Optimization Analysis on the Transmission Characteristics of Multipurpose Power Transmission Devices

Abstract

:1. Introduction

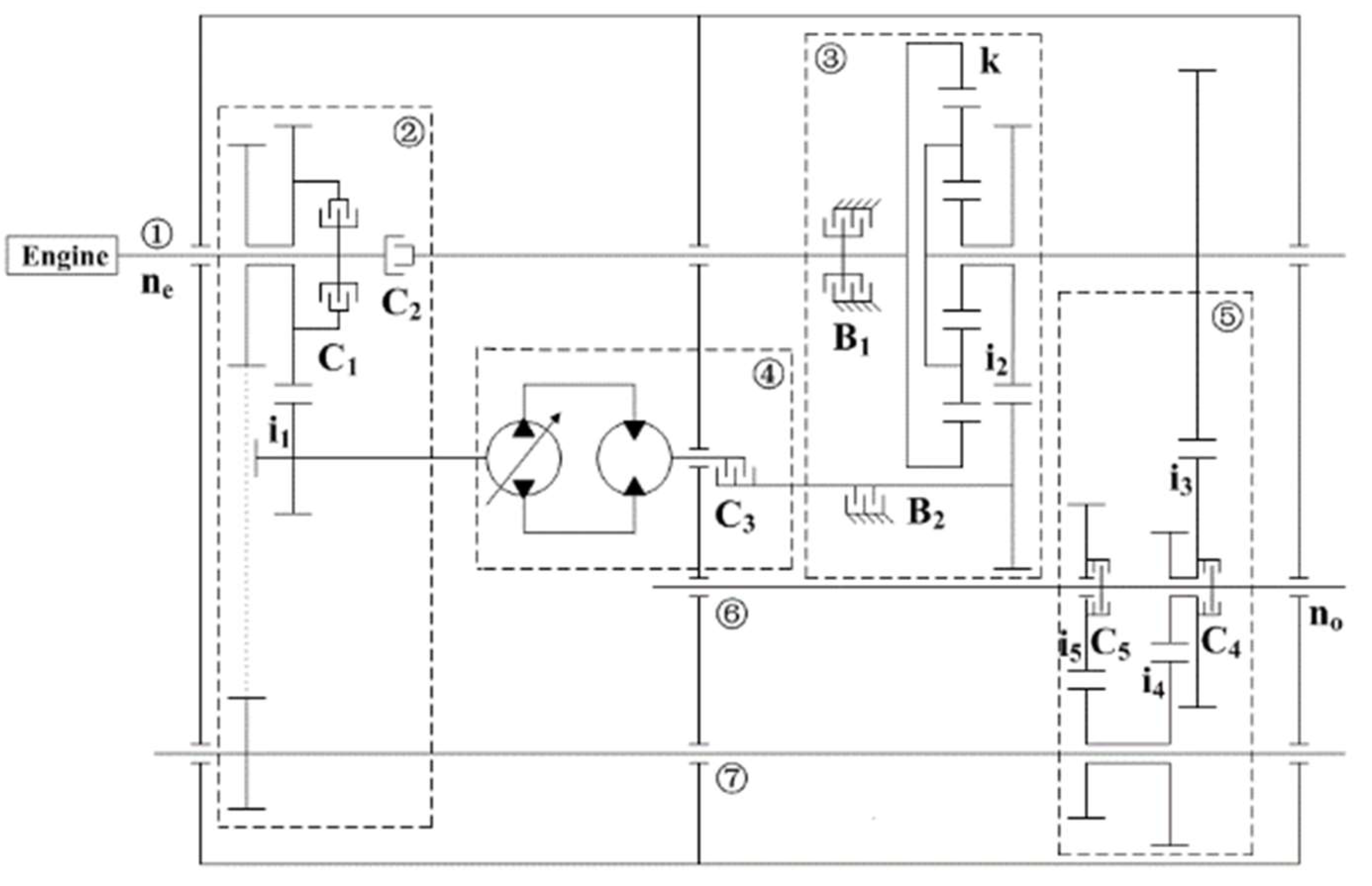

2. Design Scheme of the Multipurpose Power Transmission Device

2.1. Structure Scheme

2.2. Parameters Design

2.2.1. Kinematic and Kinetic Analysis of the Vehicle System

2.2.2. Parameters Analysis of the Hydrostatic System

2.2.3. Transmission Ratio of Each Range

3. Transmission Characteristics of the Multipurpose Power Transmission Device

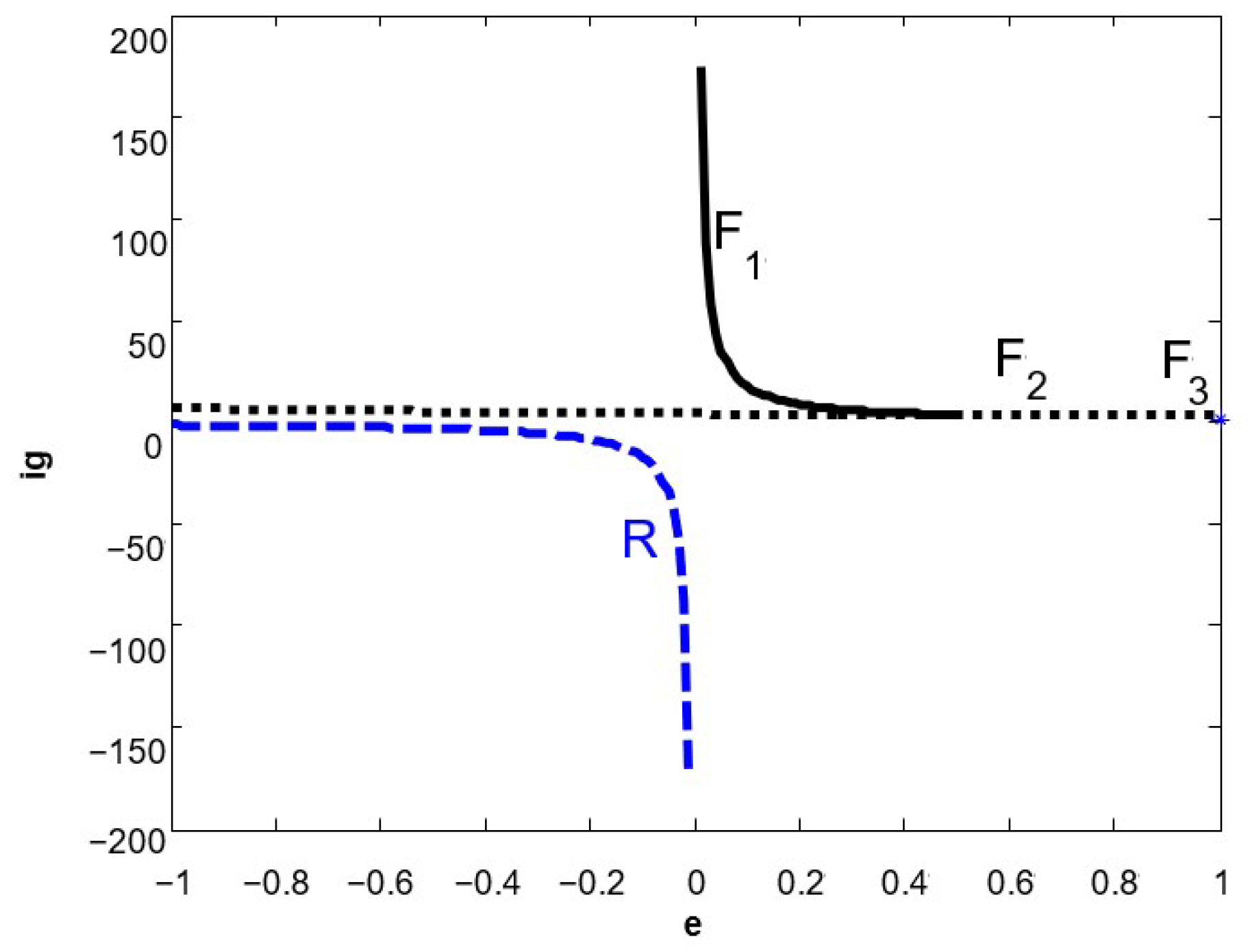

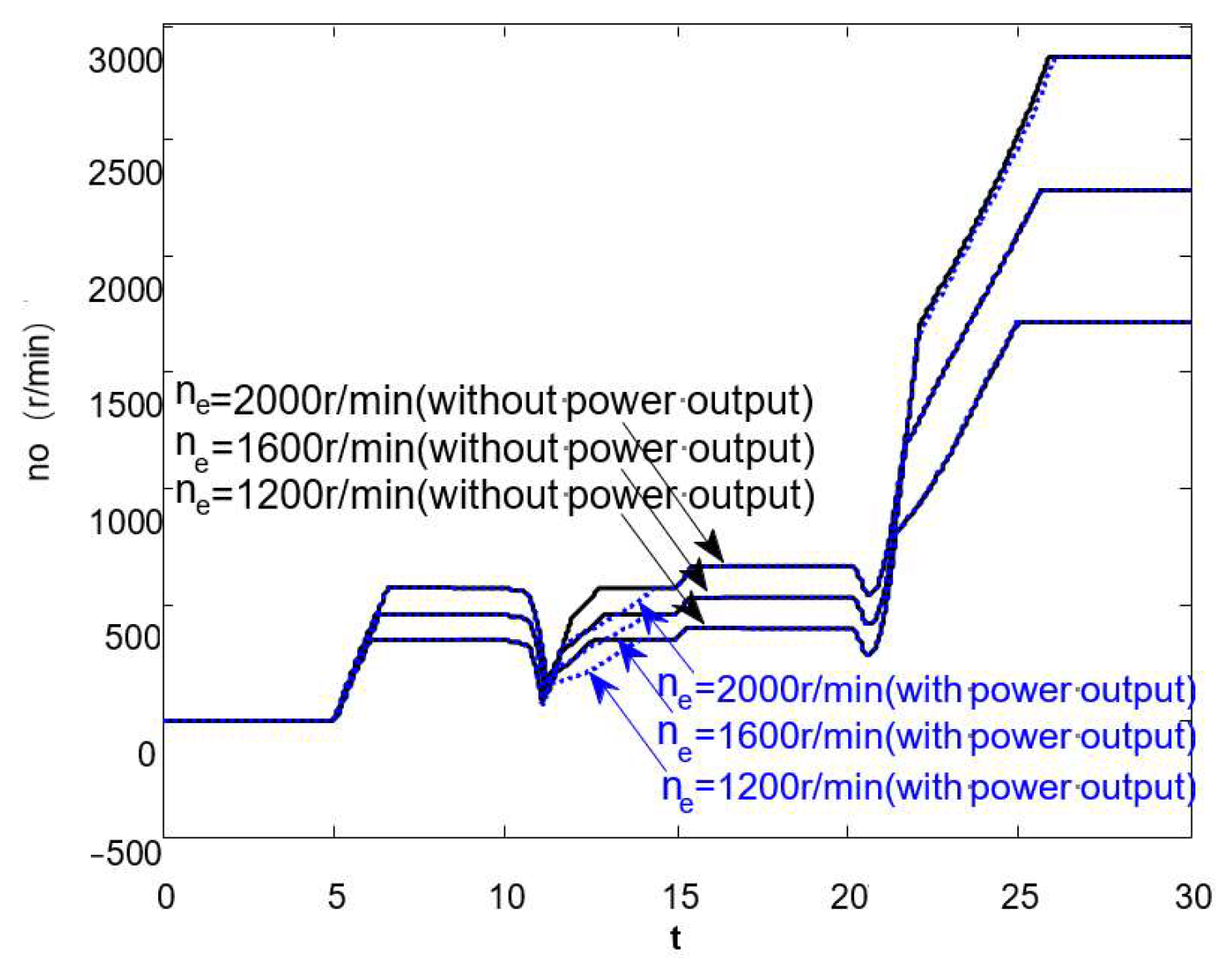

3.1. Speed Regulation Characteristics

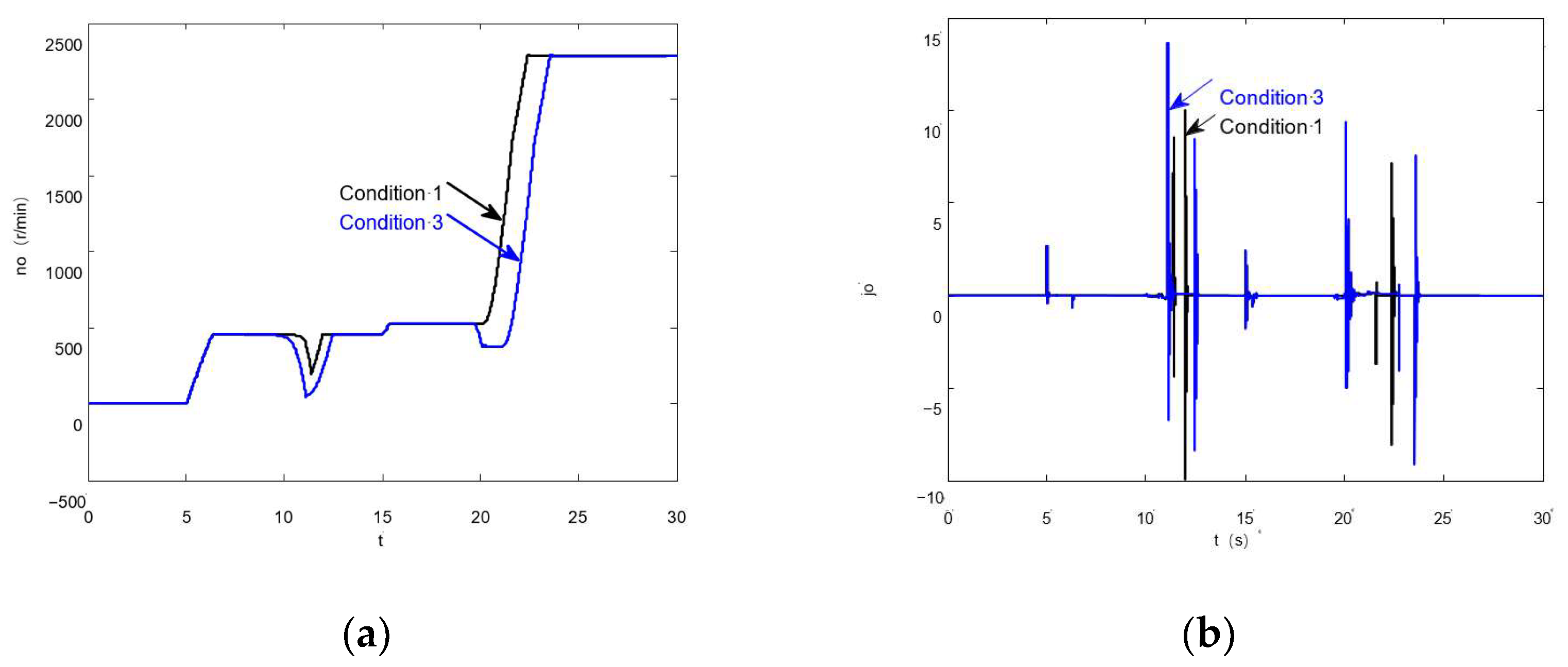

3.2. Shift Characteristic

3.3. Efficiency Characteristic

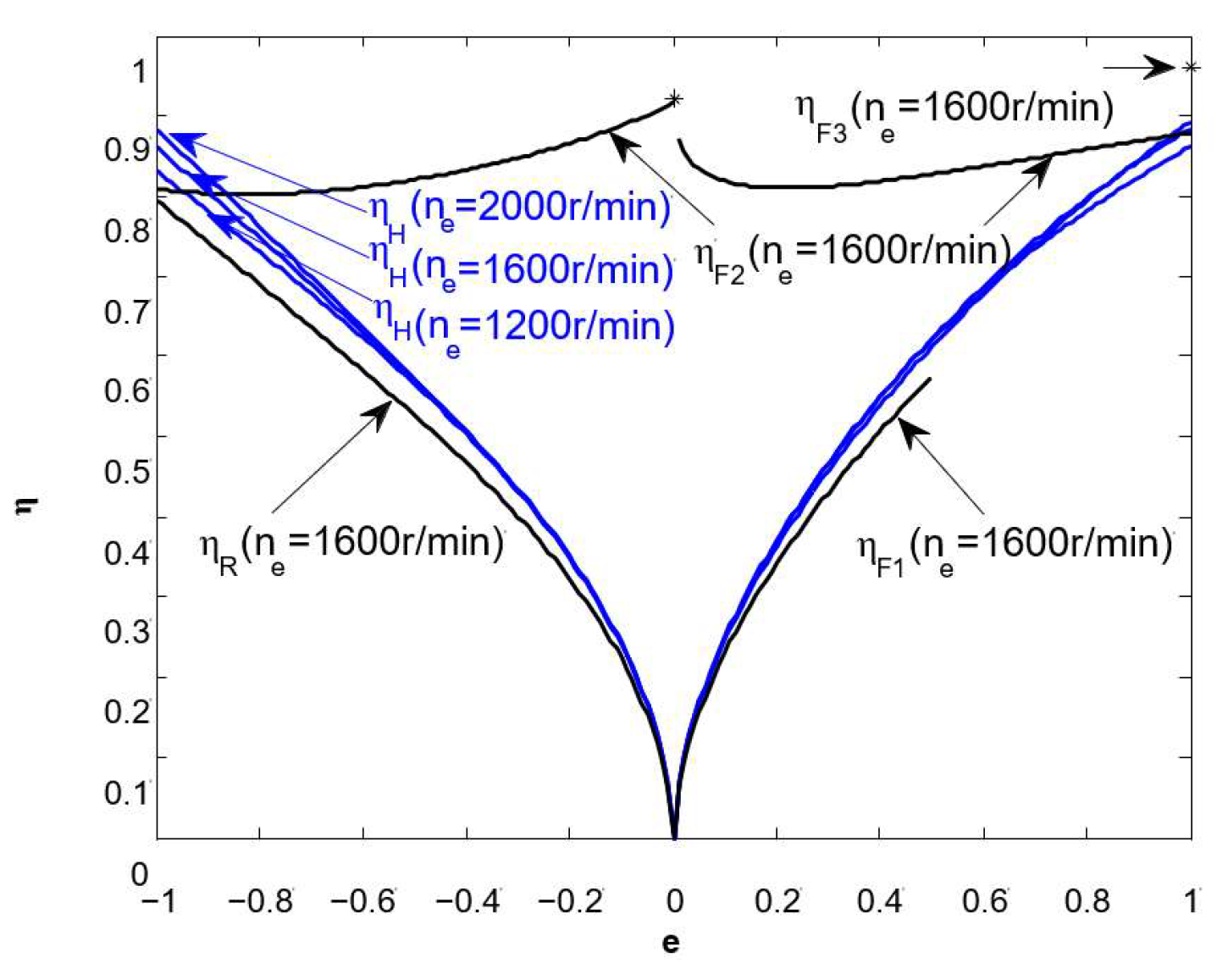

3.3.1. Efficiency Characteristic Analysis Using Empirical Formulas

3.3.2. Efficiency Characteristic Analysis Using Empirical Formulas

4. Conclusions

- (1)

- In this paper, we introduce a multipurpose power transmission device that can realize switching among hydrostatic, hydro-mechanical, and mechanical transmission with clutches and brakes, and the relevant parameters are obtained using kinematic and kinetic analysis for a vehicle system. We also analyze the transmission characteristics of the multipurpose power transmission device, including speed regulation characteristics, shift characteristics, and efficiency characteristics.

- (2)

- The speed regulation characteristics show that the multipurpose power transmission device can realize flexible start using hydrostatic transmission, stepless speed change using hydro-mechanical transmission, and efficient transportation using mechanical transmission. The power output shaft can also output power to drive other mechanisms, which reflects perfect transmission and output characteristics.

- (3)

- The shift strategy shows that shift quality can be improved effectively by controlling the switch sequence of actuators using the orthogonal analysis method. The optimal shift strategy under different conditions should be recorded in the controller to ensure perfect shift quality and excellent transmission performance.

- (4)

- The efficiency characteristic shows that the hydrostatic system possesses preferable efficiency characteristics under the working conditions including larger displacement, higher speed, and medium pressure. Although the hydrostatic transmission efficiency is relatively low, it can realize flexible operation. The mechanical transmission efficiency is relatively high, so it demands much of road conditions, and the hydro-mechanical composite transmission can realize efficiency improvement easily in the scope of higher speed and the whole displacement ratio.

5. Patents

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| total resistance of vehicle operating system () | |

| rolling resistance () | |

| air resistance () | |

| slope resistance () | |

| acceleration resistance () | |

| maximum tangential tractive force () | |

| vehicle gravity () | |

| coefficient of rolling resistance | |

| road slope angle | |

| adhesive force () | |

| adhesion coefficient | |

| transmission ratio of power transmission device | |

| engine speed () | |

| output speed of power transmission device () | |

| displacement ratio | |

| pump displacement () | |

| motor displacement () | |

| vehicle speed () | |

| driving wheel power radius () | |

| transmission ratio of main reducer | |

| transmission ratio of wheel-side reducer | |

| pump speed () | |

| engine torque () | |

| pump torque () | |

| System pressure of the pump () | |

| mechanical efficiency of the pump | |

| transmission ratios of general gears | |

| transmission ratios of forward ranges | |

| transmission ratio of reverse range | |

| characteristic parameter of planet gear | |

| motor torque () | |

| output torque of power transmission device () | |

| severity of braking | |

| time () | |

| oil pressure of main circuit () | |

| flow rate of speed control valve () | |

| shift jerk of intermediate shaft | |

| shift jerk of output shaft | |

| hydraulic fluid kinetic viscosity () | |

| laminar flow leakage coefficient | |

| maximum pressure of pump system () | |

| laminar flow resistance coefficient | |

| mechanical resistance coefficient | |

| pump efficiency | |

| motor efficiency | |

| maximum pressure of pump system () | |

| maximum pressure of motor system () | |

| motor speed () | |

| hydrostatic system efficiency | |

| efficiency of forward ranges | |

| efficiency of general gears | |

| efficiency of planet gear | |

| power loss coefficient of planet gear |

References

- Cai, R.; Zhang, M.; Wang, J.; Jia, F. Analysis of the Influence of Clutch Drag Torque on the Efficiency of Hydro-mechanical Continuously Variable Transmission. J. Mech. Transm. 2022, 46, 63–67+94. [Google Scholar]

- Zhang, M.; Wang, J.; Wang, J.; Guo, Z.; Guo, F.; Xi, Z.; Xu, J. Speed changing control strategy for improving tractor fuel economy. Trans. Chin. Soc. Agric. Eng. 2020, 36, 82–89. [Google Scholar]

- Chung, C.-T.; Wu, C.-H.; Hung, Y.-H. Effects of Electric Circulation on the Energy Efficiency of the Power Split e-CVT Hybrid Systems. Energies 2018, 11, 2342. [Google Scholar] [CrossRef]

- Antonio, R.; Alarico, M. Control strategies for a powertrain with hydro-mechanical transmission. In Proceedings of the 73rd Conference of the Italian Thermal Machines Engineering Association, Pisa, Italy, 12–14 September 2018; Volume 148, pp. 978–985. [Google Scholar]

- Zhang, G.; Wang, K.; Xiao, M.; Zhou, M. HMCVT Steady State Transmission Efficiency Based on HST-EGT Torque Ratio. Trans. Chin. Soc. Agric. Mach. 2021, 52 (Suppl. S1), 533–541. [Google Scholar]

- Li, J.; Zhao, Y.; Zhai, Z.; Han, B.; Du, Y.; Wang, L.; Zhu, Z. Research on Design and Analysis Method of the Double Planetary HMCVT Based on High Efficiency Transmission. Agriculture 2022, 12, 1958. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, D.; Sun, X.; Zeng, L.; Cai, Y.; Chen, L. Configuration analysis of hydro-mechanical composite transmission devices. J. Jilin Univ. (Eng. Technol. Ed.) 2022, 52, 2265–2277. [Google Scholar]

- Cao, J.; Peng, J.; He, H. Modeling and Simulation Research on Power-split Hybrid Electric Vehicle. Energy Procedia 2016, 104, 354–359. [Google Scholar] [CrossRef]

- Zhu, Z. Optimization Research on the Performance of Hydro-Mechanical Continuously Variable Transmission. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2016. [Google Scholar]

- Shamshirband, S.; Petkovic, D.; Amini, A.; Anuar, N.B.; Nikolic, V.; Cojbasic, Z.; Mat Kiah, M.L.; Gani, A. Support vector regression methodology for wind turbine reaction torque prediction with power-split hydrostatic continuous variable transmission. Energy 2014, 67, 623–630. [Google Scholar] [CrossRef]

- Rossetti, A.; Macor, A.; Benato, A. Impact of control strategies on the emissions in a city bus equipped with power-split transmission. Transp. Res. Part D 2017, 50, 357–371. [Google Scholar] [CrossRef]

- Xiang, Y.; Li, R.; Brach, C.; Liu, X.; Geimer, M. A Novel Algorithm for Hydrostatic-Mechanical Mobile Machines with a Dual-Clutch Transmission. Energies 2022, 15, 2095. [Google Scholar] [CrossRef]

- Zhu, Z.; Gao, X.; Pan, D. Hydro-Mechanical Double Power-Flow Composite Transmission Gearbox with Single Planetary Confluence Mechanism. China Patent CN201410337988.0, 16 July 2014. [Google Scholar]

- Abdollahi, E.; Wang, H.; Lahdelma, R. An optimization method for multi-area combined heat and power production with power transmission network. Appl. Energy 2016, 168, 248–256. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, Z.; Zhang, T.; Li, M. Mode transition coordinated control for a compound power-split hybrid car. Mech. Syst. Signal Process. 2017, 87, 192–205. [Google Scholar] [CrossRef]

- Janulevičius, A.; Giedra, K. Analysis of main dynamic parameters of split power transmission. Transport 2008, 23, 112–118. [Google Scholar] [CrossRef]

- Li, J.; Hu, Q. Power Analysis and Efficiency Calculation of the Complex and Closed Planetary Gears Transmission. Energy Procedia 2016, 100, 423–433. [Google Scholar]

- Pennestrì, E.; Mariti, L.; Valentini, P.P.; Mucino, V.H. Efficiency evaluation of gearboxes for parallel hybrid vehicles: Theory and applications. Mech. Mach. Theory 2012, 49, 157–176. [Google Scholar] [CrossRef]

- Montazeri-Gh, M.; Mahmoodi-k, M. Development a new power management strategy for power split hybrid electric vehicles. Transp. Res. Part D 2015, 37, 79–96. [Google Scholar] [CrossRef]

- Zeng, X.; Yang, N.; Wang, J.; Dafeng, S.; Nong, Z.; Mingli, S.; Jianxin, L. Predictive-model-based dynamic coordination control strategy for power-split hybrid electric bus. Mech. Syst. Signal Process. 2015, 60–61, 785–798. [Google Scholar] [CrossRef]

- Liu, Y.; Qin, D.; Jiang, H.; Zhang, Y. Shift control strategy and experimental validation for dry dual clutch transmissions. Mech. Mach. Theory 2014, 75, 41–53. [Google Scholar] [CrossRef]

- Oh, J.J.; Choi, S.B.; Kim, J. Driveline modeling and estimation of individual clutch torque during gear shifts for dual clutch transmission. Mechatronics 2014, 24, 449–463. [Google Scholar] [CrossRef]

- Cao, F. Study on Hydro-Mechanic Differential Turning Performance Analysis and parameters Matching of Tracked Vehicle. Ph.D. Thesis, Xi’an University of Technology, Xi’an, China, 2009. [Google Scholar]

- Zhang, L.; Yang, S.; Li, X.; Han, B.; Pang, Y. Research on kinematic characteristics of two-stage hydro-mechanical continuously variable transmission mechanism. Chin. J. Eng. Des. 2021, 28, 268–277. [Google Scholar]

- Wang, G.; Zhu, S.; Shi, L.; Ni, X.; Ruan, W.; Ouyang, D. Simulation and experiment on efficiency characteristics of hydraulic mechanical continuously variable transmission for tractor. Trans. Chin. Soc. Agric. Eng. 2013, 29, 42–48. [Google Scholar]

- Zhu, Z.; Gao, X.; Pan, D.; Xia, C.; Shang, G.; Han, J. Efficiency Test Bench of Electro-Hydraulic Proportional Pump Motor Control System. China Patent CN201410405732.9, 18 August 2014. [Google Scholar]

- Zhu, Z.; Gao, X.; Pan, D.; Xia, C.; Shang, G.; Han, J. Test Bench of Hydro-Mechanical Continuously Variable Transmission. China Patent CN201410330354.2, 11 July 2014. [Google Scholar]

- Do, H.T.; Park, H.G.; Ahn, K.K. Application of an adaptive fuzzy sliding mode controller in velocity control of a secondary controlled hydrostatic transmission system. Mechatronics 2014, 24, 1157–1165. [Google Scholar] [CrossRef]

- Macor, A.; Rossetti, A. Optimization of hydro-mechanical power split transmissions. Mech. Mach. Theory 2011, 46, 1901–1919. [Google Scholar] [CrossRef]

- Yang, Y.; Hu, X.; Pei, H. Comparison of power-split and parallel hybrid powertrain architectures with a single electric machine: Dynamic programming approach. Appl. Energy 2016, 168, 683–690. [Google Scholar] [CrossRef]

- Ivanov, K.; Gonzalez-Cruz, C.A.; Ceccarelli, M.; Ozhiken, A.K.; Cafolla, D. Design and Experiences of a Planetary Gear Box for Adaptive Drives. In EuCoMeS 2018. Mechanisms and Machine Science; Corves, B., Wenger, P., Hüsing, M., Eds.; Springer: Cham, Switzerland, 2019; Volume 59. [Google Scholar]

| Range | C1 | C2 | C3 | C4 | C5 | B1 | B2 |

|---|---|---|---|---|---|---|---|

| F1 | ● | ● | ● | ● | |||

| F2 | ● | ● | ● | ● | |||

| F3 | ● | ● | ● | ● | |||

| R | ● | ● | ● |

| Ground | ||||

|---|---|---|---|---|

| Clay soil | 0.02~0.05 | 0.67~0.72 | 0.36~0.39 | 0.67~0.72 |

| Sandy loam | 0.03~0.06 | 0.48~0.52 | 0.37~0.40 | 0.48~0.52 |

| Grass | 0.07~0.08 | 0.38~0.43 | 0.41~0.42 | 0.38~0.43 |

| Farmland | 0.10~0.12 | 0.68~0.74 | 0.44~0.46 | 0.68~0.74 |

| t | 0–5 | 5–10 | 10–15 | 15–20 | 20–25 | 25–30 |

|---|---|---|---|---|---|---|

| e | 0 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 |

| Range | F1 | F1 | F2 | F2 | F3 | F3 |

| Shift Components | C1 (J) | C2 (J) | C4 (J) | C5 (J) | B1 (J) | B2 (J) |

|---|---|---|---|---|---|---|

| Condition 1 | 5216 | 84,531 | 55,332 | 8573 | 1140 | 7678 |

| Condition 2 | 5366 | 45,106 | 52,610 | 5011 | 1034 | 6346 |

| Condition 3 | 6095 | 44,709 | 57,042 | 3082 | 1011 | 1773 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Zhang, Q.; Chen, L.; Tian, X.; Cai, Y. Optimization Analysis on the Transmission Characteristics of Multipurpose Power Transmission Devices. Energies 2023, 16, 6989. https://doi.org/10.3390/en16196989

Zhu Z, Zhang Q, Chen L, Tian X, Cai Y. Optimization Analysis on the Transmission Characteristics of Multipurpose Power Transmission Devices. Energies. 2023; 16(19):6989. https://doi.org/10.3390/en16196989

Chicago/Turabian StyleZhu, Zhen, Qinbo Zhang, Long Chen, Xiang Tian, and Yingfeng Cai. 2023. "Optimization Analysis on the Transmission Characteristics of Multipurpose Power Transmission Devices" Energies 16, no. 19: 6989. https://doi.org/10.3390/en16196989

APA StyleZhu, Z., Zhang, Q., Chen, L., Tian, X., & Cai, Y. (2023). Optimization Analysis on the Transmission Characteristics of Multipurpose Power Transmission Devices. Energies, 16(19), 6989. https://doi.org/10.3390/en16196989