Systematic Overview of Newly Available Technologies in the Green Maritime Sector

Abstract

1. Introduction

2. Recent Available Technologies for Green Maritime Sector

2.1. Alternative Fuels

- It is recommended to replace primary marine fuels such as LSHFO and MDO because replacing them would take time. Prior to the start of a new age of alternative marine fuels, the choice of the most promising route is extremely crucial. Given the modest potential for carbon reductions and the significant infrastructure expenditure, LNG or LPG should be used with caution as a marine fuel.

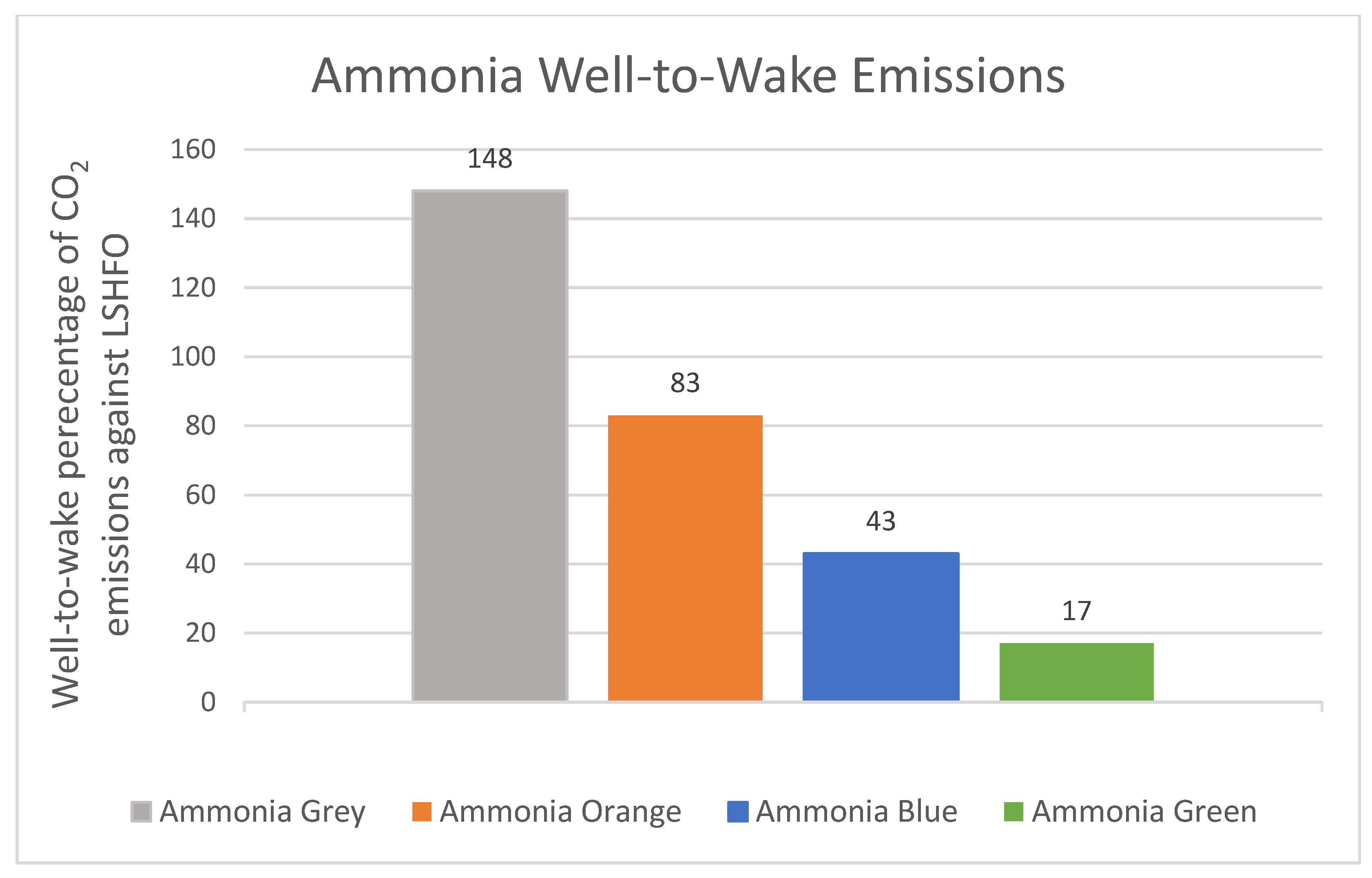

- In some areas, hydrogen and ammonia are the best fuels for coastal shipping since they are carbon-free fuels with already promising futures in the road transportation sector. The present cost structure is still excessive, and the infrastructure is insufficient, so based on local low-carbon development objectives, encouragement for the implementation of national and regional incentives should be given. Additionally, they are not advised for deep-sea application due to their low volumetric energy density and limited potential.

- The unreliable fuel supply for biofuels, including so-called carbon-neutral fuels such as RNG, biogenic methanol, bioethanol and biodiesel, is a result of the varied geographic distribution of land and water resources as well as competition from other energy-consuming industries. As a result, the future of biofuels in international shipping is not encouraging. However, there could be advantages to using them in local and regional shipping, but that needs further investigation. Liquid biofuels could start to be used more frequently in shipping and aviation as a result of the growing electrification of road transportation. RNG and methanol may be produced using fossil and renewable feedstocks, as well as with renewable and fossil energy combined with captured CO2.

- The most viable alternative fuel for international transport is methanol, both current fossil methanol and future renewable methanol. Therefore, the international shipping community must come to an agreement and establish a united plan of action given the lengthy timelines connected with marine fuel replacement.

- The combination of alternative marine fuels suggested in this study includes hydrogen, ammonia, and biodiesel produced from renewable energy sources for short-sea shipping, and methanol for worldwide shipping. It is recommended that LSHFO and MDO are gradually phased out and it is suggested that the development of vessels powered by LNG and LPG should be carried out cautiously. Consequently, future research and development efforts should place a high priority on fuel cell devices that run on hydrogen, ammonia, and methanol.

- When building infrastructure, it is important to consider cogeneration (cooling, heating, and electricity) while utilizing raw and recycled materials in the process of creating alternative fuels. This would be a significant step in lowering production costs, which are still a major barrier to the broad use of alternative marine fuels.

| Fuel | Chem. Formula | Well-to-Wake Energy (rel. to HFO) | Well-to-Wake Cost (rel. to HFO) | Scalability | Regulations | Technology Readiness | ICE Combustion Emissions | |||

|---|---|---|---|---|---|---|---|---|---|---|

| CO2 | NOx | SOx | PM | |||||||

| LSHFO | C8-C25 | 100% | 100% | Scalable | IGF Code | Commercialized | 100% | 100% | 100% | 100% |

| LNG | CH4 | 101% | 110% | Scalable | IGF Code | Commercialized | 92% | 7% | 0% | 4% |

| Blue H2 | H2 | 138% | 306% | Scalable | Require amendment of IGF Code | Small scale | 17% | 100% | 0% | 0% |

| Blue H2 (FC) | H2 | 112% | 469% | Scalable | Require amendment of IGF Code | Small scale | 14% | 0% | 0% | 0% |

| Blue methanol | CH3OH | 177% | 221% | Scalable | Require amendment of IGF Code | Small scale | 129% | 19% | 0% | 0% |

| Bio-methanol | CH3OH | 134% | 384% | Challenging | Require amendment of IGF Code | Small scale | 15% | 108% | 11% | 26% |

| Biodiesel | C18-C18 | 100% | 190% | Challenging | ISO 8217:2017 standard | Small scale | 1% | 108% | 11% | 26% |

| Ammonia | NH3 | 178% | 371% | Scalable | IGF code not approved | Small scale | 34% | 100% | 0% | 0% |

| Ammonia (FC) | NH3 | 145% | 521% | Scalable | IGF code not approved | Small scale | 27% | 0% | 0% | 0% |

2.2. Alternative Propulsion and Auxiliary Systems

- Rotors: yhese rotating cylinders, which are positioned on deck and use the Magnus effect to provide forward propulsion, are also known as Flettner rotors since Anton Flettner was the person who first patented them.

- Towing kites: by generating lift from high-altitude winds, towing kites propel ships.

- Suction wings: similar to the wings of an airplane, suction wings provide an upward lift force.

- Rigid sails/wing sails: rigid sails or wing sails are foils that may be modified to produce aerodynamic forces.

- Soft sails: soft sails are traditional sails with modern characteristics. The DynaRig, which is presently employed mostly on big sailing yachts, serves as an example [79].

- Wind turbines: these are turbines mounted on a ship’s deck that produce thrust or power used for propulsion.

- Hull sails: hull sails are ship hulls that use the relative wind with their symmetrical hull foils to generate aerodynamic lift.

2.3. Digitalization

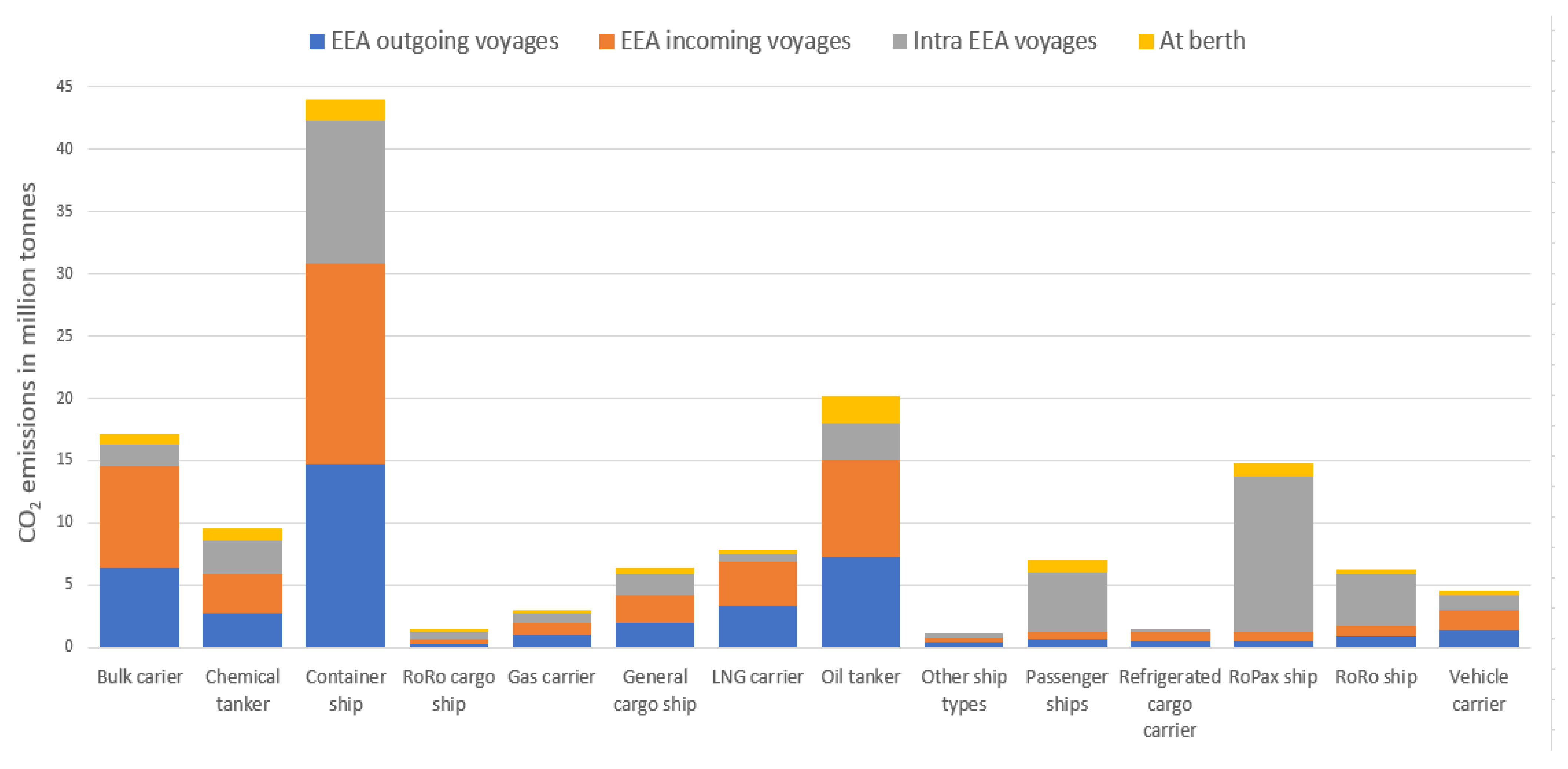

- Steps toward stricter legislation and regulations linked to alternative fuels and ship design need to be adopted at the international level in order to achieve sustainability targets for the shipping sector and reduce GHG emissions.

- The port can still help with the process of decreasing GHG emissions, though, by providing alternative fuel supplies in the port and employing ecologically differentiated port taxes, for example.

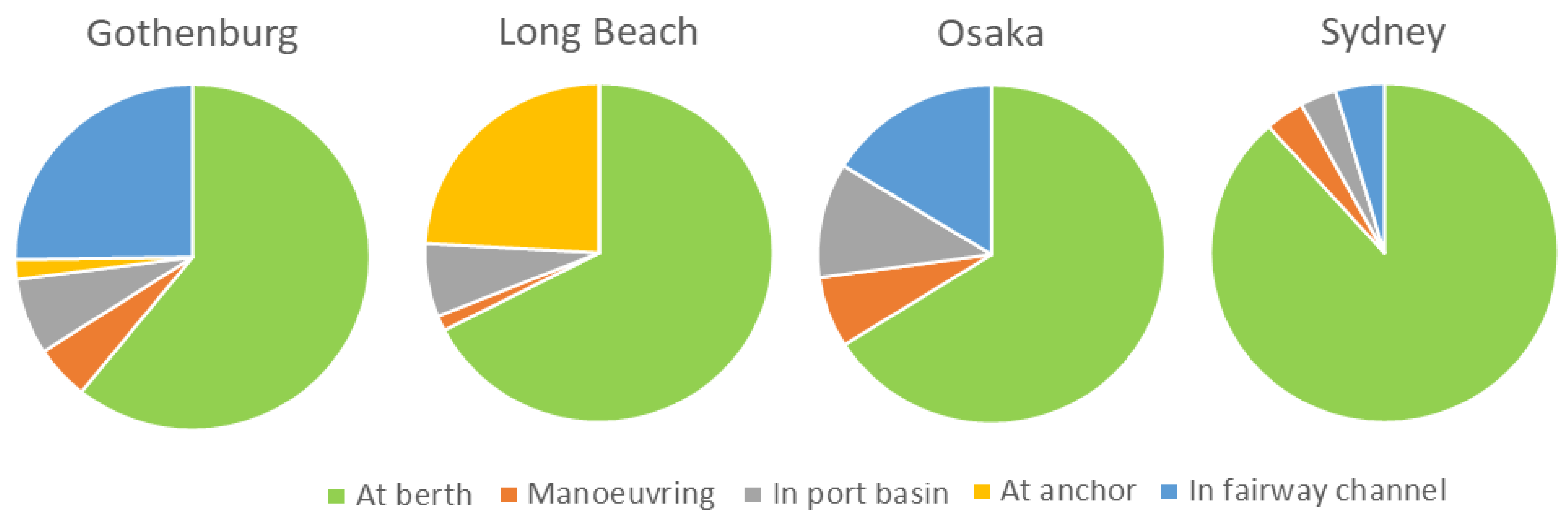

- Measures that particularly target emissions from the at-berth mode, such as decreased time at berth and on-shore power supply, are also beneficial, particularly for terminals with a high volume of ships in liner service.

- The findings also show that it is very challenging to perform accurate comparisons of ship emissions in ports from the standpoint of conducting international benchmarking studies. Given the different conditions each port faces, it is likely that emission reduction strategies should be customized for each port.

2.4. Hull Optimization

- The benefit of using ALS seems doubtful (only in the ship design phase the application of this system improves the EEDI value, which is interesting for ship designers and ship owners)

- The use of ALS for the entire speed range of the ship is not beneficial. There are minimum and maximum speeds beyond which the use of the system does not lead to the assumed savings.

- The equipment included in the structure of the ALS, including the main blowers, requires high investment costs and high operating costs.

2.5. Carbon Capturing Technologies

3. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| AIS | Automatic identification system |

| ALS | Air Lubrication System |

| BDA | Big data analysis |

| CCC | Cryogenic carbon capture |

| CCS | Carbon capture and storage |

| CO2 | Carbon dioxide |

| EEDI | Energy efficiency design index |

| EGCS | Exhaust gas cleaning systems |

| ESS | Extended storage system |

| GHG | Greenhouse gases |

| HFO | Heavy fuel oil |

| HVO | Hydrogenated vegetable oil |

| IMO | International maritime organization |

| LGI | Liquid gas injection |

| LH2 | Liquid hydrogen |

| LNG | Liquified natural gas |

| LPG | Liquefied petroleum gas |

| LSHFO | Low sulfate heavy fuel oil |

| MDO | Marine diesel oil |

| MGO | Marine gas oil |

| ML | Machine learning |

| MPC | Model predictive control |

| NOx | Nitrogen oxides |

| OCCS | Onboard carbon capture and storage system |

| PEMFC | Proton exchange membrane fuel cells |

| PM | Particulate matter |

| PM10 | Particulate matter below 10 μm |

| PTI | Power take-in |

| PTO | Power take-off |

| RNG | Renewable natural gas |

| SCR | Selective catalytic reduction |

| SOC | State of charge |

| SOx | Sulfur oxides |

| UCG | Underground coal gasification |

| VRFB | Vanadium redox flow batteries |

| WASP | Wind-assisted ship propulsion |

References

- Elgohary, M.M.; Seddiek, I.; Salem, A. Overview of alternative fuels with emphasis on the potential of liquefied natural gas as future marine fuel. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2014, 229, 365–375. [Google Scholar] [CrossRef]

- Sirimanne, S.N.; Hoffman, J.; Juan, W.; Asariotis, R.; Assaf, M.; Ayala, G.; Benamara, H.; Chantrel, D.; Hoffmann, J.; Premti, A. Review of maritime transport 2019. In Proceedings of the United Nations Conference on Trade and Development, Geneva, Switzerland, 25 September 2019. [Google Scholar]

- Munim, Z.H.; Schramm, H.-J. Forecasting container shipping freight rates for the Far East–Northern Europe trade lane. Marit. Econ. Logist. 2017, 19, 106–125. [Google Scholar] [CrossRef]

- Yang, D.; Jiang, L.; Notteboom, T. Innovative solutions for shipping market turmoil: The search for profitability, sustainability and resilience. Transp. Policy 2019, 82, 75–76. [Google Scholar] [CrossRef]

- Yazawa, N. Analysis of the Factors in the Fluctuations of Japanese Transportation Sector Energy Consumption. In Proceedings of the 21st IAEE International Conference, Quebec, QC, Canada, 13–16 May 1998. [Google Scholar]

- ABS. Setting the Course to Low Carbon Shipping; American Bureau of Shipping: Houston, TX, USA, 2019. [Google Scholar]

- Bengtsson, S.; Andersson, K.; Fridell, E. A comparative life cycle assessment of marine fuels: Liquefied natural gas and three other fossil fuels. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2011, 225, 97–110. [Google Scholar] [CrossRef]

- Bengtsson, S.; Fridell, E.; Andersson, K. Environmental assessment of two pathways towards the use of biofuels in shipping. Energy Policy 2012, 44, 451–463. [Google Scholar] [CrossRef]

- Bengtsson, S.K.; Fridell, E.; Andersson, K. Fuels for short sea shipping: A comparative assessment with focus on environmental impact. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2014, 228, 44–54. [Google Scholar] [CrossRef]

- Brynolf, S.; Fridell, E.; Andersson, K. Environmental assessment of marine fuels: Liquefied natural gas, liquefied biogas, methanol and bio-methanol. J. Clean. Prod. 2014, 74, 86–95. [Google Scholar] [CrossRef]

- Le, V.V.; Huynh, T.T.; Ölçer, A.; Hoang, A.T.; Le, A.T.; Nayak, S.K.; Pham, V.V. A remarkable review of the effect of lockdowns during COVID-19 pandemic on global PM emissions. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–16. [Google Scholar] [CrossRef]

- Zou, Z.; Zhao, J.; Zhang, C.; Zhang, Y.; Yang, X.; Chen, J.; Xu, J.; Xue, R.; Zhou, B. Effects of cleaner ship fuels on air quality and implications for future policy: A case study of Chongming Ecological Island in China. J. Clean. Prod. 2020, 267, 122088. [Google Scholar] [CrossRef]

- Rutherford, D.; Comer, B. The International Maritime Organization’s Initial Greenhouse Gas Strategy. 2018. Available online: https://theicct.org/sites/default/files/publications/IMO%20GHG%20strategy%20rapid%20analysis%20vf.pdf (accessed on 12 December 2022).

- Dnv, G. Maritime Forecast to 2050. 2020. Available online: https://www.dnv.com/maritime/publications/maritime-forecast-2022/index.html (accessed on 5 October 2022).

- Zhu, M.; Yuen, K.F.; Ge, J.W.; Li, K.X. Impact of maritime emissions trading system on fleet deployment and mitigation of CO2 emission. Transp. Res. Part D Transp. Environ. 2018, 62, 474–488. [Google Scholar] [CrossRef]

- Lin, C.-Y. Strategies for promoting biodiesel use in marine vessels. Mar. Policy 2013, 40, 84–90. [Google Scholar] [CrossRef]

- Florentinus, A.; Hamelinck, C.; van den Bos, A.; Winkel, R.; Cuijpers, M. Potential of Biofuels for Shipping; ECOFYS Netherlands BV: Utrecht, The Netherlands, 2012. [Google Scholar]

- Tyrovola, T.; Dodos, G.; Kalligeros, S.; Zannikos, F. The introduction of biofuels in marine sector. J. Environ. Sci. Eng. A 2017, 6, 415–421. [Google Scholar] [CrossRef]

- Andersson, K.; Salazar, C.M. Methanol as a marine fuel report. FCBI Energy 2015, 1–46. [Google Scholar]

- Maggio, G.; Nicita, A.; Squadrito, G. How the hydrogen production from RES could change energy and fuel markets: A review of recent literature. Int. J. Hydrogen Energy 2019, 44, 11371–11384. [Google Scholar] [CrossRef]

- Welaya, Y.M.; El Gohary, M.M.; Ammar, N.R. A comparison between fuel cells and other alternatives for marine electric power generation. Int. J. Nav. Archit. Ocean. Eng. 2011, 3, 141–149. [Google Scholar] [CrossRef]

- McCoy, T.J. Electric ships past, present, and future [technology leaders]. IEEE Electrif. Mag. 2015, 3, 4–11. [Google Scholar] [CrossRef]

- Shahsavari, A.; Akbari, M. Potential of solar energy in developing countries for reducing energy-related emissions. Renew. Sustain. Energy Rev. 2018, 90, 275–291. [Google Scholar] [CrossRef]

- Mander, S. Slow steaming and a new dawn for wind propulsion: A multi-level analysis of two low carbon shipping transitions. Mar. Policy 2017, 75, 210–216. [Google Scholar] [CrossRef]

- Raucci, C.; Smith, T.; Rehmatulla, N.; Palmer, K.; Balani, S.; Pogson, G. Zero-Emission Vessels 2030: How Do We Get There? 2017. Available online: https://www.lr.org/en/insights/articles/zev-report-article/ (accessed on 2 November 2022).

- Busch, J.; Barthlott, W.; Brede, M.; Terlau, W.; Mail, M. Bionics and green technology in maritime shipping: An assessment of the effect of Salvinia air-layer hull coatings for drag and fuel reduction. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2019, 377, 20180263. [Google Scholar] [CrossRef]

- Kawakita, C.; Sato, S.; Okimoto, T. Application of simulation technology to Mitsubishi air lubrication system. Mitsubishi Heavy Ind. Tech. Rev. 2015, 52, 50–56. [Google Scholar]

- Kirstein, L.; Halim, R.; Merk, O. Decarbonising Maritime Transport—Pathways to Zero-Carbon Shipping by 2035; International Transportation Forum: Paris, France, 2018.

- Balcombe, P.; Brierley, J.; Lewis, C.; Skatvedt, L.; Speirs, J.; Hawkes, A.; Staffell, I. How to decarbonise international shipping: Options for fuels, technologies and policies. Energy Convers. Manag. 2019, 182, 72–88. [Google Scholar] [CrossRef]

- Gilbert, P.; Bows-Larkin, A.; Mander, S.; Walsh, C. Technologies for the high seas: Meeting the climate challenge. Carbon Manag. 2014, 5, 447–461. [Google Scholar] [CrossRef]

- Xing, H.; Stuart, C.; Spence, S.; Chen, H. Alternative fuel options for low carbon maritime transportation: Pathways to 2050. J. Clean. Prod. 2021, 297, 126651. [Google Scholar] [CrossRef]

- Hoang, A.T.; Tran, V.D.; Dong, V.H.; Le, A.T. An experimental analysis on physical properties and spray characteristics of an ultrasound-assisted emulsion of ultra-low-sulphur diesel and Jatropha-based biodiesel. J. Mar. Eng. Technol. 2022, 21, 73–81. [Google Scholar] [CrossRef]

- Ampah, J.D.; Yusuf, A.A.; Afrane, S.; Jin, C.; Liu, H. Reviewing two decades of cleaner alternative marine fuels: Towards IMO’s decarbonization of the maritime transport sector. J. Clean. Prod. 2021, 320, 128871. [Google Scholar] [CrossRef]

- Law, L.C.; Foscoli, B.; Mastorakos, E.; Evans, S. A comparison of alternative fuels for shipping in terms of lifecycle energy and cost. Energies 2021, 14, 8502. [Google Scholar] [CrossRef]

- Dnv, G. Comparison of Alternative Marine Fuels; Report, No.: 2019-0567; SEALNG, DNV GL: Høvik, Norway, 2019. [Google Scholar]

- Hansson, J.; Månsson, S.; Brynolf, S.; Grahn, M. Alternative marine fuels: Prospects based on multi-criteria decision analysis involving Swedish stakeholders. Biomass Bioenergy 2019, 126, 159–173. [Google Scholar] [CrossRef]

- Bioenergy, I. Biofuels for the Marine Shipping Sector. No. October 2017. Available online: https://www.ieabioenergy.com/wp-content/uploads/2018/02/Marine-biofuel-report-final-Oct-2017.pdf (accessed on 6 November 2022).

- Brynolf, S.; Taljegard, M.; Grahn, M.; Hansson, J. Electrofuels for the transport sector: A review of production costs. Renew. Sustain. Energy Rev. 2018, 81, 1887–1905. [Google Scholar] [CrossRef]

- Svanberg, M.; Ellis, J.; Lundgren, J.; Landälv, I. Renewable methanol as a fuel for the shipping industry. Renew. Sustain. Energy Rev. 2018, 94, 1217–1228. [Google Scholar] [CrossRef]

- Ryan, T.W., III; Maymar, M.; Ott, D.; LaViolette, R.; MacDowall, R. Combustion and emissions characteristics of minimally processed methanol in a diesel engine without ignition assist. SAE Trans. 1994, 103, 398–405. [Google Scholar]

- Stenhede, T. WP2 Present and Future Maritime Fuels; Effship: Gothenburg, Sweden, 2013. [Google Scholar]

- Stojcevski, T.; Jay, D.; Vicenzi, L. Operation experience of world’s first methanol engine in a ferry installation. In Proceedings of the 28th CIMAC World Congress, Helsinki, Finland, 6–9 June 2016. [Google Scholar]

- Mayer, S.; Sjöholm, J.; Murakami, T.; Shimada, K.; Kjemtrup, N. Performance and emission results from the MAN B&W LGI Low-Speed Engine Operating on Methanol. In Proceedings of the CIMAC Congress, Helsinki, Finland, 6–9 June 2016. [Google Scholar]

- Song, R.; Liu, J.; Wang, L.; Liu, S. Performance and emissions of a diesel engine fuelled with methanol. Energy Fuels 2008, 22, 3883–3888. [Google Scholar] [CrossRef]

- Landälv, I. Methanol as a Renewable Fuel—A Knowledge Synthesis; The Swedish Knowledge Centre for Renewable Transportation Fuels: Luleå, Sweden, 2017; p. 6. [Google Scholar]

- Chalaris, I.; Jeong, B.; Jang, H. Application of parametric trend life cycle assessment for investigating the carbon footprint of ammonia as marine fuel. Int. J. Life Cycle Assess. 2022, 27, 1145–1163. [Google Scholar] [CrossRef]

- Solutions, M.E. MAN B&W Two-Stroke Engine Operating on Ammonia; MAN Energy Solutions: Copenhagen, Denmark, 2020. [Google Scholar]

- De Vries, N. Safe and Effective Application of Ammonia as a Marine Fuel. In Proceedings of the 2019 AIChE Annual Meeting, Orlando, FL, USA, 10–15 November 2019. [Google Scholar]

- Bicer, Y.; Dincer, I. Life cycle assessment of nuclear-based hydrogen and ammonia production options: A comparative evaluation. Int. J. Hydrogen Energy 2017, 42, 21559–21570. [Google Scholar] [CrossRef]

- Atilhan, S.; Park, S.; El-Halwagi, M.M.; Atilhan, M.; Moore, M.; Nielsen, R.B. Green hydrogen as an alternative fuel for the shipping industry. Curr. Opin. Chem. Eng. 2021, 31, 100668. [Google Scholar] [CrossRef]

- Challiwala, M.; Ghouri, M.; Linke, P.; El-Halwagi, M.; Elbashir, N. A combined thermo-kinetic analysis of various methane reforming technologies: Comparison with dry reforming. J. CO2 Util. 2017, 17, 99–111. [Google Scholar] [CrossRef]

- Safari, F.; Dincer, I. A review and comparative evaluation of thermochemical water splitting cycles for hydrogen production. Energy Convers. Manag. 2020, 205, 112182. [Google Scholar] [CrossRef]

- Noureldin, M.M.; Elbashir, N.O.; Gabriel, K.J.; El-Halwagi, M.M. A process integration approach to the assessment of CO2 fixation through dry reforming. ACS Sustain. Chem. Eng. 2015, 3, 625–636. [Google Scholar] [CrossRef]

- Baldi, F.; Bengtsson, S.; Andersson, K. The influence of propulsion system design on the carbon footprint of different marine fuels. In Proceedings of the Low Carbon Shipping Conference, London, UK, 9–10 September 2013. [Google Scholar]

- Seddiek, I.S.; Elgohary, M.M.; Ammar, N.R. The hydrogen-fuelled internal combustion engines for marine applications with a case study. Brodogr. Teor. Praksa Brodogr. Pomor. Teh. 2015, 66, 23–38. [Google Scholar]

- Carlton, J.; Aldwinkle, J.; Anderson, J. Future Ship Powering Options: Exploring Alternative Methods of Ship Propulsion; Royal Academy of Engineering: London, UK, 2013. [Google Scholar]

- Jelić, M.; Mrzljak, V.; Radica, G.; Račić, N. An alternative and hybrid propulsion for merchant ships: Current state and perspective. Energy Sources Part A Recover. Util. Environ. Eff. 2021, 1–33. [Google Scholar] [CrossRef]

- Geertsma, R.; Negenborn, R.; Visser, K.; Hopman, J. Design and control of hybrid power and propulsion systems for smart ships: A review of developments. Appl. Energy 2017, 194, 30–54. [Google Scholar] [CrossRef]

- Kwasieckyj, B. Efficiency Analysis and Design Methodology of Hybrid Propulsion Systems. 2013. Available online: http://resolver.tudelft.nl/uuid:5baa1059-6a25-4bfc-8328-ae6fda18c598 (accessed on 12 November 2022).

- Bennabi, N.; Charpentier, J.; Menana, H.; Billard, J.; Genet, P. Hybrid propulsion systems for small ships: Context and challenges. In Proceedings of the 2016 XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016. [Google Scholar]

- Nguyen, H.P.; Hoang, A.T.; Nizetic, S.; Nguyen, X.P.; Le, A.T.; Luong, C.N.; Chu, V.D.; Pham, V.V. The electric propulsion system as a green solution for management strategy of CO2 emission in ocean shipping: A comprehensive review. Int. Trans. Electr. Energy Syst. 2021, 31, e12580. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Schjølberg, I. Operational profiles of ships in Norwegian waters: An activity-based approach to assess the benefits of hybrid and electric propulsion. Transp. Res. Part D Transp. Environ. 2018, 65, 500–523. [Google Scholar] [CrossRef]

- Commission, E. 2020 Annual Report on CO2 Emissions from Maritime Transport. 2021. Available online: https://european-accreditation.org/wp-content/uploads/2022/06/2020-Annual-report-from-the-Commission.pdf (accessed on 12 December 2022).

- Nguyen, X.P.; Hoang, A.T. The flywheel energy storage system: An effective solution to accumulate renewable energy. In Proceedings of the 2020 6th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, India, 6–7 March 2020. [Google Scholar]

- Koumentakos, A.G. Developments in electric and green marine ships. Appl. Syst. Innov. 2019, 2, 34. [Google Scholar] [CrossRef]

- Prousalidis, J.; Patsios, C.; Kanellos, F.; Sarigiannidis, A.; Tsekouras, N.; Antonopoulos, G. Exploiting shaft generators to improve ship efficiency. In Proceedings of the 2012 Electrical Systems for Aircraft, Railway and Ship Propulsion, Bologna, Italy, 16–18 October 2012. [Google Scholar]

- Sarigiannidis, A.; Kladas, A.; Chatzinikolaou, E.; Patsios, C. High efficiency Shaft Generator drive system design for Ro-Ro trailer-passenger ship application. In Proceedings of the 2015 International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles (ESARS), Aachen, Germany, 3–5 March 2015. [Google Scholar]

- Perez, J.R.; Reusser, C.A. Optimization of the emissions profile of a marine propulsion system using a shaft generator with optimum tracking-based control scheme. J. Mar. Sci. Eng. 2020, 8, 221. [Google Scholar] [CrossRef]

- Planakis, N.; Papalambrou, G.; Kyrtatos, N. A real-time power-split strategy for a hybrid marine power plant using MPC. Int. J. Model. Identif. Control 2020, 34, 147–157. [Google Scholar] [CrossRef]

- Haseltalab, A.; Negenborn, R.R.; Lodewijks, G. Multi-level predictive control for energy management of hybrid ships in the presence of uncertainty and environmental disturbances. IFAC-PapersOnLine 2016, 49, 90–95. [Google Scholar] [CrossRef]

- Yoo, S.; Aguerrevere, J.; Jeong, J.; Jung, W.; Chang, D. Hybrid marine propulsion power system with the redox flow batteries of comprehensive aging model. Int. J. Nav. Arch. Ocean Eng. 2021, 13, 674–690. [Google Scholar] [CrossRef]

- Derr, I. Electrochemical Degradation and Chemical Aging of Carbon Felt Electrodes in All-Vanadium Redox Flow Batteries. Doctoral Dissertation, Freie Universität Berlin, Berlin, Germany, 2017. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwjbhtiJqK_8AhXws1YBHe8SBFkQFnoECAoQAQ&url=https%3A%2F%2Fd-nb.info%2F1135184836%2F34&usg=AOvVaw2DTh9EMZmfhmChtp_G6ydM (accessed on 12 December 2022).

- Bindner, H.; Ekman, C.; Gehrke, O.; Isleifsson, F. Characterization of Vanadium Flow Battery; Risø-R-1753(EN); February 2011. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwig07XXqK_8AhV6klYBHX7ADVcQFnoECAsQAQ&url=https%3A%2F%2Fwww.osti.gov%2Fetdeweb%2Fservlets%2Fpurl%2F1033711&usg=AOvVaw1UJ_4KnZJznLJlXo7JpAic (accessed on 12 December 2022).

- Menictas, C.; Skyllas-Kazacos, M. Performance of vanadium-oxygen redox fuel cell. J. Appl. Electrochem. 2011, 41, 1223–1232. [Google Scholar] [CrossRef]

- Aaron, D.; Liu, Q.; Tang, Z.; Grim, G.; Papandrew, A.; Turhan, A.; Zawodzinski, T.; Mench, M. Dramatic performance gains in vanadium redox flow batteries through modified cell architecture. J. Power Sources 2012, 206, 450–453. [Google Scholar] [CrossRef]

- Zhang, J.; Li, L.; Nie, Z.; Chen, B.; Vijayakumar, M.; Kim, S.; Wang, W.; Schwenzer, B.; Liu, J.; Yang, Z. Effects of additives on the stability of electrolytes for all-vanadium redox flow batteries. J. Appl. Electrochem. 2011, 41, 1215–1221. [Google Scholar] [CrossRef]

- Chou, T.; Kosmas, V.; Acciaro, M.; Renken, K. A comeback of wind power in shipping: An economic and operational review on the wind-assisted ship propulsion technology. Sustainability 2021, 13, 1880. [Google Scholar] [CrossRef]

- Delft, C.; Fraunhofer, I. Study on the Analysis of Market Potentials and Market Barriers for Wind Propulsion Technologies for Ships. 2016. Available online: https://cedelft.eu/wp-content/uploads/sites/2/2021/04/CE_Delft_7G92_Wind_Propulsion_Technologies_Final_report.pdf (accessed on 11 November 2022).

- Dnv, G. Assessment of Selected Alternative Fuels and Technologies in Shipping. DNV GL. 2019. Available online: https://www.dnvgl.com/maritime/publications (accessed on 13 October 2022).

- Traut, M.; Gilbert, P.; Walsh, C.; Bows, A.; Filippone, A.; Stansby, P.; Wood, R. Propulsive power contribution of a kite and a Flettner rotor on selected shipping routes. Appl. Energy 2014, 113, 362–372. [Google Scholar] [CrossRef]

- Naaijen, P.; Koster, V.; Dallinga, R. On the power savings by an auxiliary kite propulsion system. Int. Shipbuild. Prog. 2006, 53, 255–279. [Google Scholar]

- Tillig, F.; Ringsberg, J.W. A 4 DOF simulation model developed for fuel consumption prediction of ships at sea. Ships Offshore Struct. 2019, 14 (Suppl. 1), 112–120. [Google Scholar] [CrossRef]

- Bentin, M.; Zastrau, D.; Schlaak, M.; Freye, D.; Elsner, R.; Kotzur, S. A new routing optimization tool-influence of wind and waves on fuel consumption of ships with and without wind assisted ship propulsion systems. Transp. Res. Procedia 2016, 14, 153–162. [Google Scholar] [CrossRef]

- Smith, T.; Newton, P.; Winn, G.; Grech La Rosa, A. Analysis Techniques for Evaluating the Fuel Savings Associated with Wind Assistance. 2013. Available online: https://discovery.ucl.ac.uk/id/eprint/1413459/1/Newton%20et%20al.pdf (accessed on 15 October 2022).

- Leloup, R.; Roncin, K.; Behrel, M.; Bles, G.; Leroux, J.B.; Jochum, C.; Parlier, Y. A continuous and analytical modeling for kites as auxiliary propulsion devoted to merchant ships, including fuel saving estimation. Renew. Energy 2016, 86, 483–496. [Google Scholar] [CrossRef]

- Lu, R.; Ringsberg, J.W. Ship energy performance study of three wind-assisted ship propulsion technologies including a parametric study of the Flettner rotor technology. Ships Offshore Struct. 2020, 15, 249–258. [Google Scholar] [CrossRef]

- Wu, P.; Bucknall, R. Hybrid fuel cell and battery propulsion system modelling and multi-objective optimisation for a coastal ferry. Int. J. Hydrogen Energy 2020, 45, 3193–3208. [Google Scholar] [CrossRef]

- Dicks, A.L.; Rand, D.A. Fuel Cell Systems Explained; John Wiley & Sons: Hoboken, NJ, USA, 2018. [Google Scholar]

- Fletcher, T.; Thring, R.; Watkinson, M. An Energy Management Strategy to concurrently optimise fuel consumption & PEM fuel cell lifetime in a hybrid vehicle. Int. J. Hydrogen Energy 2016, 41, 21503–21515. [Google Scholar]

- Zheng, F.; Xing, Y.; Jiang, J.; Sun, B.; Kim, J.; Pecht, M. Influence of different open circuit voltage tests on state of charge online estimation for lithium-ion batteries. Appl. Energy 2016, 183, 513–525. [Google Scholar] [CrossRef]

- Sima, V.; Gheorghe, I.G.; Subić, J.; Nancu, D. Influences of the industry 4.0 revolution on the human capital development and consumer behavior: A systematic review. Sustainability 2020, 12, 4035. [Google Scholar] [CrossRef]

- Tay, Z.Y.; Hadi, J.; Chow, F.; Loh, D.J.; Konovessis, D. Big data analytics and machine learning of harbour craft vessels to achieve fuel efficiency: A review. J. Mar. Sci. Eng. 2021, 9, 1351. [Google Scholar] [CrossRef]

- Cheliotis, M.; Lazakis, I.; Theotokatos, G. Theotokatos, Machine learning and data-driven fault detection for ship systems operations. Ocean Eng. 2020, 216, 107968. [Google Scholar] [CrossRef]

- Sullivan, G.; Pugh, R.; Melendez, A.P.; Hunt, W. Operations & Maintenance Best Practices—A Guide to Achieving Operational Efficiency (Release 3); Pacific Northwest National Lab (PNNL): Richland, WA, USA, 2010. [Google Scholar]

- Gershanik, V. Weather routing optimisation–challenges and rewards. J. Mar. Eng. Technol. 2011, 10, 29–40. [Google Scholar] [CrossRef]

- Barthwal, N.; Agarwala, C.D.N. Industry 4.0 in the Shipping Industry: Challenges and Preparedness—The Prevailing Scenario. Available online: https://www.maritimeindia.org/View%20Profile/636993498101359304.pdf (accessed on 28 October 2022).

- Jeon, M.; Noh, Y.; Shin, Y.; Lim, O.; Lee, I.; Cho, D. Prediction of ship fuel consumption by using an artificial neural network. J. Mech. Sci. Technol. 2018, 32, 5785–5796. [Google Scholar] [CrossRef]

- Matulić, N.; Radica, G.; Nižetić, S. Engine model for onboard marine engine failure simulation. J. Therm. Anal. Calorim. 2020, 141, 119–130. [Google Scholar] [CrossRef]

- Rudzki, K.; Gomulka, P.; Hoang, A.T. Optimization Model to Manage Ship Fuel Consumption and Navigation Time. Pol. Marit. Res. 2022, 29, 141–153. [Google Scholar] [CrossRef]

- Munim, Z.H. Autonomous ships: A review, innovative applications and future maritime business models. Supply Chain. Forum Int. J. 2019, 20, 266–279. [Google Scholar] [CrossRef]

- Rødseth, Ø.J. From concept to reality: Unmanned merchant ship research in Norway. In Proceedings of the Underwater Technology (UT), Busan, Republic of Korea, 21–24 February 2017. [Google Scholar]

- Ghaderi, H. Autonomous technologies in short sea shipping: Trends, feasibility and implications. Transp. Rev. 2019, 39, 152–173. [Google Scholar] [CrossRef]

- Munim, Z.H.; Haralambides, H. Competition and cooperation for intermodal container transhipment: A network optimization approach. Res. Transp. Bus. Manag. 2018, 26, 87–99. [Google Scholar] [CrossRef]

- Tseng, P.-H.; Cullinane, K. Key criteria influencing the choice of Arctic shipping: A fuzzy analytic hierarchy process model. Marit. Policy Manag. 2018, 45, 422–438. [Google Scholar] [CrossRef]

- Yu, H.; Fang, Z.; Fu, X.; Liu, J.; Chen, J. Literature review on emission control-based ship voyage optimization. Transp. Res. Part D Transp. Environ. 2021, 93, 102768. [Google Scholar] [CrossRef]

- Zis, T.; North, R.J.; Angeloudis, P.; Ochieng, W.Y.; Harrison Bell, M.G. Evaluation of cold ironing and speed reduction policies to reduce ship emissions near and at ports. Marit. Econ. Logist. 2014, 16, 371–398. [Google Scholar] [CrossRef]

- Du, Y.; Chen, Q.; Lam, J.S.; Xu, Y.; Cao, J.X. Modeling the impacts of tides and the virtual arrival policy in berth allocation. Transp. Sci. 2015, 49, 939–956. [Google Scholar] [CrossRef]

- Schwartz, H.; Gustafsson, M.; Spohr, J. Emission abatement in shipping–is it possible to reduce carbon dioxide emissions profitably? J. Clean. Prod. 2020, 254, 120069. [Google Scholar] [CrossRef]

- Poulsen, R.T.; Sampson, H. ‘Swinging on the anchor’: The difficulties in achieving greenhouse gas abatement in shipping via virtual arrival. Transp. Res. Part D Transp. Environ. 2019, 73, 230–244. [Google Scholar] [CrossRef]

- Poulsen, R.T.; Ponte, S.; Lister, J. Buyer-driven greening? Cargo-owners and environmental upgrading in maritime shipping. Geoforum 2016, 68, 57–68. [Google Scholar] [CrossRef]

- Jia, H.; Adland, R.; Prakash, V.; Smith, T. Energy efficiency with the application of Virtual Arrival policy. Transp. Res. Part D Transp. Environ. 2017, 54, 50–60. [Google Scholar] [CrossRef]

- Pauksztat, B. Effects of job demands and social interactions on fatigue in short sea cargo shipping. Marit. Policy Manag. 2017, 44, 623–640. [Google Scholar] [CrossRef]

- Habibi, M.; Rehmatulla, N. Carbon Emission Policies in the Context of the Shipping Industry; CASS Business School, City University of London: London, UK, 2009. [Google Scholar]

- Vakili, S.; Ölçer, A.I.; Schönborn, A.; Ballini, F.; Hoang, A.T. Energy-related clean and green framework for shipbuilding community towards zero-emissions: A strategic analysis from concept to case study. Int. J. Energy Res. 2022, 46, 20624–20649. [Google Scholar] [CrossRef]

- Acciaro, M.; Ghiara, H.; Cusano, M.I. Energy management in seaports: A new role for port authorities. Energy Policy 2014, 71, 4–12. [Google Scholar] [CrossRef]

- Gössling, S.; Meyer-Habighorst, C.; Humpe, A. A global review of marine air pollution policies, their scope and effectiveness. Ocean Coast. Manag. 2021, 212, 105824. [Google Scholar] [CrossRef]

- Styhre, L.; Winnes, H.; Black, J.; Lee, J.; Le-Griffin, H. Greenhouse gas emissions from ships in ports–Case studies in four continents. Transp. Res. Part D Transp. Environ. 2017, 54, 212–224. [Google Scholar] [CrossRef]

- Winnes, H.; Styhre, L.; Fridell, E. Reducing GHG emissions from ships in port areas. Res. Transp. Bus. Manag. 2015, 17, 73–82. [Google Scholar] [CrossRef]

- Wan, Z.; Zhang, T.; Sha, M.; Guo, W.; Jin, Y.; Guo, J.; Liu, Y. Evaluation of emission reduction strategies for berthing containerships: A case study of the Shekou Container Terminal. J. Clean. Prod. 2021, 299, 126820. [Google Scholar] [CrossRef]

- Toscano, D.; Murena, F.; Quaranta, F.; Mocerino, L. Assessment of the impact of ship emissions on air quality based on a complete annual emission inventory using AIS data for the port of Naples. Ocean Eng. 2021, 232, 109166. [Google Scholar] [CrossRef]

- Toscano, D.; Murena, F. Atmospheric ship emissions in ports: A review. Correlation with data of ship traffic. Atmospheric Environ. X 2019, 4, 100050. [Google Scholar] [CrossRef]

- Xing, H.; Spence, S.; Chen, H. A comprehensive review on countermeasures for CO2 emissions from ships. Renew. Sustain. Energy Rev. 2020, 134, 110222. [Google Scholar] [CrossRef]

- Lindstad, H.; Eskeland, G.S. Low carbon maritime transport: How speed, size and slenderness amounts to substantial capital energy substitution. Transp. Res. Part D Transp. Environ. 2015, 41, 244–256. [Google Scholar] [CrossRef]

- Adland, R.; Cariou, P.; Jia, H.; Wolff, F. The energy efficiency effects of periodic ship hull cleaning. J. Clean. Prod. 2018, 178, 1–13. [Google Scholar] [CrossRef]

- Farkas, A.; Degiuli, N.; Martić, I.; Ančić, I. Energy savings potential of hull cleaning in a shipping industry. J. Clean. Prod. 2022, 374, 134000. [Google Scholar] [CrossRef]

- Oliveira, D.R.; Lagerström, M.; Granhag, L.; Werner, S.; Larsson, A.I.; Ytreberg, E. A novel tool for cost and emission reduction related to ship underwater hull maintenance. J. Clean. Prod. 2022, 356, 131882. [Google Scholar] [CrossRef]

- Farkas, A.; Degiuli, N.; Martić, I.; Vujanović, M. Greenhouse gas emissions reduction potential by using antifouling coatings in a maritime transport industry. J. Clean. Prod. 2021, 295, 126428. [Google Scholar] [CrossRef]

- Giernalczyk, M.; Kaminski, P. Assessment of the propulsion system operation of the ships equipped with the air lubrication system. Sensors 2021, 21, 1357. [Google Scholar] [CrossRef]

- Latorre, R. Ship hull drag reduction using bottom air injection. Ocean Eng. 1997, 24, 161–175. [Google Scholar] [CrossRef]

- Cucinotta, F.; Guglielmino, E.; Sfravara, F. An experimental comparison between different artificial air cavity designs for a planing hull. Ocean Eng. 2017, 140, 233–243. [Google Scholar] [CrossRef]

- An, H.; Pan, H.; Yang, P. Research Progress of Air Lubrication Drag Reduction Technology for Ships. Fluids 2022, 7, 319. [Google Scholar] [CrossRef]

- Song, C.; Liu, Q.; Deng, S.; Li, H.; Kitamura, Y. Cryogenic-based CO2 capture technologies: State-of-the-art developments and current challenges. Renew. Sustain. Energy Rev. 2019, 101, 265–278. [Google Scholar] [CrossRef]

- Berstad, D.; Anantharaman, R.; Nekså, P. Low-temperature CO2 capture technologies—Applications and potential. Int. J. Refrig. 2013, 36, 1403–1416. [Google Scholar] [CrossRef]

- Lee, S.; Yoo, S.; Park, H.; Ahn, J.; Chang, D. Novel methodology for EEDI calculation considering onboard carbon capture and storage system. Int. J. Greenh. Gas Control 2021, 105, 103241. [Google Scholar] [CrossRef]

- Font-Palma, C.; Cann, D.; Udemu, C. Review of cryogenic carbon capture innovations and their potential applications. C 2021, 7, 58. [Google Scholar] [CrossRef]

- Willson, P.; Lychnos, G.; Clements, A.; Michailos, S.; Font-Palma, C.; Diego, M.E.; Pourkashanian, M.; Howe, J. Evaluation of the performance and economic viability of a novel low temperature carbon capture process. Int. J. Greenh. Gas Control 2019, 86, 1–9. [Google Scholar] [CrossRef]

- Feenstra, M.; Monteiro, J.; van den Akker, J.T.; Abu-Zahra, M.R.; Gilling, E.; Goetheer, E. Ship-based carbon capture onboard of diesel or LNG-fuelled ships. Int. J. Greenh. Gas Control 2019, 85, 1–10. [Google Scholar] [CrossRef]

- Zhang, Y.; Sachde, D.; Chen, E.; Rochelle, G. Modeling of absorber pilot plant performance for CO2 capture with aqueous piperazine. Int. J. Greenh. Gas Control 2017, 64, 300–313. [Google Scholar] [CrossRef]

- Einbu, A.; Pettersen, T.; Morud, J.; Tobiesen, A.; Jayarathna, C.; Skagestad, R.; Nysæther, G. Energy assessments of onboard CO2 capture from ship engines by MEA-based post combustion capture system with flue gas heat integration. Int. J. Greenh. Gas Control 2022, 113, 103526. [Google Scholar] [CrossRef]

- Liu, H.; Yao, M.; Zhang, B.; Zheng, Z. Effects of inlet pressure and octane numbers on combustion and emissions of a homogeneous charge compression ignition (HCCI) engine. Energy Fuels 2008, 22, 2207–2215. [Google Scholar] [CrossRef]

- Tang, Q.; Liu, H.; Li, M.; Yao, M.; Li, Z. Study on ignition and flame development in gasoline partially premixed combustion using multiple optical diagnostics. Combust. Flame 2017, 177, 98–108. [Google Scholar] [CrossRef]

- Yi, W.; Liu, H.; Feng, L.; Wang, Y.; Cui, Y.; Liu, W.; Yao, M. Multiple optical diagnostics on effects of fuel properties on spray flames under oxygen-enriched conditions. Fuel 2021, 291, 120129. [Google Scholar] [CrossRef]

| Study | Dimensions of the Technology | Ship Type | Route | Fuel Savings Found |

|---|---|---|---|---|

| [78] | 2 Flettner rotors: h = 22 m, d = 3 m 3 Flettner rotors: h = 48 m, d = 6 m | 5k dwt Tanker 90k dwt Tanker | Worldwide trade of each ship type according to AIS data | 5–7% 9–13% |

| [85] | 1 kite: a = 320 m2, l = 300 m | 50k dwt Tanker | N.A. | 10–50% |

| [86] | 1 wingsail (rigid): h = 50 m, w = 20 m | Aframax Tanker | Cape Lopez–Point Tupper Angra dos Reis–Rotterdam | 8.8% 6.1% |

| [86] | 1 Dynarig (soft): area = 1000 m2 | Aframax Tanker | Cape Lopez–Point Tupper Angra dos Reis–Rotterdam | 5.6% 4.2% |

| [78] | 1 wind turbine: height (h) = 20 m, diameter (d) = 38 m | 5k dwt Tanker | Worldwide trades of each ship type according to AIS data | 1–2% |

| Ports | Port Calls | Tonnes of CO2 Equivalent Per Port Call | Total (Tonnes of CO2 Equivalent) | |||||

|---|---|---|---|---|---|---|---|---|

| Container | Dry Bulk | Liquid Bulk | General Cargo | Ferry/RoRo | Cruise | |||

| Gothenburg | 5999 | 33.34 | 2.33 | 31.89 | 0.23 | 23.21 | 41.67 | 150,000 |

| Long Beach | 2806 | 73.95 | 35.64 | 134.76 | 34.93 | 28.00 | 67.32 | 240,000 |

| Osaka | 12,399 | 8.33 | 7.46 | 3.69 | 3.89 | 10.57 | 0.00 | 97,000 |

| Sydney | 1370 | 76.70 | 21.90 | 70.48 | 20.07 | 0.00 | 54.01 | 95,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidović, T.; Šimunović, J.; Radica, G.; Penga, Ž. Systematic Overview of Newly Available Technologies in the Green Maritime Sector. Energies 2023, 16, 641. https://doi.org/10.3390/en16020641

Vidović T, Šimunović J, Radica G, Penga Ž. Systematic Overview of Newly Available Technologies in the Green Maritime Sector. Energies. 2023; 16(2):641. https://doi.org/10.3390/en16020641

Chicago/Turabian StyleVidović, Tino, Jakov Šimunović, Gojmir Radica, and Željko Penga. 2023. "Systematic Overview of Newly Available Technologies in the Green Maritime Sector" Energies 16, no. 2: 641. https://doi.org/10.3390/en16020641

APA StyleVidović, T., Šimunović, J., Radica, G., & Penga, Ž. (2023). Systematic Overview of Newly Available Technologies in the Green Maritime Sector. Energies, 16(2), 641. https://doi.org/10.3390/en16020641