Integrated Energy System Powered a Building in Sharjah Emirates in the United Arab Emirates

Abstract

1. Introduction

- Build a hybrid system to produce green hydrogen for a residential office building in Sharjah in the United Arab Emirates.

- Optimize the size of the components of the hybrid system using the optimizer tool in HOMER Pro software.

- Compare the green hydrogen hybrid system with the base case hybrid system based on solar PV, diesel generator, and battery system in terms of the 3E aspects.

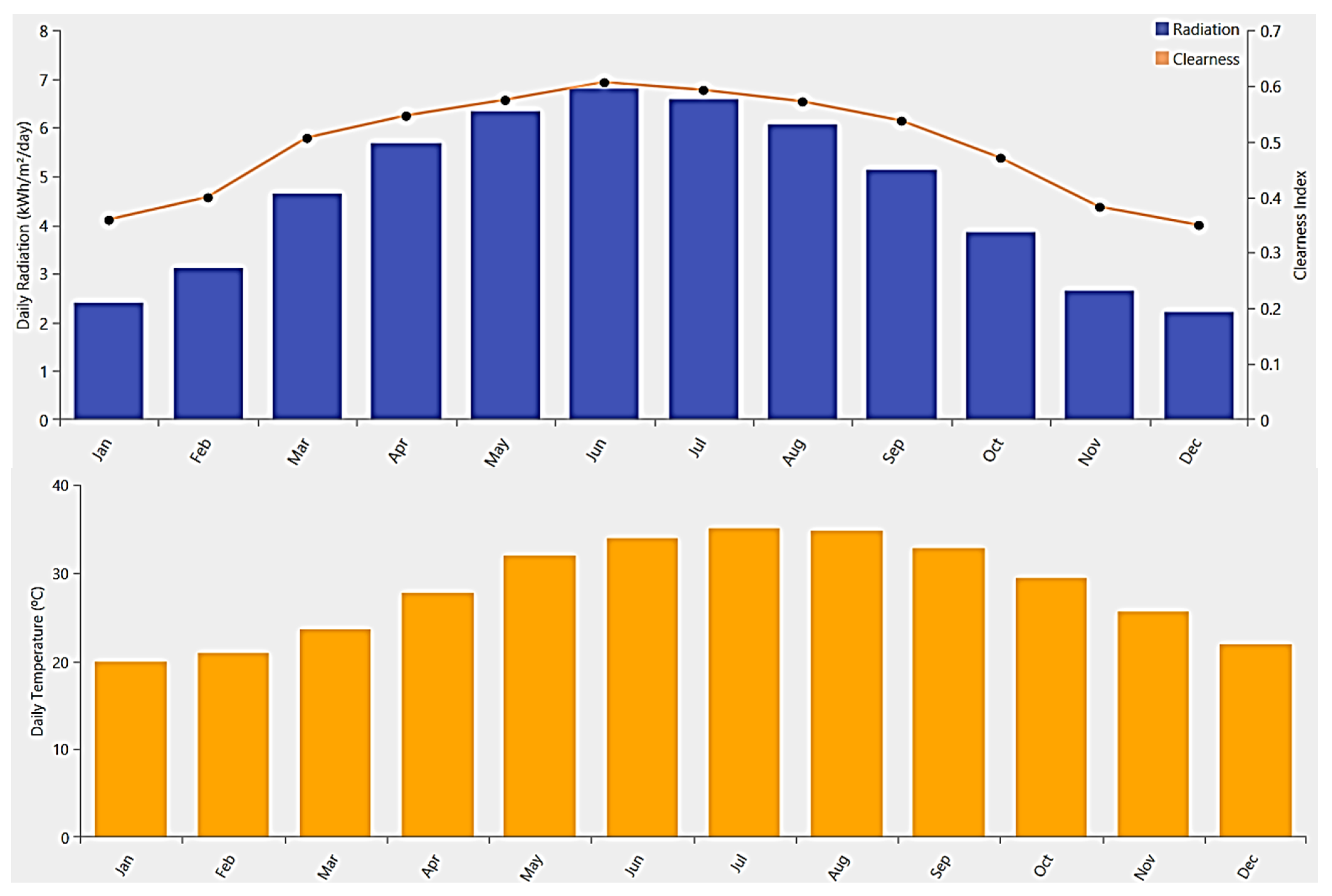

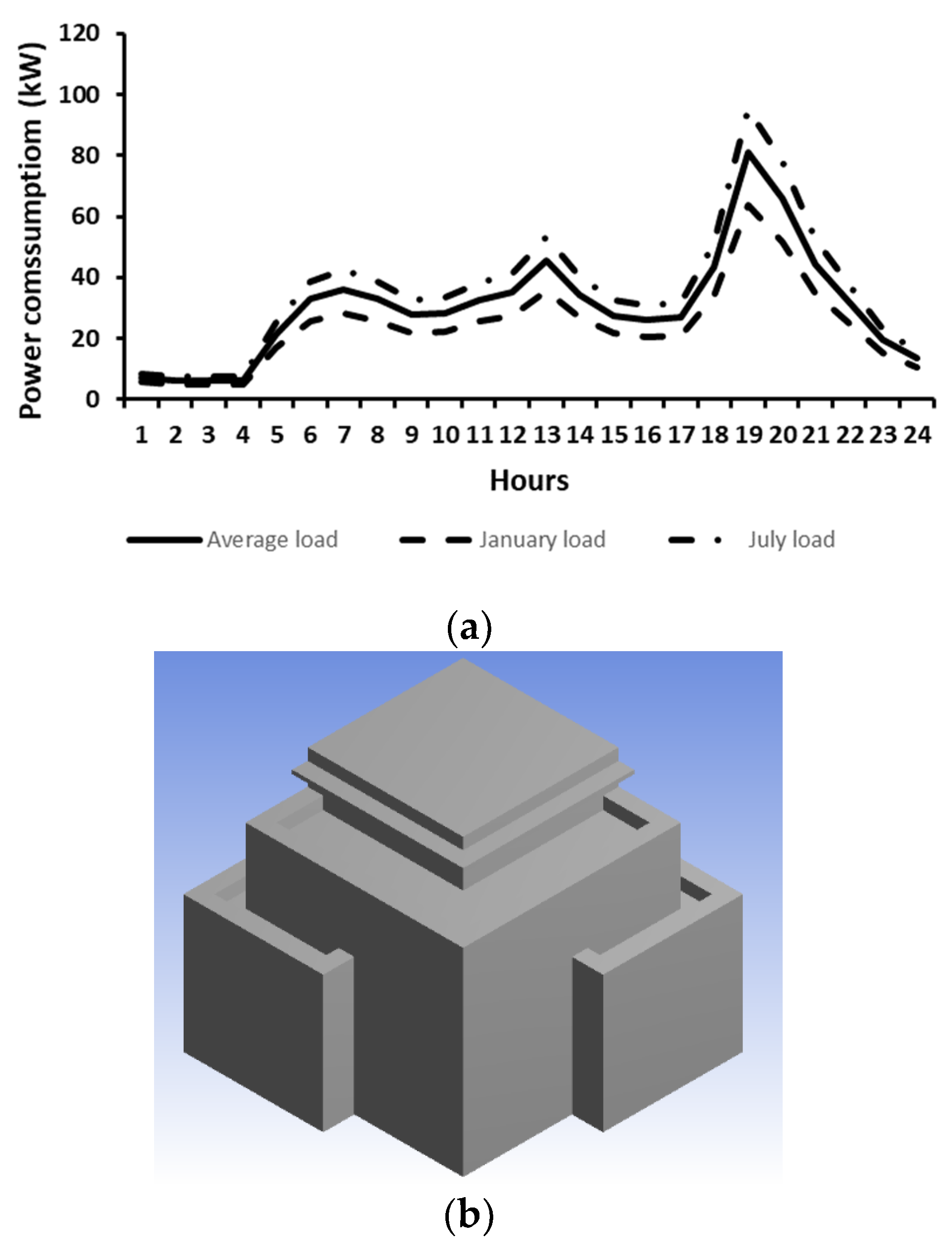

2. Energy Resources, Weather Conditions, and Load

3. Sizing and Modelling of the Green Hydrogen Energy System

3.1. Photovoltaic Array

3.2. Fuel Cell

3.3. Electrolyzer

3.4. Diesel Generator

3.5. Converter

3.6. Battery Energy Storage System

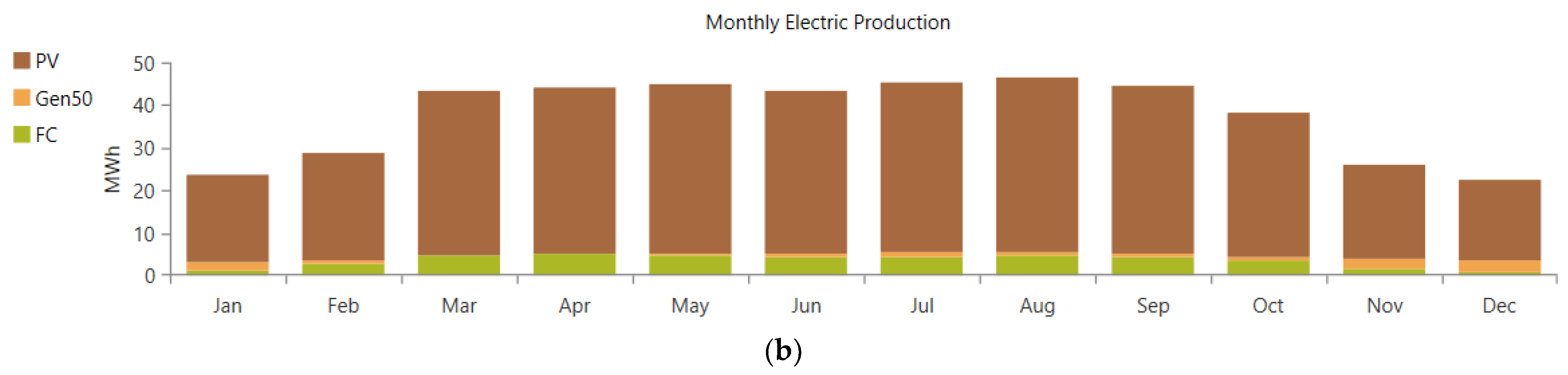

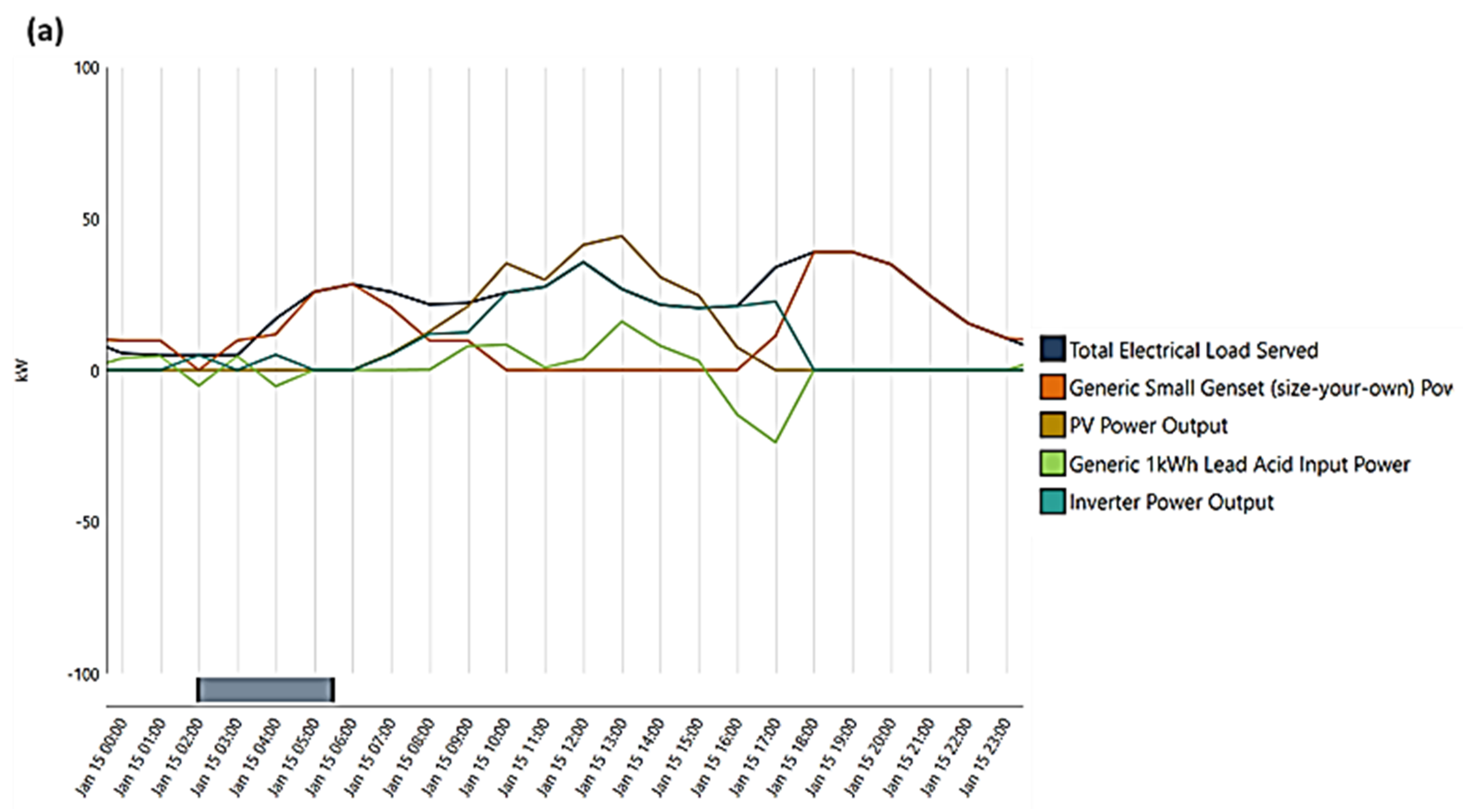

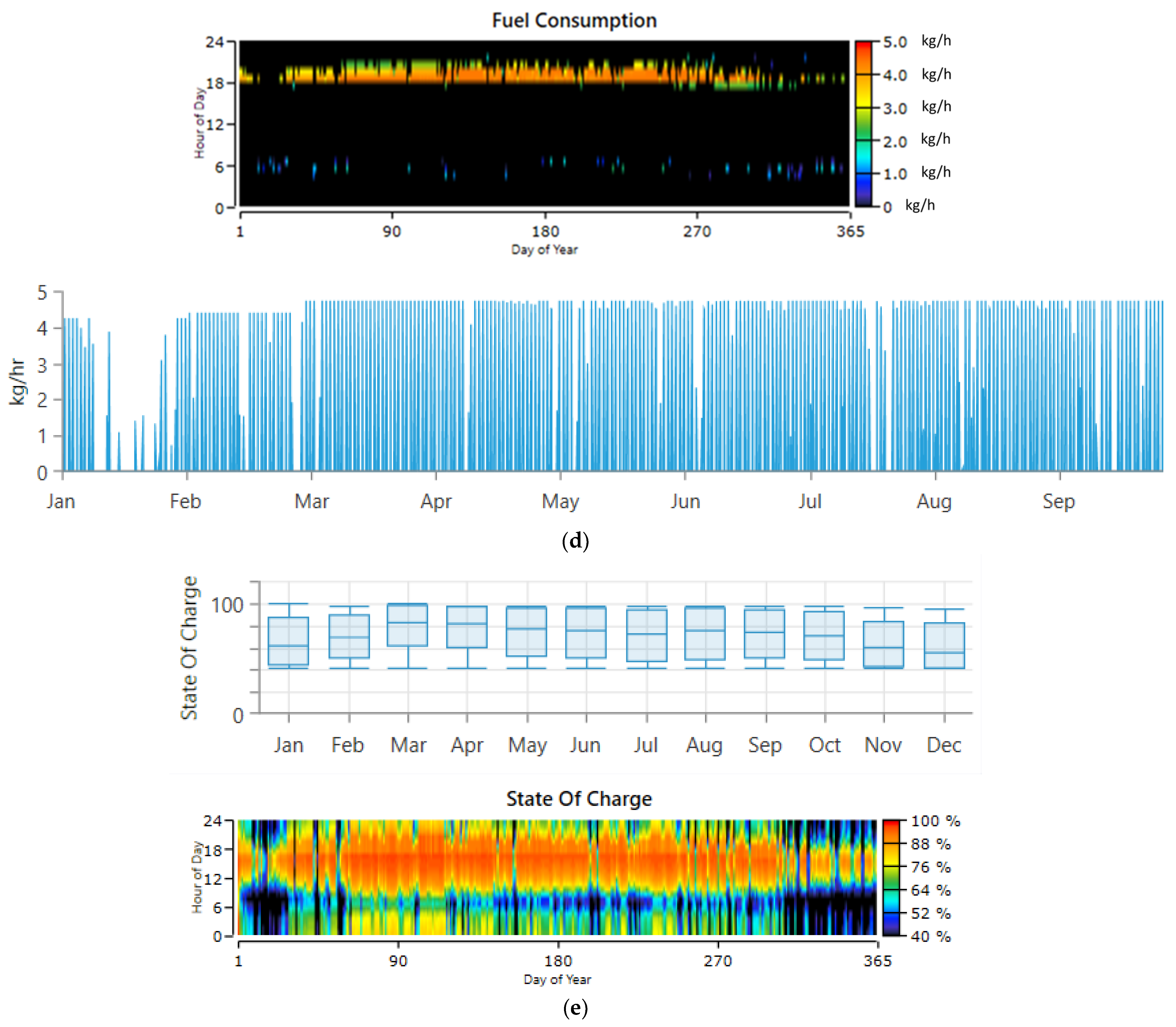

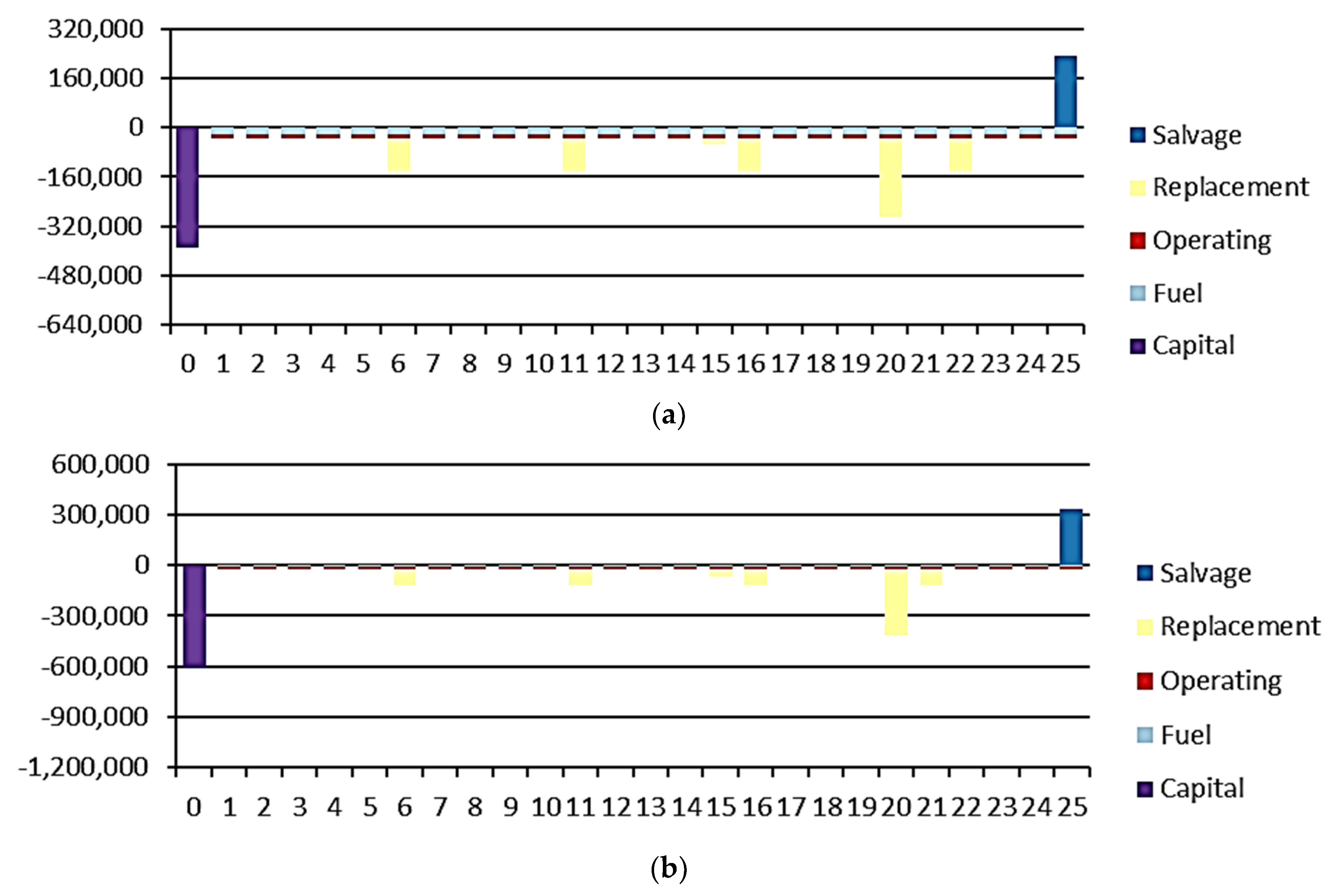

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AWE | Alkaline water electrolyzer |

| APV | The PV panel’s area. |

| COE | The cost of energy |

| CO2 | Carbon Dioxide |

| CO | Carbon Monoxide |

| DOD | Depth of discharge |

| Econs | The total energy consumption |

| Enonren | The conventional energy source |

| fPV | The solar PV’s derating factor |

| fren | The system’s fraction of utilized renewable energy |

| F0and F1 | The manufacturer’s fuel consumption coefficients |

| GT | The actual amount of solar insolation |

| GFC | The consumption of fuel in the DG |

| GFC | the generator fuel consumption rate. |

| GSTC | The amount of solar insolation at 1000 W/m2 and 25 °C during STC |

| HC | Hydrocarbons |

| HOMER Pro | Hybrid Optimization Model for Multiple Energy Resources |

| Higher heating value of the hydrogen fuel | |

| HRES | Hybrid renewable energy systems |

| Value of the charging current | |

| LCOH | The Levelized Cost of hydrogen |

| LCOE | Levelized Cost of Electricity |

| LHV | Lower heating value-based DG efficiency |

| LHVD | The calorific value of diesel based on water vapor |

| The mass rate of hydrogen in the electrolyzer in kg/s | |

| N | The number of cells in series |

| Ns | Solar PV arrays with multiple panels connected in series |

| Np | Solar PV arrays with multiple panels connected in parallel |

| NOx | Nitrogen oxides |

| PV-DG-FC-BES | Solar PV, a fuel cell, a diesel generator, and battery energy storage system |

| PV-DG-BES | Solar PV, a Diesel Generator, and Battery Energy Storage |

| PV-DG-FC-BES | Solar PV, fuel cell, diesel generator, and battery energy storage |

| PPV | The power production from the PV panel |

| PmSTC | The solar PV panel power at a maximum point under STC. |

| Pm | The solar PV panel’s maximum power under the actual operating conditions |

| The electrolyzer’s power consumption | |

| PDG | The power production from the generator |

| PL | The power demand |

| PFC | The amount of the fuel’s chemical energy that is not converted into fuel cell electricity |

| PInvOut | The output power to the inverter, |

| PInvIn | The input of the power to the inverter |

| The battery’s discharge power | |

| The power of the battery bank | |

| RES | Renewable energy system |

| STC | Standard test conditions |

| SOC | Battery’s electrical charge or state of charge |

| SOCmax | The maximum allowed SOC |

| SOCmin | The minimum limit of the SOC |

| SOx | Sulphur oxides |

| Tc,STC | The solar PV’s cell temperature under STC, |

| Tc | The solar PV’s cell temperature, |

| t | The current time |

| UAE | United Arab Emirates |

| USC | Single-cell voltage |

| Vbat | the terminal voltage of the battery terminal. |

| YDG | The DG’s nominal power. |

| αP | The temperature coefficient of power. |

| δ | The self-discharge coefficient |

| ηmp,STC | PV panels’ maximum efficiency at STC |

| The actual efficiency of the Fuel cell | |

| ηEZ | The electrolyzer’s efficiency |

| The inverter efficiency. | |

| ηch | The battery’s efficiency |

| ηdch | The discharge efficiency |

| Δt | Time interval |

References

- Olabi, A.G.; Rezk, H.; Sayed, E.T.; Ghoniem, R.M.; Abdelkareem, M.A. Boosting carbon dioxide adsorption capacity applying Jellyfish optimization and ANFIS-based modelling. Ain Shams Eng. J. 2022, 14, 101931. [Google Scholar] [CrossRef]

- Olabi, A.G.; Wilberforce, T.; Elsaid, K.; Sayed, E.T.; Maghrabie, H.M.; Abdelkareem, M.A. Large scale application of carbon capture to process industries—A review. J. Clean. Prod. 2022, 362, 132300. [Google Scholar] [CrossRef]

- Caponi, R.; Bocci, E.; Del Zotto, L. Techno-economic model for scaling up of hydrogen refueling stations. Energies 2022, 15, 7518. [Google Scholar] [CrossRef]

- Bresa, Q.; Kovač, A.; Marciuš, D. Introduction of hydrogen in the Kosovo transportation sector. Energies 2022, 15, 7275. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Soudan, B.; Mahmoud, M.S.; Sayed, E.T.; AlMallahi, M.N.; Inayat, A.; Radi, M.A.; Olabi, A.G. Progress of artificial neural networks applications in hydrogen production. Chem. Eng. Res. Des. 2022, 182, 66–86. [Google Scholar] [CrossRef]

- De Simio, L.; Iannaccone, S.; Masi, M.; Gobbato, P. Experimental study and optimisation of a non-conventional ignition system for reciprocating engines operation with hydrogen–methane blends, syngas, and biogas. Energies 2022, 15, 8270. [Google Scholar] [CrossRef]

- Acar, C.; Beskese, A.; Temur, G.T. Sustainability analysis of different hydrogen production options using hesitant fuzzy AHP. Int. J. Hydrogen Energy 2018, 43, 18059–18076. [Google Scholar] [CrossRef]

- Demir, M.E.; Dincer, I. Cost assessment and evaluation of various hydrogen delivery scenarios. Int. J. Hydrogen Energy 2018, 43, 10420–10430. [Google Scholar] [CrossRef]

- Diab, J.; Fulcheri, L.; Hessel, V.; Rohani, V.; Frenklach, M. Why turquoise hydrogen will Be a game changer for the energy transition. Int. J. Hydrogen Energy 2022, 47, 25831–25848. [Google Scholar] [CrossRef]

- Chen, S.; Pei, C.; Gong, J. Insights into interface engineering in steam reforming reactions for hydrogen production. Energy Environ. Sci. 2019, 12, 3473–3495. [Google Scholar] [CrossRef]

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen production for energy: An overview. Int. J. Hydrogen Energy 2020, 45, 3847–3869. [Google Scholar] [CrossRef]

- Hermesmann, M.; Müller, T.E. Green, turquoise, blue, or grey? Environmentally friendly hydrogen production in transforming energy systems. Prog. Energy Combust. Sci. 2022, 90, 100996. [Google Scholar] [CrossRef]

- Grigoriev, S.A.; Fateev, V.N.; Bessarabov, D.G.; Millet, P. Current status, research trends, and challenges in water electrolysis science and technology. Int. J. Hydrogen Energy 2020, 45, 26036–26058. [Google Scholar] [CrossRef]

- Fragiacomo, P.; Genovese, M. Technical-economic analysis of a hydrogen production facility for power-to-gas and hydrogen mobility under different renewable sources in Southern Italy. Energy Convers. Manag. 2020, 223, 113332. [Google Scholar] [CrossRef]

- Hurtubia, B.; Sauma, E. Economic and environmental analysis of hydrogen production when complementing renewable energy generation with grid electricity. Appl. Energy 2021, 304, 117739. [Google Scholar] [CrossRef]

- Karayel, G.K.; Javani, N.; Dincer, I. Green hydrogen production potential for Turkey with solar energy. Int. J. Hydrogen Energy 2022, 47, 19354–19364. [Google Scholar] [CrossRef]

- Kakoulaki, G.; Kougias, I.; Taylor, N.; Dolci, F.; Moya, J.; Jäger-Waldau, A. Green hydrogen in Europe—A regional assessment: Substituting existing production with electrolysis powered by renewables. Energy Convers. Manag. 2021, 228, 113649. [Google Scholar] [CrossRef]

- Bhandari, R. Green hydrogen production potential in West Africa—Case of Niger. Renew. Energy 2022, 196, 800–811. [Google Scholar] [CrossRef]

- Barhoumi, E.M.; Okonkwo, P.C.; Ben Belgacem, I.; Zghaibeh, M.; Tlili, I. Optimal sizing of photovoltaic systems based green hydrogen refueling stations case study Oman. Int. J. Hydrogen Energy 2022, 47, 31964–31973. [Google Scholar] [CrossRef]

- Hoelzen, J.; Silberhorn, D.; Zill, T.; Bensmann, B.; Hanke-Rauschenbach, R. Hydrogen-powered aviation and its reliance on green hydrogen infrastructure—Review and research gaps. Int. J. Hydrogen Energy 2022, 47, 3108–3130. [Google Scholar] [CrossRef]

- Longoria, G.; Lynch, M.; Curtis, J. Green hydrogen for heating and its impact on the power system. Int. J. Hydrogen Energy 2021, 46, 26725–26740. [Google Scholar] [CrossRef]

- Benalcazar, P.; Komorowska, A. Prospects of green hydrogen in Poland: A techno-economic analysis using a Monte Carlo approach. Int. J. Hydrogen Energy 2022, 47, 5779–5796. [Google Scholar] [CrossRef]

- Kuckshinrichs, W.; Koj, J.C. Levelized cost of energy from private and social perspectives: The case of improved alkaline water electrolysis. J. Clean. Prod. 2018, 203, 619–632. [Google Scholar] [CrossRef]

- Nasser, M.; Megahed, T.F.; Ookawara, S.; Hassan, H. Performance evaluation of PV panels/wind turbines hybrid system for green hydrogen generation and storage: Energy, exergy, economic, and enviroeconomic. Energy Convers. Manag. 2022, 267, 115870. [Google Scholar] [CrossRef]

- Salameh, T.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A.G.; Rezk, H. Optimal selection and management of hybrid renewable energy System: Neom city as a case study. Energy Convers. Manag. 2021, 244, 114434. [Google Scholar] [CrossRef]

- Rezk, H.; Sayed, E.T.; Al-Dhaifallah, M.; Obaid, M.; El-Sayed, A.H.M.; Abdelkareem, M.A.; Olabi, A.G. Fuel cell as an effective energy storage in reverse osmosis desalination plant powered by photovoltaic system. Energy 2019, 175, 423–433. [Google Scholar] [CrossRef]

- Lee, B.; Lee, H.; Cho, H.-S.; Cho, W.-C.; Kim, C.-H.; Lim, H. Projected economic outlook and scenario analysis for H2 production by alkaline water electrolysis on the basis of the unit electricity price, the learning rate, and the automation level. Sustain. Energy Fuels 2019, 3, 1799–1807. [Google Scholar] [CrossRef]

- Al-Badi, A.; Al Wahaibi, A.; Ahshan, R.; Malik, A. Techno-economic feasibility of a solar-wind-fuel cell energy system in Duqm, Oman. Energies 2022, 15, 5379. [Google Scholar] [CrossRef]

- Pal, P.; Mukherjee, V.; Kumar, P.; Makhatha, M.E. Viability analysis of Direct Current (DC) standalone hybrid Photovoltaic (PV)/Hydrogen Fuel Cell (HFC) energy system: A techno-economic approach. Mater. Today Proc. 2021, 39, 1807–1812. [Google Scholar] [CrossRef]

- Pal, P.; Mukherjee, V. Off-grid solar photovoltaic/hydrogen fuel cell system for renewable energy generation: An investigation based on techno-economic feasibility assessment for the application of end-user load demand in North-East India. Renew. Sustain. Energy Rev. 2021, 149, 111421. [Google Scholar] [CrossRef]

- Tiam Kapen, P.; Medjo Nouadje, B.A.; Chegnimonhan, V.; Tchuen, G.; Tchinda, R. Techno-economic feasibility of a PV/battery/fuel cell/electrolyzer/biogas hybrid system for energy and hydrogen production in the far north region of cameroon by using HOMER pro. Energy Strategy Rev. 2022, 44, 100988. [Google Scholar] [CrossRef]

- Han, J.; Feng, J.; Chen, P.; Liu, Y.; Peng, X. A review of key components of hydrogen recirculation subsystem for fuel cell vehicles. Energy Convers. Manag. X 2022, 15, 100265. [Google Scholar] [CrossRef]

- Venkatasatish, R.; Dhanamjayulu, C. Reinforcement learning based energy management systems and hydrogen refuelling stations for fuel cell electric vehicles: An overview. Int. J. Hydrogen Energy 2022, 47, 27646–27670. [Google Scholar] [CrossRef]

- Olabi, A.G.; Wilberforce, T.; Alanazi, A.; Vichare, P.; Sayed, E.T.; Maghrabie, H.M.; Elsaid, K.; Abdelkareem, M.A. Novel trends in proton exchange membrane fuel cells. Energies 2022, 15, 4949. [Google Scholar] [CrossRef]

- Rezk, H.; Ferahtia, S.; Sayed, E.T.; Abdelkareem, M.A.; Olabi, A.G. Robust parameter identification strategy of solid oxide fuel cells using bald eagle search optimization algorithm. Int. J. Energy Res. 2022, 46, 10535–10552. [Google Scholar] [CrossRef]

- Kumar, P.; Pal, N.; Sharma, H. Techno-economic analysis of solar photo-voltaic/diesel generator hybrid system using different energy storage technologies for isolated islands of India. J. Energy Storage 2021, 41, 102965. [Google Scholar] [CrossRef]

- Arif, M.S.B.; Mustafa, U.; Prabaharan, N.; Ayob, S.B.M.; Ahmad, J. Performance evaluation of a hybrid solar PV system with reduced emission designed for residential load in subtropical region. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–23. [Google Scholar] [CrossRef]

- Rezk, H.; Kanagaraj, N.; Al-Dhaifallah, M. Design and sensitivity analysis of hybrid photovoltaic-fuel-cell-battery system to supply a small community at Saudi NEOM City. Sustainability 2020, 12, 3341. [Google Scholar] [CrossRef]

| System Component | System I (PV-DG-BES) | System II (PV-FC-DG-BES) |

|---|---|---|

| Solar PV |

| |

| DG |

| |

| Fuel cell, Electrolyzer and Hydrogen tank |

| |

| Battery |

| |

| Converter |

| |

| Pollutant | Basic Hybrid System | Hydrogen Hybrid System |

|---|---|---|

| CO2 “Carbon Dioxide” (kg/yr.) | 54,293 | 11,864 |

| CO “Carbon Monoxide” (kg/yr.) | 339 | 90.5 |

| Unburned HC “Hydrocarbons” (kg/yr.) | 14.9 | 5.07 |

| Particulate Matter (kg/yr.) | 2.03 | 1.67 |

| SO2 “Sulphur Dioxide” (kg/yr.) | 133 | 29.1 |

| NOx “Nitrogen Oxides” (kg/yr.) | 319 | 215 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salameh, T.; Olabi, A.G.; Abdelkareem, M.A.; Masdar, M.S.; Kamarudin, S.K.; Sayed, E.T. Integrated Energy System Powered a Building in Sharjah Emirates in the United Arab Emirates. Energies 2023, 16, 769. https://doi.org/10.3390/en16020769

Salameh T, Olabi AG, Abdelkareem MA, Masdar MS, Kamarudin SK, Sayed ET. Integrated Energy System Powered a Building in Sharjah Emirates in the United Arab Emirates. Energies. 2023; 16(2):769. https://doi.org/10.3390/en16020769

Chicago/Turabian StyleSalameh, Tareq, Abdul Ghani Olabi, Mohammad Ali Abdelkareem, Mohd Shahbudin Masdar, Siti Kartom Kamarudin, and Enas Taha Sayed. 2023. "Integrated Energy System Powered a Building in Sharjah Emirates in the United Arab Emirates" Energies 16, no. 2: 769. https://doi.org/10.3390/en16020769

APA StyleSalameh, T., Olabi, A. G., Abdelkareem, M. A., Masdar, M. S., Kamarudin, S. K., & Sayed, E. T. (2023). Integrated Energy System Powered a Building in Sharjah Emirates in the United Arab Emirates. Energies, 16(2), 769. https://doi.org/10.3390/en16020769