Thermochemical Technologies for the Optimization of Olive Wood Biomass Energy Exploitation: A Review

Abstract

:1. Introduction

2. Process Analysis

2.1. Combustion

2.2. Gasification

2.3. Pyrolysis

2.4. HydroThermal Carbonization

3. Products

3.1. Solid Materials

Biochar and Hydrochar

3.2. Liquid Materials

3.3. Gaseous Materials

4. Discussion

4.1. Process Analysis Summary

4.2. Energy Analysis

| Chips | Pellet | Hydrochar | Char from Pyrolysis | Char from Torrefaction | Syngas | Refs. | |

|---|---|---|---|---|---|---|---|

| YIELD (kgproduct or Nm3, syngas/kgolive wood) | 1 | 0.8 | 0.46 | 0.35 | 0.45 | 2.5 | [44,62,131] |

| LHV (MJ/kgproduct) | 14.2 | 17.8 | 21.0 | 21.3 | 23.8 | 4.1 | [44,54,124,132] |

| EFFECTIVE ENERGY (MJ/kgolive wood) | 14.2 | 14.3 | 9.7 | 7.4 | 10.7 | 10.3 | |

| ENERGY FOR THE PROCESS (MJ/kgolive wood) | 0.04 | 1.4 | 3.9 | 1.4 | 3.3 | 0.04 | [44,52,133,134] |

| ENERGY BALANCE (MJ/kgolive wood) | 14.1 | 12.9 | 5.8 | 6.0 | 7.4 | 10.3 |

5. Conclusions and Future Perspectives

Funding

Data Availability Statement

Conflicts of Interest

References

- Panchal, R.; Singh, A.; Diwan, H. Does circular economy performance lead to sustainable development? A systematic literature review. J. Environ. Manag. 2021, 293, 112811. [Google Scholar] [CrossRef] [PubMed]

- Costa, M.; Piazzullo, D.; Di Battista, D.; De Vita, A. Sustainability assessment of the whole biomass-to-energy chain of a combined heat and power plant based on biomass gasification: Biomass supply chain management and life cycle assessment. J. Environ. Manag. 2022, 317, 115434. [Google Scholar] [CrossRef] [PubMed]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Costa, M.; Buono, A.; Caputo, C.; Carotenuto, A.; Cirillo, D.; Costagliola, M.A.; Di Blasio, G.; La Villetta, M.; Macaluso, A.; Martoriello, G.; et al. The “INNOVARE” project: Innovative plants for distributed polygeneration by residual biomass. Energies 2020, 13, 4020. [Google Scholar] [CrossRef]

- Suardi, A.; Latterini, F.; Alfano, V.; Palmieri, N.; Bergonzoli, S.; Pari, L. Analysis of the work productivity and costs of a stationary chipper applied to the harvesting of olive tree pruning for bio-energy production. Energies 2020, 13, 1359. [Google Scholar] [CrossRef]

- Parascanu, M.M.; Puig-Gamero, M.; Soreanu, G.; Valverde, J.L.; Sanchez-Silva, L. Comparison of three Mexican biomasses valorization through combustion and gasification: Environmental and economic analysis. Energy 2019, 189, 116095. [Google Scholar] [CrossRef]

- Di Blasi, C.; Tanzi, V.; Lanzetta, M. A study on the production of agricultural residues in Italy. Biomass Bioenergy 1997, 12, 321–331. [Google Scholar] [CrossRef]

- Bernetti, I.; Fagarazzi, C.; Fratini, R. A methodology to anaylse the potential development of biomass-energy sector: An application in Tuscany. For. Policy Econ. 2004, 6, 415–432. [Google Scholar] [CrossRef]

- Beccali, M.; Columba, P.; D’Alberti, V.; Franzitta, V. Assessment of bioenergy potential in Sicily: A GIS-based support methodology. Biomass Bioenergy 2009, 33, 79–87. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; Fernández-González, E.; López-Cortés, I.; Salazar-Hernández, D.M. Quantification of the residual biomass obtained from pruning of trees in Mediterranean olive groves. Biomass Bioenergy 2011, 35, 3208–3217. [Google Scholar] [CrossRef]

- Scarlat, N.; Blujdea, V.; Dallemand, J.-F. Assessment of the availability of agricultural and forest residues for bioenergy production in Romania. Biomass Bioenergy 2011, 35, 1995–2005. [Google Scholar] [CrossRef]

- Mahishi, M.; Goswami, D.Y.; Ibrahim, G.; Elnashaie, S.S.E.H. Hydrogen Production from Biomass and Fossil Fuels. In Handbook of Hydrogen Energy, 1st ed.; CRC Press: Boca Raton, FL, USA, 2014; pp. 113–137. [Google Scholar]

- Padilla-Rivera, A.; Barrette, J.; Blanchet, P.; Thiffault, E. Environmental Performance of Eastern Canadian Wood Pellets as Measured Through Life Cycle Assessment. Forests 2017, 8, 352. [Google Scholar] [CrossRef]

- Li, N.; Hakvoort, R.A.; Lukszo, Z. Cost allocation in integrated community energy systems—A review. Renew. Sustain. Energy Rev. 2021, 144, 111001. [Google Scholar] [CrossRef]

- Dorahaki, S.; Rashidinejad, M.; Ardestani, S.F.F.; Arbollahi, A.; Salehizadeh, M.R. An integrated model for citizen energy communities and Renew. Energy communities based on clean energy package: A two-stage risk-based approach. Energy 2023, 277, 127727. [Google Scholar] [CrossRef]

- Romero-García, J.M.; Niño, L.; Martínez-Patiño, C.; Álvarez, C.; Castro, E.; Negro, M.J. Biorefinery based on olive biomass, State of the art and future trends. Bioresour. Technol. 2014, 159, 421–432. [Google Scholar] [CrossRef]

- Ruiz, E.; Romero-García, J.M.; Romero, I.; Manzanares, P.; Negro, M.J.; Castro, E. Olive-derived biomass as a source of energy and chemicals. Biofuels Bioprod. Biorefin. 2017, 11, 1077–1094. [Google Scholar] [CrossRef]

- Dutournié, P.; Jeguirim, M.; Khiari, B.; Goddard, M.L.; Jellali, S. Olive mill waste water: From a pollutant to green fuels, agricultural water source, and bio-fertilizer. Part 2: Water Recovery. Water 2019, 1, 768. [Google Scholar] [CrossRef]

- Soltero, V.M.; Román, L.; Peralta, M.E.; Chacartegui, R. Sustainable biomass pellets using trunk wood from olive groves at the end of their life cycle. Energy Rep. 2020, 6, 2627–2640. [Google Scholar] [CrossRef]

- Contreras, M.d.M.; Romero, I.; Moya, M.; Castro, E. Olive-derived biomass as a renewable source of value-added products. Process Biochem. 2020, 97, 43–56. [Google Scholar] [CrossRef]

- Kougioumtzis, M.A.; Karampinis, E.; Grammelis, P.; Kakaras, E. Integrated harvesting and biomass haulage of olive tree prunings. Evaluation of a two year harvesting campaign in central Greece and fuel characterization of the prunings collected. Biomass Bioenergy 2022, 165, 106572. [Google Scholar] [CrossRef]

- Picchi, G.; Lombardini, C.; Pari, L.; Spinelli, R. Physical and chemical characteristics of renewable fuel obtained from pruning residues. J. Clean. Prod. 2018, 171, 457–463. [Google Scholar] [CrossRef]

- Malico, I.; Nepomuceno Pereira, R.; Gonçalves, A.C.; Sousa, A.M.O. Current status and future perspectives for energy production from solid biomass in the European industry. Renew. Sustain. Energy Rev. 2019, 112, 960–977. [Google Scholar] [CrossRef]

- IPCC Climate Change. Synthesis Report Contribution of Working Groups I, II and III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- IEA (International Energy Agency). Energy Technology Perspectives; International Energy Agency: Paris, France, 2010. [Google Scholar]

- Barbosa, A.; Brusca, I. Governance structures and their impact on tariff levels of Brazilian water and sanitation corporations. Util. Policy 2015, 34, 94–105. [Google Scholar] [CrossRef]

- Yu, S.; Yang, X.; Li, Q.; Zhang, Y.; Zhou, H. Breaking the temperature limit of hydrothermal carbonization of lignocellulosic biomass by decoupling temperature and pressure. Green Energy Environ. 2023, 8, 1216–1227. [Google Scholar] [CrossRef]

- Wu, X.; Luo, N.; Xie, S.; Zhang, H.; Zhang, Q.; Wang, F.; Wang, Y. Photocatalytic transformations of lignocellulosic biomass into chemicals. Chem. Soc. Rev. 2020, 49, 6198–6223. [Google Scholar] [CrossRef]

- Zhou, C.H.; Xia, X.; Lin, C.X.; Tong, D.S.; Beltramini, J. Catalytic conversion of lignocellulosic biomass to fine chemicals and fuels. Chem. Soc. Rev. 2011, 40, 5588–5617. [Google Scholar] [CrossRef]

- Cao, L.; Yu, I.K.M.; Xiong, X.; Tsang, D.C.W.; Zhang, S.; Clark, J.H.; Hu, C.; Ng, Y.H.; Shang, J.; Ok, Y.S. Biorenewable hydrogen production through biomass gasification: A review and future prospects. Environ. Res. 2020, 186, 109547. [Google Scholar] [CrossRef]

- Ahn, J.; Kim, H.J. Combustion process of a Korean wood pellet at a low temperature. Renew. Energy 2020, 145, 391–398. [Google Scholar] [CrossRef]

- Bridgeman, T.; Jones, J.; Shield, I.; Williams, P. Torrefaction of reed canary grass, wheat straw and willow to enhance solid fuel qualities and combustion properties. Fuel 2008, 87, 844–856. [Google Scholar] [CrossRef]

- Pimchuai, A.; Dutta, A.; Basu, P. Torrefaction of agriculture residue to enhance combustible properties. Energy Fuels 2010, 24, 4638–4645. [Google Scholar] [CrossRef]

- Khan, A.; De Jong, W.; Jansens, P.; Spliethoff, H. Biomass combustion in fluidized bed boilers: Potential problems and remedies. Fuel Process. Technol. 2009, 90, 21–50. [Google Scholar] [CrossRef]

- Yip, K.; Tian, F.; Hayashi, J.-I.; Wu, H. Effect of alkali and alkaline earth metallic species on biochar reactivity and syngas compositions during steam gasification. Energy Fuels 2009, 24, 173–181. [Google Scholar] [CrossRef]

- Demirbas, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Demirbaş, A. Estimating of structural composition of wood and non-wood biomass samples. Energy Sources 2005, 27, 761–767. [Google Scholar] [CrossRef]

- Gòmez-Muñoz, B.; Valero-Valenzuela, J.D.; Hinojosa, M.B.; García-Ruiz, R. Management of tree pruning residues to improve soil organic carbon in olive groves. Eur. J. Soil Biol. 2016, 74, 104–113. [Google Scholar] [CrossRef]

- Romero-Garcìa, J.M.; Lòpez-Linares, J.C.; Contreras, M.d.M.; Romero, I.; Castro, E. Exploitation of olive tree pruning biomass through hydrothermal pretreatments. Ind. Crops Prod. 2022, 176, 114425. [Google Scholar] [CrossRef]

- Donner, M.; Erraach, Y.; Lòpez-I-Gelats, F.; Manuel-I-Martin, J.; Yatribi, T.; Radic, I.; El Hadad-Gauthier, F. Circular bioeconomy for olive oil waste and by-product valorisation: Actors’ strategies and conditions in the Mediterranean area. J. Environ. Manag. 2022, 321, 115836. [Google Scholar] [CrossRef]

- Donner, M.; Gohier, R.; de Vries, H. A new circular business model typology for creating value from agro-waste. Sci. Total Environ. 2020, 716, 137065. [Google Scholar] [CrossRef]

- Negro, M.J.; Manzanares, P.; Ruiz, E.; Castro, E.; Ballesteros, M. The biorefinery concept for the industrial valorization of residues from olive oil industry. In Olive Mill Waste: Recent Advances for Sustainable Management; Academic Press: Cambridge, MA, USA; Elsevier: London, UK, 2017; pp. 57–78. [Google Scholar] [CrossRef]

- Hernàndez, V.; Romero-García, J.M.; Dàvila, J.A.; Castro, E.; Cardona, C.A. Techno-economic and environmental assessment of an olive stone based biorefinery. Resour. Conserv. Recycl. 2014, 92, 145–150. [Google Scholar] [CrossRef]

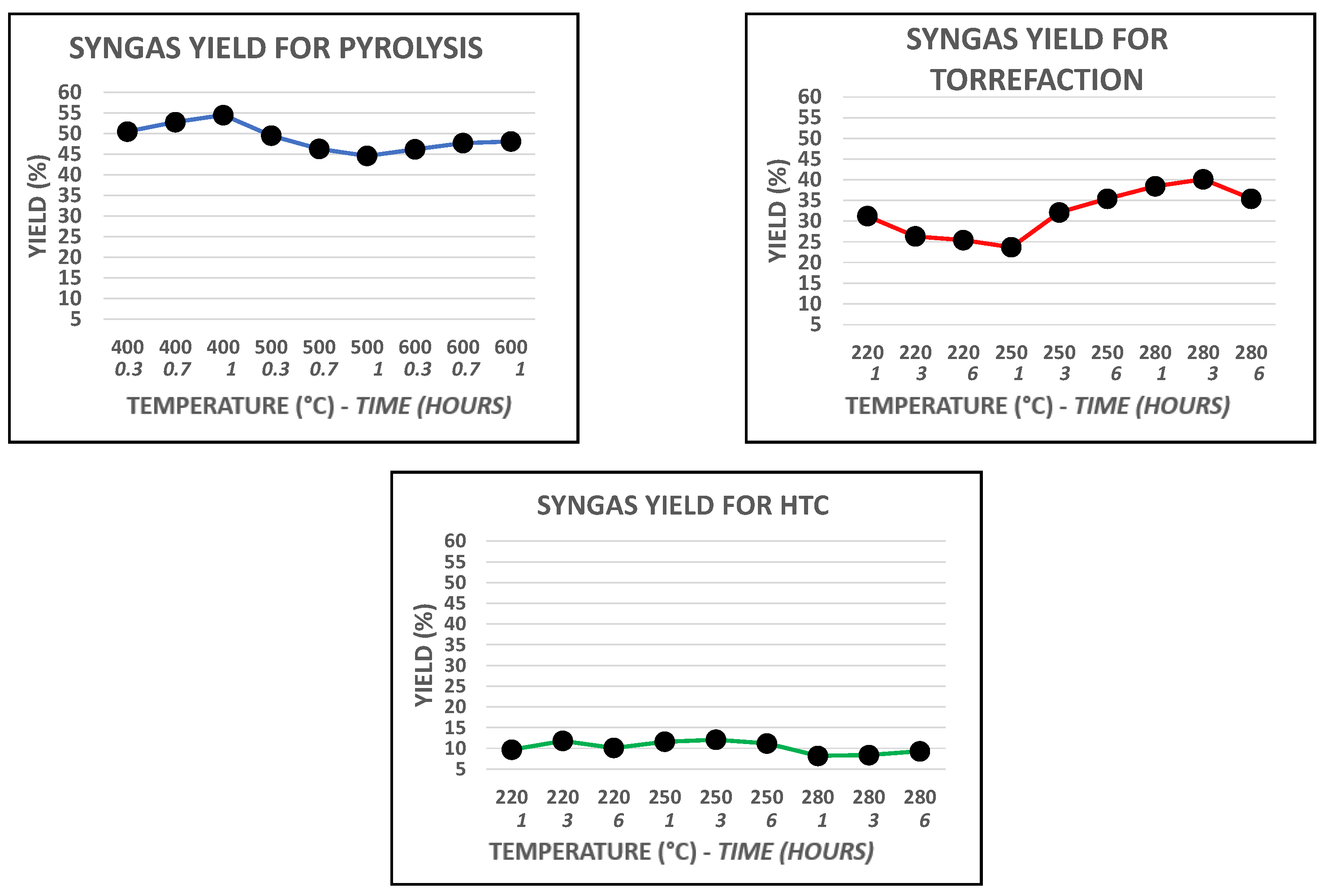

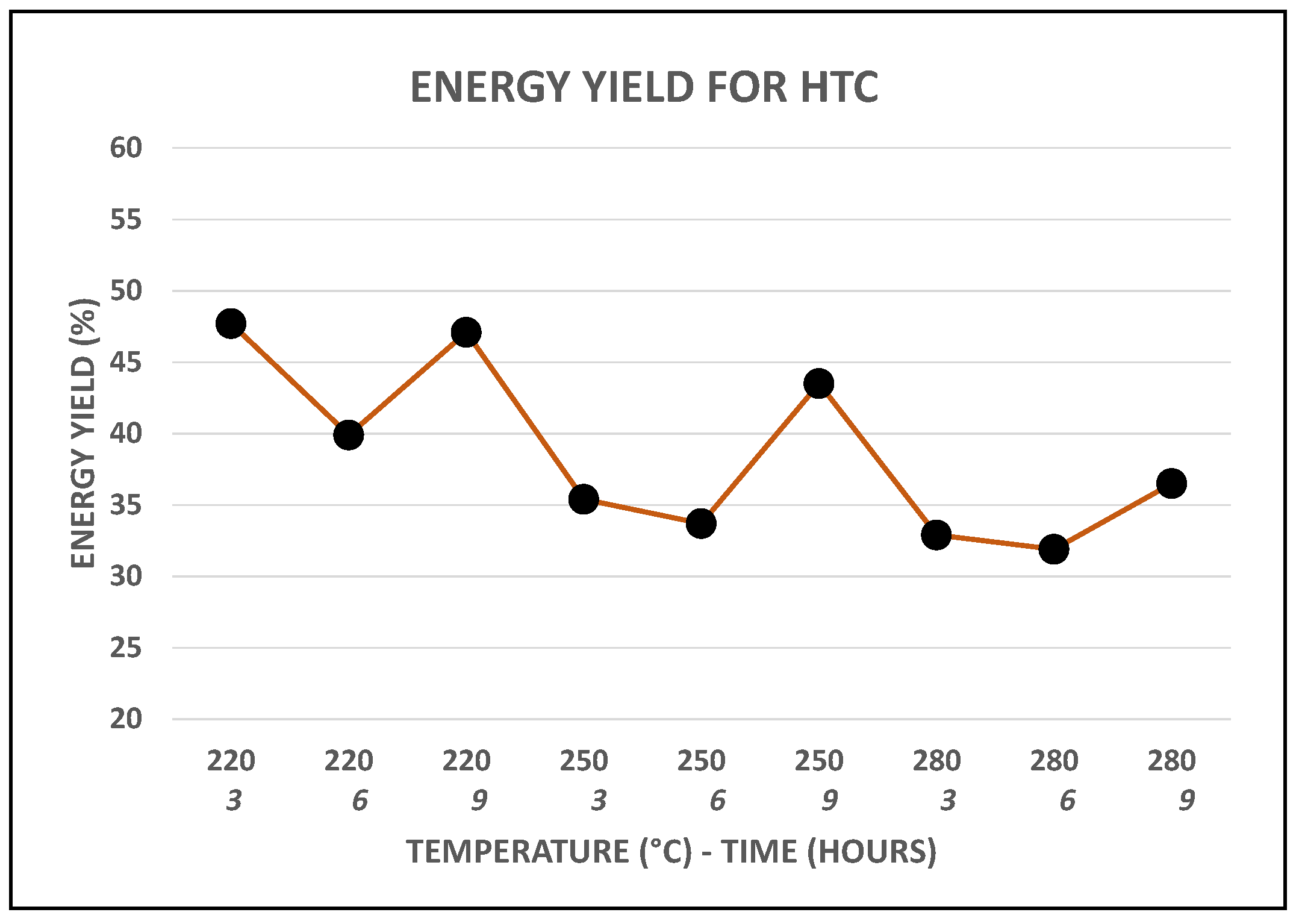

- Gonzàlez-Arias, J.; Gòmez, X.; Gonzàlez-Castano, M.; Sànchez, M.E.; Rosas, J.C.; Cara-Jimènez, J. Insights into the product quality and energy requirements for solid biofuel production: A comparison of hydrothermal carbonization, pyrolysis and torrefaction of olive tree pruning. Energy 2022, 238, 122022. [Google Scholar] [CrossRef]

- Li, J.; Dou, B.; Zhang, H.; Zhang, H.; Chen, H.; Xu, Y.; Wu, C. Pyrolysis characteristics and non-isothermal kinetics of waste wood biomass. Energy 2021, 226, 120358. [Google Scholar] [CrossRef]

- Lin, Y.L.; Zheng, N.Y.; Lin, C.S. Repurposing Washingtonia filifera petiole and Sterculia foetida follicle waste biomass for renewable energy through torrefaction. Energy 2021, 223, 120101. [Google Scholar] [CrossRef]

- Colantoni, A.; Villarini, M.; Marcantonio, V.; Gallucci, F.; Cecchini, M. Performance analysis of a small-scale ORC trigeneration system powered by the combustion of olive pomace. Energies 2019, 12, 2279. [Google Scholar] [CrossRef]

- Amirante, R.; Clodoveo, M.L.; Distaso, E.; Ruggiero, F.; Tamburrano, P. A tri-generation plant fuelled with olive tree pruning residues in Apulia: An energetic and economic analysis. Renew. Energy 2016, 89, 411–421. [Google Scholar] [CrossRef]

- Servian-Rivas, L.D.; Ruiz Pachón, E.; Rodríguez, M.; González-Miquel, M.; González, E.J.; Díaz, I. Techno-economic and environmental impact assessment of an olive tree pruning waste multiproduct biorefinery. Food Bioprod. Process. 2022, 134, 95–108. [Google Scholar] [CrossRef]

- IEA. Net Zero by 2050: A Roadmap for the Global Energy Sector 222; IEA: Paris, France, 2021. [Google Scholar]

- Saponari, M.; Giampetruzzi, A.; Loconsole, G.; Boscia, D.; Saldarelli, P. Xylella Fastidiosa in Olive in Apulia: Where We Stand. Phytopathology 2019, 109, 175–186. [Google Scholar] [CrossRef]

- Zambon, I.; Colosimo, F.; Monarca, D.; Cecchini, M.; Gallucci, F.; Proto, A.R.; Lord, R.; Colantoni, A. An innovative agro-forestry supply chain for residual biomass: Physicochemical characterisation of biochar from olive and hazelnut pellets. Energies 2016, 9, 526. [Google Scholar] [CrossRef]

- Boschiero, M.; Cherubini, F.; Nati, C.; Zerbe, S. Life cycle assessment of bioenergy production from orchards woody residues in Northern Italy. J. Clean. Prod. 2016, 112, 2569–2580. [Google Scholar] [CrossRef]

- Kougioumtzis, M.A.; Kanaveli, I.P.; Karampinis, E.; Grammelis, P.; Kakaras, E. Combustion of olive tree pruning pellets versus sunflower husk pellets at industrial boiler. Monitoring of emissions and combustion efficiency. Renew. Energy 2021, 171, 516–525. [Google Scholar] [CrossRef]

- Costa, P.; Dell’Omo, P.P.; La Froscia, S. Multistage milling and classification for improving both pellet quality and biogas production from hazelnut and olive pruning. Ann. Chim. Sci. Mat. 2018, 42, 471–487. [Google Scholar] [CrossRef]

- Garcia-Maraver, A.; Rodriguez, M.L.; Serrano-Bernardo, F.; Diaz, L.F.; Zamorano, M. Factors affecting the quality of pellets made from residual biomass of olive trees. Fuel Process. Technol. 2015, 129, 1–7. [Google Scholar] [CrossRef]

- Sánchez, S.; Moya, A.J.; Moya, M.; Romero, I.; Torrero, R.; Bravo, V.; San Miguel, M.P. Aprovechamiento del residuo de poda del olivar mediante conversión termoquímica. Ing. Quim. 2002, 391, 194–202. [Google Scholar]

- García, J.F.; Sánchez, S.; Bravo, V.; Cuevas, M.; Rigal, L.; Gaset, A. Xylitol production from olive-pruning debris by sulphuric acid hydrolysis and fermentation with Candida tropicalis. Holzforschung 2011, 65, 59–65. [Google Scholar] [CrossRef]

- Brewer, C.E.; Schmidt-Rohr, K.; Satrio, J.A.; Brown, R.C. Characterization of biochar from fast pyrolysis and gasification systems. Environ. Prog. Sustain. Energy 2009, 28, 386–396. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef] [PubMed]

- Livi, M.; Magrini, I. Gassificazione di Legna Vergine per la Produzione di Energia Elettrica e Calore. Available online: http://www.soc.chim.it/sites/default/files/chimind/pdf/2016_2_46_ca.pdf (accessed on 13 July 2023).

- Rajavanshi, A.K. Biomass Gasification in Alternative Energy in Agriculture; CRC Press: Boca Raton, FL, USA, 1986; Volume 2, pp. 83–102. [Google Scholar]

- Zabaniotou, A.; Rovas, D.; Monteleone, M. Management of olive grove pruning and solid waste from olive oil extraction via thermochemical processes. Waste Biomass Valorization 2015, 6, 831–842. [Google Scholar] [CrossRef]

- Vera, D.; De Mena, B.; Jurado, F.; Schories, G. Study of a downdraft gasifier and gas engine fueled with olive oil industry wastes. Appl. Therm. Eng. 2013, 51, 119–129. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Margaritis, N.K.; Grammelis, P. Experimental and economic study of a gasification plant fuelled with olive industry wastes. Energy Sustain. Dev. 2014, 23, 247–257. [Google Scholar] [CrossRef]

- Inayat, M.; Sulaiman, S.A.; Inayat, A.; Shaik, N.B.; Gilal, A.R.; Shahbaz, M. Modeling and parametric optimization of air catalytic co-gasification of wood-oil palm fronds blend for clean syngas (H2 + CO) production. Int. J. Hydrogen Energy 2021, 4, 30559–30580. [Google Scholar] [CrossRef]

- Skoulou, V.; Zabaniotou, A.; Stavropoulos, G.; Sakelaropoulos, G. Syngas production from olive tree cuttings and olive kernels in a downdraft fixed-bed gasifier. Int. J. Hydrogen Energy 2008, 33, 1185–1194. [Google Scholar] [CrossRef]

- Nilsson, S.; Gòmez-Barrea, A.; Fuentes-Cano, D.; Campoy, M. Gasification kinetics of char from olive tree pruning in fluidized bed. Fuel 2014, 125, 192–199. [Google Scholar] [CrossRef]

- Mishra, R.K.; Kumar, D.J.P.; Narula, A.; Chistie, S.M.; Naik, S.U. Production and beneficial impact of biochar for environmental application: A review on types of feedstocks, chemical compositions, operating parameters, techno-economic study, and life cycle assessment. Fuel 2023, 343, 127968. [Google Scholar] [CrossRef]

- Tripathi, M.; Sahu, J.; Ganesan, P.; Dey, T. Effect of temperature on dielectric properties and penetration depth of oil palm shell (OPS) and OPS char synthesized by microwave pyrolysis of OPS. Fuel 2015, 153, 257–266. [Google Scholar] [CrossRef]

- Mishra, R.K.; Kumar, V.; Kumar, P.; Mohanty, K. Hydrothermal liquefaction of biomass for biocrude production: A review on feedstocks, chemical compositions, operating parameters, reaction kinetics, techno-economic study, and life cycle assessment. Fuel 2022, 316, 123377. [Google Scholar] [CrossRef]

- Calahorro, C.V.; Serrano, V.G.; Alvaro, J.H.; García, A.B. The use of waste matter after olive grove pruning for the preparation of charcoal. The influence of the type of matter, particle size and pyrolysis temperature. Bioresour. Technol. 1992, 40, 17–22. [Google Scholar] [CrossRef]

- Bartoli, M.; Rosi, L.; Giovannelli, A.; Frediani, P.; Frediani, M. Characterization of bio-oil and bio-char produced by low-temperature microwave-assisted pyrolysis of olive pruning residue using various absorbers. Waste Manag. Res. 2020, 38, 213–225. [Google Scholar] [CrossRef]

- Pérez, A.; Martín-Lara, M.A.; Gálvez-Pérez, A.; Calero, M.; Ronda, A. Kinetic analysis of pyrolysis and combustion of the olive tree pruning by chemical fractionation. Bioresour. Technol. 2018, 249, 557–566. [Google Scholar] [CrossRef]

- Martín-Lara, M.A.; Ronda, A.; Zamora, M.C.; Calero, M. Torrefaction of olive tree pruning: Effect of operating conditions on solid product properties. Fuel 2017, 202, 109–117. [Google Scholar] [CrossRef]

- Fermanelli, C.S.; Cordoba, A.; Pierella, L.B.; Saux, C. Pyrolysis and copyrolysis of three lignocellulosic biomass residues from the agro-food industry: A comparative study. Waste Manag. 2020, 102, 362–370. [Google Scholar] [CrossRef]

- Rollinson, A.N.; Oladejo, J.M. ‘Patented blunderings’, efficiency awareness, and self-sustainability claims in the pyrolysis energy from waste sector. Resour. Conserv. Recycl. 2019, 141, 233–242. [Google Scholar] [CrossRef]

- Picciotto Maniscalco, M.; Volpe, M.; Messineo, A. Hydrothermal Carbonization as a Valuable Tool for Energy and Environmental Applications: A Review. Energies 2020, 13, 4098. [Google Scholar] [CrossRef]

- Seow, Y.X.; Tan, Y.H.; Mubarak, N.M.; Kansedo, J.; Khalid, M.; Ibrahim, M.L.; Ghasemi, M. A review on biochar production from different biomass wastes by recent carbonization technologies and its sustainable applications. J. Environ. Chem. Eng. 2022, 10, 107017. [Google Scholar] [CrossRef]

- Chen, W.H.; Lu, C.Y.; Chou, W.S.; Sharma, A.K.; Saravanakumar, A.; Tran, K.Q. Design and optimization of a crossflow tube reactor system for hydrogen production by combining ethanol steam reforming and water gas shift reaction. Fuel 2023, 334, 126628. [Google Scholar] [CrossRef]

- Yay, A.S.E.; Birinci, B.; Açıkalın, S.; Yay, K. Hydrothermal carbonization of olive pomace and determining the environmental impacts of post-process products. J. Clean. Prod. 2021, 315, 128087. [Google Scholar] [CrossRef]

- Petrović, J.; Simić, M.; Mihajlović, M.; Koprivica, M.; Kojić, M.; Nuić, I. Upgrading fuel potentials of waste biomass via hydrothermal carbonization. Hem. Ind. 2021, 75, 297–305. [Google Scholar] [CrossRef]

- Volpe, M.; Goldfarb, J.L.; Fiori, L. Hydrothermal carbonization of Opuntia ficus-indica cladodes: Role of process parameters on hydrochar properties. Bioresour. Technol. 2018, 247, 310–318. [Google Scholar] [CrossRef]

- Kruse, A.; Funke, A.; Titirici, M.-M. Hydrothermal conversion of biomass to fuels and energetic materials. Curr. Opin. Chem. Biol. 2013, 17, 515–521. [Google Scholar] [CrossRef]

- Volpe, M.; Fiori, L.; Volpe, R.; Messineo, A. Upgrading of olive tree trimmings residue as biofuel by hydrothermal carbonization and torrefaction: A comparative study. Chem. Eng. Trans. 2016, 50, 113–118. [Google Scholar] [CrossRef]

- González-Arias, J.; Sánchez, M.E.; Martínez, E.J.; Covalski, C.; Alonso-Simón, A.; González, R.; Cara-Jiménez, J. Hydrothermal Carbonization of Olive Tree Pruning as a Sustainable Way for Improving Biomass Energy Potential: Effect of Reaction Parameters on Fuel Properties. Processes 2020, 8, 1201. [Google Scholar] [CrossRef]

- Rodríguez Correa, C.; Ngamying, C.; Klank, D.; Kruse, A. Investigation of the textural and adsorption properties of activated carbon from HTC and pyrolysis carbonizates. Biomass Convers. Biorefin. 2018, 8, 317–328. [Google Scholar] [CrossRef]

- Düdder, H.; Wütscher, A.; Stoll, R.; Muhler, M. Synthesis and characterization of lignite-like fuels obtained by hydrothermal carbonization of cellulose. Fuel 2016, 171, 54–58. [Google Scholar] [CrossRef]

- Saba, A.; Saha, P.; Toufiq Reza, M. Co-Hydrothermal Carbonization of coal-biomass blend: Influence of temperature on solid fuel properties. Fuel Process. Technol. 2017, 167, 711–720. [Google Scholar] [CrossRef]

- Carrasco, S.; Pino-Cortés, E.; Barra-Marín, A.; Fierro-Gallegos, A.; León, M. Use of Hydrochar Produced by Hydrothermal Carbonization of Lignocellulosic Biomass for Thermal Power Plants in Chile: A Techno-Economic and Environmental Study. Sustainability 2022, 14, 8041. [Google Scholar] [CrossRef]

- Lucian, M.; Volpe, M.; Fiori, L. Hydrothermal carbonization kinetics of lignocellulosic agro-wastes: Experimental data and modeling. Energies 2019, 12, 516. [Google Scholar] [CrossRef]

- Arauzo, P.J.; Olszewski, M.P.; Kruse, A. Hydrothermal carbonization brewer’s spent grains with the focus on improving the degradation of the feedstock. Energies 2018, 11, 3226. [Google Scholar] [CrossRef]

- Ulbrich, M.; Preßl, D.; Fendt, S.; Gaderer, M.; Spliethoff, H. Impact of HTC reaction conditions on the hydrochar properties and CO2 gasification properties of spent grains. Fuel Process. Technol. 2017, 167, 663–669. [Google Scholar] [CrossRef]

- Basso, D.; Patuzzi, F.; Castello, D.; Baratieri, M.; Rada, E.C.; Weiss-Hortala, E.; Fiori, L. Agro-industrial waste to solid biofuel through hydrothermal carbonization. Waste Manag. 2016, 47, 114–121. [Google Scholar] [CrossRef]

- Mamaní, A.; Maturano, Y.; Mestre, V.; Montoro, L.; Gassa, L.; Deiana, C.; Sardella, F. Valorization of olive tree pruning. Application for energy storage and biofuel production. Ind. Crops Prod. 2021, 173, 114082. [Google Scholar] [CrossRef]

- Ponce, M.F.; Mamani, A.; Jerez, F.; Castilla, J.; Ramos, P.B.; Acosta, G.G.; Sardella, M.F.; Bavio, M.A. Activated carbon from olive tree pruning residue for symmetric solid-state supercapacitor. Energy 2022, 260, 125092. [Google Scholar] [CrossRef]

- Saletnik, B.; Saletnik, A.; Zagu, G.; Bajcar, M.; Puchalski, C. The Use of Wood Pellets in the Production of High Quality Biocarbon Materials. Material 2022, 15, 4404. [Google Scholar] [CrossRef]

- Kambo, H.S.; Dutta, A. A comparative review of biochar and hydrochar in terms of production, physico-chemical properties and applications. Renew. Sustain. Energy Rev. 2015, 45, 359–378. [Google Scholar] [CrossRef]

- Cavali, M.; Libardi Junior, N.; de Almeida Mohedano, R.; Belli Filho, P. Rejane Helena Ribeiro da Costa, Armando Borges de Castilhos Junior Biochar and hydrochar in the context of anaerobic digestion for a circular approach: An overview. Sci. Total Environ. 2022, 822, 153614. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Kavindi, G.A.G.; Lei, Z. 14—Environmental sustainability-based comparison for production, properties, and applications of biochar and hydrochar. In Current Developments in Biotechnology and Bioengineering-Biochar towards Sustainable Environment; Ngo, H.H., Guo, W., Pandey, A., Varjani, S., Tsang, D.C.W., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 387–414. [Google Scholar] [CrossRef]

- Ippolito, J.A.; Laird, D.A.; Busscher, W.J. Environmental benefits of biochar. J. Environ. Qual. 2012, 41, 967–972. [Google Scholar] [CrossRef] [PubMed]

- Baxter, L.L.; Miles, T.R.; Miles, T.R., Jr.; Jenkins, B.M.; Milne, T.; Dayton, D.; Bryers, R.W.; Oden, L.L. The behavior of inorganic material in biomass-fired power boilers: Field and laboratory experiences. Fuel Process. Technol. 1998, 54, 47–78. [Google Scholar] [CrossRef]

- Cassoni, A.C.; Costa, P.; Mota, I.; Vasconcelos, M.W.; Pintado, M. Recovery of lignins with antioxidant activity from Brewer’s spent grain and olive tree pruning using deep eutectic solvents. Chem. Eng. Res. Des. 2023, 192, 34–43. [Google Scholar] [CrossRef]

- Zabed, H.; Sahu, J.N.; Suely, A.; Boyce, A.N.; Faruq, G. Bioethanol production from renewable sources: Current perspectives and technological progress. Renew. Sustain. Energy Rev. 2017, 71, 475–501. [Google Scholar] [CrossRef]

- Martin, J.F.G.; Cuevas, M.; Feng, C.H.; Mateos, P.A.; Garcia, M.T.; Sànchez, S. Energetic Valorisation of Olive Biomass: Olive-Tree Pruning, Olive Stones and Pomaces. Processes 2020, 8, 511. [Google Scholar] [CrossRef]

- Hassan, S.S.; Williams, G.A.; Jaiswal, A.K. Review. Emerging technologies for the pretreatment of lignocellulosic biomass. Bioresour. Technol. 2018, 262, 310–318. [Google Scholar] [CrossRef]

- Yang, B.; Boussaid, A.; Mansfield, S.D.; Gregg, D.J.; Saddler, J.N. Fast and efficient alkaline peroxide treatment to enhance the enzymatic digestibility of steam-exploded softwood substrates. Biotechnol. Bioeng. 2002, 77, 678–684. [Google Scholar] [CrossRef]

- Cara, C.; Ruiz, E.; Oliva, J.M.; Sáez, F.; Castro, E. Conversion of olive tree biomass into fermentable sugars by dilute acid pretreatment and enzymatic saccharification. Bioresour. Technol. 2008, 99, 1869–1876. [Google Scholar] [CrossRef]

- Martínez-Patiño, J.C.; Romero-García, J.M.; Ruiz, E.; Oliva, J.M.; Álvarez, C.; Romero, I.; Negro, M.J.; Castro, E. High solids loading pretreatment of olive tree pruning with dilute. Energy Fuels 2015, 29, 1735–1742. [Google Scholar] [CrossRef]

- Romero-García, J.M.; Martínez-Patiño, C.; Ruiz, E.; Romero, I.; Castro, E. Ethanol production from olive stone hydrolysates by xylose fermenting microorganisms. Bioethanol 2016, 2, 51–65. [Google Scholar] [CrossRef]

- Puentes, J.C.; Mateo, S.; Fonseca, B.G.; Roberto, I.C.; Sánchez, S.; Moya, A.J. Monomeric carbohydrates production from olive tree pruning biomass: Modeling of dilute acid hydrolysis. Bioresour. Technol. 2013, 149, 149–154. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Patiño, J.C.; Ruiz, E.; Cara, C.; Romero, I.; Castro, E. Advanced bioethanol production from olive tree biomass using different bioconversion schemes. Biochem. Eng. J. 2018, 137, 172–181. [Google Scholar] [CrossRef]

- El Asli, A.; Qatibi, A. Ethanol production from olive cake biomass substrate. Biotechnol. Bioprocess Eng. 2009, 14, 118–122. [Google Scholar] [CrossRef]

- López-Linares, J.C.; Moya, M.; Peláez, L.; Ruiz, E.; Romero, I.; Cara, C.; Castro, E. Valorization of olive mill leaves in a biorefinery context. Aqueous extraction in autoclave. Rev. Quim. Teor. Appl. 2019, 76, 93–102. [Google Scholar]

- Martínez-Patiño, J.C.; Ruiz, E.; Romero, I.; Cara, C.; López-Linares, J.C.; Castro, E. Combined acid/alkaline-peroxide pretreatment of olive tree biomass for bioethanol production. Bioresour. Technol. 2017, 239, 326–335. [Google Scholar] [CrossRef]

- Negro, M.J.; Alvarez, C.; Ballesteros, I.; Romero, I.; Ballesteros, M.; Castro, E.; Manzanares, P.; Moya, M.; Oliva, J.M. Ethanol production from glucose and xylose obtained from steam exploded water-extracted olive tree pruning using phosphoric acid as catalyst. Bioresour. Technol. 2014, 153, 101–107. [Google Scholar] [CrossRef] [PubMed]

- Cuevas, M.; Sánchez, S.; Bravo, V.; García, J.F.; Baeza, J.; Parra, C.; Freer, J. Determination of optimal pre-treatment conditions for ethanol production from olive-pruning debris by simultaneous saccharification and fermentation. Fuel 2010, 89, 2891–2896. [Google Scholar] [CrossRef]

- Fernandes-Klajn, F.; Romero-García, J.M.; Díaz, M.J.; Castro, E. Comparison of fermentation strategies for ethanol production from olive tree pruning biomass. Ind. Crops Prod. 2018, 122, 98–106. [Google Scholar] [CrossRef]

- del Mar Contreras, M.; Lama-Muñoz, A.; Espínola, F.; Romero, I.; Castro, E.; Moya, M. Valorization of olive mill leaves through ultrasound-assisted extraction. Food Chem. 2020, 314, 126218. [Google Scholar] [CrossRef]

- Susmozas, A.; Moreno, A.D.; Romero-García, J.M.; Manzanares, P.; Ballesteros, M. Designing an olive tree pruning biorefinery for the production of bioethanol, xylitol and antioxidants: A techno-economic assessment. Holzforschung 2019, 73, 15–23. [Google Scholar] [CrossRef]

- Romero-García, J.M.; Lama-Muñoz, A.; Rodríguez-Gutiérrez, G.; Moya, M.; Ruiz, E.; Fernández-Bolaños, J.; Castro, E. Obtaining sugars and natural antioxidants from olive leaves by steam-explosion. Food Chem. 2016, 210, 457–465. [Google Scholar] [CrossRef] [PubMed]

- Ghodke, P.K.; Sharma, A.K.; Jayaseelan, A.; Gopinath, K.P. Hydrogen-rich syngas production from the lignocellulosic biomass by catalytic gasification: A state of art review on advance technologies, economic challenges, and future prospectus. Fuel 2023, 342, 127800. [Google Scholar] [CrossRef]

- Lin, S.; Kiga, T.; Nakayama, K.; Suzuki, Y. GHGT-10. Coal Power Generation with In-Situ CO2 Capture-HyPr-RING method-Effect of Ash Separation on Plant Efficiency. Energy Procedia 2011, 4, 378–384. [Google Scholar] [CrossRef]

- Gallucci, F.; Longo, L.; Santangelo, E.; Guerriero, E.; Paolini, V.; Carnevale, M.; Colantoni, A.; Tonolo, A. Assessment of syngas produced from gasification of olive tree pruning in a drowndraft reactor. In Proceedings of the 26th European Biomass Conference and Exhibition, Copenhagen, Denmark, 14–17 May 2018. [Google Scholar] [CrossRef]

- Li, W.; Dang, Q.; Brown, R.C.; Laird, D.; Wright, M.M. The impacts of biomass properties on pyrolysis yields, economic and environmental performance of the pyrolysis-bioenergy-biochar platform to carbon negative energy. Bioresour. Technol. 2017, 241, 959–968. [Google Scholar] [CrossRef]

- Chen, D.; Li, Y.; Cen, K.; Luo, M.; Li, H.; Lu, B. Pyrolysis polygeneration of poplar wood: Effect of heating rate and pyrolysis temperature. Bioresour. Technol. 2016, 218, 780–788. [Google Scholar] [CrossRef]

- Abdullah, N.; Taib, R.M.; Mohamad Aziz, N.S.; Omar, M.R.; Nisa, N.M.D. Banana pseudo-stem biochar derived from slow and fast pyrolysis process. Heliyon 2023, 9, e12940. [Google Scholar] [CrossRef]

- Yildiz, G.; Ronsse, F.; Venderbosch, R.; van Duren, R.; Kersten, S.R.A.; Prins, W. Effect of biomass ash in catalytic fast pyrolysis of pine wood. Appl. Catal. B Environ. 2015, 168–169, 203–2011. [Google Scholar] [CrossRef]

- Yildirim, O.; Tunay, D.; Ozkaya, B.; Demir, A. Optimization of oxalic and sulphuric acid pretreatment conditions to produce bio-hydrogen from olive tree biomass. Int. J. Hydrogen Energy 2022, 47, 26316–26325. [Google Scholar] [CrossRef]

- Channiwala, S.A.; Parikh, P.P. A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 2002, 81, 1051–1063. [Google Scholar] [CrossRef]

- Taichang. Available online: https://www.tcpel.com/it/ (accessed on 8 September 2023).

- Kougioumtzis, M.A.; Karampinis, E.; Grammelis, P.; Kakaras, E. Exploitation of olive tree prunings. Evaluation of an integrated harvesting demonstration in Central Greece. In Proceedings of the 27th European Biomass Conference and Exhibition, Lisbon, Portugal, 27–30 May 2019. [Google Scholar] [CrossRef]

- Vermeer Italia. Available online: https://www.vermeeritalia.it (accessed on 8 September 2023).

- Oliva Service. Available online: http://www.olivaservice.it/it/ (accessed on 8 September 2023).

| Thermochemical Process | Operating Temperature (°C) | Pressure | Time (Range) | Oxidizing Agent | Byproducts | Ref. |

|---|---|---|---|---|---|---|

| Combustion | 750–1500 °C | 0–0.6 MPa | / | oxygen | ashes | [21,54] |

| Gasification | 600–1200 °C | / | 10–20 s | oxygen | char: <10% and condensable organic compounds | [21,59,60,61,62,105] |

| Pyrolysis | 400–600 °C | 0–13 MPa | 0.3–1 h | absent | [21,44,52] | |

| HTC | 220–350 °C | 0–13 MPa | 1–9 h | vapor steam | [21,44] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maggiotto, G.; Colangelo, G.; Milanese, M.; de Risi, A. Thermochemical Technologies for the Optimization of Olive Wood Biomass Energy Exploitation: A Review. Energies 2023, 16, 6772. https://doi.org/10.3390/en16196772

Maggiotto G, Colangelo G, Milanese M, de Risi A. Thermochemical Technologies for the Optimization of Olive Wood Biomass Energy Exploitation: A Review. Energies. 2023; 16(19):6772. https://doi.org/10.3390/en16196772

Chicago/Turabian StyleMaggiotto, Giuseppe, Gianpiero Colangelo, Marco Milanese, and Arturo de Risi. 2023. "Thermochemical Technologies for the Optimization of Olive Wood Biomass Energy Exploitation: A Review" Energies 16, no. 19: 6772. https://doi.org/10.3390/en16196772

APA StyleMaggiotto, G., Colangelo, G., Milanese, M., & de Risi, A. (2023). Thermochemical Technologies for the Optimization of Olive Wood Biomass Energy Exploitation: A Review. Energies, 16(19), 6772. https://doi.org/10.3390/en16196772