Primary Energy Resources and Environmental Impacts of Various Heating Systems Based on Life Cycle Assessment

Abstract

:1. Introduction

1.1. Research Background

1.2. The Literature Review

1.3. Research Aims

2. Materials and Methods

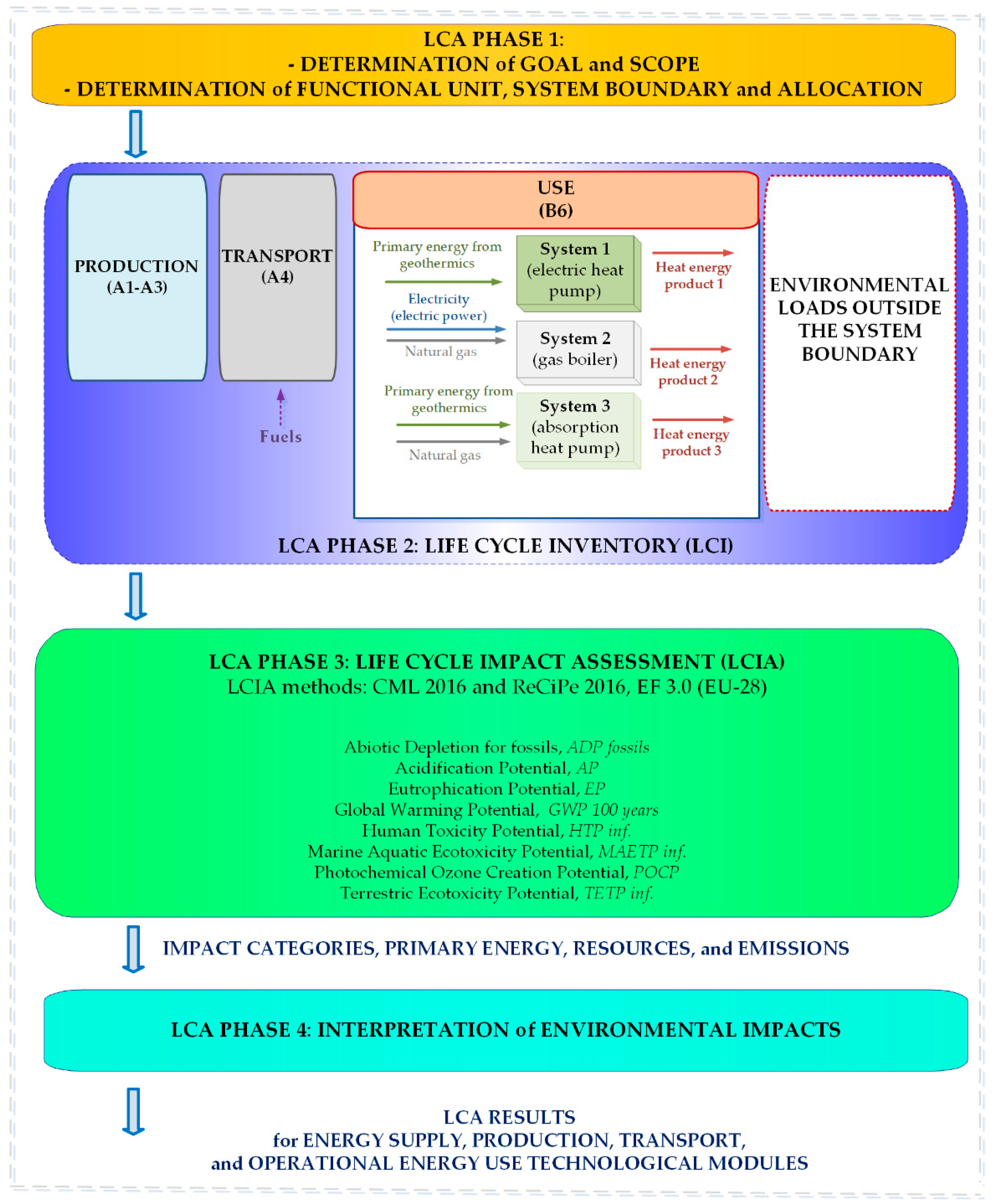

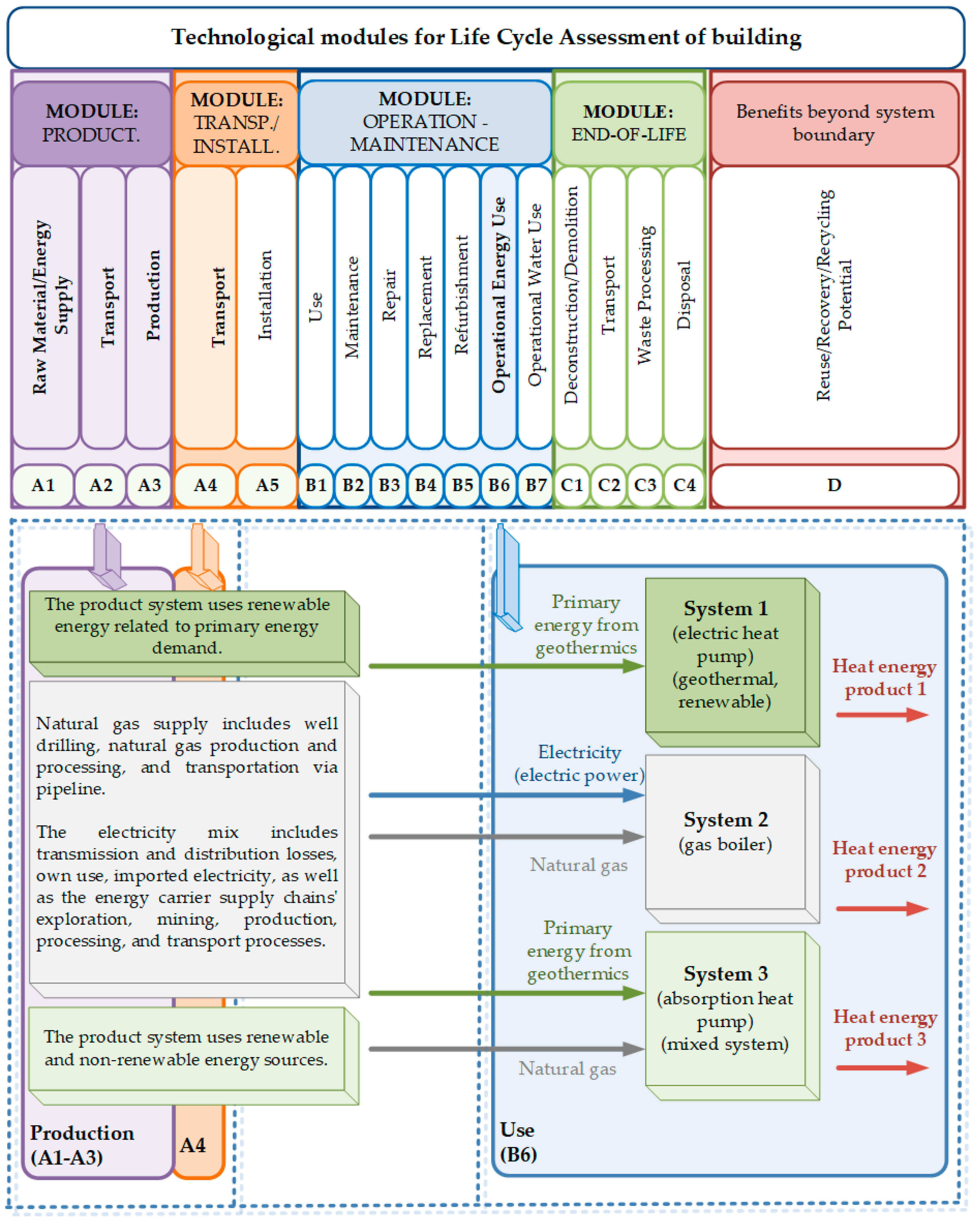

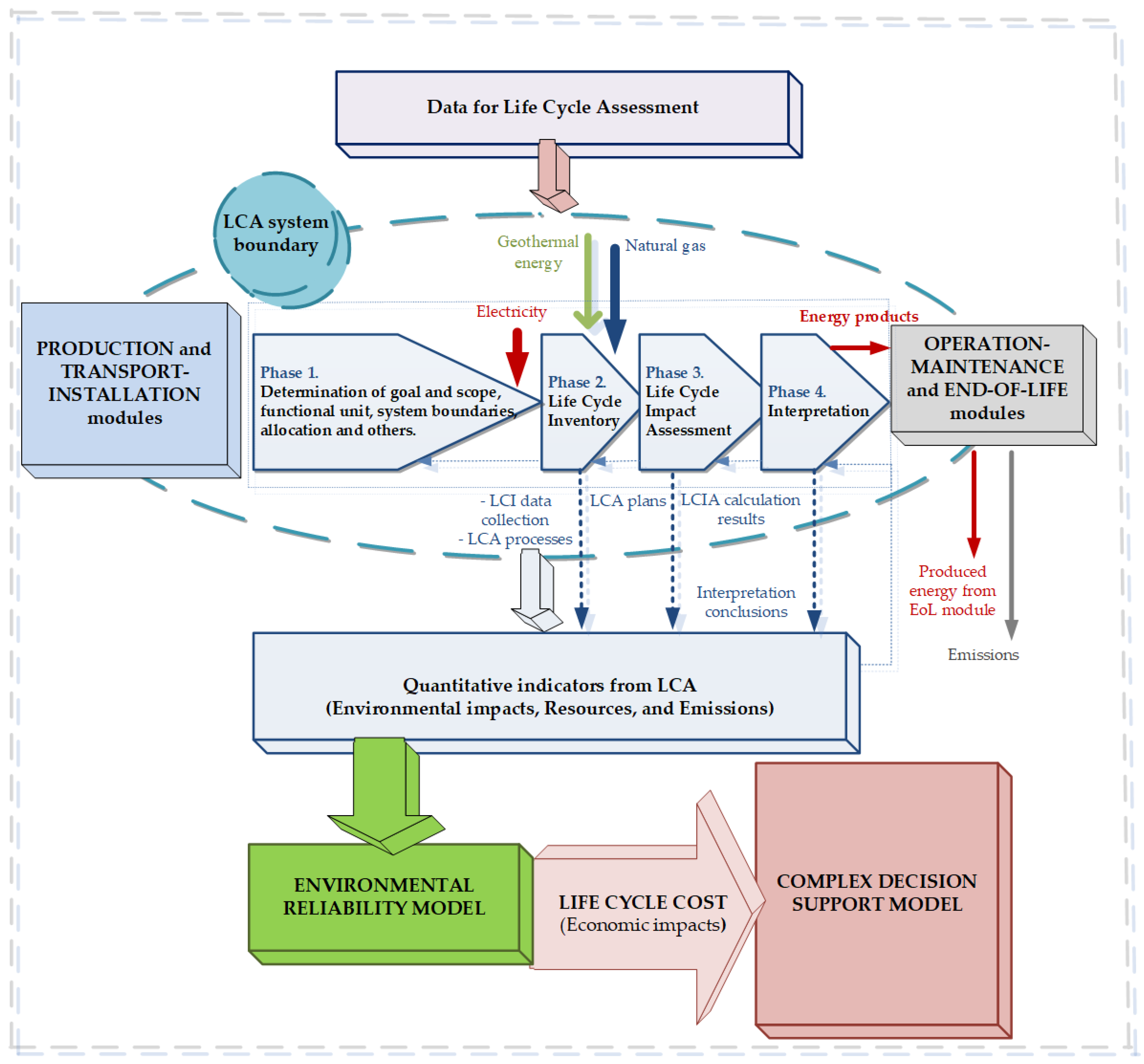

2.1. Life Cycle Assessment Method and System Boundary

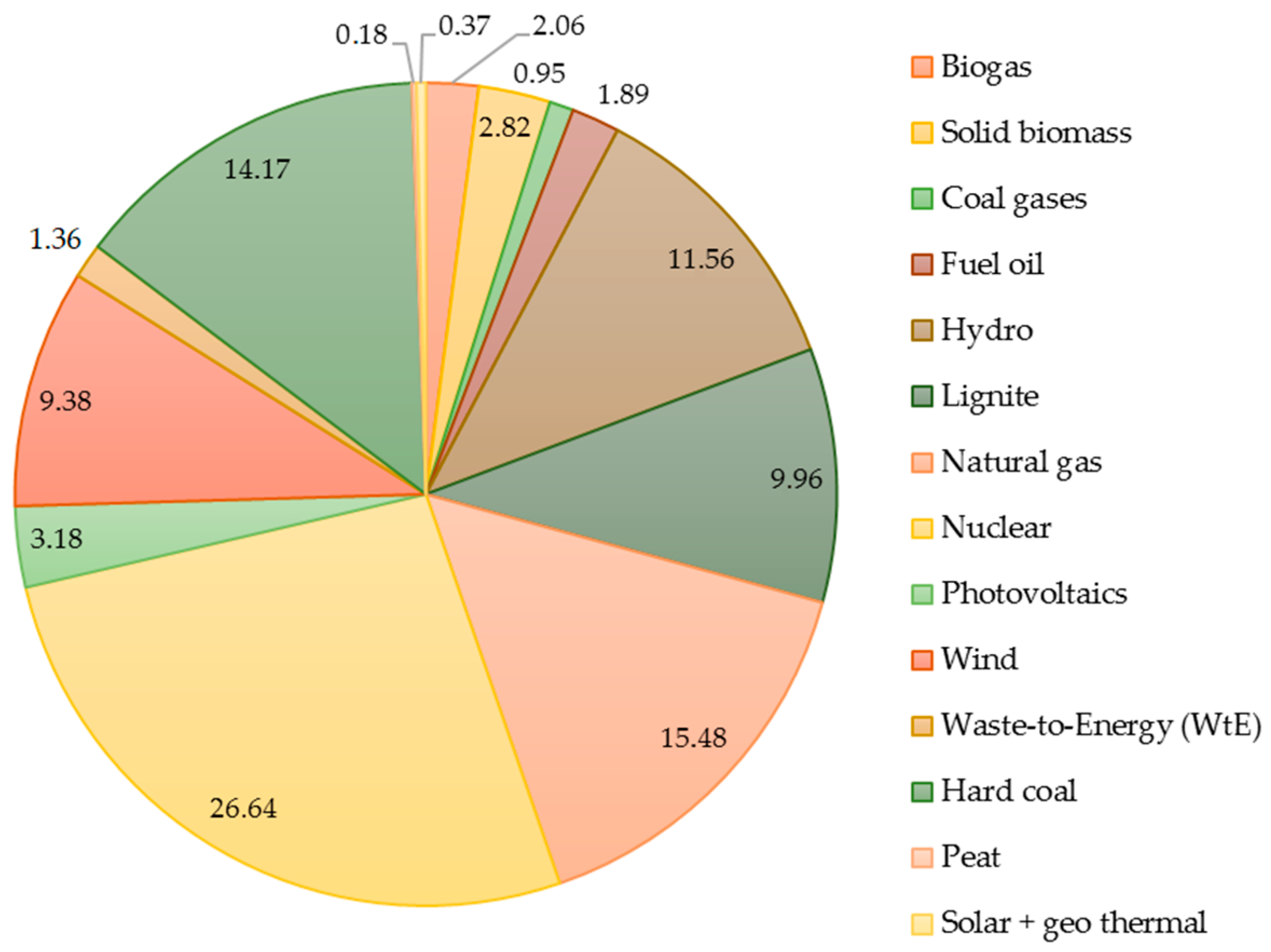

2.2. Life Cycle Inventory and Functional Unit

2.3. Life Cycle Impact Assessment Method

2.4. Empirical Method for the Development of an Environmental Reliability Model

- Production module: The composition of the individual system elements and material components is crucial. The LCA can be more precise by considering each system unit’s exact place of origin.

- Transport–installation module: To determine the environmental loads, it is advisable to assess the energy demand and environmental impact of the materials used for transporting, installing, and assembling the thermal system units. This includes considering the packaging and subsequent waste. Conducting a life cycle assessment and specifying the distance, utilization, and method of transportation is advisable. It is recommended to design the most optimal heating system.

- Operational module: During the operational phase, it is crucial to prioritize the energy consumption of the thermal units. It is recommended to minimize the amount of energy being consumed. Modern types of heat generation equipment today include gas-condensing boilers and renewable-energy-based heat production. In terms of heat exchange surfaces, heating surfaces with lower temperatures offer energy-efficient heating. For this module, it is advisable to use a computerized building management system (BMS). A BMS automatically controls and monitors heating systems, security systems, electrical units, and other BMSs, reducing energy costs. A building monitoring system enables checking the entire building from a single point. With well-planned building management, higher energy efficiency, lower operating costs, improved comfort, and increased productivity can be achieved.

- Maintenance module: Facility management services related to buildings are now more emphasized, particularly in building maintenance, energy management, and work-related services. It is recommended to perform major maintenance on heating technology once a year. All entrances and exits of an apartment or building must be thoroughly inspected. During the life cycle of a building, the components of the thermal system may need to be repaired and replaced multiple times. This implies that purchasing, transporting, installing, and replacing worn-out materials and components require energy. The discarded units or elements create an environmental burden as waste, which is managed at the end of their lifecycle. The use of a BMS is also recommended for this module.

- End-of-life module: If the examined system boundaries are well defined, a more accurate life cycle inventory and impact assessment can be established for the end-of-life stage. This module primarily consists of either landfilling or processing.

2.5. Theoretical Method for the Development of a Complex Decision-Support Model

3. Results

4. Discussion

5. Conclusions

- .

- The emissions associated with the use of electricity and natural gas can be reduced by changing the composition of the electricity grid and the source of natural gas.

- .

- The impacts of energy transport can be reduced by using low-emission transportation methods.

- .

- Greenhouse gas emissions and acidification can be reduced by modifying the procedures for manufacturing the materials required for ground heat exchange pipes and improving the method of transporting dust from drilling operations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ADPE | Abiotic depletion potential for elements |

| ADPF | Abiotic depletion potential for fossils |

| AP | Acidification potential |

| ASHP | Air-source heat pump |

| CE | Circular economy |

| CGB | Condensing gas boiler |

| EAHX | Earth-to-air heat pump |

| EGD | European Green Deal |

| EP | Eutrophication potential |

| EU | European Union |

| FAETP | Freshwater aquatic ecotoxicity potential |

| GSHP | Groundsource heat pump |

| GWP | Global warming potential |

| HTP | Human toxicity potential |

| HVAC | Heating, ventilation, and air conditioning |

| LCA | Life cycle assessment |

| LCI | Life cycle inventory |

| LCIA | Life cycle impact assessment |

| MAETP | Marine aquatic ecotoxicity potential |

| nZEB | Nearly zero-energy building |

| POCP | Photochemical ozone creation potential |

| SDGs | Sustainable development goals |

| TETP | Terrestrial ecotoxicity potential |

| WSHP | Water-source heat pump |

References

- The Global Risks Report 2020; The World Economic Forum: Geneva, Switzerland, 2020; Available online: https://www.weforum.org/reports/the-global-risks-report-2020 (accessed on 15 October 2021).

- Santamouris, M.; Vasilakopoulou, K. Present and future energy consumption of buildings: Challenges and opportunities towards decarbonization. e-Prime-Adv. Electr. Eng. Electron. Energy 2021, 1, 100002. [Google Scholar] [CrossRef]

- Moran, P.; O’Connell, J.; Goggins, J. Sustainable energy efficiency retrofits as residenial buildings move towards nearly zero energy building (NZEB) standards. Energy Build. 2020, 211, 109816. [Google Scholar] [CrossRef]

- Dodd, N.; Cordella, M.; Traverso, M.; Donatello, S. JRC Technical Reports: Level(s)—A Common EU Framework of Core Sustainability Indicators for Office and Residential Buildings Part 3. European Commission Joint Research Centre, Luxembourg. 2017. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC109286 (accessed on 3 January 2018).

- Moran, P.; Goggins, J.; Hajdukiewicz, M. Super-insulate or use renewable technology? Life cycle cost, energy and global warming potential analysis of nearly zero energy buildings (NZEB) in a temperate oceanic climate. Energy Build. 2017, 139, 590–607. [Google Scholar] [CrossRef]

- Impact Assessment Report 2021: Accompanying the Proposal for a Directive of the European Parliament and of the Council on Energy Efficiency (Recast); Commission staff working document, SWD (2021b), 623 final; European Commission: Brussels, Belgium. 2021. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:daf643a4-5da2-11ec-9c6c-01aa75ed71a1.0001.02/DOC_1&format=PDF (accessed on 15 December 2021).

- Emissions Gap Report 2022: The Closing Window—Climate Crisis Calls for Rapid Transformation of Societies. United Nations; Environment Programme (UNEP): Nairobi, Kenya, 2022; Available online: https://www.unep.org/resources/emissions-gap-report-2022 (accessed on 22 October 2022).

- Pintanel, M.T.; Martinez-Gracia, U.H.; del Amo, A.; Bayod-Rújula, Á.; Uson, S.; Arauso, I. Energy and environmental benefits of an integrated solar photovoltaic and thermal hybrid, seasonal storage and heat pump system for social housing. Appl. Therm. Eng. 2022, 213, 118662. [Google Scholar] [CrossRef]

- Hunter, A.K. Comparative Life Cycle Assessment: Ground source heat pump system versus gas furnace and air conditioner system. 2017.

- Rodríguez, J.; Bangueses, I.; Castro, M. Life cycle analysis of a geothermal heatpump installation and comparison with a conventional fuel boiler system in a nursery school in Galicia (Spain). In Proceedings of the EPJ Web of Conferences, Berlin, Germany, 10–15 August 2012; Volume 33, p. 05003. [Google Scholar] [CrossRef]

- Huang, B.; Mauerhofer, V. Life cycle sustainability assessment of ground source heat pump in Shanghai, China. J. Clean. Prod. 2016, 119, 207–214. [Google Scholar] [CrossRef]

- Michopoulos, A.; Voulgari, V.; Tsikaloudaki, A.; Zachariadis, T. Evaluation of ground source heat pump systems for residential buildings in warm Mediterranean regions: The example of Cyprus. Energy Effic. 2016, 9, 1421–1436. [Google Scholar] [CrossRef]

- Bristow, D.; Kennedy, C.A. Potential of building-scale alternative energy to alleviate risk from the future price of energy. Energy Policy 2010, 38, 1885–1894. [Google Scholar] [CrossRef]

- Saner, D.; Juraske, R.; Kübert, M.; Blum, P.; Hellweg, S.; Bayer, P. Is it only CO2 that matters? A life cycle perspective on shallow geothermal systems. Renew. Sustain. Energy Rev. 2010, 14, 1798–1813. [Google Scholar] [CrossRef]

- Tariq, S.; Safder, U.; Yoo, C. Exergy-based weighted optimization and smart decision-making for renewable energy systems considering economics, reliability, risk, and environmental assessments. Renew. Sustain. Energy Rev. 2022, 162, 112445. [Google Scholar] [CrossRef]

- Milousi, M.; Pappas, A.; Vouros, A.P.; Mihalakakou, G.; Souliotis, M.; Papaefthimiou, S. Evaluating the Technical and Environmental Capabilities of Geothermal Systems through Life Cycle Assessment. Energies 2022, 15, 5673. [Google Scholar] [CrossRef]

- Greco, A.; Gundabattini, E.; Solomon, D.G.; Singh Rassiah, R.; Masselli, C. A Review on Geothermal Renewable Energy Systems for Eco-Friendly Air-Conditioning. Energies 2022, 15, 5519. [Google Scholar] [CrossRef]

- Clark, C.; Sullivan, J.; Harto, C.; Han, J.; Wang, M. Life cycle environmental impacts of geothermal systems. In Proceedings of the 37th Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 30 January–1 February 2012. [Google Scholar]

- Martínez-Corona, J.I.; Gibon, T.; Hertwich, E.G.; Parra-Saldívar, R. Hybrid life cycle assessment of a geothermal plant: From physical to monetary inventory accounting. J. Clean. Prod. 2017, 142, 2509–2523. [Google Scholar] [CrossRef]

- Greening, B.; Azapagic, A. Domestic heat pumps: Life cycle environmental impacts and potential implications for the UK. Energy 2012, 39, 205–217. [Google Scholar] [CrossRef]

- Nitkiewicz, A.; Sekret, R. Comparison of LCA results of low temperature heat plant using electric heat pump, absorption heat pump and gas-fired boiler. Energy Convers. Manag. 2014, 87, 647–652. [Google Scholar] [CrossRef]

- Naumann, G.; Schropp, E.; Gaderer, M. Life Cycle Assessment of an Air-Source Heat Pump and a Condensing Gas Boiler Using an Attributional and a Consequential Approach. Procedia CIRP 2022, 105, 351–356. [Google Scholar] [CrossRef]

- Sevindik, S.; Spataru, C.; Domenech Aparisi, T.; Bleischwitz, R. A Comparative Environmental Assessment of Heat Pumps and Gas Boilers towards a Circular Economy in the UK. Energies 2021, 14, 3027. [Google Scholar] [CrossRef]

- Abusoglu, A.; Sedeeq, M.S. Comparative exergoenvironmental analysis and assessment of various residential heating systems. Energy Build. 2013, 62, 268–277. [Google Scholar] [CrossRef]

- Kim, H.G.; Jeong, D.W.; Kwon, S.J.; Kim, S.S. Development of Building Energy Performance Benchmark for Hospitals. Buildings 2023, 13, 12. [Google Scholar] [CrossRef]

- Lee, J.-H.; Kim, D.-G.; Jeong, S.-K.; Song, Y.-h. Analysis of Heat Source System Degradation Due to Aging and Evaluation of Its Effect on Energy Consumption. Energies 2022, 15, 9217. [Google Scholar] [CrossRef]

- Bolteya, A.M.; Elsayad, M.A.; El Monayeri, O.D.; Belal, A.M. Impact of Phase Change Materials on Cooling Demand of an Educational Facility in Cairo, Egypt. Sustainability 2022, 14, 15956. [Google Scholar] [CrossRef]

- Banks, A.; Grist, C.; Heller, J.; Lim, H. Field Measurement of Central CO2 Heat Pump Water Heater for Multifamily Retrofit. Sustainability 2022, 14, 8048. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, J.; Yang, M.; Gong, K.; Yang, M. Environmental and Economic Analysis of Heating Solutions for Rural Residences in China. Sustainability 2022, 14, 5117. [Google Scholar] [CrossRef]

- AlAli, M.; Mattar, Y.; Alzaim, M.A.; Beheiry, S. Analysis of Electricity and Water Consumption in Existing Mosque Buildings in the UAE. Buildings 2023, 13, 1007. [Google Scholar] [CrossRef]

- Li, M. Life Cycle Assessment of Residential Heating and Cooling Systems in Minnesota A comprehensive analysis on life cycle greenhouse gas (GHG) emissions and cost-effectiveness of ground source heat pump (GSHP) systems compared to the conventional gas furnace and air conditioner system. University of Minnesota. 2013. Available online: https://hdl.handle.net/11299/146449 (accessed on 6 October 2023).

- Shirazi, A.; Ashuri, B. Embodied Life Cycle Assessment (LCA) comparison of residential building retrofit measures in Atlanta. Build. Environ. 2020, 171, 106644. [Google Scholar] [CrossRef]

- Vioalante, A.C.; Donato, F.; Guidi, G.; Proposito, M. Comparative life cycle assessment of the ground source heat pump vs air source heat pump. Renew. Energy 2022, 188, 1029–1037. [Google Scholar] [CrossRef]

- Asdrubali, F.; Grazieschi, G. Life cycle assessment of energy efficient buildings. Energy Rep. 2020, 6, 270–285. [Google Scholar] [CrossRef]

- Grazieschi, G.; Gori, P.; Lombardi, L.; Asdrubali, F. Life cycle energy minimization of autonomous buildings. J. Build. Eng. 2020, 30, 101229. [Google Scholar] [CrossRef]

- Ziółkowski, P.; Hyrzyński, R.; Lemański, M.; Kraszewski, B.; Bykuć, S.; Głuch, S.; Sowiżdżał, A.; Pająk, L.; Wachowicz-Pyzik, A.; Badur, J. Different design aspects of an Organic Rankine Cycle turbine for electricity production using a geothermal binary power plant. Energy Convers. Manag. 2021, 245, 114672. [Google Scholar] [CrossRef]

- Mannheim, V.; Feher, Z.S.; Siménfalvi, Z. Innovative solutions for the building industry to improve sustainability performance with Life Cycle Assessment modelling. In Solutions for Sustainable Development; CRC Press: Boca Raton, FL, USA, 2019; pp. 245–253. [Google Scholar] [CrossRef]

- Asdrubali, F.; Ballarini, I.; Corrado, V.; Evangelisti, L.; Grazieschi, G.; Guattari, C. Energy and environmental payback times for an NZEB retrofit. Build. Environ. 2019, 147, 461–472. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 6 June 2019).

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 6 June 2019).

- CML. Institute of Environmental Sciences, Leiden University. 2016. CML-IA Characterisation Factors Portal. Available online: https://www.universiteitleiden.nl/en/research/researchoutput/science/cml-ia-characterisation-factors (accessed on 29 June 2018).

- Van Oers, L.; De Koning, A.; Guinée, J.B.; Huppes, G. Abiotic resource depletion in LCA. In Improving Characterisation Factors for Abiotic Resource Depletion as Recommended in the New Dutch LCA Handbook; RWS-DWW: Delft, The Netherlands, 2002; Available online: http://www.leidenuniv.nl/cml/ssp/projects/lca2/report_abiotic_depletion_web.pdf (accessed on 29 February 2016).

- Kupfer, T.; Baitz, M.; Colodel, C.M.; Kokborg, M.; Schöll, S.; Rudolf, M.; Thellier, L.; Bos, U.; Bosch, F.; Gonzalez, M. GaBi Database & Modeling Principles. In GaBi Thinkstep AG; Sphera: Chicago, IL, USA, 2018. [Google Scholar]

- Buyle, M.; Braet, J.; Audenaert, A. Life cycle assessment in the construction sector: A review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar] [CrossRef]

- Kasner, R. The Environmental Efficiency of Materials Used in the Lifecycle of a Wind Farm. Sustain. Mater. Technol. 2022, 34, e00512. [Google Scholar] [CrossRef]

- Danko, G.L.; Baracza, M.K. Numerical Demonstration of an Unconventional EGS Arrangement. Energies 2022, 15, 20. [Google Scholar] [CrossRef]

- Bahramian, M.; Yetilmezsoy, K. Life cycle assessment of the building industry: An overview of two decades of research (1995–2018). Energy Buildings. 2020, 219, 109917. [Google Scholar]

- Bałdowska-Witos, P.; Kruszelnicka, W.; Tomporowski, A. LCA analyzes were also performed for the production of PET bottle. Life cycle assessment of beverage bottles. J. Phys. Conf. Ser. 2020, 1426, 012038. [Google Scholar] [CrossRef]

- Mannheim, V. Life Cycle Assessment Model of Plastic Products: Comparing Environmental Impacts for Different Scenarios in the Production Stage. Polymers 2021, 13, 777. [Google Scholar] [CrossRef]

- Alwaeli, M.; Mannheim, V. Investigation into the Current State of Nuclear Energy and Nuclear Waste Management—A State-of-the-Art Review. Energies 2022, 15, 4275. [Google Scholar] [CrossRef]

- Bayer, P.; Saner, D.; Bolay, S.; Rybach, L.; Blum, P. Greenhouse gas emission savings of ground source heat pump systems in Europe: A review. Renew. Sustain. Energy Rev. 2012, 16, 1256–1267. [Google Scholar] [CrossRef]

| Authors | Ref. Number | Renewable Energy Sources | Country | Conventional Energy Sources | Environmental Impact Analysis | Energy Analysis |

|---|---|---|---|---|---|---|

| Huang, B. and Mauerhofer, V. | [11] | geothermic | Cyprus | n. gas | yes | yes |

| Michopoulos, A. et al. | [12] | geothermic | Spain | n. gas | yes | no |

| Bristow, D. and Kennedy, C. | [13] | geothermic | China | n. gas | yes | yes |

| Tariq, S. et al. | [15] | solar energy | Korea | coal, fuel oil, and n. gas | yes | yes |

| Milousi, M. et al. | [16] | geothermic | Greece | - | yes | no |

| Clark, C. et al. | [18] | geothermic, thermal water | USA | n. gas, electricity | yes | yes |

| Martínez-Corona, J.I. et al. | [19] | - | Norway and Mexico | n. gas, electricity | yes | no |

| Greening, B. and Azapagic, A | [20] | - | United Kingdom | n. gas, electricity | yes | no |

| Nitkiewicz, A. and Sekret, R. | [21] | thermal water | Poland | n. gas, electricity | yes | no |

| Naumann, G. et al. | [22] | - | Germany | n. gas, electricity | yes | no |

| Sevindik, S. et al. | [23] | - | United Kingdom | n. gas, electricity | yes | yes |

| Abusoglu, A. and Sedeeq, M.S | [24] | - | Türkiye | electricity, coal, n. gas | yes | no |

| Kim, H. et al. | [25] | - | Korea | electricity | no | yes |

| Lee, J.-H. et al. | [26] | - | Korea | electricity | no | yes |

| Bolteya, A. et al. | [27] | phase-change materials | Cairo | - | no | yes |

| Zhang, Z. et al. | [29] | - | China | electricity, n. gas, coal | yes | yes |

| AlAli, M. et al. | [30] | - | UAE | - | no | yes |

| Li, Mo. | [31] | geothermic | Munsta, Canada | n. gas, electricity | yes | yes |

| Asdrubali, F. and Grazieschi, G. | [34] | - | Italy | n. gas, electricity | yes | yes |

| Ziółkowski, P. et al. | [36] | geothermic | Poland | - | yes | yes |

| Flow Type | Process Flow Name | Plan Flow Name | Amount |

|---|---|---|---|

| System 1 | |||

| Input | Primary energy from geothermics (renewable energy) | Electricity from geothermal (European Union) | 75.2 MJ 20.9 kWh |

| Output | Thermal energy from heating (thermal energy) | Product heat energy | 75.2 MJ |

| System 2 | |||

| Input | Natural gas (at consumer Hungary) | Natural gas mix (Hungary) | 8.8 kg 412 MJ 114.4 kWh |

| Input | Electricity (electric power) | Electricity grid mix (production mix, Hungary) | 7.92 MJ 2.2 kWh |

| Output | Thermal energy from heating (thermal energy) | Product heat energy | 419.92 MJ |

| System 3 | |||

| Input | Natural gas (at consumer Hungary) | Natural gas mix (Hungary) | 4.82 kg 226 MJ 62.7 kWh |

| Input | Primary energy from geothermics (renewable energy) | Electricity from geothermal (European Union) | 11.9 MJ 3.3 kWh |

| Output | Thermal energy from heating (thermal energy) | Product heat energy | 237.9 MJ |

| Input Names | Background of System Inputs |

|---|---|

| Natural gas | The LCI dataset covers the entire natural gas supply chain. This includes drilling, natural gas production, processing, and transportation via pipelines. The main technologies in Hungary include conventional (primary, secondary, and tertiary) and unconventional production (shale gas, tight gas, and coal seam gas). These technologies encompass various parameters, including energy consumption, transport distances, and gas processing technologies. Pipeline transportation between the gas field and the coast was considered. Hungarian natural gas consumption consists of a combination of domestically produced natural gas and imported natural gas from the respective producing countries. An average regional distribution (via pipelines) was estimated for the total supply of natural gas, including domestic production and imports. The inventory was primarily based on secondary data. |

| Electricity | Electricity was modelled according to the specific circumstances of the European Union. The modelling of the electricity mix included accounting for transmission and distribution losses as well as self-consumption by energy producers such as power plants and other sources like pumped-storage power plants. It also took into consideration the importing of electricity. Secondly, the national emission and efficiency standards of power plants were modelled as well as the proportion of electricity plants and combined heat and power (CHP) plants. Thirdly, the analysis considered the supply of specific energy carriers, taking into account both imported and domestically produced energy sources. This included examining the properties of the energy carriers, such as their composition and energy content. The exploration, extraction, production, processing, and transportation processes of the energy carrier supply chains were modelled according to the EU situation. |

| Geothermal energy | The product system used renewable-energy-related primary energy demand; for 1 MJ of electricity from geothermal power, 1.98 MJ of primary geothermal power was used. The product system utilized renewable energy sources, which resulted in a primary energy demand related to renewable energy. For every 1 MJ of electricity generated from geothermal power, 1.98 MJ of primary geothermal power was consumed. |

| Energy carriers and refinery products | The energy carriers were modelled based on the specific supply situation (refer to the electricity section above). A parameterized refinery model simulated diesel fuel, gasoline, technical gases, fuel oils, lubricants, and residues, such as bitumen, using specific models for each country. The refinery model represents the current national standard in refining techniques, including emission levels, internal energy consumption, and other factors. It also took into consideration the specific product output spectrum of each country, which can vary from one country to another. The supply of crude oil was modelled based on the specific situation of each country and the properties of the available resources. |

| Name of Parameters | |

|---|---|

| Economic aspects | Productivity |

| Delivery, installation, operation, and maintenance costs | |

| Energy costs, decommissioning costs during replacement, operational, and life-cycle costs | |

| The management cost of system units that have become waste | |

| Method and safety of energy supply, type of energy, and type of fuel used | |

| Rate and unit price of energy and water consumption | |

| Primary energy saving and energy transmission loss | |

| Power generation method and utilization of generated heat | |

| The life cycle of thermal engineering units, downtime, and amortization | |

| Property, work and fire protection, and safety technology | |

| Building value, financing options, and innovation | |

| Environmental aspects | Reduction in energy and material resources |

| Lifetime and life cycle of the building | |

| Emissions, carbon footprint, environmental impact categories, and reduction | |

| Primary energy savings | |

| Inspection and control of heat engineering units and utilities | |

| Indoor air quality and thermal comfort | |

| Environmental building assessment system and building environmental performance | |

| Environmental impact of installation, use, and end-of-life stages | |

| Use of low-carbon, renewable technologies | |

| Polluting substances, type of waste, amount, and treatment method | |

| Energetic aspects | Method of energy supply and heating system |

| Energy/primary energy consumption and savings | |

| Percentage of use of renewable and fossil energy sources | |

| Building technical systems and system design | |

| Building energy requirements | |

| Energy efficiency and its improvement, energy efficiency measures, and certificates | |

| Energy transmission loss | |

| Peak winter heating performance and reduction | |

| Off-peak heating performance and its increase | |

| Application of storage tanks and temperature control | |

| Reduction in the mass flow of primary district heating water | |

| Utilization and recovery rate of heat generated during electricity and energy production | |

| Energy and waste heat utilization technology from the treatment of units that have become waste | |

| Type and efficiency of thermal energy storage techniques | |

| Building energy performance | |

| Building qualification and certification system |

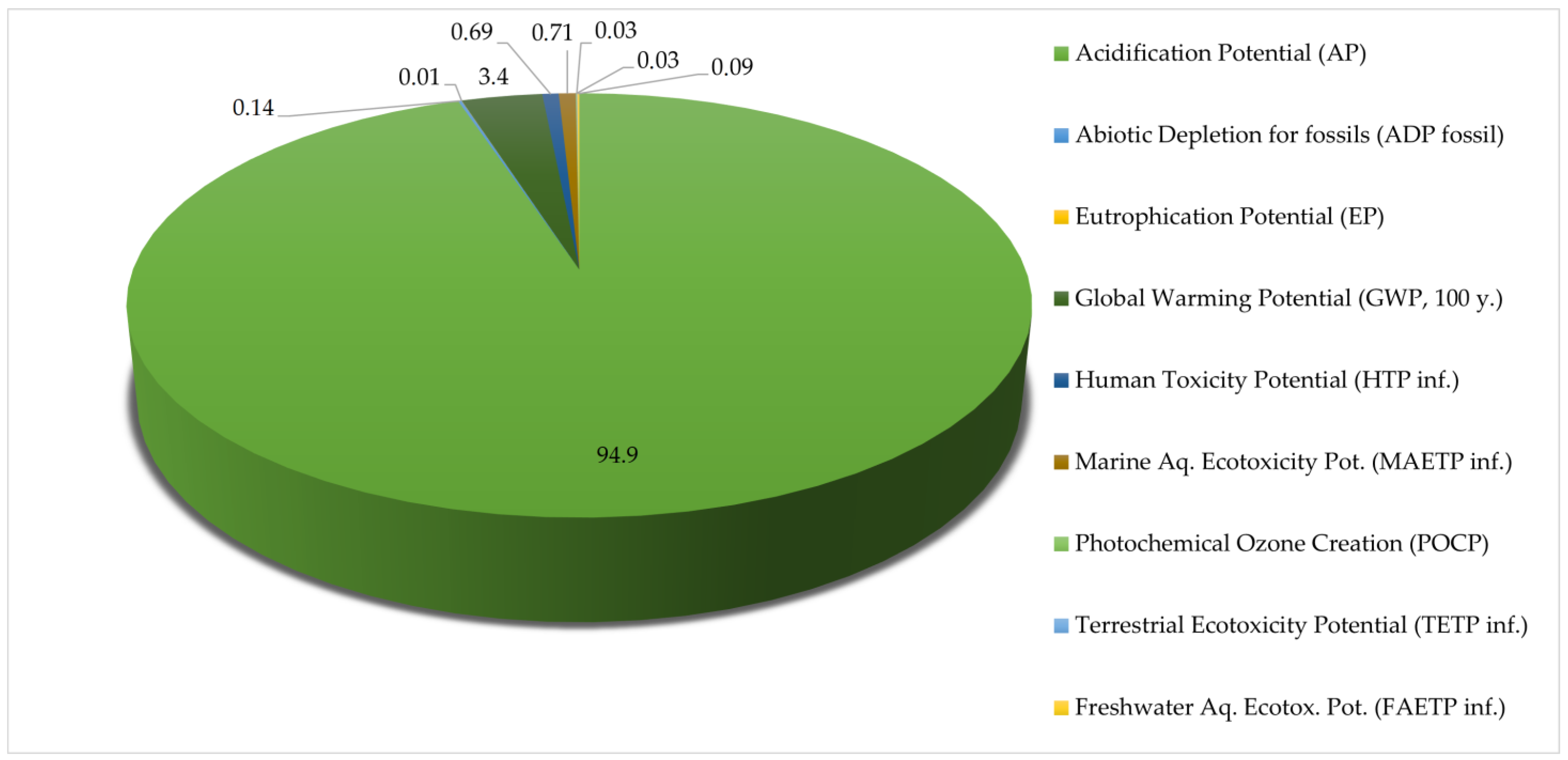

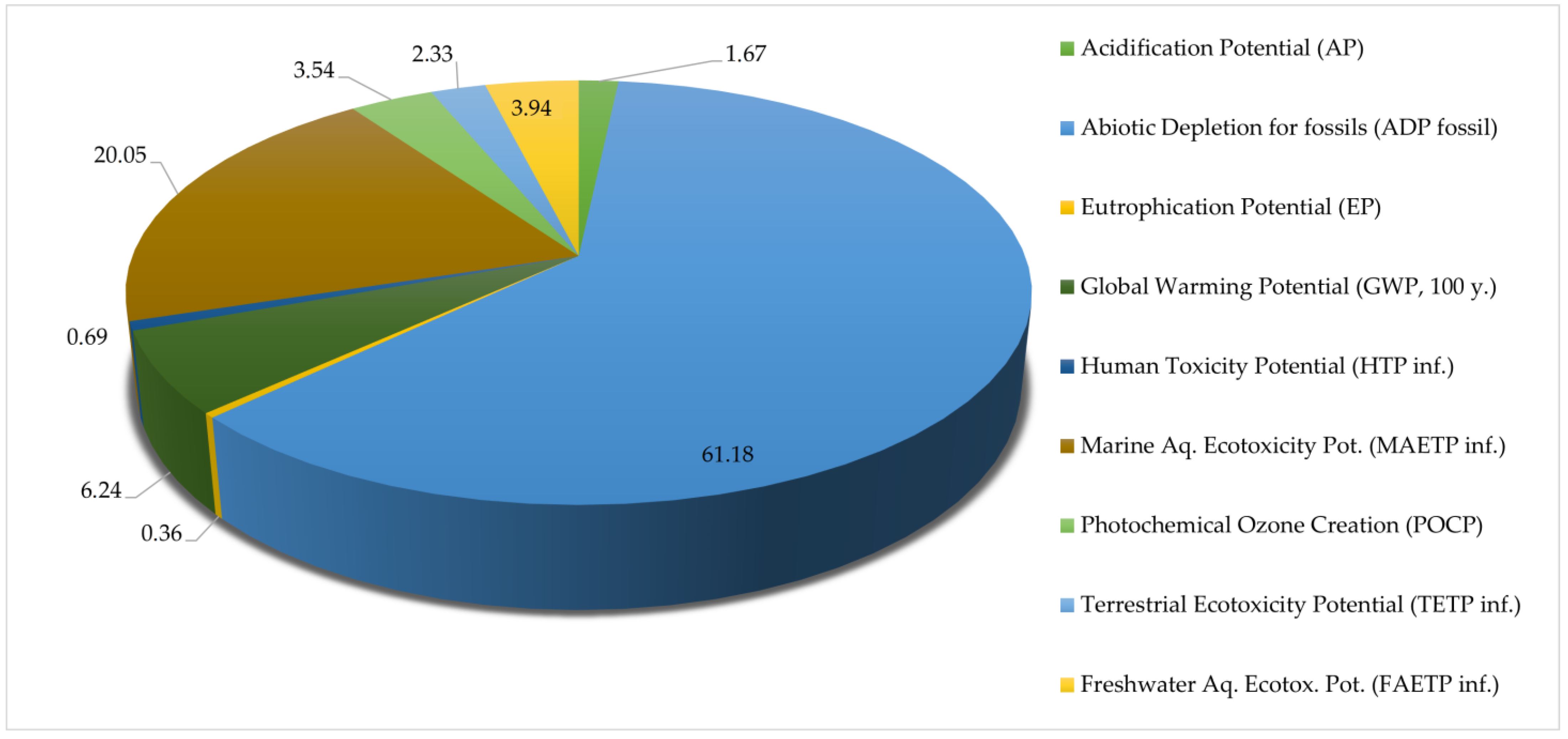

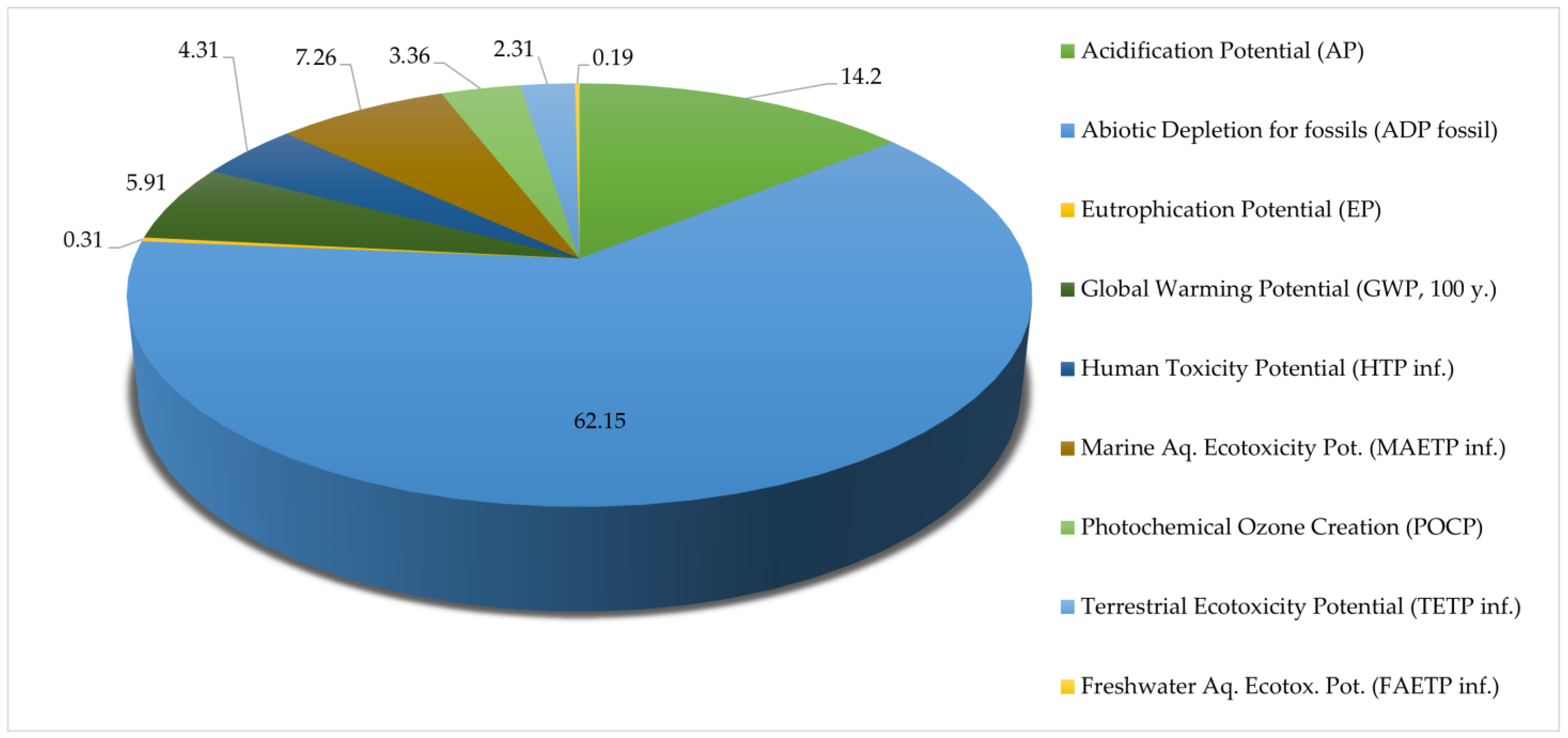

| Environmental Impact Quantities (CML 2016) | System 1 (Electric Heat Pump) | System 2 (Gas Boiler) | System 3 (Absorption Heat Pump) |

|---|---|---|---|

| Abiotic Depletion ADP fossils | 0.09 | 88.20 | 47.4 |

| Acidification Potential AP | 62.90 | 2.41 | 11.0 |

| Eutrophication Potential EP | 0.01 | 0.516 | 0.24 |

| Global Warming Pot. GWP 100 years | 2.28 | 9.0 | 4.55 |

| Human Toxicity Potential HTP inf. | 0.46 | 6.38 | 3.32 |

| Marine A. Ecotox. Pot. MAETP inf. | 0.47 | 28.9 | 5.54 |

| Photochem. Ozone Creat. Pot. POCP | 0.02 | 5.11 | 2.57 |

| Terrestrial Ecotoxicity Pot. TETP inf. | 0.02 | 3.36 | 1.80 |

| Environmental Impact Quantities (ReCiPe 2016) | System 1 | System 2 | System 3 |

|---|---|---|---|

| Climate change human health (default) | 0.0508 | 0.216 | 0.11 |

| Fossil depletion | 0.00423 | 3.6 | 1.95 |

| Human toxicity (cancer) | 0.0148 | 0.0159 | 0.00813 |

| Environmental Impact Quantities (EF 3.0) | System 1 | System 2 | System 3 |

| Climate change-total | 0.00352 | 0.0151 | 0.00767 |

| Land use | 1.92 × 10−6 | 6.67 × 10−6 | 5.56 × 10−6 |

| Particulate matter | 3.88 × 10−5 | 1200 × 10−5 | 585 × 10−5 |

| Water use | 482 × 10−5 | 3.09 × 10−5 | 76.8 × 10−5 |

| Primary Energy Quantities | System 1 | System 2 | System 3 |

|---|---|---|---|

| Primary energy demand from ren. and non-ren. resources (gross cal. value) | 341 | 552 | 343 |

| Primary energy demand from ren. and non-ren. resources (net cal. value) | 341 | 499 | 314 |

| Primary energy from non-renewable resources (gross cal. value) | 0.556 | 548 | 289 |

| Primary energy from non-renewable resources (net cal. value) | 0.52 | 496 | 260 |

| Primary energy from renewable resources (gross cal. value) | 341 | 3.56 | 54 |

| Primary energy from renewable resources (net cal. value) | 341 | 3.56 | 54 |

| Resources and Emissions | System 1 | System 2 | System 3 |

|---|---|---|---|

| Energy resources | 0.0142 | 11.3 | 5.93 |

| Energy resources from electricity mix | - | 0.5 | - |

| Energy resources from Hungarian natural gas | - | 10.8 | 5.9278 |

| Energy resources from geothermal | 0.0142 | - | 0.0022 |

| Material resources | 173 | 1240 | 183 |

| Material resources from non-renewable resources | 0.089 | 40 | 15 |

| Material resources from renewable resources | 172.91 | 1200 | 168 |

| Emissions to air | 153 | 29.5 | 28.5 |

| Emissions to fresh water | 17.9 | 1500 | 145 |

| Emissions to sea water | 0.041 | 1.02 | 0.535 |

| Environmental Impacts (EF 3.0) | System 1 | System 2 | System 3 |

|---|---|---|---|

| Climate change-total | 4 | 17 | 13 |

| Ecotoxicity freshwater-total | 90 | 0.65 | 21 |

| Human toxicity (non-cancer)-total | 0.019 | 2.7 | 2.1 |

| Water use | 5.5 | 0.035 | 1.3 |

| Resource use, fossils | 0.076 | 72 | 57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mannheim, V.; Nehéz, K.; Brbhan, S.; Bencs, P. Primary Energy Resources and Environmental Impacts of Various Heating Systems Based on Life Cycle Assessment. Energies 2023, 16, 6995. https://doi.org/10.3390/en16196995

Mannheim V, Nehéz K, Brbhan S, Bencs P. Primary Energy Resources and Environmental Impacts of Various Heating Systems Based on Life Cycle Assessment. Energies. 2023; 16(19):6995. https://doi.org/10.3390/en16196995

Chicago/Turabian StyleMannheim, Viktoria, Károly Nehéz, Salman Brbhan, and Péter Bencs. 2023. "Primary Energy Resources and Environmental Impacts of Various Heating Systems Based on Life Cycle Assessment" Energies 16, no. 19: 6995. https://doi.org/10.3390/en16196995

APA StyleMannheim, V., Nehéz, K., Brbhan, S., & Bencs, P. (2023). Primary Energy Resources and Environmental Impacts of Various Heating Systems Based on Life Cycle Assessment. Energies, 16(19), 6995. https://doi.org/10.3390/en16196995