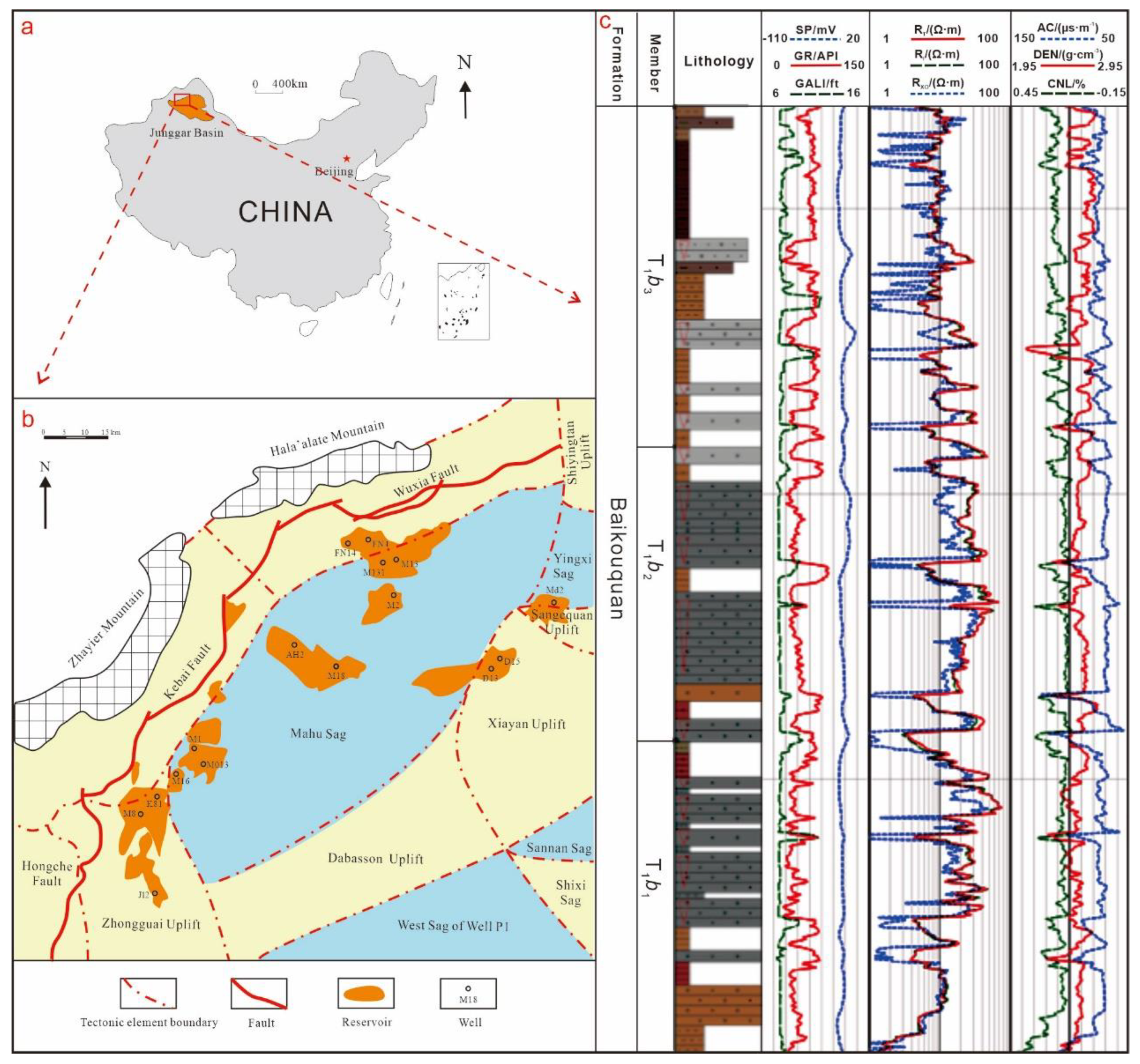

Study on Microscopic Pore Structure Classification for EOR of Low Permeability Conglomerate Reservoirs in Mahu Sag

Abstract

:1. Introduction

2. Experimental Methods

2.1. Samples

2.2. Materials and Instruments

2.3. CMI Steps

2.4. NMR Steps

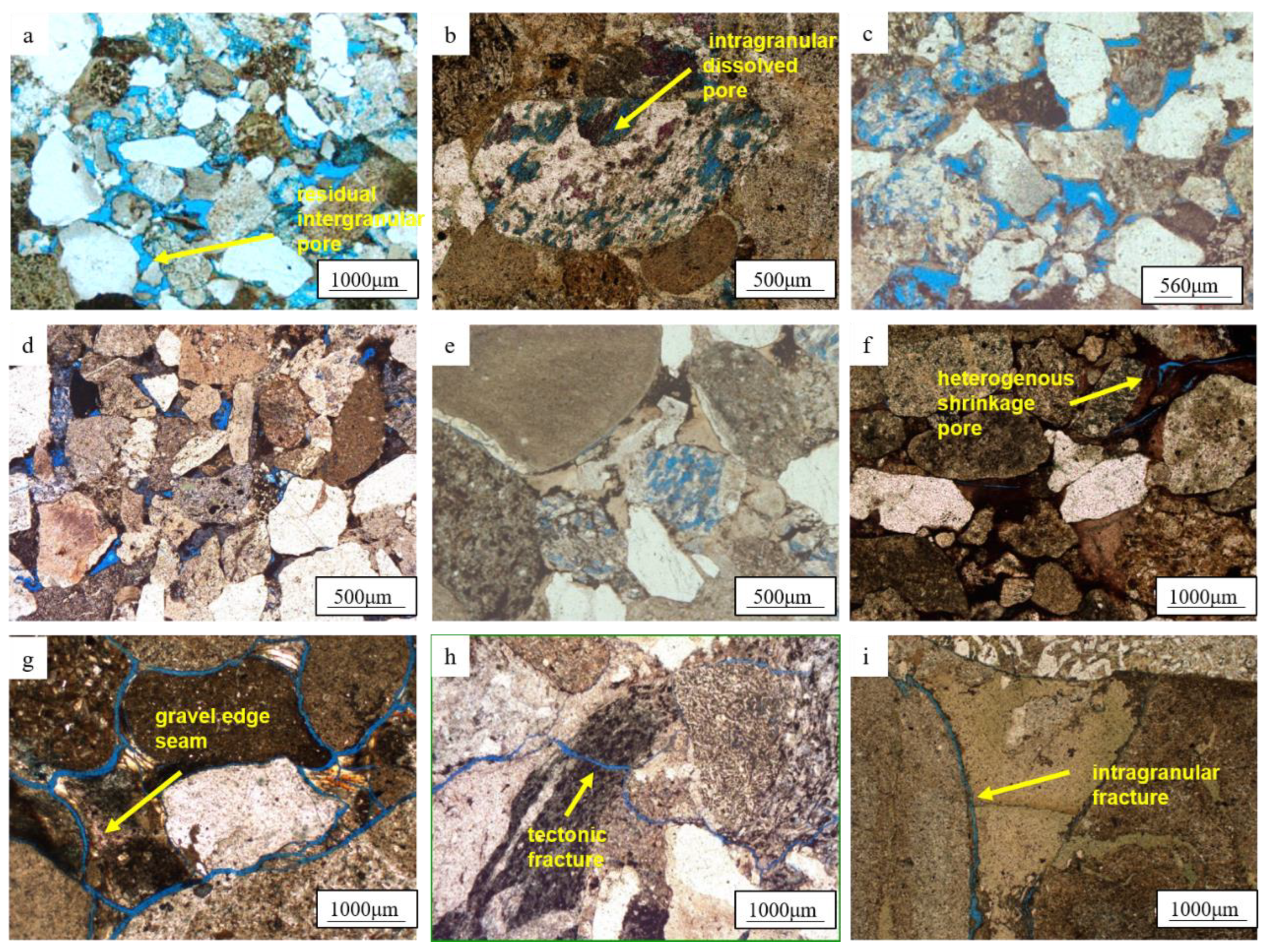

3. Microscopic Pore Throat Characteristics

3.1. Pore Types

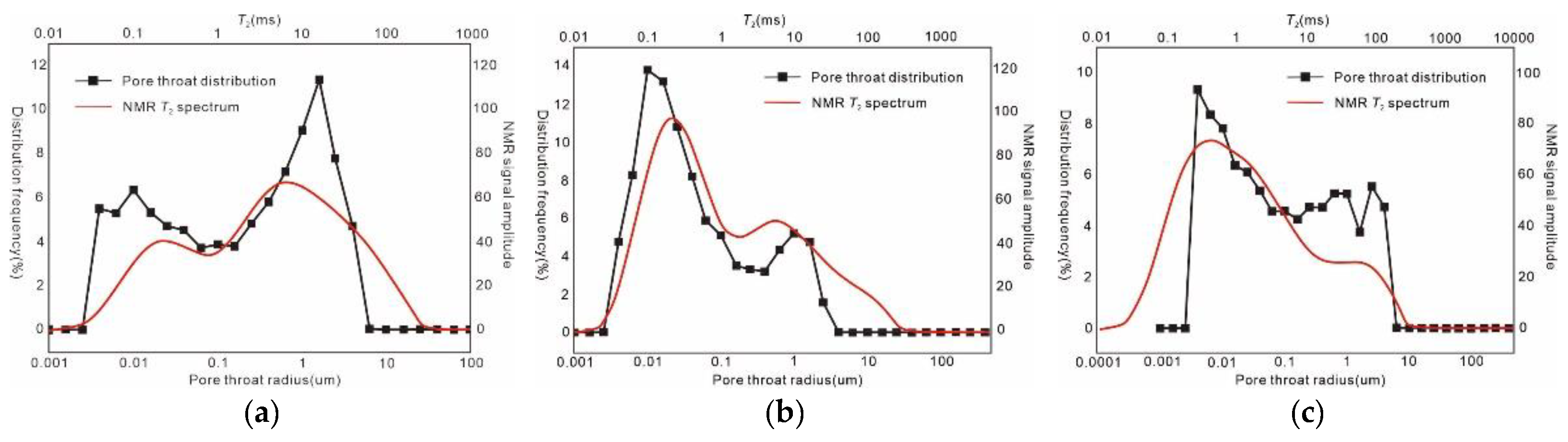

3.2. Microscopic Pore Throat Structure

4. Reservoir Classification

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; Zhu, Y.; Yu, C.; Zhao, L.; Chen, D. Pore Size Distribution in the Tight Sandstone Reservoir of the Ordos Basin, China and Their Differential Origin. J. Nat. Gas Geosci. 2020, 5, 45–55. [Google Scholar] [CrossRef]

- Xu, Y.; He, Y.; Bu, G.; Chen, L.; Liu, L.; Zhu, Y. Establishment of classification and evaluation criteria for tight reservoirs based on characteristics of microscopic pore throat structure and percolation: A case study of Chang 7 reservoir in Longdong area, Ordos Basin. Pet. Geol. Exp. 2019, 41, 451–460. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, W.; Du, J.; He, H.; Hu, S.; Guo, X.; Wang, J. Decision management and implementation effect of venture exploration projects of CNPC. China Pet. Explor. 2021, 26, 1. [Google Scholar] [CrossRef]

- Fan, Z.; Hou, J.; Xing, D.; Ge, X.; Zhang, F. Core NMR experiments for low permeability reservoir and its field application. J. China Univ. Pet. Ed. Nat. Sci. 2019, 43, 53–59. [Google Scholar] [CrossRef]

- Jia, C.; Zheng, M.; Zhang, Y. Unconventional hydrocarbon resources in China and the prospect of exploration and development. Pet. Explor. Dev. 2012, 39, 129–136. [Google Scholar] [CrossRef]

- Zhu, R.; Wu, S.; Su, L.; Cui, J.; Mao, Z.; Zhang, X. Problems needing attention and future development direction of pore structure characterization of tight reservoirs in China. Acta Pet. Sin. 2016, 37, 1323–1336. [Google Scholar] [CrossRef]

- Ablimiti, Y.; Tang, Y.; Cao, J.; Chen, G.; Chen, J.; Tao, K. Reservoir forming mechanism and enrichment law of “continuous” reservoir outside the source of Baikouquan formation of Lower Triassic in Mahu sag, Junggar Basin. Nat. Gas Geosci. 2016, 27, 241–250. [Google Scholar] [CrossRef]

- Zhang, C.; Yin, T.; Tang, Y.; Guo, X.; Zhao, K.; Pan, J.; Chen, M. Advances in sedimentological reservoir research in Mahu sag and northwest margin of Junggar Basin. J. Paleogeogr. Chin. Ed. 2020, 22, 129–146. [Google Scholar] [CrossRef]

- Li, J.; Tang, Y.; Wu, T.; Zhao, J.; Wu, H.; Wu, W.; Bai, Y. Overpressure origin and its effects on petroleum accumulation in the conglomerate oil province in Mahu Sag, Junggar Basin, NW China. Pet. Explor. Dev. 2020, 47, 679–690. [Google Scholar] [CrossRef]

- Xiao, M.; Yuan, X.; Wu, S.; Cao, Z.; Tang, Y.; Xie, Z.; Wang, R. Conglomerate reservoir characteristics and main controlling factors for the Baikouquan formation in Mahu sag, Junggar Basin. Earth Sci. Front. 2019, 26, 212–224. [Google Scholar] [CrossRef]

- Lei, D.; Chen, G.; Liu, H.; Li, X.; Ablimiti, Y.; Tao, K.; Cao, J. Study on formation conditions and exploration direction of large oil (gas) area in Mahu sag, Junggar Basin. Acta Geol. Sin. 2017, 91, 1604–1619. [Google Scholar]

- Li, P.; Sun, W.; Wang, Z.; Huang, H.; Zhe, W. Features of Microscopic Pore Structure and Their Influence on Oil Displacement Efficiency in Chang 81 Reservoir of Xifeng Oilfield, Ordos Basin. Geoscience 2018, 32, 1194–1202. [Google Scholar] [CrossRef]

- Wu, H.; Kang, X.; Qin, M.; Lian, L.; Li, J.; Cao, J. Pore structure characteristics and genesis of heterogeneous conglomerate reservoir of Baikouquan Formation in Mahu sag, Junggar Basin. J. Cent. South Univ. Technol. 2022, 53, 3337–3353. [Google Scholar] [CrossRef]

- Du, M.; Xiang, Y.; Jia, N.; Lv, W.; Zhang, J.; Zhang, D. Pore structure characteristics of tight glutenite reservoirs of Baikouquan Formation in Mahu Sag. Lithologic Reservoirs. Lithol. Reserv. 2021, 33, 120–131. [Google Scholar] [CrossRef]

- Jin, G.; Wang, T.; Liu, Z.; Xie, R.; Shao, L.; Li, B. Classification and productivity prediction of glutenite reservoirs based on NMR logging. Acta Pet. Sin. 2022, 43, 648–657. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, K.; Xie, B.; Huang, X.; Wang, J.; Sun, H.; Huang, B. Classification and Log Evaluation to Low Permeability Conglomerate Reservoirs of Baikouquan Formation in Mahu Depression Junggar Basin. Well Logging Technol. 2020, 44, 305–311. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, Z.; Fan, W.; Wang, J.; Li, Z. Evaluating the Sedimentological and Diagenetic Impacts on Terrestrial Lacustrine Fan Delta Sandy Conglomerates Reservoir Quality: Insights from the Triassic Baikouquan Formation in the Mahu Sag, Junggar Basin, Western China. Mar. Pet. Geol. 2022, 146, 105973. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, Z.; Jiang, Q.; Wang, J.; Feng, Y.; Zheng, J.; Baffour, B.A. Evaluation of Low Permeability Conglomerate Reservoirs Based on Petrophysical Facies: A Case Study from the Triassic Baikouquan Formation, Northern Mahu Sag, Junggar Basin, China. J. Pet. Sci. Eng. 2022, 219, 111082. [Google Scholar] [CrossRef]

- Zhi, D. Discovery and reservoir forming mechanism of quasi continuous high efficiency reservoir of Baikouquan formation in Mahu sag. Xinjiang Pet. Geol. 2016, 37, 373–382. [Google Scholar] [CrossRef]

- Gao, Y. Physical property classification and controlling factors of glutenite reservoirs in Mahu sag, Junggar Basin, China. J. Chengdu Univ. Technol. Sci. Technol. Ed. 2022, 49, 542–551+560. [Google Scholar] [CrossRef]

- Tan, F.; Liu, W.; Ma, C.; Cheng, H.; Li, X.; Zhang, C. Classification Methods of Conglomerate Reservoirs Based on the Adsorption and Retention Law of Surfactant-Polymer Binary Systems. J. Pet. Sci. Eng. 2022, 208, 109195. [Google Scholar] [CrossRef]

- Zhu, S.; Qian, G.; Liu, S.; Wang, Y.; Xu, C. Secondary Development of Karamay Conglomerate Reservoir; Petroleum Industry Press: Beijing, China, 2015; ISBN 978-7-5183-0772-2. [Google Scholar]

- Li, G.; Qin, J.; Xian, C.; Fan, X.; Zhang, J.; Ding, Y. Theoretical understandings, key technologies and practices of tight conglomerate oilfield efficient development: A case study of the Mahu oilfield, Junggar Basin, NW China. Pet. Explor. Dev. 2020, 47, 1185–1197. [Google Scholar] [CrossRef]

- Tan, F.-Q.; Ma, C.-M.; Zhang, X.-Y.; Zhang, J.-G.; Tan, L.; Zhao, D.-D.; Li, X.-K.; Jing, Y.-Q. Migration Rule of Crude Oil in Microscopic Pore Throat of the Low-Permeability Conglomerate Reservoir in Mahu Sag, Junggar Basin. Energies 2022, 15, 7359. [Google Scholar] [CrossRef]

- Wang, Z.; Ge, H.; Zhou, W.; Wei, Y.; Wang, B.; Liu, S.; Zhou, H.; Du, S. Characterization of Pores and Microfractures in Tight Conglomerate Reservoirs. Int. J. Hydrog. Energy 2022, 47, 26901–26914. [Google Scholar] [CrossRef]

- Abitkazy, T.; Shuheng, D.U.; Feng, X.U.; Shi, Y. Pore Structure Characterization of Clay Minerals in the Lower Karamay Formation Conglomerate Reservoir in the Junggar Basin and Its Impact on Hydrocarbon Storage and Seepage. Acta Geol. Sin. Engl. Ed. 2021, 95, 558–569. [Google Scholar] [CrossRef]

- Yang, Y.; Xiao, W.; Bernabe, Y.; Xie, Q.; Wang, J.; He, Y.; Li, M.; Chen, M.; Ren, J.; Zhao, J.; et al. Effect of Pore Structure and Injection Pressure on Waterflooding in Tight Oil Sandstone Cores Using NMR Technique and Pore Network Simulation. J. Pet. Sci. Eng. 2022, 217, 110886. [Google Scholar] [CrossRef]

- Lu, X.; Sun, D.; Xie, X.; Chen, X.; Zhang, S.; Zhang, S.; Sun, G.; Shi, J. Microfacies Characteristics and Reservoir Potential of Triassic Baikouquan Formation, Northern Mahu Sag, Junggar Basin, NW China. J. Nat. Gas Geosci. 2019, 4, 47–62. [Google Scholar] [CrossRef]

- Lei, D.; Qu, J.; An, Z. Hydrocarbon Accumulation Conditions and Enrichment Regularity of Low-Permeability Glutenite Reservoirs of Baikouquan Formation in Mahu Sag, Junggar Basin. Xinjiang Pet. Geol. 2015, 36, 642–647. [Google Scholar]

- Wang, R.; Qi, H.; Lv, X.; Guo, D. Characteristics and controlling factors of movable fluid in deep-buried high-pressure and low-permeability sandstone reservoirs: A case study of middle section of 3rd member of Shahejie Formation in Wendong Oil Field, Dongpu Sag. Pet. Geol. Exp. 2014, 36, 123–128. [Google Scholar] [CrossRef]

| Formation Water | Water type | CaCl2 | Crude Oil | Density (g/cm3) | 0.827 | |

| Total salinity (mg/L) | 11,047.4 | Viscosity at 50 ℃ (MPa•s) | 8.6 | |||

| Main ion mineralization (mg/L) | Na++K+ | 3054.2 | Wax content (%) | 8.2 | ||

| Mg2+ | 38.5 | |||||

| Ca2+ | 1055.3 | Freezing point (℃) | 16.6 | |||

| SO42− | 105.5 | |||||

| Cl− | 6295.1 | Initial boiling point (℃) | 137.2 | |||

| HCO3− | 538.9 | |||||

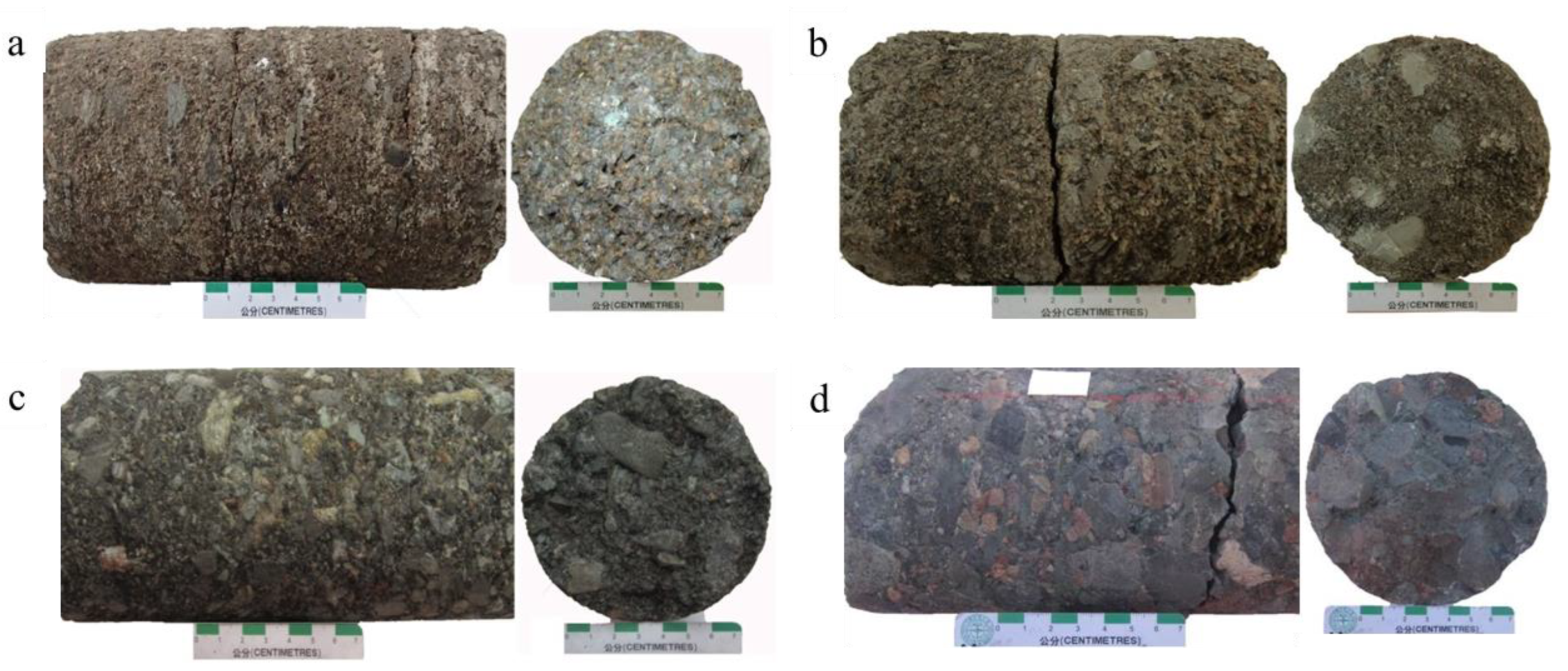

| Lithology | Sandy-Grain-Supported Conglomerate | Gravelly Coarse Sandstone | Sandy-Gravelly Matrix-Supported Conglomerate | Argillaceous-Supported Conglomerate |

|---|---|---|---|---|

| Core Photos |  |  |  |  |

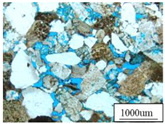

| CTS |  |  |  |  |

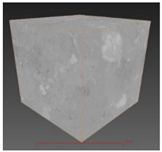

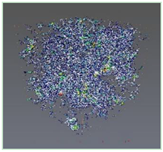

| 3D Digital Cores |  |  |  |  |

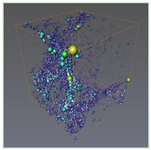

| Pore Network Model |  |  |  |  |

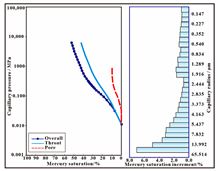

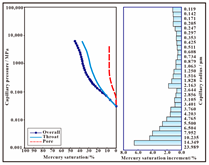

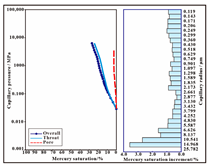

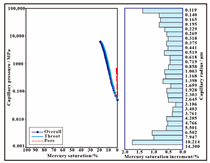

| CMI |  |  |  |  |

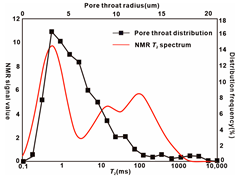

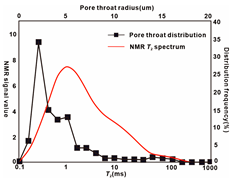

| NMR |  |  |  |  |

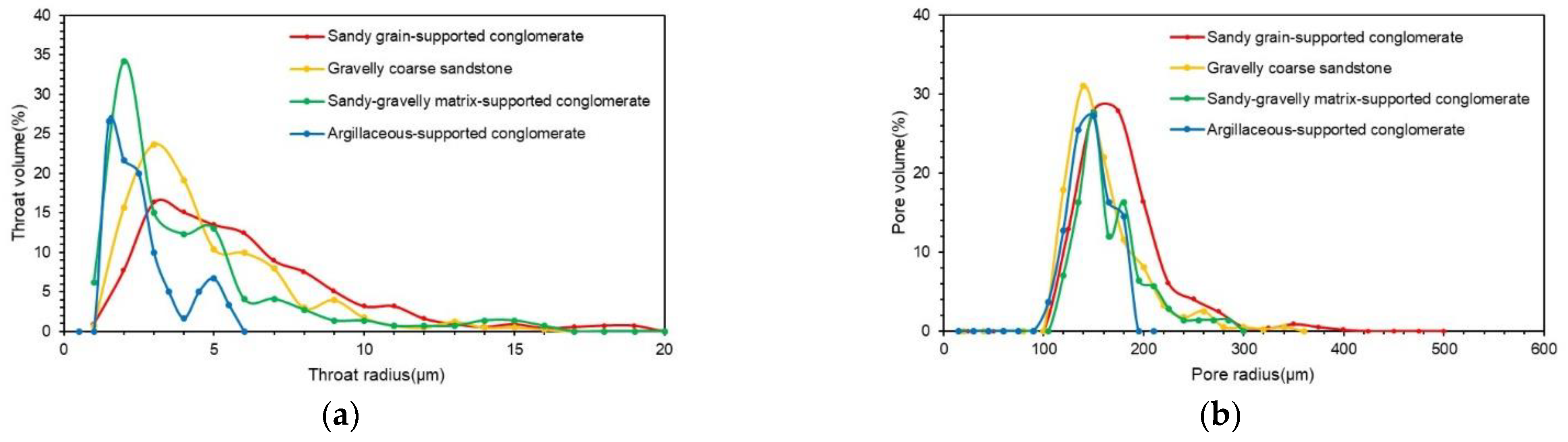

| Lithology | Sandy Grain-Supported Conglomerate | Gravelly Coarse Sandstone | Sandy-Gravelly Matrix-Supported Conglomerate | Argillaceous-Supported Conglomerate |

|---|---|---|---|---|

| Average Throat Radius (mm) | 5.94 | 3.24 | 3.83 | 2.95 |

| Average Pore Radius (mm) | 178.31 | 160.13 | 169.94 | 160.14 |

| Average Pore/Throat Radius Ratio | 45.85 | 110.92 | 91.99 | 91.67 |

| Average Pore Volume (nl) | 28.74 | 22.16 | 26.9 | 23.12 |

| Average Capillary Radius (mm) | 5.97 | 3.1 | 3.23 | 2.43 |

| Root Mean Square Value of Throat Radius (ΜM) | 7.87 | 4.19 | 4.46 | 3.48 |

| The radius of Main Throat (mm) | 3 | 2 | 2 | 2.33 |

| Final Mercury Saturation (%) | 52.38 | 34.71 | 49.22 | 27.59 |

| Total Pore Mercury Saturation (%) | 9.92 | 5.21 | 16.63 | 2.75 |

| Total Throat Mercury Saturation (%) | 42.46 | 29.5 | 32.5 9 | 24.83 |

| Total Pore/Throat Volume Ratio | 0.23 | 0.17 | 0.44 | 0.11 |

| Displacement Pressure (MPa) | 0.01 | 0.08 | 0.45 | 0.1 |

| Reservoir Type | Porosity (%) | Permeability (mD) | Displacement Pressure (MPa) | Maximum Pore Throat Radius (mm) | Median Pressure (MPa) | Median Radius (mm) | Average Capillary Radius (mm) | Saturated Pore Volume Percentage (%) | Mercury Ejection Efficiency (%) |

|---|---|---|---|---|---|---|---|---|---|

| Type Ⅰ | 5.9–14.8 9.46 | 0.32–86.4 2.85 | 0.16 | 35.8 | 0.5 | 1.12 | 35.8–0.035 1.42 | 77.5 | 18.6 |

| Type Ⅱ | 4.7–12.6 8.36 | 0.27–73.6 1.54 | 0.2 | 8.96 | 1.8 | 0.58 | 8.96–0.035 0.92 | 78.4 | 19.4 |

| Type Ⅲ | 4.3–10.7 7.72 | 0.18–25.3 1.06 | 0.32 | 4.59 | 10.1 | 0.26 | 4.59–0.03 0.51 | 66.3 | 16.4 |

| Type Ⅳ | 2.7–9.2 5.86 | 0.04–8.93 0.43 | 0.36 | 2.32 | 11.2 | 0.14 | 2.32–0.03 0.29 | 60.4 | 21.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhao, X.; Tang, C.; Zhang, X.; Ma, C.; Yi, X.; Tan, F.; Zhao, D.; Li, J.; Jing, Y. Study on Microscopic Pore Structure Classification for EOR of Low Permeability Conglomerate Reservoirs in Mahu Sag. Energies 2023, 16, 626. https://doi.org/10.3390/en16020626

Wang Y, Zhao X, Tang C, Zhang X, Ma C, Yi X, Tan F, Zhao D, Li J, Jing Y. Study on Microscopic Pore Structure Classification for EOR of Low Permeability Conglomerate Reservoirs in Mahu Sag. Energies. 2023; 16(2):626. https://doi.org/10.3390/en16020626

Chicago/Turabian StyleWang, Yong, Xubin Zhao, Chuanyi Tang, Xuyang Zhang, Chunmiao Ma, Xingyu Yi, Fengqi Tan, Dandan Zhao, Jie Li, and Yuqian Jing. 2023. "Study on Microscopic Pore Structure Classification for EOR of Low Permeability Conglomerate Reservoirs in Mahu Sag" Energies 16, no. 2: 626. https://doi.org/10.3390/en16020626