Micro Gas Turbine Role in Distributed Generation with Renewable Energy Sources

Abstract

1. Introduction

2. Alternative Fuels in Micro Gas Turbines

2.1. Syngas

2.2. Hydrogen

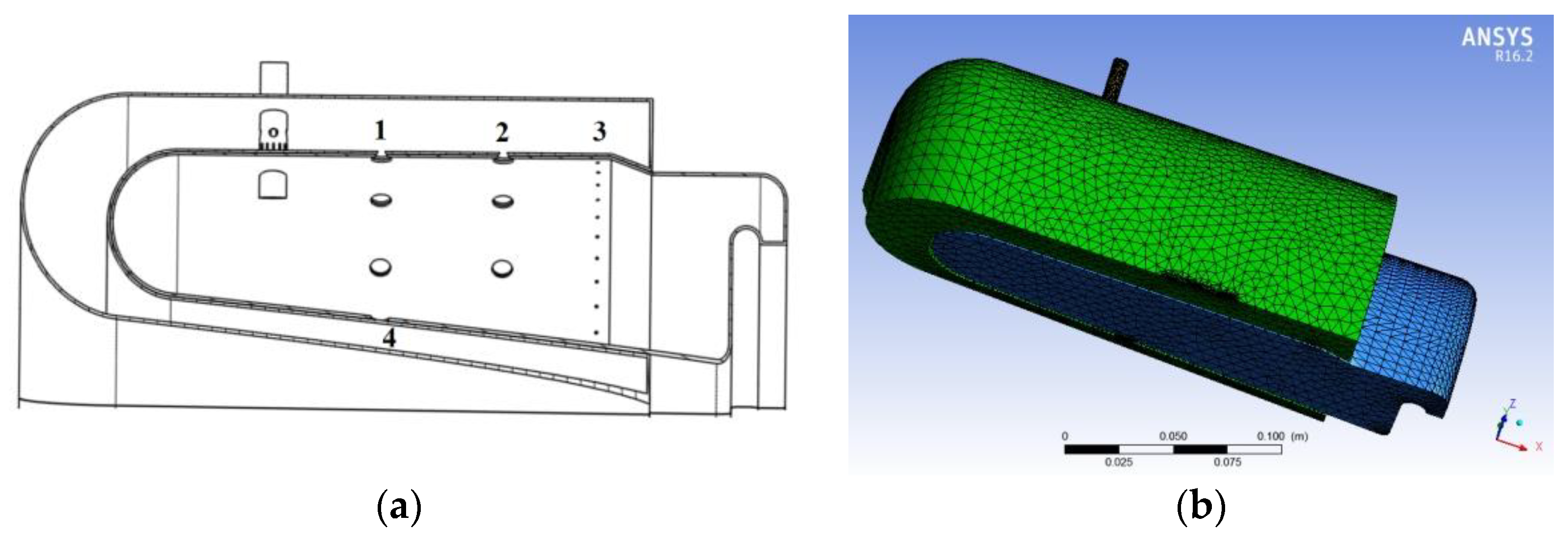

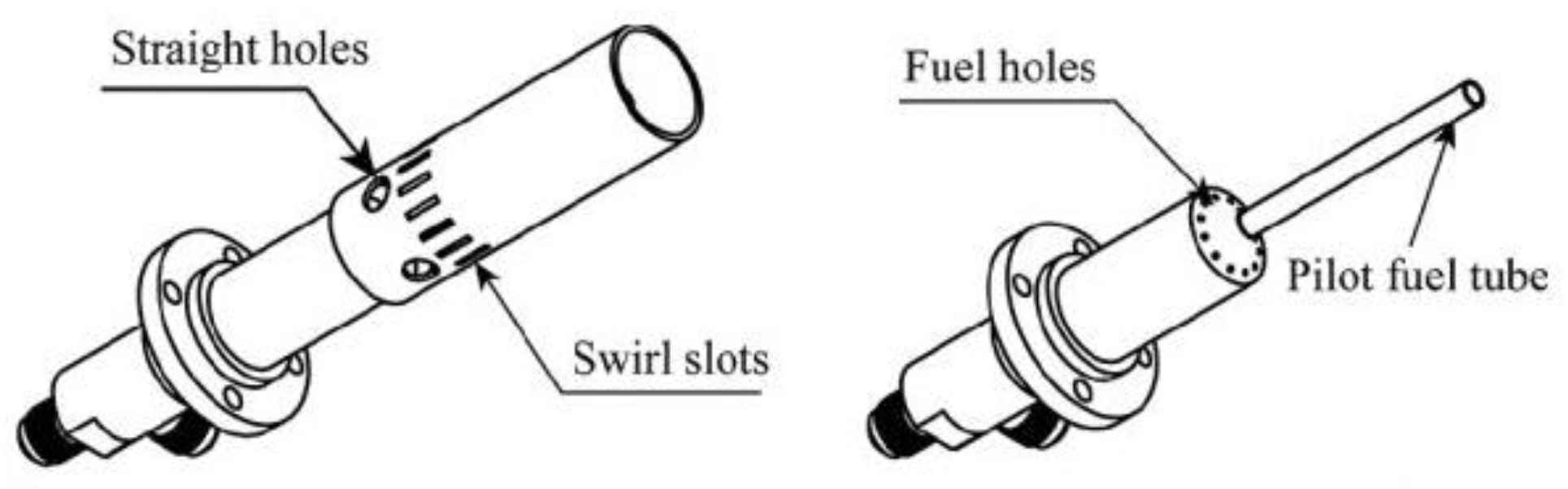

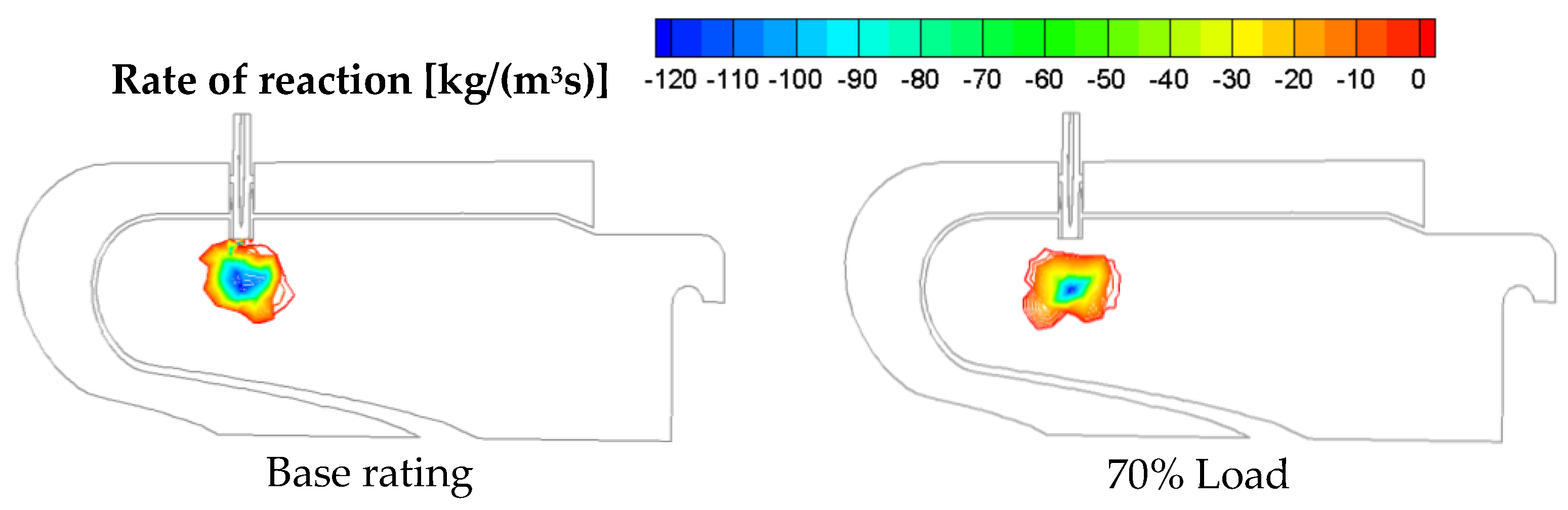

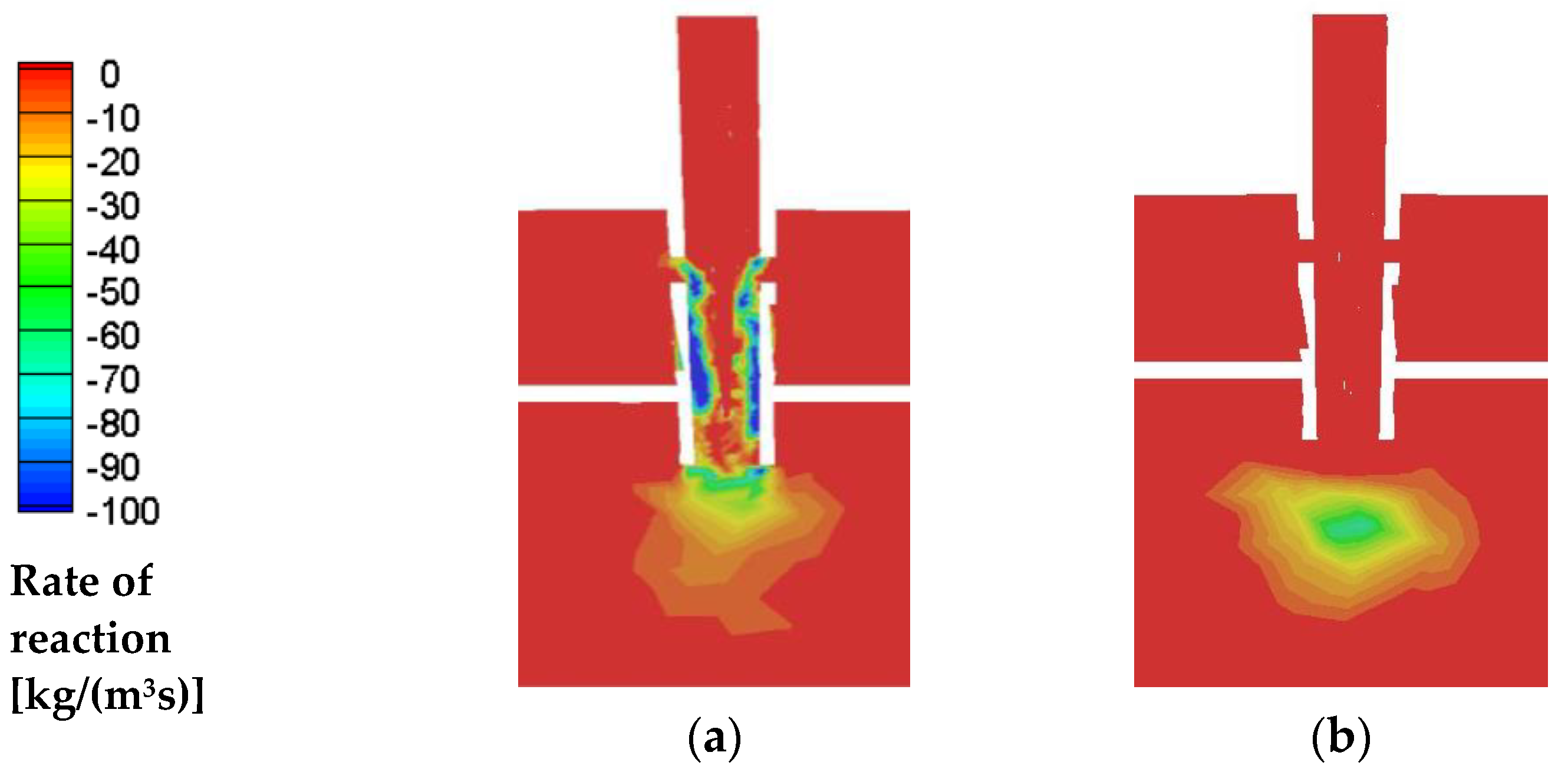

2.3. Liquid Biofuels

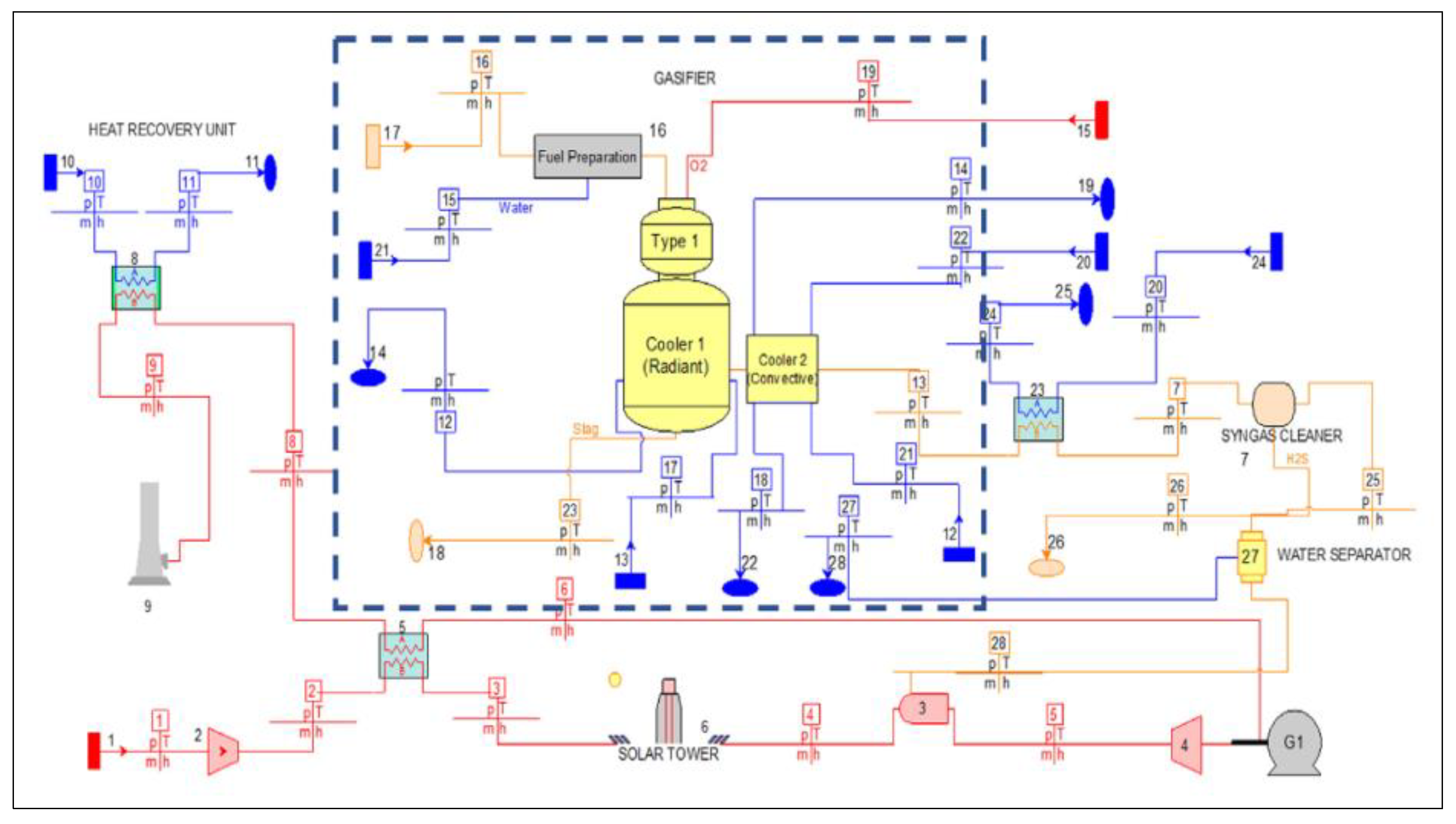

2.4. Gasification

2.5. Ammonia

2.6. Externally Fired Gas Turbines

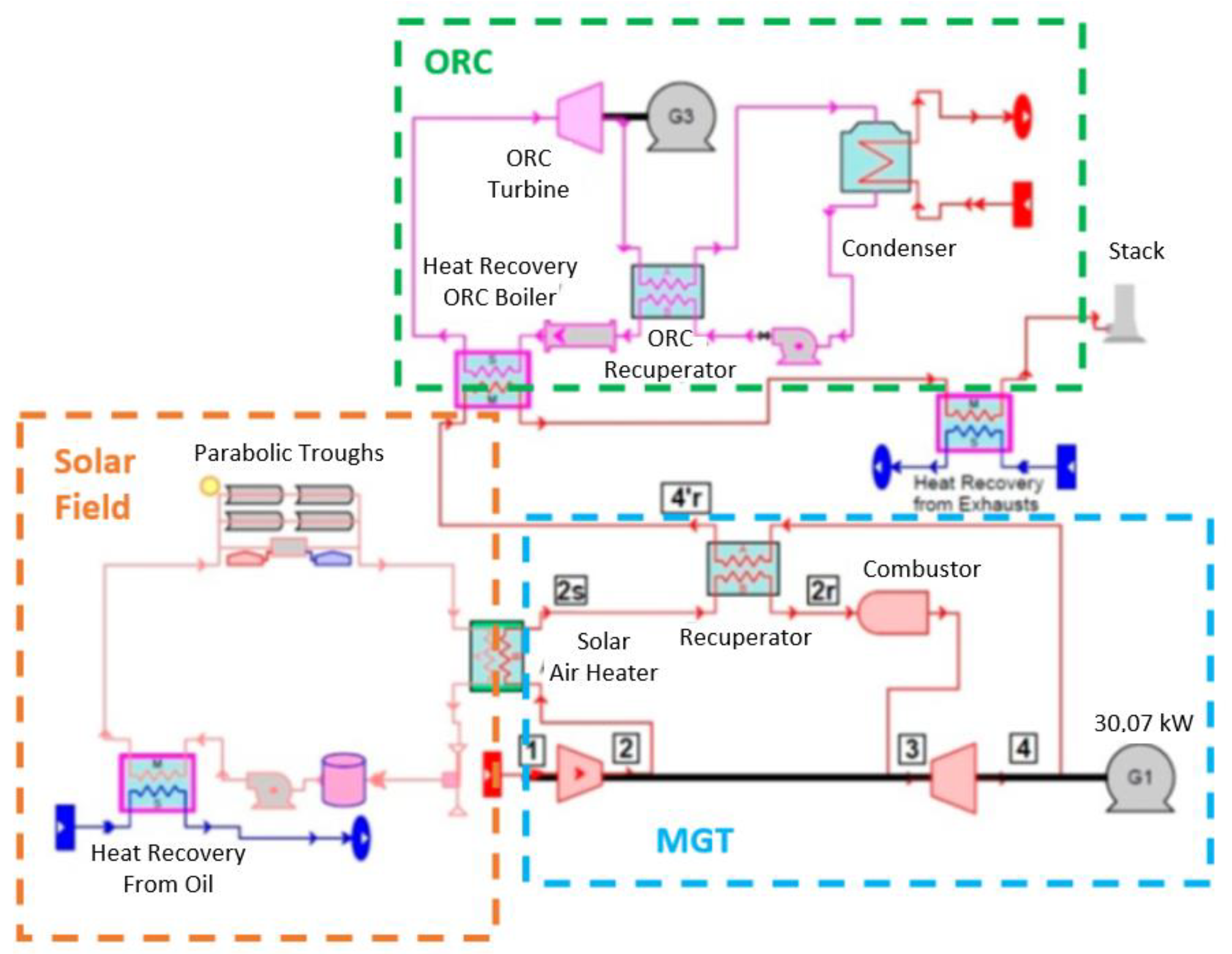

3. Micro Gas Turbine Integrated with Solar Field

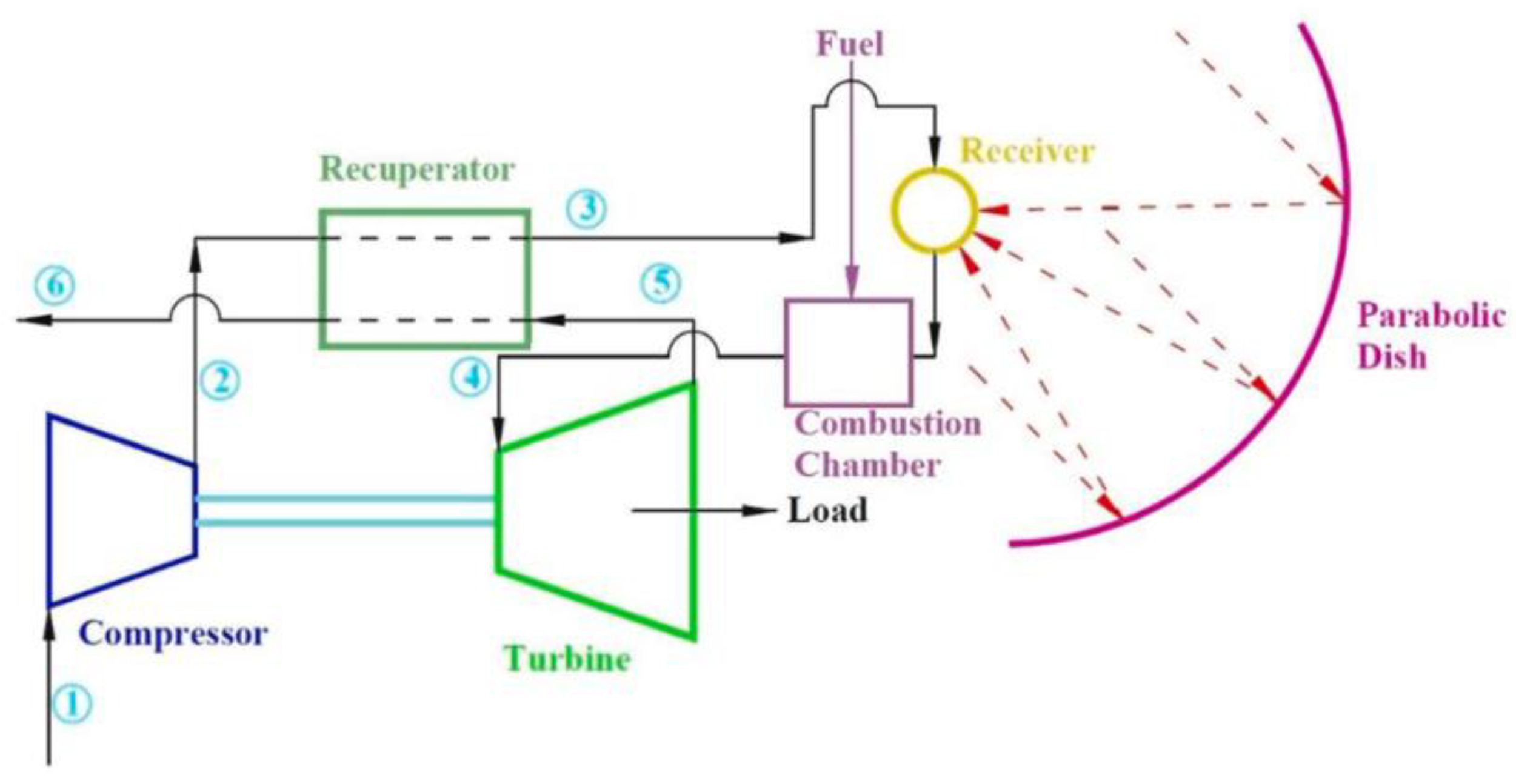

3.1. Parabolic Dish

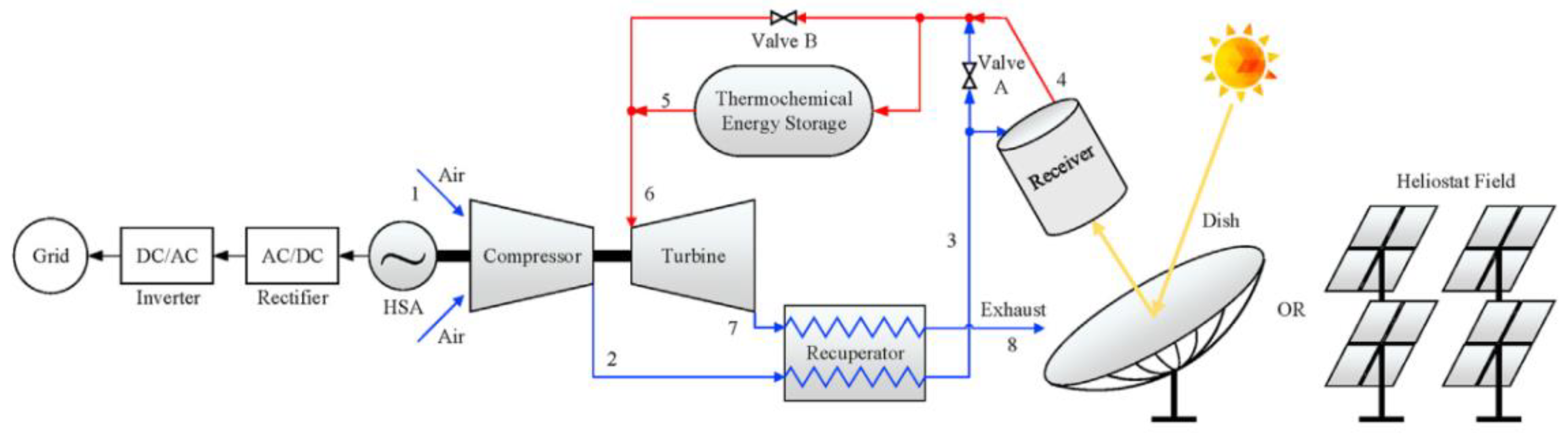

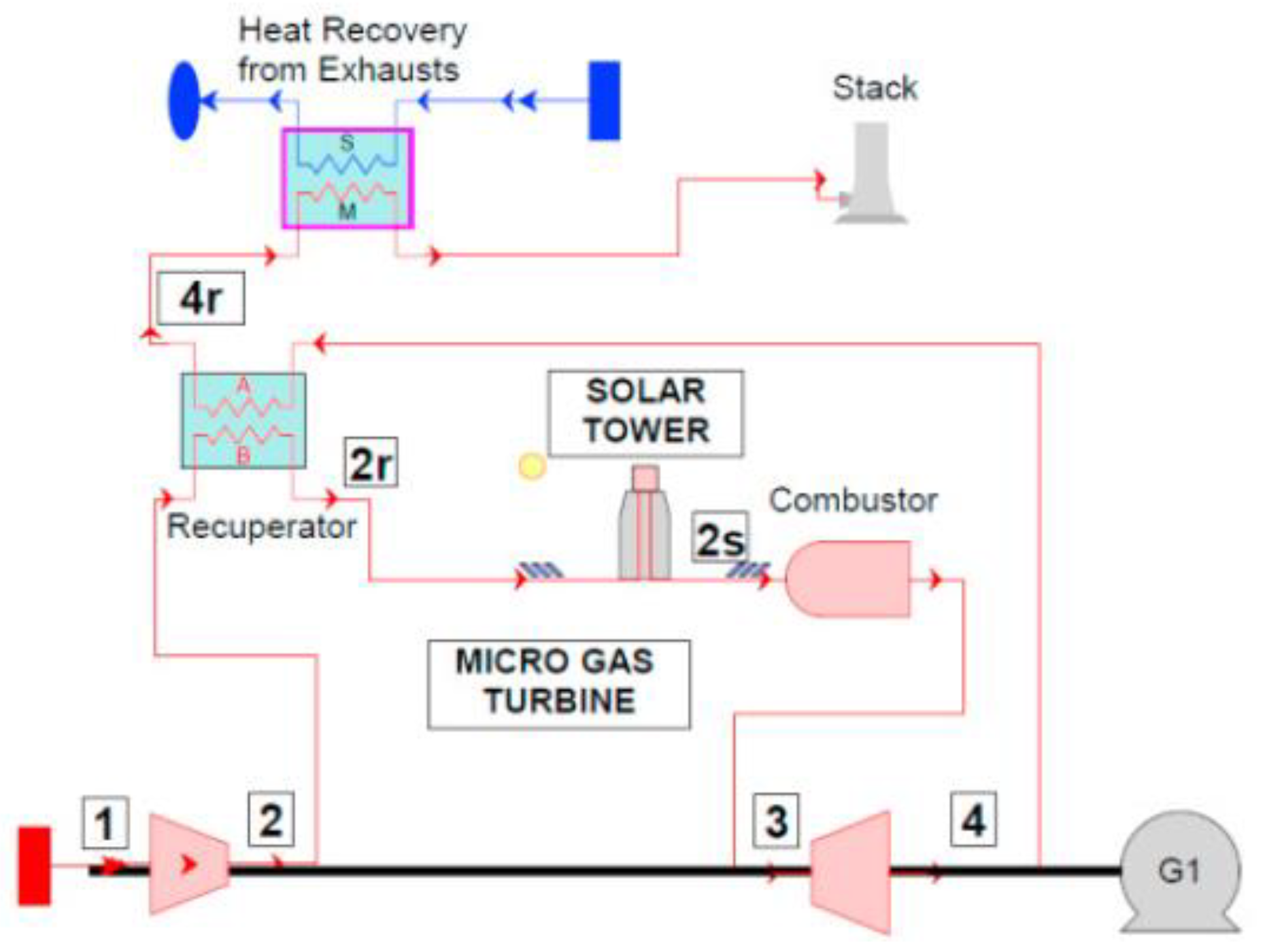

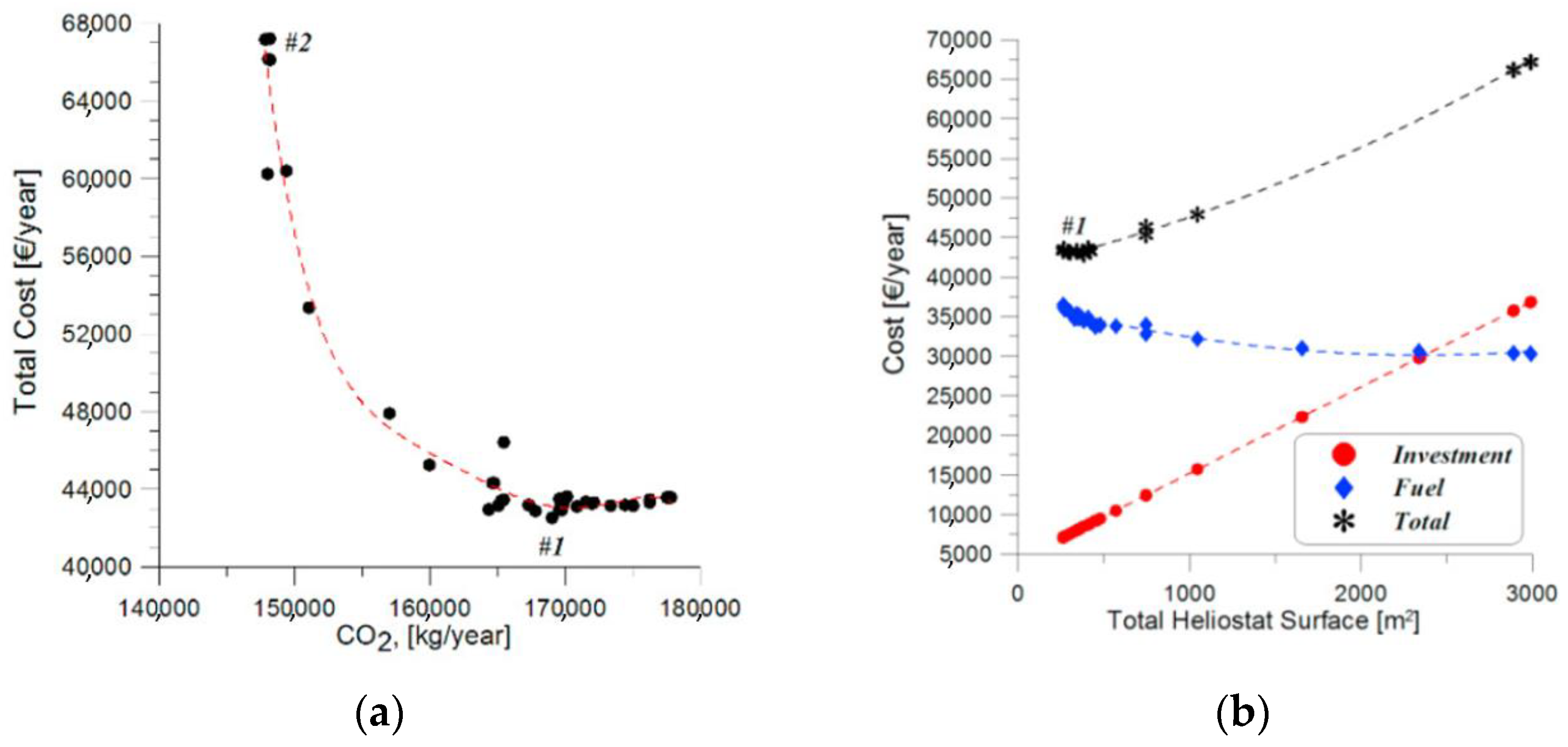

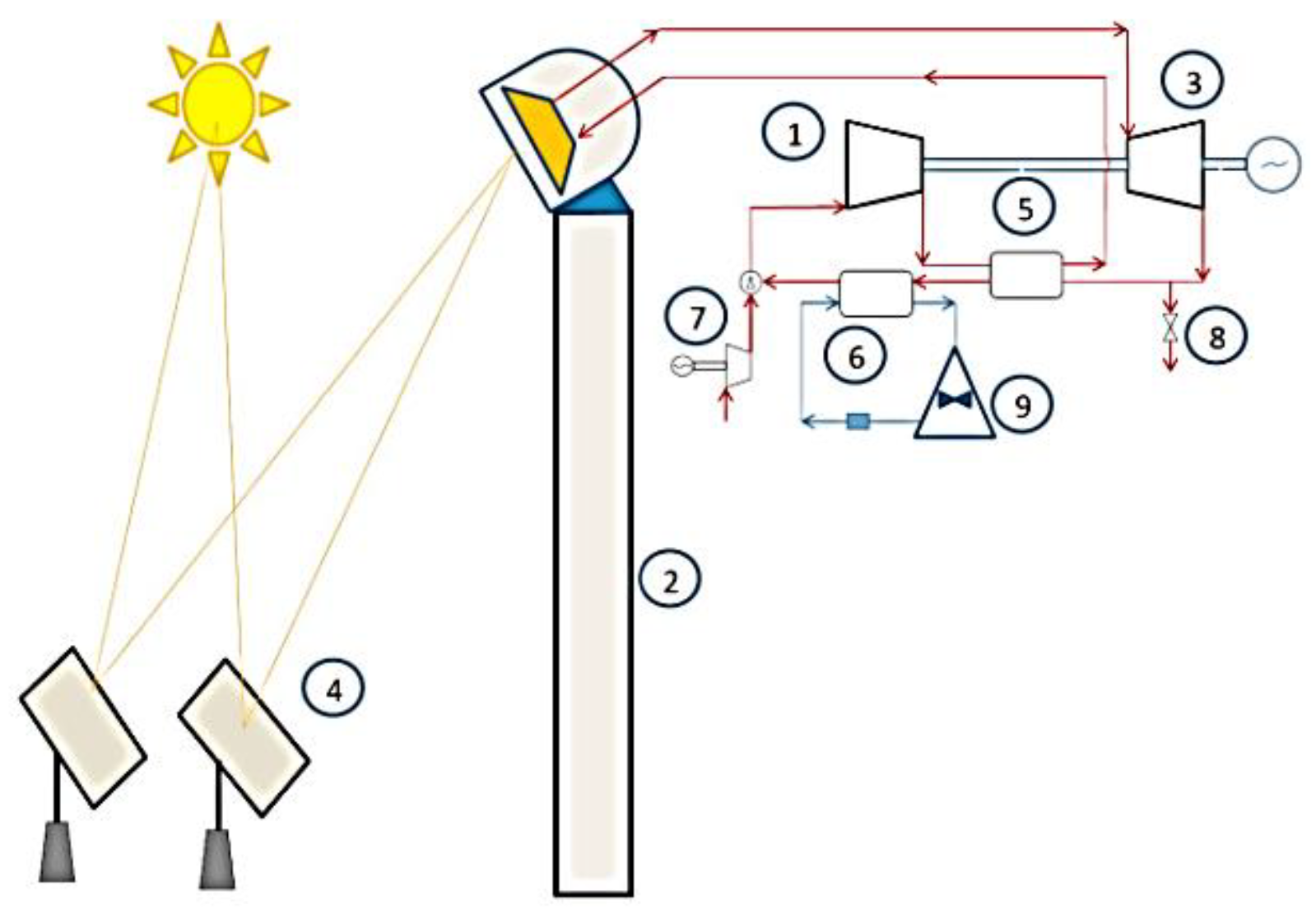

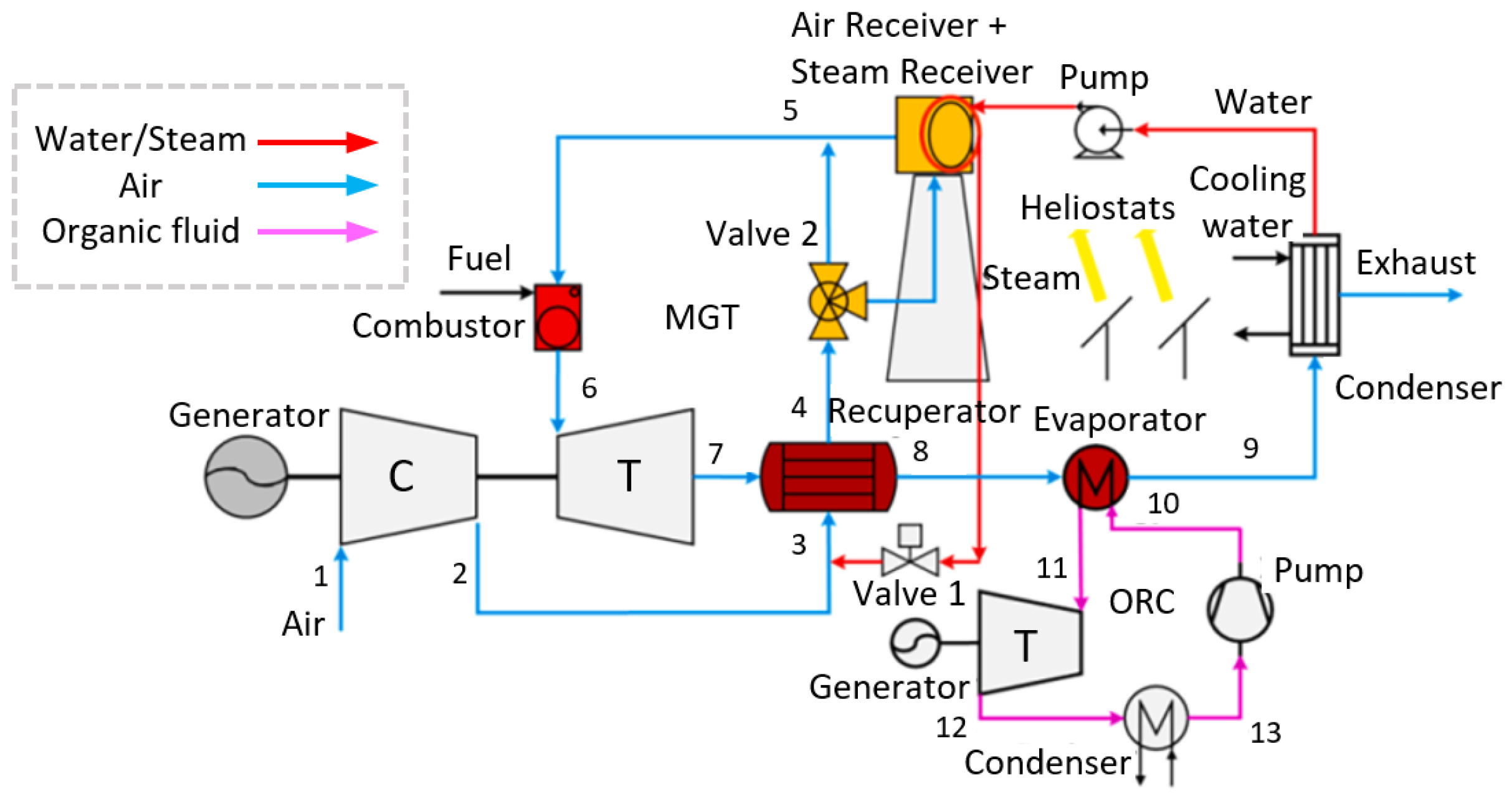

3.2. Solar Tower

4. Micro Gas Turbine Integrated with Organic Rankine Cycles

5. Micro Gas Turbine Integrated with Fuel Cells

5.1. SOFC

5.2. MCFC

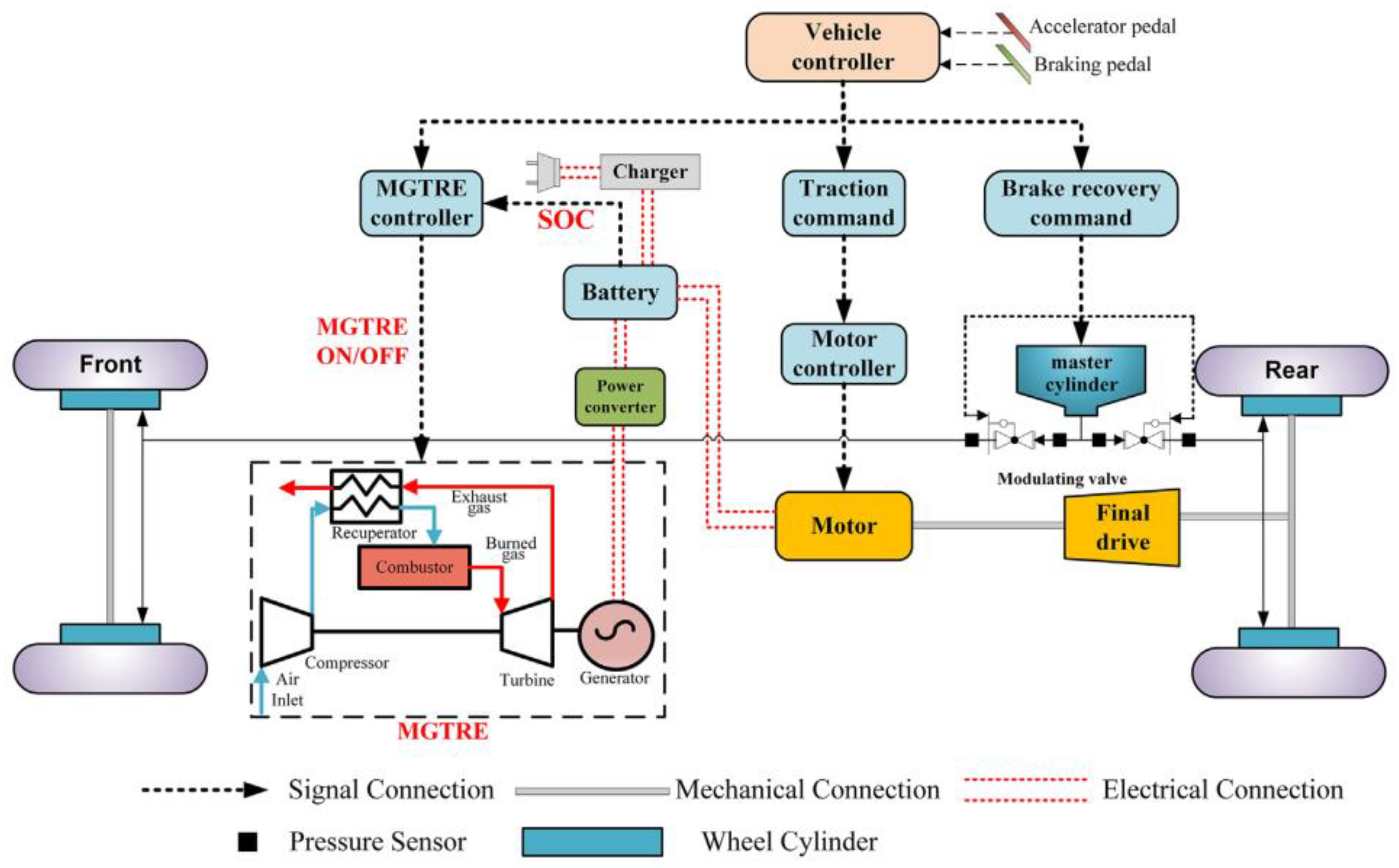

6. Micro Gas Turbine in Mobility Applications

7. Conclusions

- (1)

- Thanks to the higher temperatures achieved by CSP plants, especially with parabolic dishes and solar towers, they can be used as a heat source for the micro gas turbine. In turn, MGT fueling can compensate for solar radiation fluctuations on both a daily and yearly basis. Depending on the overall system design, a significant reduction of fuel consumption can be attained.

- (2)

- The flexibility of MGT reaches the maximum level when combined with an ORC. Indeed, based on the utilizer demand, the high exergy contents in the gas turbine exhausts can be used to produce more electricity.

- (3)

- SOFC and MCFC have proven to perfectly fit with MGTs because these two types of FCs can be fuelled with natural gas and biomass (rich of H2 and CO), and can operate at high temperatures; hence, the exhaust gases from the FC can properly expand in the turbine of the MGT increasing the produced power, with or without an afterburn process.

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AB | Afterburner |

| APU | Auxiliary Power Unit |

| BEV | Battery Electric Vehicle |

| BHPR | Biomass Heatpipe Reformer |

| CC | Combustion Chamber |

| CCHP | Combined Cooling Heat and Power |

| CCS | Carbon Capture and Storage |

| CFD | Computational Fluid Dynamics |

| CHP | Combined Heat and Power |

| CSP | Concentrating Solar Power |

| CT | Cold Tank |

| DLN | Dry Low NOx |

| DNI | Direct Normal Irradiance |

| EDC | Eddy Dissipation Concept |

| EFGT | Externally Fired Gas Turbines |

| EGR | Exhaust Gas Recirculation |

| EGT | Exhaust Gas Temperature |

| FC | Fuel Cell |

| FLOX | Flameless Oxidation |

| FRED | Finite Rate—Eddy Dissipation |

| FTIR | Fourier Transform Infrared |

| HAT | Humid Air Turbine |

| HHV | High Heating Value |

| HRSG | Heat Recovery Steam Generator |

| HRU | Heat Recovery Unit |

| HT | Hot Tank |

| HX | Heat Exchanger |

| ICE | Internal Combustion Engine |

| IIR | Indirect Internal Reformer |

| LCOE | Levelized Cost Of Electricity |

| LED | Large Eddy Simulation |

| LHV | Lower Heating Value |

| MCFC | Molten Carbonate Fuel Cell |

| MGT | Micro Gas Turbine |

| MGTRE | Micro Gas Turbine Range Extender |

| MILD | Moderate and Intense Low-Oxygen Dilution |

| MM | Molar Mass |

| NEDC | New European Driving Cycle |

| NG | Natural Gas |

| ORC | Organic Rankine Cycle |

| PCM | Phase Change Material |

| PF | Pattern Factor |

| PIV | Particle Image Velocimetry |

| PLIF | Planar Laser Induced Fluorescence |

| PR | Pre-reformer |

| PTC | Parabolic Trough Collectors |

| RANS | Reynolds Averaged Navier Stokes |

| REEV | Range Extender Electric Vehicle |

| RQL | Rich-Quick-Lean |

| SOC | State Of Charge |

| SOFC | Solid Oxide Fuel Cell |

| TCES | Thermochemical Energy Storage |

| TIT | Turbine Intel Temperature |

| TOT | Turbine Outlet Temperature |

References

- European Commission. Latest EU Policy Actions on Climate Change. Available online: https://www.consilium.europa.eu/it/policies/climate-change/eu-climate-action/ (accessed on 2 September 2022).

- European Commission. Recovery Plan for Europe. Available online: https://ec.europa.eu/info/strategy/recovery-plan-europe_en (accessed on 2 September 2022).

- Guan, J.; Lv, X.; Spataru, C.; Weng, Y. Experimental and numerical study on self-sustaining performance of a 30-kW micro gas turbine generator system during startup process. Energy 2021, 236, 121468. [Google Scholar] [CrossRef]

- Adamou, A.; Turner, J.; Costall, A.; Jones, A.; Copeland, C. Design, simulation, and validation of additively manufactured high-temperature combustion chambers for micro gas turbines. Energy Convers. Manag. 2021, 248, 114805. [Google Scholar] [CrossRef]

- Reale, F.; Sannino, R. Numerical Modeling of Energy Systems Based on Micro Gas Turbine: A Review. Energies 2022, 15, 900. [Google Scholar] [CrossRef]

- Grimm, F.; Enderle, B.; Kislat, O.; Izadi, S.; Zanger, J.; Kutne, P.A.M. A re-design study based on a high pressure cyclonic combustor operated with liquid fuel. In Proceedings of the ASME Turbo Expo 2019, Phoenix, AZ, USA, 17–21 June 2019. GT2019-91528. [Google Scholar] [CrossRef]

- De Paepe, W.; Carrero, M.M.; Bram, S.; Parente, A.; Contino, F. Advanced humidified gas turbine cycle concepts applied to micro gas turbine applications for optimal waste heat recovery. Energy Procedia 2017, 105, 1712–1718. [Google Scholar] [CrossRef]

- Xiao, G.; Yang, T.; Liu, H.; Ni, D.; Ferrari, M.; Li, M.; Luo, Z.; Cen, K.; Ni, M. Recuperators for micro gas turbines: A review. Appl. Energy 2017, 197, 83–99. [Google Scholar] [CrossRef]

- Kosowski, K.; Piwowarski, M. Design Analysis of Micro Gas Turbines in Closed Cycles. Energies 2020, 13, 5790. [Google Scholar] [CrossRef]

- Zong, C.; Ji, C.; Cheng, J.; Zhu, T.; Guo, D.; Li, C. Toward off-design loads: Investigations on combustion and emissions characteristics of a micro gas turbine combustor by external combustion-air adjustments. Energy 2022, 253, 124194. [Google Scholar] [CrossRef]

- Lin, P.; Du, X.; Shi, Y.; Sun, X.-M. Modeling and controller design of a micro gas turbine for power generation. ISA Trans. 2022, 124, 411–426. [Google Scholar] [CrossRef]

- Shen, W.; Xing, C.; Liu, H.; Liu, L.; Hu, Q.; Wu, G.; Yang, Y.; Wu, S.; Qiu, P. Exhaust gas recirculation effects on flame heat release rate distribution and dynamic characteristics in a micro gas turbine. Energy 2022, 249, 123680. [Google Scholar] [CrossRef]

- Best, T.; Finney, K.; Ingham, D.; Pourkashanian, M. CO2-enhanced and humidified operation of a micro-gas turbine for carbon capture. J. Clean. Prod. 2018, 176, 370–381. [Google Scholar] [CrossRef]

- Bellas, J.-M.; Finney, K.; Diego, M.; Ingham, D.; Pourkashanian, M. Experimental investigation of the impacts of selective exhaust gas recirculation on a micro gas turbine. Int. J. Greenh. Gas Control 2019, 90, 102809. [Google Scholar] [CrossRef]

- De Paepe, W.; Coppitters, D.; Abraham, S.; Tsirikoglou, P.; Ghorbaniasl, G.; Contino, F. Robust Operational Optimization of a Typical micro Gas Turbine. Energy Procedia 2018, 158, 5795–5803. [Google Scholar] [CrossRef]

- Pilavachi, P. Mini- and micro-gas turbines for combined heat and power. Appl. Therm. Eng. 2002, 22, 2003–2014. [Google Scholar] [CrossRef]

- Carrero, M.M.; De Paepe, W.; Bram, S.; Parente, A.; Contino, F. Does humidification improve the micro Gas Turbine cycle? Thermodynamic assessment based on Sankey and Grassmann diagrams. Appl. Energy 2017, 204, 1163–1171. [Google Scholar] [CrossRef]

- De Paepe, W.; Pappa, A.; Carrero, M.M.; Bricteux, L.; Contino, F. Reducing waste heat to the minimum: Thermodynamic assessment of the M-power cycle concept applied to micro Gas Turbines. Appl. Energy 2020, 279, 115898. [Google Scholar] [CrossRef]

- Pratt, R.; Balducci, P.; Gerkensmeyer, C.; Katipamula, S.; Kintner-Meyer, M.; Sanquist, T.; Schneider, K.; Secrest, T. The Smart Grid: An Estimation of the Energy and CO2 Benefits; Pacific Northwest National Laboratory: Richland, WA, USA, 2010. [Google Scholar]

- Balli, O.; Caliskan, H. Various thermoeconomic assessments of a heat and power system with a micro gas turbine engine used for industry. Energy Convers. Manag. 2022, 252, 114984. [Google Scholar] [CrossRef]

- Maghsoudia, P.; Sadeghi, S. A novel economic analysis and multi-objective optimization of a 200-kW recuperated micro gas turbine considering cycle thermal efficiency and discounted payback period. Appl. Therm. Eng. 2020, 166, 114644. [Google Scholar] [CrossRef]

- Akorede, M.F.; Hizam, H.; Pouresmaeil, E. Distributed energy resources and benefits to the environment. Renew. Sustain. Energy Rev. 2010, 14, 724–734. [Google Scholar] [CrossRef]

- Mirzaeea, M.; Zareb, R.; Sadeghzadehc, M.; Maddaha, H.; Ahmadid, M.; Acıkkalpe, E.; Chen, L. Thermodynamic analyses of different scenarios in a CCHP system with micro turbine—Absorption chiller, and heat exchanger. Energy Convers. Manag. 2019, 198, 111919. [Google Scholar] [CrossRef]

- Nascimento, M.R.; de Oliveira Rodrigues, L.; Santos, E.C.; Gomes, E.E.B.; Dias, F.L.G.; Velásques, E.G.; Carrillo, R.M. Micro Gas Turbine Engine: A Review. In Progress in Gas Turbine Performance; BoD–Books on Demand: Norderstedt, Germany, 2014; Chapter 5. [Google Scholar] [CrossRef]

- Malmquist, A.; Aglén, O.; Keller, E.; Suter, M.; Wickström, J. Microturbines: Speeding the Shift to Distributed Heat and Power. ABB Rev. 2000, 3, 22–30. [Google Scholar]

- Capstone. Available online: https://www.capstonegreenenergy.com/ (accessed on 15 November 2022).

- ETGroup. Available online: https://www.etgroup.nl/en/micro-gas-turbine/ (accessed on 10 October 2022).

- Yinger, R.J. Behavior of Capstone and Honeywell Microturbine Generators During Load Changes; Lawrence Berkeley National Lab. (LBNL): Berkeley, CA, USA, 2000. [Google Scholar] [CrossRef]

- Visser, W.; Shakariyants, S.; Oostveen, M. Development of a 3 kW Microturbine for CHP Applications. J. Eng. Gas Turbines Power 2011, 133, 042301-1. [Google Scholar] [CrossRef]

- Available online: https://www.ansaldoenergia.com/business-lines/new-units/microturbines/ (accessed on 12 October 2022).

- Cavarzere, A.; Morini, M.; Pinelli, M.; Spina, P.; Vaccari, A.; Venturini, M. Experimental Analysis of a Micro Gas Turbine Fuelled with Vegetable Oils from Energy Crops. Energy Procedia 2014, 45, 91–100. [Google Scholar] [CrossRef]

- Kun-Balong, A.; Sztankó, K. Reduction of pollutant emissions from a rapeseed oil fired micro gas turbine burner. Fuel Process. Technol. 2015, 134, 352–359. [Google Scholar] [CrossRef]

- Cameretti, M.C.; Tuccillo, R. Combustion features of a bio-fuelled micro-gas turbine. Appl. Therm. Eng. 2015, 89, 280–290. [Google Scholar] [CrossRef]

- Delattin, F.; Di Lorenzo, G.; Rizzo, S.; Bram, S.; De Ruyck, J. Combustion of syngas in a pressurized microturbine-like combustor: Experimental results. Appl. Energy 2010, 87, 1441–1452. [Google Scholar] [CrossRef]

- Abagnale, C.; Cameretti, M.; De Robbio, R.; Tuccillo, R. CFD Study of a MGT Combustor supplied with Syngas. Energy Procedia 2016, 101, 933–940. [Google Scholar] [CrossRef]

- Cameretti, M.C.; De Robbio, R.; Tuccillo, R. CFD Study of a Micro—Combustor Under Variable Operating Conditions. In Proceedings of the ASME Turbo Expo 2017, Charlotte, NC, USA, 26–30 June 2017. GT2017-63661. [Google Scholar] [CrossRef]

- Tuccillo, R.; Cameretti, M.; De Robbio, R.; Reale, F.; Chiariello, F. Methane—Hydrogen Blends in Micro Gas Turbines: Comparison of Different Combustor Concepts. In Proceedings of the ASME Turbo Expo 2019, Phoenix, AZ, USA, 17–21 June 2019. GT2019-90229. [Google Scholar] [CrossRef]

- Pappa, A.; Bricteux, L.; Benard, P.; De Paepe, W. Can water dilution avoid flashback on a hydrogen enriched micro gas turbine combustion?—A large eddy simulation study. J. Eng. Gas Turbines Power 2021, 143, 041008-1. [Google Scholar] [CrossRef]

- Adinolfi, G.; Cigolotti, V.; Graditi, G.; Ferruzzi, G. Grid integration of Distributed Energy Resources: Technologies, potentials contributions and future prospects. In Proceedings of the International Conference on Clean Electrical Power, Alghero, Italy, 11–13 June 2013. [Google Scholar] [CrossRef]

- Sharf, M.; Romm, I.; Palman, M.; Zelazo, D.; Cukurel, B. Economic dispatch of a single micro gas turbine under CHP operation with uncertain demands. Appl. Energy 2022, 309, 118391. [Google Scholar] [CrossRef]

- Directive, E.U. Directive 2001/77/ec of the european parliament and of the council of 27 September 2001 on the promotion of electricity produced from renewable energy sources in the internal electricity market. Off. J. Eur. Communities 2001, 283. [Google Scholar]

- Available online: https://www.ipcc.ch/sr15/chapter/glossary/ (accessed on 20 October 2022).

- Gómez, M.Á.; Martín, R.; Collazo, J.; Porteiro, J. CFD Steady Model Applied to a Biomass Boiler Operating in Air Enrichment Conditions. Energies 2018, 11, 2513. [Google Scholar] [CrossRef]

- Zornek, T.; Monz, T.; Aigner, M. Performance analysis of the micro gas turbine Turbec T100 with a new FLOX-combustion system for low calorific fuels. Appl. Energy 2015, 159, 276–284. [Google Scholar] [CrossRef]

- Fortunato, V.; Giraldo, A.; Rouabah, M.; Nacereddine, R.; Delanaye, M.; Parente, A. Experimental and Numerical Investigation of a MILD Combustion Chamber for Micro Gas Turbine Applications. Energies 2018, 11, 3363. [Google Scholar] [CrossRef]

- Corrêa, P.S.J.P.; Zhang, J.; Lora, E.S.; Andrade, R.V.; de Mello e Pinto, L.; Ratner, A. Experimental study on applying biomass-derived syngas in a microturbine. Appl. Therm. Eng. 2019, 146, 328–337. [Google Scholar] [CrossRef]

- Liu, A.; Yang, Y.; Chen, L.; Zeng, W.; Wang, C. Experimental study of biogas combustion and emissions for a micro gas turbine. Fuel 2020, 267, 117312. [Google Scholar] [CrossRef]

- Liu, H.; Qian, W.; Zhu, M.; Li, S. Kinetics modeling on NOx emissions of a syngas turbine combustor using Rich-Burn, Quick-Mix, Lean-Burn combustion method. J. Eng. Gas Turbines Power 2020, 142, 021005, GTP-19-1654. [Google Scholar] [CrossRef]

- Di Nardo, A.; Bo, A.; Calchetti, G.; Giacomazzi, E.; Messina, G. Study on the Fuel Flexibility of a Microgas Turbine Combustor Burning Different Mixtures of H2, CH4, and CO2. J. Eng. Gas Turbines Power 2020, 142, 061001, GTP-19-1277. [Google Scholar] [CrossRef]

- Nicolosi, F.F.; Renzi, M. Design and CFD simulation of a micro gas turbine combustor fuelled with low LHV producer gas. In Proceedings of the ASME Turbo Expo 2020, Virtual, 21–25 September 2020. GT2020-14978. [Google Scholar] [CrossRef]

- Liu, Y.; Nikolaidis, T.; Madani, S.H.; Sarkandi, M.; Gamil, A.; Sainal, M.F.; Hosseini, S.V. Multi-Fidelity Combustor Design and Experimental Test for. Energies 2022, 15, 2342. [Google Scholar] [CrossRef]

- Ajvad, M.; Shih, H.-Y. Modeling syngas combustion performance of a can combustor with rotating casing for an innovative micro gas turbine. Int. J. Hydrogen Energy 2020, 45, 31188–31201. [Google Scholar] [CrossRef]

- Bazooyar, B.; Darabkhani, H.G. Design, manufacture and test of a micro-turbine renewable energy. Energy Convers. Manag. 2020, 213, 112782. [Google Scholar] [CrossRef]

- Liu, A.; Fan, R.; Liu, Q.; Xi, L.; Zeng, W. Numerical and Experimental Study on Combustion Characteristics of Micro-Gas Turbine Biogas Combustor. Energies 2022, 15, 8302. [Google Scholar] [CrossRef]

- Escamilla, A.; Sánchez, D.; García-Rodríguez, L. Assessment of power-to-power renewable energy storage based on the smart integration of hydrogen and micro gas turbine technologies. Int. J. Hydrogen Energy 2022, 47, 17505–17525. [Google Scholar] [CrossRef]

- di Gaeta, A.; Reale, F.; Chiariello, F.; Massoli, P. A dynamic model of a 100 kW micro gas turbine fuelled with natural gas and hydrogen blends and its application in a hybrid energy grid. Energy 2017, 129, 299–320. [Google Scholar] [CrossRef]

- Cappelletti, A.; Martelli, F.; Bianchi, E.; Trifoni, E. Numerical redesign of 100kw MGT combustor for 100% H2 fueling. Energy Procedia 2014, 45, 1412–1421. [Google Scholar] [CrossRef]

- García-Conde, A.; Martínez, C.; Prada, G.; Vélez-Bracho, V.; Benito, J. Modifications of an existing microturbine to use hydrogen as fuel. In Proceedings of the 20th Worlds Hydrogen Energy Conference 2014, Gwangju, Republic of Korea, 15–20 June 2014. [Google Scholar]

- Deymi-Dashtebayaz, M.; Ebrahimi-Moghadam, A.; Pishbin, S.; Pourramezan, M. Investigating the effect of hydrogen injection on natural gas thermo-physical properties with various compositions. Energy 2019, 167, 235–245. [Google Scholar] [CrossRef]

- Meziane, S.; Bentebbiche, A. Numerical study of blended fuel natural gas-hydrogen combustion in rich/quench/lean combustor of a micro gas turbine. Int. J. Hydrogen Energy 2019, 44, 15610–15621. [Google Scholar] [CrossRef]

- Lu, J.; Fu, Z.; Liu, J.; Pan, W. Influence of air distribution on combustion characteristics of a micro gas turbine fuelled by hydrogen-doped methane. Energy Rep. 2022, 8, 207–216. [Google Scholar] [CrossRef]

- Bo, A.; Giacomazzi, E.; Messina, G.; Di Nardo, A. Analysis of a Fuel Flexible Micro Gas Turbine Combustor Through Numerical Simulations. J. Eng. Gas Turbines Power 2018, 140, 121504-1. [Google Scholar] [CrossRef]

- De Robbio, R. Innovative combustion analysis of a micro-gas turbine burner supplied with hydrogen-natural gas mixtures. Energy Procedia 2017, 126, 858–866. [Google Scholar] [CrossRef]

- Jachimowski, C. An Analytical Study of Hydrogen-Air Reaction Mechanism with Application to Scramjet Combustion; NASA-TP-2791; National Aeronautics and Space Administration: Washington, DC, USA, 1988.

- Novosselov, I.; Malte, P. Development and Application of an Eight-Step Global Mechanism for CFD and CRN Simulations of lean-premixed combustors. In Proceedings of the ASME Turbo Expo 2007, Montreal, QC, Canada, 1 January 2007. GT2007-27990. [Google Scholar] [CrossRef]

- Smith, G. Available online: http://www.me.berkeley.edu/gri_mech/ (accessed on 11 November 2022).

- Reale, F. Effects of Steam Injection on the Permissible Hydrogen Content and Gaseous Emissions in a Micro Gas Turbine Supplied by a Mixture of CH4 and H2: A CFD Analysis. Energies 2022, 15, 2914. [Google Scholar] [CrossRef]

- Nazari, M.A.; Alavi, M.; Salem, M.; El Haj Assad, M. Utilization of hydrogen in gas turbines: A comprehensive review. Int. J. Low-Carbon Technol. 2022, 17, 513–519. [Google Scholar] [CrossRef]

- Toit, M.; Engelbrecht, N.; Oelofse, S.; Bessarabov, D. Performance evaluation and emissions reduction of a micro gas turbine via the co-combustion of H2/CH4/CO2 fuel blends. Sustain. Energy Technol. Assess. 2020, 39, 100718. [Google Scholar] [CrossRef]

- de Santoli, L.; Basso, G.L.; Barati, S.; D’Ambra, S.; Fasolilli, C. Seasonal energy and environmental characterization of a micro gas turbine fueled with H2NG blends. Energy 2020, 193, 116678. [Google Scholar] [CrossRef]

- Chiaramonti, D.; Rizzo, A.; Spadi, A.; Prussi, M.; Riccio, G.; Martelli, F. Exhaust emissions from liquid fuel micro gas turbine fed with diesel oil, biodiesel and vegetable oil. Appl. Energy 2013, 101, 349–356. [Google Scholar] [CrossRef]

- Annunziata, G.; Cameretti, M.; De Robbio, R.; Tuccillo, R. Numerical Investigation of Spray Development in a Micro Gas Turbine LPP Combustor with Airblast Atomizar. In Proceedings of the ASME Turbo Expo 2018, Oslo, Norway, 11–15 June 2018. GT2018-75789. [Google Scholar] [CrossRef]

- Adamou, A.; Kennedy, I.; Farmer, B.; Hussein, A.; Copeland, C. Experimental and Computational Analysis of an Additive Manufactured Vaporization Injector for a Micro-Gas Turbine. In Proceedings of the ASME Turbo Expo 2019, Phoenix, AZ, USA, 17–21 June 2019. GT2019-90245. [Google Scholar] [CrossRef]

- Tan, E.; Kuruman, P.; Indra, T.; Yoshikawa, K. Effect of Non-Edible Biodiesel Physical and Chemical Properties as Microturbine Fuel. Energy Procedia 2017, 142, 413–418. [Google Scholar] [CrossRef]

- Cameretti, M.C.; Tuccillo, R.; Reale, F.; Piazzesi, R. Liquid Bio-Fuels in an EGR Equipped Micro Gas Turbine. In Proceedings of the ASME 2011 Turbo Expo, Vancouver, BC, Canada, 6–10 June 2011. GT2011-46341. [Google Scholar] [CrossRef]

- Cameretti, M.C.; Tuccillo, R.; Piazzesi, R. Study of an exhaust gas recirculation equipped micro gas turbine supplied with bio-fuels. Appl. Therm. Eng. 2013, 59, 162–173. [Google Scholar] [CrossRef]

- Cameretti, M.; Tuccillo, R.; Reale, F.; Piazzesi, R. Numerical Simulation of Liquid Bio-Fuel Combustion in an EGR Equipped Micro Gas Turbine. Am. J. Appl. Sci. 2015, 12, 463–478. [Google Scholar] [CrossRef]

- Laranci, P.; Zampilli, M.; D’Amico, M.; Bartocci, P.; Bidini, G.; Fantozzi, F. Geometry optimization of a commercial annular RQL combustor of a micro gas turbine for use with natural gas and vegetable oils. Energy Procedia 2017, 126, 875–882. [Google Scholar] [CrossRef]

- Seljak, T.; Pavalec, K.; Buffi, M.; Valera-Medina, A.; Chiaramonti, D.; Katrasnik, T. Challenges and Solutions for Utilization of Bioliquids in Microturbines. J. Eng. Gas Turbines Power 2019, 141, 031401. [Google Scholar] [CrossRef]

- Enagi, I.I.; Al-attab, K.; Zainal, Z.; Teoh, Y. Palm biodiesel spray and combustion characteristics in a new micro gas turbine combustion chamber design. Energy 2022, 254, 124335. [Google Scholar] [CrossRef]

- Allouis, C.; Amoresano, A.; Capasso, R.; Langella, G.; Niola, V.; Quaremba, G. The impact of biofuel properties on emissions and performances of a micro gas turbine using combustion vibrations detection. Fuel Process. Technol. 2018, 179, 10–16. [Google Scholar] [CrossRef]

- Roy, P.; Datta, A.; Chakraborty, N. An assessment of different biomass feedstocks in a downdraft gasifier for engine application. Fuel 2013, 106, 864–868. [Google Scholar] [CrossRef]

- Karellas, S.; Karl, J.; Karakas, E. An innovative biomass gasification process and its coupling with microturbine and fuel cell systems. Energy 2008, 33, 284–291. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Panopoulos, K.; Grammelis, P. Modelling of biomass gasifier and microturbine for the olive oil industry. Int. J. Energy Res. 2012, 36, 355–367. [Google Scholar] [CrossRef]

- Movahed, P.; Avami, A. Techno-economic optimization of biogas-fueled micro gas turbine cogeneration systems in sewage treatment plant. Energy Convers. Manag. 2020, 218, 11296. [Google Scholar] [CrossRef]

- Al-attab, K.; Zainal, Z. Performance of a biomass fueled two-stage micro gas turbine (MGT) system with hot air production heat recovery unit. Appl. Therm. Eng. 2014, 70, 61–70. [Google Scholar] [CrossRef]

- Moradi, R.; Marcantonio, V.; Cioccolanti, L.; Bocci, E. Integrating biomass gasification with a steam-injected micro gas turbine and an Organic Rankine Cycle unit for combined heat and power production. Energy Convers. Manag. 2020, 205, 112464. [Google Scholar] [CrossRef]

- Cameretti, M.C. Modelling of a Hybrid Solar Micro-Gas Turbine fuelled by biomass from agriculture product. Energy Rep. 2020, 6, 105–116. [Google Scholar] [CrossRef]

- Lee, H.; Lee, M. Recent advances in ammonia combustion technology in thermal power generation system for carbon emission reduction. Energies 2021, 14, 5604. [Google Scholar] [CrossRef]

- Kurata, O.; Iki, N.; Inoue, T.; Matsunuma, T.; Tsujimura, T.; Furutani, H.; Kawano, M.; Arai, K.; Okafor, E.; Hayakawa, A.; et al. Development of a wide range-operable, rich-lean low-NOx combustor for NH3 fuel gas-turbine power generation. Proc. Combust. Inst. 2019, 37, 4587–4595. [Google Scholar] [CrossRef]

- Okafor, E.C.; Kunkuma, K.; Somarathne, A.; Ratthanan, R.; Kawano, M.; Kudo, T.; Kurata, O.; Iki, N.; Tsujimura, T.; Furutani, H.; et al. Control of NOx and other emissions in micro gas turbine combustors fuelled with mixtures of methane and ammonia. Combust. Flame 2020, 211, 406–416. [Google Scholar] [CrossRef]

- Ayaz, S.; Altuntas, O.; Caliskan, H. Enhanced life cycle modelling of a micro gas turbine fuelled with various fuels for sustainable electricity production. Renew. Sustain. Energy Rev. 2021, 149, 111323. [Google Scholar] [CrossRef]

- Bonasio, V.; Ravelli, S. Performance Analysis of an Ammonia-Fueled Micro Gas Turbine. Energies 2022, 15, 3874. [Google Scholar] [CrossRef]

- Kautz, M.; Hansen, U. The externally-fired gas-turbine (EFGT-Cycle) for decentralized use of biomass. Appl. Energy 2007, 84, 795–805. [Google Scholar] [CrossRef]

- Pantaleo, A.M.; Camporeale, S.; Shah, N. Natural gas–biomass dual fuelled microturbines: Comparison of operating strategies in the Italian residential sector. Appl. Therm. Eng. 2014, 71, 686–696. [Google Scholar] [CrossRef]

- Cordiner, S.; Mulone, V. Experimental–numerical analysis of a biomass fueled microgeneration power-plant based on microturbine. Appl. Therm. Eng. 2014, 71, 905–912. [Google Scholar] [CrossRef]

- The National Renewable Energy Laboratory. Concentrating Solar Power Projects. Available online: https://solarpaces.nrel.gov/ (accessed on 16 November 2022).

- Llamas, J.M.; Bullejos, D.; de Adana, M.R. Optimal Operation Strategies into Deregulated Markets for 50 MWe Parabolic Trough Solar Thermal Power Plants with Thermal Storage. Energies 2019, 12, 935. [Google Scholar] [CrossRef]

- Aichmayer, L.; Spelling, J.; Laumert, B. Preliminary design and analysis of a novel solar receiver for a micro gas-turbine based solar dish system. Sol. Energy 2015, 114, 378–396. [Google Scholar] [CrossRef]

- Mingaleeva, G.; Afanaseva, O.; Nguen, D.T.; Pham, D.N.; Zunino, P. The Integration of Hybrid Mini Thermal Power Plants into the Energy Complex of the Republic of Vietnam. Energies 2020, 13, 5848. [Google Scholar] [CrossRef]

- Kumar, L.; Ahmed, J.; El Haj Assad, M.; Hasanuzzaman, M. Prospects and Challenges of Solar Thermal for Process Heating: A Comprehensive Review. Energies 2022, 15, 8501. [Google Scholar] [CrossRef]

- Cameretti, M.C.; Cappiello, A.; De Robbio, R.; Tuccillo, R. Comparison between Hydrogen and Syngas fuels in an integrated Mi-cro Gas Turbine/Solar field with Storage. Energies 2020, 13, 4764. [Google Scholar] [CrossRef]

- Mazzoni, S.; Cerria, G.; Chennaoui, L. A simulation tool for concentrated solar power based on micro gas turbine engines. Energy Convers. Manag. 2018, 174, 844–854. [Google Scholar] [CrossRef]

- Delavar, M.A.; Wang, J. Simulation of a hybrid system of solar-microturbines in cold climate regions. Appl. Therm. Eng. 2021, 182, 1359–4311. [Google Scholar] [CrossRef]

- Chahartaghi, M.; Baghaee, A. Technical and economic analyses of a combined cooling, heating and power system based on a hybrid microturbine (solar-gas) for a residential building. Energy Build. 2020, 217, 110005. [Google Scholar] [CrossRef]

- Ghavami, M.; Al-Zaili, J.; Sayma, A.I. A methodology for techno-economic and operation strategy optimisation of micro gas turbine-based solar powered dish-engine systems. Energy 2022, 251, 123873. [Google Scholar] [CrossRef]

- Yang, J.; Xiao, G.; Ghavami, M.; Al-Zaili, J.; Yang, T.A.; Ni, D. Thermodynamic modelling and real-time control strategies of solar microgas turbine system with thermochemical energy storage. J. Clean. Prod. 2021, 304, 127010. [Google Scholar] [CrossRef]

- Bashir, M.A.; Giovannelli, A.; Ali, H.M. Design of high-temperature solar receiver integrated with short-term thermal storage for Dish-Micro Gas Turbine systems. Sol. Energy 2019, 190, 156–166. [Google Scholar] [CrossRef]

- Bashir, M.A.; Daabo, A.; Amber, K.; Khan, M.; Arshad, A.; Elahi, H. Effect of phase change materials on the short-term thermal storage in the solar receiver of dish-micro gas turbine systems: A numerical analysis. Appl. Therm. Eng. 2021, 195, 117179. [Google Scholar] [CrossRef]

- Giostri, A.; Binotti, M.; Sterpos, G.; Lozza, G. Small scale solar tower coupled with micro gas turbine. Renew. Energy 2020, 147, 570–583. [Google Scholar] [CrossRef]

- Available online: https://www.energy.gov/eere/articles/concentrating-solar-power-could-provide-flexibility-and-reliability-us-electric-grid (accessed on 15 November 2022).

- Cameretti, M.; De Robbio, R.; Pirone, E.; Tuccillo, R. Thermo-Economic Analysis of a Hybrid Solar Micro Gas Turbine Power Plant. Energy Procedia 2017, 126, 667–674. [Google Scholar] [CrossRef]

- Abagnale, C.; Cameretti, M.; De Robbio, R.; Tuccillo, R. Thermal cycle and Combustion Analysis of a Solar-assisted Micro Gas Turbine. Energies 2017, 10, 773. [Google Scholar] [CrossRef]

- Rovense, F.; Amelio, M.; Scornaienchi, N.; Ferraro, V. Performance analysis of a solar-only gas micro turbine, with mass flow control. Energy Procedia 2017, 126, 675–682. [Google Scholar] [CrossRef]

- Amelio, M.; Pèrez, M.S.; Ferraro, V.; Rovense, F.; Bova, S. Dynamic simulation of the temperature inlet turbine control system for an unfired micro gas turbine in a concentrating solar tower. Energy Procedia 2018, 148, 712–719. [Google Scholar] [CrossRef]

- Rovense, F.; Reyes-Belmonte, M.; Romero, M.; González-Aguilar, J. Combined Heat/Cooling and Power Generation Using Hybrid Micro Gas Turbine in a CST Plant for a Residential Off-grid Application. AIP Conf. Proc. 2020, 2303, 080006. [Google Scholar] [CrossRef]

- Ssebabi, B.; Dinter, F.; van der Spuy, J.; Schatz, M. Predicting the performance of a micro gas turbine under solar-hybrid operation. Energy 2019, 177, 121–135. [Google Scholar] [CrossRef]

- Invernizzi, C.; Iora, P.; Silva, P. Bottoming micro-Rankine cycles for micro-gas turbines. Appl. Therm. Eng. 2007, 27, 100–110. [Google Scholar] [CrossRef]

- de Campos, G.B.; Bringhenti, C.; Traverso, A.; Tomita, J.T. A Review on Combining Micro Gas Turbines with Organic Rankine Cycles. E3S Web Conf. 2019, 113, 03007. [Google Scholar] [CrossRef]

- de Campos, G.B.; Bringhenti, C.; Traverso, A.; Tomita, J.T. Thermoeconomic optimization of organic Rankine bottoming cycles for micro gas turbines. Appl. Therm. Eng. 2020, 164, 114477. [Google Scholar] [CrossRef]

- Benato, A.; Stoppato, A.; Mirandola, A.; Del Medico, M. Design and Off-Design Analysis of an ORC Coupled with a Micro-Gas Turbine. Energy Procedia 2017, 129, 551–558. [Google Scholar] [CrossRef]

- Yoon, S.; Kim, M.; Kim, I.; Kim, T. Comparison of micro gas turbine heat recovery systems using ORC and trans-critical CO2 cycle focusing on off-design performance. Energy Procedia 2017, 129, 987–994. [Google Scholar] [CrossRef]

- Chacartegui, R.; Becerra, J.; Blanco, M.; Muñoz-Escalona, J.M. A Humid Air Turbine–Organic Rankine Cycle combined cycle for distributed microgeneration. Energy Convers. Manag. 2015, 104, 115–126. [Google Scholar] [CrossRef]

- Kim, S.; Sung, T.; Kim, K.C. Thermodynamic Performance Analysis of a Biogas-Fuelled Micro-Gas Turbine with a Bottoming Organic Rankine Cycle for Sewage Sludge and Food Waste Treatment Plants. Energies 2017, 10, 275. [Google Scholar] [CrossRef]

- Javidmehr, M.; Joda, F.; Mohammadi, A. Thermodynamic and economic analyses and optimization of a multi-generation system composed by a compressed air storage, solar dish collector, micro gas turbine, organic Rankine cycle, and desalination system. Energy Convers. Manag. 2018, 168, 467–481. [Google Scholar] [CrossRef]

- Xiao, G.; Chen, J.; Ni, M.; Cen, K. A solar micro gas turbine system combined with steam injection and ORC bottoming cycle. Energy Convers. Manag. 2021, 243, 114032. [Google Scholar] [CrossRef]

- Zhu, Y.; Tomsovic, K. Development of models for analyzing the load-following performance of microturbines and fuel cells. Electr. Power Syst. Res. 2002, 62, 1–11. [Google Scholar] [CrossRef]

- Damo, U.; Ferrari, M.; Turan; Massardo, A. Solid oxide fuel cell hybrid system: A detailed review of an environmentally clean and efficient source of energy. Energy 2019, 168, 235–246. [Google Scholar] [CrossRef]

- Traverso, A.; Magistri, L.; Massardo, A. Turbomachinery for the air management and energy recovery in fuel cell gas turbine hybrid systems. Energy 2010, 35, 764–777. [Google Scholar] [CrossRef]

- Komatsu, Y.; Kimijima, S.; Szmyd, J. Performance analysis for the part-load operation of a solid oxide fuel cell–micro gas turbine hybrid system. Energy 2010, 35, 982–988. [Google Scholar] [CrossRef]

- Leto, L.; Dispenza, C.; Moreno, A.; Calabrò, A. Simulation model of a molten carbonate fuel cellemicroturbine hybrid system. Appl. Therm. Eng. 2011, 31, 1263–1271. [Google Scholar] [CrossRef]

- Bakalis, D.P.; Stamatis, A.G. Incorporating available micro gas turbines and fuel cell: Matching considerations and performance evaluation. Appl. Energy 2013, 103, 607–617. [Google Scholar] [CrossRef]

- Bang-Møller, C.; Rokni, M. Thermodynamic performance study of biomass gasification, solid oxide fuel cell and micro gas turbine hybrid systems. Energy Convers. Manag. 2010, 51, 2330–2339. [Google Scholar] [CrossRef]

- Calise, F.; Dentice d’Accadia, M.; Palombo, A.; Vanoli, L. Simulation and exergy analysis of a hybrid Solid Oxide Fuel Cell (SOFC)–Gas Turbine System. Energy 2006, 31, 3278–3299. [Google Scholar] [CrossRef]

- Kaneko, T.; Brouwer, J.; Samuelsen, G. Power and temperature control of fluctuating biomass gas fueled solid oxide fuel cell and micro gas turbine hybrid system. J. Power Sources 2006, 160, 316–325. [Google Scholar] [CrossRef]

- Baudoin, S.; Vechiu, I.; Camblong, H.J.-M.; Barelli, L. Sizing and control of a Solid Oxide Fuel Cell/Gas microTurbine hybrid power system using a unique inverter for rural microgrid integration. Appl. Energy 2016, 176, 272–281. [Google Scholar] [CrossRef]

- Di Carlo, A.; Borello, D.; Bocci, E. Process simulation of a hybrid SOFC/mGT and enriched air/steam fluidized bed gasifier power plant. Int. J. Hydrogen Energy 2013, 38, 5857–5874. [Google Scholar] [CrossRef]

- Jia, J.; Abudula, A.; Wei, L.; Sun, B.; Shi, Y. Effect of operating parameters on performance of an integrated biomass gasifier, solid oxide fuel cells and micro gas turbine system. Biomass Bioenergy 2015, 75, 35–45. [Google Scholar] [CrossRef]

- Jia, J.; Shu, L.; Zang, G.; Xu, L.; Abudula, A.; Ge, K. Energy analysis and techno-economic assessment of a co-gasification of woody biomass and animal manure, solid oxide fuel cells and micro gas turbine hybrid system. Energy 2018, 149, 750–761. [Google Scholar] [CrossRef]

- Fryda, L.; Panopoulos, K.; Kakaras, E. Integrated CHP with autothermal biomass gasification and SOFC–MGT. Energy Convers. Manag. 2008, 49, 281–290. [Google Scholar] [CrossRef]

- Wongchanapai, S.; Iwai, H.; Saito, M.; Yoshida, H. Performance evaluation of a direct-biogas solid oxide fuel cell-micro gas turbine (SOFC-MGT) hybrid combined heat and power (CHP) system. J. Power Sources 2013, 223, 9–17. [Google Scholar] [CrossRef]

- Perna, A.; Minutillo, M.; Jannelli, E.; Cigolotti, V.; Nam, S.; Yoon, K.J. Performance assessment of a hybrid SOFC/MGT cogeneration power plant fed by syngas from a biomass down-draft gasifier. Appl. Energy 2018, 227, 80–91. [Google Scholar] [CrossRef]

- You, H.; Han, J.; Liu, Y. Conventional and advanced exergoeconomic assessments of a CCHP and MED system based on solid oxide fuel cell and micro gas turbine. Int. J. Hydrogen Energy 2020, 45, 12143–12160. [Google Scholar] [CrossRef]

- Karimi, M.H.; Chitgar, N.; Emadi, M.; Ahmadi, P.; Rosen, M.A. Performance assessment and optimization of a biomass-based solid oxide fuel cell and micro gas turbine system integrated with an organic Rankine cycle. Int. J. Hydrogen Energy 2020, 45, 6262–6277. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Moradpoor, I. Combined solid oxide fuel cell, micro-gas turbine and organic Rankine cycle for power generation (SOFC–MGT–ORC). Energy Convers. Manag. 2016, 116, 120–133. [Google Scholar] [CrossRef]

- Zheng, Z.; Liu, T.; Liu, Q.; Lei, J.; Fang, J. A distributed energy system integrating SOFC-MGT with mid-and-low temperature solar thermochemical hydrogen fuel production. Int. J. Hydrogen Energy 2021, 46, 19846–19860. [Google Scholar] [CrossRef]

- Isfahani, S.N.R.; Sedaghat, A. A hybrid micro gas turbine and solid state fuel cell power plant with hydrogen production and CO2 capture. Int. J. Hydrogen Energy 2016, 41, 9490–9499. [Google Scholar] [CrossRef]

- Huang, H.; Li, J.; He, Z.; Zeng, T.; Kobayashi, N.; Kubota, M. Performance Analysis of a MCFC/MGT Hybrid Power System Bi-Fueled by City Gas and Biogas. Energies 2015, 8, 5661–5677. [Google Scholar] [CrossRef]

- Yang, C.; Deng, K.; He, H.; Wu, H.; Yao, K.; Fan, Y. Real-Time Interface Model Investigation for MCFC-MGT HILS Hybrid Power System. Energies 2019, 12, 2192. [Google Scholar] [CrossRef]

- Karvountzis-Kontakiotis, A.; Andwari, A.; Pesyridis, A.; Russo, S.; Tuccillo, R.; Esfahanian, V. Application of Micro Gas Turbine in Range-Extended Electric Vehicles Application of Micro Gas Turbine in Range-Extended Electric Vehicles. Energy 2018, 147, 351–361. [Google Scholar] [CrossRef]

- Ji, F.; Zhang, X.; Du, F.; Ding, S.; Zhao, Y.; Xu, Z.; Wang, Y.; Zhou, Y. Experimental and numerical investigation on micro gas turbine as a range extender for electric vehicle. Appl. Therm. Eng. 2020, 173, 115236. [Google Scholar] [CrossRef]

- Javed, A.; Khalid, H.; Arif, S.U.; Imran, M.; Rezk, A.; Khan, Z.A. Micro Gas Turbine Small-Scale Effects in Range Extended Electric Vehicles. J. Energy Resour. Technol. 2021, 143, 120906. [Google Scholar] [CrossRef]

- Shah, R.M.R.A.; McGordon, A.; Rahman, M.; Amor-Segan, M.; Jennings, P. Characterisation of micro turbine generator as a range extender using an automotive drive cycle for series hybrid electric vehicle application. Appl. Therm. Eng. 2021, 184, 116302. [Google Scholar] [CrossRef]

| Manufacturer | Model | Power Output | Efficiency | Pressure Ratio | TIT/EGT | Nominal Speed | CO2 |

|---|---|---|---|---|---|---|---|

| kWel | % | °C | rpm | g/kWhel | |||

| ABB [25] | MT 100 | 100 | 30 | 4.5 | 950/300 | 70,000 | 660 |

| Bladon Jets | MTG12TL | 12 | - | - | - | 134,000 | - |

| Bowman | - | 80 | 27 | 4.3 | 680/300 | 68,000 | 733.33 |

| Capstone [26] | C30 | 30 | 26 | 3.2 | 871/275 | 96,000 | 761.54 |

| C65 | 65 | 28 | 3.2 | 871/309 | 85,000 | 707.14 | |

| C200 HP | 200 | 33 | 3.2 | 870/280 | 45,000 | 600 | |

| Elliott Energy System | TA 45 | 45 | 30 | 4.0 | 871/280 | 116,000 | 660 |

| TA 80 | 80 | 30 | 4.0 | 871/280 | 68,000 | 660 | |

| TA 200 | 200 | 30 | 4.0 | 871/280 | 43,000 | 660 | |

| ET Group [27] | - | 45 | 28 | - | - | 60,000 | 707.14 |

| Honeywell (AlliedSignal) [28] | Parallon 75 | 75 | 28.5 | 3.7 | 900/250 | 85,000 | 694.74 |

| Ingersoll-Rand | - | 70 | 33 | 3.3 | 870/200 | 60,000 | 594.59 |

| MTT BV [29] | - | 3 | 16 | 2.8 | - | 240,000 | 1237.5 |

| Nissan | - | 2.6 | 8–10 | 2.8 | 850/250 | 100,000 | 2200 |

| Power WorksTM | - | 70 | 30 (HHV) | 3 | 704/- | - | 660 |

| Turbec (Ansaldo Energia) [30] | AE-T100 | 100 | 30 | 4.5 | 950/270 | 70,000 | 660 |

| Fuel Compos. [%, molar] | NG | BIOM O | BIOM AD | SW |

|---|---|---|---|---|

| CH4 | 92.00 | 18.00 | 65.00 | 7.00 |

| C2H6 | 3.70 | 2.00 | - - | 7.00 |

| C3H8 | 1.00 | 2.00 | - - | 7.00 |

| C4H10 | 0.25 | 2.00 | - - | - - |

| N2 | 2.90 | 8.00 | - - | - - |

| H2 | - - | 25.00 | - - | 18.00 |

| CO | - - | 33.00 | - - | 61.00 |

| CO2 | 0.15 | 10.00 | 35.00 | - - |

| H2O | - - | - - | - - | - - |

| Mol. Mass [g/mol] | 17.34 | 21.92 | 25.83 | 23.76 |

| LHV [kJ/kg] | 47,182 | 19,198 | 20,183 | 21,697 |

| fst | 0.0620 | 0.1680 | 0.145 | 0.1530 |

| Taf [K] | 2220 | 2231 | 2126 | 2300 |

| f | 0.0087 | 0.0208 | 0.0198 | 0.0184 |

| φ | 0.137 | 0.123 | 0.136 | 0.1203 |

| NG | BIOM O | BIOM AD | SW | |

|---|---|---|---|---|

| Tout [K] | 1176 | 1140 | 1165 | 1183 |

| Tmax [K] | 2557 | 2753 | 2511 | 2689 |

| NO [%] | - - | 50.6 | −31.6 | 39.8 |

| CO [%] | - - | −8.3 | 14.7 | −1.8 |

| CH4 [%] | - - | −27.7 | 44.2 | −93.0 |

| Standard Operation 3D | Standard Operation | Solar Tower | Solar Tower ADgas | |

|---|---|---|---|---|

| O2 [mol%] | 11.1 | 10.2 | 13.3 | 12.9 |

| Tmax [K] | 2511 | 2468 | 2480 | 2265 |

| Tmean,out [K] | 1164 | 1173 | 1147 | 1150 |

| NO [ppm] | 226 | 86 | 74 | 7 |

| CO [ppm] | 1200 | 3400 | 900 | 1300 |

| UHC [ppm] | 2 | 5 | 0.5 | 2 |

| MM [kg/mol] | Tcrit [°C] | pcrit [kPa] | Tsat@pamb [°C] | |

|---|---|---|---|---|

| Water | 18.01 | 374 | 22,064 | 100 |

| Butane | 58.12 | 151.98 | 3796 | −0.49 |

| Pentane | 72.15 | 196.55 | 3379 | 36.06 |

| Heptane | 100.2 | 266.98 | 2736 | 98.38 |

| Cyclopentane | 70.13 | 288.87 | 4571 | 49.26 |

| Benzene | 78.11 | 288.87 | 1894 | 80.07 |

| Toluene | 92.14 | 318.6 | 4126 | 110.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Robbio, R. Micro Gas Turbine Role in Distributed Generation with Renewable Energy Sources. Energies 2023, 16, 704. https://doi.org/10.3390/en16020704

De Robbio R. Micro Gas Turbine Role in Distributed Generation with Renewable Energy Sources. Energies. 2023; 16(2):704. https://doi.org/10.3390/en16020704

Chicago/Turabian StyleDe Robbio, Roberta. 2023. "Micro Gas Turbine Role in Distributed Generation with Renewable Energy Sources" Energies 16, no. 2: 704. https://doi.org/10.3390/en16020704

APA StyleDe Robbio, R. (2023). Micro Gas Turbine Role in Distributed Generation with Renewable Energy Sources. Energies, 16(2), 704. https://doi.org/10.3390/en16020704