Numerical Simulation of the Effects of Blade–Arm Connection Gap on Vertical–Axis Wind Turbine Performance

Abstract

:1. Introduction

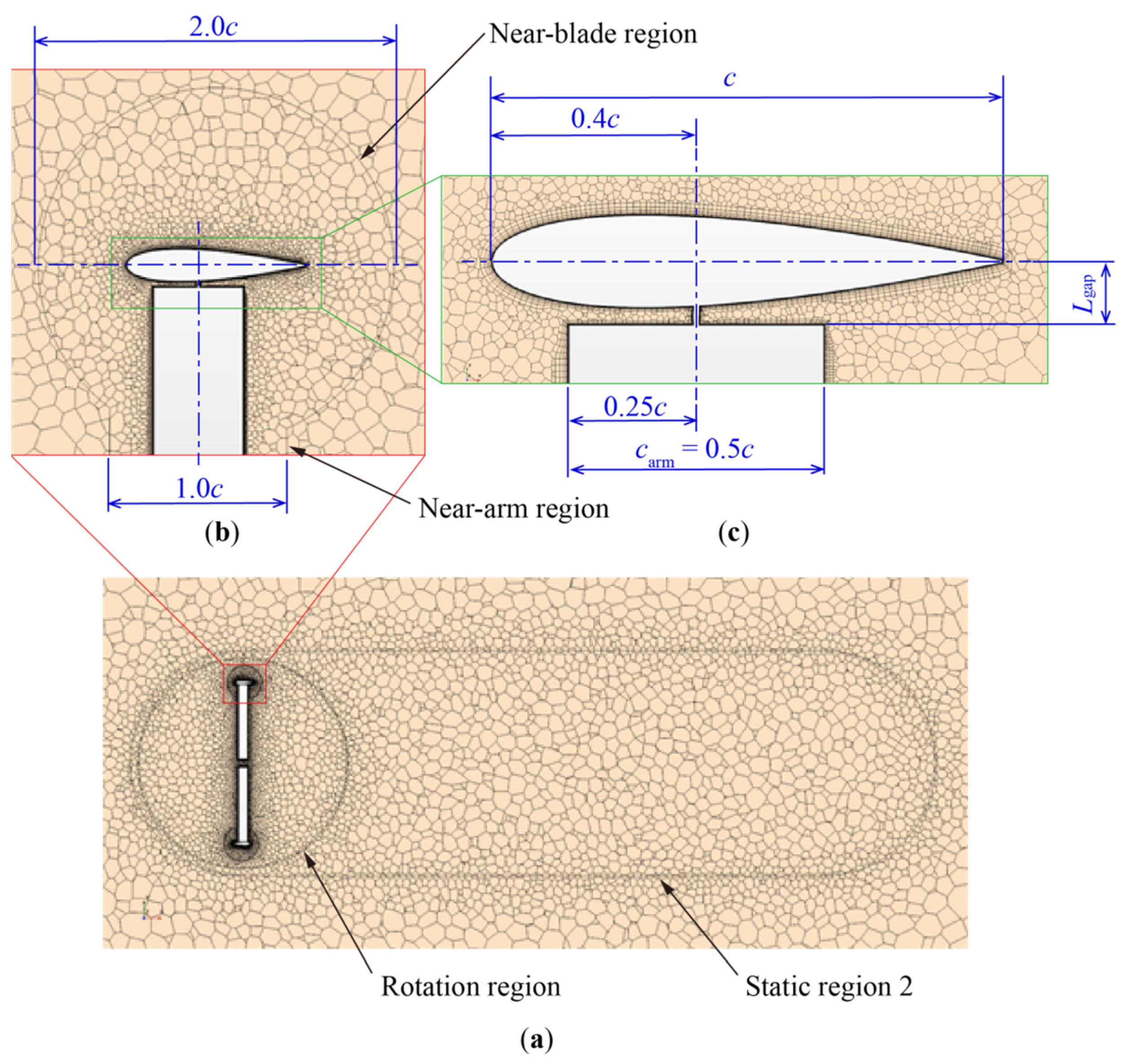

2. Methods

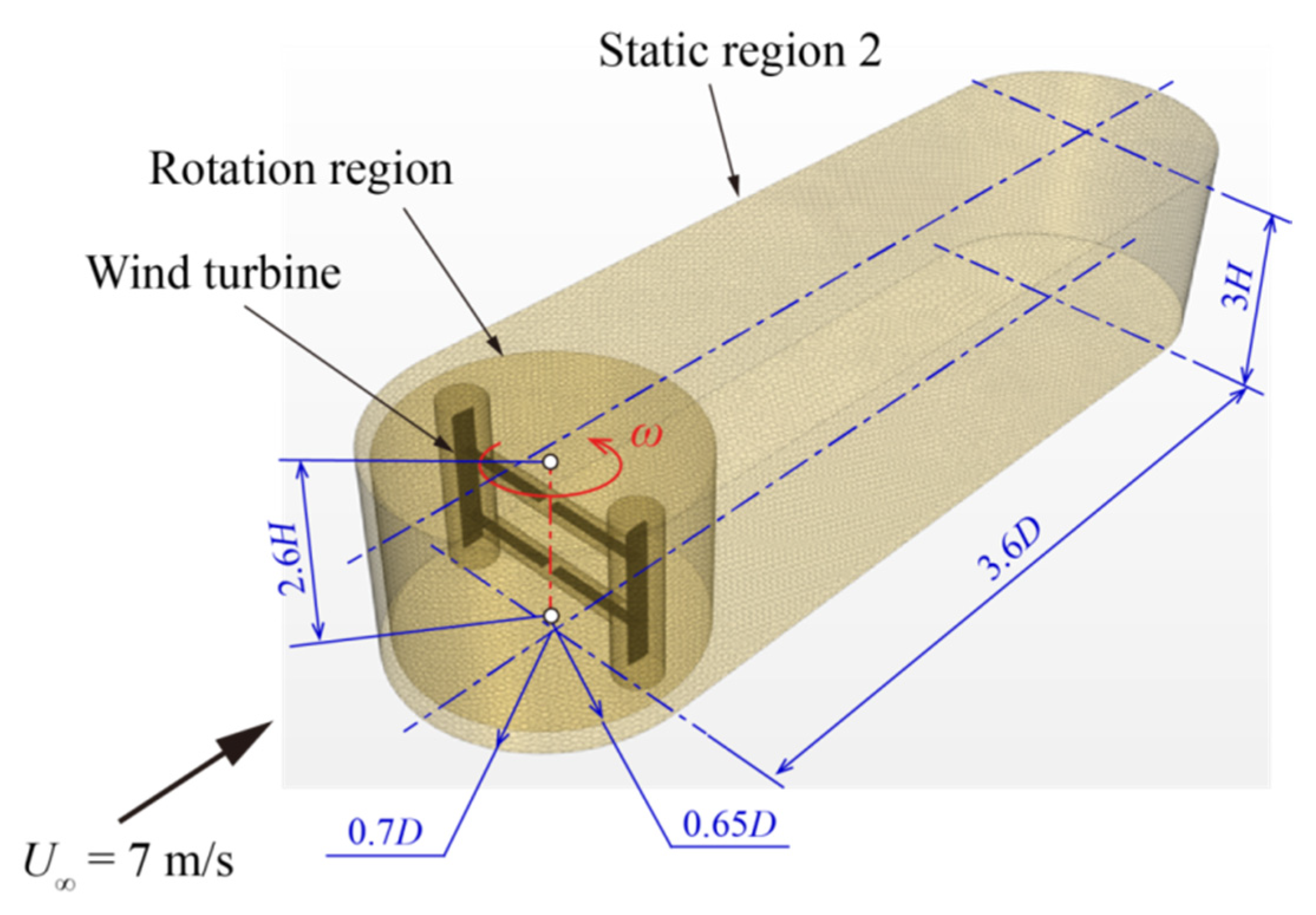

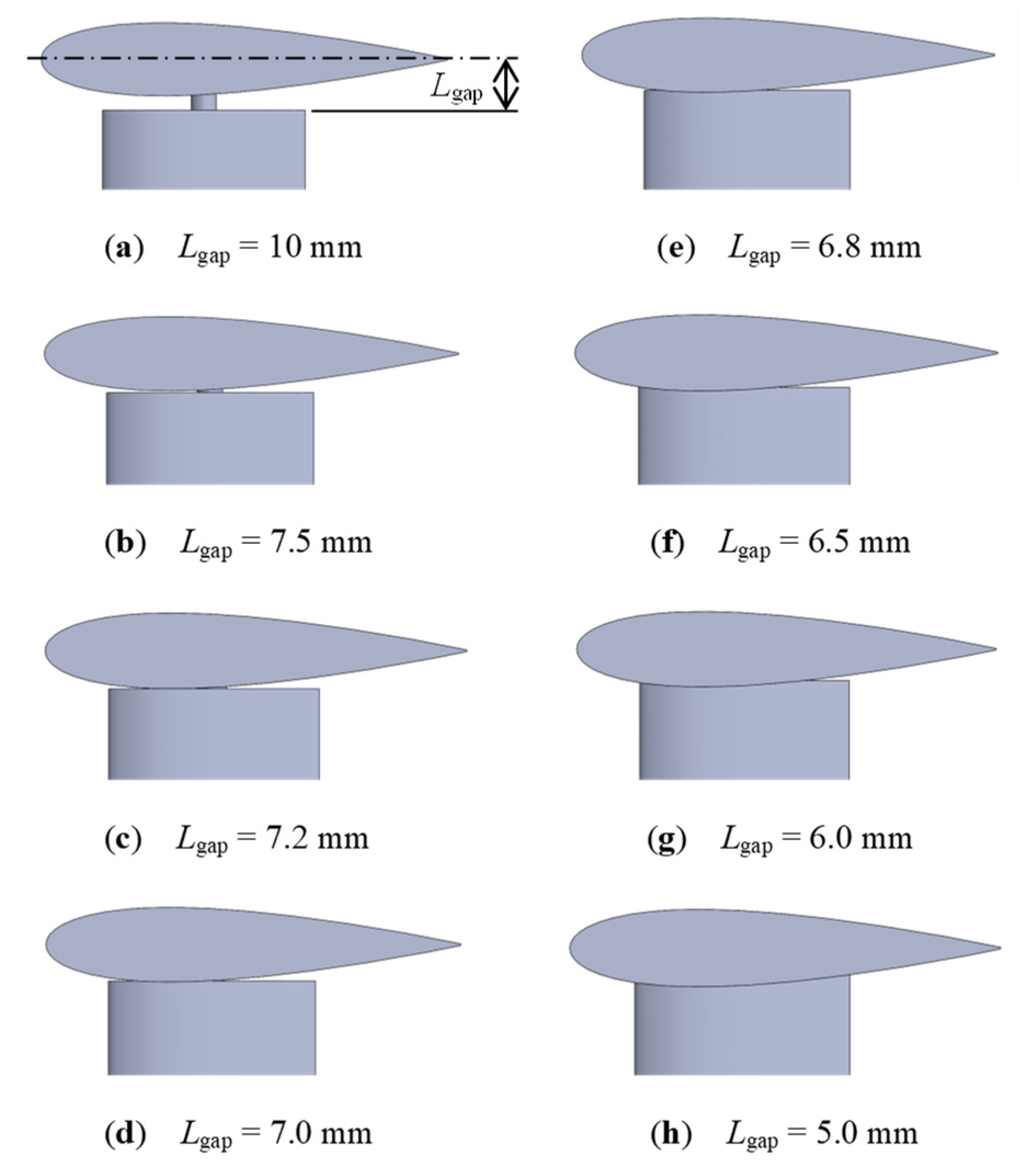

2.1. Object Model for Calculation

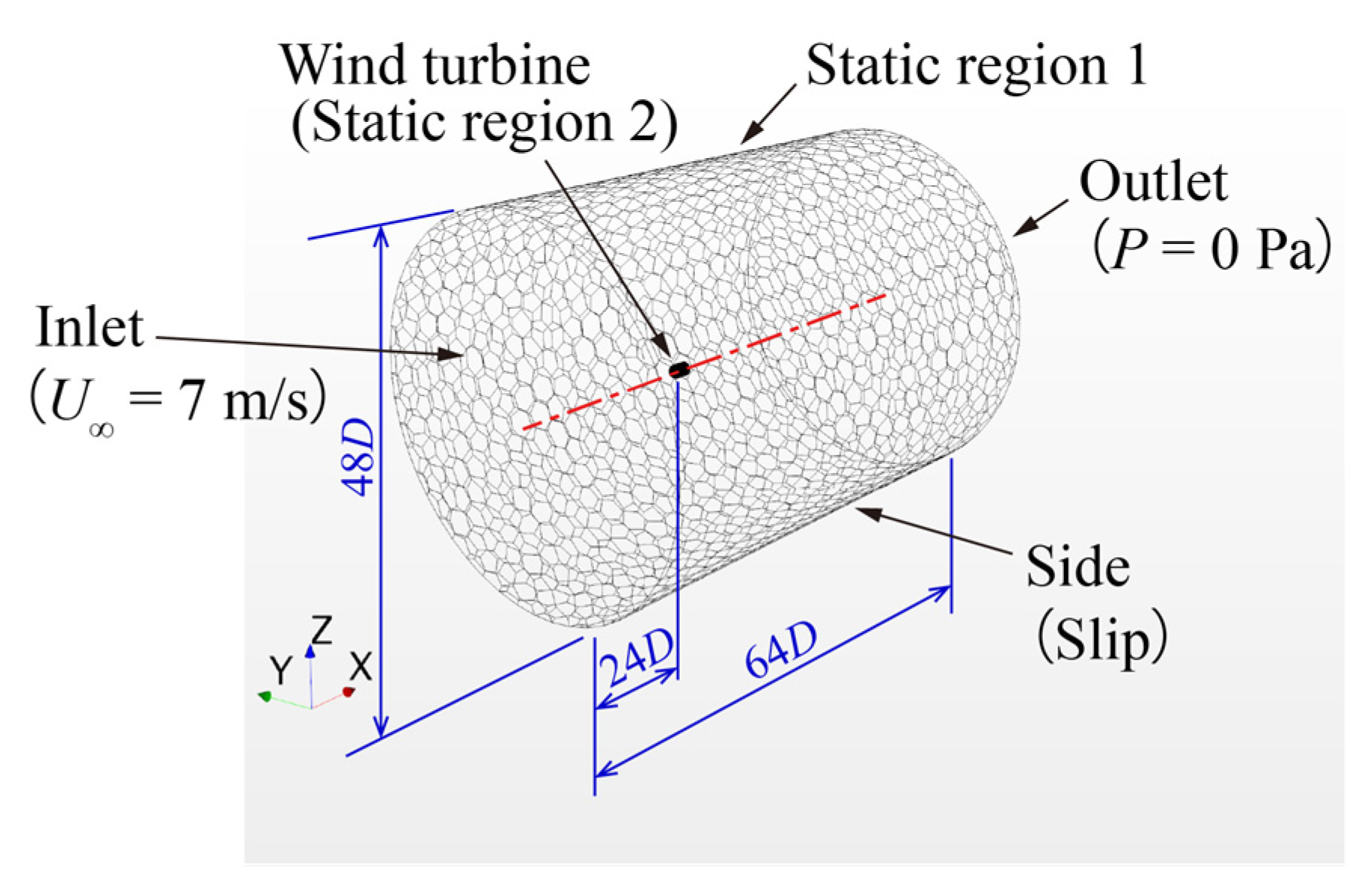

2.2. Settings of Numerical Analysis

3. Results and Discussion

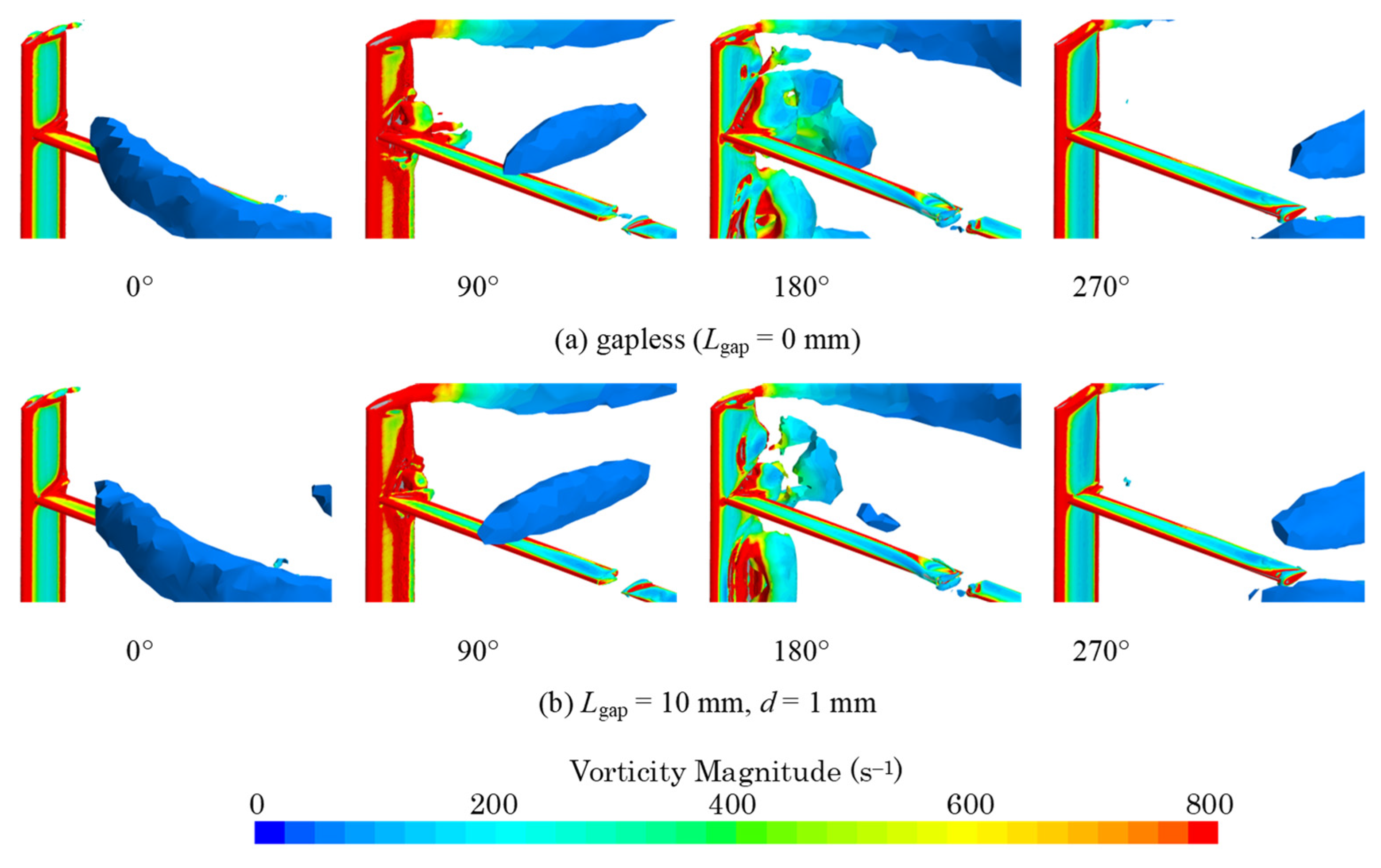

3.1. Vortex Shedding from the Connection Part

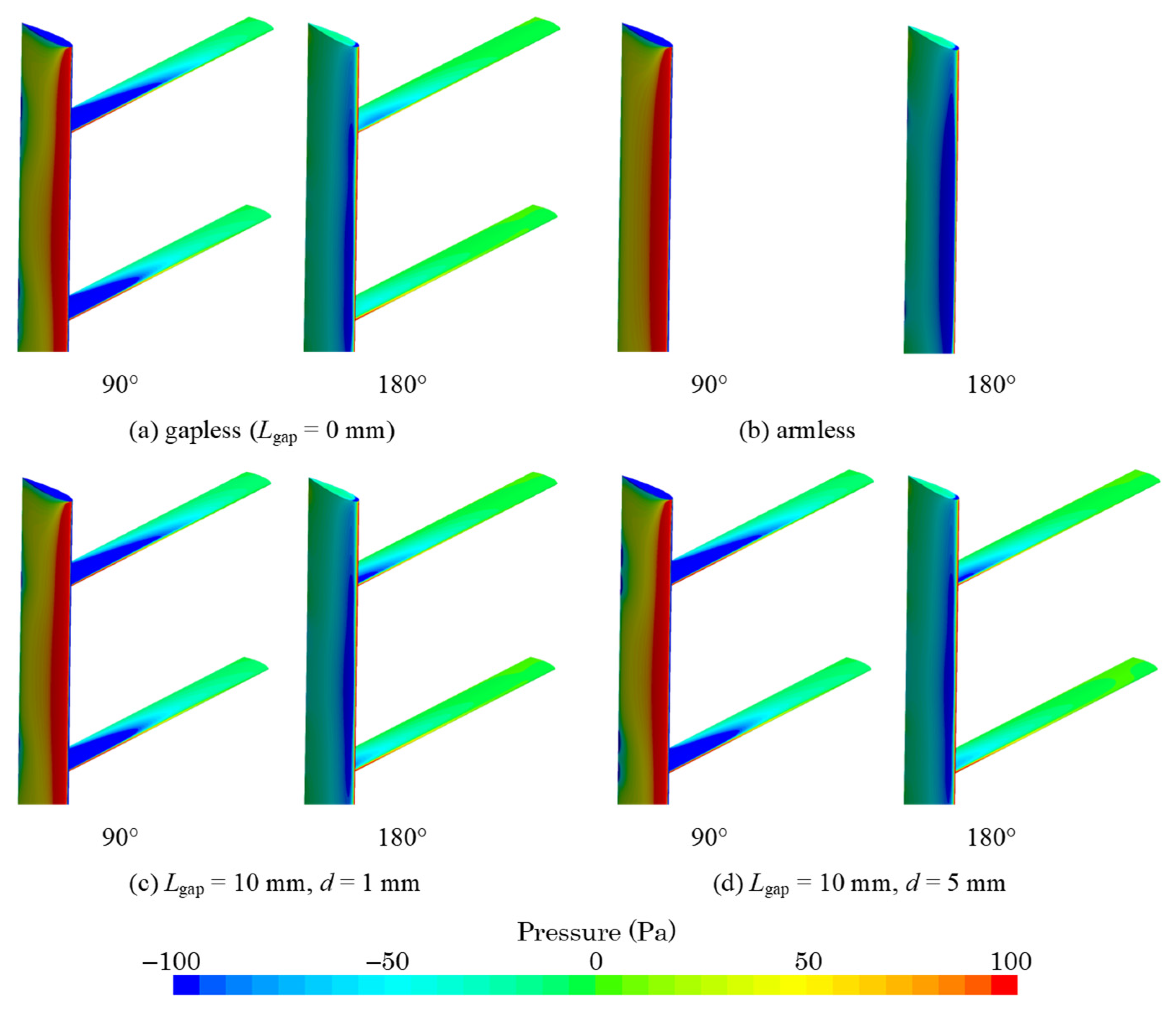

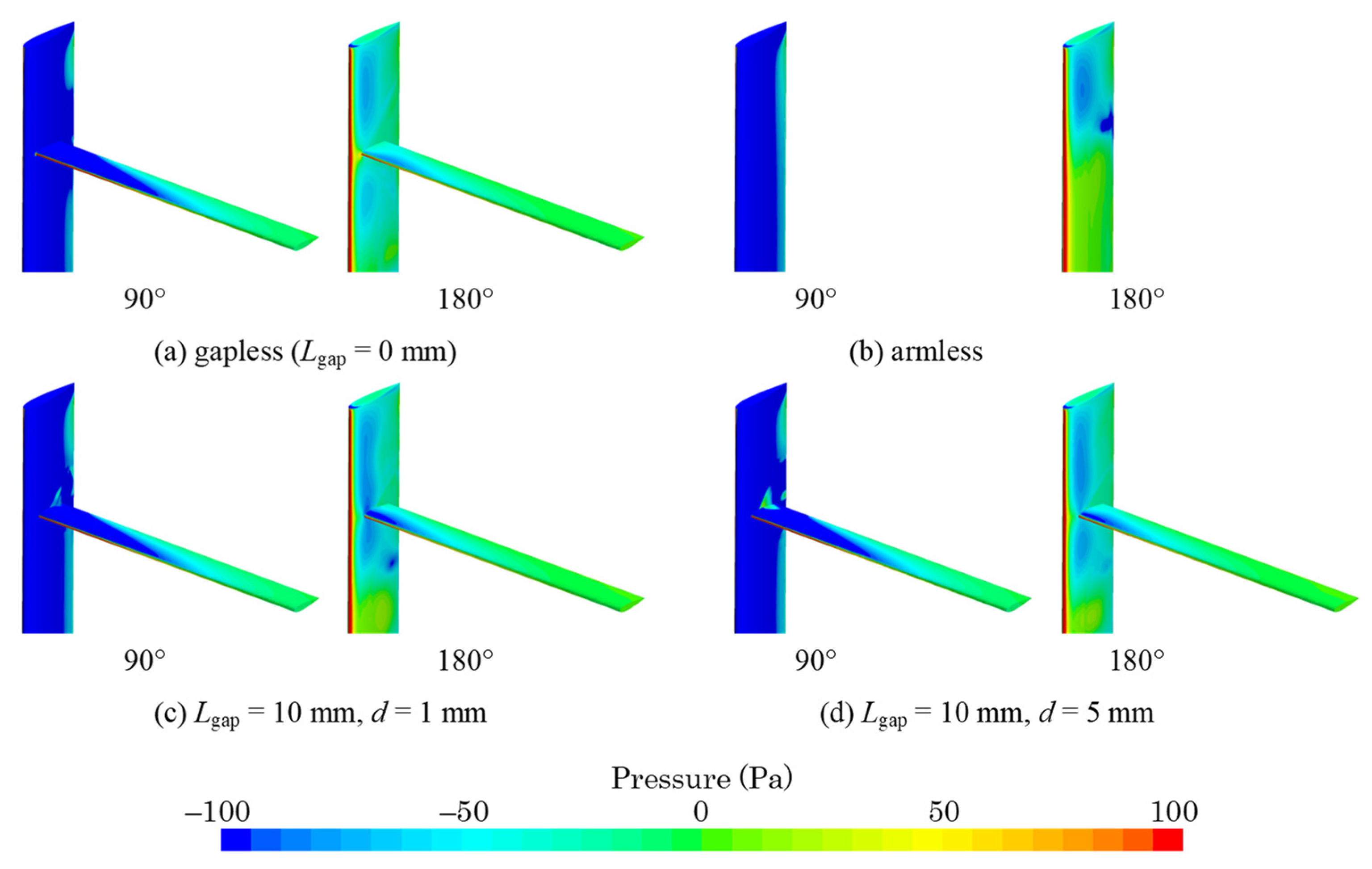

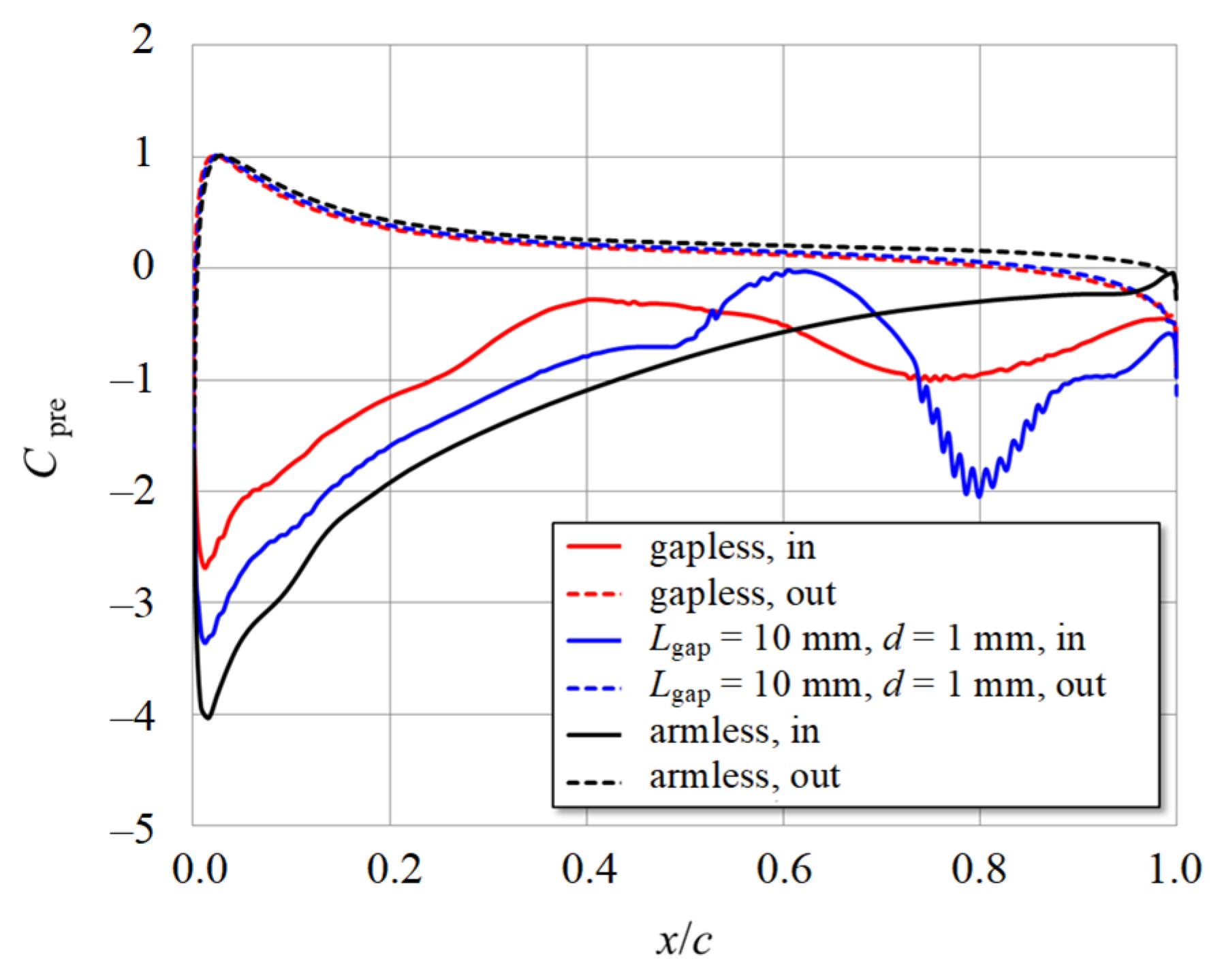

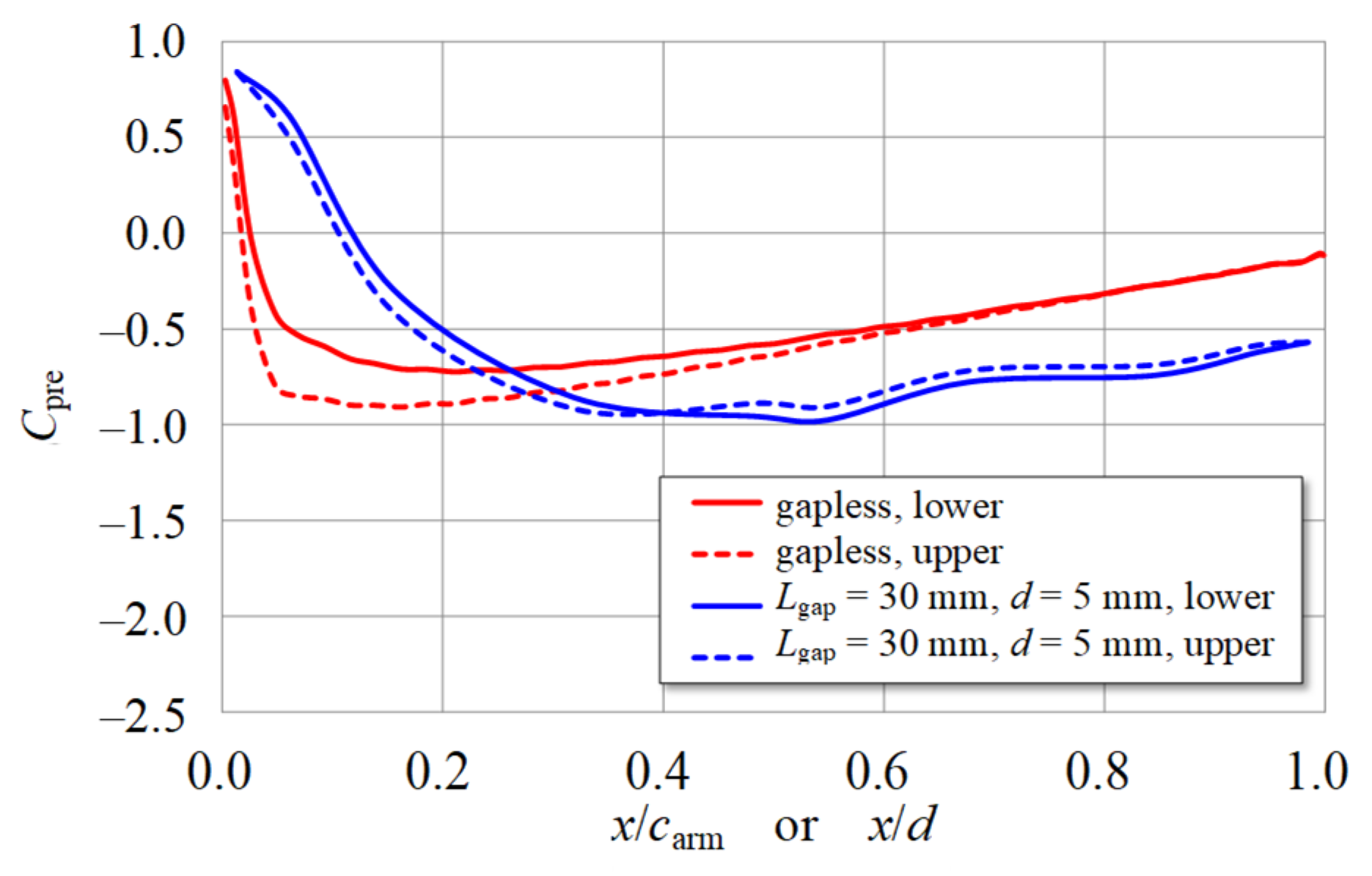

3.2. Surface Pressure Distribution around the Connection Part

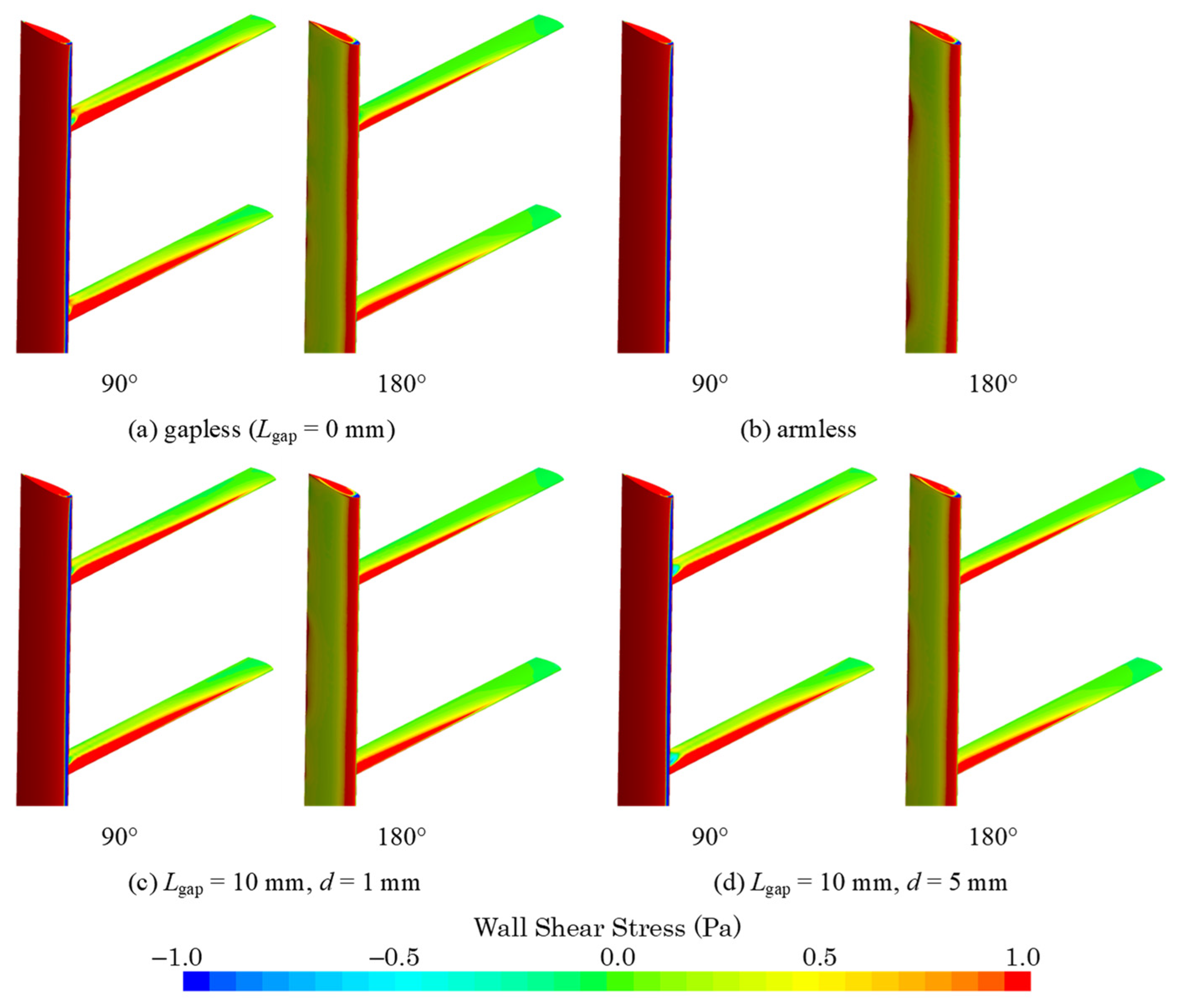

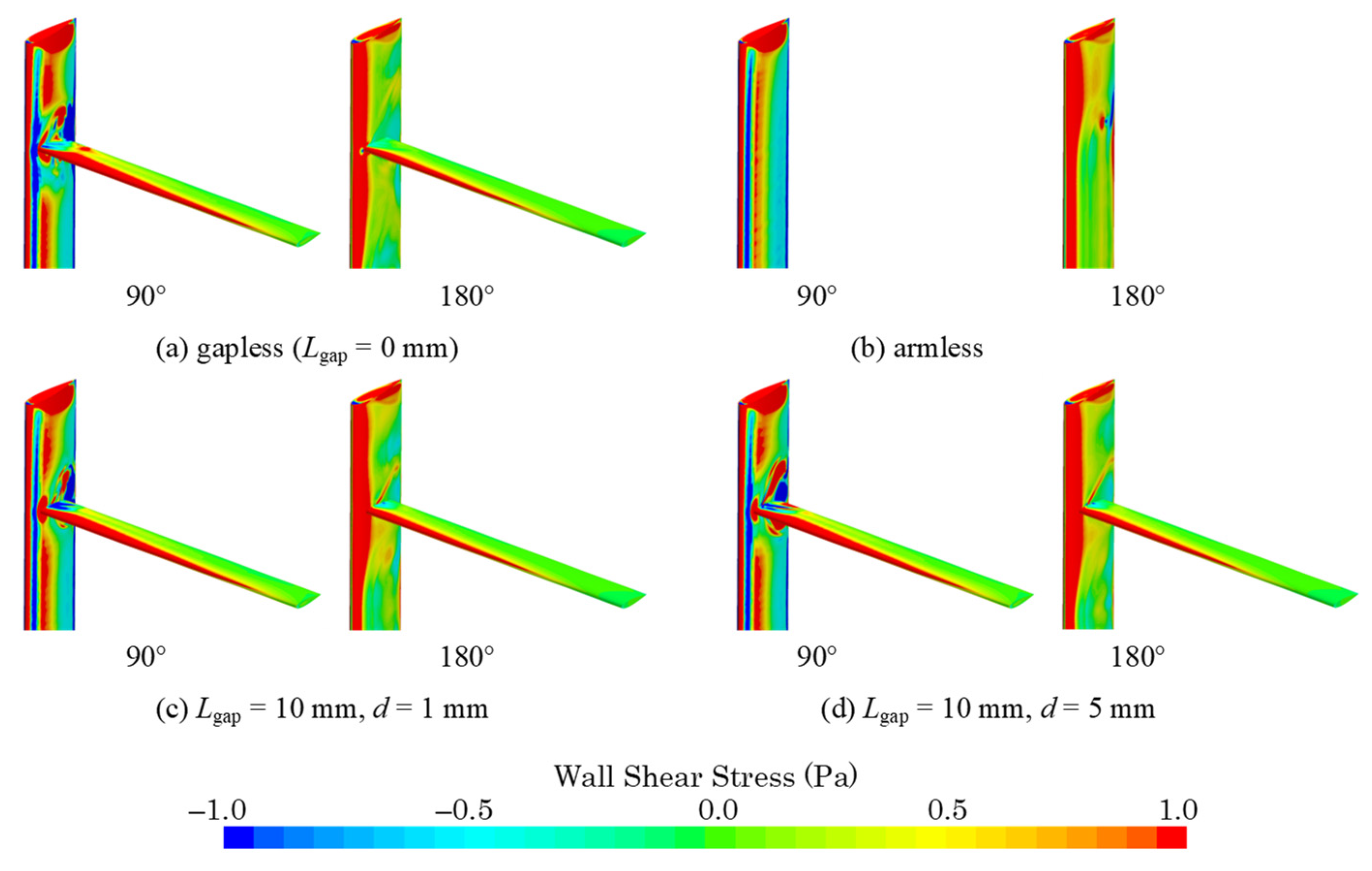

3.3. Wall Shear Stress Distribution around Connection Part

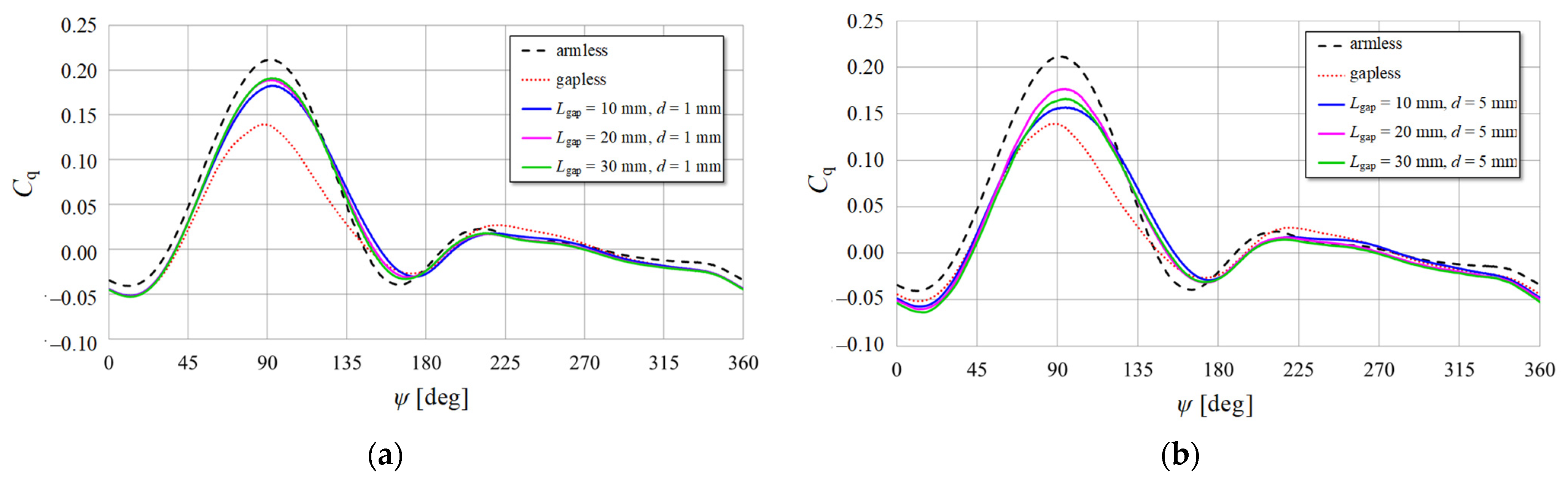

3.4. Gap Length Dependency of One-Blade Torque Variation in One Rotation

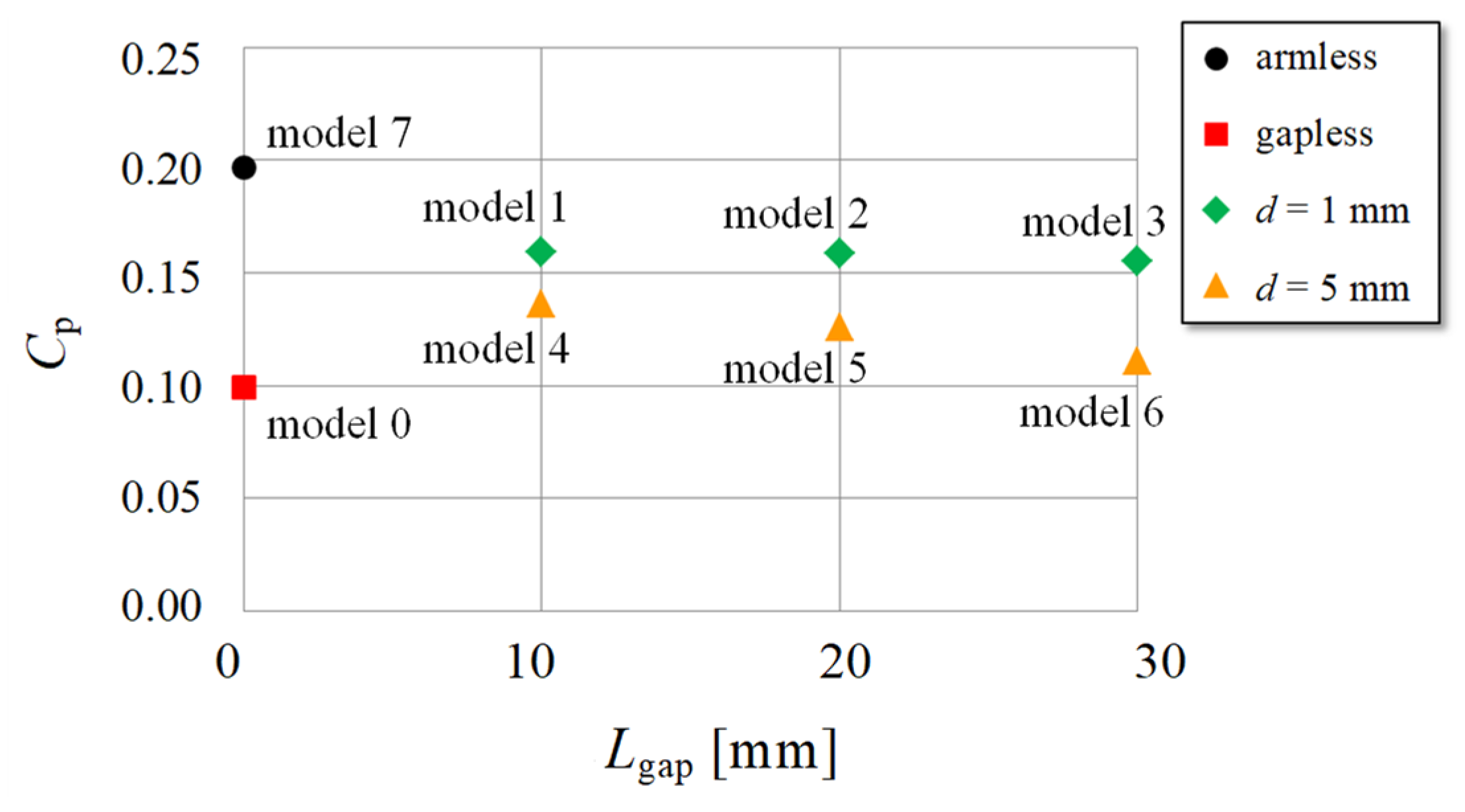

3.5. Effects of Connection Gap on Power Coefficient

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Ahmed, N.A.; Cameron, M. The challenges and possible solutions of horizontal axis wind turbines as a clean energy solution for the future. Renew. Sustain. Energy Rev. 2014, 38, 439–460. [Google Scholar] [CrossRef]

- Luo, L.; Zhang, X.; Song, D.; Tang, W.; Yang, J.; Li, L.; Tian, X.; Wen, W. Optimal design of rated wind speed and rotor radius to minimizing the cost of energy for offshore wind turbines. Energies 2018, 11, 2728. [Google Scholar] [CrossRef]

- Islam, M.; Fartaj, A.; Carriveau, R. Analysis of the design parameters related to a fixed-pitch straight-bladed vertical axis wind turbine. Wind Eng. 2008, 32, 491–507. [Google Scholar] [CrossRef]

- Islam, M.; Ting, D.S.K.; Fartaj, A. Aerodynamic models for Darrieus-type straight-bladed vertical axis wind turbines. Renew. Sustain. Energy Rev. 2008, 12, 1087–1109. [Google Scholar] [CrossRef]

- Kumar, R.; Raahemifar, K.; Fung, A.S. A critical review of vertical axis wind turbines for urban applications. Renew. Sust. Energ. Rev. 2018, 89, 281–291. [Google Scholar] [CrossRef]

- Li, Y.; Calisal, S.M. Three-dimensional effects and arm effects on modeling a vertical axis tidal current turbine. Renew. Sustain. Energy Rev. 2010, 35, 2325–2334. [Google Scholar] [CrossRef]

- Qin, N.; Howell, R.; Durrani, N.; Hamada, K.; Smith, T. Unsteady flow simulation and dynamic stall behaviour of vertical axis wind turbine blades. Wind Eng. 2011, 35, 511–527. [Google Scholar] [CrossRef]

- De Marco, A.; Coiro, D.P.; Cucco, D.; Nicolosi, F. A numerical study on a vertical-axis wind turbine with inclined arms. Int. J. Aerosp. Eng. 2014, 2014, 180498. [Google Scholar] [CrossRef]

- Marsh, P.; Ranmuthugala, D.; Penesis, I.; Thomas, G. Three-dimensional numerical simulations of straight-bladed vertical axis tidal turbines investigating power output, torque ripple and mounting forces. Renew. Energy 2015, 83, 67–77. [Google Scholar] [CrossRef]

- Li, Q.A.; Maeda, T.; Kamada, Y.; Murata, J.; Shimizu, K.; Ogasawara, T.; Nakai, A.; Kasuya, T. Effect of solidity on aerodynamic forces around straight-bladed vertical axis wind turbine by wind tunnel experiments (depending on number of blades). Renew. Energy 2016, 96, 928–939. [Google Scholar] [CrossRef]

- Aihara, A.; Mendoza, V.; Goude, A.; Bernhoff, H. A numerical study of strut and tower influence on the performance of vertical axis wind turbines using computational fluid dynamics simulation. Wind Energy 2022, 25, 897–913. [Google Scholar] [CrossRef]

- Kirke, B.K.; Lazauskas, L. Limitations of fixed pitch Darrieus hydrokinetic turbines and the challenge of variable pitch. Renew. Energy 2011, 36, 893–897. [Google Scholar] [CrossRef]

- The SeaTwirl Concept. Web Page. Available online: https://seatwirl.com/products/ (accessed on 19 September 2023).

- Hara, Y.; Horita, N.; Yoshida, S.; Akimoto, H.; Sumi, T. Numerical analysis of effects of arms with different cross-sections on straight-bladed vertical axis wind turbine. Energies 2019, 12, 2106. [Google Scholar] [CrossRef]

- Mertens, S.; van Kuik, G.; van Bussel, G. Performance of an H-Darrieus in the skewed flow on a roof. J. Sol. Energy Eng. 2003, 125, 433–440. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Van Bussel, G.J.W.; Polinder, H.; Sidler, H.F.A. TURBY®: Concept and realisation of a small VAWT for the built environment. In Proceedings of the EAWE/EWEA Special Topic Conference “The Science of Making Torque from Wind”, Delft, The Netherlands, 19–21 April 2004; p. 8. [Google Scholar]

- Fu, W.-S.; Lai, Y.-C.; Li, C.-G. Estimation of turbulent natural convection in horizontal parallel plates by the Q criterion. Int. Commun. Heat Mass Transf. 2013, 45, 41–46. [Google Scholar] [CrossRef]

- Sheldahl, R.E.; Klimas, P.C. Aerodynamic Characteristics of Seven Symmetrical Airfoil Sections through 180-Degree Angle of Attack for Use in Aerodynamic Analysis of Vertical Axis Wind Turbines; SAND-80-2114; Sandia National Labs.: Albuquerque, NM, USA, 1981; pp. 43–44. [Google Scholar]

- White, F.M. Fluid Mechanics, 4th ed.; McGraw-Hill: New York, NY, USA, 1999. [Google Scholar]

| Model No. | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|---|

| Lgap | 0 | 10 | 20 | 30 | 10 | 20 | 30 | ∞ |

| Larm | 355 | 345 | 335 | 325 | 345 | 335 | 325 | 0 |

| d | - | 1 | 1 | 1 | 5 | 5 | 5 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hara, Y.; Miyashita, A.; Yoshida, S. Numerical Simulation of the Effects of Blade–Arm Connection Gap on Vertical–Axis Wind Turbine Performance. Energies 2023, 16, 6925. https://doi.org/10.3390/en16196925

Hara Y, Miyashita A, Yoshida S. Numerical Simulation of the Effects of Blade–Arm Connection Gap on Vertical–Axis Wind Turbine Performance. Energies. 2023; 16(19):6925. https://doi.org/10.3390/en16196925

Chicago/Turabian StyleHara, Yutaka, Ayato Miyashita, and Shigeo Yoshida. 2023. "Numerical Simulation of the Effects of Blade–Arm Connection Gap on Vertical–Axis Wind Turbine Performance" Energies 16, no. 19: 6925. https://doi.org/10.3390/en16196925

APA StyleHara, Y., Miyashita, A., & Yoshida, S. (2023). Numerical Simulation of the Effects of Blade–Arm Connection Gap on Vertical–Axis Wind Turbine Performance. Energies, 16(19), 6925. https://doi.org/10.3390/en16196925