol mixtures on performance and emissions at different injection pressures. Therm. Sci. 2017, 21, 555–566. [Google Scholar] [CrossRef]

- Wei, L.; Cheung, C.S.; Huang, Z. Effect of n-pentanol addition on the combustion, performance and emission characteristics of a direct-injection diesel engine. Energy 2014, 70, 172–180. [Google Scholar] [CrossRef]

- Fu, J.; Shu, J.; Zhou, F.; Liu, J.; Xu, Z.; Zeng, D. Experimental investigation on the effects of compression ratio on in-cylinder combustion process and performance improvement of liquefied methane engine. Appl. Therm. Eng. 2017, 113, 1208–1218. [Google Scholar] [CrossRef]

- Imran, A.; Varman, M.; Masjuki, H.H.; Kalam, M.A. Review on alcohol fumigation on diesel engine: A viable alternative dual fuel technology for satisfactory engine performance and reduction of environment concerning emission. Renew. Sustain. Energy Rev. 2013, 26, 739–751. [Google Scholar] [CrossRef]

- Atmanlı, A.; İleri, E.; Yüksel, B. Effects of higher ratios of n-butanol addition to diesel–vegetable oil blends on performance and exhaust emissions of a diesel engine. J. Energy Inst. 2015, 88, 209–220. [Google Scholar] [CrossRef]

- Atmanli, A.; Ileri, E.; Yuksel, B.; Yilmaz, N. Extensive analyses of diesel–vegetable oil–n-butanol ternary blends in a diesel engine. Appl. Energy 2015, 145, 155–162. [Google Scholar] [CrossRef]

- Rahimi, H.; Ghobadian, B.; Yusaf, T.; Najafi, G.; Khatamifar, M. Diesterol: An environment-friendly IC engine fuel. Renew. Energy 2009, 34, 335–342. [Google Scholar] [CrossRef]

- Yilmaz, N. Comparative analysis of biodiesel–ethanol–diesel and biodiesel–methanol–diesel blends in a diesel engine. Energy 2012, 40, 210–213. [Google Scholar] [CrossRef]

- Sayin, C.; Canakci, M. Effects of injection timing on the engine performance and exhaust emissions of a dual-fuel diesel engine. Energy Convers. Manag. 2009, 50, 203–213. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Anand, V.; Aravind, K.M.; Jeevanantham, A.K.; Balusamy, S. Effects of n-octanol as a fuel blend with biodiesel on diesel engine characteristics. Fuel 2019, 235, 363–373. [Google Scholar] [CrossRef]

- Deep, A.; Kumar, N.; Karnwal, A.; Gupta, D.; Vibhanshu, V.; Sharma, A.; Patel, J.S. Assessment of the Performance and Emission Characteristics of 1-Octanol/Diesel Fuel Blends in a Water Cooled Compression Ignition Engine; SAE Technical Paper 2014-01-2830; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Mahalingam, Y.; Munuswamy, A.; Devarajan, D.B. Emission and performance analysis on the effect of exhaust gas recirculation in alcohol-biodiesel aspirated research diesel engine. Environ. Sci. Pollut. Res. 2018, 25, 12641–12647. [Google Scholar] [CrossRef]

- Babu, D.; Anand, R. Effect of biodiesel-diesel-n-pentanol and biodiesel-diesel-n-hexanol blends on diesel engine emission and combustion characteristics. Energy 2017, 133, 761–776. [Google Scholar] [CrossRef]

- Phoon, L.Y.; Mustaffa, A.A.; Hashim, H.; Mat, R.; Manan, Z.A.; Yunus, N.A. Performance and emission characteristics of green diesel blends containing diethyl-succinate and 1-octanol. J. Clean. Prod. 2017, 161, 1192–1202. [Google Scholar] [CrossRef]

- Mohammadi, M.; Neshat, E. Accurate prediction of NOx emissions from diesel engines considering in-cylinder ion current. Environ. Pollut. 2020, 266, 115347. [Google Scholar] [CrossRef] [PubMed]

- Balamurugan, T.; Nalini, R. Experimental investigation on performance, combustion and emission characteristics of four stroke diesel engine using diesel blended with alcohol as fuel. Energy 2014, 78, 356–363. [Google Scholar] [CrossRef]

- Nanthagopal, K.; Ashok, B.; Saravanan, B.; Patel, D.; Sudarshan, B.; Aaditya Ramasamy, R. An assessment on the effects of 1-pentanol and 1-butanol as additives with Calophyllum Inophyllum biodiesel. Energy Convers. Manag. 2018, 158, 70–80. [Google Scholar] [CrossRef]

- Soloiu, V.; Moncada, J.D.; Gaubert, R.; Muiños, M.; Harp, S.; Ilie, M.; Zdanowicz, A.; Molina, G. LTC (low-temperature combustion) analysis of PCCI (premixed charge compression ignition) with n-butanol and cotton seed biodiesel versus combustion and emissions characteristics of their binary mixtures. Renew. Energy 2018, 123, 323–333. [Google Scholar] [CrossRef]

- Akar, M.A. Performance and emission characteristics of compression ignition engine operating with false flax biodiesel and butanol blends. Adv. Mech. Eng. 2016, 8, 1687814016632677. [Google Scholar] [CrossRef]

- Li, L.; Wang, J.; Wang, Z.; Xiao, J. Combustion and emission characteristics of diesel engine fueled with diesel/biodiesel/pentanol fuel blends. Fuel 2015, 156, 211–218. [Google Scholar] [CrossRef]

- Randazzo, M.L.; Sodré, J.R. Exhaust emissions from a diesel powered vehicle fuelled by soybean biodiesel blends (B3–B20) with ethanol as an additive (B20E2–B20E5). Fuel 2011, 90, 98–103. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).