Lime Hemp Concrete with Unfired Binders vs. Conventional Building Materials: A Comparative Assessment of Energy Requirements and CO2 Emissions

Abstract

1. Introduction

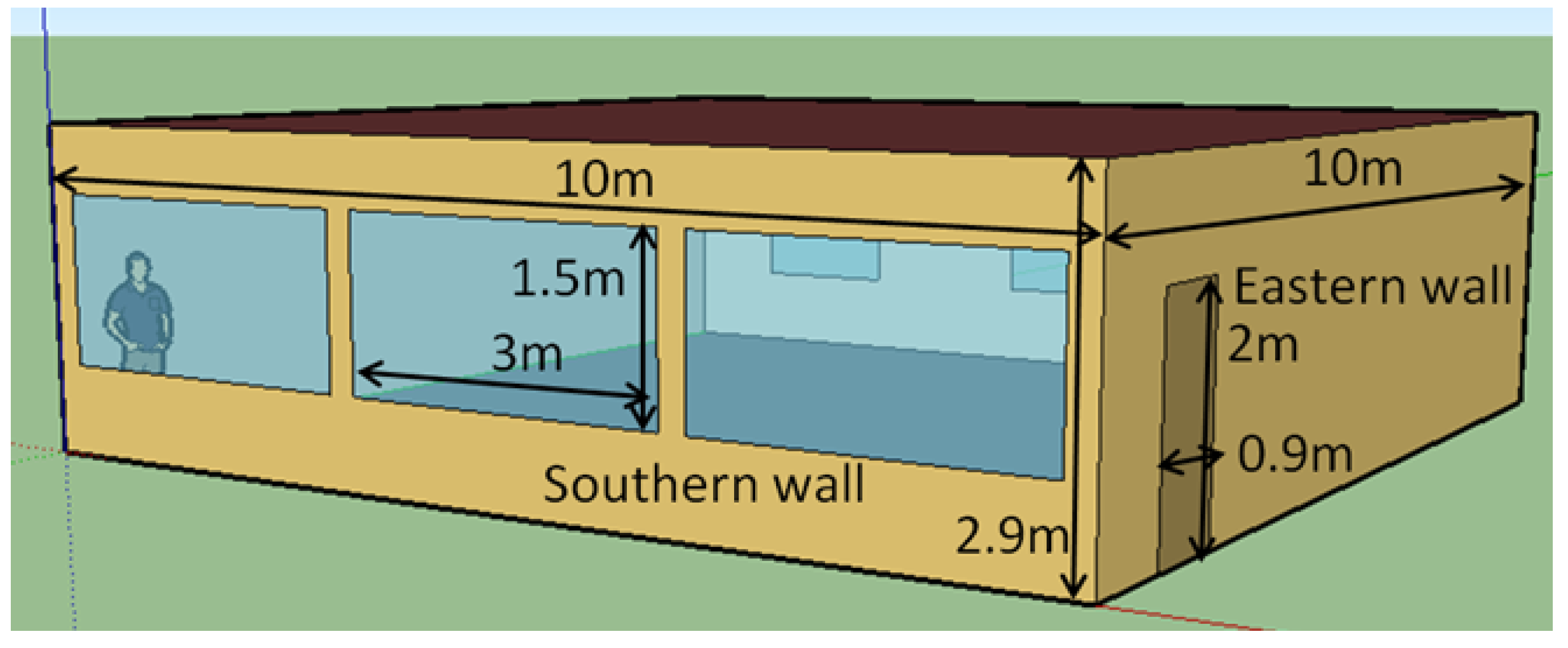

2. Materials and Methods

2.1. Methodology, Boundaries and Assumptions

- A 50-year life span is assumed for a building.

- The annual energy required for acclimatization is assumed to be constant over its life span.

- Manufacture of the machines, tools, vehicles, etc., involved in the production.

- Transportation: all materials are assumed to be manufactured locally.

- Lighting and other electric appliances which are not directly involved in the acclimatization of the building.

- Maintenance and repairs of the building.

- The post-use phase was excluded due to the high level of future uncertainty.

2.2. EE and EC Values

2.3. OE and OC Values

3. Results and Discussion

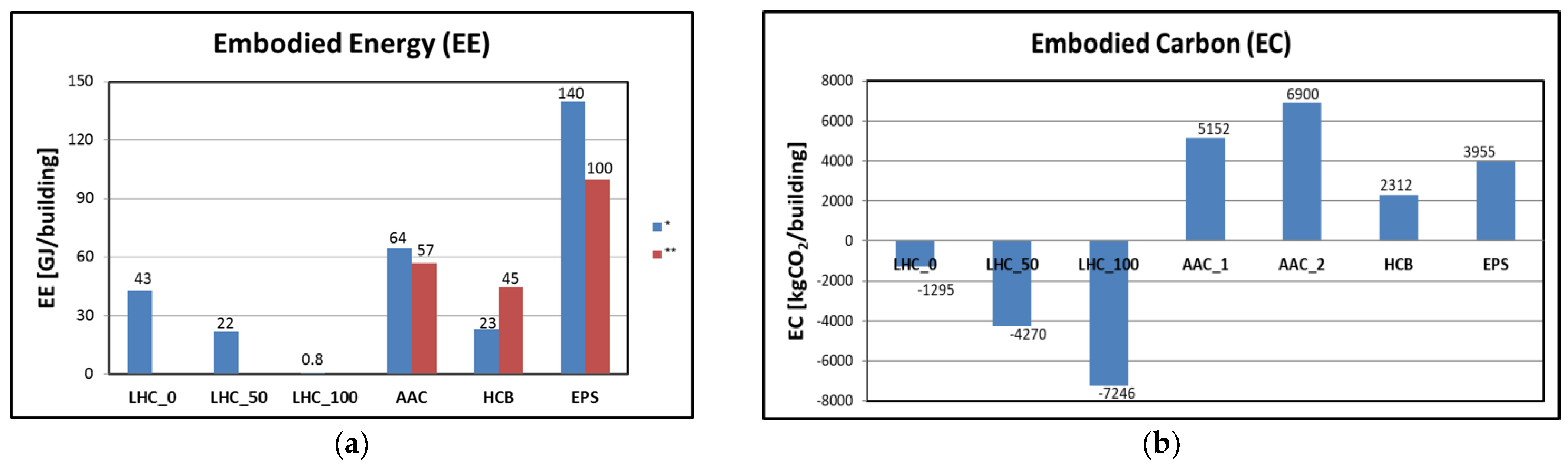

3.1. Pre-Use Phase: EE and EC Values

3.2. Use-Phase: OE and OC Values

3.3. Total Energy Requirements and CO2 Emissions

4. Conclusions

- Replacing the lime in LHC with unfired binders significantly reduces the environmental impact compared to standard LHC mainly of the pre-use phase, i.e., reduction in the EE and EC values, as the OE and OC of all LHC mixtures are similar (due to similar thermal performance).

- Using LHC with unfired binders is beneficial both in the pre-use (lower EE and EC values) and the use phases (lower OE and OC values) as compared to conventional building materials. Therefore, it can lead to significant savings in energy consumption, and in CO2 emissions.

Author Contributions

Funding

Conflicts of Interest

References and Notes

- Gabay, H.; Meir, I.A.; Schwartz, M.; Werzberger, E. Cost-benefit analysis of green buildings: An Israeli office buildings case study. Energy Build. 2014, 76, 558–564. [Google Scholar] [CrossRef]

- Laurenzi, M.P. Building Energy Efficiency—An Asia Business Council Book; 2007

- IEA. Annex 31, Energy-Related Environmental Impact of Buildings, Energy Conservation in Buildings and Community Systems; International Energy Agency: Paris, France, 2001. [Google Scholar]

- EC. 20% Energy Savings by 2020—Memo; European Commission—Directorate General for Energy and Transport: 2005

- EIA. Annual Energy Review; Energy Information Administration: Washington, DC, USA, 2005. [Google Scholar]

- Huberman, N.; Pearlmutter, D. A life-cycle energy analysis of building materials in the Negev desert. Energy Build. 2008, 40, 837–848. [Google Scholar] [CrossRef]

- Huberman, N.; Pearlmutter, D.; Gal, E.; Meir, I.A. Optimizing structural roof form for life-cycle energy efficiency. Energy Build. 2015, 104, 336–349. [Google Scholar] [CrossRef]

- Malhotra, V.M. Role of supplementary cementing materials in reducing greenhouse gas emissions. In Concrete Technology for a Sustainable Development in the 21st Century; E&FN Spon: London, UK, 2000; pp. 35–226. [Google Scholar]

- Mayer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Meir, I.A. Green technologies in planning and design vis-à-vis climatic uncertainty. In Encyclopedia of Energy Engineering and Technology, 2nd ed.; Taylor & Francis: Abingdon, UK, 2015; pp. 796–803. [Google Scholar]

- Meir, I.A.; Pearlmutter, D. Building for climate change: Planning and design considerations in time of climatic uncertainty. Corrosion Engineering. Sci. Technol. 2010, 45, 70–75. [Google Scholar]

- Reider, R.; Meir, I.A. Comparing the energy implications of FRP and concrete residential construction in a hot arid climate. Energy Build. 2019, 186, 98–107. [Google Scholar] [CrossRef]

- Bevan, R.; Wooley, T. Hemp Lime Construction: A Guide to Building with Hemp Lime Composites; IHS BRE Press: London, UK, 2010. [Google Scholar]

- Hirst, E.; Walker, A.; Paine, P.; Yates, K. Characterization of low density hemp-lime composite building materials under compression loading. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; pp. 1395–1405. [Google Scholar]

- Ip, K.; Miller, A. Life cycle greenhouse gas emissions of hemp–lime wall constructions in the UK. Resour. Conserv. Recycl. 2012, 69, 1–9. [Google Scholar] [CrossRef]

- Pittaua, F.; Krausea, F.; Lumia, G.; Habert, G. Fast-growing bio-based materials as an opportunity for storing carbon in exterior walls. Build. Environ. 2018, 129, 117–129. [Google Scholar] [CrossRef]

- Zampori, L.; Dotelli, G.; Vernelli, V. Life cycle assessment of hemp cultivation and use of hemp-based thermal insulator materials in buildings. Environ. Sci. Technol. 2013, 47, 7413–7420. [Google Scholar] [CrossRef]

- Evrard, A. Sorption behaviour of Lime-Hemp Concrete and its relation to indoor comfort and energy demand. In Proceedings of the 23rd International Conference on Passive and Low Energy Architecture, Geneva, Switzerland, 6–8 September 2006; pp. 1553–1557. [Google Scholar]

- Evrard, A.; De Herde, A. Dynamical interactions between heat and mass flows in Lime-Hemp Concrete. In Research in Building Physics and Building Engineering; Taylor & Francis: Abingdon, UK, 2006; pp. 69–76. [Google Scholar]

- Cerezo, V. Propriétés Mécaniques, Thermiques et Acoustiques d’un Matériau à base de Particules Végétales: Approche Expérimentale et Modélisation Théorique. Ph.D. Thesis, Institut National des Sciences Appliquées de Lyon, Villeurbanne, France, 2005. [Google Scholar]

- Ahlberg, J.; Georges, E.; Norlén, M. The Potential of Hemp Buildings in Different Climates and the Hempcrete Building System. A Comparison between a Common Passive House and the Hempcrete Building System. Bachelor’s Thesis, Uppsala University, Uppsala, Sweden, 2014. [Google Scholar]

- Shea, A.; Lawrence, M.; Walker, P. Hygrothermal performance of an experimental hemp–lime building. Constr. Build. Mater. 2012, 36, 270–275. [Google Scholar] [CrossRef]

- Costantine, G.; Maalouf, C.; Moussa, T.; Polidori, G. Experimental and numerical investigations of thermal performance of a Hemp Lime external building insulation. Build. Environ. 2018, 131, 140–153. [Google Scholar] [CrossRef]

- Maalouf, C.; Ingrao, C.; Scrucca, F.; Moussa, T.; Bourdot, A.; Tricase, C.; Presciutti, A.; Asdrubali, F. An energy and carbon footprint assessment upon the usage of hemp-lime concrete and recycled-PET façades for office facilities in France and Italy. J. Clean. Prod. 2018, 170, 1640–1653. [Google Scholar] [CrossRef]

- Arnaud, L.; Gourlay, E. Experimental study of parameters influencing mechanical properties of hemp concretes. Constr. Build. Mater. 2012, 28, 50–56. [Google Scholar] [CrossRef]

- De Bruijn, P.B.; Jeppsson, K.H.; Sandin, K.; Nilsson, C. Mechanical properties of lime–hemp concrete containing shives and fibres. Biosyst. Eng. 2009, 103, 474–479. [Google Scholar] [CrossRef]

- Jami, T.; Karade, S.R.; Singh, L.P. A review of the properties of hemp concrete for green building applications. J. Clean. Prod. 2019, 239, 117852. [Google Scholar] [CrossRef]

- Wadi, H.; Amziane, S.; Toussaint, E.; Taazount, M. Lateral load-carrying capacity of hemp concrete as a natural infill material in timber frame walls. Eng. Struct. 2019, 180, 264–273. [Google Scholar] [CrossRef]

- Florentin, Y. A Comparative Life-Cycle Energy and Carbon Analysis of Hemp-based Building Materials in an Arid Environment. Master’s Thesis, The Jacob Blaustein Institutes for Desert Research, Ben-Gurion University of the Negev, Be’er Sheva, Israel, 2015. [Google Scholar]

- Florentin, Y.; Pearlmutter, D.; Givoni, B.; Gal, E. A life-cycle energy and carbon analysis of hemp-lime bio-composite building materials. Energy Build. 2017, 156, 293–305. [Google Scholar] [CrossRef]

- Arizzi, A.; Brümmer, M.; Martín-Sánchez, I.; Molina, E.; Cultrone, G. Optimization of lime and clay-based hemp-concrete wall formulations for a successful lime rendering. Constr. Build. Mater. 2018, 184, 76–86. [Google Scholar] [CrossRef]

- Busbridge, R.; Rhydwen, R. An investigation of the Thermal Properties of Hemp and Clay Monolithic Walls. Proceedings of the The School of Computing & Technology 5th Annual Conference, University of East London. 2010, pp. 163–170. Available online: https://www.researchgate.net/publication/47529650_An_investigation_of_the_thermal_properties_of_hemp_and_clay_monolithic_walls (accessed on 1 December 2022).

- Hammond, G.; Jones, C. Inventory of Carbon and Energy (ICE); Sustainable Energy Research Team, Department of Mechanical Engineering, University of Bath: Bath, UK, 2008. [Google Scholar]

- Wilkinson, S. A Study of the Moisture Buffering Potential of Hemp in Combination with Lime and Clay-Based Binders. Master’s Thesis, School of Computing and Technology, University of East London, London, UK, 2009. [Google Scholar]

- Haik, R.; Bar-Nes, G.; Peled, A.; Meir, I.A. Sustainable lime hemp concrete (LHC): Alternative unfired binders as lime replacement. Constr. Build. Mater. 2020, 241, 117981. [Google Scholar] [CrossRef]

- Haik, R.; Peled, A.; Meir, I.A. The thermal performance of lime hemp concrete (LHC) with alternative binders. Energy Build. 2020, 210, 109740. [Google Scholar] [CrossRef]

- Haik, R.; Peled, A.; Meir, I.A. Thermal performance of a lime hemp concrete (LHC) building with alternative binders: A comparison with conventional building materials. Build. Res. Inf. 2021, 49, 763–776. [Google Scholar] [CrossRef]

- Arrigoni, A.; Pelosato, R.; Melia, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Life cycle assessment of natural building materials: The role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. J. Clean. Prod. 2017, 149, 1051–1061. [Google Scholar] [CrossRef]

- Sinka, M.; Van den Heede, P.; De Belieb, N.; Bajarea, D.; Sahmenkoa, G.; Korjakins, A. Comparative life cycle assessment of magnesium binders as an alternative for hemp concrete. Resour. Conserv. Recycl. 2018, 133, 288–299. [Google Scholar] [CrossRef]

- United Nations Decade for Deserts and the Fight Against Desertification, 2010. UN 2010-2020 DDD (Drylands Deserts and Desertification). Available online: https://www.un.org/en/events/desertification_decade/whynow.shtml (accessed on 6 October 2022).

- International Organization for Standardization (I.S.O.). 14040: Life Cycle Assessment—Principles and Framework; ISO: London, UK, 2006. [Google Scholar]

- Pearlmutter, D.; Meir, I.A.; Huberman-Meraiot, N. The Embodied Energy of Building Materials in Israel. The Jacob Blaustein Institutes for Desert Research, Ben-Gurion University of the Negev: Ben-Gurion, Israel, 2013. [Google Scholar]

| LHC Ingredient | EE [MJ/kg] | EC [kg CO2/kg] |

|---|---|---|

| Hemp shives | 0.0014 1 | −1.8 1 |

| Lime | 5.3 | 0.74 |

| Unfired binder | 0.1 | 0.005 |

| Material | Density [kg/m3] | Weight [kg/Building] | EE [MJ/kg] | EE [MJ/m3] | EC [kgCO2/kg] |

|---|---|---|---|---|---|

| LHC_0 | 330 | 12,144 | 3.53 | 1166 | −0.11 |

| LHC_50 | 330 | 12,144 | 1.8 | 594 | −0.35 |

| LHC_100 | 330 | 12,144 | 0.067 | 22 | −0.60 |

| AAC | 500 | 18,400 | 3.5 1 | 1536 2 | 0.3–0.288 1 |

| HCB | 1030 | 37,904 | 0.6 1 | 1216 2 | 0.06 1 |

| EPS | 43 | 1582 | 88.6 1 | 2710 2 | 2.5 1 |

| Material | EE Savings [%] | EC Savings [%] |

|---|---|---|

| LHC_0 | 98 | 82 |

| LHC_50 | 96 | 41 |

| AAC | 99 | 171–195 |

| HCB | 96 1–98 2 | 132 |

| EPS | 99 | 154 |

| Operational Energy (OE) | Operational Carbon (OC) | |||

|---|---|---|---|---|

| [kWh/Year] | [GJ/Year] | [GJ/50 Years] | [kgCO2/50 Years] | |

| LHC | 719 | 2.59 | 129 | 28,468 |

| AAC | 1173 | 4.22 | 211 | 46,442 |

| HCB | 6847 | 24.65 | 1232 | 271,128 |

| EPS | 1185 | 4.27 | 213 | 46,948 |

| Energy Savings [%] | CO2 Savings [%] | ||

|---|---|---|---|

| LHC_0 | 24 | 22 | |

| LHC_50 | 14 | 12 | |

| AAC | 53 * | 51 ** | 59–60 |

| HCB | 90 * | 90 ** | 92 |

| EPS | 63 * | 58 ** | 58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haik, R.; Meir, I.A.; Peled, A. Lime Hemp Concrete with Unfired Binders vs. Conventional Building Materials: A Comparative Assessment of Energy Requirements and CO2 Emissions. Energies 2023, 16, 708. https://doi.org/10.3390/en16020708

Haik R, Meir IA, Peled A. Lime Hemp Concrete with Unfired Binders vs. Conventional Building Materials: A Comparative Assessment of Energy Requirements and CO2 Emissions. Energies. 2023; 16(2):708. https://doi.org/10.3390/en16020708

Chicago/Turabian StyleHaik, Rotem, Isaac A. Meir, and Alva Peled. 2023. "Lime Hemp Concrete with Unfired Binders vs. Conventional Building Materials: A Comparative Assessment of Energy Requirements and CO2 Emissions" Energies 16, no. 2: 708. https://doi.org/10.3390/en16020708

APA StyleHaik, R., Meir, I. A., & Peled, A. (2023). Lime Hemp Concrete with Unfired Binders vs. Conventional Building Materials: A Comparative Assessment of Energy Requirements and CO2 Emissions. Energies, 16(2), 708. https://doi.org/10.3390/en16020708