Application of an Independent Temporary Spent Fuel Storage Pool Cooling System for Decommissioning of Pressurized Water Reactor Kori Units 3 and 4

Abstract

:1. Introduction

2. Feasibility

2.1. Case Study

2.1.1. SONGS Units 2&3

2.1.2. Maine Yankee

2.1.3. Trojan

2.2. Cost Analysis

2.2.1. Installation Cost

2.2.2. Operating Cost

3. System Requirements

3.1. Cooling Capacity

3.1.1. Decay Heat Estimation

3.1.2. Required Cooling Capacity

3.2. Single Failure

3.3. Design Classes

3.4. Applicable System Requirements

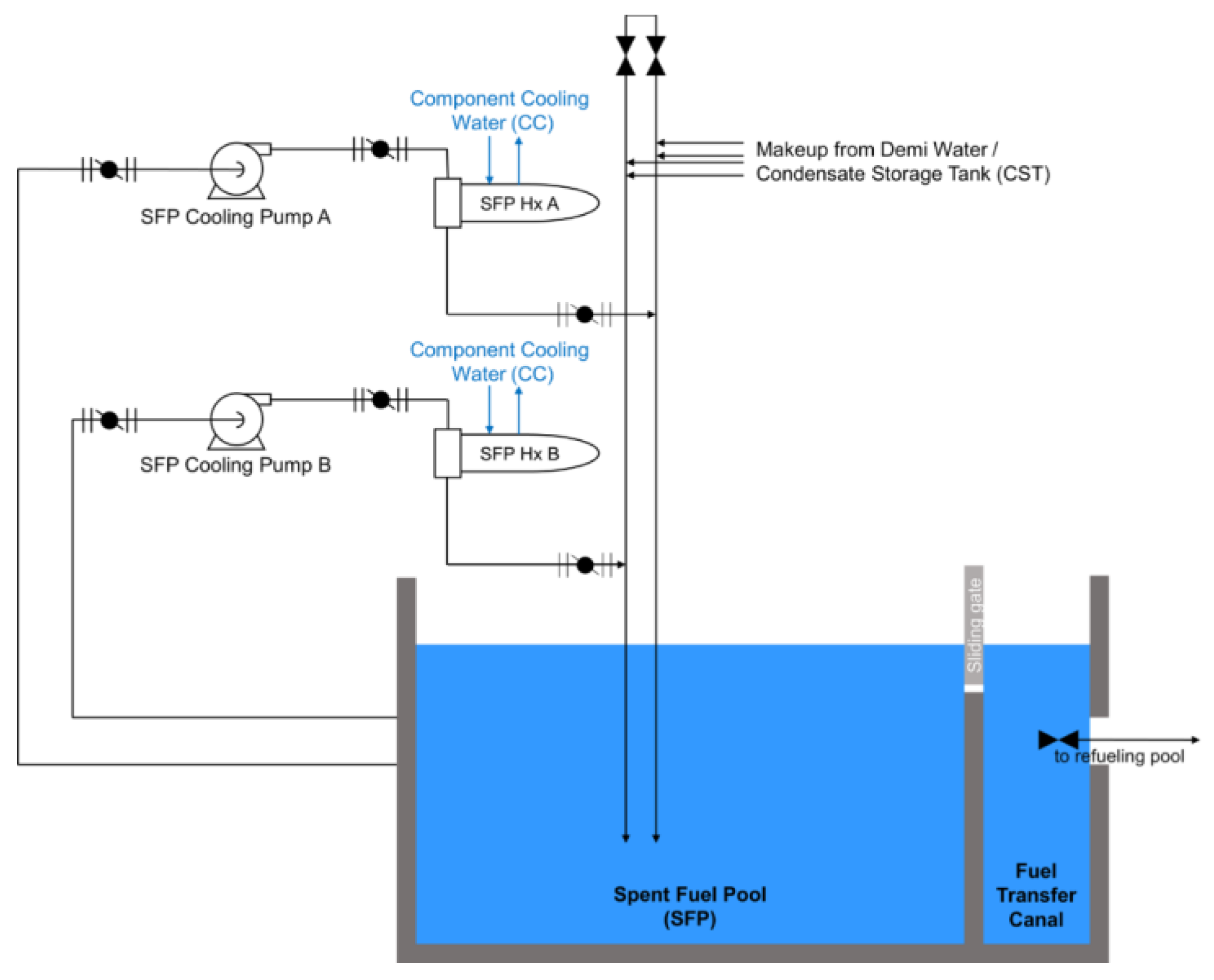

4. System Design

4.1. Cooling Method Selection

4.1.1. Ocean-Cooled, Indirect Heat Exchange

4.1.2. Air-Cooled, Indirect Heat Exchange

4.1.3. Module, Direct Heat Exchange

4.1.4. Selection of Cooling System

4.2. Applicable Configuration

4.3. Primary Cooling Loop Components

4.4. Secondary Cooling Loop Components

4.5. Makeup Water

4.6. Power

5. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Ministry of Trade, Industry and Energy (MOTIE). The Second Plan for High Level Radioactive Waste Management; Notice 2021-836; MOTIE: Sejong, Republic of Korea, 2021; pp. 16–17.

- Korea Hydro and Nuclear Power (KHNP). Final Safety Analysis Report for Kori units 3 and 4; KHNP: Gyeongju-si, Republic of Korea, 2006; Volume 9, pp. 9.1-6–9.1-12. [Google Scholar]

- Songa, M.; Kim, C.L.; Kessel, D.S. Consideration of Spent Fuel Pool Island as an Interim Management Option of Spent Nuclear Fuel for Kori unit 3&4 during Decommissioning of Kori site. Energy Strategy Rev. 2018, 21, 163–171. [Google Scholar]

- Jun, S.H. Feasibility Study of Applying the Spent Fuel Pool Island to Kori Units 3&4; KEPCO International Nuclear Graduate School: Ulsan, Republic of Korea, 2021; p. 51. [Google Scholar]

- Southern California Edison (SCE). San Onofre Nuclear Generating Station Units 2&3 Defueled Safety Analysis Report (DSAR), Rev.4; SCE: Rosemead, CA, USA, 2018; Volume 9, pp. 9-16–9-24. [Google Scholar]

- Wood, C. Maine Yankee Decommissioning—Experience Report, Electric Power Research Institute (EPRI) Technical Report; TR-1011734; EPRI: Washington, DC, USA, 2005; pp. 5-2–5-5. [Google Scholar]

- Lackey, M.B.; Fischer, J.P.; Rogan, F. Spent Fuel Pool Cooling and Cleanup during Decommissioning—Experience at Trojan Nuclear Power Plant, Electric Power Research Institute (EPRI) Technical Report; TR-112351; EPRI: Washington, DC, USA, 1999; pp. 2-2–3-6. [Google Scholar]

- Kenrich Group LLC (KRG). San Onofre Nuclear Generating Station units 2&3 2017 Decommissioning Cost Estimate, Rev.1; KRG: Washington, DC, USA, 2018; Appendix C; p. 1. [Google Scholar]

- National Aeronautics and Space Administration (NASA). NASA Cost Estimating Handbook; NASA CEH v.4.0; NASA: Washington, DC, USA, 2015; Appendix C; p. 15.

- EVC Valuation. The Cost-to-Capacity Method and Scale Factors. 2015. Available online: https://evcvaluation.com/the-cost-to-capacity-method-and-scale-factors/ (accessed on 1 October 2022).

- Florida Power & Light Company (FPL). Air-Cooled Chillers—An FPL Technical Primer. pp. 3–4. Available online: https://infpl.fpl.com/business/pdf/air-cooled-chillers-primer.pdf (accessed on 1 October 2022).

- Lee, J.S. Prediction on Korean Spent Nuclear Fuel Management. Nucl. Ind. 1992, 12, 26–33. [Google Scholar]

- Kim, G. Current status of nuclear fuel development. J. Electr. World 2000, 13, 16–23. [Google Scholar]

- Choi, H.-J.; Cho, D.; Kook, D.; Choi, J. Current status of spent fuels and the development of computer programs for the PWR spent fuel management in Korea. Nucl. Energy 2011, 53, 290–297. [Google Scholar] [CrossRef]

- Cho, D.K.; Kim, J.W.; Kim, I.Y.; Lee, J.Y. Investigation of PWR Spent Fuels for the Design of a Deep Geological Repository. J. Nucl. Fuel Cycle Waste Technol. 2019, 17, 339–346. [Google Scholar] [CrossRef]

- Dho, H.S.; Kim, T.M.; Cho, C.H. The Evaluation of Minimum Cooling Period for Loading of PWR Spent Nuclear Fuel of a Dual Purpose Metal Cask. J. Fuel Cycle Waste Technol. 2016, 14, 411–422. [Google Scholar] [CrossRef]

- NSSC. Provisions for Delivering Spent Nuclear Fuel; Korean Nuclear Safety and Security Committee (NSSC) Notice 2021-22§7; NSSC: Daejeon, Republic of Korea, 2021.

- Park, S.R. Design Class Study for Applying Spent Fuel Pool Island to Kori Units 3 and 4; KEPCO International Nuclear Graduate School: Ulsan, Republic of Korea, 2021; pp. 44–59. [Google Scholar]

- Korea Institute of Nuclear Safety (KINS). Regulation Guidance and Criteria for Pressurized Water Reactor; KINS/RS-N10.00; KINS: Daejeon, Republic of Korea, 2015; Chapter 10.

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; Dewitt, D.P. Fundamentals of Heat and Mass Transfer, 7th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011; pp. 708–730. [Google Scholar]

- Cold Shot Chillers. Chiller Sizing Information; pp. 2–4. Available online: https://waterchillers.com/chiller-resources/sizing-information.html (accessed on 1 October 2022).

- Southern California Edison (SCE). Q&A about San Onofre Spent Fuel Pool Cooling Island Project. SCE Supplemental Information SFPI. 2015, pp. 10–13. Available online: https://sanonofresafety.files.wordpress.com/2011/11/sce-supplemental-information-sfpi-3-20-2015dgilmoreresponse.pdf (accessed on 1 October 2022).

| Case | Required Cooling Capacity |

|---|---|

| Normal operation | to remove heat load while maintaining pool temperature less than 48.8 °C (120 °F) Unit 3: 5.62 MW (19.2 × 106 Btu/h) from - one-third of a core 150 hours after shutdown - 40 previous refueling, one-third core each Unit 4: 6.29 MW (21.46 × 106 Btu/h) Btu/h from - 64 assemblies 150 hours after shutdown - 13.45 reactor cores (2112 assemblies) |

| Residual heat | to remove residual heat load while maintaining pool temperature less than 48.8 °C (120 °F) Unit 3: 13.21 MW (45.1 × 106 Btu/h) from - a full-core 150 hours after shutdown - one-third of a core 480 hours after shutdown - 40 previous refueling, one-third core each Unit 4: 12.9 MW (44.1 × 106 Btu/h) from - a full-core 150 hours after shutdown - 13.45 reactor cores (2112 assemblies) |

| Single failure | to comply with the cooling capacity, in the case of single failure of any component, assuming loss of power |

| Earthquake | to comply with the cooling capacity, in the case of safe shutdown earthquake |

| Inspection | to be capable of being inspected and tested during plant power generation operation |

| Storage Options | Capital Cost (USD) | Inflated, Escalated, and Discounted Cost (USD) |

|---|---|---|

| SFPI | 98,045,443.68 | 119,759,230.47 |

| Concrete cask | 166,330,355.70 | 203,333,372.80 |

| Metal cask | 539,125,633.70 | 658,690,398.80 |

| Duel-purpose cask | 715,448,023.70 | 874,064,218.80 |

| Burnup Rate (MWd/tU) | Decay Heat (Watt) | Decay Heat (Btu/h) |

|---|---|---|

| 45,705 | 1.56 (106) | 5.33 (106) |

| 50,000 | 1.76 (106) | 6.00 (106) |

| 55,002 | 2.00 (106) | 6.84 (106) |

| Labor | Material | Contract | Other | Overheads | Total | |

|---|---|---|---|---|---|---|

| Unit 2 | 139 | 2814 | 1159 | 31 | 129 | 4272 |

| Unit 3 | 139 | 2814 | 1159 | 31 | 129 | 4272 |

| Total | 278 | 5628 | 2318 | 62 | 258 | 8544 |

| Year | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 |

|---|---|---|---|---|---|---|---|

| Value | 100 | 98.18 | 101.57 | 103.48 | 103.50 | 103.03 | 109.60 |

| Average | - | −1.8 | 3.5 | 1.9 | 0.0 | −0.5 | 6.4 |

| Year | 2017 | 2018 | 2019 | 2020 | 2021 | 2022 | 2023 | 2024 | 2025 |

|---|---|---|---|---|---|---|---|---|---|

| Inflation | base | 1.9 | 0.0 | −0.5 | 6.4 | 2.2 | 2.2 | 2.2 | 2.2 |

| Cost | 8.08 | 8.23 | 8.23 | 8.19 | 8.72 | 8.91 | 9.10 | 9.30 | 9.51 |

| Groups | Burnup Rate (GWd/tU) | Cooling Time (Year) | Applicable Years | Decay Heat 1 (Watt) |

|---|---|---|---|---|

| 1 | 45 | 30 | 1985~2000 | 489 |

| 2 | 45 | 25 | 2001~2005 | 534 |

| 3 | 45 | 20 | 2006~2009 | 586 |

| 4 | 55 | 20 | 2010~2010 | 741 |

| 5 | 55 | 15 | 2011~2015 | 827 |

| 6 | 55 | 10 | 2016~2020 | 968 |

| 7 | 55 | 5 | 2021~2025 | 1483 |

| Year | Quantity | Type | Burnup Rate (MWd/tU) | Cooling Year | Group | Decay Heat (Watt) |

|---|---|---|---|---|---|---|

| 1985 | - | - | - | - | - | - |

| 1986 | 56.5 | STD | 30~45 | 44 | 1 | 27,629 |

| 1987 | 56.5 | STD | 30~45 | 43 | 1 | 27,629 |

| 1988 | 56.5 | OFA | 30~45 | 42 | 1 | 27,629 |

| 1989 | 56.5 | OFA | 30~45 | 41 | 1 | 27,629 |

| 1990 | 56.5 | OFA | 30~45 | 40 | 1 | 27,629 |

| 1991 | 56.5 | KOFA | 30~45 | 39 | 1 | 27,629 |

| 1992 | 56.5 | KOFA | 30~45 | 38 | 1 | 27,629 |

| 1993 | 56.5 | KOFA | 30~45 | 37 | 1 | 27,629 |

| 1994 | 56.5 | KOFA | 30~45 | 36 | 1 | 27,629 |

| 1995 | 56.5 | KOFA | 30~45 | 35 | 1 | 27,629 |

| 1996 | 56.5 | V5H | 30~45 | 34 | 1 | 27,629 |

| 1997 | 56.5 | V5H | 30~45 | 33 | 1 | 27,629 |

| 1998 | 56.5 | V5H | 30~45 | 32 | 1 | 27,629 |

| 1999 | 56.5 | V5H | 30~45 | 31 | 1 | 27,629 |

| 2000 | 56.5 | V5H | 30~45 | 30 | 1 | 27,629 |

| 2001 | 56.5 | V5H | 30~45 | 29 | 2 | 30,171 |

| 2002 | 56.5 | V5H | 30~45 | 28 | 2 | 30,171 |

| 2003 | 56.5 | V5H | 30~45 | 27 | 2 | 30,171 |

| 2004 | 56.5 | V5H | 30~45 | 26 | 2 | 30,171 |

| 2005 | 56.5 | V5H | 30~45 | 25 | 2 | 30,171 |

| 2006 | 56.5 | V5H | 30~45 | 24 | 3 | 33,109 |

| 2007 | 56.5 | RFA | 30~45 | 23 | 3 | 33,109 |

| 2008 | 56.5 | RFA | 30~45 | 22 | 3 | 33,109 |

| 2009 | 56.5 | RFA | 30~45 | 21 | 3 | 33,109 |

| 2010 | 56.5 | RFA | 30~45 | 20 | 4 | 41,867 |

| 2011 | 56.5 | ACE7 | 55 | 19 | 5 | 46,726 |

| 2012 | 56.5 | ACE7 | 55 | 18 | 5 | 46,726 |

| 2013 | 56.5 | ACE7 | 55 | 17 | 5 | 46,726 |

| 2014 | 56.5 | ACE7 | 55 | 16 | 5 | 46,726 |

| 2015 | 56.5 | ACE7 | 55 | 15 | 5 | 46,726 |

| 2016 | 56.5 | ACE7 | 55 | 14 | 6 | 54,692 |

| 2017 | 56.5 | ACE7 | 55 | 13 | 6 | 54,692 |

| 2018 | 56.5 | ACE7 | 55 | 12 | 6 | 54,692 |

| 2019 | 56.5 | ACE7 | 55 | 11 | 6 | 54,692 |

| 2020 | 56.5 | ACE7 | 55 | 10 | 6 | 54,692 |

| 2021 | 56.5 | ACE7 | 55 | 9 | 7 | 83,790 |

| 2022 | 56.5 | ACE7 | 55 | 8 | 7 | 83,790 |

| 2023 | 56.5 | ACE7 | 55 | 7 | 7 | 83,790 |

| 2024 | 56.5 | ACE7 | 55 | 6 | 7 | 83,790 |

| 2025 | 56.5 | ACE7 | 55 | 5 | 7 | 83,790 |

| Total | 2260 | - | - | - | - | 1,665,620 |

| Component | Single Failure | Response |

|---|---|---|

| Cooling pumps | Cooling pump fails. | Two redundant trains shall be provided. |

| Power supply | Normal power supply fails. | A back-up diesel generator shall be provided. |

| Plants | Safety Class | SSCs |

|---|---|---|

| SONGS 2&3 | Non-safety-related | - SFP cooling system - SFP makeup system |

| Safety-related | - SFP and related structural components (pool liner, structure, racks) | |

| Zion 1&2 | Non-safety-related | - All SSCs under ITDC |

| Maine Yankee | Non-safety-related | - All SSCs under ITDC |

| Category | Description | Response |

|---|---|---|

| Cooling Capacity | to remove heat load of 1.67 MW while maintaining pool temperature less than 120 °F (48.8 °C) | Cooling capacity to remove the decay heat greater than 1.67 MW is provided. |

| Cooling pump failure | in a case of cooling pump failure | Two cooling loop trains are provided. |

| Normal power failure | in a case of a loss of power | A back-up diesel generator is provided. |

| Earthquake | in a case of safe shutdown earthquake | Clearer regulatory guideline for related SSCs should be established. |

| Inspection | to be capable of being inspected and tested during plant power generation operation | Clearer regulatory guideline for related SSCs should be established. |

| Type | Description | Similar Practices |

|---|---|---|

| Ocean-cooled indirect | Sea water of East sea is used as the ultimate heat sink. | Current SFPCCS, Yankee Rowe |

| Air-cooled indirect | Air outside is used as the ultimate heat sink. | SONGS 2&3, Maine Yankee, Connecticut Yankee |

| Module direct | Air outside is used as the ultimate heat sink. Module type cooling system is installed on the SFP. | Trojan |

| Criteria | Advantage | Disadvantage |

|---|---|---|

| Radiation safety | Two closed cooling loops act as a barrier for leakage | More potential leak through the long piping |

| Technology maturity | Similar system commonly used for normal SFP cooling system | - |

| Regulation | Similar to the current SFPCCS may become the most agreeable. | - |

| Economic feasibility | Current components and piping may be re-used | Highest cost expected due to large modification |

| Secondary waste | Current components and piping may be re-used | Largest waste expected due to medium modification |

| Criteria | Advantage | Disadvantage |

|---|---|---|

| Radiation safety | Two closed cooling loops act as a barrier for leakage | - |

| Technology maturity | Similar technology used for plant chiller systems | Not used for normal SFP cooling system |

| Regulation | Indirect heat exchanging like SFPCCS may become agreeable. | - |

| Economic feasibility | Lower cost expected due to medium modification | - |

| Secondary waste | Small waste expected due to medium modification | - |

| Criteria | Advantage | Disadvantage |

|---|---|---|

| Radiation safety | - | No barrier for a potential leakage from the system |

| Technology maturity | - | Not commonly used in nuclear industry |

| Regulation | - | Direct heat exchanging may not be fully convincible. |

| Economic feasibility | Lowest cost expected due to modular design | - |

| Secondary waste | Smallest waste expected due to modular design | - |

| Parameter | Symbol | Unit | Value |

|---|---|---|---|

| Primary loop inlet temperature | Th,i | °C | 37.8 |

| Primary loop outlet temperature | Th,o | °C | 31.1 |

| Primary loop mass flow rate | ṁh | kg/s | 37.77 |

| Primary loop heat capacity rate | Ch | J/K∙s | 1.58 × 105 |

| Secondary loop inlet temperature | Tc,i | °C | 24.4 |

| Secondary loop outlet temperature | Tc,o | °C | 29.2 |

| Secondary loop mass flow rate | ṁc | kg/s | 57.88 |

| Secondary loop heat capacity rate | Cc | J/K∙s | 2.42 × 105 |

| Required heat removal rate for SFPI | q | W | 1.66 × 106 |

| Overall heat transfer coefficient | U | W/m2∙K | 850~1700 |

| Chiller Capacity (ton) | Unit Price (USD/ton) |

|---|---|

| <150 | 400~1000 |

| ≥150 | 350~500 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mah, W.; Kim, C.-L. Application of an Independent Temporary Spent Fuel Storage Pool Cooling System for Decommissioning of Pressurized Water Reactor Kori Units 3 and 4. Energies 2023, 16, 1009. https://doi.org/10.3390/en16021009

Mah W, Kim C-L. Application of an Independent Temporary Spent Fuel Storage Pool Cooling System for Decommissioning of Pressurized Water Reactor Kori Units 3 and 4. Energies. 2023; 16(2):1009. https://doi.org/10.3390/en16021009

Chicago/Turabian StyleMah, Wonjune, and Chang-Lak Kim. 2023. "Application of an Independent Temporary Spent Fuel Storage Pool Cooling System for Decommissioning of Pressurized Water Reactor Kori Units 3 and 4" Energies 16, no. 2: 1009. https://doi.org/10.3390/en16021009

APA StyleMah, W., & Kim, C.-L. (2023). Application of an Independent Temporary Spent Fuel Storage Pool Cooling System for Decommissioning of Pressurized Water Reactor Kori Units 3 and 4. Energies, 16(2), 1009. https://doi.org/10.3390/en16021009