Neural-Network-Based Time Control for Microwave Oven Heating of Food Products Distributed by a Solar-Powered Vending Machine with Energy Management Considerations

Abstract

:1. Introduction

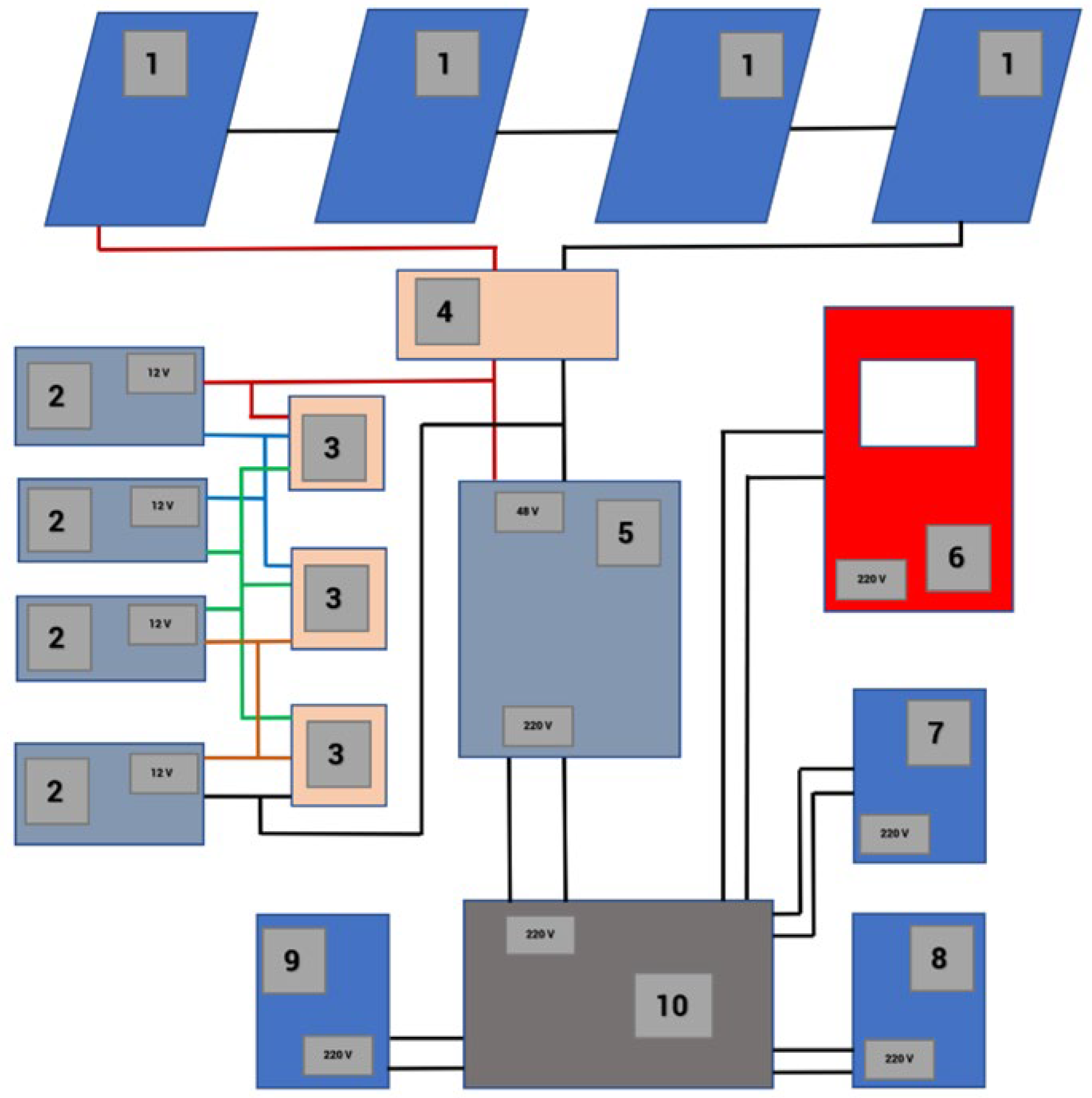

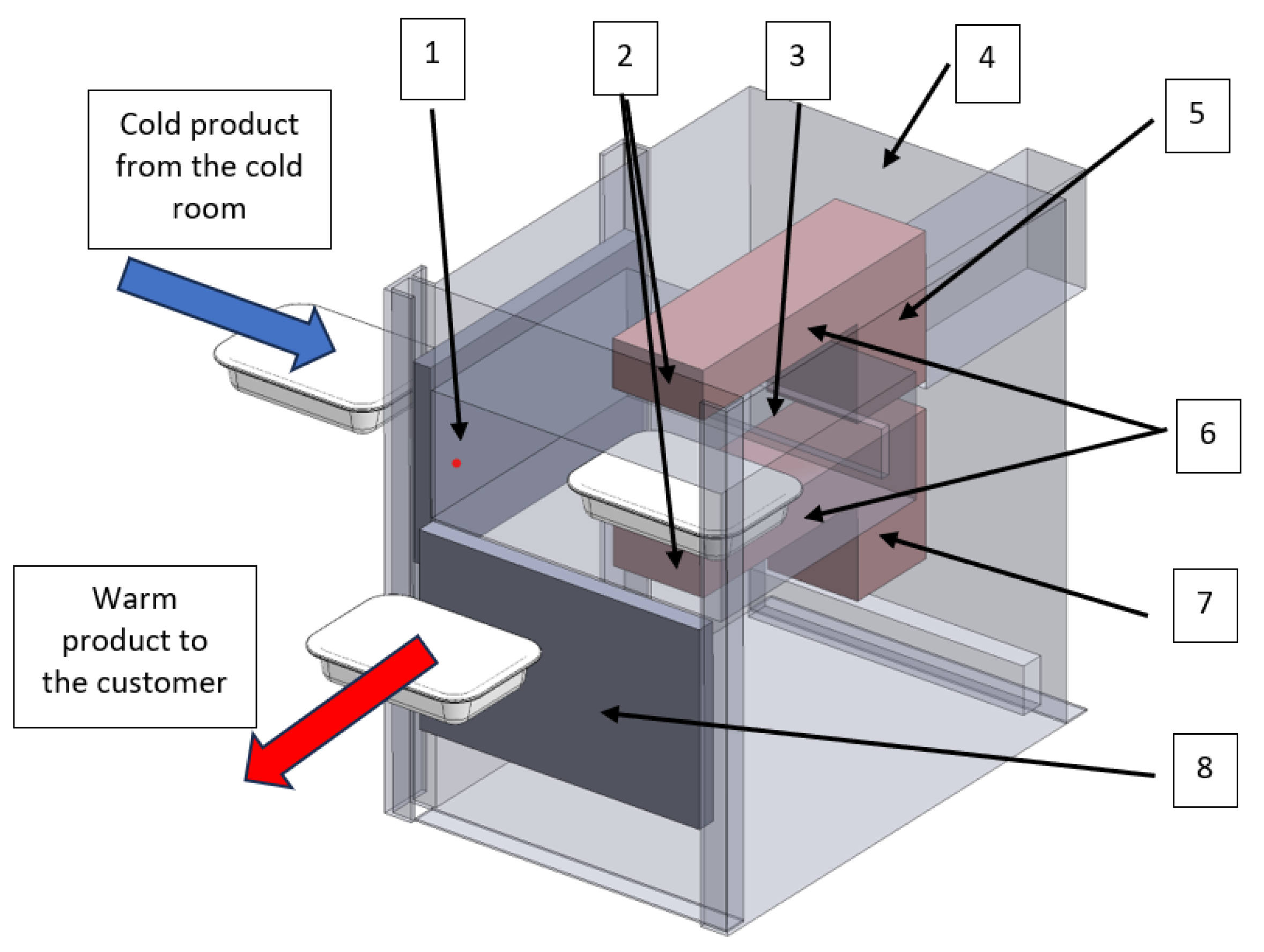

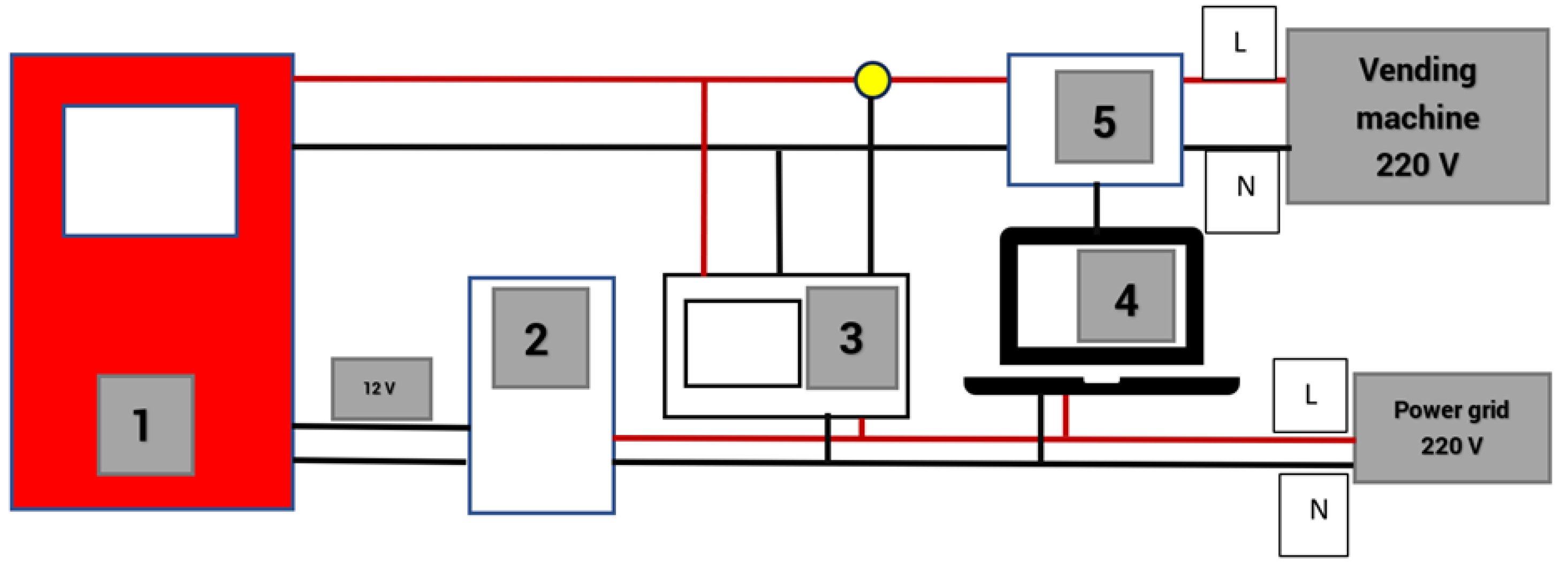

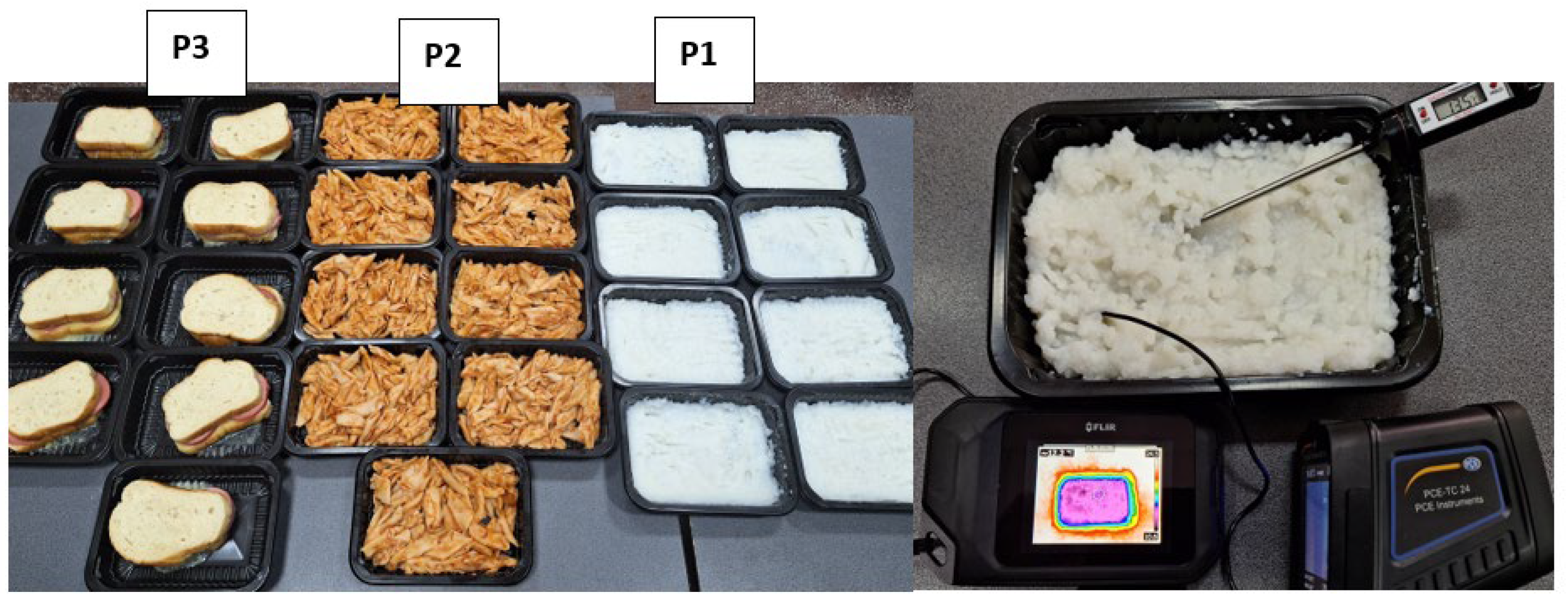

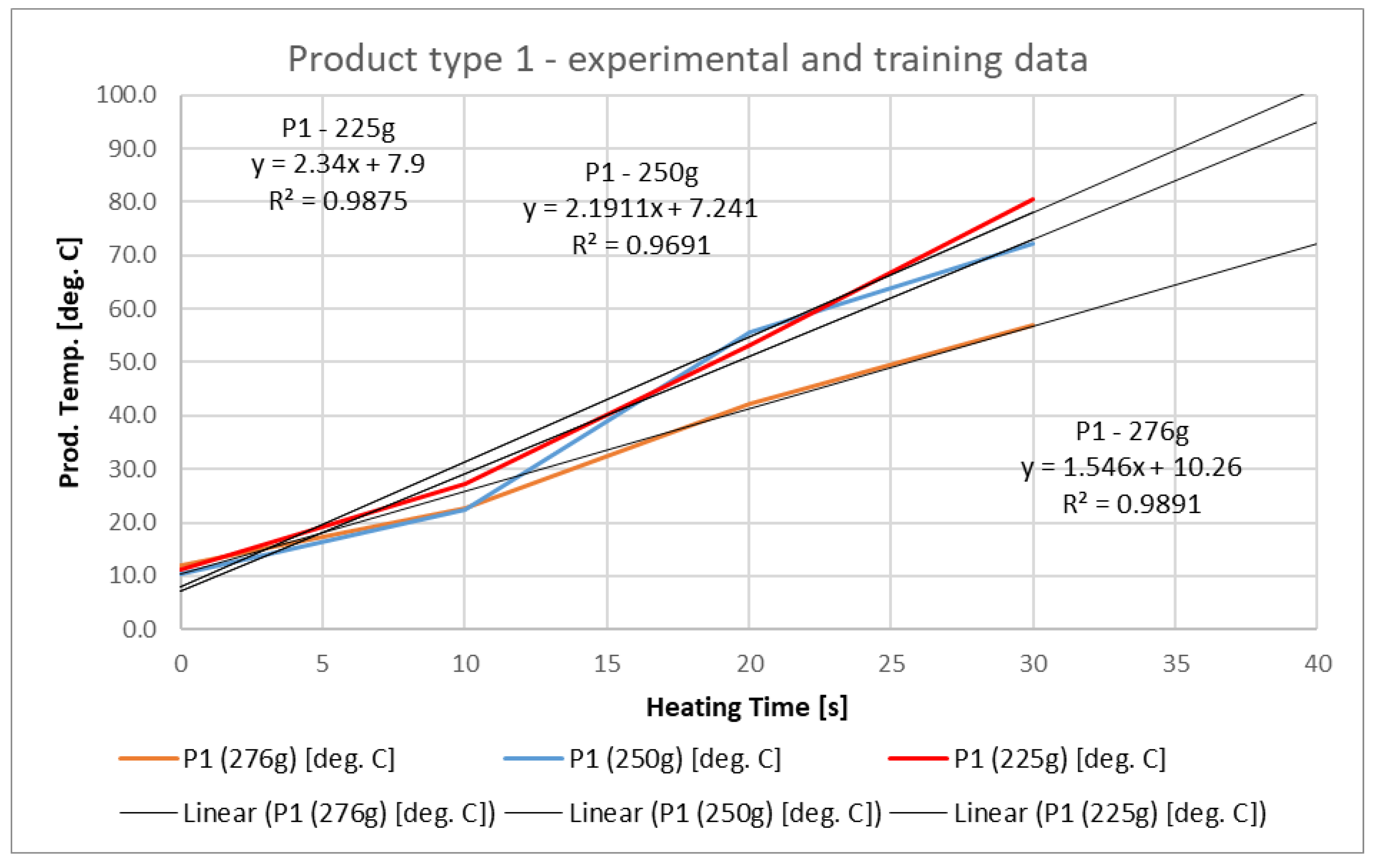

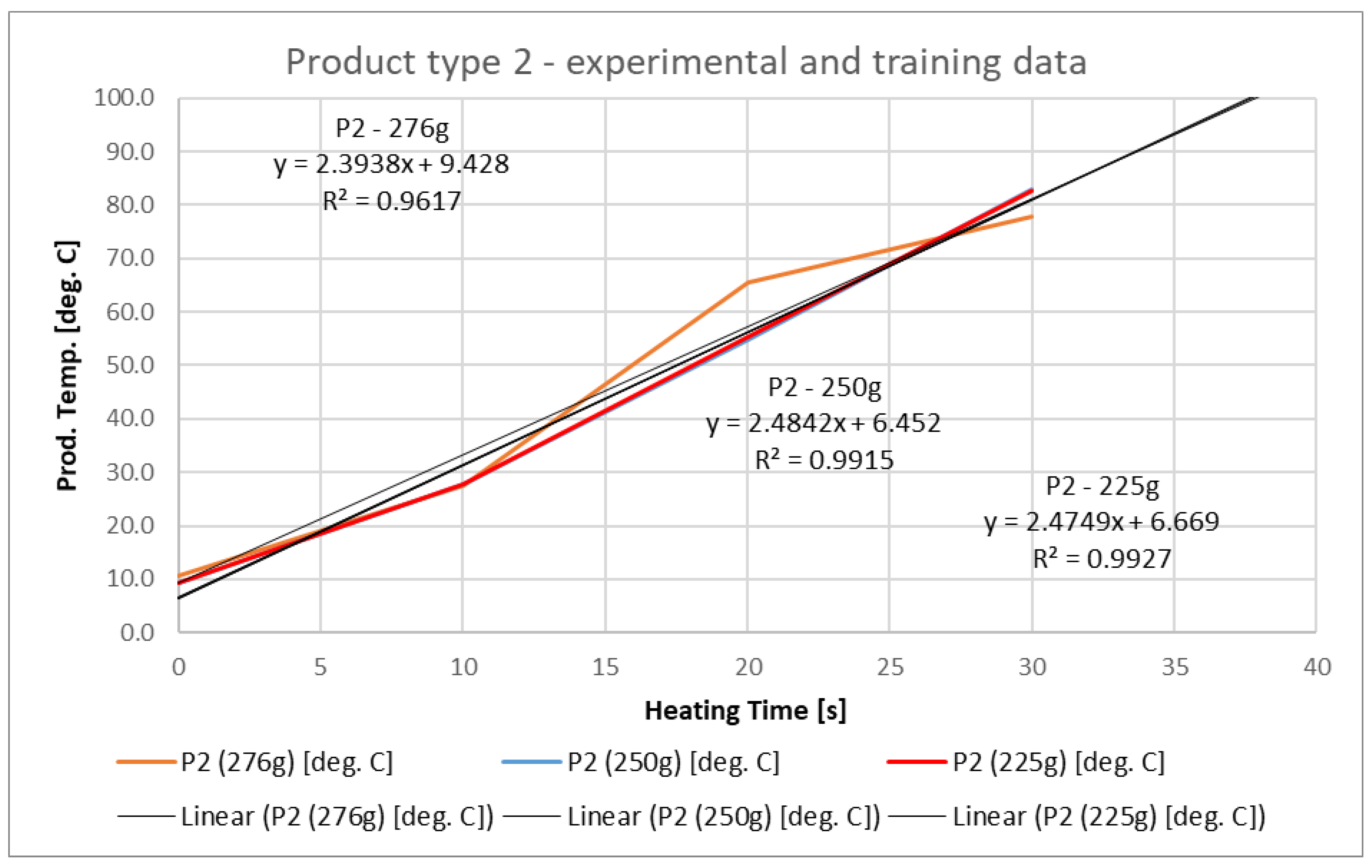

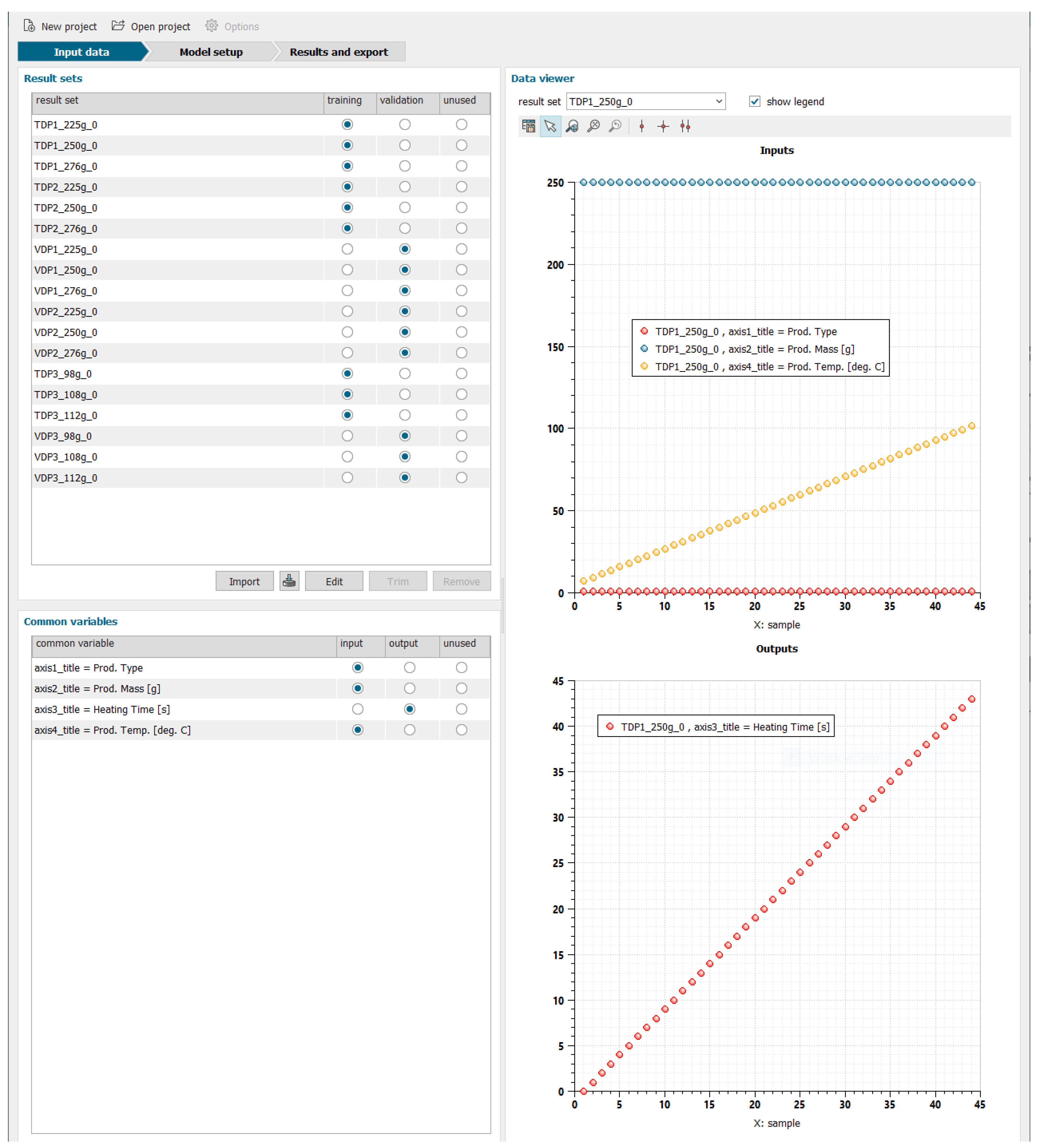

2. Materials and Methods

3. Results

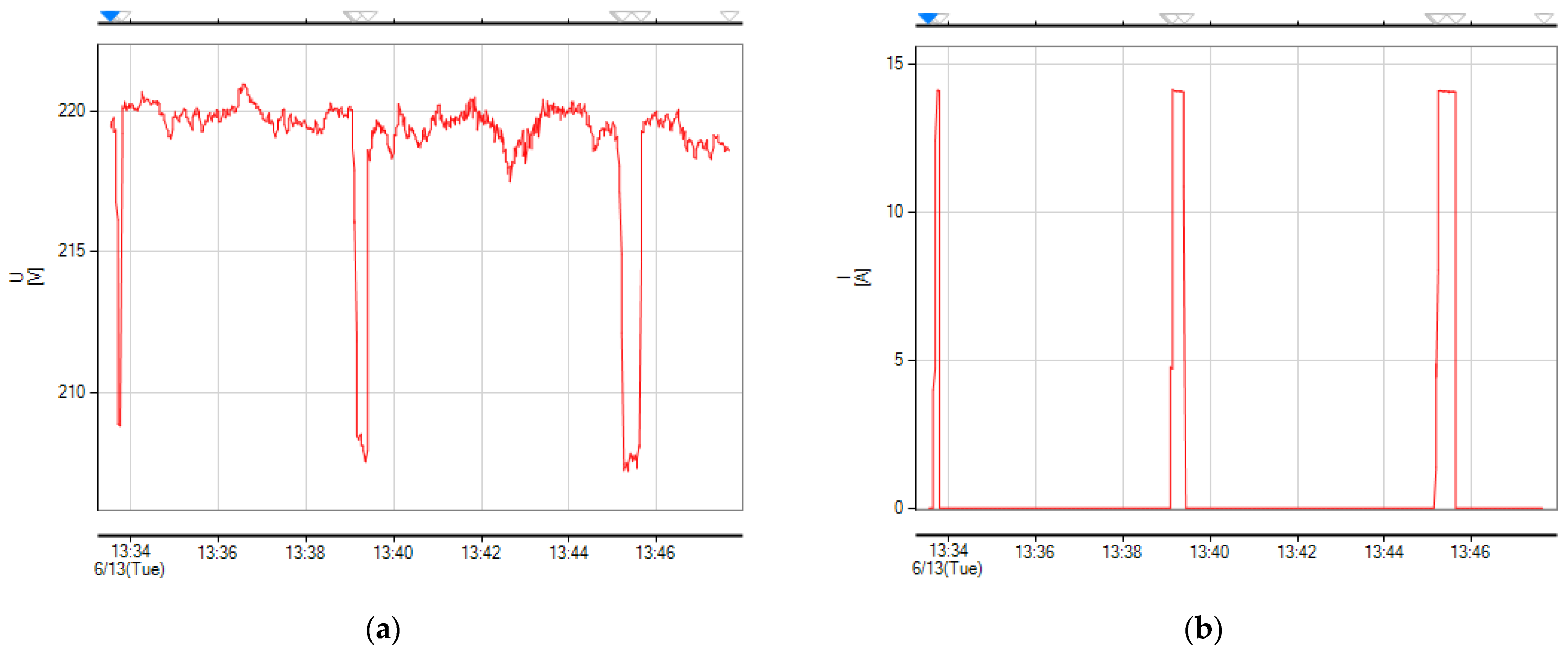

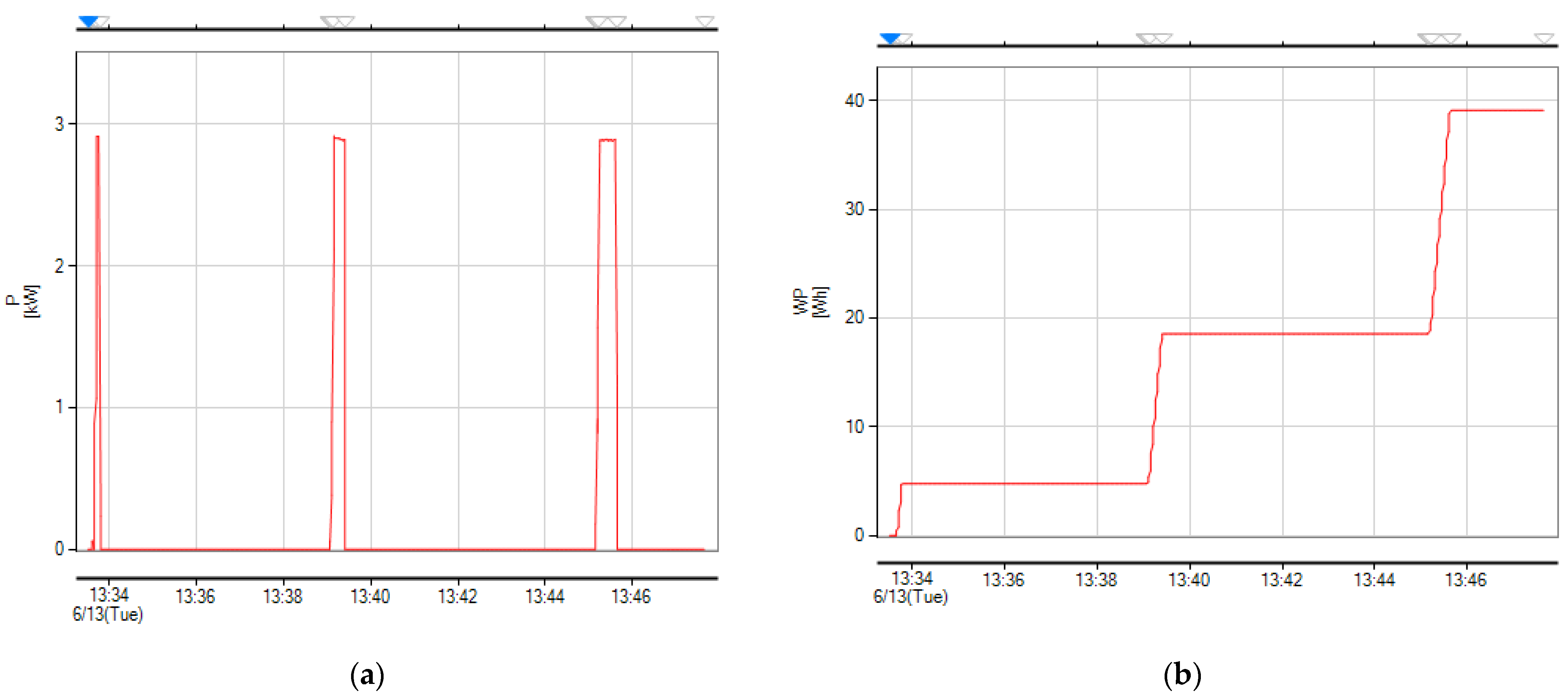

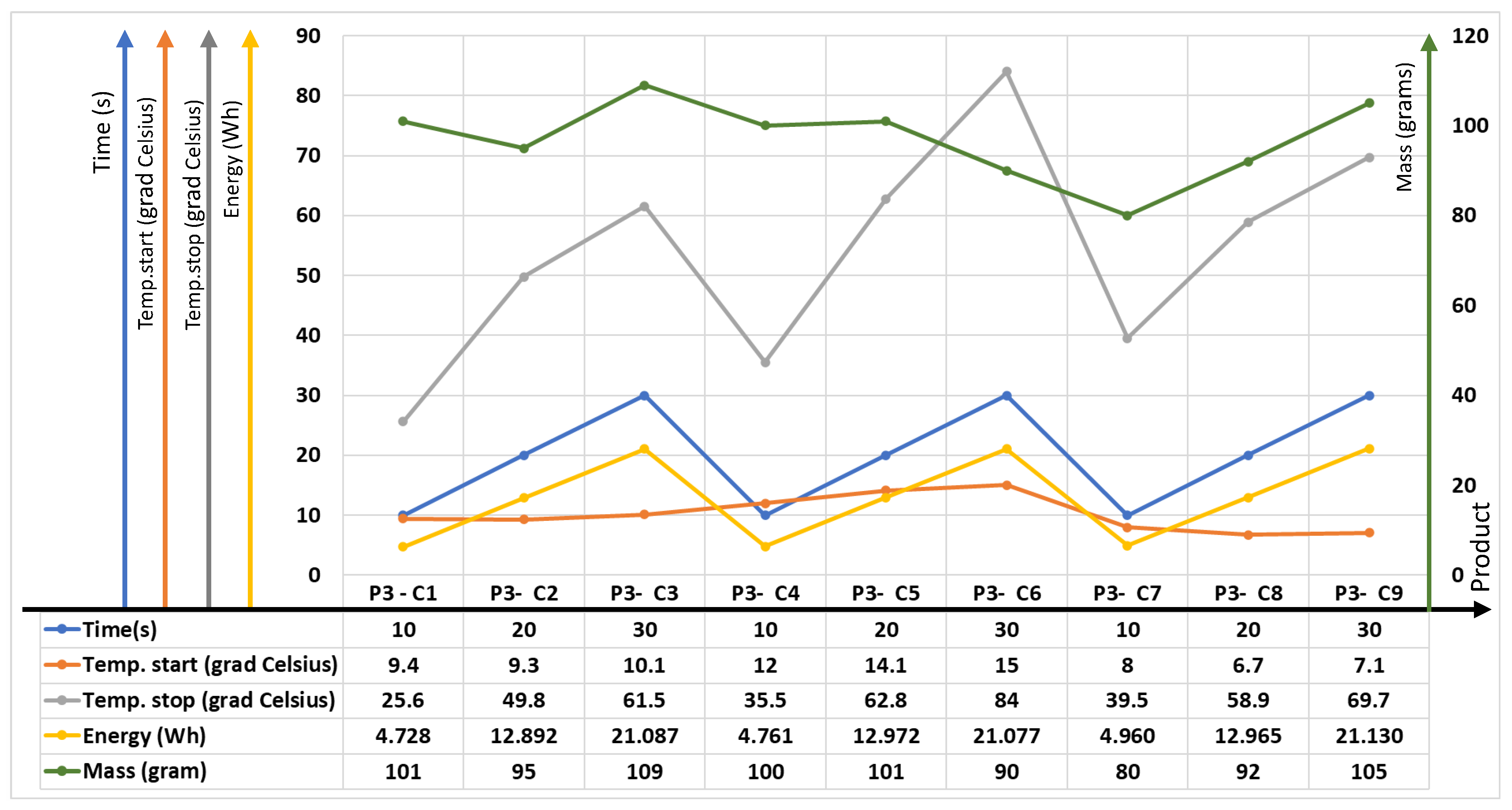

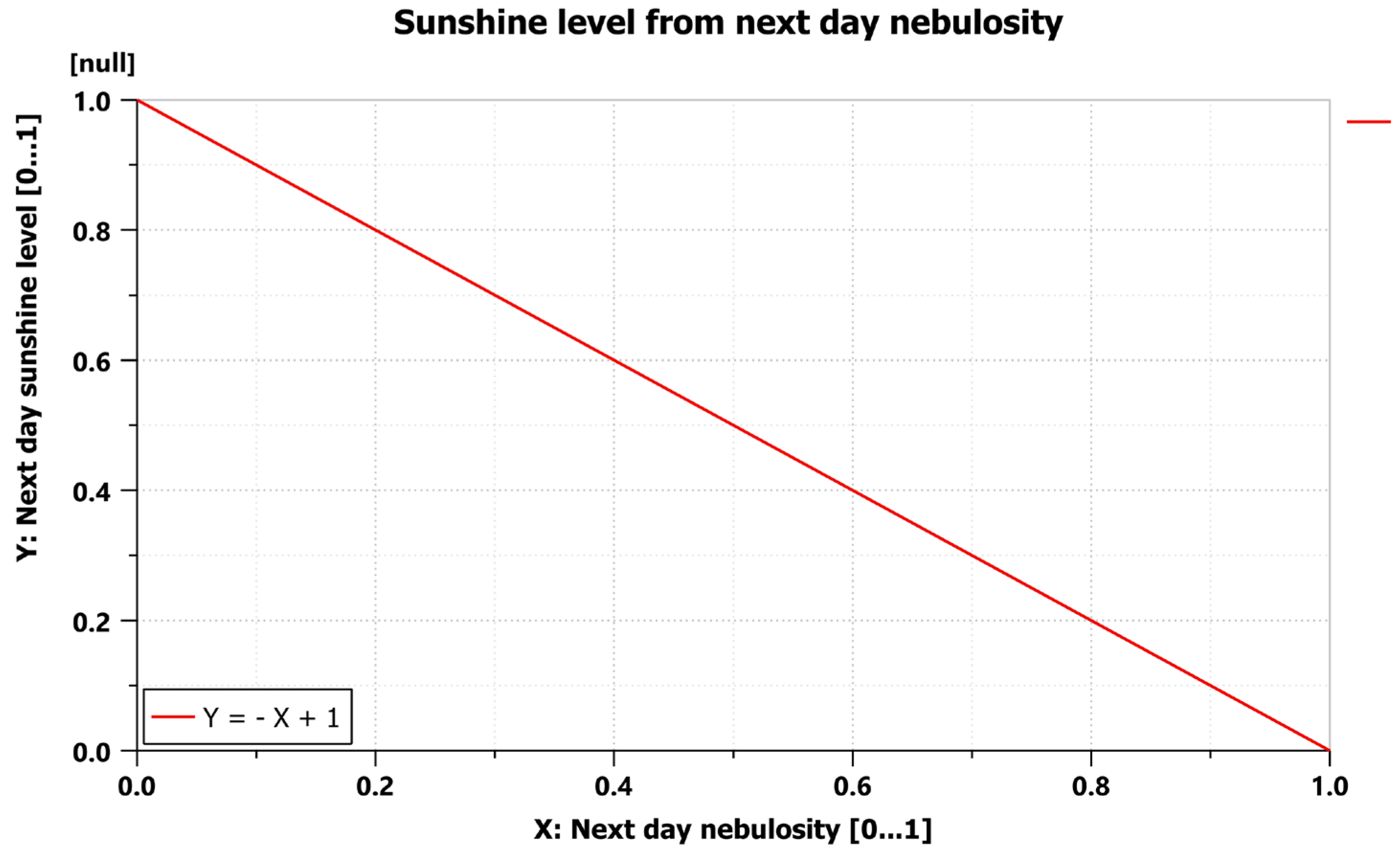

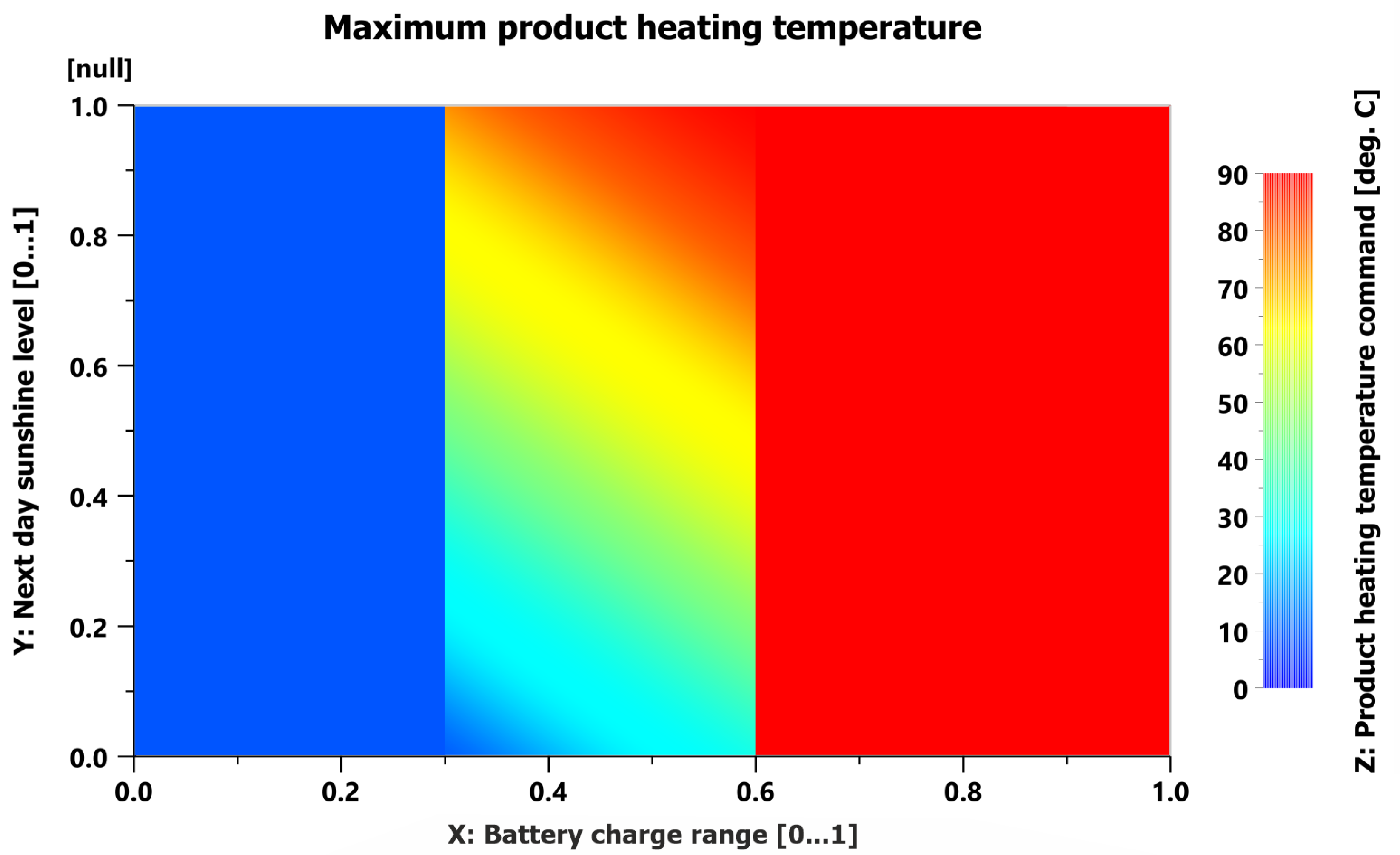

3.1. Electrical and Thermal

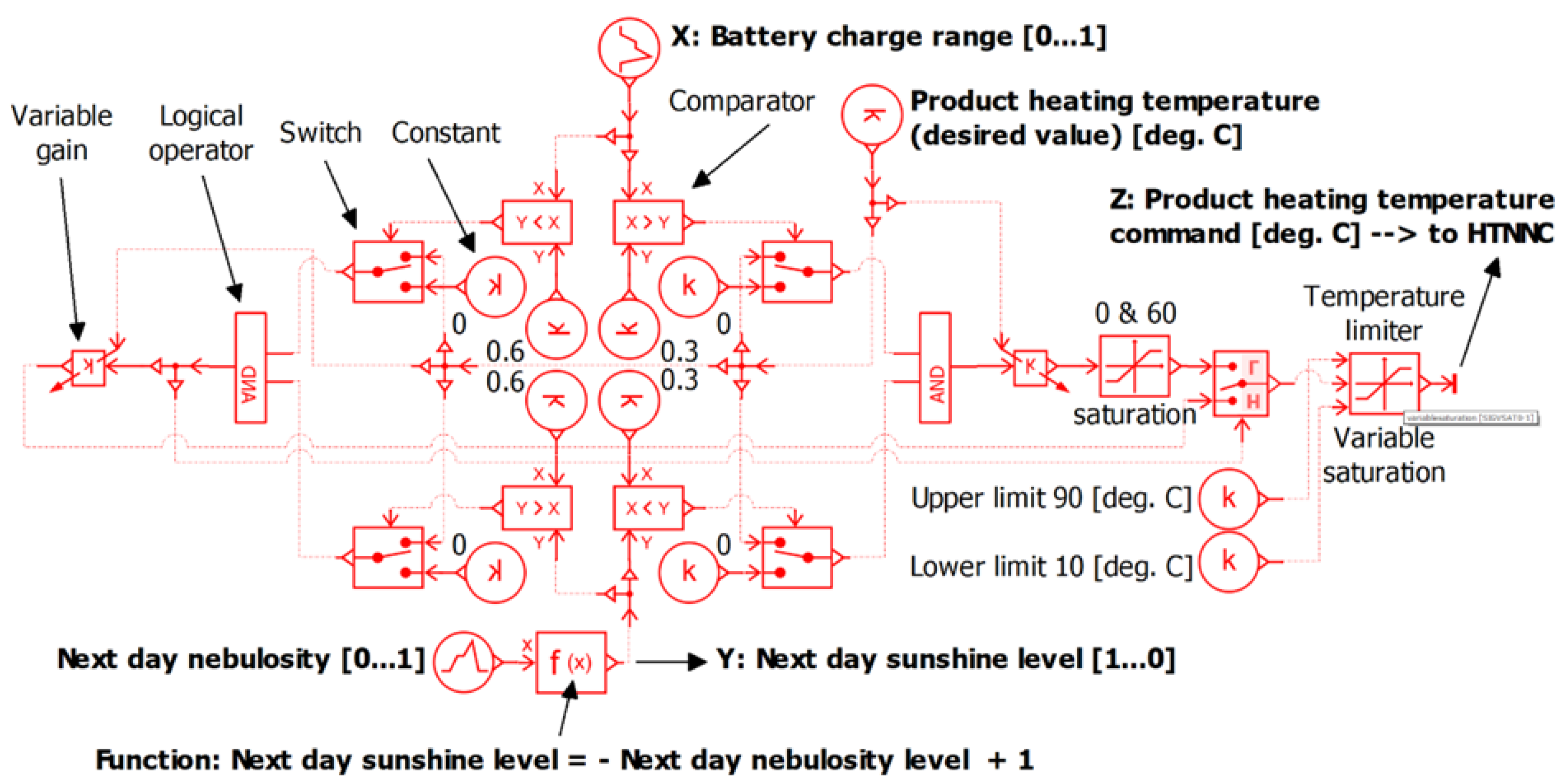

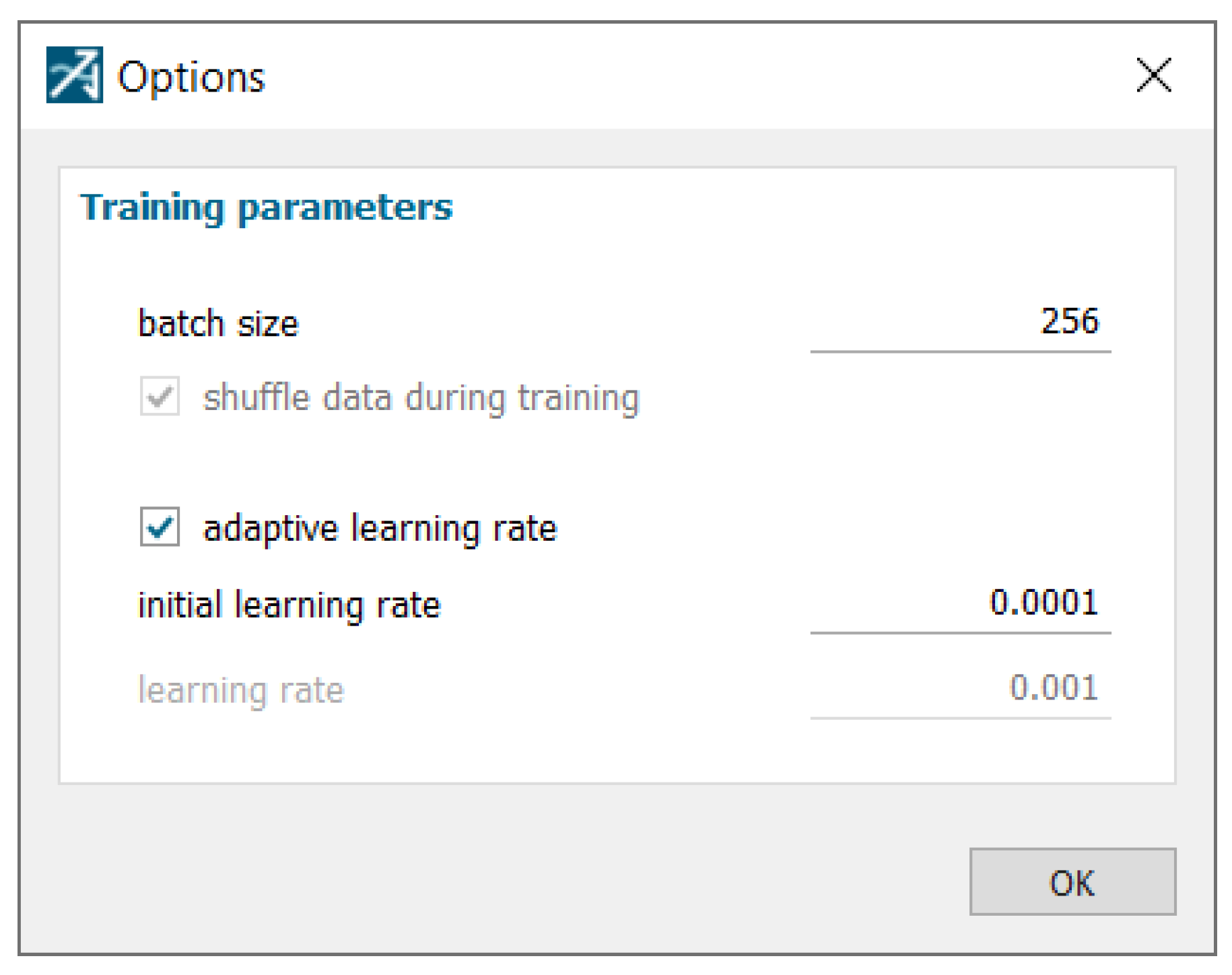

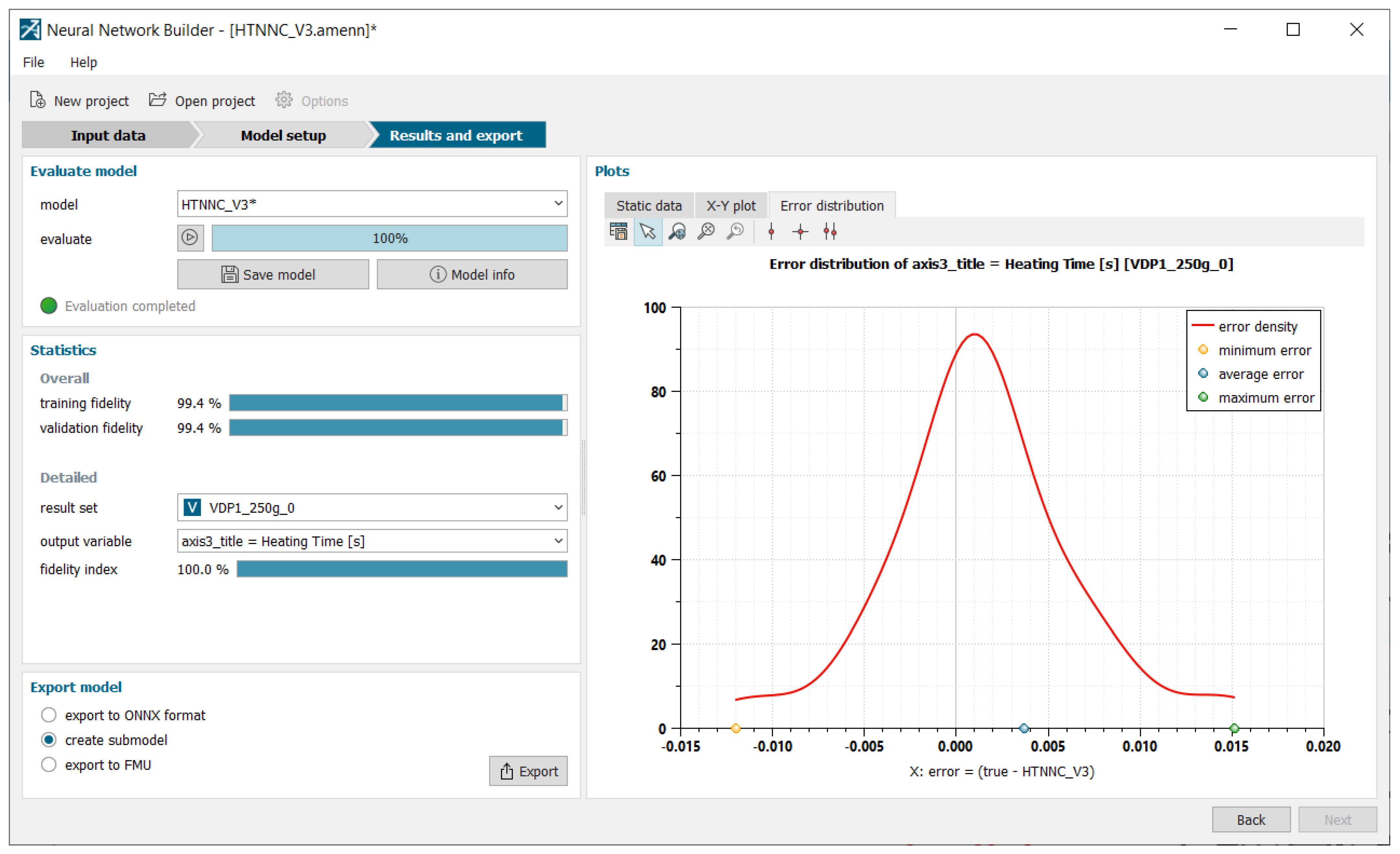

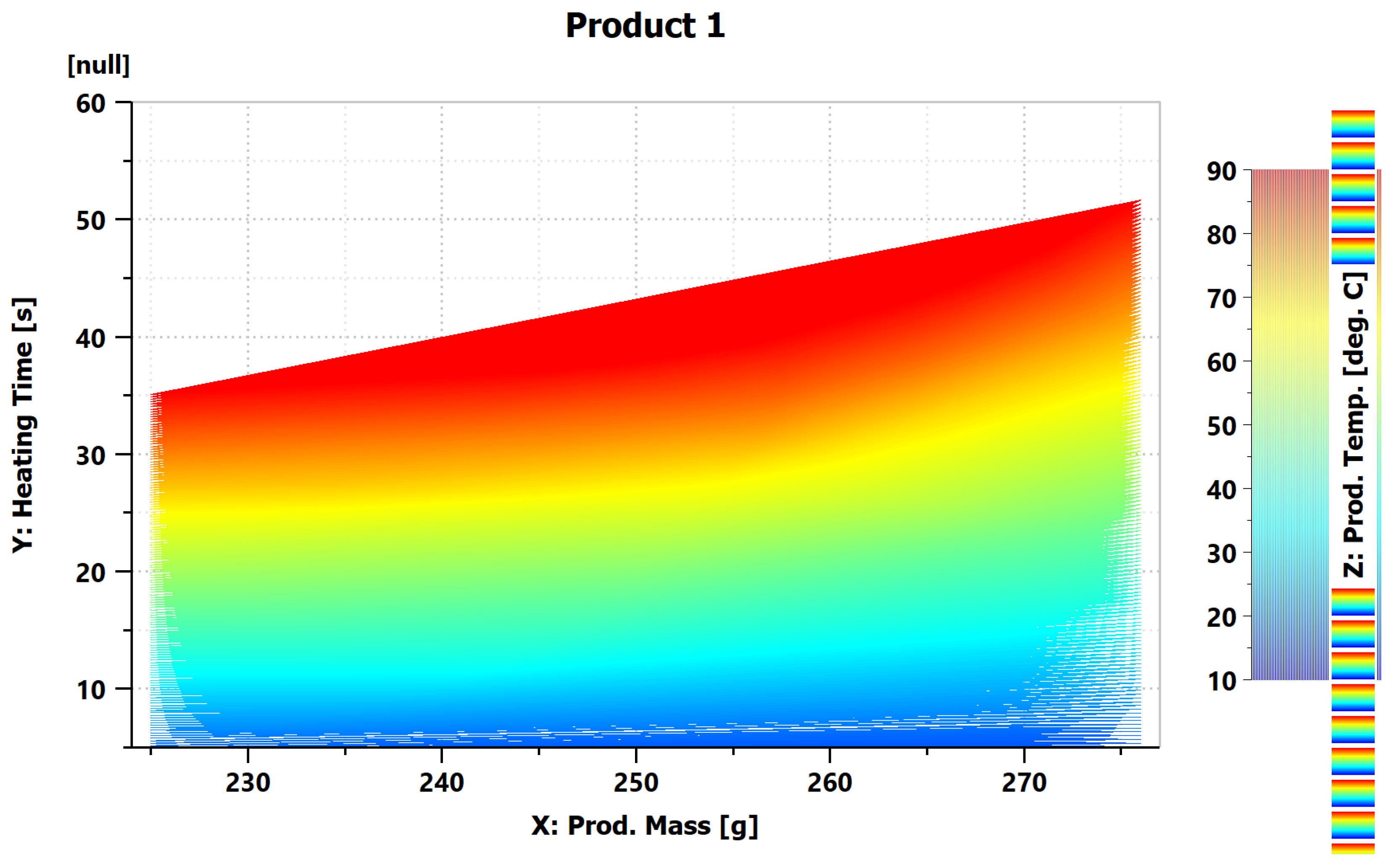

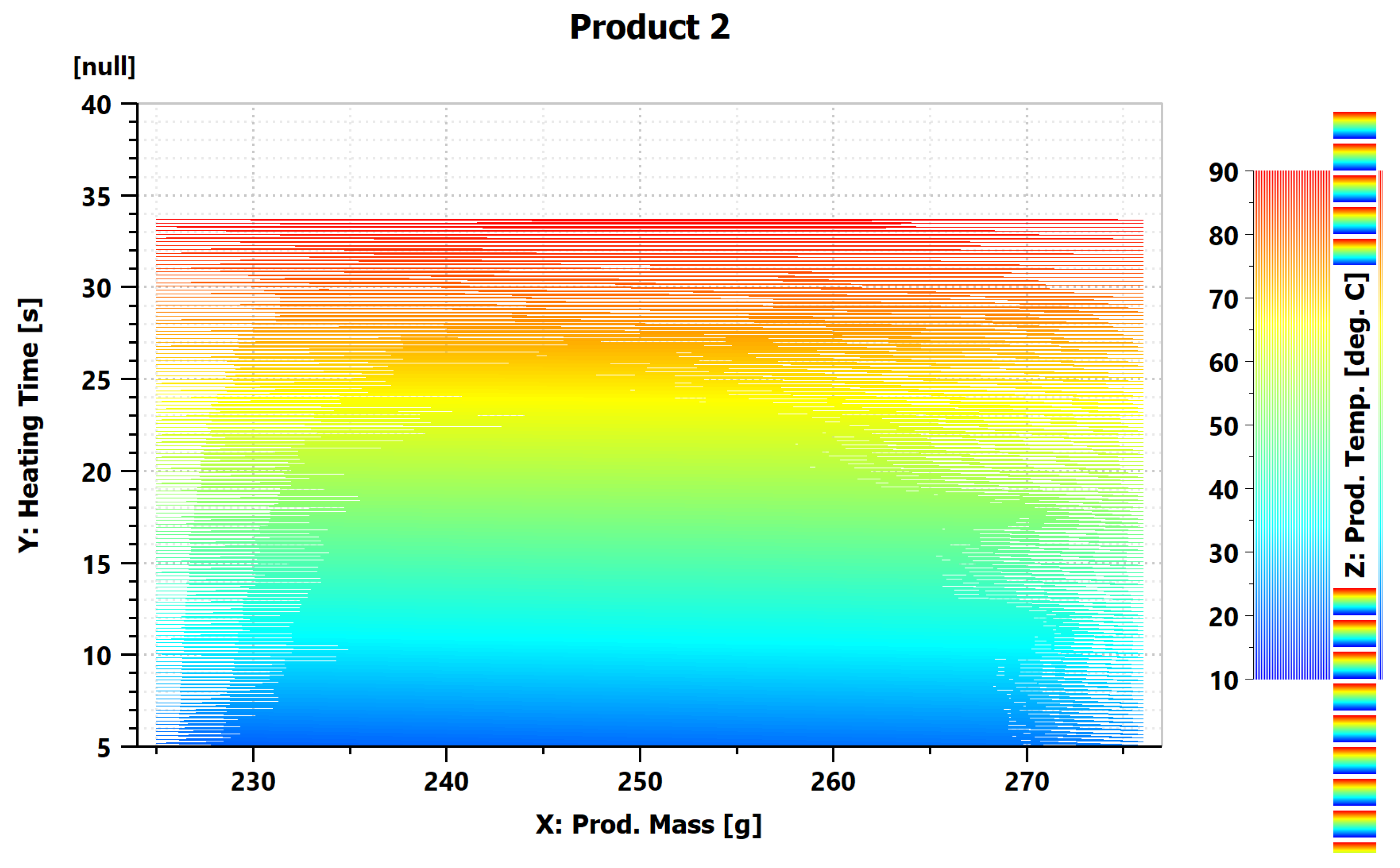

3.2. Neural Network Controller

4. Discussions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hasan, H.; Faris, M.A.-I.E.; Mohamad, M.N.; Al Dhaheri, A.S.; Hashim, M.; Stojanovska, L.; Al Daour, R.; Rashid, M.; El-Farra, L.; Alsuwaidi, A.; et al. Consumption, Attitudes, and Trends of Vending Machine Foods at a University Campus: A Cross-Sectional Study. Foods 2021, 10, 2122. [Google Scholar] [CrossRef] [PubMed]

- Anker. How Can Solar Powered Vending Machines Help Get More Profit? Available online: https://www.anker.com/blogs/solar/solar-powered-vending-machines (accessed on 20 July 2023).

- EcoFriend. Solar Energy Powers Awesome Vending Machines. Available online: https://ecofriend.com/solar-energy-powers-awesome-vending-machines.html (accessed on 20 July 2023).

- Research and Markets. Intelligent Vending Machines: Global Strategic Business Report. Available online: https://www.researchandmarkets.com/reports/3301146/intelligent-vending-machines-global-strategic?gclid=EAIaIQobChMI8pqNmdrogAMVxepRCh08qALVEAAYASAAEgIz8vD_BwE#product--toc (accessed on 20 July 2023).

- EU Green Public Procurement Criteria for Food, Catering Services and Vending Machines. Available online: https://circabc.europa.eu/ui/group/44278090-3fae-4515-bcc2-44fd57c1d0d1/library/9cd7f542-d33c-43f6-91af-b3838c08c395/details (accessed on 20 July 2023).

- Zhou, X.; Pedrow, P.D.; Tang, Z.; Bohnet, S.; Sablani, S.S.; Tang, J. Heating performance of microwave ovens powered by magnetron and solid-state generators. Innov. Food Sci. Emerg. Technol. 2023, 83, 103240. [Google Scholar] [CrossRef]

- Datta, A.K. Porous media approaches to studying simultaneous heat and mass transfer in food processes. I: Problem formulations. J. Food Eng. 2007, 80, 80–95. [Google Scholar] [CrossRef]

- Verma, D.K.; Mahanti, N.K.; Thakur, M.; Chakraborty, S.; Srivastav, P.P. Microwave Heating: Alternative Thermal Process Technology for Food Application. In Emerging Thermal and Nonthermal Technologies in Food Processing; Apple Academic Press: Palm Bay, FL, USA, 2020. [Google Scholar] [CrossRef]

- Li, J.; Xiong, Q.; Wang, K.; Shi, X.; Liang, S.; Gao, M. Temperature Control During Microwave Heating Process by Sliding Mode Neural Network. Dry. Technol. 2015, 34, 215–226. [Google Scholar] [CrossRef]

- Lee, S.; Cho, S.; Kim, S.-H.; Kim, J.; Chae, S.; Jeong, H.; Kim, T. Deep Neural Network Approach for Prediction of Heating Energy Consumption in Old Houses. Energies 2021, 14, 122. [Google Scholar] [CrossRef]

- Nabipour, M.; Nayyeri, P.; Jabani, H.; Mosavi, A.; Salwana, E.; Shahab, S. Deep Learning for Stock Market Prediction. Entropy 2020, 22, 840. [Google Scholar] [CrossRef]

- Chen, C.R.; Ramaswamy, H.S. Analysis of critical control points in deviant thermal processes using artificial neural networks. J. Food Eng. 2003, 57, 225–235. [Google Scholar] [CrossRef]

- Kollia, I.; Stevenson, J.; Kollias, S. AI-Enabled Efficient and Safe Food Supply Chain. Electronics 2021, 10, 1223. [Google Scholar] [CrossRef]

- Sharma, S.; Gahlawat, V.K.; Rahul, K.; Mor, R.S.; Malik, M. Sustainable Innovations in the Food Industry through Artificial Intelligence and Big Data Analytics. Logistics 2021, 5, 66. [Google Scholar] [CrossRef]

- Calota, R.; Savaniu, M.; Girip, A.; Nastase, I.; Georgescu, M.R.; Tonciu, O. Study on Energy Efficiency of an Off-Grid Vending Machine with Compact Heat Exchangers and Low GWP Refrigerant Powered by Solar Energy. Energies 2022, 15, 4433. [Google Scholar] [CrossRef]

- Culcea, M.; Darie, E.; Gheorghe, S.; Pecsi, R.; Savaniu, M.I. The influence of a DC-AC inverter used in a stand-alone vending machine equipped with photovoltaic panels. In IOP Conference Series: Earth and Environmental Science, Proceedings of the 8th Conference of the Sustainable Solutions for Energy and Environment EENVIRO 2022, Bucharest, Romania, 16–21 October 2022; IOP Publishing Ltd.: Bristol, UK, 2023; Volume 1185. [Google Scholar] [CrossRef]

- Calotă, R.; Girip, A.; Ilie, A.; Glavă, G.; Savaniu, M. Study on the heat transfer with regard to an off-grid vending machine having a low impact on the environment. In IOP Conference Series: Earth and Environmental Science, Proceedings of the 8th Conference of the Sustainable Solutions for Energy and Environment EENVIRO 2022, Bucharest, Romania, 16–21 October 2022; IOP Publishing Ltd.: Bristol, UK, 2023; Volume 1185, p. 1185. [Google Scholar] [CrossRef]

- Victron Energy. MPPT Solar Charger Manual; Victron Energy, B.V., Ed.; Victron Energy Manuals Publishing House: Almere, The Netherlands, 2021. [Google Scholar]

- Available online: http://www.chinaxhwb.com/ (accessed on 20 July 2023).

- Available online: https://www.hioki.com/global/products/pqa/power-quality/id_5824 (accessed on 20 July 2023).

- Available online: https://www.hioki.com/global/support/download/software/versionup/detail/id_562 (accessed on 20 July 2023).

- EN 61000-4-30:2009; Electromagnetic Compatibility (EMC)—Part 4-30: Testing and Measurement Techniques—Power Quality Measurement Methods. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2009.

- Zaica, A.; Nedelcu, A.; Ciupercă, R.; Popa, L.; Păun, A.; Lazăr, G.; Ștefan, V.; Petcu, A.; Zaica, A. Theoretical aspects of the aeration drying process with application in the hay technology. Ann. Univ. Craiova—Agric. Mont. Cadastre Ser. 2015, 45, 259–267. [Google Scholar]

- Ikeuchi, D.; Vargas-Uscategui, A.; Wu, X.; King, P.C. Data-Efficient Neural Network for Track Profile Modelling in Cold Spray Additive Manufacturing. Appl. Sci. 2021, 11, 1654. [Google Scholar] [CrossRef]

- Xu, C.; Coen-Pirani, P.; Jiang, X. Empirical Study of Overfitting in Deep Learning for Predicting Breast Cancer Metastasis. Cancers 2023, 15, 1969. [Google Scholar] [CrossRef] [PubMed]

- Alom, M.Z.; Taha, T.M.; Yakopcic, C.; Westberg, S.; Sidike, P.; Nasrin, M.S.; Hasan, M.; Van Essen, B.C.; Awwal, A.A.S.; Asari, V.K. A State-of-the-Art Survey on Deep Learning Theory and Architectures. Electronics 2019, 8, 292. [Google Scholar] [CrossRef]

- Zhang, X.; Xie, F.; Ji, T.; Zhu, Z.; Zheng, Y. Multi-fidelity deep neural network surrogate model for aerodynamic shape optimization. Comput. Methods Appl. Mech. Eng. 2021, 373, 113485. [Google Scholar] [CrossRef]

- Ryu, S.; Noh, J.; Kim, H. Deep Neural Network Based Demand Side Short Term Load Forecasting. Energies 2017, 10, 3. [Google Scholar] [CrossRef]

- Bilal, M.A.; Wang, Y.; Ji, Y.; Akhter, M.P.; Liu, H. Earthquake Detection Using Stacked Normalized Recurrent Neural Network (SNRNN). Appl. Sci. 2023, 13, 8121. [Google Scholar] [CrossRef]

- Huang, C.-J.; Kuo, P.-H. A Deep CNN-LSTM Model for Particulate Matter (PM2.5) Forecasting in Smart Cities. Sensors 2018, 18, 2220. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savaniu, I.M.; Chiriță, A.-P.; Tonciu, O.; Culcea, M.; Neagu, A. Neural-Network-Based Time Control for Microwave Oven Heating of Food Products Distributed by a Solar-Powered Vending Machine with Energy Management Considerations. Energies 2023, 16, 6953. https://doi.org/10.3390/en16196953

Savaniu IM, Chiriță A-P, Tonciu O, Culcea M, Neagu A. Neural-Network-Based Time Control for Microwave Oven Heating of Food Products Distributed by a Solar-Powered Vending Machine with Energy Management Considerations. Energies. 2023; 16(19):6953. https://doi.org/10.3390/en16196953

Chicago/Turabian StyleSavaniu, Ioan Mihail, Alexandru-Polifron Chiriță, Oana Tonciu, Magdalena Culcea, and Ancuta Neagu. 2023. "Neural-Network-Based Time Control for Microwave Oven Heating of Food Products Distributed by a Solar-Powered Vending Machine with Energy Management Considerations" Energies 16, no. 19: 6953. https://doi.org/10.3390/en16196953

APA StyleSavaniu, I. M., Chiriță, A.-P., Tonciu, O., Culcea, M., & Neagu, A. (2023). Neural-Network-Based Time Control for Microwave Oven Heating of Food Products Distributed by a Solar-Powered Vending Machine with Energy Management Considerations. Energies, 16(19), 6953. https://doi.org/10.3390/en16196953