Axisymmetric Flow and Heat Transfer in

Abstract

1. Introduction

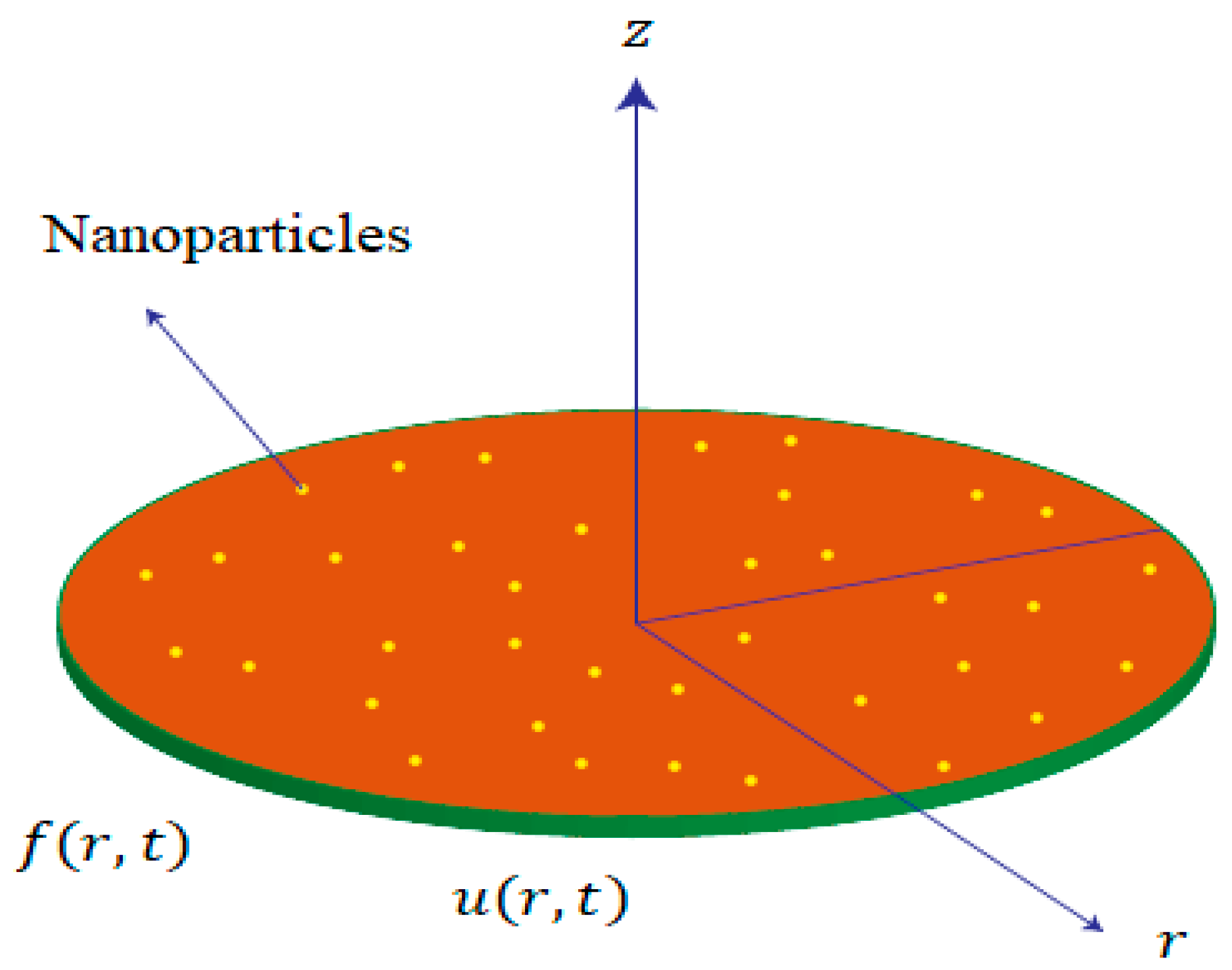

2. Mathematical Description of the Problem

3. Numerical Scheme for Solution

4. Results and Discussion

5. Key Findings of Performed

- Dimensionless velocity shows a decreasing nature for the unsteadiness parameter and velocity slip parameter while, the reverse behavior for volume fraction

- Augmenting values of velocity slip and unsteadiness parameters retards the velocity field;

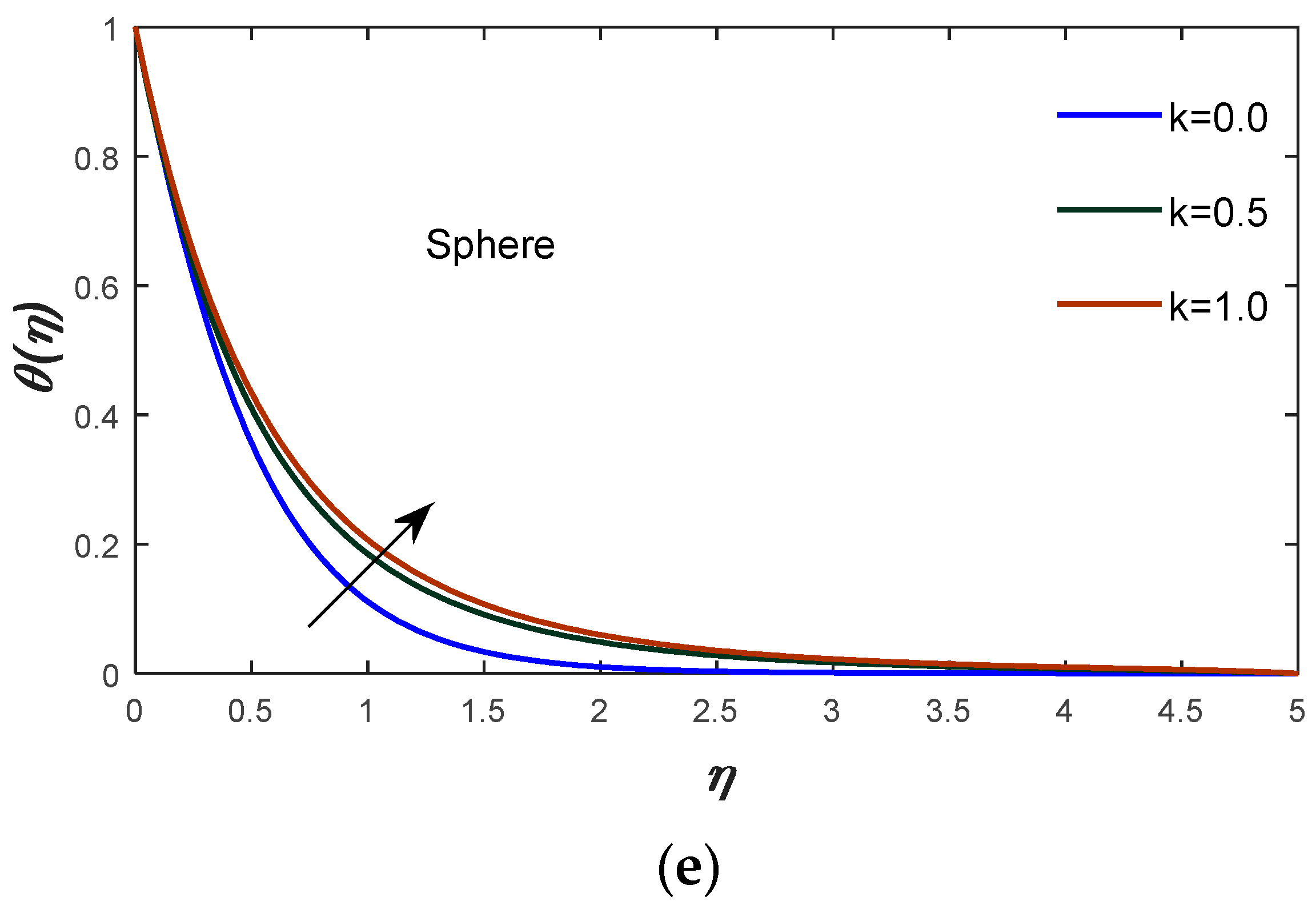

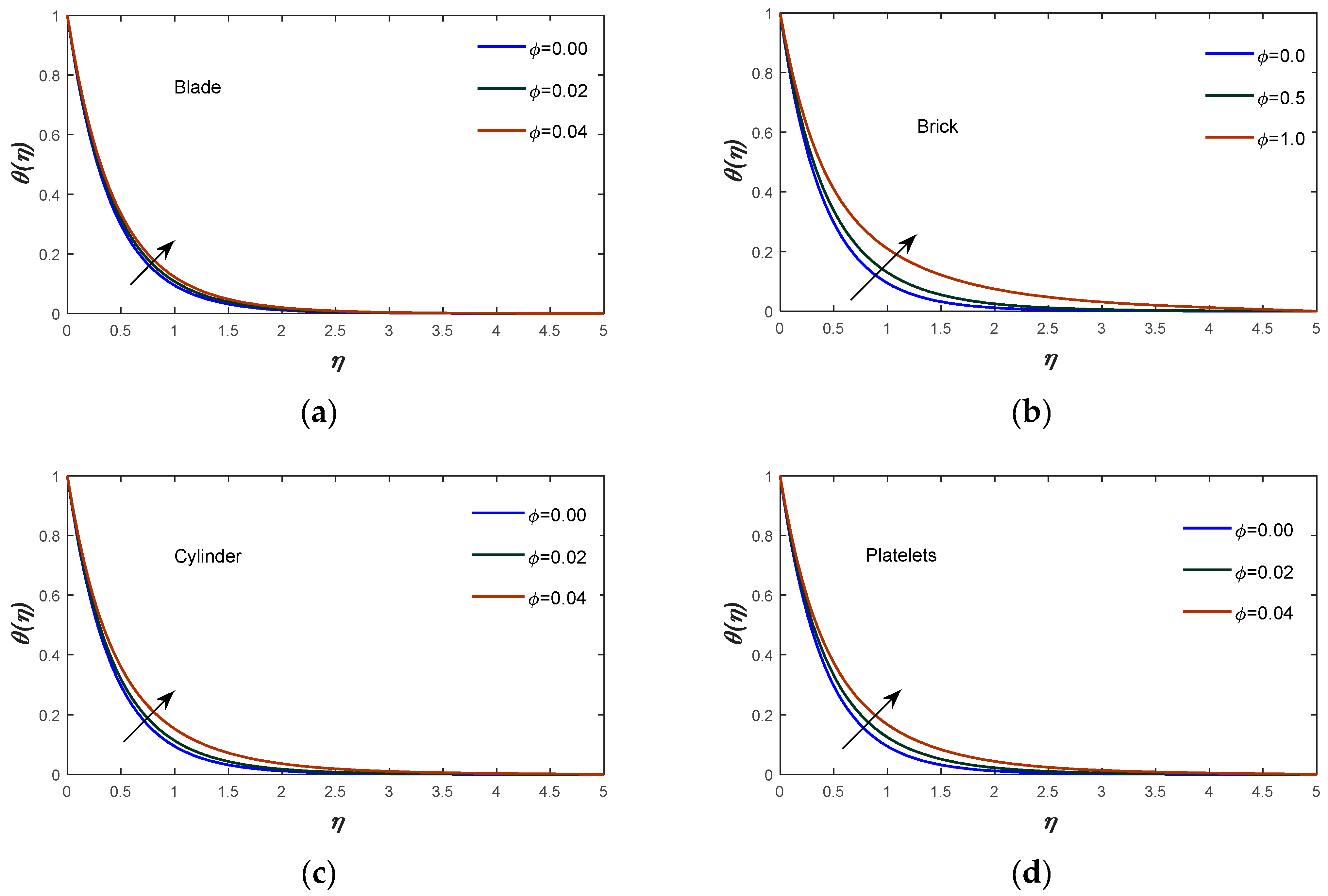

- Higher estimation of the volume fraction boosts the fluid’s temperature;

- For a rise in the volume fraction parameter causes the enhancement in temperature profile on the other hand the reverse behavior is observed in case of increasing the unsteadiness parameter and velocity slip parameter

- Higher values of the Prandtl number results to decrease the temperature field and connected layer thickness;

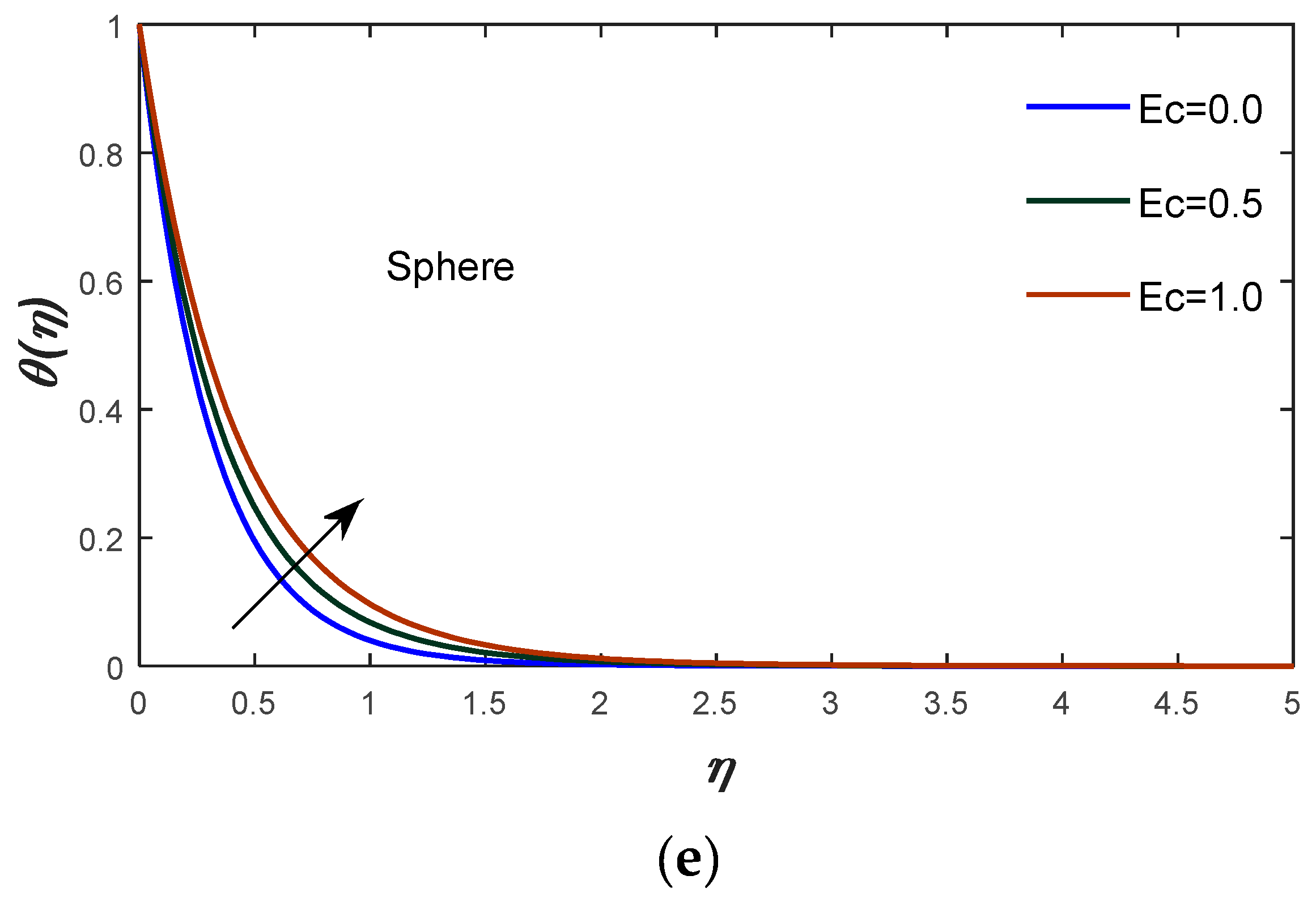

- The increasing effect of the Eckert number on the temperature field is observed;

- It is concluded from the obtained results that the impact of the Eckert number and Prandtl number is opposite in nature;

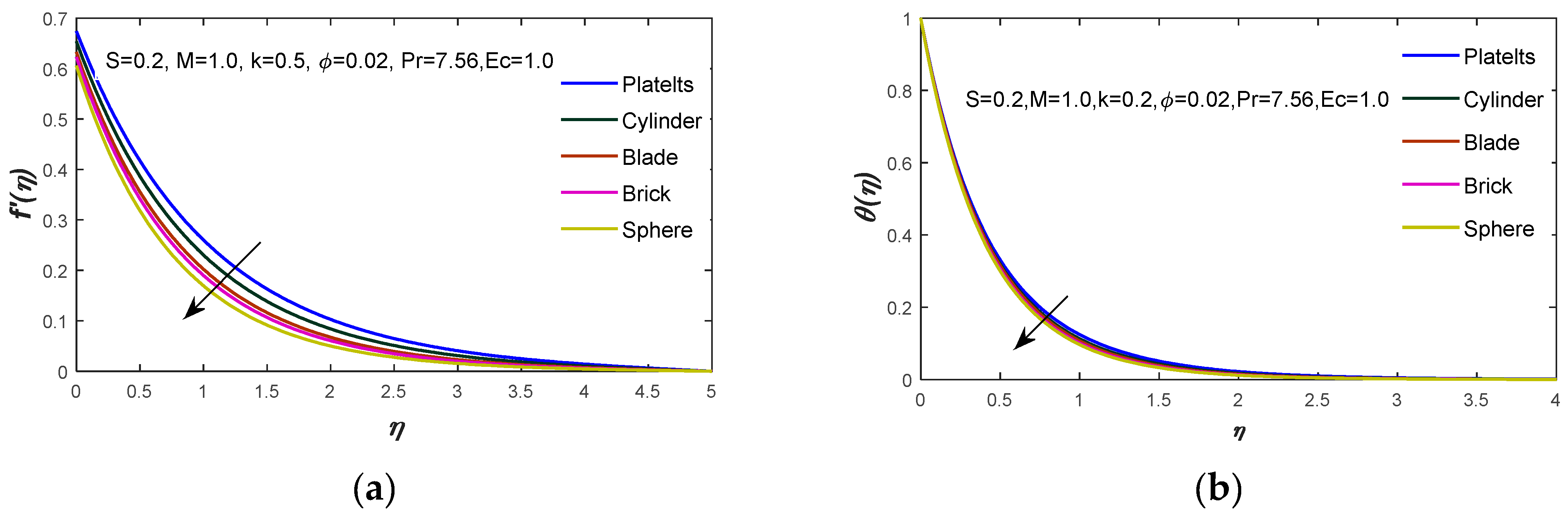

- On the platelet and sphere-shaped nanoparticles, the velocity profile of nanofluid reaches its maximum and minimum, respectively, while thermal conductivity follows a similar pattern.

- Maximum surface force is developed against higher values of the magnetic number, while the minimum production of surface force is generated with respect to higher values of the unsteadiness parameter;

- A significant performance of nanoparticles is observed for enhancement of thermal conductivity and production of heat energy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Unsteadiness parameter | |

| Slip parameter | |

| Solid volume fraction of nanofluid | |

| Magnetic parameter | |

| Prandtl number | |

| Eckert number | |

| Similarity Variable | |

| Reynolds number | |

| Stream function | |

| Velocity components | |

| Density of base fluid | |

| Dynamic viscosity | |

| Electrical conductivity | |

| Local skin friction coefficient | |

| Thermal conductivity | |

| Skin friction coefficient | |

| Density of nanoparticles | |

| Nanoparticle’s electrical conductivity | |

| Nanoparticle’s dynamic viscosity | |

| Nanoparticle’s thermal conductivity | |

| Nanoparticle’s heat capacitance | |

| Nano fluid’s Viscosity | |

| Nano fluid’s Density | |

| Nano fluid’s Thermal conductivity | |

| Nano fluid’s heat capacitance | |

| Constants | |

| Local Nusselt number |

References

- Maxwell, J.C. A Treatise on Electricity and Magnetism; Clarendon Press: Oxford, UK, 1873; Volume 1. [Google Scholar]

- Hamilton, R.L.; Crosser, O.K. Thermal conductivity of heterogeneous two-component systems. Ind. Eng. Chem. Fundam. 1962, 1, 187–191. [Google Scholar] [CrossRef]

- Choi, S.U.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles (No. ANL/MSD/CP-84938; CONF-951135-29); Argonne National Lab.: Lemont, IL, USA, 1995.

- Ghasemi, S.E.; Vatani, M.; Hatami, M.; Ganji, D.D. Analytical and numerical investigation of nanoparticle effect on peristaltic fluid flow in drug delivery systems. J. Mol. Liq. 2016, 215, 88–97. [Google Scholar] [CrossRef]

- Abbas, M.A.; Bai, Y.Q.; Rashidi, M.M.; Bhatti, M.M. Application of drug delivery in magnetohydrodynamics peristaltic blood flow of nanofluid in a non-uniform channel. J. Mech. Med. Biol. 2016, 16, 1650052. [Google Scholar] [CrossRef]

- Leong, K.Y.; Saidur, R.; Kazi, S.N.; Mamun, A.H. Performance investigation of an automotive car radiator operated with nanofluid-based coolants (nanofluid as a coolant in a radiator). Appl. Therm. Eng. 2010, 30, 2685–2692. [Google Scholar] [CrossRef]

- Kakavand, H.; Molana, M. A numerical study of heat transfer characteristics of a car radiator involved nanofluids. Heat Transf. —Asian Res. 2018, 47, 88–102. [Google Scholar] [CrossRef]

- Molana, M. On the nanofluids application in the automotive radiator to reach the enhanced thermal performance: A review. Am. J. Heat Mass Transf. 2017, 4, 168–187. [Google Scholar] [CrossRef]

- Kumar, V.; Pandya, N.; Pandya, B.; Joshi, A. Synthesis of metal-based nanofluids and their thermo-hydraulic performance in compact heat exchanger with multi-louvered fins working under laminar conditions. J. Therm. Anal. Calorim. 2019, 135, 2221–2235. [Google Scholar] [CrossRef]

- Nithyadevi, N.; Gayathri, P.; Chamkha, A. Three dimensional MHD stagnation point flow of Al-Cu alloy suspended water based nanofluid with second order slip and convective heating. Int. J. Numer. Methods Heat Fluid Flow 2017, 27, 2879–2901. [Google Scholar] [CrossRef]

- Molana, M. A comprehensive review on the nanofluids application in the tubular heat exchangers. Am. J. Heat Mass Transf. 2016, 3, 352–381. [Google Scholar] [CrossRef]

- Alsabery, A.I.; Chamkha, A.J.; Saleh, H.; Hashim, I.; Chanane, B. Effects of finite wall thickness and sinusoidal heating on convection in nanofluid-saturated local thermal non-equilibrium porous cavity. Phys. A Stat. Mech. Its Appl. 2017, 470, 20–38. [Google Scholar] [CrossRef]

- Izadi, S.; Armaghani, T.; Ghasemiasl, R.; Chamkha, A.J.; Molana, M. A comprehensive review on mixed convection of nanofluids in various shapes of enclosures. Powder Technol. 2019, 343, 880–907. [Google Scholar] [CrossRef]

- Buongiorno, J.; Hu, L.W.; Kim, S.J.; Hannink, R.; Truong, B.; Forrest, E. Nanofluids for enhanced economics and safety of nuclear reactors: An evaluation of the potential features, issues, and research gaps. Nucl. Technol. 2008, 162, 80–91. [Google Scholar] [CrossRef]

- Li, Z.; Sheikholeslami, M.; Jafaryar, M.; Shafee, A.; Chamkha, A.J. Investigation of nanofluid entropy generation in a heat exchanger with helical twisted tapes. J. Mol. Liq. 2018, 266, 797–805. [Google Scholar] [CrossRef]

- Sakhri, N.; Menni, Y.; Chamkha, A.J.; Lorenzini, E.; Kaid, N.; Ameur, H.; Bensafi, M. Study of heat and mass transfer through an earth to air heat exchanger equipped with fan in South West of Algeria. Int. J. Heat Technol. 2019, 37, 689–695. [Google Scholar] [CrossRef]

- Chamkha, A.J. Unsteady laminar hydromagnetic flow and heat transfer in porous channels with temperature-dependent properties. Int. J. Numer. Methods Heat Fluid Flow 2001, 11, 430–448. [Google Scholar] [CrossRef]

- Chamkha, A.J. Flow of two-immiscible fluids in porous and nonporous channels. J. Fluids Eng. 2000, 122, 117–124. [Google Scholar] [CrossRef]

- Chamkha, A.J. Non-Darcy fully developed mixed convection in a porous medium channel with heat generation/absorption and hydromagnetic effects. Numer. Heat Transf. Part A Appl. 1997, 32, 653–675. [Google Scholar] [CrossRef]

- Umavathi, J.C.; Chamkha, A.J.; Mateen, A.; Al-Mudhaf, A. Unsteady oscillatory flow and heat transfer in a horizontal composite porous medium channel. Nonlinear Anal. Model. Control 2009, 14, 397–415. [Google Scholar] [CrossRef]

- Sohail, M.; Naz, R. Modified heat and mass transmission models in the magnetohydrodynamic flow of Sutterby nanofluid in stretching cylinder. Phys. A Stat. Mech. Its Appl. 2020, 5549, 124088. [Google Scholar] [CrossRef]

- Naz, R.; Tariq, S.; Sohail, M.; Shah, Z. Investigation of entropy generation in stratified MHD Carreau nanofluid with gyrotactic microorganisms under Von Neumann similarity transformations. Eur. Phys. J. Plus 2020, 135, 178. [Google Scholar] [CrossRef]

- Khan, M.I.; Hayat, T.; Alsaedi, A.; Qayyum, S.; Tamoor, M. Entropy optimization and quartic autocatalysis in MHD chemically reactive stagnation point flow of Sisko nanomaterial. Int. J. Heat Mass Transf. 2018, 127, 829–837. [Google Scholar] [CrossRef]

- Ghadikolaei, S.S.; Hosseinzadeh, K.; Hatami, M.; Ganji, D.D. MHD boundary layer analysis for micropolar dusty fluid containing Hybrid nanoparticles (Cu-Al2O3) over a porous medium. J. Mol. Liq. 2018, 268, 813–823. [Google Scholar] [CrossRef]

- Nadeem, S.; Hussain, S.T. Analysis of MHD Williamson Nano Fluid Flow over a Heated Surface. J. Appl. Fluid Mech. 2016, 9, 729–739. [Google Scholar] [CrossRef]

- Khanafer, K.; Vafai, K.; Lightstone, M. Buoyancy-driven heat transfer enhancement in a two-dimensional enclosure utilizing nanofluids. Int. J. Heat Mass Transf. 2003, 46, 3639–3653. [Google Scholar] [CrossRef]

- Oztop, H.F.; Abu-Nada, E. Numerical study of natural convection in partially heated rectangular enclosures filled with nanofluids. Int. J. Heat Fluid Flow 2008, 29, 1326–1336. [Google Scholar] [CrossRef]

- Hamad, M.A.A. Analytical solution of natural convection flow of a nanofluid over a linearly stretching sheet in the presence of magnetic field. Int. Commun. Heat Mass Transf. 2011, 38, 487–492. [Google Scholar] [CrossRef]

- Heris, S.Z.; Etemad, S.G.; Esfahany, M.N. Experimental investigation of oxide nanofluids laminar flow convective heat transfer. Int. Commun. Heat Mass Transf. 2006, 33, 529–535. [Google Scholar] [CrossRef]

- Shah, Z.; Dawar, A.; Kumam, P.; Khan, W.; Islam, S. Impact of nonlinear thermal radiation on MHD nanofluid thin film flow over a horizontally rotating disk. Appl. Sci. 2019, 9, 1533. [Google Scholar] [CrossRef]

- Wang, C.Y. Flow due to a stretching boundary with partial slip—an exact solution of the Navier–Stokes equations. Chem. Eng. Sci. 2002, 57, 3745–3747. [Google Scholar] [CrossRef]

- Andersson, H.I. Slip flow past a stretching surface. Acta Mech. 2002, 158, 121–125. [Google Scholar] [CrossRef]

- Ariel, P.D.; Hayat, T.; Asghar, S. The flow of an elastico-viscous fluid past a stretching sheet with partial slip. Acta Mech. 2006, 187, 29–35. [Google Scholar] [CrossRef]

- Ariel, P.D. Two dimensional stagnation point flow of an elastico-viscous fluid with partial slip. ZAMM-J. Appl. Math. Mech./Z. Angew. Math. Mech. Appl. Math. Mech. 2008, 88, 320–324. [Google Scholar] [CrossRef]

- Yang, F. Slip boundary condition for viscous flow over solid surfaces. Chem. Eng. Commun. 2009, 197, 544–550. [Google Scholar] [CrossRef]

- Abbas, Z.; Wang, Y.; Hayat, T.; Oberlack, M. Slip effects and heat transfer analysis in a viscous fluid over an oscillatory stretching surface. Int. J. Numer. Methods Fluids 2009, 59, 443–458. [Google Scholar] [CrossRef]

- Mukhopadhyay, S. Analysis of boundary layer flow over a porous nonlinearly stretching sheet with partial slip at the boundary. Alex. Eng. J. 2013, 52, 563–569. [Google Scholar] [CrossRef]

- Noghrehabadi, A.; Pourrajab, R.; Ghalambaz, M. Effect of partial slip boundary condition on the flow and heat transfer of nanofluids past stretching sheet prescribed constant wall temperature. Int. J. Therm. Sci. 2012, 54, 253–261. [Google Scholar] [CrossRef]

- Raisi, A.; Ghasemi, B.; Aminossadati, S.M. A numerical study on the forced convection of laminar nanofluid in a microchannel with both slip and no-slip conditions. Numer. Heat Transf. Part A Appl. 2011, 59, 114–129. [Google Scholar] [CrossRef]

- Kho, Y.B.; Hussanan, A.; Mohamed, M.K.A.; Salleh, M.Z. Heat and mass transfer analysis on flow of Williamson nanofluid with thermal and velocity slips: Buongiorno model. Propuls. Power Res. 2019, 8, 243–252. [Google Scholar] [CrossRef]

- Prasad, P.D.; Kumar, R.K.; Varma, S.V.K. Heat and mass transfer analysis for the MHD flow of nanofluid with radiation absorption. Ain Shams Eng. J. 2018, 9, 801–813. [Google Scholar] [CrossRef]

- Zangooee, M.R.; Hosseinzadeh, K.; Ganji, D.D. Hydrothermal analysis of MHD nanofluid (TiO2-GO) flow between two radiative stretchable rotating disks using AGM. Case Stud. Therm. Eng. 2019, 14, 100460. [Google Scholar] [CrossRef]

- Islam, M.R.; Shabani, B.; Rosengarten, G. Electrical and thermal conductivities of 50/50 water-ethylene glycol based TiO2 nanofluids to be used as coolants in PEM fuel cells. Energy Procedia 2017, 110, 101–108. [Google Scholar] [CrossRef]

- Bobbo, S.; Fedele, L.; Benetti, A.; Colla, L.; Fabrizio, M.; Pagura, C.; Barison, S. Viscosity of water based SWCNH and TiO2 nanofluids. Exp. Therm. Fluid Sci. 2012, 36, 65–71. [Google Scholar] [CrossRef]

- Fedele, L.; Colla, L.; Bobbo, S. Viscosity and thermal conductivity measurements of water-based nanofluids containing titanium oxide nanoparticles. Int. J. Refrig. 2012, 35, 1359–1366. [Google Scholar] [CrossRef]

- Fakour, M.; Rahbari, A.; Khodabandeh, E.; Ganji, D.D. Nanofluid thin film flow and heat transfer over an unsteady stretching elastic sheet by LSM. J. Mech. Sci. Technol. 2018, 32, 177–183. [Google Scholar] [CrossRef]

- Shahzad, A.; Gulistan, U.; Ali, R.; Iqbal, A.; Benim, A.C.; Kamran, M.; Khan, S.U.D.; Khan, S.U.D.; Farooq, A. Numerical Study of Axisymmetric Flow and Heat Transfer in a Liquid Film over an Unsteady Radially Stretching Surface. Math. Probl. Eng. 2020, 2020, 6737243. [Google Scholar] [CrossRef]

- Ahmed, J.; Shahzad, A.; Farooq, A.; Kamran, M.; Khan, S.U.D.; Khan, S.U.D. Radiative heat transfer in Homann stagnation-point flow of hybrid nanofluid. Appl. Nanosci. 2020, 10, 5305–5314. [Google Scholar] [CrossRef]

- Bibi, S.; Elahi, Z.; Shahzad, A. Impacts of different shapes of nanoparticles on SiO2 nanofluid flow and heat transfer in a liquid film over a stretching sheet. Phys. Scr. 2020, 95, 115217. [Google Scholar] [CrossRef]

- Sikdar, S.; Basu, S.; Ganguly, S. Investigation of electrical conductivity of titanium dioxide nanofluids. Int. J. Nanopart. 2011, 4, 336–349. [Google Scholar] [CrossRef]

- Pushpa, B.V.; Sankar, M.; Mebarek-Oudina, F. Buoyant Convective Flow and Heat Dissipation of Cu–H2O Nanoliquids in an Annulus through a Thin Baffle. J. Nanofluids 2021, 10, 292–304. [Google Scholar] [CrossRef]

- Marzougui, S.; Mebarek-Oudina, F.; Magherbi, M.; Mchirgui, A. Entropy generation and heat transport of Cu–water nanoliquid in porous lid-driven cavity through magnetic field. Int. J. Numer. Methods Heat Fluid Flow 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Shafiq, A.; Mebarek-Oudina, F.; Sindhu, T.N.; Abidi, A. A study of dual stratification on stagnation point Walters’ B nanofluid flow via radiative Riga plate: A statistical approach. Eur. Phys. J. Plus 2021, 136, 407. [Google Scholar] [CrossRef]

- Swain, K.; Mebarek-Oudina, F.; Abo-Dahab, S.M. Influence of MWCNT/Fe3O4 hybrid nanoparticles on an exponentially porous shrinking sheet with chemical reaction and slip boundary conditions. J. Therm. Anal. Calorim. 2021, 1–10. [Google Scholar] [CrossRef]

- Mebarek-Oudina, F.; Fares, R.; Aissa, A.; Lewis, R.W.; Abu-Hamdeh, N.H. Entropy and convection effect on magnetized hybrid nano-liquid flow inside a trapezoidal cavity with zigzagged wall. Int. Commun. Heat Mass Transf. 2021, 125, 105279. [Google Scholar] [CrossRef]

- Mebarek-Oudina, F.; Reddy, N.K.; Sankar, M. Heat source location effects on buoyant convection of nanofluids in an annulus. In Advances in Fluid Dynamics; Springer: Singapore, 2021; pp. 923–937. [Google Scholar]

- Sohail, M.; Nazir, U.; Bazighifan, O.; El-Nabulsi, R.A.; Selim, M.M.; Alrabaiah, H.; Thounthong, P. Significant Involvement of Double Diffusion Theories on Viscoelastic Fluid Comprising Variable Thermophysical Properties. Micromachines 2021, 12, 951. [Google Scholar] [CrossRef] [PubMed]

- Nazir, U.; Sohail, M.; Hafeez, M.B.; Krawczuk, M. Significant Production of Thermal Energy in Partially Ionized Hyperbolic Tangent Material Based on Ternary Hybrid Nanomaterials. Energies 2021, 14, 6911. [Google Scholar] [CrossRef]

- Nazir, U.; Sohail, M.; Selim, M.M.; Alrabaiah, H.; Kumam, P. Finite element simulations of hybrid nano-Carreau Yasuda fluid with hall and ion slip forces over rotating heated porous cone. Sci. Rep. 2021, 11, 19604. [Google Scholar] [CrossRef] [PubMed]

- Vanaki, S.M.; Mohammed, H.A.; Abdollahi, A.; Wahid, M.A. Effect of nanoparticle shapes on the heat transfer enhancement in a wavy channel with different phase shifts. J. Mol. Liq. 2014, 196, 32–42. [Google Scholar] [CrossRef]

| Nanoparticle/Based Fluid | ||||

|---|---|---|---|---|

| Nanoparticle Shapes | Blade | Brick | Cylinder | Platelets | Sphere |

|---|---|---|---|---|---|

| Reference [47] | Present | ||||

|---|---|---|---|---|---|

| 0 | 1.0 | 0.7 | 0.2 | 1.2784767 | 1.1353469 |

| 1 | - | - | - | 1.6237276 | 1.5146317 |

| 2 | - | - | - | 1.9067150 | 1.8155125 |

| 1 | 0.8 | 0.7 | 0.2 | 1.674472 | 1.6107074 |

| - | 1.0 | - | - | 1.6650959 | 1.6571311 |

| - | 1.2 | - | - | 1.6186823 | 1.7025145 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naseem, T.; Shahzad, A.; Sohail, M.; Askar, S.

Axisymmetric Flow and Heat Transfer in

Naseem T, Shahzad A, Sohail M, Askar S.

Axisymmetric Flow and Heat Transfer in

Naseem, Tahir, Azeem Shahzad, Muhammad Sohail, and Sameh Askar.

2023. "Axisymmetric Flow and Heat Transfer in

Naseem, T., Shahzad, A., Sohail, M., & Askar, S.

(2023). Axisymmetric Flow and Heat Transfer in