Predictive Current Control of Sensorless Linear Permanent Magnet Synchronous Motor

Abstract

:1. Introduction

- (1)

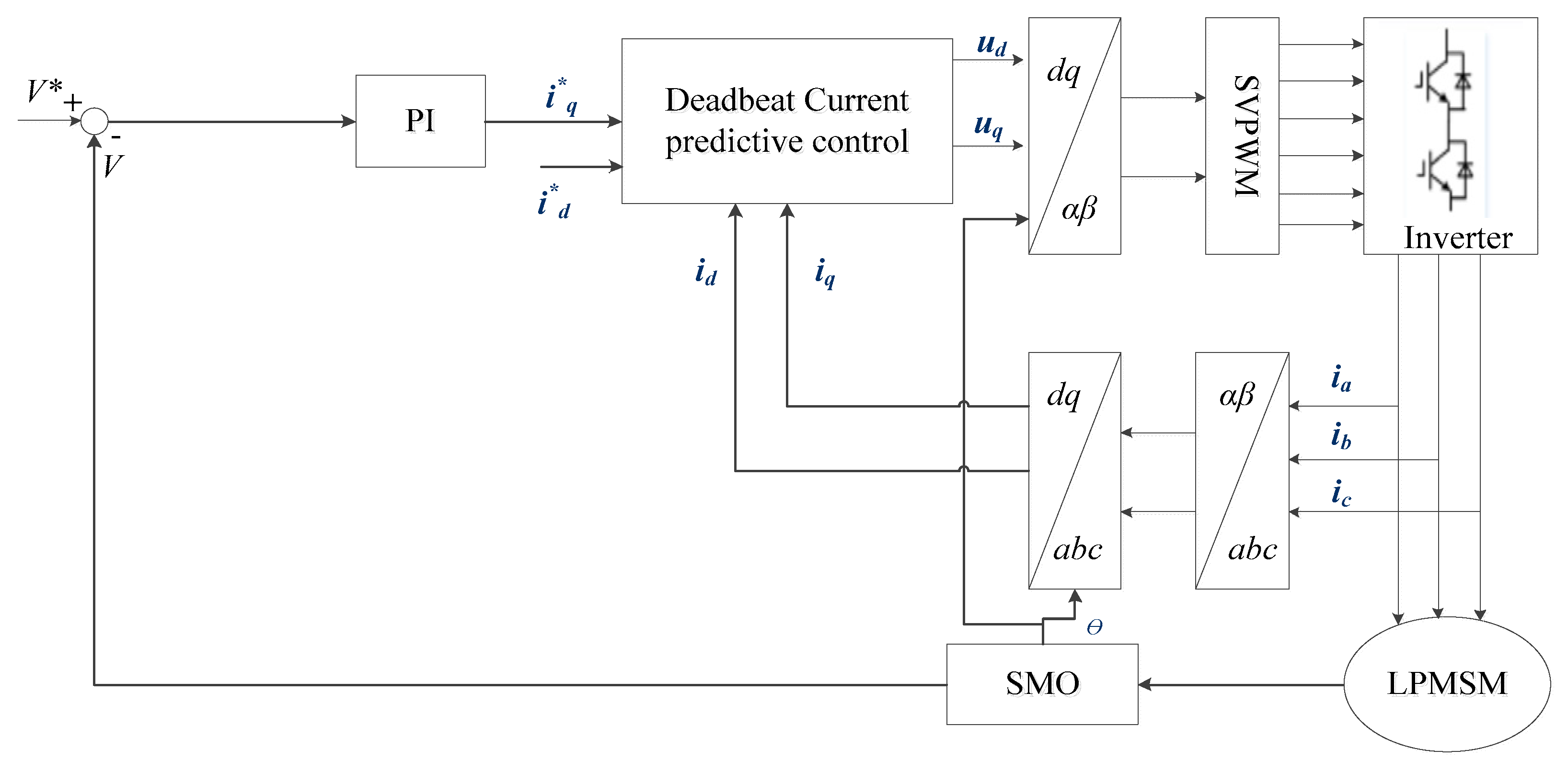

- The SMO is used to observe the LPMSM velocity value, which reduces the impact of environmental uncertainty disturbance.

- (2)

- The deadbeat current predictive controller is designed to replace the PI controller. The influence of sliding-mode-observer chatter is reduced. It solves the problem that the PI controller’s parameters’ tuning is difficult.

- (3)

- The new deadbeat predictive current control has a better performance compared with the PI control.

2. Design of Sliding-Mode Speed Observer Based on LPMSM

3. Deadbeat Predictive Current Control

4. Simulation Analysis

4.1. Simulation Results of SMO

4.2. Simulation Results of SMO and DBPC

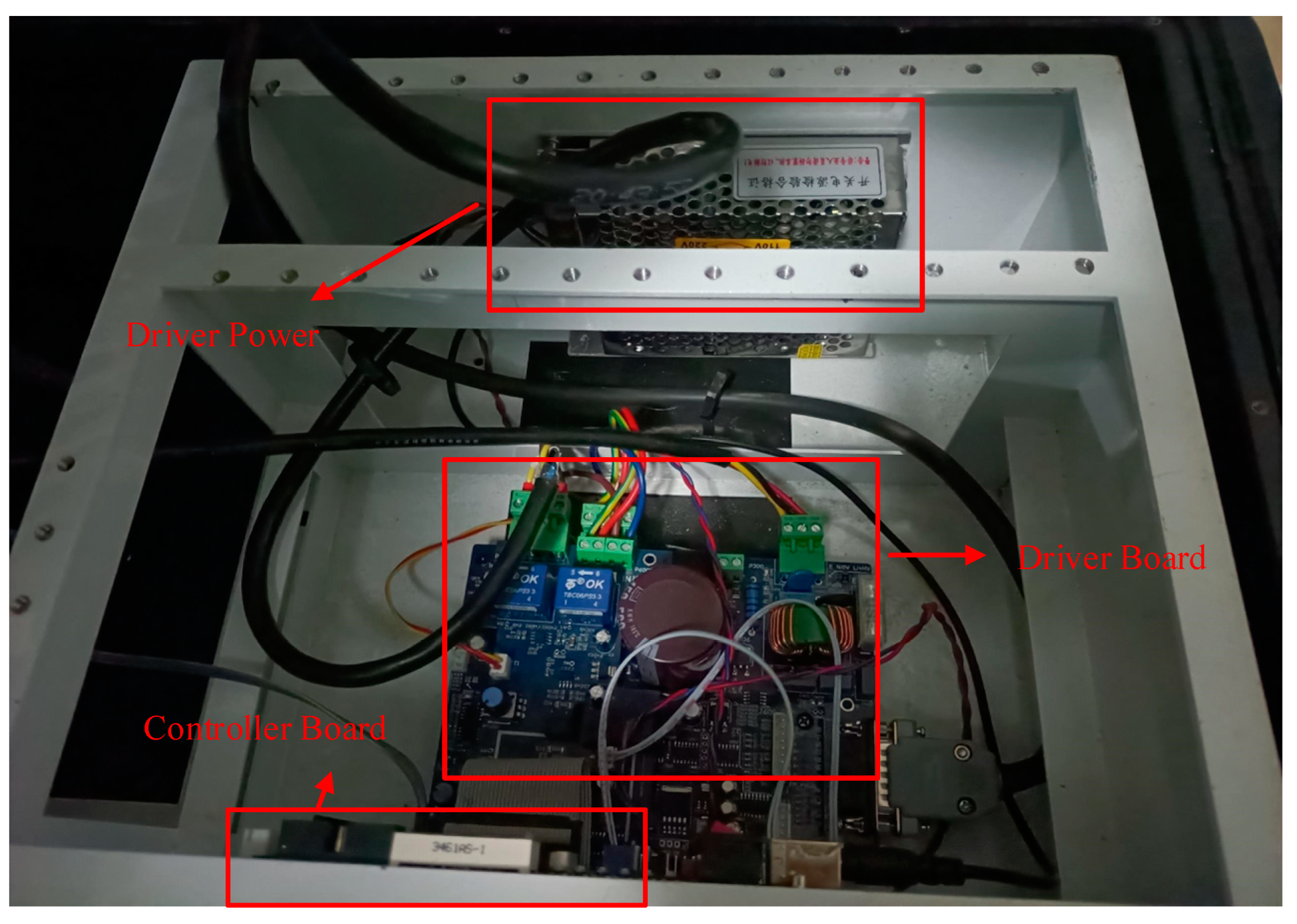

5. Analysis of Experimental Results

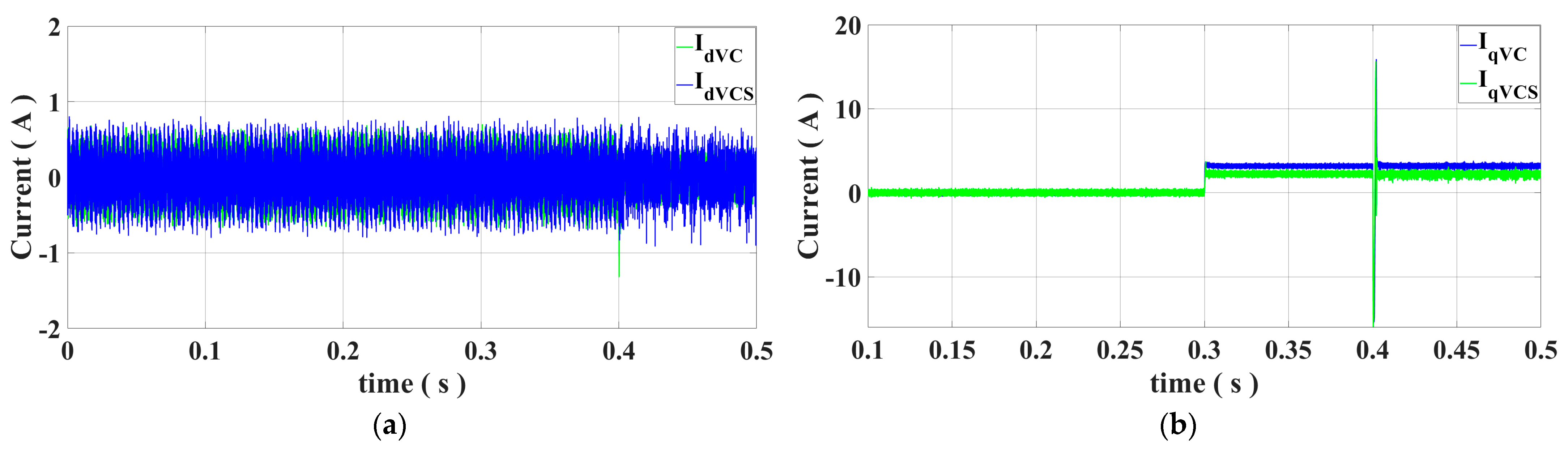

5.1. Analysis of Experimental Results of VC and Sensorless VC

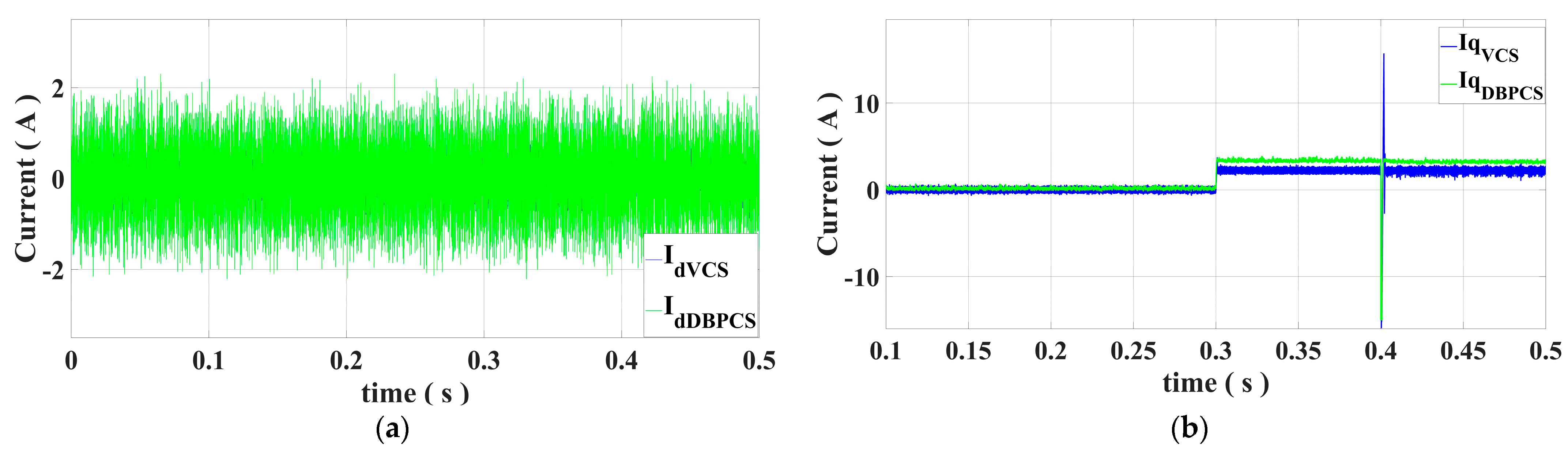

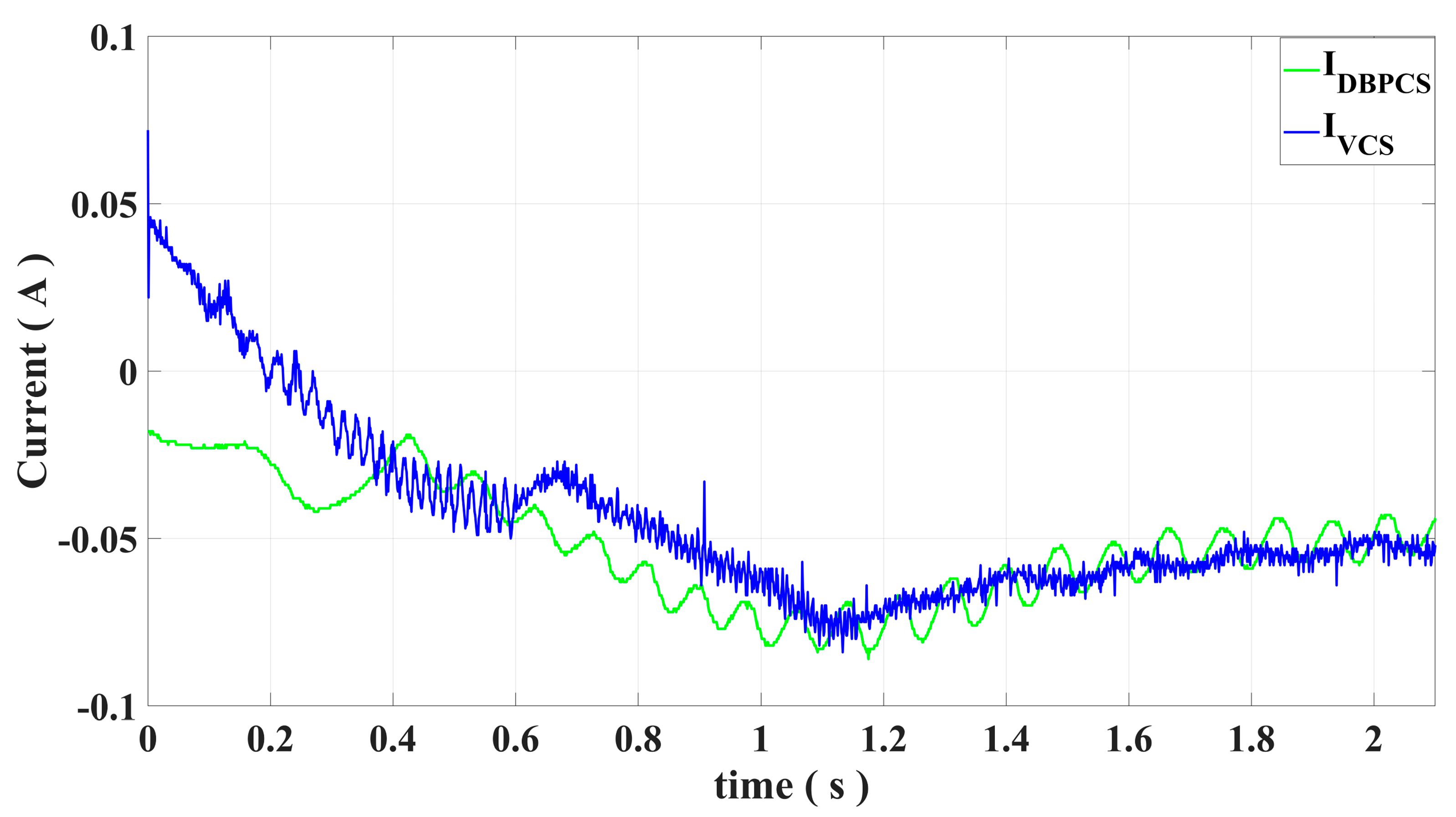

5.2. Analysis of Experimental Results of Sensorless DBPC and Sensorless VC

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, T.; Lu, K.; Zhu, J.; Lei, G.; Guo, Y.; Tang, W. Calculation of Eddy Current Loss in a Tubular Oscillatory LPMSM Using Computationally Efficient FEA. IEEE Trans. Ind. Electron. 2019, 66, 6200–6209. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Y.; Feng, L.; Jiang, S.; Wang, Q.; Hu, J. Permanent-Magnet Synchronous Motor Sensorless Control Using Proportional-Integral Linear Observer with Virtual Variables: A Comparative Study with a Sliding Mode Observer. Energies 2019, 12, 877. [Google Scholar] [CrossRef] [Green Version]

- Cao, F.; An, Q.; Zhang, J.; Zhao, M.; Li, S. Variable Weighting Coefficient of EMF Based Enhanced Sliding Mode Observer for Sensorless PMSM Drives. Energies 2017, 15, 6001. [Google Scholar] [CrossRef]

- Wu, T.; Feng, Z.; Wu, C.; Lei, G.; Guo, Y.; Zhu, J.; Wang, X. Multiobjective Optimization of a Tubular Coreless LPMSM Based on Adaptive Multiobjective Black Hole Algorithm. IEEE Trans. Ind. Electron. 2019, 67, 3901–3910. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, G.; Liu, G.; Zhao, W.; Lin, Z.; Liu, L. Torque Ripple Reduction in Five-Phase Interior Permanent Magnet Motors by Lowering Interactional MMF. IEEE Trans. Ind. Electron. 2018, 65, 8520–8531. [Google Scholar] [CrossRef]

- Zhu, X.; Huang, J.; Quan, L.; Xiang, Z.; Shi, B. Comprehensive Sensitivity Analysis and Multi-Objective Optimization Research of Permanent Magnet Flux-Intensifying Motors. IEEE Trans. Ind. Electron. 2019, 66, 2613–2627. [Google Scholar] [CrossRef]

- Sun, X.; Hu, C.; Zhu, J.; Wang, S.; Zhou, W.; Yang, Z.; Lei, G.; Li, K.; Zhu, B.; Guo, Y. MPTC for PMSMs of EVs with Multi-Motor Driven System Considering Optimal Energy Allocation. IEEE Trans. Magn. 2019, 55, 8104306. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, J.; Zhao, Z.; Xu, W.; Dorrell, G. An Improved Direct Torque Control for Three-Level Inverter-Fed Induction Motor Sensorless Drive. IEEE Trans. Power Electron. 2012, 27, 1502–1513. [Google Scholar] [CrossRef]

- Kim, S.; Yoon, I.; Jung, S.; Ko, J. Robust Sensorless Control of Interior Permanent Magnet Synchronous Motor Using Deadbeat Extended Electromotive Force Observer. Energies 2022, 15, 7568. [Google Scholar] [CrossRef]

- Schroedl, M. Sensorless Control of AC Machines at Low Speed and Standstill Based on the “INFORM” Method. In Proceedings of the Conference Record of the 1996 IEEE Industry Applications Conference Thirty-First IAS Annual Meeting, San Diege, CA, USA, 6–10 October 1996; pp. 270–277. [Google Scholar]

- Morimoto, S.; Kawamoto, K.; Sanada, M.; Takeda, Y. Sensorless Control Strategy for Salient-Pole PMSM Based on Extended EMF in Rotating Reference Frame. IEEE Trans. Ind. Appl. 2002, 38, 1054–1061. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, W.; Mu, C.; Zhu, J.; Dian, R. An Improved Third-Order Generalized Integral Flux Observer for Sensorless Drive of PMSMs. IEEE Trans. Ind. Electron. 2019, 66, 9149–9160. [Google Scholar] [CrossRef]

- Almarhoon, A.; Zhu, Q.; Xu, P. Improved Rotor Position Estimation Accuracy by Rotating Carrier Signal Injection Utilizing Zero-Sequence Carrier Voltage for Dual Three-Phase PMSM. IEEE Trans. Ind. Electron. 2017, 35, 3767–3776. [Google Scholar] [CrossRef]

- Tang, Q.; Shen, A.; Luo, X.; Xu, J. PMSM Sensorless Control by Injecting HF Pulsating Carrier Signal into ABC Frame. IEEE Trans. Power Electron. 2017, 32, 3767–3776. [Google Scholar] [CrossRef]

- Corley, J.; Lorenz, D. Rotor Position and Velocity Estimation for a Salient-Pole Permanent Magnet Synchronous Machine at Standstill and High Speeds. IEEE Trans. Ind. Appl. 1998, 34, 784–789. [Google Scholar] [CrossRef] [Green Version]

- Cirrincione, M.; Pucci, M. Sensorless Direct Torque Control of an Induction Motor by a TLS-Based MRAS Observer with Adaptive Integration. Automatic 2005, 41, 1843–1854. [Google Scholar] [CrossRef]

- Gao, W.; Guo, Z. Speed Sensorless Control of PMSM using Model Reference Adaptive System and RBFN. J. Netw. 2013, 8, 213–220. [Google Scholar] [CrossRef]

- Fadi, A.; Ahmad, A.; Rabia, S.; Cristina, M.; Ibrahim, K. Velocity Sensor Fault-Tolerant Controller for Induction Machine using Intelligent Voting Algorithm. Energies 2022, 15, 3084. [Google Scholar]

- Zbede, B.; Gadoue, M.; Atkinson, J. Model Predictive MRAS Estimator for Sensorless Induction Motor Drives. IEEE Trans. Ind. Electron. 2016, 63, 3511–3521. [Google Scholar] [CrossRef] [Green Version]

- Zou, J.; Xu, W.; Zhu, J.; Liu, Y. Low-Complexity Finite Control Set Model Predictive Control With Current Limit for Linear Induction Machines. IEEE Trans. Ind. Electron. 2018, 65, 9243–9254. [Google Scholar] [CrossRef]

- Khan, A.; Guo, Y.; Zhu, J. Model Predictive Observer Based Control for Single-Phase Asymmetrical T-Type AC/DC Power Converter. IEEE Trans. Ind. Electron. 2019, 55, 2033–2044. [Google Scholar] [CrossRef]

- Sun, X.; Gao, J.; Lei, G.; Zhu, J. Speed Sensorless Control for Permanent Magnet Synchronous Motors Based on Finite Position Set. IEEE Trans. Ind. Electron. 2020, 67, 6089–6100. [Google Scholar] [CrossRef]

- Alathamneh, E.; Ghanayem, H.; Yang, X.; Nelms, R. Three-Phase Grid-Connected Inverter Power Control under Unbalanced Grid Conditions Using a Proportional-Resonant Control Method. Energies 2022, 15, 7051. [Google Scholar] [CrossRef]

- Liu, T.; Chang, K.; Li, J. Design and Implementation of Periodic Control for a Matrix Converter-Based Interior Permanent Magnet Synchronous Motor Drive System. Energies 2021, 14, 8073. [Google Scholar] [CrossRef]

- Xin, G.; Li, Y.; Chen, W.; Jin, X. Improved Deadbeat Predictive Control Based Current Harmonic Suppression Strategy for IPMSM. Energies 2022, 15, 3943. [Google Scholar]

- Zeng, X.; Wang, W.; Wang, H. Adaptive PI and RBFNN PID Current Decoupling Controller for Permanent Magnet Synchronous Motor Drives: Hardware- Validated Results. Energies 2022, 15, 6353. [Google Scholar] [CrossRef]

- Lin, J.; Zhao, Y.; Zhang, P.; Wang, J.; Su, H. Research on Compound Sliding Mode Control of a Permanent Magnet Synchronous Motor in Electromechanical Actuators. Energies 2021, 14, 7293. [Google Scholar] [CrossRef]

| Symbol | Value | Unit |

|---|---|---|

| 0.0085 | [H] | |

| 2.875 | [] | |

| 0.175 | [Wb] | |

| 4 | - | |

| 3 | cm | |

| 4.3 | [kg] | |

| 1.3 | [N·s/m] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Wu, T.; Guo, Y.; Lei, G.; Wang, X. Predictive Current Control of Sensorless Linear Permanent Magnet Synchronous Motor. Energies 2023, 16, 628. https://doi.org/10.3390/en16020628

Wang H, Wu T, Guo Y, Lei G, Wang X. Predictive Current Control of Sensorless Linear Permanent Magnet Synchronous Motor. Energies. 2023; 16(2):628. https://doi.org/10.3390/en16020628

Chicago/Turabian StyleWang, He, Tao Wu, Youguang Guo, Gang Lei, and Xinmei Wang. 2023. "Predictive Current Control of Sensorless Linear Permanent Magnet Synchronous Motor" Energies 16, no. 2: 628. https://doi.org/10.3390/en16020628