Abstract

Aeroengines and heavy-duty gas turbines are the core power equipment in the field of national defense and energy. Their research and development (R&D) level and manufacturing level represent the status of a country’s heavy industry in the world. The common cooling technologies of turbine blades including impingement cooling, film cooling, effusion cooling, layer cooling, pin fin cooling, and rough ribs were introduced in this paper. With the continuous improvement of the efficiency and performance of aeroengines and gas turbines, the turbine inlet temperature increases gradually every year; turbine blades will be exposed to higher gas temperatures in the future as gas temperatures break 2000 K. In order to ensure the safe operation of turbine blades under severe super-high temperature working conditions, cooling technology must be developed emphatically. This paper first reviews the research status of turbine blade cooling technology and points out future research focuses. The development trends of next-generation turbine blade cooling technology for above 2000 K temperature are summarized from several aspects: the innovative excavation of high-efficiency composite cooling configuration, multi-objective cooperative cooling structure and optimization design based on 3D printing, composite cooling structure design and optimization based on an artificial intelligence algorithm, tapping the cooling potential of new cooling media and heat pipes, integrated thermal protection with new thermal insulators, and the application of low-resistance and high-efficiency surface dimple cooling. The summary of this paper can provide a reference for the researchers of turbine blade cooling technology.

1. Introduction

Gas turbines are widely used in electricity generation, ship power, and other energy and national defense fields. Representing a comprehensive level of development in multiple theoretical subjects and engineering fields, the gas turbine is high-tech core power equipment for national security and national economic development. Gas turbine engines also occupy a dominant position in the power systems of modern aircraft and are widely used in all types of civil and military aircraft.

At present, electricity generation based on gas turbines and combined-cycle power stations accounts for around 22% of global electricity production and continues to increase steadily. The inlet temperature of typical F-series heavy-duty gas turbines reaches around 1670 K, with a single-cycle efficiency of 38% and a combined-cycle efficiency of 57%, while the inlet temperature of advanced G/H/J-series gas turbines reaches around 1770–1870 K, with single-cycle and combined-cycle efficiencies of 40–41% and 60–61%, respectively [1]. The inlet temperature of the 9HA-series gas turbine of the GE Corporation also reaches 1927 K [2], marking a world-advanced level of inlet temperature of around 1920 K.

For aero engines, improving the turbine inlet temperature can increase the thrust-to-weight ratio and efficiency; with each increase of 100 K in the turbine inlet temperature, the engine efficiency can increase by 2–3%. The current turbine inlet temperature of the fourth-generation military aero engine F135 reaches 1850–1950 K, which is far beyond the temperature limit of nickel-based alloys [3]. As the performance of the aero engine is further improved, the turbine inlet gas temperature will exceed 2200 K.

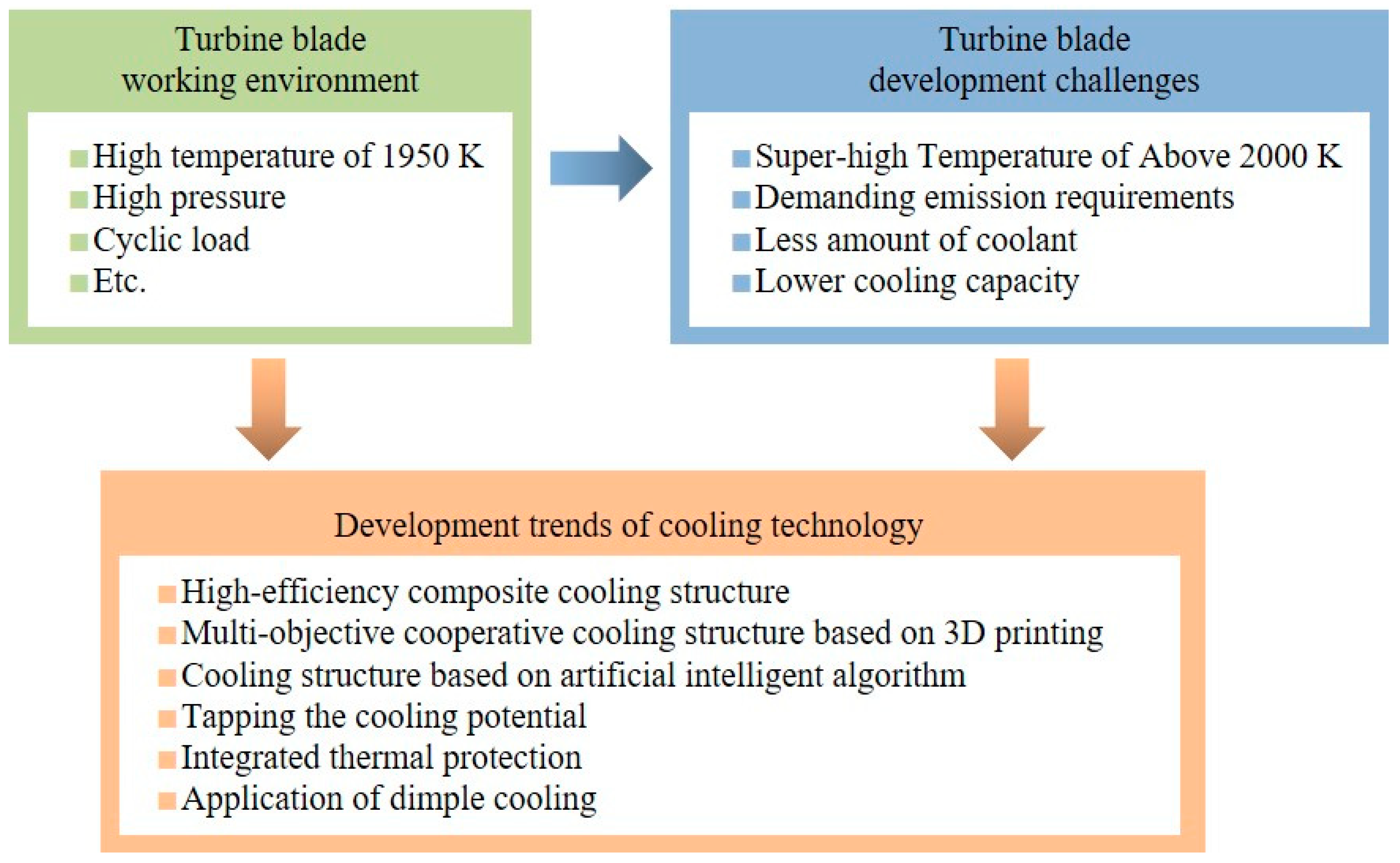

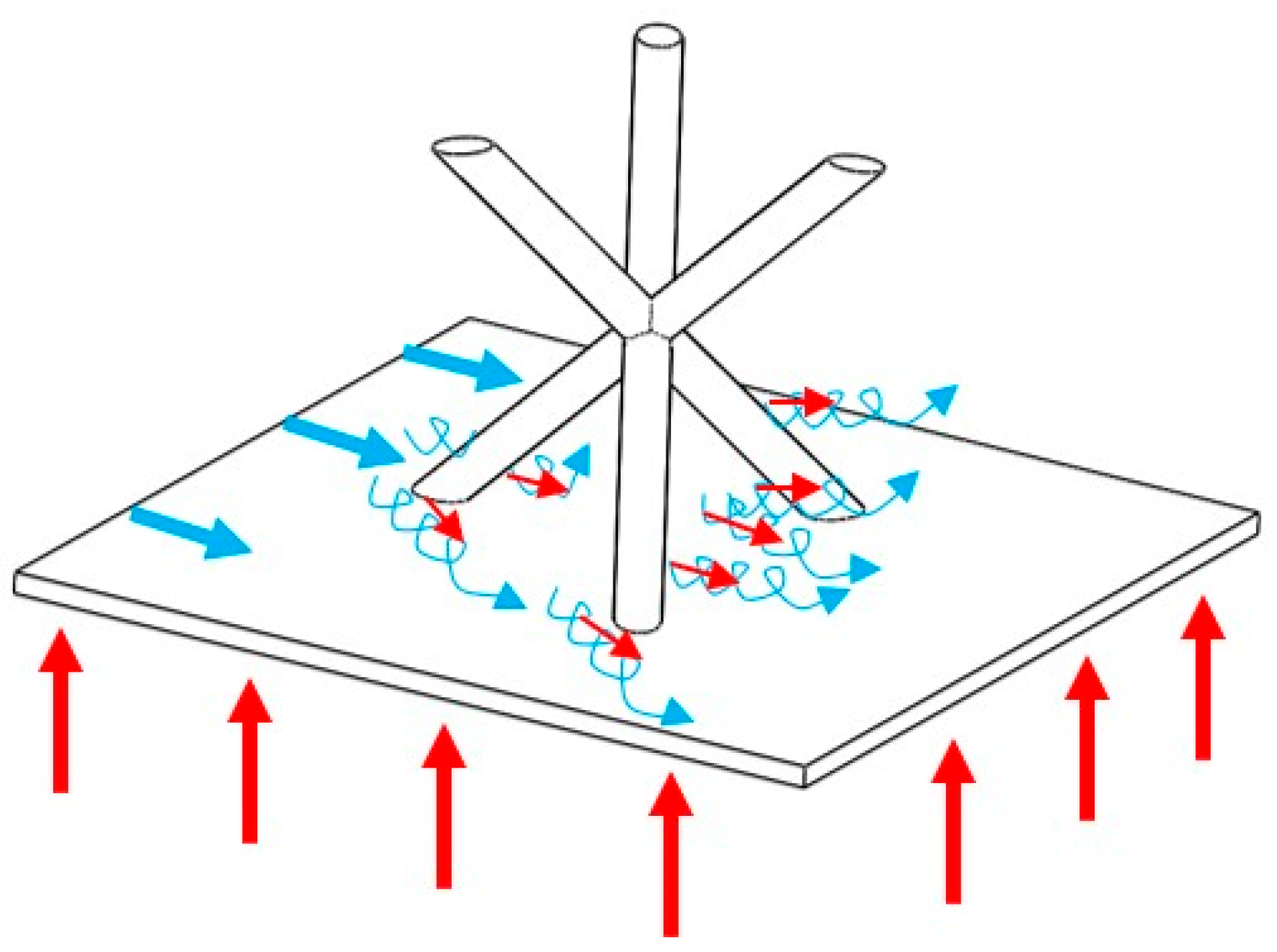

In order to further improve the combined cycle efficiency of heavy-duty gas turbines and the operation performance of aeroengines. The gas turbine inlet temperature must be continuously increased, which means that the next generation of turbine blades for 2000 K gas are facing even more severe cooling challenges. Currently, the most advanced nickel-based single-crystal alloy can withstand a maximum temperature of about 1423 K [4]. Even though the use of thermal barrier coating of 100–400μm thickness can reduce the metal temperature by 100 to 300 K, the TBC has problems of short life and easy to peel off failure. Turbine inlet gas temperatures breaking 2000 K inevitably pose numerous core technical challenges for the turbine or aeroengine, among which one of the most central technical challenges must be the reliability of the high-temperature components. The heat protection of high-temperature components is not only limited by the increasingly demanding emission requirements of low pollution and low harmful gas content but also influenced by the contradiction that the full burn of the combustion chamber of high-power and large-capacity engines requires more air for burning, which will reduce the amount of air required for the cooling of the high-temperature components. Moreover, the improvement of the compression ratio of the compression system will lead to an increase in the temperature of the cooling air and reduce its cooling quality, causing the air participating in the cooling difficulty in meeting the cooling requirements to a certain extent. To solve all these issues, research on advanced and efficient cooling technology to meet the heat protection of the high-temperature components with less and higher cooling capacity cooling air is urgently required, as shown in Figure 1.

Figure 1.

Article overview.

2. Research Status of Turbine Blade Cooling Technology

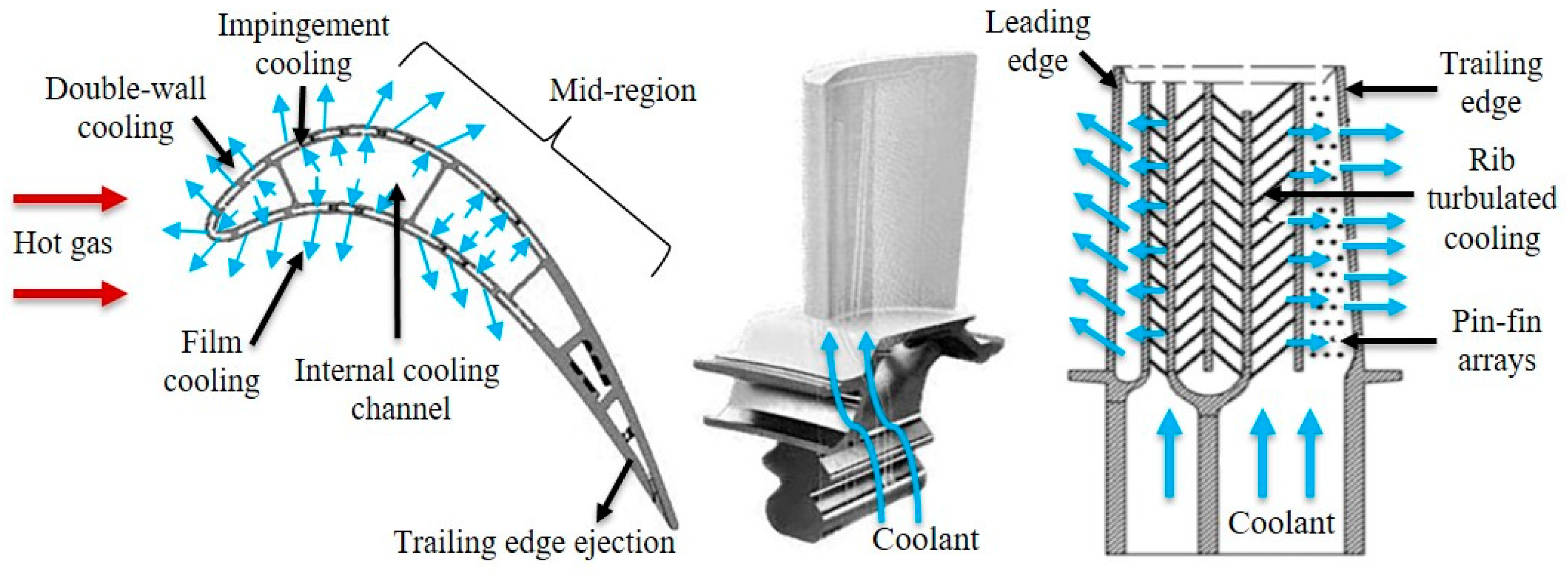

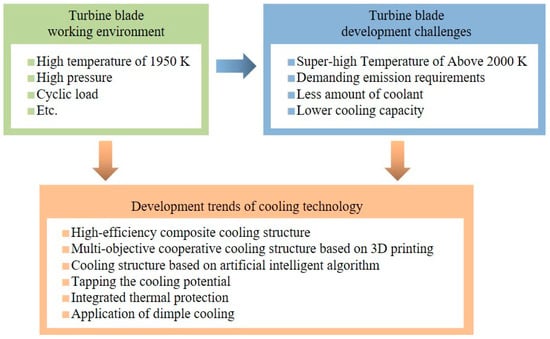

The turbine blades of the high-temperature components are under high displacement controlled thermal stresses related to the temperature field in the metal and high force-controlled stresses induced by centrifugal and aerodynamic loading. This is extensively discussed by Roger Reed and Skamniotis et al. [5]. In order to cope with thermal protection requirements, turbine blades adopt complex composite cooling structures, which consist of internal cooling and external cooling structures as shown in Figure 2. External cooling mainly depends on cooling air jets injected on the wall surface to form an air film. Internal cooling usually uses enhanced heat transfer methods such as jet impingement, the channel with ribs, disturbing pin fins, etc. [6,7]. In addition, there are new cooling structures such as transpiration cooling and double-wall cooling. These cooling techniques are reviewed as follows.

Figure 2.

Schematic of cooling technology in gas turbines.

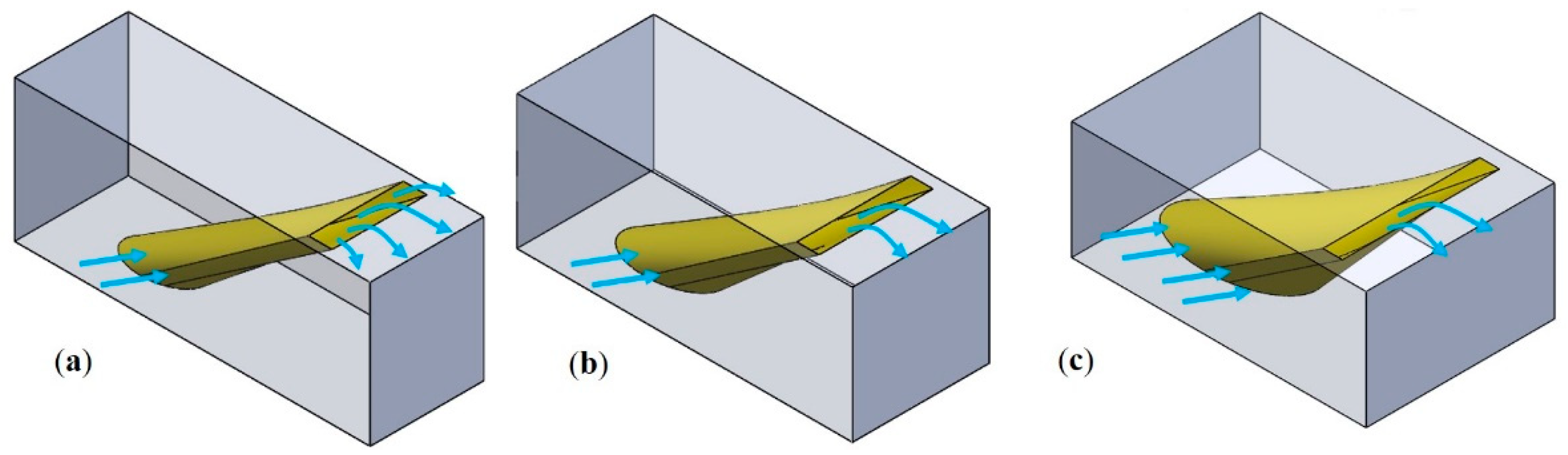

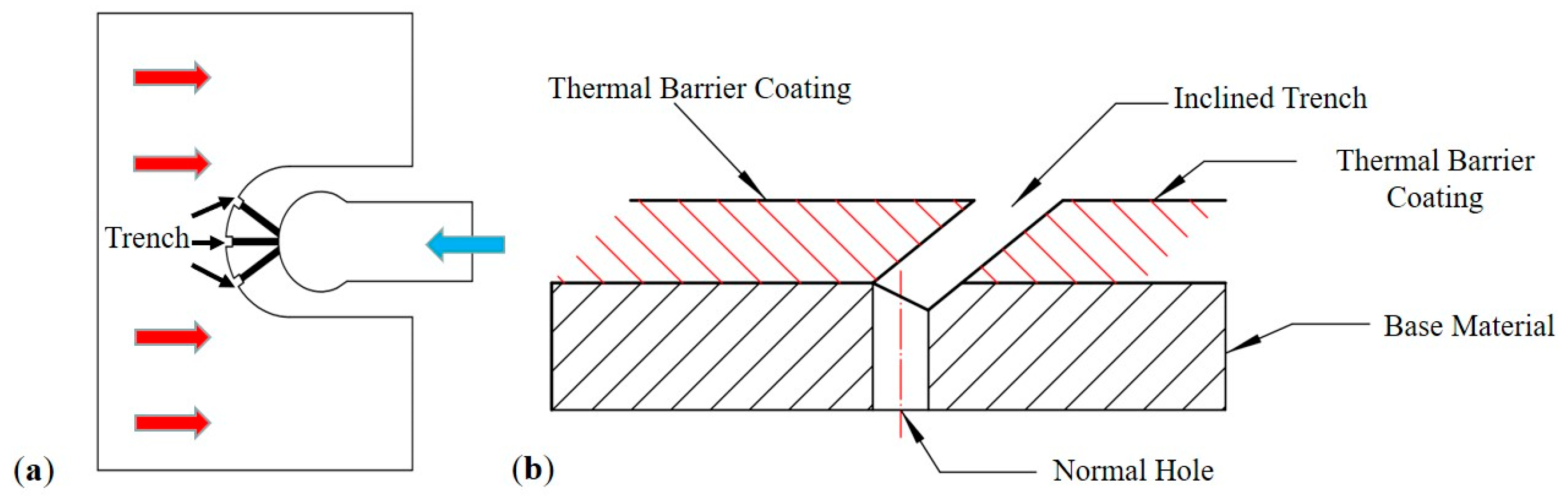

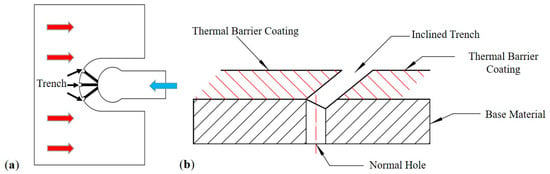

2.1. External Cooling Technology

One of the most effective external cooling methods is film cooling. Film cooling provides heat protection by arranging film holes in the heated wall surface and then forming a film from the coolant injected through the holes, which directly carries away heat from the area near the wall surface. The leading edge and end wall of turbine blades are all cooled by the film cooling with discrete holes. Therefore, as one of the main technical measures for efficient cooling of high-temperature components, the cooling enhancement of film cooling is vital to improve the overall cooling efficiency of the high-temperature components, thus it has also become a frontier technology and a focus issue of interest for researchers all around the world. After years of research, various forms of film holes have been developed to enhance film cooling, among which the development of shaped holes to control the interference mechanism between the jet and the main flow and consequently improve the film cooling efficiency is considered to be a landmark development in film cooling technologies. Its cooling efficiency is usually related to the shape, arrangement, and parameters of film holes. Moreover, the expanded film holes were proposed to improve cooling efficiency. Pu et al. [8] studied the combined effects of compound angle, wall curvature, and cooling air flow rate on the film effectiveness and cooling instability of common fan-shaped holes. The fan-shaped hole with a compound angle of 30° causes the maximum film efficiency and the lowest percentage of cooling instability at the convex wall. Zamiri et al. [9] used a large eddy simulation (LES) method to compare six different cases of expanded film holes to a reference hole. Compared with averaged Navier–Stokes (RANS) model, the LES method had a better capacity approach to resolving the time and length scales of the flow field in the diffuser section of the shaped holes. As design parameters, they took into account the injection angle, metering length, forward expansion angle, and lateral expansion angle. Different combinations of parameters make up six different cases. The outcomes demonstrated that the cooling properties were significantly influenced by the cooling hole design parameters. Additionally, Case6 (injection angle 43.1°, metering length 0.9 mm, forward expansion angle 0°, and lateral expansion angle 18°) showed an improvement in area-averaged film-cooling efficacy of roughly 32%. Li et al. [10] studied the influence of crossflow Reynolds number (50,000 and 100,000) and blowing ratio (0.5, 1.0, and 2.0) on the cooling performance of Y-shaped holes experimentally. By using the transient liquid crystal (TLC) measuring technique, the Y-shaped hole showed a better film cooling action, a lower heat transfer coefficient, and a higher emission coefficient as compared to the cylindrical hole under the same conditions. Apart from the expanded-shaped hole, Zhu et al. [11] proposed a converged round-to-slot shape film hole (RTSH) with a typical round entry area and a very narrow slit exit area, as in Figure 3. For RTSH, Huang et al. [12] constructed the optimal model by selecting the discharge coefficient and spatially averaged adiabatic film cooling effectiveness as independent objective functions to optimize the design parameters. The optimized shape of RTSH had a better cooling or flow performance. Liu et al. [13] investigated the effect of the crossflow Reynolds number on the film cooling characteristics in a low-speed flat-plate facility. They carried out a converging slot hole and a cylindrical hole at two crossflow Reynolds numbers of 50,000 and 100,000, and three blowing ratios of 0.5, 1.0 and 2.0. The result showed that the converging slot hole presents better film coverage in the whole region. The method of enhanced film cooling also includes trenched film cooling holes. Hou et al. [14] took the Realizable k-ε turbulence model, which aligns with the experimental study, then employed trenched film holes to improve the cooling performance under conditions of different swirl numbers and blowing ratios. The results showed that trenched film holes have a cooling performance enhancement under typical mainstream flow characteristics in turbines, and the cooling performance of trenched film holes was further investigated in real turbine blades. Barahate et al. [15] experimentally measured the cooling efficiency, heat transfer coefficient, and net heat flux of the trenched film holes for different geometry parameters with different blowing ratios. They showed that the trenched film holes have a smaller heat transfer coefficient and a smaller heat flux which improves the film cooling efficiency, both trenched holes are shown in Figure 4. Therefore, in the future, the design of the film hole shape which combines with the working section shape of the blade as well as the optimized layout of film holes under the turbine blade operating conditions needs to be focused on.

Figure 3.

Schematic diagram of typical RTSH model: (a) expansion hole; (b) reference hole; (c) convergence hole.

Figure 4.

Schematic diagram of typical trenched film holes: (a) leading edge of the trenched hole; (b) inclined trenched hole.

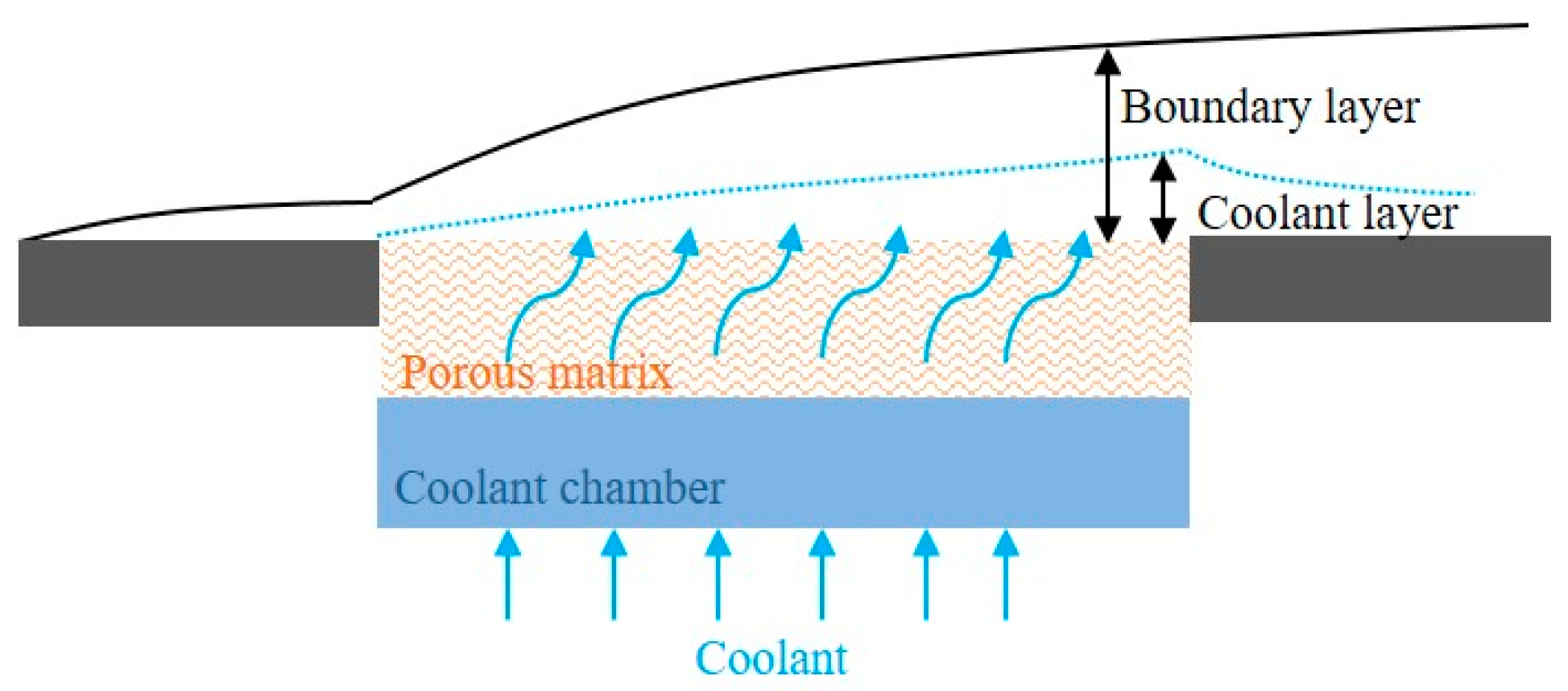

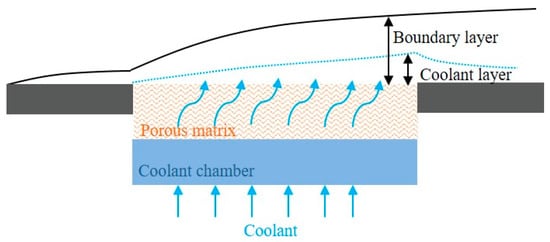

Transpiration cooling refers to a new type of external cooling method that combines the advantages of film cooling and the characteristics of porous media materials. The transpiration cooling can uniformly disperse the cooling fluid outflow and provide sufficient heat exchange space based on the large specific surface area and internal volume of the porous media, which facilitates the realization of large and reusable thermal protection and also enables it to withstand certain force impacts by separating the cooling structure from the force supporting structure of the heated component, as Figure 5. Consequently, as one of the most effective external cooling methods for advanced gas turbines with active thermal protection, it may be a priority research direction for external cooling methods in the future. Nowadays, transpiration cooling has already demonstrated excellent cooling performance. New porous double layer (PDL) transpiration cooling technologies can allow gas turbine entry temperature to be increased beyond current limits towards higher engine efficiency. However, a major challenge in integrating PDLs into real turbine components is to address specific life requirements despite the stress-raising effects near holes and sharp pedestal corners [16]. The unknown severity of thermal stresses associated with the potentially large temperature differences between the two layers has hindered the life assessment of the new systems [17]. Thus Skamniotis et al. [18] established links between elastic-inelastic analyses and between material phenomena-PDL geometry and indicates pathways for improving life. Alexander et al. [19,20] modified the Goldstein–Sellers method for film cooling across effusion-cooled configurations and complex double-walled effusion-cooled turbine blades, which showed good agreement with experimental results and literature results. This method represents a tool that could be easily implemented in the industry for rapid assessment of novel cooling geometries. Alexander et al. [21] also presented both an experimental and computational investigation into the cooling performance of effusion systems. Two flat-plate geometries (with primary hole pitches of 3.0 D and 5.75 D) were experimentally investigated. The experimental data demonstrated the 3.0 D pitched hole geometry displayed strong spanwise jet interactions with near complete spanwise films being developed at blowing ratios as low as 0.3. Ding et al. [22] studied the combined cooling effect in a separate porous matrix integrating transpiration and film cooling. A detailed comparison was made between the combined cooling impact of a single porous matrix and binary porous matrix. The results indicated that the integrated cooling impact of a binary porous matrix was significantly superior to that of a single porous matrix. Kim et al. [23] comprehensively investigated micro cooling performance by applying effusion and transpiration cooling to C3X blades arranged in a cascade. The results showed that effusion cooling and transpiration cooling achieve an overall cooling effectiveness of 0.4 and 0.6, respectively. Vikulin et al. [24] presented the results of the investigation of models with a transpiration cooling system made of sintered stainless-steel fibers and indicated that the implementation of transpiration cooling offers the prospects for increasing the maximum allowable gas turbine temperature up to 2200 K. It implies that transpiration cooling is suitable for higher temperature high-temperature surfaces and can protect heated components in harsh high-temperature conditions and require less coolant amount. Even though transpiration cooling is still in the initial research stage, its excellent performance in blade cooling is a vital cooling technology for future breakthroughs in higher-temperature gas, and its progress toward practical application requires more detailed research.

Figure 5.

Schematic diagram of transpiration cooling.

2.2. Internal Cooling Technology

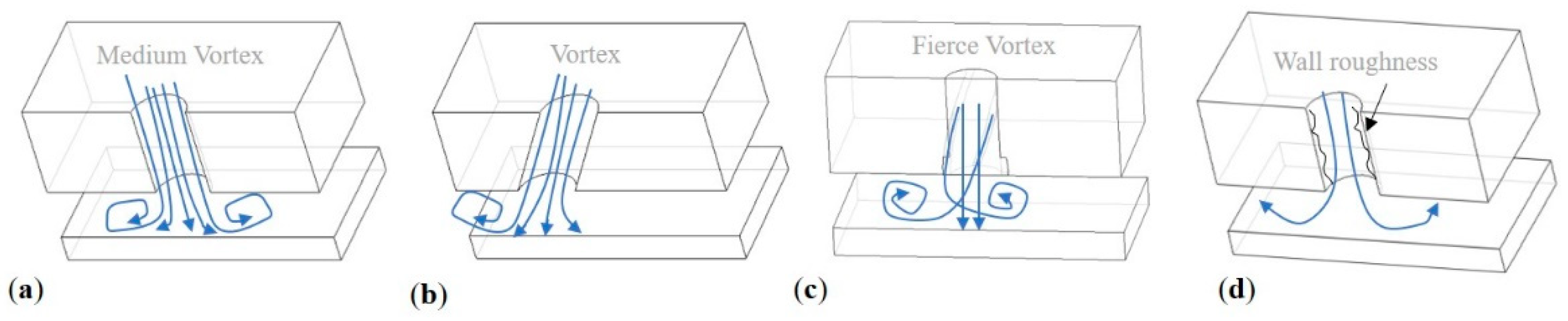

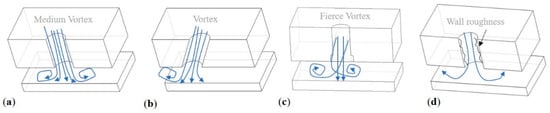

As for the internal cooling technologies, jet impingement cooling operates with cold airflow as the working mass and employs the intense convective heat transfer that occurs when a high-speed jet hits the wall to achieve efficient cooling in areas of high heat flow locally. Of all the heat transfer enhancement technologies, jet impingement cooling is the most effective method to improve local heat transfer coefficients. The impingement jet heat transfer is most appropriate where the heat load is extremely high, such as on the leading edge of turbine blades. For the inside of the turbine blades, the internal compartments are allowed to form an array of impingement cooling fields through the inserts of the impingement jets by means of a clever configuration of the structure. Its efficiency is often related to factors such as jet flow angle, impingement hole shape, impingement hole arrangement, the roughness of the target wall, and jet spacing. Xing et al. [25] conducted a numerical study of impingement cooling by the Baseline turbulence model. They considered target surface curvature and jet-to-surface spacing under various crossflow Reynolds numbers (15,000, 30,000, 45,000, and 60,000). The findings demonstrated that the target surface curvature is observed to have favorable effects on enhancing heat transfer. Large jet-to-surface spacing permits a greater degree of jet flow formation. Zhou et al. [26] investigated the impact of changing jet diameter on single-row jet impingement cooling performance. They discovered that while the jet diameter distribution has no visible impact on flow losses and overall heat transfer, it has a significant impact on mass velocity ratio and heat transfer uniformity within the impingement zones. Xu et al. [27] investigated the swirling impinging jet (SIJ) generated from the 45° threaded holes in the inclined situation. Jet inclination angle, jet-to-plate separation, and Reynolds number were studied. The findings indicated that, in contrast to the Reynolds number, the inclination angle and the distance between the jet and the plate had a significant impact on the size, shape, and location of vortices. Ravanji et al. [28] investigated a single jet with elliptical pin fins. They found that elliptical pin fins with a larger curvature can greatly improve heat transfer, several typical impingement cooling methods are shown in Figure 6. More efficient jet impingement cooling in the future may need to take into consideration both the joint action of the swirling impinging jet with a certain angle and the target surface with a special structure, as well as to study the mechanism of the conjugate action of each influencing factor thoroughly.

Figure 6.

Schematic diagram of typical impingement cooling: (a) cylinder hole; (b) inclined hole; (c) swirling hole; (d) AM hole.

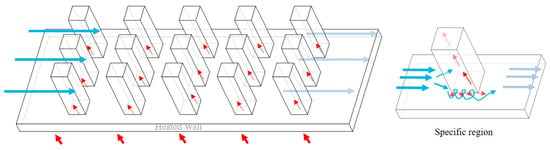

Other effective cooling approaches for the internal cooling techniques are to raise the turbulence of the coolant by placing ribs, pin fins, truss lattice or changing the roughness of the target surface to enhance heat transfer greatly. The channel regulates the entry of airflow by setting ribs so that the airflow can form a more complex vortex quickly after passing through the ribs with the different forms of ribs in front and behind. Ribs to enhance heat transfer are commonly used in the middle region of the turbine vane, as high-speed rotation in the vane is not conducive to impingement jets, and the blade space is also small to increase the difficulty of manufacturing complex cooling structures, making the channel ribs with simple structure and better heat transfer become the major and suitable components. Single and U-shaped channels with turbulent ribs are common in the middle chord of the blade, and the heat transfer capacity is improved by changing the rib distribution and using different rib shapes such as inclined ribs, V-shaped ribs, fin ribs, and W-shaped ribs. Tanda et al. [29] investigated forced convection heat transfer in a high aspect ratio (5:1) rectangular channel with 45° angled ribs. In the pursuit of heat transfer enhancement, they added longitudinal ribs (termed intersecting ribs) to the angled ribs, which oriented parallel to the mainstream. The results showed that the thermal performance based on the same pumping power is increased in the case of the insertion of one intersecting rib, while two intersecting ribs are unable to provide further enhancements. Zhao et al. [30] investigated heat transfer and pressure drop in a channel with a common 2-D micro rib. They found that small rib height in the boundary layer causes better overall thermal performance. Zhang et al. [31] investigated flow and heat transfer performances in the channels with micro V-shaped ribs, dimples, and their hybrid structures. They discovered that the micro V-shaped rib-dimple hybrid structure offers an even more pronounced improvement in heat transfer. At present, the heat transfer in the cooling channel is significantly improved by adding ribs to enhance the heat transfer coefficient on the walls and increase the heat transfer area. However, at the same time, the hindering effect on the cooling airflow separation increases the cooling air pressure loss and reduces the overall cooling efficiency. Moreover, the heat transfer and pressure loss performances represent two mutually constraining and contradictorily performance parameters, so future research will focus on finding a balance to obtain a good heat transfer and suitable pressure loss for the disturbance ribs.

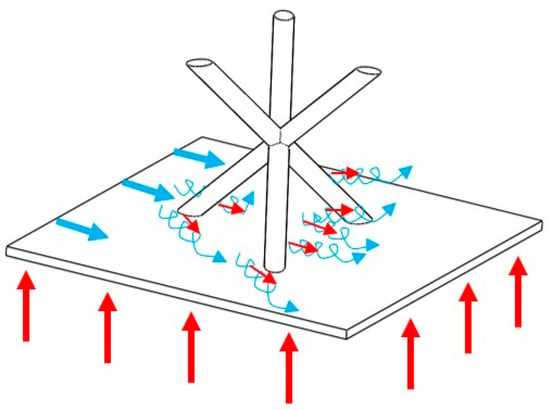

Disturbance pin fin cooling enhances heat transfer by increasing the heat transfer area and improving the turbulent energy of the cooling airflow, as in Figure 7. However, it is often accompanied by huge flow resistance and tends to be employed in components with high heat transfer requirements. Usually, the trailing edge of the turbine blade sets the pin fin to increase the disturbance of the airflow inside the turbine blade. During the disturbance process, the trailing vortex can be formed promptly, which accelerates the separation of the boundary layer of each wall inside the turbine blade and further improves the heat transfer efficiency of the turbine blade. This makes the turbine blade achieve effective convection heat transfer immediately when the huge airflow enters and realizes the purpose of cooling the blade; at the same time, it can also better perform its thermal conductivity and support the trailing edge structure. The cooling efficiency closely relates to the shape and arrangement of the pin fin. Bhandari [32] investigated the square-shaped micro pin fin structure of a micro-channel heat sink under different geometrical variations. The step variations were either along the channel length alone (unidirectional) or along the channel length plus channel width (bidirectional); the pin fin height changed in levels of two or three lines. The results clearly showed that the stepped setting has a better performance compared to the common setting; the bidirectional step has a great performance compared to the unidirectional step. Kemerli et al. [33] numerically studied the effect of Kagome rod length and diameter on conjugate forced convection heat transfer under the two boundary conditions of constant heat flux and a constant temperature. They pointed out that pressure drop increases with decreasing rod length and increasing rod diameter; the average heat transfer rate increases significantly with decreasing in rod length, but the influence of rod diameter is not significant. In recent years the cooling characteristics of pin fin under rotating conditions have become popular. Yan et al. [34] studied the heat transfer performance of different pin fins (upright, curved and inclined) under stationary and rotating conditions. For rotating conditions, compared to the other two pin fins, the heat transfer effect of the curved pin fins is significantly less sensitive to the rotation speed. Yeranee et al. [35] also pointed out that a large number of studies on the internal cooling of gas turbine blades have been carried out so far, mainly under static conditions. However, stationary studies neglect Coriolis and buoyancy forces, which influence the velocity, turbulence and temperature distribution under rotating conditions. Then the future for pin fin cooling needs not only to explore the new pin fin structure and special arrangement but also to consider the heat transfer performance under rotating conditions. The research under rotating conditions is also bound to involve the aforementioned film cooling, transpiration cooling, jet impingement cooling, and channel with ribs.

Figure 7.

Schematic diagram of heat exchange from pin fin structure.

Layer cooling, also referred to as double-wall cooling, normally contains three cell cooling structures which are impingement holes, disturbance columns, and film holes. The potential of layer cooling is to achieve better cooling with lower flow resistance and less airflow; its cooling capacity is also better than the previously mentioned cell cooling structures. Layer cooling is commonly applied to the leading edge of turbine blades, and its cooling efficiency is related to these structural parameters, operation conditions, and arrangements. Liu et al. [36] investigated the total cooling impact of a double-wall cooling structure with pin fins. The outcomes demonstrated that the double-wall cooling had an area-averaged total cooling impact that was more than 30% of the two single cooling strategies. At high blowing ratios, the contribution of impingement cooling was greater than that of effusion cooling. Courtis et al. [37] reported on a combined aerothermal-mechanical study of a transpiration-cooled double-wall turbine blade. They discovered that a system with high porosity showed better cooling performance and reduced the temperature difference across the two walls. Ahmed et al. [38] investigated the incorporation of a unique reverse jet impingement into a double-wall cooling structure. The reverse jet impingement design showed the ability to increase beneficial fluid flow while reducing adverse crossflow effects without significantly lowering the discharge coefficient. Click et al. [39] studied the influence of various coolant supply systems on the thermal performance of a double-walled cooling system. The topics discussed included cross-flow-only, impinging jet arrays, and crossflow and impinging jet arrays combined. The combined crossflow/impingement design had lower adiabatic film cooling values for areas upstream of the jet plate than the impingement-only setup. Liu et al. [40] presented the flow and heat transfer performance of a double-wall cooling with an inline short film cooling hole layout. They discovered that the inline layout could achieve comparable cooling performance with a smaller pressure loss than the staggered layout. As a newly developed composite unit structure, the layout of the layer structure between its unit structure and the influence of the unit structure parameters on each other is more complex. Therefore, how to find a novel layer structure with higher cooling capacity is the core concern of this structure.

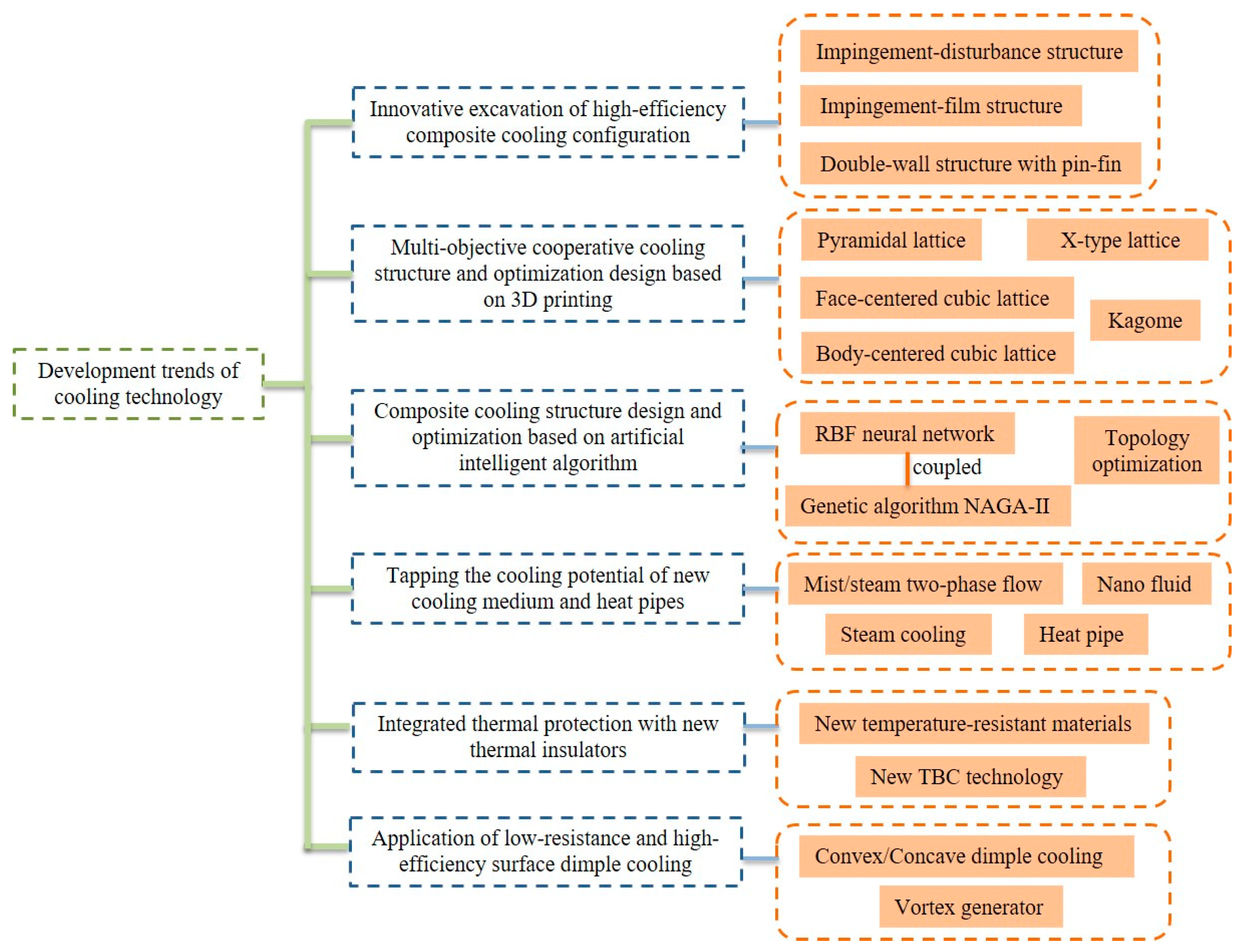

3. Development Trends of Cooling Technology for Blades with Super-High Temperature

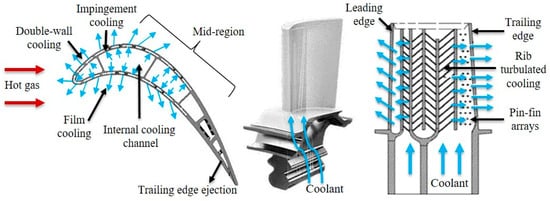

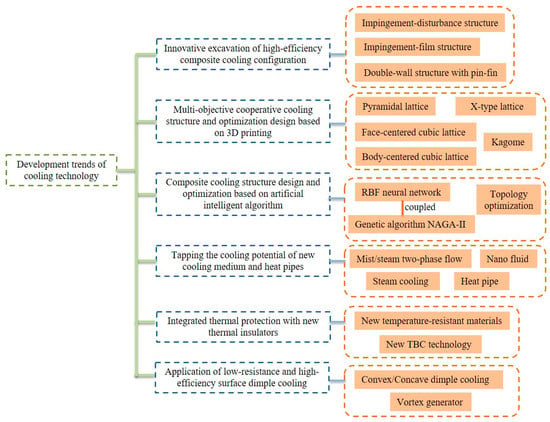

According to the introduction of the turbine blade cooling technology research status, in order to face the development of turbine blades for above 2000 K temperature, we believe that the future turbine blade cooling technology research highlights will focus on the following aspects among the current wide range of cooling technologies, as in Figure 8.

Figure 8.

Development trends of cooling technology.

3.1. Innovative Excavation of High-Efficiency Composite Cooling Configuration

The high-efficient composite cooling structures tend to be the core direction of cooling technology development to improve the heated capacity of the turbine blades and the cooling potential of the cooling air. The high-efficient composite cooling structures include an impingement-disturbance structure, an impingement-film structure and a double-wall structure with a pin fin. Among them, the impingement-disturbance structures with ribs, cylinders and various convex structures are usually arranged on the leading edge of the blade. Their cooling efficiency is also closely related to the structure parameters of the impingement hole and the pin fin. Zhang et al. [41] investigated the contribution of the impinging surface, pin fin surface, and target surface to the total heat transfer rate of the double-wall structure using the TLC technique. The results showed that the target surface contributed the most to the heat transfer rate with a value of about 62%. Wu et al. [42] examined the flow and heat transfer properties of pin fins and integrated array jets. The results showed that as compared to a smooth target surface, the heat transfer from parallel and cross-arranged pin fins increased by around 30% and 10%, respectively. Moreover, Qiu et al. [43] investigated the effects of pin fin layout and jet Reynolds number on heat transfer and flow of a concave surface with pin fin. The results showed that the increase and uniformity of heat transfer are positively influenced by the distance of pin fin. As a result, for the impingement-disturbance structure, the disturbance structure as well as the target surface has a great influence on the cooling efficiency. This paper suggests that the cooling potential of this structure is not sufficient considering only the impingement hole and the pin fin, which should be integrated with the rough target surface structure with better cooling performance so as to change the two-unit composite structure into a three-unit composite structure.

The impingement-film cooling is the most common composite cooling structure. Early studies were limited to comparing the effect of one cooling structure on the cooling efficiency or heat transfer of another cooling structure but later developed into conjugated heat transfer to study this composite structure which also changed into hole parameters, hole arrangement, cooling air characteristics, and rotation factors. Zhang et al. [44] investigated the interaction of heat and flow on the composite cooling structure at the leading edge of the first stage of GE-E3. They analyzed the effect of the angle of the leading edge film holes on the composite cooling characteristics when the leading edge film holes were arranged symmetrically. Their results showed that the average integrated cooling efficiency of the leading edge of the turbine blades is higher when the angle of the film holes was smaller and the cooling airflow mass flow ratio is higher. Singh and Udayraj [45] investigated how film cooling and jet impingement affected fluid flow. The results showed that the impact of the jet impingement was substantial and that the direction of the hole and the blowing ratio had an impact on the efficiency of film cooling. Pu et al. [46] studied the cooling air effect on the metal’s overall effectiveness and proposed the modified laminated cooling layout which can acquire a uniform distribution. The new layout revealed that on the leading edge of the pressure side, the novel film cooling design and dense layout of the impingement-hole are effective. Wang et al. [47] have studied a rectangular channel of the leading edge with impingement-film cooling in rotating conditions. They found that the Coriolis forces cause the jet to deviate which results in reduced cooling capacity; the Coriolis forces generated by different rotating directions profoundly affect the flow field in the channel, causing different heat transfer distributions. It can be seen that for this structure, the influence of cooling and rotating conditions has been studied. Moreover, the influence of the blade pressure surface and the suction surface is different. Therefore, the application of the impingement-film cooling in the real blade model as well as the real working conditions will be the investigation of the cooling potential of the composite structure.

A double-wall structure with pin fins can enhance the heat transfer capacity of the jet flow by incorporating a pin fin structure on the target surface on the basis of a double-wall structure. As a new hybrid structure, its heat transfer capacity is also related to the film hole parameters, pin fin parameters, arrangement methods and other factors. Rao et al. [48] explored multi-jet impingement heat transfer in a double-walled cooling structure. According to the experimental findings, pin fins and jet holes considerably improved uniform heat transmission over the whole target plate by reducing crossflow intensity in the downstream region. The research conducted by Fan [49] is of particular significance for the study of double-walled blades with pin fins. To investigate the innovative cooling methods, they fully investigated the four groups of combined cooling methods, disturbing objects, rows of bridge holes and the existence of film holes. Last but not least, the vortex double wall cooling technique demonstrates its potential as a cooling technique. As a novel, three-unit composite cooling structure, the double-walled structure with pin fin has an extraordinarily large number of factors affecting the cooling efficiency, but its in-depth study is extremely promising with its comprehensive cooling performance potential.

For these composite innovative structures, the research to explore the flow and heat transfer mechanism is an important work in the early stage to lay the foundation for the practical application of these high-performance structures to turbine blades in engineering in the future.

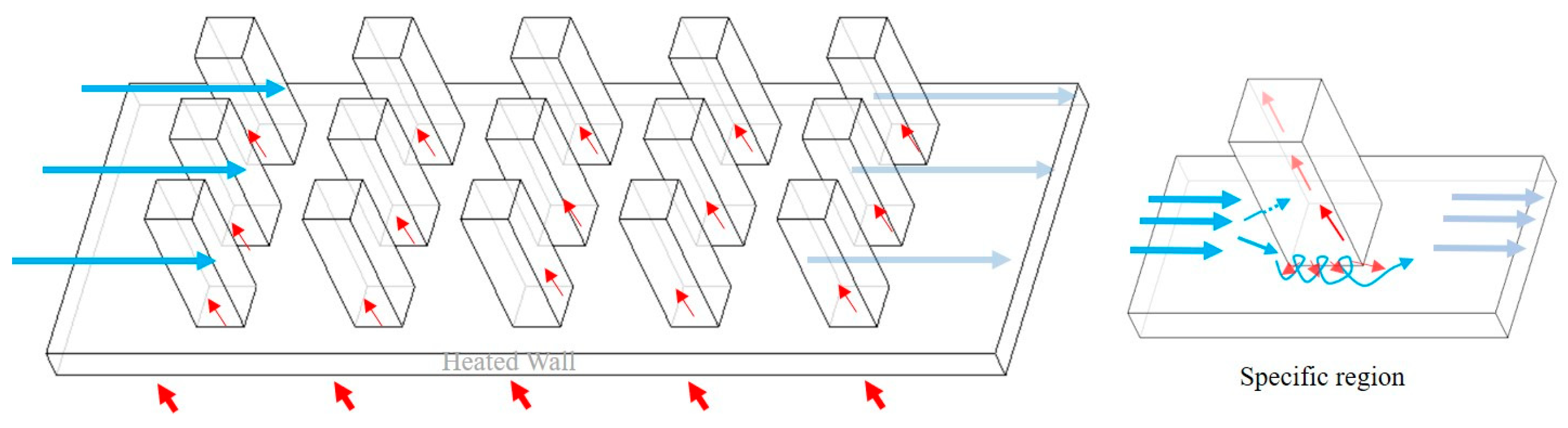

3.2. Multi-Objective Cooperative Cooling Structure and Optimization Design Based on 3D Printing

Additive manufacturing (AM) is a relatively recent rapid manufacturing technique. Its ability to manufacture complex parts without the use of a mold is one of its characteristics. Due to its distinctive capability, it will likely dominate the production of sophisticated gas turbine components in the future [50,51]. Parts manufactured on the basis of this technology can be synergistically optimized for their thermal, aerodynamic, strength, vibration, lightweight, and other multifaceted objectives. Siemens has produced turbine blades manufactured by 3d printing using polycrystalline nickel superalloy powder, which was applied to an SGT-400 industrial gas turbine, with operating conditions of 13,000 r/min and 1250 °C and it passed the test. Other manufactured parts included replacing the multi-rib structure of the internal cooling channel with a truss lattice structure with high porosity. Ma et al. [52] proposed a new sandwich plate by adding a multifunctional pyramid lattice into the plate. The results showed that at a particular Reynolds number, the pyramid lattice significantly increased the plate’s total Nussle number by up to 150%. Xi et al. [53] developed a novel cooling channel filled with a revolutionary X-type truss array construction that exhibited greater overall thermal performance. Liang et al. [54] examined the influence of element shape (circular, rectangular, and elliptical) of the face-centered cubic (FCC) lattice structure on flow and end wall heat transfer in a rectangular channel. The finding showed that, at the same Reynolds number, the heat transfer performance of the elliptical and rectangular FCC lattices is, respectively, 27–31% and 25–26% higher than that of the circular FCC lattice. Wang et al. [55] explored the effective thermal conductivity and heat transfer characteristics for a series of body-centered cubic lattice sandwich panels. The results showed that the body-centered cubic lattice has a superior mechanical performance in terms of heat transfer properties. Our team even carried out a multi-objective optimization study based on the X-type lattice [56,57] to establish the empirical correlations between the first-order natural frequency, elasticity modulus, relative density, and Nusselt number, which provides a method for the functional integration of the cooling structure with a 3D print while considering the heat transfer and mechanical properties of the lattice structure.

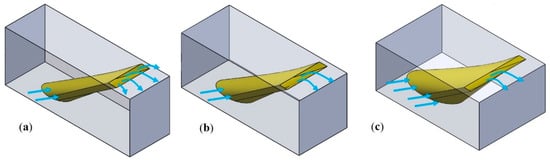

In addition, Kagome structures, as in Figure 9, which exhibit excellent structural and strength properties can also be manufactured by 3D printing technology. Yang et al. [58] found that the Kagome lattice can produce a better heat transfer rate compared to the tetrahedral lattice, but it leads to a higher pressure drop. Shen et al. [59,60] found that the Kagome sandwich panel has a similar pressure drop but 26–31% higher overall heat transfer compared to the wire-woven bulk Kagome sandwich panel for the same porosity. They also numerically studied the heat transfer characteristics of the wedge-shaped channels for a defined Reynolds number and porosity and pointed out that the Kagome structure used in the channel has a better heat transfer effect than the needle fin and ribbed column structures. Sarwesh et al. [61] studied the thermal performance of the microchannels embedded in the Inconel 718 Kagome lattice. The results showed that the heat transfer enhancement of the Kagome lattice is three to six times better than that of the smooth channel. These results showed that truss lattice structures produced by 3D printing technology for the synergistic multi-targeting of thermal, aerodynamic, strength, vibration, and lightweight are highly promising advanced cooling structures for the future.

Figure 9.

Schematic diagram of heat exchange from Kagome structure.

Moreover, for film holes processed by AM, Aghasi et al. [62] investigated the effect of fused deposition AM processed with different layer thicknesses and AM directions on the effective degree of film cooling. Compared with conventional machining the experimental results showed that the higher intra-hole roughness delayed the film cooling blow-off and increased the effective film cooling at high blowing ratios. Schroeder et al. [63] investigated the effect of intra-hole roughness on fan-shaped film cooling by AM. Compared to smooth holes, the roughness of the hole led to a reduction in the cooling adiabatic effect, and the higher the hole roughness and the higher the blowing ratio, the more the area-averaged adiabatic film cooling effectiveness decreased. However, there are many shaped film holes proposed by the simulation that we cannot ignore the difficulty of manufacturing, and AM is a suitable way to manufacture shaped film holes. Therefore, we need AM to process various shaped film holes and to reduce the roughness by improving the process, which will provide better cooling and less stress concentration with respect to conventional casting manufacturing techniques.

3.3. Composite Cooling Structure Design and Optimization Based on Artificial Intelligent Algorithm

For the optimal design of composite structures, the three main elements are the objective function, design variables, and constraints. Moreover, the multi-objective optimal design is often required in practical engineering. It is critical to select the appropriate optimization method for parameter optimization and shape optimization. The previous section has mentioned many composite cooling structures, and common structural optimization requires the establishment of a design database. Bu et al. [64] investigated the effects of geometric parameters (impingement hole-to-hole pitch, impingement hole diameter, impingement channel height, and film hole diameter) related to the double-wall structure. Then a database that represented the design space was compiled using the uniform design method. Through CFD, performance standards for the cooling system were assessed. To organize the design space, they constructed a Kriging model using the database, and then they examined the variance to look into the primary effects of each parameter and their relationships. Zhang et al. [65] instead used an agent prediction model based on RBF neural network, which selected training samples using Latin sampling and randomly chosen test samples to obtain an accurate prediction model. Then, the optimal solution was obtained by using the genetic algorithm NAGA-II. Additionally, topology optimization which adjusts the layout of the material in the design domain to improve the structural performance has already been applied in the lattice structure design in recent years. Hoang et al. [66] studied the lattice structure (LS) utilizing a direct multiscale topological optimization approach, which provides a low-cost and efficient method for obtaining the optimum LS. Zhang et al. [67] presented LS topology optimization. The results showed that the compressive, flexural, and energy absorption stiffness of the optimum LS were significantly enhanced. Yeranee et al. [68] considered density-based topology optimization with the turbulent flow to improve the thermal performance of the cooling channel. The results showed that the topological structure provides better temperature uniformity. Moreover, the topological structure resulted in less pressure drop as compared to the identical solid volume scenario. Therefore, for cooling structure design, we believe it is promising to apply the topology optimization method in the optimal design of the heat transfer structure and to obtain the optimized structure with thermal boundary conditions as constraints.

3.4. Tapping the Cooling Potential of New Cooling Medium and Heat Pipes

Confronted with the increasingly severe working conditions of the turbine blades, the trend of the gas engine will inevitably develop towards high temperature and high heat capacity. Tapping into the cooling potential of airflow at the same flow rate or low flow rate is the core trend of the current cooling technology development. At present, cooled cooling air (CCA) technology, which can greatly improve the cooling quality of cooling air and realize the comprehensive energy utilization of the engine, has become one of the key ways to solve the above problems [69]. In this regard, we also believe that the research of new work cooling media and the application of heat pipe technology can be used to exploit the cooling potential.

The concept of steam cooling also a part of the new work medium was proposed in the 1990s, with the core being the heat recovery steam generator (HRSG) and closed-loop steam cooling systems. Steam cooling can significantly reduce the air consumption of the compressor, while closed-loop steam cooling helps to avoid mixing loss between the mainstream and cooling air, thus improving the overall efficiency of the gas turbine. It is worth noting that the thermodynamics of the HRSG in steam cooling alone accounts for 28.88% of the total thermodynamics loss [70] for which re-cooling enhancements can deeply exploit the cooling potential of the cooling steam. Steam cooling technology is also widely used in advanced international heavy-duty gas turbine products, with the H-class gas turbine of GE using closed-loop steam cooling for the first two stages. However, the value of mist/steam two-phase has been explored in recent years [71,72]. The internal cooling channels of the blades were cooled using a mist/steam two-phase flow, which employed a small amount of water droplets to mix with steam as the working fluid. Zhang et al. [73] established a detailed vane model with a double-wall cooling structure. They discovered that when air is used as the coolant, the average surface temperature decreases by 35 K; however, when droplets make up 10% of the coolant, the average temperature decreases significantly by 156–174 K. Additionally, it has been observed that a smaller droplet helps to improve the performance. Jiang et al. [74] investigated mist/steam coolant flow and heat transfer properties in a U-shaped gas turbine cooling channel. The findings demonstrated that as the mass ratio of mist to steam increases, the heat transfer of the ribbed-wall gradually increases. Jiang et al. [75] recommended using a mist/steam two-phase flow in the column rib channel. According to the findings, consistently raising the mist/steam mass ratio will contribute to improving both the effectiveness and unevenness of the heat transfer in the heated walls. Zhang et al. [76] used a mist/air mixture to test the influence of the serrated structure on the cooling performance of trench holes. The results showed that the performance of the film cooling could be greatly enhanced by the serrated transverse trench construction and the addition of mist to the cooling air. Meanwhile, nanofluid-enhanced heat transfer technology could also be a focus of research for new steam cooling processes since it is low-cost, flexible in control and versatile in form [77]. Xi et al. [78,79] also carried out parameter optimization of steam-cooled ribbed channels in blades, all of which indicate the potential of mist/steam two-phase flow or steam medium as advanced cooling technology.

In addition, the heat pipe has good thermal conductivity, ideal isothermal properties, adjustable heat flow density, reversible heat transfer direction, and good adaptability as a highly efficient heat transfer device [80]. The heat pipe can be grouped according to temperature into deep cold heat pipes, low-temperature heat pipes, medium-temperature heat pipes, and high-temperature heat pipes. Among them, high-temperature heat pipes can as well be divided into siphon heat pipes, standard heat pipes, and rotating heat pipes according to the return flow method for gas turbine blades, of which rotating heat pipes have been studied in the turbine blade operating environment. Taamneh [81] investigated a simpler turbine disk with installed heat pipes. The maximum temperature of the disk can be reduced by more than 100 degrees when there are 32 heat pipes, according to extensive research. However, rotating heat pipes are often used in various rotating machines and their performance is also related to various input parameters. Chen et al. [82] proposed incorporating a rotating heat pipe into the annular disk of a grinding wheel. Additionally, they investigated how various evaporator geometries, input heat flow, filling rates, and rotational speeds affected the efficiency of the heat transfer. Wang et al. [83] designed and built a rotating heat pipe with a cylindrical inner surface. They discovered that the rotating heat pipe’s thermal resistance typically ranged from 0.1 to 0.6 K/W. When the heating power and cooling temperature are increased, the thermal resistance decreases monotonically. Additionally, because of the centrifugal force factor, radially rotating heat pipes are appropriate for rotating blades. For other types of heat pipes, most of the studies are on the performance of the heat pipes themselves. Wang et al. [84] developed a comprehensive CFD model. The CFD model could simulate the liquid up-throwing phenomenon and show how the production of hydrogen buffers affected heat transfer. Yilgor and Shi [85] described the law of proportionality for two-phase flow and heat transfer in heat pipes and thermo-couples, which makes it possible to use low-temperature working fluids to study various phenomena in high-temperature heat pipes. At present, the application of heat pipes to turbine blades is still relatively poor and it is a difficult problem to arrange the heat pipes in a sensible way within the structural strength of the turbine blades. However, there is full potential for future research as the circulation of the heat transfer process enables the significant conservation of the use of cooling air. Therefore, the researchers need to focus on the rational arrangement of heat pipes under practical working conditions.

3.5. Integrated Thermal Protection with New Thermal Insulators

For the high-temperature component of a turbine engine, the technology of nickel-based and cobalt-based ultra-high-temperature alloys is currently relatively mature. Besides the addition of trace elements to improve performance, thermal barrier coatings (TBC) are commonly used to protect the metal substrate and extend the service life of the high-temperature component, which means that a low thermal conductivity ceramic layer is added to the surface of the heated part and the metal bonding layer relieves the thermal stress due to a mismatch in the coefficient of the thermal expansion between the ceramic coating and the metal substrate. The contribution of TBC to the cooling of the blades is significant among TBC and air cooling. Pu et al. [86] investigated the effect of exterior surface TBC on double-wall cooling structures. The combined impact of coating thickness, impingement design, and cooling airflow on the total thermal performance was thoroughly studied. According to the findings, TBC has a considerably bigger impact than simply increasing the amount of cooled air. Greater insulation performance is produced by thicker TBCs, but they also have a higher risk of thermal degradation on their own and reduce the benefits of bigger cooling air volumes. Meanwhile, ceramic matrix composites (CMCs) which have excellent high-temperature strength, are emerging as excellent advanced lightweight composites for aerospace applications. CMCs as a substitute for high-temperature alloys, have high-temperature resistance and are able to reduce structural density, to achieve lightweight development [87]. For the turbine blade manufacturing process, integrated thermal protection with TBC and CMCs is undoubtedly crucial. The surface temperature of the high-temperature components is reduced by 380–440 K using TBC with a thickness of 250 μm under the existing cooling technology [88]. Yttria Stable Zirconia (YSZ) is a conventional ceramic thermal barrier coating that usually adds elements such as Sc, La, Al, and Ni to improve its performance. MHI has developed a TBC of A2B2O7 pyrochlore structure with higher thermal insulation temperature that meets the development needs of an 1850 K gas turbine. GE and Siemens have already applied integrated thermal protection technology to their latest gas turbine products. The third stage of the 7/9HA-series turbine blades of GE is made of a directionally solidified single-crystal alloy with newly developed TBC technology [89]. The first and second-stage blades of the H-series gas turbines of Siemens also feature directional crystalline materials and improved TBC technology, while the HL-series incorporates advanced modular TBC and freestanding fourth-stage blades. Evidently, integrated thermal protection technology which differs from active thermal protection; passive thermal protection has already been developed and produced by international advanced gas turbine companies. Its cooling capacity under high-temperature conditions is better than various active thermal protection technologies as well. Therefore, exploitation of the integrated thermal protection capability of CMCs and new TBC technologies is a key technology to make the gas temperature breakthrough of 2000 K

3.6. Application of Low-Resistance and High-Efficiency Surface Dimple Cooling

A sensible combination of any two cooling technologies can deliver better performance than a single technology. Moreover a greater degree of improvement is expected when a third cooling technology is added. The roughing up of the target surface is undoubtedly the third crucial cooling technology, which generates more coherent vortices and detaches and restarts the boundary layer more often, hence performing higher heat transfer. The current common rough target surface is the grooved surface formed by rectangles. Zontul et al. [90] studied the heat transfer characteristics of flow in a channel with rectangular grooves by experimental and numerical simulation. The standard k-ε model was adopted in numerical simulation. The Reynolds numbers were between 2000 and 6500. They found that grooved channels obtain 1.9–2.4 times larger Nusselt values compared with straight channels, although the corrugated groove channel caused an increase in pressure loss. However, the dimple structure is a novel way of roughing up the target surface, which has better heat transfer performance. Ahmed et al. [91] analyzed a heat sink consisting of a separate convex/concave dimpled aluminum plate and multiple phase change materials, which cooled the solar panel. The results showed that the arrangement with eight dimples provides the longest uniform operating temperature duration and effectively reduces the solar panel temperature. Qi et al. [92] investigated jet impingement for three different target surfaces (flat, concave, and V-shape) and various surface arrangements of convex/concave dimples and triangular ribs. According to the studies, convex/concave dimples can achieve excellent heat transfer performance, especially for the convex dimple structure, and concave dimples cause a low resistance. Meanwhile, the vortex generator always combined with dimple cooling. Jeong et al. [93] investigated a dimpled cooling channel with a crescent-shaped protrusion vortex generator, which is mounted downstream of the dimple. Moreover, Yang et al. [94] proposed a general dimple structure combined with a wedge-shaped vortex generator on the upstream dimple. The main purpose of two vortex generators is to enhance the flow mixing and achieve better heat transfer. The dimpled channels with a vortex generator both showed better thermo-performances than the general dimpled channel. Therefore, a dimpled surface with a vortex generator has high heat transfer capacity with relatively low pressure loss compared with other types of approaches. The application of low-resistance and high-efficiency surface dimple cooling is one of the methods for effective cooling technology.

4. Conclusions

For the current development status of turbine blade cooling technology supported by the research carried out by the authors in recent years and the published academic papers of various peers, the authors consider that the future development trend of turbine blade cooling technology should focus on multiple new cooling methods. Traditional single cooling has long failed to keep up with the increasing temperatures; this is the internal and external cooling mentioned in chapter 2. Therefore, the newly proposed cooling including composite cooling configuration, topology structure, AM truss, steam/mist medium, heat pipe, new TBC, and dimple cooling, is summarized into six appropriate trends in chapter 3. We can only hope that the aforementioned six points will be useful to all of our colleagues as a reference. The authors are certain that with our combined efforts, turbine blade cooling technology can continue to develop vigorously.

Author Contributions

Conceptualization, L.X. (Liang Xu) and Z.S.; methodology, L.X. (Liang Xu); validation, L.X. (Liang Xu), Z.S. and L.X. (Lei Xi); formal analysis, Q.R.; investigation, Q.R.; resources, L.X. (Liang Xu) and J.G.; data curation, Z.S.; writing—original draft preparation, L.X. (Liang Xu); writing—review and editing, Z.S.; visualization, Z.S.; supervision, Y.L. and L.X. (Liang Xu); project administration, J.G. and Y.L.; funding acquisition, L.X. (Liang Xu) and L.X. (Lei Xi). All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to express their sincere gratitude to the National Natural Science Foundation of China (Grant No.: 51876157), the Natural Science Foundation of Shaanxi Province in China (Grant No.: 2019JM-096), the Project Supported by Natural Science Basic Research Plan in Shaanxi Province of China (2022JQ-545) and the Project funded by China Postdoctoral Science Foundation (2021M702573) for providing financial support for this work.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| RTSH | Round-to-slot shaped film-hole |

| SIJ | Swirling impinging jet |

| TLC | Thermochromic liquid crystal |

| AM | Additive manufacturing |

| PDL | Porous double layer |

| FCC | Face-centered cubic |

| Pi | Impingement hole-to-hole pitch |

| Di | Impingement hole diameter |

| CMCs | Ceramic matrix composites |

| H | Impingement channel height |

| Df | Film hole diameter |

| RBF | Radial Basis Function |

| LS | lattice structure |

| HRSG | Heat recovery steam generator |

| TBC | Thermal barrier coatings |

| YSZ | Yttria Stable Zirconia |

| CCA | Cooled Cooling Air |

References

- Jiang, H.D.; Ren, J.; Li, X.Y.; Tan, X.Y. Status and development trend of the heavy duty gas turbine. Proc. CSEE 2014, 34, 5096–5102. (In Chinese) [Google Scholar]

- Zheng, L.; Wang, B.; Zhao, L.; Zhang, S.; Xiao, Y. The Cooling Air and Firing Temperature Estimation for GE’s Heavy Duty Gas Turbines. Proc. CSEE 2019, 39, 6943. (In Chinese) [Google Scholar]

- Du, K.; Chen, Q.-H.; Meng, X.-L.; Wang, L.-Q.; Pei, X.-P.; Li, H.-R.; Liu, C.-L.; Jiao, Y.-C. Advancement in Application and Thermal Analysis of Ceramic Matrix Composites in Aeroengine Hot Components. J. Propuls. Technol. 2022, 43, 107–125. (In Chinese) [Google Scholar]

- Shuai, S.-S.; Li, S.-L.; Xuan, W.-D.; Ren, X.-F.; Tu, T.-S.; He, L.; Wang, J.; Ren, Z.-M. Research Progress of Materials and Key Manufacturing Technologies of Heavy-Duty Gas Turbine Blades. Therm. Turbine 2022, 51, 161–169. (In Chinese) [Google Scholar]

- Skamniotis, C.; Courtis, M.; Cocks, A.C.F. Multiscale analysis of thermomechanical stresses in double wall transpiration cooling systems for gas turbine blades. Int. J. Mech. Sci. 2021, 207. [Google Scholar] [CrossRef]

- Nourin, F.N.; Amano, R.S. Review of Gas Turbine Internal Cooling Improvement Technology. J. Energy Resour. Technol. Trans. Asme 2021, 143, 080801. [Google Scholar] [CrossRef]

- Umesh, U.; Vigor, Y. A review of cooling technologies for high temperature rotating components in gas turbine. Propuls. Power Res. 2022, 11, 293–310. [Google Scholar]

- Pu, J.; Zhang, T.; Wang, J.-h. Experimental study of combined influences of wall curvature and compound angle on film cooling effectiveness of a fan-shaped film-hole. Int. Commun. Heat Mass Transf. 2022, 130. [Google Scholar] [CrossRef]

- Zamiri, A.; Barigozzi, G.; Chung, J.T. Large eddy simulation of film cooling flow from shaped holes with different geometrical parameters. Int. J. Heat Mass Transf. 2022, 196. [Google Scholar] [CrossRef]

- Li, L.; Liu, C.-l.; Ye, L.; Zhu, H.-R.; Luo, J.-X.; Liu, S. Experimental investigation on effects of cross-flow Reynolds number and blowing ratios to film cooling performance of the Y-shaped hole. Int. J. Heat Mass Transf. 2021, 179. [Google Scholar] [CrossRef]

- Zhu, X.-d.; Zhang, J.-z.; Tan, X.-m. Numerical assessment of round-to-slot film cooling performances on a turbine blade under engine representative conditions. Int. Commun. Heat Mass Transf. 2019, 100, 98–110. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, J.-z.; Wang, C.-h. Multi-objective optimization of round-to-slot film cooling holes on a flat surface. Aerosp. Sci. Technol. 2020, 100. [Google Scholar] [CrossRef]

- Liu, C.-l.; Xie, G.; Zhu, H.-r.; Luo, J.-x. Effect of internal coolant crossflow on the film cooling performance of converging slot hole. Int. J. Therm. Sci. 2020, 154. [Google Scholar] [CrossRef]

- Hou, R.; Wen, F.; Luo, Y.; Wang, S. Influence of Inlet Swirl on Film Cooling of the Turbine Leading Edge. Heat Transf. Eng. 2020, 42, 985–1001. [Google Scholar] [CrossRef]

- Barahate, S.D.; Vedula, R.P. Film cooling performance measurement over a flat plate for a single row of holes embedded in an inclined trench. Int. J. Therm. Sci. 2020, 150. [Google Scholar] [CrossRef]

- Skamniotis, C.G.; Cocks, A.C.F. Designing against severe stresses at compound cooling holes of double wall transpiration cooled engine components. Aerosp. Sci. Technol. 2021, 116. [Google Scholar] [CrossRef]

- Skamniotis, C.G.; Cocks, A.C.F. Minimising thermal stresses in double wall transpiration cooled components for high temperature applications. Int. J. Mech. Sci. 2020, 189. [Google Scholar] [CrossRef]

- Skamniotis, C.G.; Cocks, A.C.F. Creep-plasticity-fatigue calculations in the design of porous double layers for new transpiration cooling systems. Int. J. Fatigue 2021, 151, 106304. [Google Scholar] [CrossRef]

- Ngetich, G.C.; Murray, A.V.; Ireland, P.T.; Romero, E. A Three-Dimensional Conjugate Approach for Analyzing a Double-Walled Effusion-Cooled Turbine Blade. ASME J. Turbomach. 2019, 141, 011002. [Google Scholar] [CrossRef]

- Courtis, M.; Murray, A.; Coulton, B.; Ireland, P.; Mayo, I. Influence of Spanwise and Streamwise Film Hole Spacing on Adiabatic Film Effectiveness for Effusion-Cooled Gas Turbine Blades. Int. Jourmal Turbomach. Propuls. Power 2021, 6, 37. [Google Scholar] [CrossRef]

- Murray, A.V.; Ireland, P.T.; Wong, T.H.; Tang, S.W.; Rawlinson, A.J. High Resolution Experimental and Computational Methods for Modelling Multiple Row Effusion Cooling Performance. Int. Jourmal Turbomach. Propuls. Power 2018, 3, 4. [Google Scholar] [CrossRef]

- Ding, R.; Wang, J.; He, F.; Dong, G.; Tang, L. Numerical investigation on the performances of porous matrix with transpiration and film cooling. Appl. Therm. Eng. 2019, 146, 422–431. [Google Scholar] [CrossRef]

- Kim, M.; Shin, D.H.; Lee, B.J.; Lee, J. Experimental and numerical investigation of micro-scale effusion and transpiration air cooling on cascaded turbine blades. Case Stud. Therm. Eng. 2022, 32. [Google Scholar] [CrossRef]

- Vikulin, A.V.; Yaroslavtsev, N.L.; Zemlyanaya, V.A. Investigation into Transpiration Cooling of Blades in High-Temperature Gas Turbines. Therm. Eng. 2019, 66, 397–401. [Google Scholar] [CrossRef]

- Xing, H.; Du, W.; Sun, P.; Xu, S.; He, D.; Luo, L. Influence of surface curvature and jet-to-surface spacing on heat transfer of impingement cooled turbine leading edge with crossflow and dimple. Int. Commun. Heat Mass Transf. 2022, 135. [Google Scholar] [CrossRef]

- Zhou, J.; Tian, J.; Lv, H.; Dong, H. Numerical investigation on flow and heat transfer characteristics of single row jet impingement cooling with varying jet diameter. Int. J. Therm. Sci. 2022, 179. [Google Scholar] [CrossRef]

- Xu, L.; Xiong, Y.; Xi, L.; Gao, J.; Li, Y.; Zhao, Z. Numerical Simulation of Swirling Impinging Jet Issuing from a Threaded Hole under Inclined Condition. Entropy 2019, 22, 15. [Google Scholar] [CrossRef]

- Ravanji, A.; Zargarabadi, M.R. Effects of elliptical pin-fins on heat transfer characteristics of a single impinging jet on a concave surface. Int. J. Heat Mass Transf. 2020, 152, 119532. [Google Scholar] [CrossRef]

- Tanda, G.; Satta, F. Heat transfer and friction in a high aspect ratio rectangular channel with angled and intersecting ribs. Int. J. Heat Mass Transf. 2021, 169. [Google Scholar] [CrossRef]

- Zhao, K.; Lin, W.; Li, X.; Ren, J. Effect of micro rib on aerothermal dynamic in channel flow. Int. J. Heat Mass Transf. 2021, 178. [Google Scholar] [CrossRef]

- Zhang, P.; Rao, Y.; Xie, Y.; Zhang, M. Turbulent flow structure and heat transfer mechanisms over surface vortex structures of micro V-shaped ribs and dimples. Int. J. Heat Mass Transf. 2021, 178. [Google Scholar] [CrossRef]

- Bhandari, P. Numerical investigations on the effect of multi-dimensional stepness in open micro pin fin heat sink using single phase liquid fluid flow. Int. Commun. Heat Mass Transf. 2022, 138. [Google Scholar] [CrossRef]

- Kemerli, U.; Kahveci, K. Conjugate forced convective heat transfer in a sandwich panel with a Kagome truss core: The effects of strut length and diameter. Appl. Therm. Eng. 2020, 167. [Google Scholar] [CrossRef]

- Yan, H.; Luo, L.; Zhang, J.; Du, W.; Wang, S.; Huang, D. Flow structure and heat transfer characteristics of a pin-finned channel with upright/curved/inclined pin fins under stationary and rotating conditions. Int. Commun. Heat Mass Transf. 2021, 127. [Google Scholar] [CrossRef]

- Yeranee, K.; Rao, Y. A review of recent studies on rotating internal cooling for gas turbine blades. Chin. J. Aeronaut. 2021, 34, 85–113. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, C.; Song, L.; Li, J. Influence of Biot number and geometric parameters on the overall cooling effectiveness of double wall structure with pins. Appl. Therm. Eng. 2021, 198. [Google Scholar] [CrossRef]

- Courtis, M.; Skamniotis, C.; Cocks, A.; Ireland, P. Coupled aerothermal-mechanical analysis in single crystal double wall transpiration cooled gas turbine blades with a large film hole density. Appl. Therm. Eng. 2023, 219. [Google Scholar] [CrossRef]

- Ahmed, A.; Wright, E.; Abdel-Aziz, F.; Yan, Y. Numerical investigation of heat transfer and flow characteristics of a double-wall cooling structure: Reverse circular jet impingement. Appl. Therm. Eng. 2021, 189. [Google Scholar] [CrossRef]

- Click, A.; Ligrani, P.; Ritchie, D.; Liberatore, F.; Patel, R.; Ho, Y.-H. Effects of coolant supply arrangement on double wall cooling: Hot-side effusion performance and cold-side Nusselt numbers at different initial blowing ratios. Int. J. Heat Mass Transf. 2020, 156. [Google Scholar] [CrossRef]

- Liu, Y.; Rao, Y.; Yang, L.; Xu, Y.; Terzis, A. Flow and heat transfer characteristics of double-wall cooling with multi-row short film cooling hole arrangements. Int. J. Therm. Sci. 2021, 165. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, H.; Li, G. Experimental Study of Heat Transfer on the Internal Surfaces of a Double-Wall Structure with Pin Fin Array. Energies 2020, 13, 6573. [Google Scholar] [CrossRef]

- Wu, Q.; Zhang, J.-Z.; Tan, X.-M. Numerical Study on Heat Transfer and Pressure Drop of an Integrated Array-Jets and Pin-Fins Cooling Configuration. J. Propuls. Technol. 2020, 41, 1120. (In Chinese) [Google Scholar]

- Qiu, D.; Luo, L.; Zhao, Z.; Wang, S.; Wang, Z.; Sundén, B. On heat transfer and flow characteristics of jets impingement on a concave surface with varying pin-fin arrangements. Int. J. Therm. Sci. 2021, 170. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Li, F.; Liu, Z.; Feng, Z.P. Effect of Film Hole Angle on Combined Impingement and Film Cooling on a Blade Leading Edge Model. J. Eng. Thermophys. 2021, 42, 130–135. [Google Scholar]

- Singh, K.; Udayraj. Combined film and impingement cooling of flat plate with reverse cooling hole. Appl. Therm. Eng. 2022, 208. [Google Scholar] [CrossRef]

- Pu, J.; Zhang, T.; Wang, J.-h. Experimental study of cooling air effect on overall cooling of laminated configuration at a turbine vane end-wall. Case Stud. Therm. Eng. 2022, 32. [Google Scholar] [CrossRef]

- Wang, J.; Deng, H.; Tao, Z.; Li, Y.; Zhu, J. Heat transfer in a rotating rectangular channel with impingement jet and film holes. Int. J. Therm. Sci. 2021, 163. [Google Scholar] [CrossRef]

- Rao, Y.; Liu, Y.; Wan, C. Multiple-jet impingement heat transfer in double-wall cooling structures with pin fins and effusion holes. Int. J. Therm. Sci. 2018, 133, 106–119. [Google Scholar] [CrossRef]

- Fan, X. Numerical research of a new vortex double wall cooling configuration for gas turbine blade leading edge. Int. J. Heat Mass Transf. 2022, 183. [Google Scholar] [CrossRef]

- Gebisa, A.W.; Lemu, H.G. Additive manufacturing for the manufacture of gas turbine engine components: Literature review and future perspectives. Turbo Expo Power Land Sea Air 2018, 6, 51128. [Google Scholar]

- Dutta, S.; Kaur, I.; Singh, P. Review of Film Cooling in Gas Turbines with an Emphasis on Additive Manufacturing-Based Design Evolutions. Energies 2022, 15, 6968. [Google Scholar] [CrossRef]

- Ma, Y.; Yan, H.; Xie, G. Flow and thermal performance of sandwich panels with plate fins or/and pyramidal lattice. Appl. Therm. Eng. 2020, 164, 114468. [Google Scholar] [CrossRef]

- Xi, L.; Xu, L.; Gao, J.; Zhao, Z.; Li, Y. Study on flow and heat transfer performance of X-type truss array cooling channel. Case Stud. Therm. Eng. 2021, 26, 101034. [Google Scholar] [CrossRef]

- Liang, D.; Bai, W.; Chen, W.; Chyu, M.K. Investigating the effect of element shape of the face-centered cubic lattice structure on the flow and endwall heat transfer characteristics in a rectangular channel. Int. J. Heat Mass Transf. 2020, 153, 119579. [Google Scholar] [CrossRef]

- Wang, X.; Wei, K.; Wang, K.; Yang, X.; Qu, Z.; Fang, D. Effective thermal conductivity and heat transfer characteristics for a series of lightweight lattice core sandwich panels. Appl. Therm. Eng. 2020, 173, 115205. [Google Scholar] [CrossRef]

- Xu, L.; Shen, Q.; Ruan, Q.; Xi, L.; Gao, J.; Li, Y. Optimization Design of Lattice Structures in Internal Cooling Channel of Turbine Blade. Appl. Sci. 2021, 11, 5838. [Google Scholar] [CrossRef]

- Xu, L.; Ruan, Q.; Shen, Q.; Xi, L.; Gao, J.; Li, Y. Optimization Design of Lattice Structures in Internal Cooling Channel with Variable Aspect Ratio of Gas Turbine Blade. Energies 2021, 14, 3954. [Google Scholar] [CrossRef]

- Yang, G.; Hou, C.; Zhao, M.; Mao, W. Comparison of convective heat transfer for Kagome and tetrahedral truss-cored lattice sandwich panels. Sci. Rep. 2019, 9. [Google Scholar] [CrossRef]

- Shen, B.; Yan, H.; Xue, H.; Xie, G. The effects of geometrical topology on fluid flow and thermal performance in Kagome cored sandwich panels. Appl. Therm. Eng. 2018, 142, 79–88. [Google Scholar] [CrossRef]

- Shen, B.; Li, Y.; Yan, H.; Boetcher, S.K.S.; Xie, G. Heat transfer enhancement of wedge-shaped channels by replacing pin fins with Kagome lattice structures. Int. J. Heat Mass Transf. 2019, 141, 88–101. [Google Scholar] [CrossRef]

- Sarwesh, P.; Zheng, M.; Li, Y.; Minking, C. Experimental and Numerical Analysis of Additively Manufactured Inconel 718 Coupons With Lattice Structure. J. Turbomach. 2020, 142. [Google Scholar] [CrossRef]

- Aghasi, P.; Gutmark, E.; Munday, D. Dependence of film cooling effectiveness on three-dimensional printed cooling holes. J. Heat Transf. 2017, 139, 102003. [Google Scholar] [CrossRef]

- Schroeder, R.P.; Thole, K.A. Effect of In-Hole Roughness on Film Cooling from a Shaped Hole. J. Turbomach. 2017, 139, 031004. [Google Scholar] [CrossRef]

- Bu, H.; Guo, Z.; Song, L.; Li, J. Effects of Cooling Configurations on the Aerothermal Performance of a Turbine Endwall With Jet Impingement and Film Cooling. J. Turbomach. 2021, 143. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, J.-z.; Wang, C.-h. Shape-optimization of round-to-slot holes for improving film cooling effectiveness on a flat surface. Heat Mass Transf. 2018, 54, 1741–1754. [Google Scholar] [CrossRef]

- Hoang, V.-N.; Tran, P.; Vu, V.-T.; Nguyen-Xuan, H. Design of lattice structures with direct multiscale topology optimization. Compos. Struct. 2020, 252, 112718. [Google Scholar] [CrossRef]

- Zhang, J.; Yanagimoto, J. Topology optimization of microlattice dome with enhanced stiffness and energy absorption for additive manufacturing. Compos. Struct. 2021, 255. [Google Scholar] [CrossRef]

- Yeranee, K.; Rao, Y.; Yang, L.; Li, H. Enhanced thermal performance of a pin-fin cooling channel for gas turbine blade by density-based topology optimization. Int. J. Therm. Sci. 2022, 181. [Google Scholar] [CrossRef]

- Zhuang, L.; Xu, G.; Wen, J.; Dong, B.; Xiao, Y. Superiority analysis of CCA technology under typical flight mission. J. Aerosp. Power 2022, 37, 1363–1378. (In Chinese) [Google Scholar]

- Barreto, D.; Fajardo, J.; Caballero, G.C.; Escorcia, Y.C. Advanced Exergy and Exergoeconomic Analysis of a Gas Power System with Steam Injection and Air Cooling with a Compression Refrigeration Machine. Energy Technol. 2021, 9, 2000993. [Google Scholar] [CrossRef]

- Gong, J.; Ma, C.; Lu, J.; Gao, T. Effect of rib orientation on heat transfer and flow characteristics of mist/steam in square channels. Int. Commun. Heat Mass Transf. 2020, 118. [Google Scholar] [CrossRef]

- Alhajeri, H.M.; Almutairi, A.; Alenezi, A.; Gamil, A.A.A.; Al-Hajeri, M.H. Effect of mist/steam uniformity on heat transfer characteristics in unconfined jet impingement. Appl. Therm. Eng. 2021, 186. [Google Scholar] [CrossRef]

- Zhang, R.; Luo, C.; Zhou, L.; Li, L.; Zhang, H.; Du, X. Impingement/film cooling of C3X vane with double-wall cooling structure using air/mist mixture. Int. J. Heat Mass Transf. 2022, 188. [Google Scholar] [CrossRef]

- Jiang, G.; Gao, J.; Shi, X. Flow and heat transfer characteristics of mist/steam two-phase flow in the U-shaped cooling passage with 60 deg. Ribs. Int. Commun. Heat Mass Transf. 2019, 105, 73–83. [Google Scholar] [CrossRef]

- Jiang, G.; Gao, J.; Shi, X.; Li, F.; Xu, L. Flow and heat transfer characteristics of the mist/steam two-phase flow cooling the rectangular channel with column-row-ribs. Int. J. Heat Mass Transf. 2020, 156, 119737. [Google Scholar] [CrossRef]

- Zhang, R.; Song, Y.; Han, S.; Zhou, L.; Li, L.; Zhang, H.; Du, X. Film cooling performance enhancement of serrate-type trenched cooling holes by injecting mist into the cooling air. Int. J. Therm. Sci. 2022, 179. [Google Scholar] [CrossRef]

- Chen, Z.-Z.; Chen, H.-Q.; Huang, L.; Zhang, Y.-H.; Hao, N.-J. Research progress on silica nanofluids for convective heat transfer enhancement. Chin. J. Eng. 2022, 44, 812–825. (In Chinese) [Google Scholar]

- Xi, L.; Xu, L.; Gao, J.; Zhao, Z.; Li, Y. Numerical analysis and optimization on flow and heat transfer performance of a steam-cooled ribbed channel. Case Stud. Therm. Eng. 2021, 28, 101442. [Google Scholar] [CrossRef]

- Xi, L.; Gao, J.; Xu, L.; Zhao, Z.; Li, Y. Study on heat transfer performance of steam-cooled ribbed channel using neural networks and genetic algorithms. Int. J. Heat Mass Transf. 2018, 127, 1110–1123. [Google Scholar] [CrossRef]

- Zou, L.; Wang, F.; Yan, D.; Gu, M.; Li, M.; Li, M.; Liu, M.; Wang, W. Synergy investigations for the thermal transportation performance of a coaxial gravity heat pipe with internally finned in evaporator section. Int. J. Heat Mass Transf. 2022, 184. [Google Scholar] [CrossRef]

- Taamneh, Y. Thermal analysis of gas turbine disk integrated with rotating heat pipes. Case Stud. Therm. Eng. 2017, 10, 335–342. [Google Scholar] [CrossRef]

- Chen, J.; Fu, Y.; Qian, N.; Ching, C.Y.; Ewing, D.; He, Q. A study on thermal performance of revolving heat pipe grinding wheel. Appl. Therm. Eng. 2021, 182. [Google Scholar] [CrossRef]

- Wang, H.; Tang, Y.; Liu, M.; Zhu, S.; Zheng, K.; Du, X. Experimental study on heat transfer performance of axially rotating heat pipe in steady state. Int. J. Therm. Sci. 2023, 184. [Google Scholar] [CrossRef]

- Wang, X.; Shi, Y.; Liu, T.; Wang, S.; Wang, K.; Chen, H.; Wang, Y.; Zhu, Y. CFD modeling of liquid-metal heat pipe and hydrogen inactivation simulation. Int. J. Heat Mass Transf. 2022, 199. [Google Scholar] [CrossRef]

- Yilgor, I.; Shi, S. Scaling laws for two-phase flow and heat transfer in high-temperature heat pipes. Int. J. Heat Mass Transf. 2022, 189. [Google Scholar] [CrossRef]

- Pu, J.; Zhang, T.; Huang, X.; Wang, J.; Wu, W. Overall Thermal Performances of Double-Wall Effusion Cooling Covered by Simulated Thermal Barrier Coatings. J. Therm. Sci. 2022, 31, 224–238. [Google Scholar] [CrossRef]

- Guangwu, F.; Jie, S.; Xiguang, G.; Yingdong, S. Micromechanical finite element analysis of effect of multilayer interphase on crack propagation in SiC/SiC composites. Model. Simul. Mater. Sci. Eng. 2021, 29, 1–21. [Google Scholar] [CrossRef]

- Zhou, Y.C.; Yang, L.; Liu, Z.Y.; Zhu, W. Research Progress on Insulation Performance of Thermal Barrier Coatings on Turbine Blade. Mater. China 2020, 10, 707. (In Chinese) [Google Scholar]

- Zhao, L.S.; Zhong, S.M.; Wang, X.Y. Development of the Latest H class Heavy-Duty Gas Turbine. Gas Turbine Technol. 2017, 30. (In Chinese) [Google Scholar]

- Zontul, H.; Hamzah, H.; Kurtulmuş, N.; Şahin, B. Investigation of convective heat transfer and flow hydrodynamics in rectangular grooved channels. Int. Commun. Heat Mass Transf. 2021, 126, 105366. [Google Scholar] [CrossRef]

- Soliman, A.S.; Xu, L.; Dong, J.; Cheng, P. A novel heat sink for cooling photovoltaic systems using convex/concave dimples and multiple PCMs. Appl. Therm. Eng. 2022, 215, 118644. [Google Scholar] [CrossRef]

- Jing, Q.; Zhang, D.; Xie, Y. Numerical investigations of impingement cooling performance on flat and non-flat targets with dimple/protrusion and triangular rib. Int. J. Heat Mass Transf. 2018, 126, 169–190. [Google Scholar] [CrossRef]

- Jeong, M.; Ha, M.Y.; Park, Y.G. Numerical investigation of heat transfer enhancement in a dimpled cooling channel with different angles of the vortex generator. Int. J. Heat Mass Transf. 2019, 144. [Google Scholar] [CrossRef]

- Yang, J.S.; Jeong, M.; Park, Y.G.; Ha, M.Y. Numerical study on the flow and heat transfer characteristics in a dimple cooling channel with a wedge-shaped vortex generator. Int. J. Heat Mass Transf. 2019, 136, 1064–1078. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).