Airtightness Assessment under Several Low-Pressure Differences in Non-Residential Buildings

Abstract

:1. Introduction

1.1. Background and Objective

1.2. Literature Review

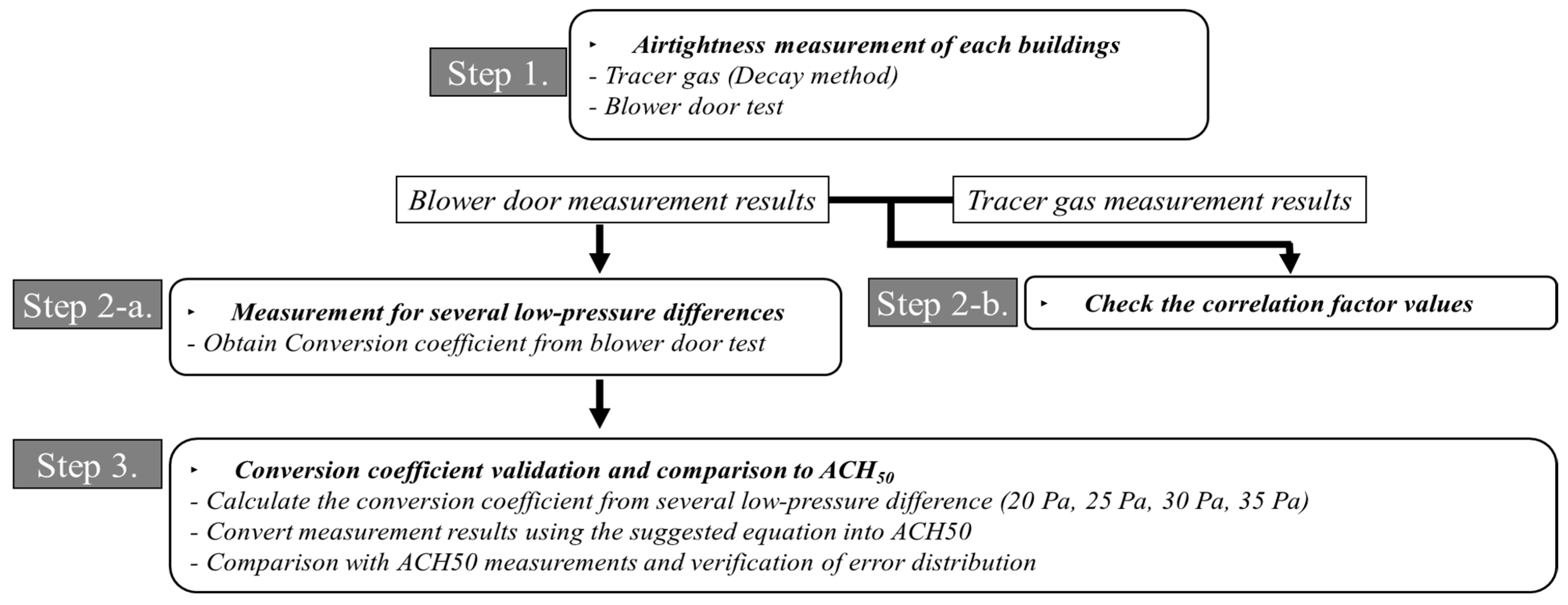

2. Methodology

2.1. Fan Pressure Method—Blower Door Test

2.2. Tracer Gas—Decay Method

2.3. Airtightness under Several Low-Pressure Differences

2.4. Building Description

3. Results

3.1. Blower Door Test Results

3.2. Tracer Gas Results and Distribution of the Correlation Factor

4. Results ACH of Several Low-Pressure Differences

5. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jones, B.; Das, P.; Chalabi, Z.; Davies, M.; Hamilton, I.; Lowe, R.; Mavrogianni, A.; Robinson, D.; Taylor, J. Assessing Uncertainty in Housing Stock Infiltration Rates Andassociated Heat Loss: English and UK Case Studies. Build. Environ. 2015, 92, 644–656. [Google Scholar] [CrossRef]

- Al-Sakkaf, A.; Bagchi, A.; Zayed, T. Evaluating Life-Cycle Energy Costs of Heritage Buildings. Buildings 2022, 12, 1271. [Google Scholar] [CrossRef]

- Economidou, M.; Todeschi, V.; Bertoldi, P.; D’Agostino, D.; Zangheri, P.; Castellazzi, L. Review of 50 years of EU Energy Efficiency Policies for Buildings. Energy Build. 2020, 225, 110322. [Google Scholar] [CrossRef]

- Lapillonne, B.; Pollier, K.; Samci, N. Energy Efficiency Trends for Households in the EU. Enerdata 2014, 22, 2015. [Google Scholar]

- Li, T.; Xia, J.; Chin, C.S.; Song, P. Investigation of the Thermal Performance of Lightweight Assembled Exterior Wall Panel (LAEWP) with Stud Connections. Buildings 2022, 12, 473. [Google Scholar] [CrossRef]

- Lee, J.; Kim, J.; Song, D.; Kim, J.; Jang, C. Impact of External Insulation and Internal Thermal Density upon Energy Consumption of Buildings in a Temperate Climate with Four Distinct Seasons. Renew. Sustain. Energy Rev. 2017, 75, 1081–1088. [Google Scholar] [CrossRef]

- Korea Energy Agency (KEA). Commentaries for Building Energy Code; Korea Energy Agency (KEA): Ulsan, Republic of Korea, 2018. [Google Scholar]

- Shim, C.; Seong, N.; Hong, G. An Analysis of ACHn for Improving the Performance of Green Remodeling through the Airtightness Measurements. KIEAE J. 2021, 21, 7–12. [Google Scholar] [CrossRef]

- Poza-Casado, I.; Meiss, A.; Padilla-Marcos, M.Á.; Feijó-Muñoz, J. Airtightness and Energy Impact of Air Infiltration in Residential Buildings in Spain. Int. J. Vent. 2021, 20, 258–264. [Google Scholar] [CrossRef]

- Hong, G.; Kim, C. Experimental Analysis of Airtightness Performance in High-Rise Residential Buildings for Improved Code-Compliant Simulations. Energy Build. 2022, 261, 111980. [Google Scholar] [CrossRef]

- Erhorn-Kluttig, H.; Erhorn, H.; Lahmidi, H. Airtightness Requirements for High Performance Building Envelopes. EPBD Build. Platf. 2009, 157, 1–6. [Google Scholar]

- Etheridge, D. A Perspective on Fifty Years of Natural Ventilation Research. Build. Environ. 2015, 91, 51–60. [Google Scholar] [CrossRef]

- Miszczuk, A. Influence of Air Tightness of the Building on Its Energy-Efficiency in Single-Family Buildings in Poland. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 117. [Google Scholar] [CrossRef]

- Jing, J.; Lee, D.S.; Joe, J.; Kim, E.J.; Cho, Y.H.; Jo, J.H. A Sensing-Based Visualization Method for Representing Pressure Distribution in a Multi-Zone Building by Floor. Sensors 2023, 23, 4116. [Google Scholar] [CrossRef] [PubMed]

- Kravchenko, I.; Kosonen, R.; Jokisalo, J.; Kilpeläinen, S. Performance of Modern Passive Stack Ventilation in a Retrofitted Nordic Apartment Building. Buildings 2022, 12, 96. [Google Scholar] [CrossRef]

- Ji, Y.; Duanmu, L. Airtightness Field Tests of Residential Buildings in Dalian, China. Build. Environ. 2017, 119, 20–30. [Google Scholar] [CrossRef]

- Vinha, J.; Manelius, E.; Korpi, M.; Salminen, K.; Kurnitski, J.; Kiviste, M.; Laukkarinen, A. Airtightness of Residential Buildings in Finland. Build. Environ. 2015, 93, 128–140. [Google Scholar] [CrossRef]

- Miszczuk, A.; Heim, D. Parametric Study of Air Infiltration in Residential Buildings—The Effect of Local Conditions on Energy Demand. Energies 2021, 14, 127. [Google Scholar] [CrossRef]

- Pasos, A.V.; Zheng, X.; Smith, L.; Wood, C. Estimation of the Infiltration Rate of UK Homes with the Divide-by-20 Rule and Its Comparison with Site Measurements. Build. Environ. 2020, 185, 107275. [Google Scholar] [CrossRef]

- Hong, G.; Kim, D.D. Airtightness of Electrical, Mechanical and Architectural Components in South Korean Apartment Buildings Using the Fan Pressurization and Tracer Gas Method. Build. Environ. 2018, 132, 21–29. [Google Scholar] [CrossRef]

- Cheong, K.W. Airflow Measurements for Balancing of Air Distribution Systems—Tracer-Gas Technique as an Alternative? Build. Environ. 2001, 36, 955–964. [Google Scholar] [CrossRef]

- Goubran, S.; Qi, D.; Saleh, W.F.; Wang, L. Comparing Methods of Modeling Air Infiltration through Building Entrances and Their Impact on Building Energy Simulations. Energy Build. 2017, 138, 579–590. [Google Scholar] [CrossRef]

- Martín-Garín, A.; Millán-García, J.A.; Hidalgo-Betanzos, J.M.; Hernández-Minguillón, R.J.; Baïri, A. Airtightness Analysis of the Built Heritage field Measurements of Nineteenth Century Buildings through Blower Door Tests. Energies 2020, 13, 6726. [Google Scholar] [CrossRef]

- Kim, M.H.; Jo, J.H.; Jeong, J.W. Feasibility of Building Envelope Air Leakage Measurement Using Combination of Air-Handler and Blower Door. Energy Build. 2013, 62, 436–441. [Google Scholar] [CrossRef]

- Resources, R.C. F16 SI: Ventilation and Infiltration. In Ashrae Handbook; ASHRAE: Norfolk, VA, USA, 2009. [Google Scholar]

- Li, X.; Zhou, W.; Duanmu, L. Research on Air Infiltration Predictive Models for Residential Building at Different Pressure. Build. Simul. 2021, 14, 737–748. [Google Scholar] [CrossRef]

- Sherman, M.H. Tracer-Gas Techniques for Measuring Ventilation in a Single Zone. Build. Environ. 1990, 25, 365–374. [Google Scholar] [CrossRef]

- Lee, D.S.; Jeong, J.W.; Jo, J.H. Experimental Study on Airtightness Test Methods in Large Buildings; Proposal of Averaging Pressure Difference Method. Build. Environ. 2017, 122, 61–71. [Google Scholar] [CrossRef]

- Cui, S.; Cohen, M.; Stabat, P.; Marchio, D. CO2 Tracer Gas Concentration Decay Method for Measuring Air Change Rate. Build. Environ. 2015, 84, 162–169. [Google Scholar] [CrossRef]

- Sherman, M.H.; Dickerhoff, D.J. Airtightness of U.S. Dwellings. ASHRAE Trans. 1998, 104, 1359–1367. [Google Scholar]

- Sherman, M.H. Estimation of Infiltration from Leakage and Climate Indicators. Energy Build. 1987, 10, 81–86. [Google Scholar] [CrossRef]

- Lutzkendorf, T.; Balouktsi, M. Energy Conservation in Buildings and Community Systems Programme; IEA: Paris, France, 2016; pp. 35–42, Annex 57; Available online: http://www.annex57.org/wp/wp-content/uploads/2017/05/ST2_Repor.pdf (accessed on 5 October 2022).

- Kang, K.; Lee, S.-W.; Lee, E.-J.; Park, M.-J.; Lim, J.-H.; Jo, B.-R.; Lee, J.-C. Infiltration : Just ACH50 Divided by 20? Concentrated on a Residential Building. SAREK Summer Conf. 2015, 6, 435–439. [Google Scholar]

- Hyon, M.J.; Ik, L.J.; Sung, K.M. Study on Estimation of Infiltration Rate (ACH Natural) Using Blower Door Test Results. J. KIAEBS 2020, 14, 687–698. [Google Scholar]

- Erin, L.; Max, H. Blower-Door Techniques for Measuring Interzonal Leakage: A Preliminary Report; Ernest Orlando Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2013. [Google Scholar]

- Bahnfleth, W.P.; Yuill, G.K.; Lee, B.W. Protocol for Field Testing of Tall Buildings to Determine Envelope Air Leakage Rate. ASHRAE Trans. 1999, 105, 27. [Google Scholar]

- Zheng, X.; Cooper, E.; Gillott, M.; Wood, C. A Practical Review of Alternatives to the Steady Pressurisation Method for Determining Building Airtightness. Renew. Sustain. Energy Rev. 2020, 132, 110049. [Google Scholar] [CrossRef] [PubMed]

- Jeong, J.W.; Firrantello, J.; Bahnfleth, W.P.; Freihaut, J.D.; Musser, A. Case Studies of Building Envelope Leakage Measurement Using an Air-Handler Fan Pressurisation Approach. Build. Serv. Eng. Res. Technol. 2008, 29, 137–155. [Google Scholar] [CrossRef]

- EN ISO 9972:2015; Thermal Performance of Buildings—Determination of Air Permeability of Buildings—Fan Pressurization Method. Standards Australia: Sydney, Australia, 2015.

- Frattolillo, A.; Stabile, L.; Dell’Isola, M. Natural Ventilation Measurements in a Multi-Room Dwelling: Critical Aspects and Comparability of Pressurization and Tracer Gas Decay Tests. J. Build. Eng. 2021, 42, 102478. [Google Scholar] [CrossRef]

- Lo, L.J.; Novoselac, A. Cross Ventilation with Small Openings: Measurements in a Multi-Zone Test Building. Build. Environ. 2012, 57, 377–386. [Google Scholar] [CrossRef]

- Nikolopoulos, N.; Nikolopoulos, A.; Larsen, T.S.; Nikas, K.S.P. Experimental and Numerical Investigation of the Tracer Gas Methodology in the Case of a Naturally Cross-Ventilated Building. Build. Environ. 2012, 56, 379–388. [Google Scholar] [CrossRef]

- Jankovic, A.; Gennaro, G.; Chaudhary, G.; Goia, F.; Favoino, F. Tracer Gas Techniques for Airflow Characterization in Double Skin Facades. Build. Environ. 2022, 212, 108803. [Google Scholar] [CrossRef]

- Almeida, R.M.S.F.; Barreira, E.; Moreira, P. A Discussion Regarding the Measurement of Ventilation Rates Using Tracer Gas and Decay Technique. Infrastructures 2020, 5, 85. [Google Scholar] [CrossRef]

- Batterman, S. Review and Extension of CO2-Based Methods to Determine Ventilation Rates with Application to School Classrooms. Int. J. Environ. Res. Public Health 2017, 14, 145. [Google Scholar] [CrossRef]

- Sinnott, D. Dwelling Airtightness: A Socio-Technical Evaluation in an Irish Context. Build. Environ. 2016, 95, 264–271. [Google Scholar] [CrossRef]

- Shin, H.K.; Jo, J.H. Air Leakage Characteristics and Leakage Distribution of Dwellings in High-Rise Residential Buildings in Korea. J. Asian Archit. Build. Eng. 2013, 12, 87–92. [Google Scholar] [CrossRef]

- KMA, Daily Data, (2021–2022). Available online: https://Www.Weather.Go.Kr/w/Obs-Climate/Land/Past-Obs/Obs-by-Day.Do (accessed on 5 October 2022).

| Building A | Building B | Building C | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|  |  | ||||||||

| Construction Year | 1987 | 1994 | 2007 | |||||||

| Room | A1 | A2 | A3 | A4 | B1 | B2 | B3 | C1 | C2 | C3 |

| Floor plan |  |  |  |  |  |  |  |  |  |  |

| Floor area (m2) | 33.6 | 100.8 | 33.6 | 100.8 | 22.7 | 58.3 | 58.3 | 49.7 | 74.2 | 74.2 |

| Volume (m3) | 90.7 | 272.2 | 90.7 | 272.2 | 51.0 | 157.5 | 157.5 | 134.1 | 200.3 | 200.3 |

| Window frame | PVC | PVC | AL | AL | PVC | PVC | AL | PVC | PVC | PVC |

| Room | Measurement Date | Indoor Temp [°C] | Outdoor Temp [°C] | Indoor/Outdoor Temperature Difference [°C] | Outdoor Wind Speed [m/s] |

|---|---|---|---|---|---|

| A1 | 16 April 2021 29 September 2021 | 22.3 24.8 | 14.8 22.6 | 7.5 2.2 | 1.3 3.8 |

| A2 | 18 April 2021 30 September 2021 | 17.0 23.1 | 13.4 22.2 | 3.6 0.9 | 2.6 1.0 |

| A3 | 17 December 2021 8 April 2022 | 17.1 16.3 | 2.3 10.1 | 14.8 6.2 | 6.8 1.3 |

| A4 | 17 December 2021 8 April 2022 | 15.0 18.7 | 2.7 10.1 | 12.3 8.6 | 4.5 1.5 |

| B1 | 30 April 2021 23 December 2021 | 20.5 16.3 | 18.3 4.8 | 2.2 11.5 | 3.6 4.1 |

| B2 | 4 May 2021 23 December 2021 | 21.5 17.4 | 19.3 4.8 | 2.2 12.6 | 1.7 3.6 |

| B3 | 23 December 2021 | 16.6 | 4.9 | 11.7 | 3.6 |

| C1 | 17 September 2021 7 January 2022 | 25.1 8.1 | 20.9 2.4 | 4.2 5.7 | 0.7 1.7 |

| C2 | 7 January 2022 15 April 2022 | 8.4 20.1 | 1.9 14.9 | 6.5 5.2 | 1.1 3.9 |

| C3 | 7 January 2022 15 April 2022 | 8.7 19.0 | 2.2 13.2 | 6.5 5.8 | 1.9 3.9 |

| Room | Air Change per Hour (h−1, ACH) Using the Decay Method | Air Change per Hour at 50 Pa (ACH50) Using the Blower Door Test | ACH50/ACH |

|---|---|---|---|

| A1 | 0.22 0.29 | 18.02 17.57 | 81.91 60.58 |

| A2 | 0.21 | 24.64 | 117.31 |

| B1 | 0.16 0.15 | 14.02 12.91 | 87.59 86.08 |

| B2 | 0.15 0.18 | 9.26 7.25 | 61.73 40.29 |

| C1 | 0.09 0.09 | 5.21 5.64 | 57.83 62.64 |

| C2 | 0.09 | 6.79 | 75.42 |

| ACH50M | ACH20/N20 (ACH50P) | Error (%) | ACH25/N25 (ACH50P) | Error (%) | ACH30/N30 (ACH50P) | Error (%) | ACH35/N35 (ACH50P) | Error (%) | |

|---|---|---|---|---|---|---|---|---|---|

| A3 | 15.2 14.1 | 14.6 13.7 | 4.4 2.5 | 14.8 13.7 | 3.2 2.8 | 14.8 13.6 | 3.1 3.2 | 14.8 13.6 | 3.1 3.2 |

| A4 | 19.6 19.6 | 19.4 19.8 | 0.8 1.3 | 19.3 19.2 | 1.2 2.1 | 19.1 19.6 | 2.4 0.3 | 19.1 19.6 | 2.4 0.3 |

| B3 | 18.5 | 19.3 | 4.4 | 18.9 | 1.9 | 18.5 | 0.1 | 18.5 | 0.1 |

| C3 | 9.1 8.9 | 9.2 8.7 | 0.7 2.1 | 9.2 8.7 | 1.0 1.8 | 9.1 8.6 | 0.4 2.3 | 9.1 8.6 | 0.4 2.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shim, C.; Hong, G. Airtightness Assessment under Several Low-Pressure Differences in Non-Residential Buildings. Energies 2023, 16, 6845. https://doi.org/10.3390/en16196845

Shim C, Hong G. Airtightness Assessment under Several Low-Pressure Differences in Non-Residential Buildings. Energies. 2023; 16(19):6845. https://doi.org/10.3390/en16196845

Chicago/Turabian StyleShim, Chanhyung, and Goopyo Hong. 2023. "Airtightness Assessment under Several Low-Pressure Differences in Non-Residential Buildings" Energies 16, no. 19: 6845. https://doi.org/10.3390/en16196845