Abstract

One of the aims of the environmental and energy policy of the European Union is to reduce the emission of air pollutants, primarily from heat and electricity production, e.g., using renewable energy sources. An example of such a fuel is agricultural biomass including animal manure, which can be used to produce energy in many ways, inter alia direct combustion. The aim of the study was to measure the concentration of NO, NOx, CO, dust and boiler efficiency during the combustion and co-combustion of wood and manure pellets. The research was conducted in the laboratory of the Poznań University of Technology using a 15 kW domestic boiler at maximum power. Manure pellets had higher moisture—9.2%, lower high heating value—17.25 MJ·kg−1, lower low heating value—16.45 MJ·kg−1, and higher ash content—11.23% than wood pellets. The average concentrations of CO, NO, NOx and dust for 100% wood pellets were 198 ± 27 mg·m−3, 129 ± 5 mg·m−3, 198 ± 8 mg·m−3 and 8.7 ± 0.5 mg·m−3, respectively. For this, the fuel boiler power was 13.6 kW (air–fuel ratio 1.48), and it was close to the maximal nominal power. Increasing the share of manure pellets in the burning mixture worsened the stability of the combustion process, and the occurrence of incomplete combustion was observed, which resulted in an increased concentration of CO and dust. Additionally, NO and NOx concentrations also increased. The average boiler power during the combustion of 100% manure pellets was 7.8 kW (air–fuel ratio 2.2), and the average concentrations of CO, NO, NOx and dust were 1548 ± 555 mg·m−3, 355 ± 53 mg·m−3, 554 ± 88 mg·m−3 and 482 ± 63 mg·m−3, respectively.

1. Introduction

One of the objectives of the environmental and energy policy of the European Union, including Poland, is to reduce the emission of air pollutants, primarily from heat and electricity production processes [1,2,3]. EU countries have set an ambitious target that by 2030, 32% of the total energy consumption will be covered by renewable sources, which is expected to contribute to reducing greenhouse gas emissions by 40% compared to 1990 levels [4]. The growing energy demand, the necessity of notable reduce greenhouse gas emissions and the changes resulting from the armed conflict in Ukraine are the main reasons for the intensive search for alternative fuels characterized by low prices and high energy value [5,6,7]. One of such fuels is biomass, which is also widely available [8].

Every production system, including those in the agriculture and agri-food industry, results in different types of residues. The agricultural and the agri-food activity generate mainly organic waste of plant and animal origin with specific fertilizing, energy and nutritional properties [9]. The high availability of agricultural biomass, in any location, in large amounts, makes it an attractive product, but its great diversity requires the use of various techniques for rational use. Most of the agricultural biomass must undergo special pre-treatment before it is used for heat and/or electricity production and for fertilization [10]. One way is biological treatment. An example is the composting process, as the result of which valuable fertilizer—compost—is generated [11]. Another biological method of biomass processing is anaerobic fermentation, which produces biogas burned for heat and energy purposes, and digestate that can be used as fertilizer or fuel [12,13,14]. An alternative to biological treatment is thermochemical processes, which result in the production of solid biofuels, which are then burned for thermal and energy purposes. Many experiments were carried out aimed at converting biomass into solid fuels in the process of gasification, pyrolysis, and pressure treatment [10,15].

The most widely used method of solid biofuels production from biodegradable waste is the process of pressure agglomeration, enabling homogenization and reduction in the mass of the raw material [16]. As a result of the agglomeration process, granules, pellets or briquettes can be produced, which facilitates the use of energy for biomass: transport, storage and combustion [7,17]. Among many types of biomasses, wood is the main raw material for pellet production [18]. Compared to agricultural biomass, wood pellets are characterized by a relatively stable chemical composition, which enables the automation of the fuel feeding process, and it has a positive effect on the emission of air pollutants during combustion. However, higher costs of wood biomass production, regional availability mainly for areas close to forests or wood, furniture industries and high transport costs from the forest or industrial area to end users limit the availability of high-quality and good priced wood pellets on the Polish market [19,20]. This has resulted in increased research interest in alternative types of biomasses, such as agricultural residues and manure, among others. Research is conducted toward the use of agricultural biomass pellets as the primary fuel or co-combustion with wood pellets [7,15,19,20].

One type of agricultural biomass is animal manure—a mixture of feces, urine, bedding material, feed, etc., which is produced in large quantities around the world during livestock production. The energy use of cattle, pig, chicken manure and others is one of the goals of sustainable development and a circular economy [21]. Such a management of animal manure can be implemented primarily in rural areas in developing and developed countries [21,22]. Research on the energy use of manure has been conducted for many years in laboratory and industrial conditions. In the 1980s, series of articles concerning the combustion of raw animal manure in fluidized bed boilers were published [23,24,25]. They used manure containing 14–18% moisture and 16–42% ash with a calorific value between 12.40 and 14.95 MJ·kg−1. The process was carried out in a recirculating bed with a combustion temperature of 620 °C to avoid problems of slagging and fouling. Similar studies were conducted by Have and Fritze [26], Madan [27] and Augustin and Bockenhauer [28]. Schuster and Stroemberg [29] burned horse manure in a boiler connected to a district heating system, and they found that there were basically no technical problems with the high-efficiency and low-emission combustion of manure using modern technologies. However, there was a risk of very low temperatures of ash softening and melting.

Another problem is the high level of chlorides, which can cause corrosion. Therefore, raw manure should not be used in existing wood-fired heating plants. Simultaneously, thermogravimetric studies were also conducted. Yurdakul [30] studied the characteristics of ignition and combustion of animal waste. He showed that the thermal decomposition profiles of poultry litter differ from carbon profiles, having slightly different values of activation energies. Jiang et al. [31] researched the ignition and combustion characteristics of cattle manure particles at various oxygen concentrations and temperatures of 873–1073 K. They confirmed that the influence of ambient temperature on the ignition and combustion of cattle manure particles was the most obvious. With the increase in the ambient temperature and oxygen concentration, the conditions of ignition and combustion improved. Moreover, the internal ignition temperature, the ignition delay and the combustion time of the volatiles decreased.

The next problem with the combustion of agricultural biomass (manure) is air pollutants, which result from the composition and characteristics of fuel. The increased ash content causes higher dust emissions, while high nitrogen content increases nitrogen oxides (NOx) emissions [20,32,33]. Additionally, high ash content and humidity are negatively correlated with the calorific value, which limits the achievement of the nominal boiler power and proper temperature in the boiler combustion chamber. This results in the deposition of slag in the boiler, which hinders heat exchange and causes faster wear of the metal components in the installation due to corrosion [34]. On the other hand, the use of such fuels in low-power (household) boilers can contribute to reducing carbon dioxide (CO2) emissions into the atmosphere. However, it may not meet the emission standards imposed by the Parliament of the European Union. According to the Ecodesign Directive, concentrations of pollutants during biomass combustion should not exceed 500 mg·Nm−3 for carbon monoxide (CO), 200 mg·Nm−3 for NOx and less than 40 mg·Nm−3 for dust at the oxygen content (O2) in exhaust gas equal to 10 mg·Nm−3 [35]. This standard has been in force in the European Union countries since 2020. For this reason, the co-combustion of agricultural biomass pellets and wood pellets has been studied in recent years. Currently, one of the possible solutions to improve the quality of pellets is their production from the mixture two or more raw materials [17]. During the production of pellets from alternative raw materials, the general tendency is to add wood materials, which increases the lignin content, improving their quality, mainly calorific value, bulk density, durability and ash content [36,37,38]. Another, simpler way is to mix two types of pellets in predetermined proportions before burning [39,40].

The aim of the study was to measure the concentration of air pollutants (NO, NOx, CO and dust) and boiler efficiency during the combustion and co-combustion of selected types of biomasses: wood pellet and manure pellet in conditions similar to a domestic boiler at maximum power.

2. Materials and Methods

2.1. Measuring Stand

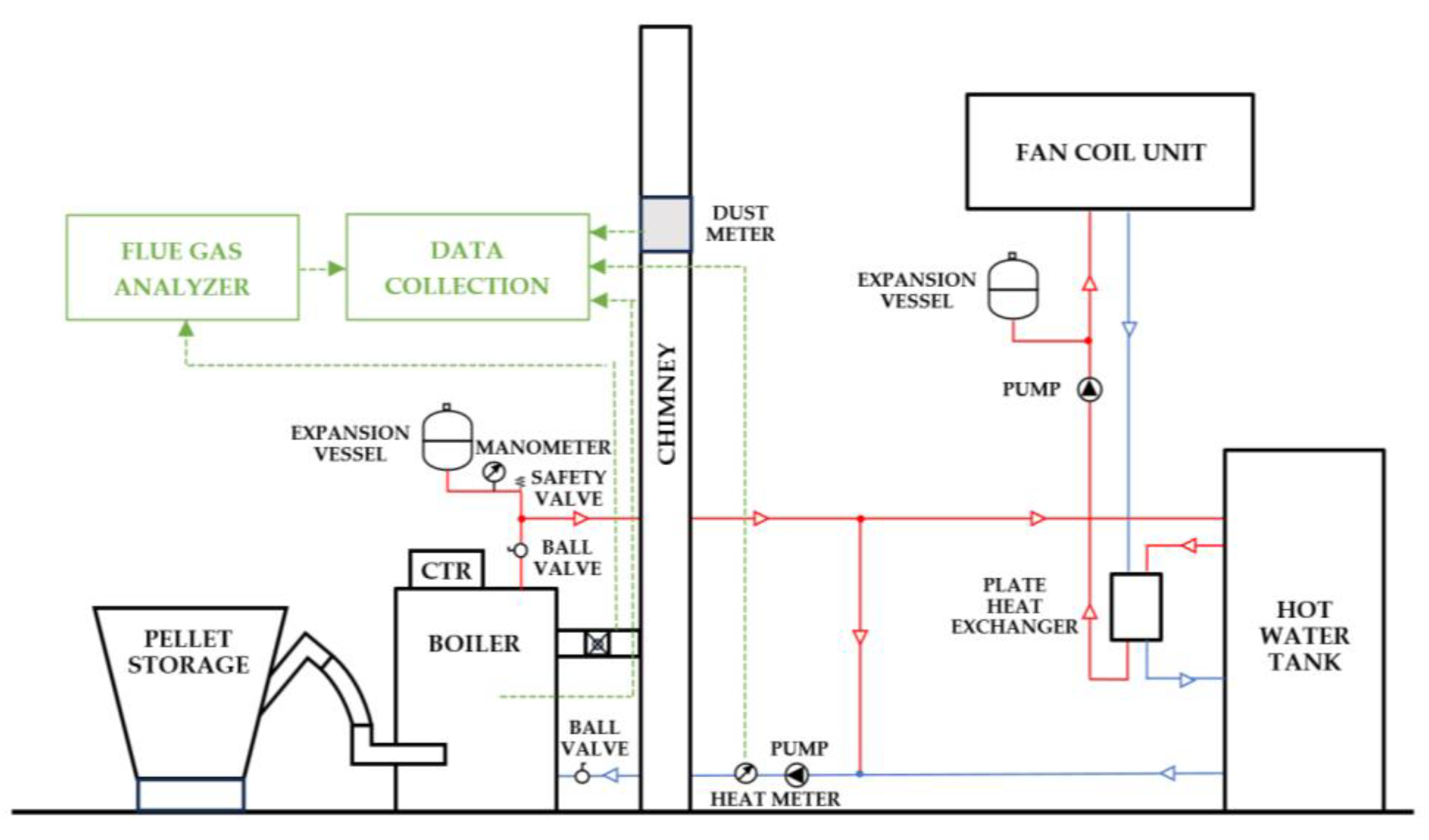

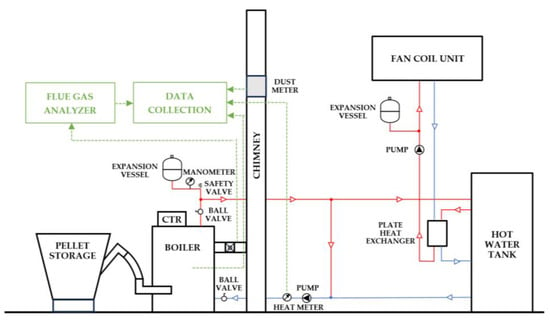

The research was carried out in the summer of 2021 in the laboratory of the Poznań University of Technology (Division of Heating, Air Conditioning and Air Protection, Institute of Environmental Engineering). Experiments were made in almost real-life conditions of small power boilers. The boiler was connected to heat receivers: water heat storages and a fan coil unit (Figure 1).

Figure 1.

The scheme of measuring stand.

The tested fuel was burned in a 15 kW boiler (LUMO Bio Max, Lumo Heating Technology, Mosina, Poland) with an automatic fuel feeding system. The device was dedicated to burning wood pellets and, according to the manufacturer’s declaration, it met the requirements of class 5 for heating devices according to the PN-EN 303-5:2021-09 standard [41] and the EU Ecodesign Directive [35]. The boiler was equipped with a retort burner (Ecotec BioLine 20, Ecotec Sweden AB, Industrivägen, Sweden) and worked with a controller from the same manufacturer.

The air pollutant concentrations in the flue gases and the temperature of flue gases were measured using the MRU Vario Plus flue gas analyzer (MRU Instruments, Humble, TX, USA). Concentrations of CO were measured using an infrared method, and oxygen (O2), nitric oxide (NO) and nitrogen dioxide (NOx) concentrations were measured using electrochemical methods. The range of measurements and the accuracy of the analyzer are presented in Table 1. The Vario Plus flue gas analyzer also calculated the air–fuel ratio and chimney losses for the boiler.

Table 1.

MRU Vario Plus flue gas analyzer technical data.

The laser dust meter (DynOptic DSL-330, Dynoptic Systems Limited, Middleton Cheney, United Kingdom) was used to measure the dust concentration. It was mounted at a height of 3 m in the chimney (measurement accuracy ±0.2 mg·m−3). The heat received by the boiler water and the boiler’s thermal power were measured using a Kamstrup Multical 602 heat meter (Kamstrup A/S, Skanderborg, Denmark). The temperature in the combustion chamber was measured by a PtRh-Pt thermocouple placed about 5 cm above the flame. All measurement data were recorded every 5 s and sent to the computer’s hard disc. The boiler efficiency was calculated using the direct method as a ratio of heat transferred to the boiler water to the product of the mass of combusted fuel and its calorific value.

2.2. Fuel

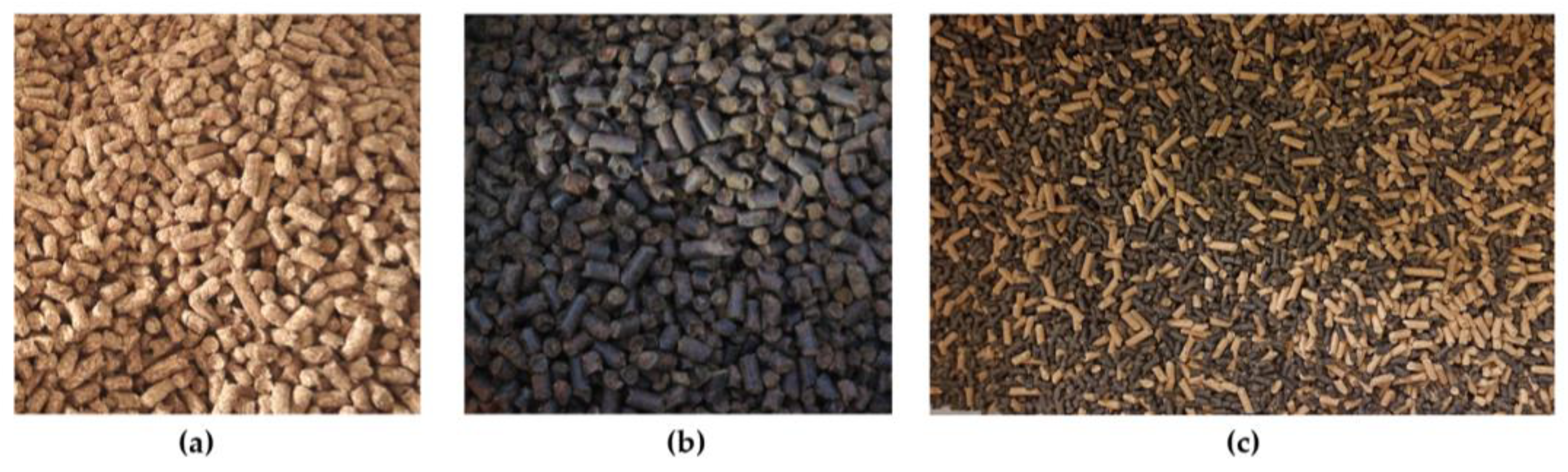

Two types of biomass pellets were used during the research: wood pellets (50% of spruce and 50% of pine) and animal manure pellets (60% of cattle and 40% of chicken manure) mixed in different proportions (Figure 2). Before starting the tests, the characteristics of both fuels were made. The following parameters were determined: relative humidity, low heat value, high heat value, length, diameter, density, and the content of ash, carbon (C), nitrogen (N), hydrogen (H), sulfur (S) and chlorine (Cl).

Figure 2.

Tested fuel: wood pellet (a), manure pellet (b), mixture of wood and manure pellet in ratio 1:3 (c).

Relative humidity was determined using the drying method in accordance with the PN-EN12880:2004 standard [42], and the ash content was determined using the gravimetric method in accordance with the PN-EN 12879:2004 standard [43] in the research laboratory of the Institute of Technology and Life Sciences, Branch in Poznań. For this purpose, a B&D HA 202 M analytical balance with an accuracy of ±0.0001 g, a Wamed KCB 30 heat chamber and a Nabertherm B150 muffle furnace were used. The high heating value (HHV) and the low heating value (LHV) of wood and manure pellets were determined using the IKA C200 an adiabatic calorimeter using the isoperibolic method. Measurements were made in accordance with PN-ISO 1928:2020-05 [44]. HHV is the amount of heat obtained from the complete combustion of a solid fuel in an oxygen atmosphere. The end products of combustion are gases at ambient temperature. The LHV is determined by subtracting the heat of vaporization of the water vapor from the HHV. It was calculated using a computer program that controls the operation of the calorimeter in accordance with PN-ISO 1928:2020-05 [44]. The chemical composition of the fuel was determined in accordance with the PN-EN 15104:2011 [45] and PN-EN 15289:2011 standards [46].

2.3. Plan of Experiment

The combustion tests were made in a boiler operating in stable conditions at maximum power. Before starting the measurements, the boiler was heated up for 1 h to stabilize the combustion conditions. Measurements during the combustion of individual pellet mixtures lasted 60 min. Before the measurement of mixtures with different contents of the tested fuels, the pellet storage and the boiler were thoroughly cleaned. The composition of pellet mixtures was determined by weight, and the research was carried out for the following mixtures:

- -

- 100% wood pellets;

- -

- 75% wood pellets and 25% manure pellets;

- -

- 50% wood pellets and 50% manure pellets;

- -

- 25% wood pellets and 75% manure pellets;

- -

- 100% manure pellets.

3. Results and Discussion

3.1. Parameters and Chemical Composition of the Tested Fuels

Table 2 presents the characteristic values and the content of selected chemical elements for the tested fuels. Organic fuels are characterized by a certain variability of composition resulting from many factors. In the case of wood pellets, these are primarily the species and type of wood; in the case of manure pellets, it is the way of feeding, the animal housing system and manure removal system.

Table 2.

Characteristics and chemical composition of the tested fuels.

For wood pellets, some parameters are required by the PN-EN ISO 17225-2: 2021-10 standard [47], which imposes on pellet producers, e.g., maintaining humidity and low heating value at standardized levels. The wood pellets used in the study met these standards, and the other parameters were within the published ranges [36,38,48,49,50,51]. In case of manure pellets, the parameters are not defined by legal acts, and their variability ranges are much larger and are for [52,53,54,55]:

- -

- Low heating value: 11.95–17.61 MJ·kg−1;

- -

- High heating value: 11.08–16.34 MJ·kg−1;

- -

- Ash content: 11.62–37.85%;

- -

- Carbon content: 25.65–44.24%;

- -

- Nitrogen content: 0.90–2.64%;

- -

- Hydrogen content: 3.43–5.69%;

- -

- Sulfur content: 0.18–0.80%;

- -

- Chlorine content: 0.10–1.04%.

The tested manure pellets have parameters that fall within these ranges or slightly exceed them.

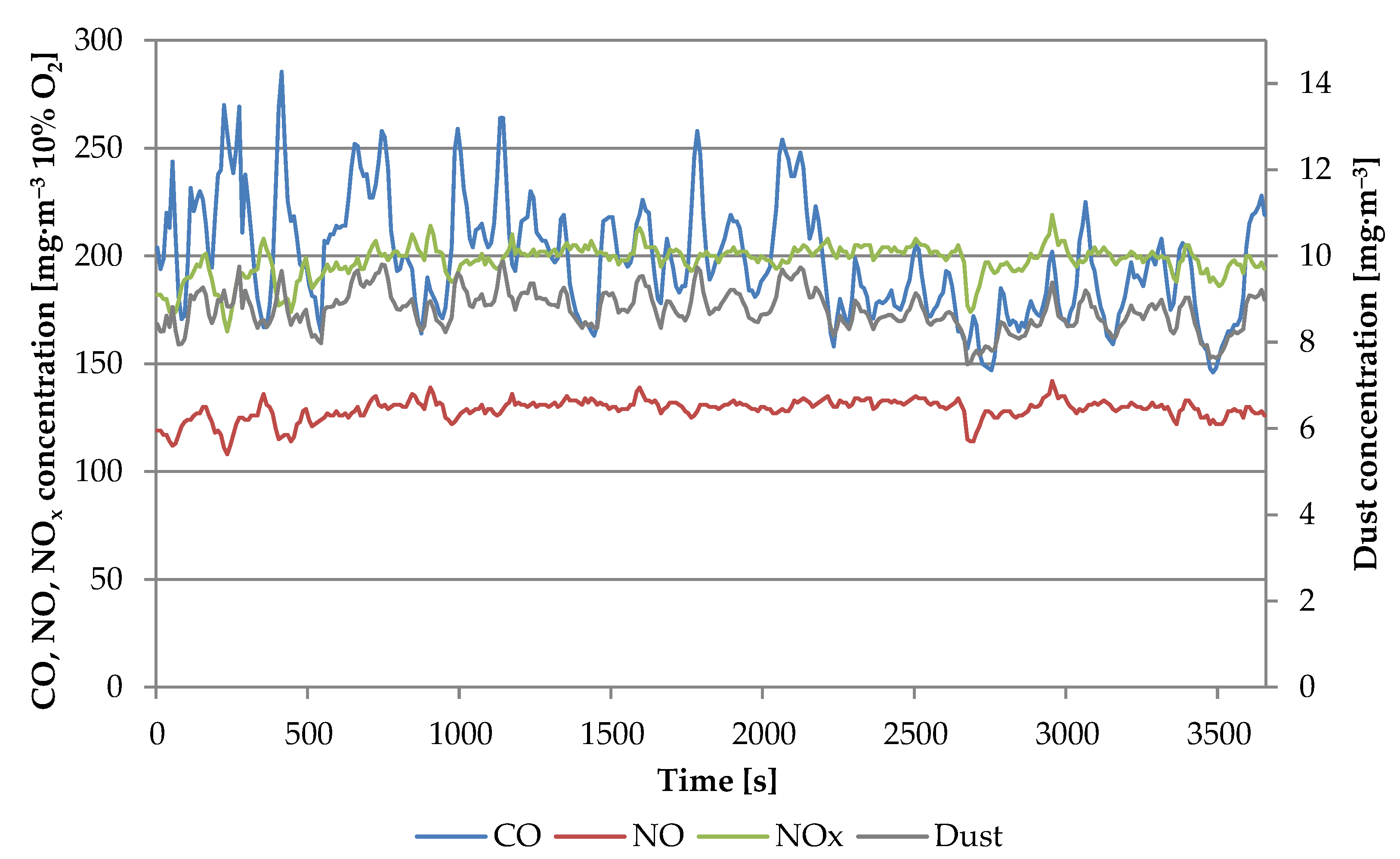

3.2. 100% Wood Pellets

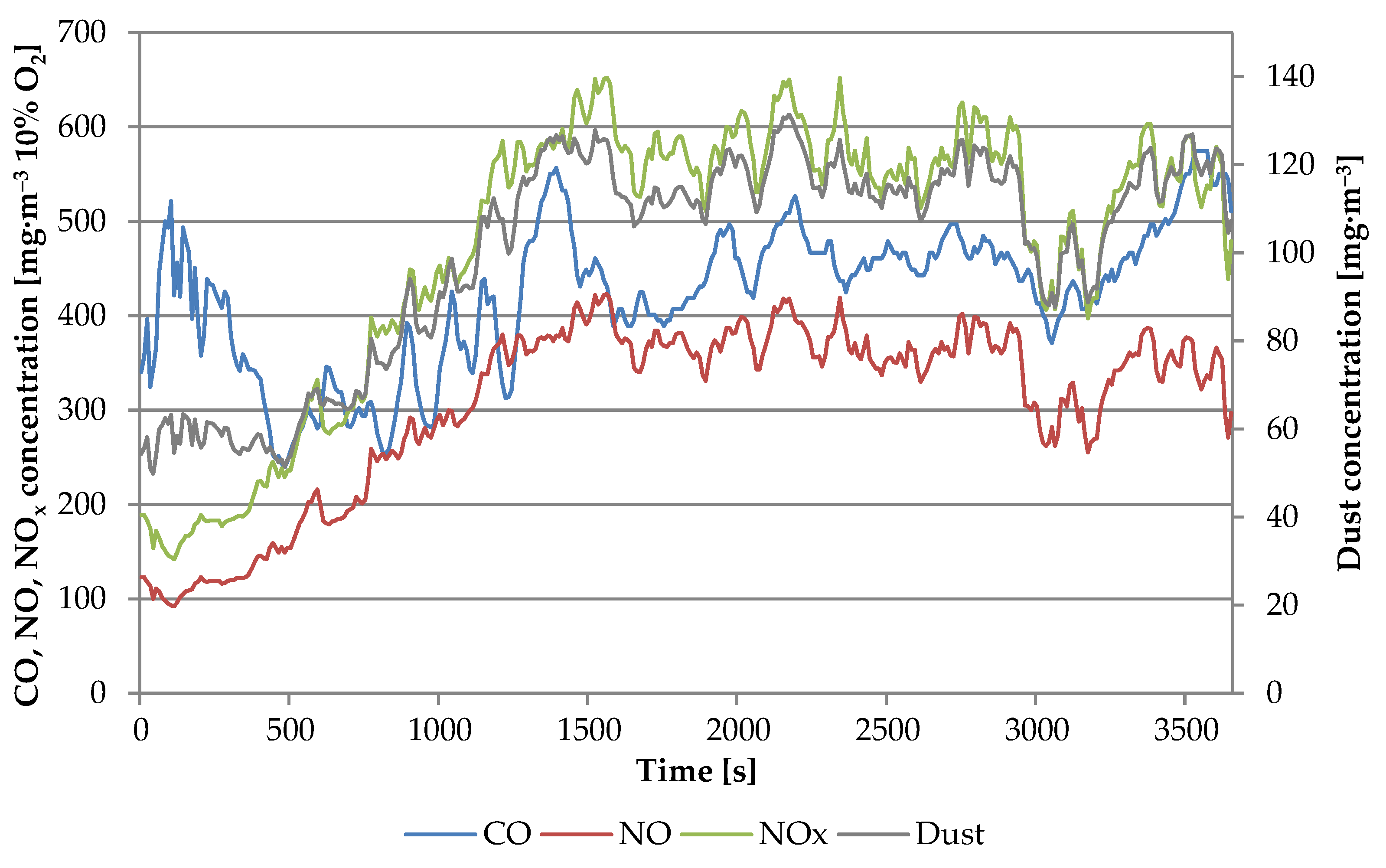

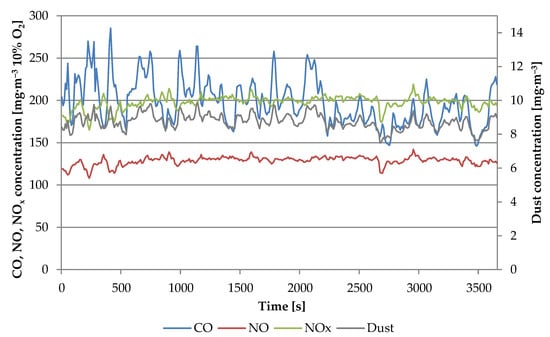

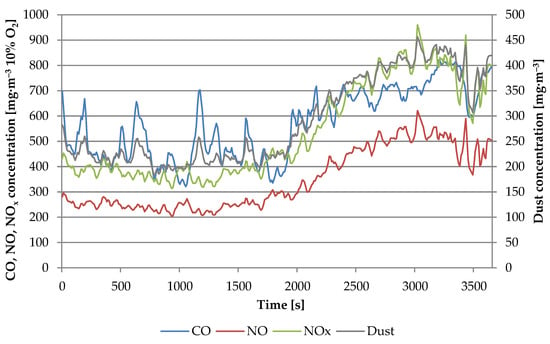

During wood pellet combustion, the power of the boiler ranged from 11.9 to 14.9 kW; on average, it was equal to 13.6 kW and it was close to the maximum nominal power. The average oxygen content was 6.8%, and the air–fuel ratio was from 1.27 to 1.64, with an average of 1.48. Both the average temperature in the combustion chamber and the flue gas temperature did not fluctuate significantly and amounted to 612 ± 15 °C and 145 ± 4 °C, respectively. The boiler efficiency during the test was 94.5%. Figure 3 shows the changes in the concentration values of the tested pollutants.

Figure 3.

Concentration of CO, NO, NOx and dust during combustion of 100% wood pellets.

The average concentrations of CO, NOx and dust were lower than the values required by the Ecodesign Directive, and they were 198 ± 27 mg·m−3, 198 ± 8 mg·m−3 and 8.7 ± 0.5 mg·m−3, respectively. The NO concentration was on average 129 ± 5 mg·m−3. The air pollutants concentrations presented in the available papers cover a wide range, which is related to the variety of material from which the pellets are made (chemical composition), the type of boiler and the type of burner used as well as the presence of recirculation, etc. However, the obtained results can be considered comparable with the results of other works. Pelełka et al. [56], during the combustion of wood pellets in a 200 kW boiler, recorded CO concentrations ranging from 78.5 to 201.2 mg·m−3, NOx from 150 to 204 mg·m−3 and dust from 12.4 to 21.8 mg·m−3. Air pollutant emissions from a 200 kW boiler were studied by Archan et al. [57], and they obtained concentrations lower than the results of this study, ranging for CO from 12 to 60 mg·m−3, for NOx from 84 to 119 mg·m−3 and for dust from 4 to 27 mg·m−3. On the other hand, Verma et al. [58], using 15–32 kW boilers, combusted DINplus wood pellets in real conditions and obtained CO, NOx and dust concentrations of 98–268 mg·m−3, 146–1576 mg·m−3, 6–35 mg·m−3, respectively.

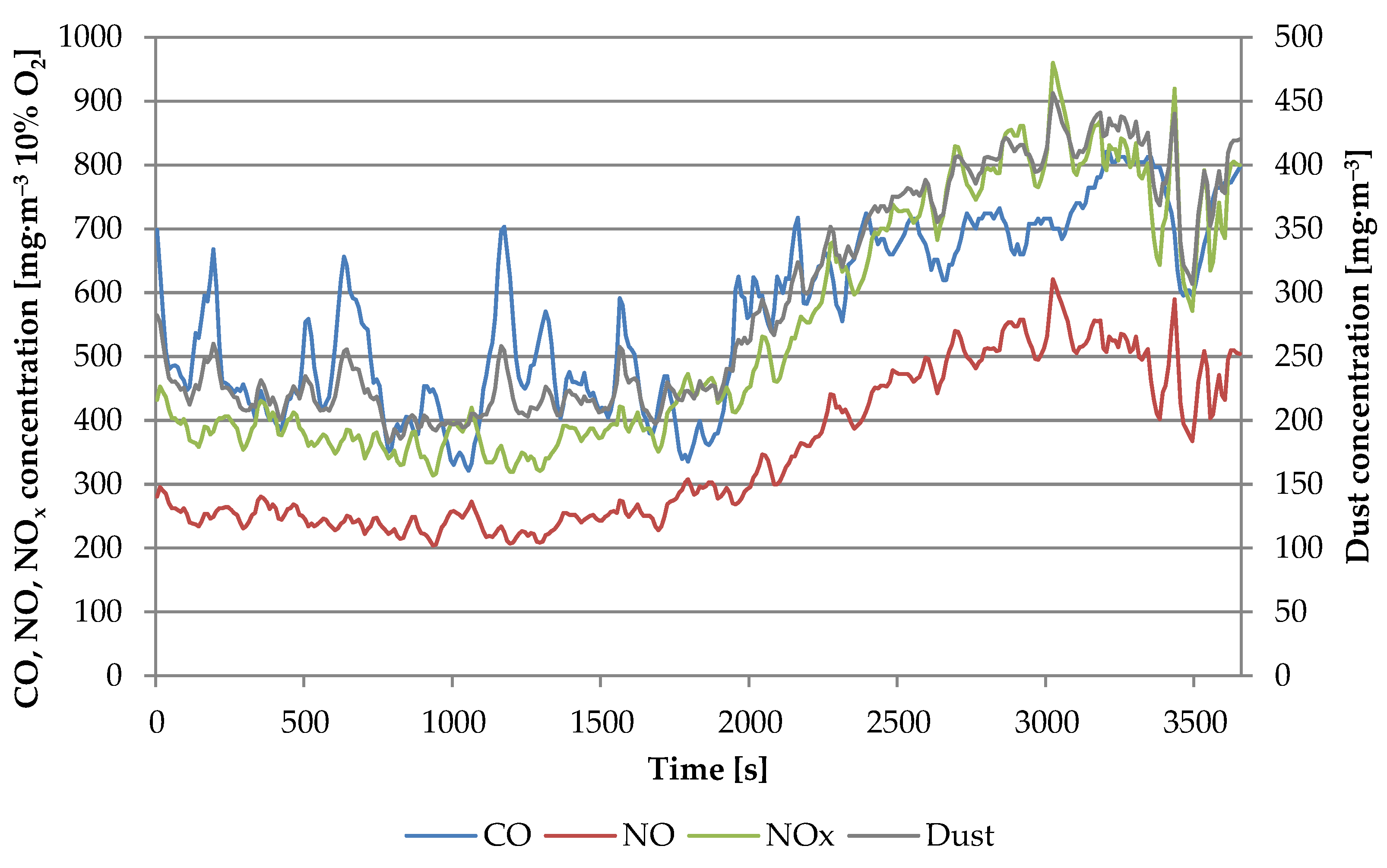

3.3. Mixture of 75% Wood Pellets and 25% Manure Pellets

The average power of the boiler fueled with a mixture of 75% wood pellets and 25% manure pellets was 12.4 kW (from 11.5 to 13.8 kW), and it was lower than power for 100% wood pellets. It results from the lower calorific value of manure pellets. The efficiency of the boiler during the test was similar and amounted to 94.3%. The average oxygen content was 7.1%, and the air–fuel ratio ranged from 1.25 to 1.75, with an average of 1.52. The values of the average temperature in the combustion chamber as well as the flue gas temperatures were 616 ± 25 °C and 138 ± 8 °C, and they were also comparable to values for 100% wood pellets. Figure 4 presents the distribution of the air pollutants concentration during the test.

Figure 4.

Concentration of CO, NO, NOx and dust during combustion mixture of 75% wood and 25% manure pellets.

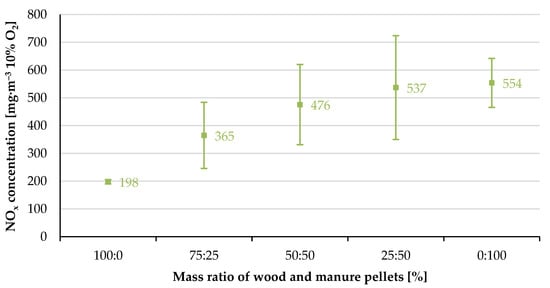

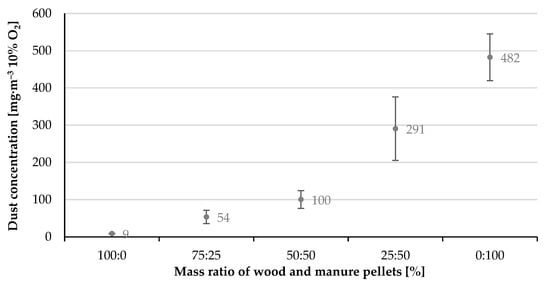

The average concentration of CO was 312 mg·m−3, and it was more than 1.5 times higher than in the case of 100% wood pellets. The dust concentration in the flue gases was also significantly higher: on average equal to 54 mg·m−3. Increased values of both dust and CO were related to the increased ash content in the tested mixture, which may lead to incomplete combustion, which is a source of CO and particulates including soot, condensable organic particles (tar), and char [59]. Moreover, particulates from complete combustion including inorganic material in the flying ash [60] are also an additional source of dust. The average concentrations of NO and NOx were over 1.8 times and almost 2 times higher than in the case of 100% wood pellets, and they were 241 mg·m−3 and 365 mg·m−3, respectively. This is related to the higher content of nitrogen in the fuel, because at the temperatures in which the combustion process was carried out, the synthesis of N2 to NOx (Zeldowicz mechanism) has little impact on the total NOx emission. This mechanism is strictly connected to temperature, and it significantly caused increases in the NOx concentration in temperature above 1200 °C. In case of such proportions of the wood and manure pellet mixture, the Ecodesign Directive is met only for CO. Other concentration (NOx and dust) standards were exceeded.

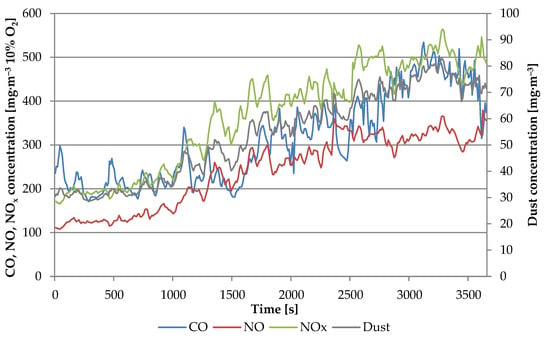

3.4. Mixture of 50% Wood Pellets and 50% Manure Pellets

Increasing the share of manure pellets in the combusted mixture (50% wood pellets and 50% manure pellets) resulted in greater power fluctuations from 10.9 to 13.9 kW and a decrease in average power to 12.2 kW, with an average efficiency of 93.5%. At the same time, the oxygen content increased to 7.7%, and the air–fuel ratio to 1.58. Musialik-Piotrowska et al. [61] indicated that when agricultural biomass was combusted in the burner retort, an increase in the air–fuel ratio may result in increased CO concentrations in the flue gases. For the tested mixture, the CO concentration increased compared to the results for a higher share of wood pellets, and its average value was 422 mg·m−3, assuming values in the range from 239 to 575 mg·m−3. According to Mustafa et al. [62], the higher concentration of CO was also influenced by the decrease in the temperature in the combustion chamber, which was on average 575 °C, with the average flue gas temperature of 132 °C. The concentrations of NO (average 307 mg·m−3), NOx (average 476 mg·m−3) and dust (average 100 mg·m−3) also increased, which results from the increased content of nitrogen and ash in the tested fuel. The changes of measured concentrations during combustion are shown in Figure 5.

Figure 5.

Concentration of CO, NO, NOx and dust during combustion mixture of 50% wood and 50% manure pellets.

The momentary concentration ranges of all tested pollutants were characterized by large fluctuations: for NO, from 92 to 423 mg·m−3; for NOx, from 142 to 652 mg·m−3; and for dust, from 50 to 131 mg·m−3. Only the CO concentration was below the standards set by the Ecodesign Directive.

3.5. Mixture of 25% Wood Pellets and 75% Manure Pellets

The next increase in the content of pellets manure in the mixture (25% of wood pellets and 75% of manure pellets) worsened most of the measured parameters, and it also widened the range of the momentary values. The average boiler power decreased to 10.8 kW. On the other hand, the efficiency of the boiler increased to 93.1%. At the same time, the oxygen content in the exhaust gas increased to 8.8%, and the average air–fuel ratio increased to 1.66. The average temperature in the combustion chamber and flue gas decreased slightly to 567 °C and to 122 °C, respectively. The change of these parameters and the chemical composition of the fuel, in accordance with the previously mentioned mechanisms, resulted in an increase in the concentration of all analyzed pollutants, as shown in Figure 6.

Figure 6.

Concentration of CO, NO, NOx and dust during combustion mixture of 25% wood and 75% manure pellets.

In this case, the concentration of CO ranged from 321 to 821 mg·m−3 (average 569 mg·m−3). Also, the range of changes in NO and NOx concentrations was wide, from 204 to 621 mg·m−3 (average 347 mg·m−3) and from 314 to 960 mg·m−3 (average 537 mg·m−3), respectively. Momentary values of dust concentration ranged from 183 to 456 mg·m−3, with an average value of 291 mg·m−3. Such a wide range of changes and high concentration values indicate low stability of the combustion process and the phenomenon of incomplete combustion. The tested parameters do not meet the Ecodesign Directive.

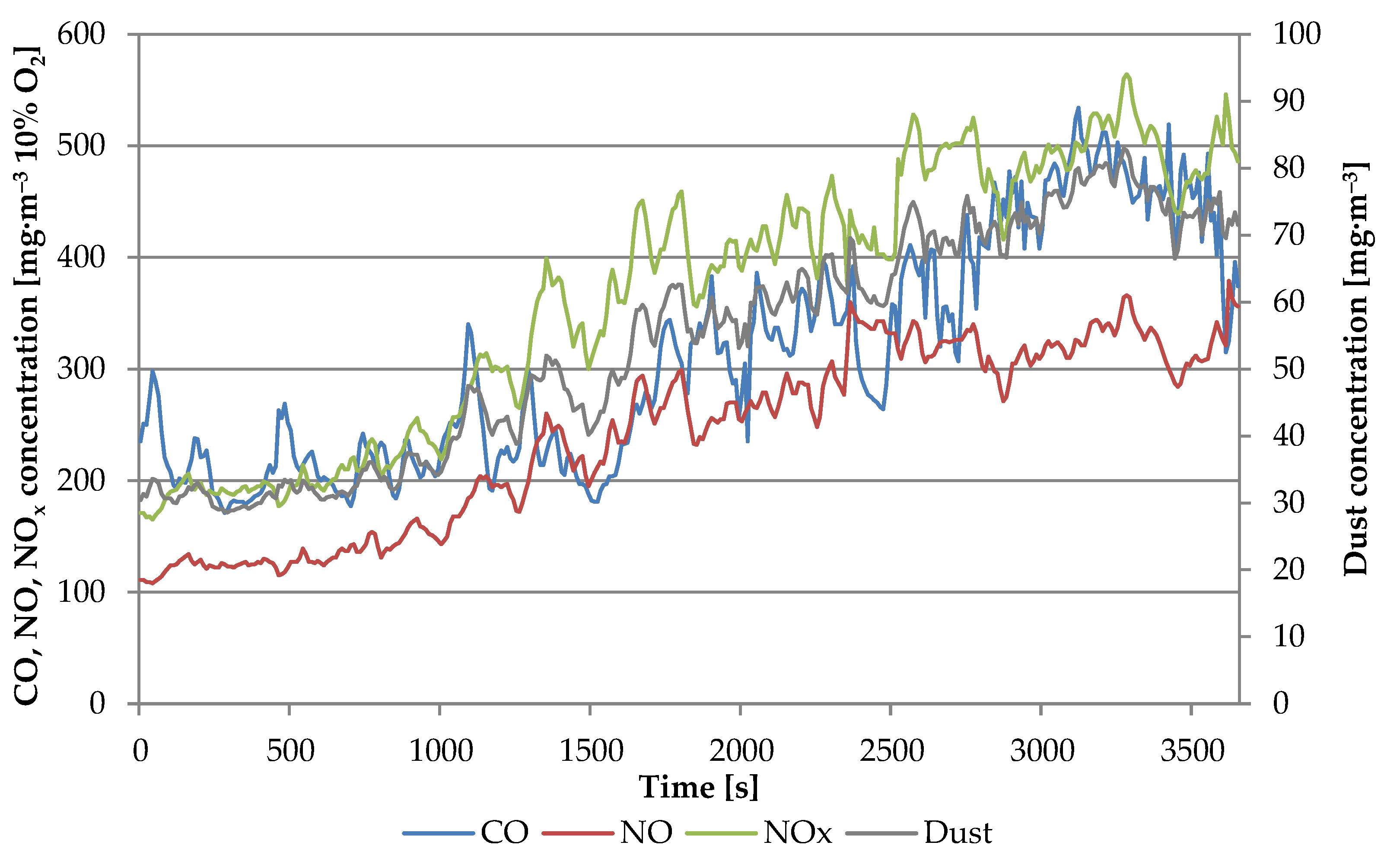

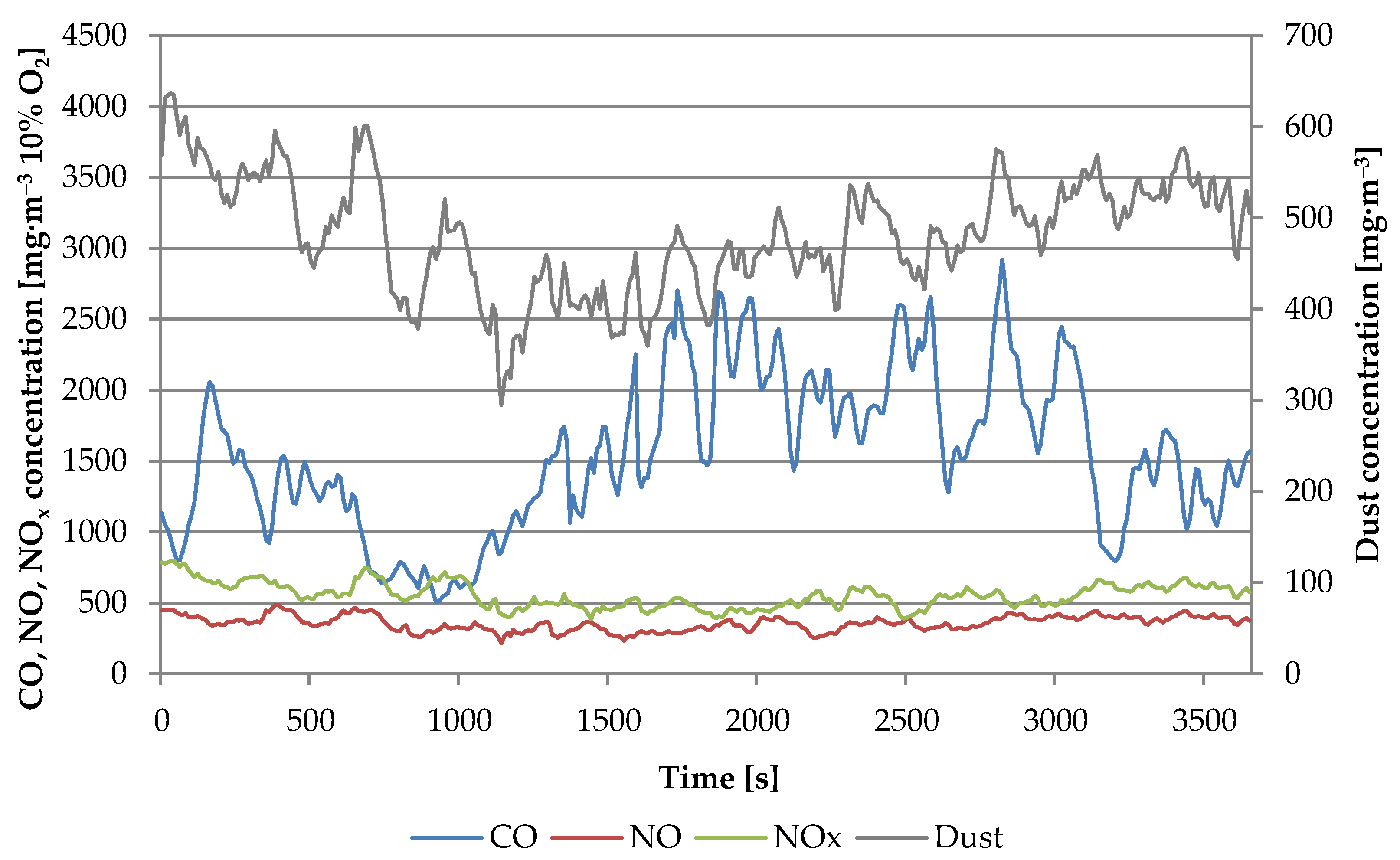

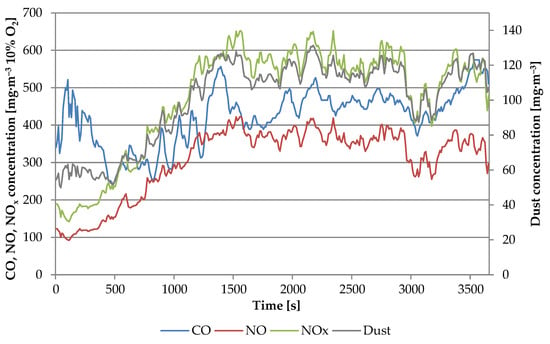

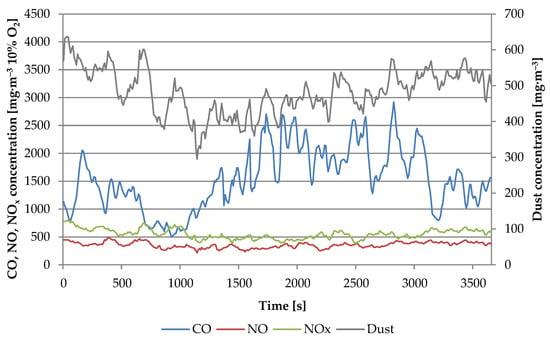

3.6. 100% Manure Pellets

The combustion parameters of manure pellets (100% manure pellets) were by far the worst in comparison with the combustion of mixtures of this fuel with wood pellets. The average boiler power decreased to almost half of the nominal maximum power, amounting to 7.8 kW (average efficiency was 92.4%). The oxygen content in the exhaust gas increased significantly, on average 11.61% (from 9.32% to 12.57%), and the air–fuel ratio ranged from 1.79 to 2.48, with an average of 2.18. This resulted in a decrease in the average temperature in the combustion chamber to 368 °C and a decrease in the average flue gas temperature to 97 °C. These parameters were not only due to the reduced calorific value of manure pellets; they were also related to the phenomenon of incomplete combustion for most of the test. This was evidenced by a very high concentration of CO from 506 to 2920 mg·m−3 (on average 1548 mg·m−3), which is more than three times higher than the Ecodesign standards and almost 10 times higher than the average concentration of particulate matter equal to 482 mg·m−3 (from 295 to 637 mg·m−3). This indicates problems with the oxidation of CO to CO2 and poor stability of the combustion process [7,10].

There were minimal changes in the average concentration of nitrogen oxides, which was comparable to the mixtures: 50% wood pellet and 50% manure pellet and 25% wood pellet and 75% manure pellet. The average concentration of NO was 355 mg·m−3 (from 214 to 485 mg·m−3), and for NOx, it was 554 mg·m−3 (from 382 to 798 mg·m−3) (Figure 7). This is most likely related to the poor mixing of fuel with oxygen caused by the formation of a large amount of dust resulting from the high ash content in manure pellets, the reduced temperature in the combustion chamber and the presence of relatively large amounts of hydrocarbons limiting nitrogen oxidation [56,62]. The obtained results indicate high concentrations of air pollutants in the flue gases, and thus, they are not compliant with the Ecodesign Directive as the main source of energy.

Figure 7.

Concentration of CO, NO, NOx and dust during combustion of 100% manure pellets.

3.7. Summary of Tests

The summarized results of combustion parameters for all measurement series are shown in Table 3. The presented below values are the arithmetic mean value on momentary reads in each series.

Table 3.

The results of all measurement series.

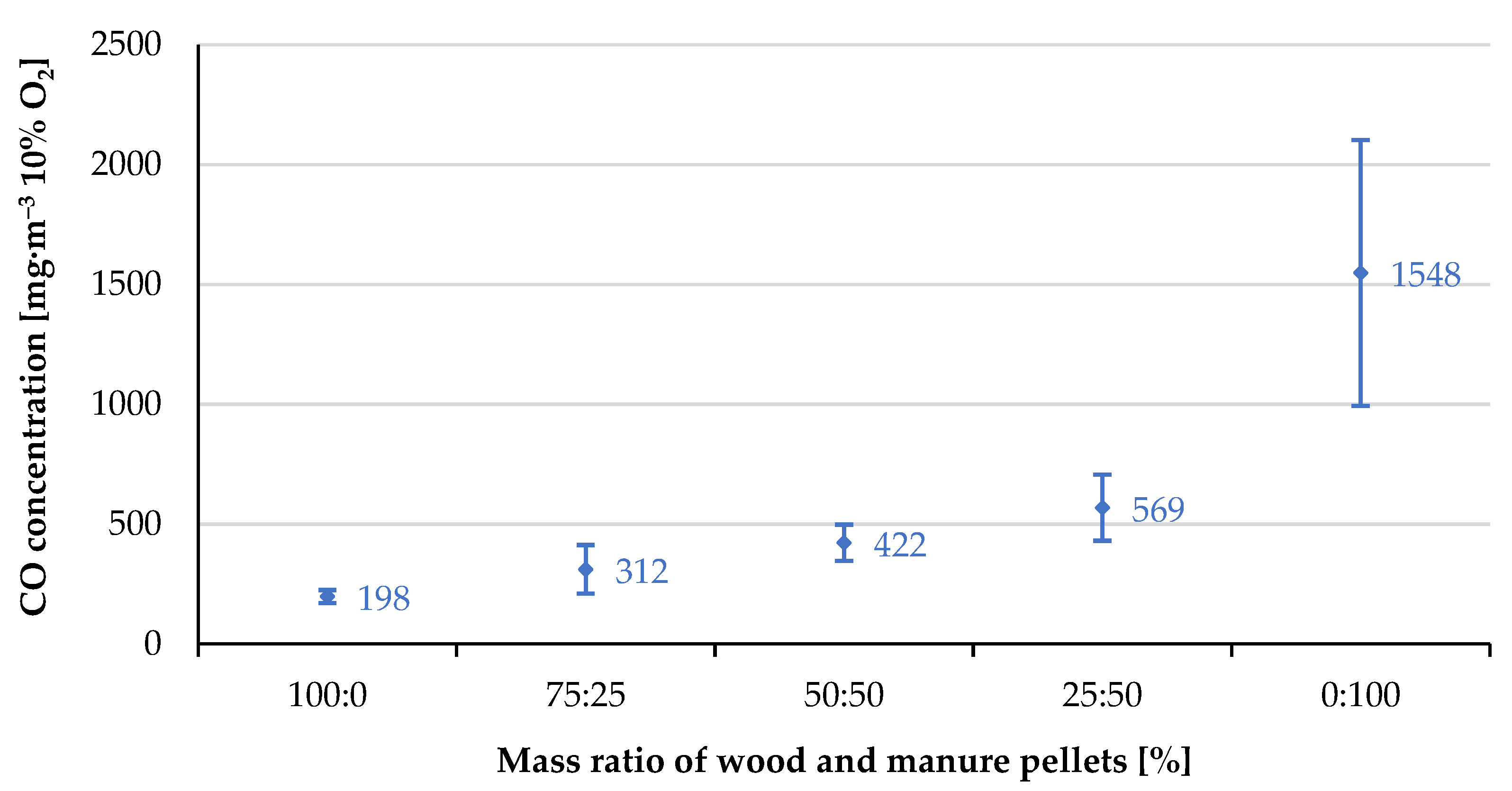

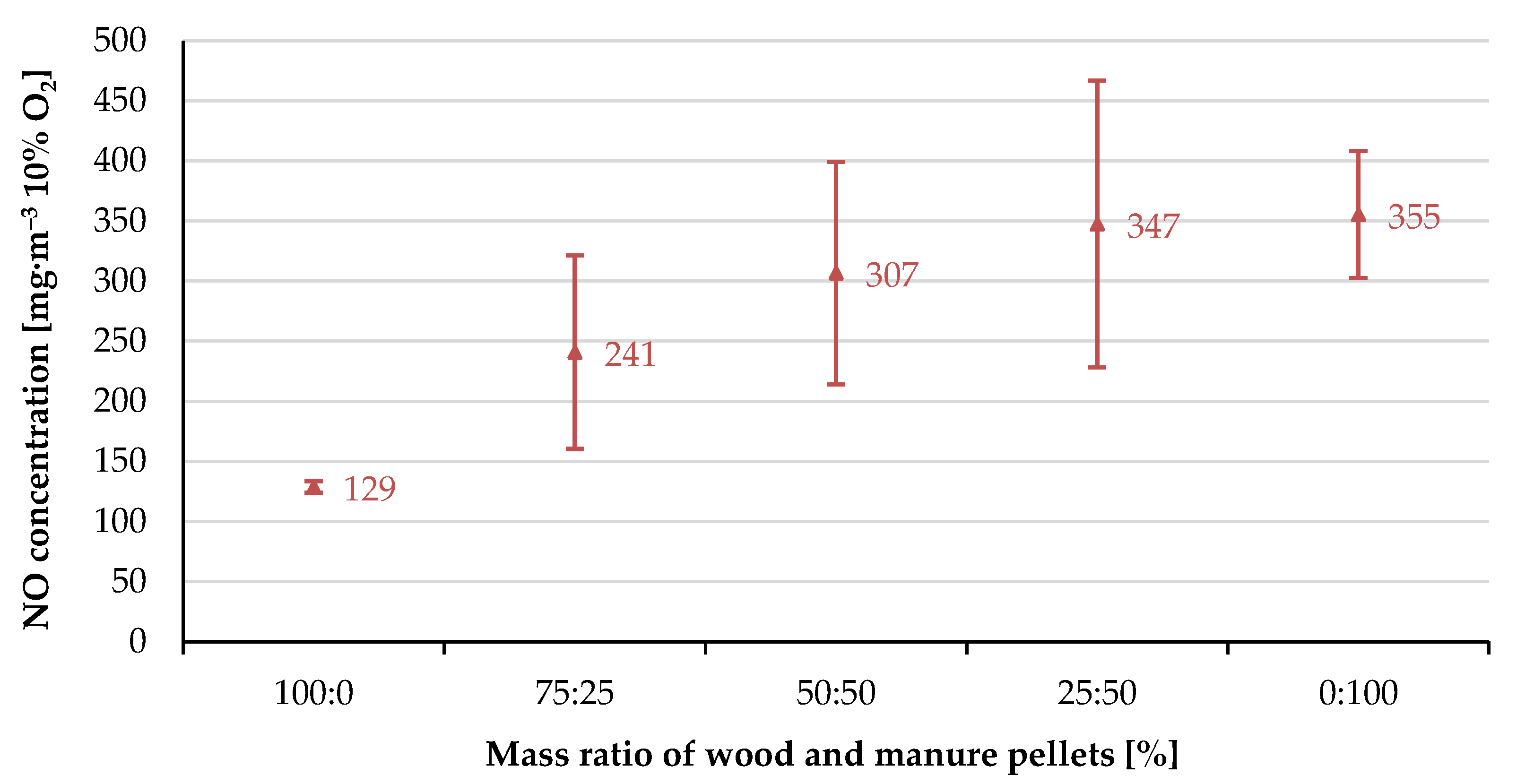

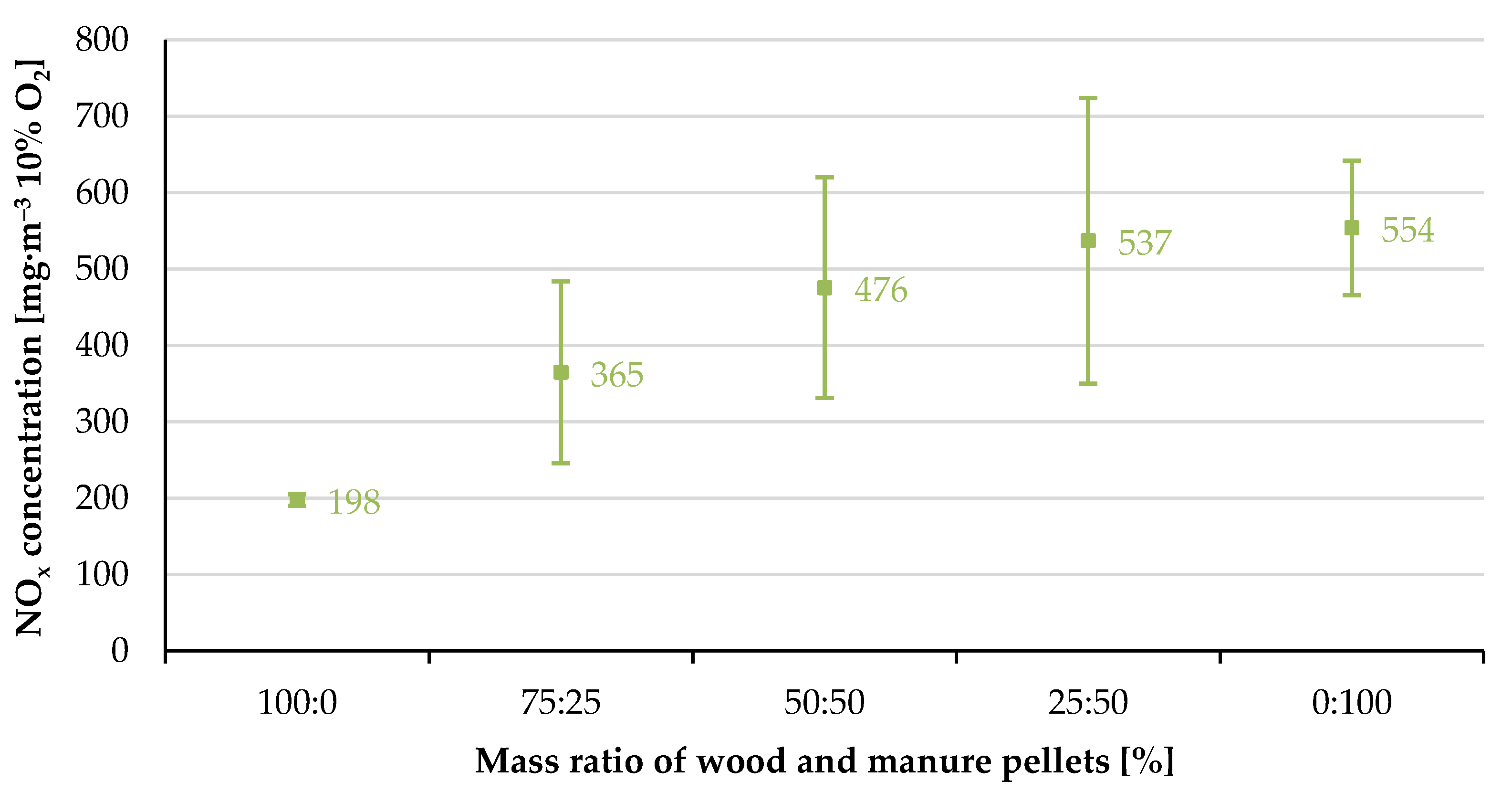

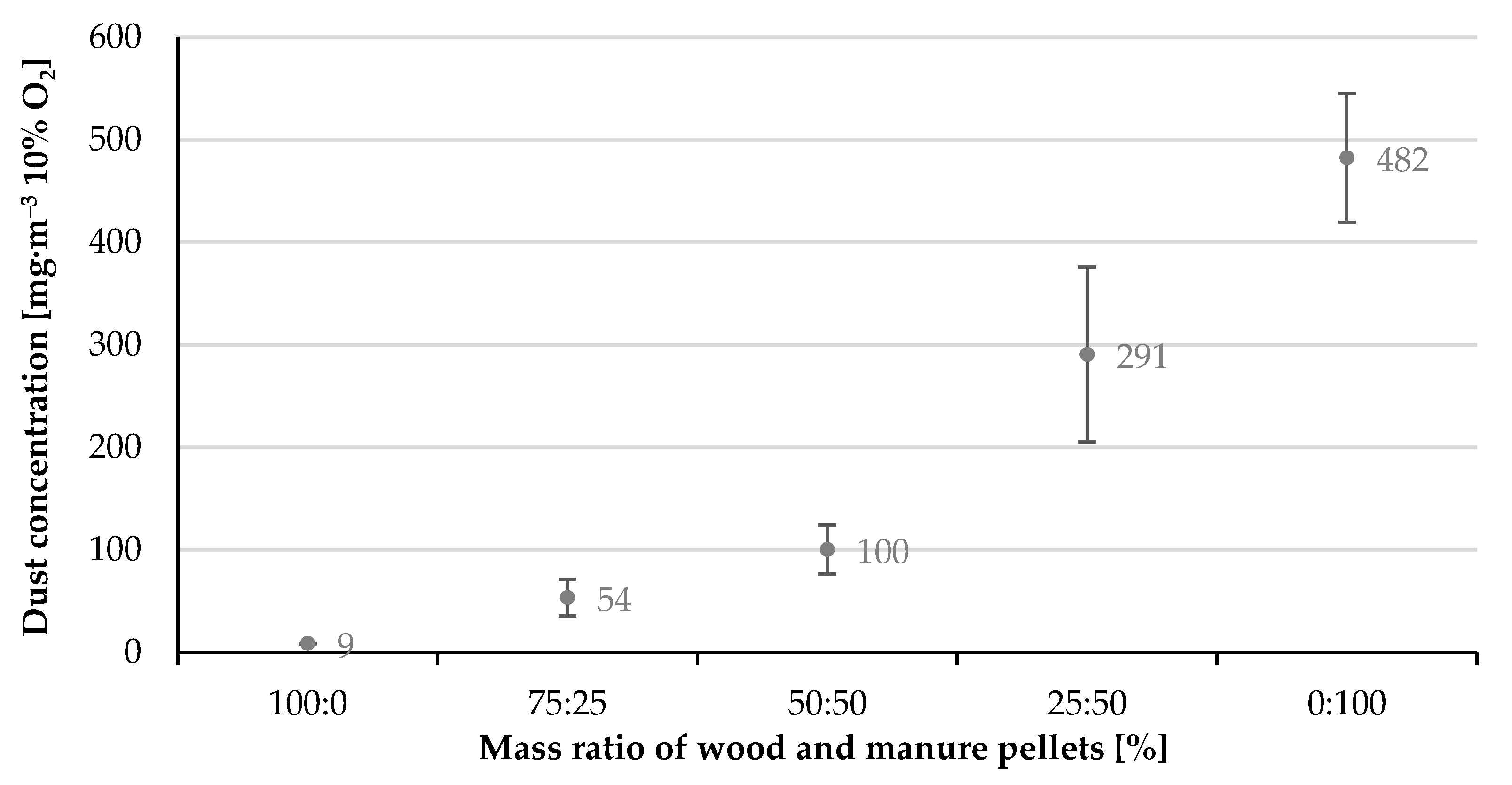

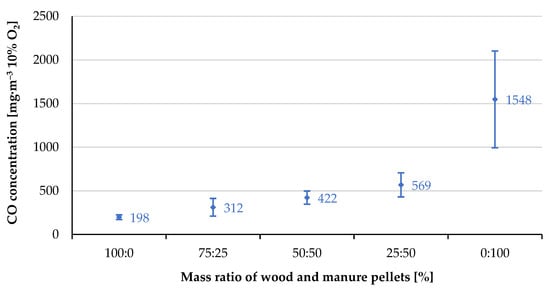

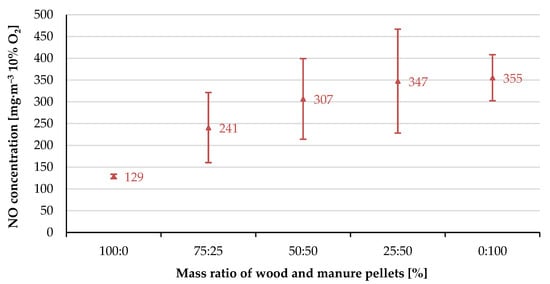

The concentrations of analyzed air pollutants are shown in Figure 8, Figure 9, Figure 10 and Figure 11. They presented the average values of air pollutants concentration with error bars (standard deviation).

Figure 8.

Concentration of CO during tests.

Figure 9.

Concentration of NO during tests.

Figure 10.

Concentration of NOx during tests.

Figure 11.

Concentration of dust during tests.

Based on the measured and calculated data, we observed the changes across all the analyzed parameters. Most of these were connected to each other. The boiler power decreased with the increasing of manure pellets in combusted mixture because of the lower calorific value of the mixture. In addition, during burning, the pellets with higher ash content emitted more dust, what made the contact between the fuel and oxide difficult. To avoid the extinguishing of fire in boiler chamber, the air ratio was increased. Despite this, the temperatures of the combustion chamber and flue gas systematically lowered. This might be caused by slug formation, whose insulating properties limited the boiler efficiency. These phenomena contributed to negative changes in air pollution concentrations. The higher nitrogen and ash content in the combusted mixture and the not well mixed fuel and air might result in increasing the NO, NOx, CO and dust concentrations. The changes of air pollutants concentration were like the results of published studies for the combustion and co-combustion of agricultural biomass. Juszczak [63] measured the concentrations of CO, NO and NOx in the flue gas during the firing of a mixture: 100% sunflower husks, 70% sunflower husks and 30% wood pellets, and 50% sunflower husks and 50% wood pellets. The concentrations of all measured air pollutants decreased with the increasing of wood pellets in the tested mixture. The CO concentration for 100% sunflower husks was from 2.4 to 5.3 times higher than that for the mixture of 50% sunflower husk and 50% wood pellets depending on the feeding ratio. Also, the NO and NOx concentrations, comparing the same fuel mixture, were 1.1–1.6 and 1.3–1.4 higher, respectively. The decreasing content of wood pellets in the mixture caused the increase in air–fuel ratio and the lowering of the boiler power. Pałaszyńska et al. [64] combusted the mixture of wood pellets and coffee husks in the following proportions 100:0, 70:30 and 30:70. During the test, the CO, NO and NOx concentrations in the flue gas were analyzed. The addition of agricultural biomass to the fuel caused a several-fold increase in the concentration of pollutants. Wasilewski et al. [65] compared the GHG concentration during the combustion of wood pellets and rape strow pellets. The NOx concentration for wood pellets was 41.1 pmm and it was 2.9 times lower than for rape straw pellets—119.2 ppm.

Agricultural biomass, including animal manure, given the relatively high C content, high heating value, low heating value and availability, seems to be an attractive fuel, especially in the perspective of decarbonization of Europe and the search for cheap and available renewable fuels. However, they are considered by many researchers to be a “difficult” fuel [65]. This is mainly due to the chemical composition, which differs significantly from wood biomass, featuring an increased nitrogen content and high ash content. Moreover, low attractiveness is also caused by fears of slag, dirt, chlorine corrosion, ash clumping and deposition in the combustion chamber, which hinders the fuel combustion process. These phenomena are undoubtedly undesirable; however, their occurrence is not obvious, as it is largely determined by the ash composition and melting tendencies [22]. These observations confirm the results of research on the use of animal manure as fuel in the combustion process. Cattle and pig manure is still less recognized as a fuel than chicken manure. Nevertheless, the use of local cattle manure may be a promising source of energy for rural communities [66,67].

Lundgren and Pettersson [68] conducted experiments to use horse manure and wood chips as fuel for heat production in Sweden. Biomass consisting of wood chips and horse manure, where wood chips typically accounted for 40–80% by weight, was a fuel for a 250 kW heating plant connected to the local district heating network. The moisture content in the studied fuel mixture ranged from 45 to 65%. During the tests, the boiler operated for 4 to 15 h at an average heat output of 150 kW. CO and NOx emissions were typically in the range of 30–460 mg·m−3 and 149–372 mg·m−3 at 10% vol. O2, respectively. These results were like the results of this study for the mixtures: 50% wood pellet and 50% manure pellet and 25% wood pellet and 75% manure pellet. Vamvuka and Alloimonos [69] made combustion tests in laboratory conditions in a fluidized bed reactor. The fuel consisted of mixtures in different proportions of olive pruning and solid fraction of swine slurry. A higher content of nitrogen was noted in animal feces, which also resulted in quite high concentrations of toxic NOx and CO. During burning a 100% solid fraction of swine slurry, they were 312–452 mg·m−3 and 921–1589 mg·m−3, respectively. It was also observed that with the increased share of animal manure, the temperature of the bed decreased, which is consistent with the results of this work. Puustinen et al. [70] described the Finnish combustion tests of a mixture of sawdust and horse manure using a 40 kW stoker feed furnace produced by Säätötuli Oy. Two type of horse manures were tested, differing in bedding material: sawdust or peat. Measurements of gases and dust concentration were carried out for a fuel mixture consisting of 40% horse manure and 60% sawdust or peat. The following results were obtained for the mixture of horse manure and sawdust: NOx 340 mg·m−3, CO 320 mg·m−3 and dust 120 mg·m−3, and for the fuel consisting of horse manure and peat, the quantities were 520 mg·m−3, 1700 mg·m−3 and 230 mg·m−3, respectively. Their results are also similar to those of this work. Szymajda et al. [52] investigated the possibility of using cow dung pellets as a fuel. Combustion tests were carried out at the Low Emission Technologies Laboratory stand, where the main device was the 25 kW UnicaVentoEko. During the experiment, approx. 10 kg of cow dung pellets was burned, and the content of NO, NOx and CO in the flue gases was measured. The obtained results indicate high concentrations of 253 mg·m−3, 387 mg·m−3 and 855 mg·m−3, respectively. The air–fuel ratio was 2.17.

Summarizing, the results of this work are similar to the results of published papers using animal manure as fuel in the combustion process. The same problems have been observed mainly due to the chemical composition of these fuels. Concentrations of CO, NO, NOx and dust were higher than the maximum concentrations from the Ecodesign Directive. The biggest problem is the high nitrogen content, which does not allow even a few percent content of manure pellets in the fuel mixture with wood pellets.

4. Conclusions

The results of the study and analysis of the co-combustion and combustion processes of manure pellets can be formulated in the following conclusions:

- -

- Manure pellets characterized by higher moisture—9.2%, lower high heating value—17.25 MJ·kg−1, lower low heating value—16.45 MJ·kg−1 and higher ash content—11.23%, than wood pellets (6.4%, 19.51 MJ·kg−1, 19.07 MJ·kg−1 and 0.39, respectively).

- -

- The average boiler power during the combustion of 100% wood pellets was 13.6 kW (air–fuel ratio 1.48), and it was close to the nominal maximum power, and the average concentrations of CO, NOx and dust were lower than the values required by the Ecodesign Directive, and they were 198 ± 27 mg·m−3, 198 ± 8 mg·m−3 and 8.7 ± 0.5 mg·m−3, respectively. The NO concentration was on average 129 ± 5 mg·m−3.

- -

- Increasing the share of manure pellets in the burning mixture worsened the stability of the combustion process, and the occurrence of incomplete combustion was observed, which resulted in an increased concentration of CO and dust. Additionally, NO and NOx concentrations also increased.

- -

- The average boiler power during the combustion of 100% manure pellets was 7.8 kW (air–fuel ratio 2.2), and the average concentrations of CO, NO, NOx and dust were 1548 ± 555 mg·m−3, 355 ± 53 mg·m−3, 554 ± 88 mg·m−3 and 482 ± 63 mg·m−3, respectively.

Nowadays, manure pellets do not meet European emission standards, so they cannot be used as the main fuel in the combustion process. Further research of the energy use of animal manure should focus on methods other than direct combustion using manure pellets or try to optimize the combustion of manure pellets in various combustion technologies, which may provide a more environmentally friendly perspective of its use as fuel.

Author Contributions

Conceptualization, W.R. and I.R.; methodology, W.R., I.R., P.M.-B. and M.U.; validation, W.R. and I.R.; formal analysis, W.R., I.R. and P.M.-B.; investigation, M.U. and W.R.; resources, W.R., I.R. and P.M.-B.; data curation, W.R. and I.R.; writing—original draft preparation, W.R. and I.R.; writing—review and editing, W.R., I.R. and P.M.-B.; visualization, W.R. and I.R.; supervision, W.R., I.R., P.M.-B. and M.U.; funding acquisition, W.R., I.R. and P.M.-B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Polish Ministry of Science and Higher Education, grant number 0713/SBAD/0981.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Papież, M.; Śmiech, S.; Frodyma, K. Determinants of renewable energy development in the EU countries. A 20-year perspective. Renew. Sustain. Energy Rev. 2018, 91, 918–934. [Google Scholar] [CrossRef]

- Manowska, A. Renewable energy sources in the Polish energy structure. Zesz. Nauk. Inst. Gospod. Surowcami Miner. Pol. Akad. Nauk 2019, 109, 111–122. [Google Scholar]

- Bórawski, P.; Bełdycka-Bórawska, A.; Szymańska, E.J.; Jankowski, K.J.; Dubis, B.; Dunn, J.W. Development of renewable energy sources market and biofuels in The European Union. J. Clean. Prod. 2019, 228, 467–484. [Google Scholar] [CrossRef]

- Rajamani, L.; Bodansky, D. The Paris rulebook: Balancing international prescriptiveness with national discretion. Int. Comp. Law Q. 2019, 68, 1023–1040. [Google Scholar] [CrossRef]

- Mohammed, K.S.; Usman, M.; Ahmad, P.; Bulgamaa, U. Do all renewable energy stocks react to the war in Ukraine? Russo-Ukrainian conflict perspective. Environ. Sci. Pollut. Res. 2022, 30, 36782–36793. [Google Scholar] [CrossRef] [PubMed]

- Ugwua, S.N.; Enweremadu, C.C. Effects of pre-treatments and co-digestion on biogas production from Okra Waste. J. Renew. Sustain. Energy 2019, 11, 013101. [Google Scholar] [CrossRef]

- Obidziński, S.; Puchlik, M.; Dołżyńska, M. Pelletization of Post-Harvest Tobacco Waste and Investigation of Flue Gas Emissions from Pellet Combustion. Energies 2020, 13, 6002. [Google Scholar] [CrossRef]

- Kowalczyk-Juśko, A.; Pochwatka, P.; Zaborowicz, M.; Czekała, W.; Mazurkiewicz, J.; Janczak, D.M.; Marczuk, A.; Dach, J. Energy value estimation of silages for substrate in biogas plants using an artificial neural network. Energy 2020, 202, 117729. [Google Scholar] [CrossRef]

- Czyżyk, F.; Strzelczyk, M. Rational utilization of production residues generated in agri-food. Arch. Gospod. Odpad. I Ochr. Sr. 2015, 17, 99–106. [Google Scholar]

- Dołżyska, M.; Obidziński, S.; Piekut, J.; Yildiz, G. The utilization of plum stones for pellet production and investigation of post-combustion flue gas emissions. Energies 2020, 13, 5107. [Google Scholar] [CrossRef]

- Ayilara, M.S.; Olanrewaju, O.S.; Babalola, O.O.; Odeyemi, O. Waste Management through Composting: Challenges and Potentials. Sustainability 2020, 12, 4456. [Google Scholar] [CrossRef]

- Koszel, M.; Lorencowicz, E. Agricultural Use of Biogas Digestate as a Replacement Fertilizers. Agric. Agric. Sci. Procedia 2015, 7, 119–124. [Google Scholar] [CrossRef]

- Hung, C.; Tsai, W.; Chen, J.; Lin, Y.; Chang, Y. Characterization of biochar prepared from biogas digestate. Waste Manag. 2017, 66, 53–60. [Google Scholar] [CrossRef] [PubMed]

- Minutillo, M.; Perna, A.; Sorce, A. Combined hydrogen, heat and electricity generation via biogas reforming: Energy and economic assessments. Int. J. Hydrogen Energy 2019, 44, 23880–23898. [Google Scholar] [CrossRef]

- Digman, B.; Joo, H.S.; Kim, D.-S. Recent Progress in Gasification/Pyrolysis Technologies for Biomass Conversion to Energy. Environ. Prog. Sustain. 2009, 28, 47–51. [Google Scholar] [CrossRef]

- Mostafa, M.E.; Hu, S.; Wang, Y.; Su, S.; Hu, X.; Elsayed, S.A.; Xiang, J. The significance of pelletization operating conditions: An analysis of physical and mechanical characteristics as well as energy consumption of biomass pellets. Renew. Sustain. Energy Rev. 2019, 105, 332–348. [Google Scholar] [CrossRef]

- Czekała, W.; Bartnikowska, S.; Dach, J.; Janczak, D.; Smurzyńska, A.; Kozłowski, K.; Bugała, A.; Lewicki, A.; Cieślik, M.; Typańnska, D.; et al. The energy value and economic efficiency of solid biofuels produced from digestate and sawdust. Energy 2018, 159, 1118–1122. [Google Scholar] [CrossRef]

- Križan, P.; Matú, M.; Šooš, L.; Beniak, J. Behavior of Beech Sawdust during Densification into a Solid Biofuel. Energies 2015, 8, 6382–6398. [Google Scholar] [CrossRef]

- Juszczak, M. Correlation between air flow rate and pollutant concentrations during two-stage oak log combustion in a 25 KW residential boiler. Chem. Process Eng.-Inz. 2016, 37, 419–428. [Google Scholar] [CrossRef]

- Katsaros, G.; Sommersacher, P.; Retschitzegger, S.; Kienzl, N.; Tassou, S.A.; Pandey, D.S. Combustion of poultry litter and mixture of poultry litter with woodchips in a fixed bed lab-scale batch reactor. Fuel 2021, 286, 119310. [Google Scholar] [CrossRef]

- Dhungana, B.; Lohani, S.P.; Marsolek, M. Anaerobic Co-Digestion of Food Waste with Livestock Manure at Ambient Temperature: A Biogas Based Circular Economy and Sustainable Development Goals. Sustainability 2022, 14, 3307. [Google Scholar] [CrossRef]

- Maj, I. Significance and Challenges of Poultry Litter and Cattle Manure as Sustainable Fuels: A Review. Energies 2022, 15, 8981. [Google Scholar] [CrossRef]

- Sweeten, J.M.; Korenberg, J.; LePori, W.A.; Annamalai, K.; Parnell, C.B. Combustion of cattle feedlot manure for energy production. Energy Agric. 1986, 5, 55–72. [Google Scholar] [CrossRef]

- Annamalai, K.; Ibrahim, M.Y.; Sweeten, J.M. Experimental studies on combustion of cattle manure in a fluidized bed combustor. J. Energy Resour. Technol. 1987, 109, 49–57. [Google Scholar] [CrossRef]

- Annamalai, K.; Madan, A.M.; Sweeten, J.M.; Chi, D. Fluidized bed combustion of manure: Experiment and theory. In Agricultural Waste Utilization and Management, Proceedings of the 5th International Symposium on Agricultural Wastes, Chicago, IL, USA, 16–17 December 1985; American Society of Agricultural Engineers: Chicago, IL, USA, 1985; pp. 37–45. [Google Scholar]

- Have, H.; Fritze, M. Heat Energy from Animal Waste by Combined Drying, Combustion and Heat Recovery. In Energy from Biomass. Solar Energy R & D in the European Community; Chartier, P., Palz, W., Eds.; Springer: Dordrecht, The Netherlands, 1981; Volume 1. [Google Scholar] [CrossRef]

- Madan, A.M. Experimental Study of Fluidized Bed Combustion of Feedlot Manure. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 1984. [Google Scholar]

- Augustin, B.; Bockenhauer, M. Electric Power Generation from Direct Combustion of Feedlot Waste. Geogr. Bull. 1987, 29, 15–20. [Google Scholar]

- Schuster, R.; Stroemberg, B. Combustion of Manure Foerbraenning av Goedsel. En Orienterande Litteraturstudie Med Kommentarer; Stiftelsen foer Vaermeteknisk Forskning: Stockholm, Sweden, 1997. [Google Scholar]

- Yurdakul, S. Determination of Co-Combustion Properties and Thermal Kinetics of Poultry Litter/Coal Blends Using Thermogravimetry. Renew. Energy 2016, 89, 215–223. [Google Scholar] [CrossRef]

- Jiang, C.; Lin, Q.; Wang, C.; Jiang, X.; Bi, H.; Bao, L. Experimental Study of the Ignition and Combustion Characteristics of Cattle Manure under Different Environmental Conditions. Energy 2020, 197, 117143. [Google Scholar] [CrossRef]

- Thengane, S.K.; Gupta, A.; Mahajani, S.M. Co-Gasification of High Ash Biomass and High Ash Coal in Downdraft Gasifier. Bioresour. Technol. 2019, 273, 159–168. [Google Scholar] [CrossRef] [PubMed]

- Hupa, M. Ash-Related Issues in Fluidized-Bed Combustion of Biomasses: Recent Research Highlights. Energy Fuels 2012, 26, 4–14. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical Characteristics of Biomass Ashes. Energies 2018, 11, 2885. [Google Scholar] [CrossRef]

- Ecodesign Directive 2015. Commission Regulation (EU) 2015/1189 of 28 April 2015 Implementing Directive 2009/125/EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Solid Fuel Boilers. Available online: https://www.legislation.gov.uk/eur/2015/1189 (accessed on 4 August 2023).

- Obidziński, S.; Joka Yildiz, M.; Dąbrowski, S.; Jasiński, J.; Czekała, W. Application of Post-Flotation Dairy Sludge in the Production of Wood Pellets: Pelletization and Combustion Analysis. Energies 2022, 15, 9427. [Google Scholar] [CrossRef]

- Azargohar, R.; Nanda, S.; Dalai, A.K. Densification of Agricultural Wastes and Forest Residues: A Review on Influential Parameters and Treatments. In Recent Advancements in Biofuels and Bioenergy Utilization; Sarangi, P., Nanda, S., Mohanty, P., Eds.; Springer: Singapore, 2018; pp. 27–51. [Google Scholar]

- García, R.; Gil, M.V.; Rubiera, F.; Pevida, C. Pelletization of wood and alternative residual biomass blends for producing industrial quality pellets. Fuel 2019, 251, 739–753. [Google Scholar] [CrossRef]

- Guo, F.; Zhong, Z. Optimization of the co-combustion of coal and composite biomass pellets. J. Clean. Prod. 2018, 185, 399–407. [Google Scholar] [CrossRef]

- Tańczuk, M.; Junga, R.; Werle, S.; Chabiński, M. Experimental analysis of the fixed bed gasification process of the mixtures of the chicken manure with biomass. Renew. Energy 2019, 136, 1055–1063. [Google Scholar] [CrossRef]

- PN-EN 303-5:2021-09; Heating Boilers—Part 5: Heating Boilers for Solid Fuels, Manually and Automatically Stoked, Nominal Heat Output of up to 500 kW—Terminology, Requirements, Testing and Marking. Polish Committee for Standardization: Warsaw, Poland, 2021.

- PN-EN12880:2004; Characterization of Sludges—Determination of Dry Residue and Water Content. Polish Committee for Standardization: Warsaw, Poland, 2004.

- PN-EN 12879:2004; Characteristics of Sewage Sludge—Determination of Losses on Ignition of Sludge Dry Mass. Polish Committee for Standardization: Warsaw, Poland, 2004.

- PN-ISO 1928:2020-05; Solid Fuels—Determination of Heat of Combustion by Bomb Calorimetric Method and Calorific Value Calculation. Polish Committee for Standardization: Warsaw, Poland, 2020.

- PN-EN 15104:2011; Solid Biofuels—Determination of Total Carbon, Hydrogen and Nitrogen Content—Instrumental Methods. Polish Committee for Standardization: Warsaw, Poland, 2011.

- PN-EN 15289:2011; Solid Biofuels—Determination of Total Sulphur and Chlorine. Polish Committee for Standardization: Warsaw, Poland, 2011.

- PN-EN ISO 17225-2:2021; Solid biofuels—Fuel Specifications and Classes—Part 2: Graded Wood Pellets. Polish Committee for Standardization: Warsaw, Poland, 2021.

- Chandrasekaran, S.R.; Hopke, P.K.; Rector, L.; Allen, G.; Lin, L. Chemical Composition of Wood Chips and Wood Pellets. Energy Fuels 2012, 26, 4932–4937. [Google Scholar] [CrossRef]

- Venturini, E.; Vassura, I.; Agostini, F.; Pizzi, A.; Toscano, G.; Passarini, F. Effect of fuel quality classes on the emissions of a residential wood pellet stove. Fuel 2018, 211, 269–277. [Google Scholar] [CrossRef]

- Telmo, C.; Lousada, J. Heating values of wood pellets from different species. Biomass Bioenergy 2011, 35, 2634–2639. [Google Scholar] [CrossRef]

- Stolarski, M.J.; Stachowicz, P.; Dudziec, P. Wood pellet quality depending on dendromass species. Renew. Energy 2022, 199, 498–508. [Google Scholar] [CrossRef]

- Szymajda, A.; Łaska, G.; Joka, M. Assessment of Cow Dung Pellets as a Renewable Solid Fuel in Direct Combustion Technologies. Energies 2021, 14, 1192. [Google Scholar] [CrossRef]

- Vankát, A.; Krepl, V.; Kára, J. Animal dung as a source of energy in remote areas of Indian Himalayas. Agric. Trop. Subtrop. 2010, 43, 140–142. [Google Scholar]

- Wang, J.; Ma, M.; Bai, Y.; Su, W.; Song, X.; Yu, G. Effect of CaO additive on co-pyrolysis behaviour of bituminous coal and cow dung. Fuel 2020, 265, 116911. [Google Scholar] [CrossRef]

- Cwalina, P.; Obidziński, S.; Kowczyk-Sadowy, M.; Krasowska, M.; Siegień, G. Management of Waste from the Dairy Industry for Energy Purposes. Environ. Sci. Proc. 2022, 18, 4. [Google Scholar] [CrossRef]

- Pełka, G.; Jach-Nocoń, M.; Paprocki, M.; Jachimowski, A.; Luboń, W.; Nocoń, A.; Wygoda, M.; Wyczesany, P.; Pachytel, P.; Mirowski, T. Comparison of Emissions and Efficiency of Two Types of Burners When Burning Wood Pellets from Different Suppliers. Energies 2023, 16, 1695. [Google Scholar] [CrossRef]

- Archan, G.; Anca-Couce, A.; Buchmayr, M.; Hochenauer, C.; Gruber, J.; Scharler, R. Experimental evaluation of primary measures for NOX and dust emission reduction in a novel 200 kW multi-fuel biomass boiler. Renew. Energy 2012, 170, 1186–1196. [Google Scholar] [CrossRef]

- Verma, V.K.; Bram, S.; Delattin, F.; De Ruyck, J. Real life performance of domestic pellet boiler technologies as a function of operational loads: A case study of Belgium. Appl. Energy 2013, 101, 357–362. [Google Scholar] [CrossRef]

- Ghafghazi, S.; Sowlati, T.; Sokhansanj, S.; Bi, X.; Melin, S. Particulate matter emissions from combustion of wood in district heating applications. Renew. Sustain. Energy Rev. 2011, 15, 3019–3028. [Google Scholar] [CrossRef]

- Johansson, L.S.; Tullin, C.; Leckner, B.; Sjövall, P. Particle emissions from biomass combustion in small combustors. Biomass Bioenergy 2003, 25, 435–446. [Google Scholar] [CrossRef]

- Musialik-Piotrowska, A.; Kordylewski, W.; Ciołek, J.; Mościcki, K. Characteristics of air pollutants emitted from biomass combustion in small retort boiler. Environ. Prot. Eng. 2010, 36, 123–131. [Google Scholar]

- Mustafa, B.G.; Kiah, M.H.M.; Irshad, A.; Andrews, G.E.; Phylaktou, H.N.; Li, H.; Gibbs, B.M. Rich biomass combustion: Gaseous and particle number emissions. Fuel 2019, 248, 221–231. [Google Scholar] [CrossRef]

- Juszczak, M. Concentrations of carbon monoxide and nitrogen oxides from a 15 kW heating boiler supplied periodically with a mixture of sunflower husk and wood pellets. Environ. Prot. Eng. 2014, 40, 65–74. [Google Scholar] [CrossRef]

- Pałaszyńska, K.; Juszczak, M.; Ostrowski, R. Carbon monoxide and nitric oxide concentrations in flue gas during combustion of agricultural biomass in the residental boiler. Drew. Pr. Nauk. Doniesienia Komun. 2021, 64, 125–144. [Google Scholar] [CrossRef]

- Wasilewski, J.; Zając, G.; Szyszlak-Bargłowicz, J.; Kuranc, A. Evaluation of Greenhouse Gas Emission Levels during the Combustion of Selected Types of Agricultural Biomass. Energies 2022, 15, 7335. [Google Scholar] [CrossRef]

- Zhai, M.; Li, X.; Yang, D.; Ma, Z.; Dong, P. Ash Fusion Characteristics of Biomass Pellets during Combustion. J. Clean. Prod. 2022, 336, 130361. [Google Scholar] [CrossRef]

- Gupta, K.K.; Aneja, K.R.; Rana, D. Current Status of Cow Dung as a Bioresource for Sustainable Development. Bioresour. Bioprocess. 2016, 3, 28. [Google Scholar] [CrossRef]

- Lundgren, J.; Pettersson, E. Combustion of horse manure for heat production. Bioresour. Technol. 2009, 100, 3121–3126. [Google Scholar] [CrossRef] [PubMed]

- Vamvuka, D.; Alloimonos, N. Combustion behavior of olive pruning/animal manure blends in a fluidized bed combustor. Heliyon 2017, 3, e00385. [Google Scholar] [CrossRef]

- Puustinen, H.; Kajolinna, T.; Pellikka, T.; Kouki, J.; Vuorio, K. Characterization of Airborne Emissions from Combustion of Horse Manure; Research report VTT-R-01295-09; VTT: Espoo, Finland, 2009; 18p. (In Finnish) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).