Energy-Consumption Pattern-Detecting Technique for Household Appliances for Smart Home Platform

Abstract

1. Introduction

- A pattern-detecting method for different appliances (cyclic and noncyclic) has been developed that is quite simple, computationally less complex, and that can accurately disaggregate energy-consumption cycles occurred in the close succession. Moreover, the algorithm developed herein could be applied to any device dataset.

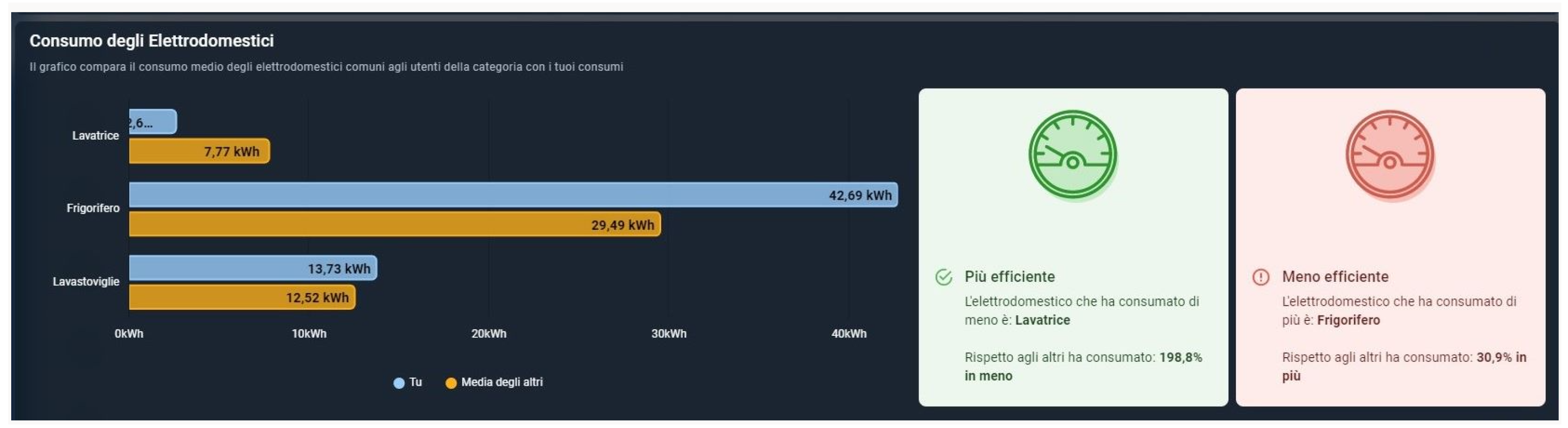

- The developed algorithms have been implemented in a code used to process the data acquired by a IoT platform developed by ENEA and currently operating in some dwellings, aimed at fostering user engagement and energy awareness by providing customised feedbacks to the users.

- The DHOMUS platform uses open and interoperable protocols for data acquisition at the device and HEMS level and, therefore, can be easily replicated in broader contexts.

2. Literature Review

3. DHOMUS Platform

3.1. Datasets

4. Methodology

4.1. Appliance Data Analysis Model

- Minimum cycle duration, i.e., shorter operations are neglected;

- Minimum cycle energy consumption, i.e., operations with a smaller consumption are neglected;

- Parameters for the separation of nearby cycles;

- Threshold to skip the analysis for those months when insufficient data are available;

- Energy threshold to distinguish low consumption cycles;

- Time threshold for short cycles; and

- Time threshold for long cycles.

4.2. Information Analysis

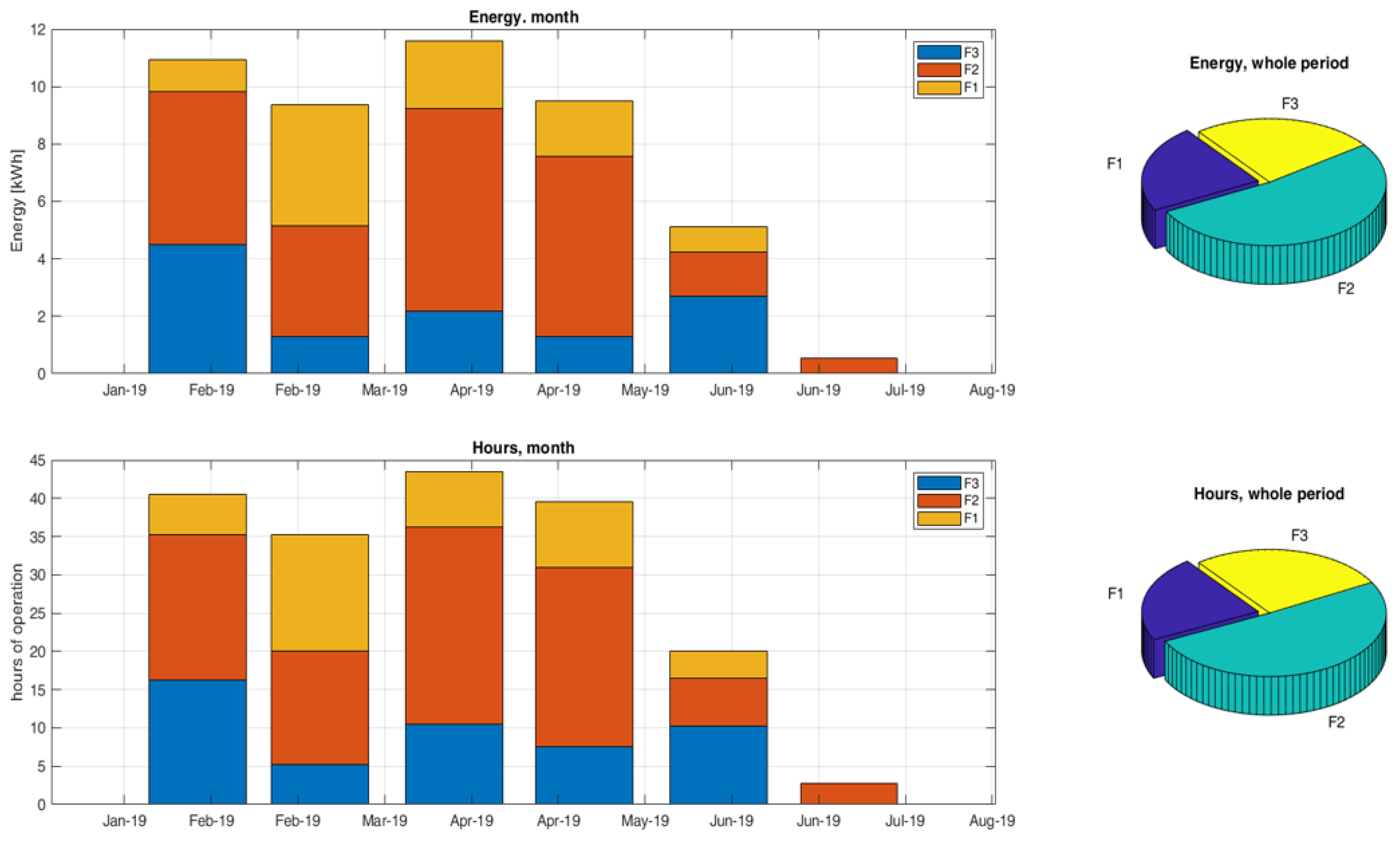

- F1: from Monday to Friday, from 8 a.m. to 7 p.m. (except holidays);

- F2: from Monday to Friday from 7 a.m. to 8 a.m. and from 7 p.m. to 11 p.m., Saturday from 7 a.m. to 11 p.m., (except holidays); and

- F3: from Monday to Saturday, from 12 a.m. to 7 a.m. and from 11 p.m. to 12 a.m., Sundays and holidays.

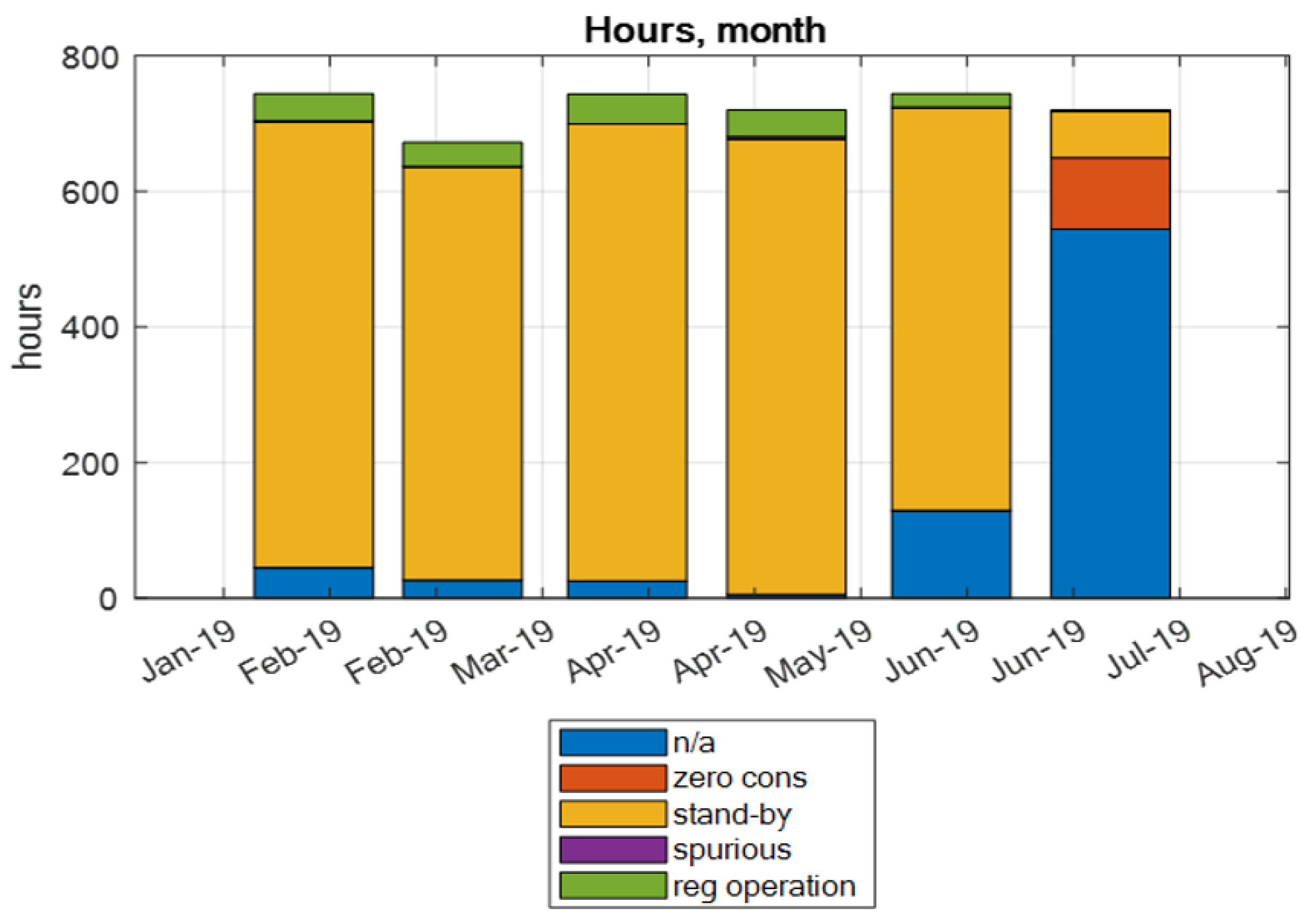

- a.

- Number of records in the dataset;

- b.

- Number of NULL records, i.e., with sensor disconnected or inactive;

- c.

- Number of records with zero consumption;

- d.

- Number of records when the appliance is in standby mode;

- e.

- Number of spurious records, i.e., characterized by either duration or consumption below the input thresholds;

- f.

- Number of records when the appliance is operative;

- g.

- Number of records when the appliance is operative during F1 time slot;

- h.

- Number of records when the appliance is operative during F2 time slot;

- i.

- Number of records when the appliance is operative during F3 time slot; and

- j.

- Number of records when the appliance is operative during the i-th custom time slot, for all daytime slots set as input.

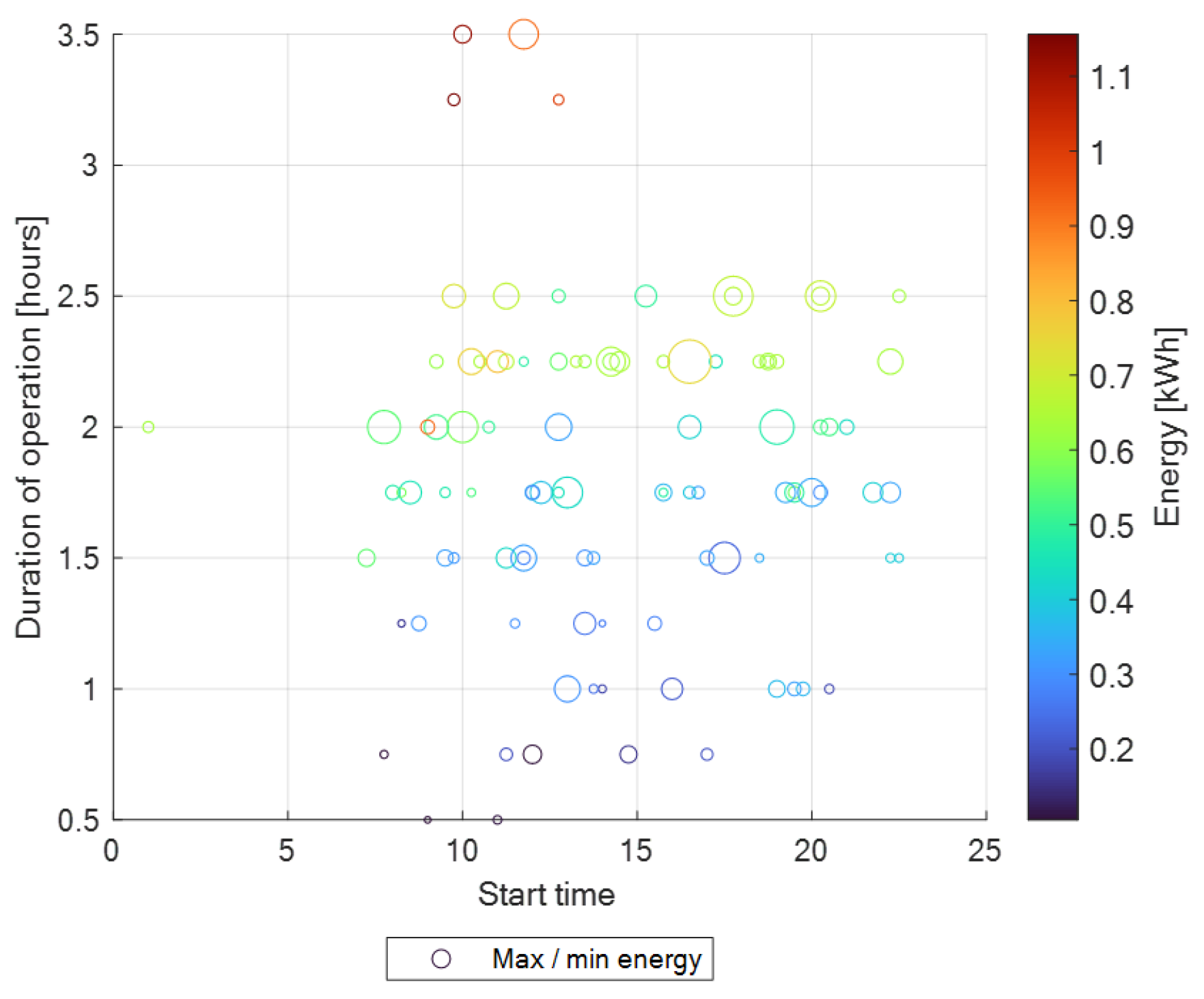

- Cycles with consumption above the minimum input value;

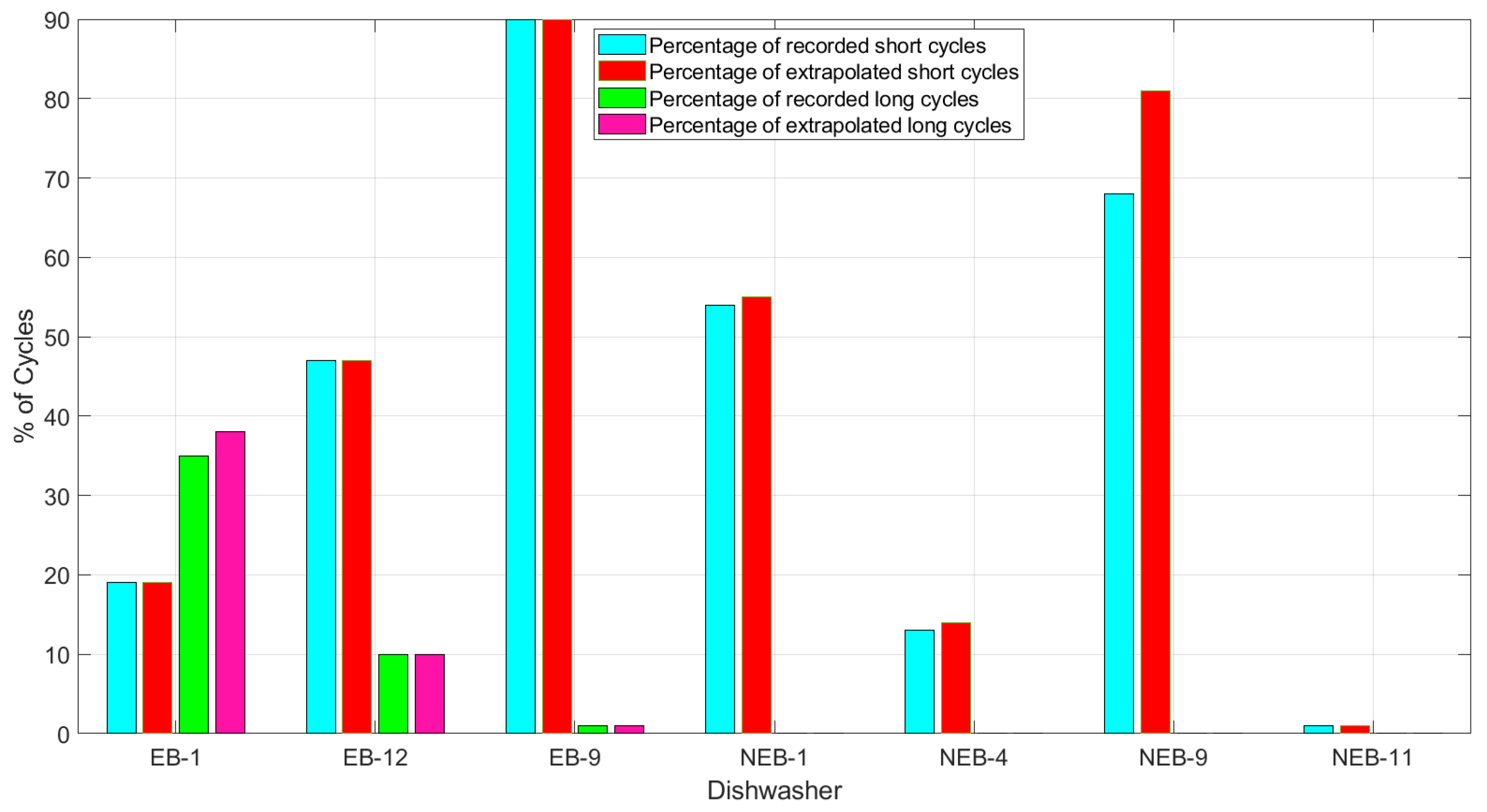

- Cycles with duration less than the input threshold (short cycles);

- Cycles with duration between boundaries and (medium cycles); and

- Cycles with duration greater than the input threshold (long cycles).

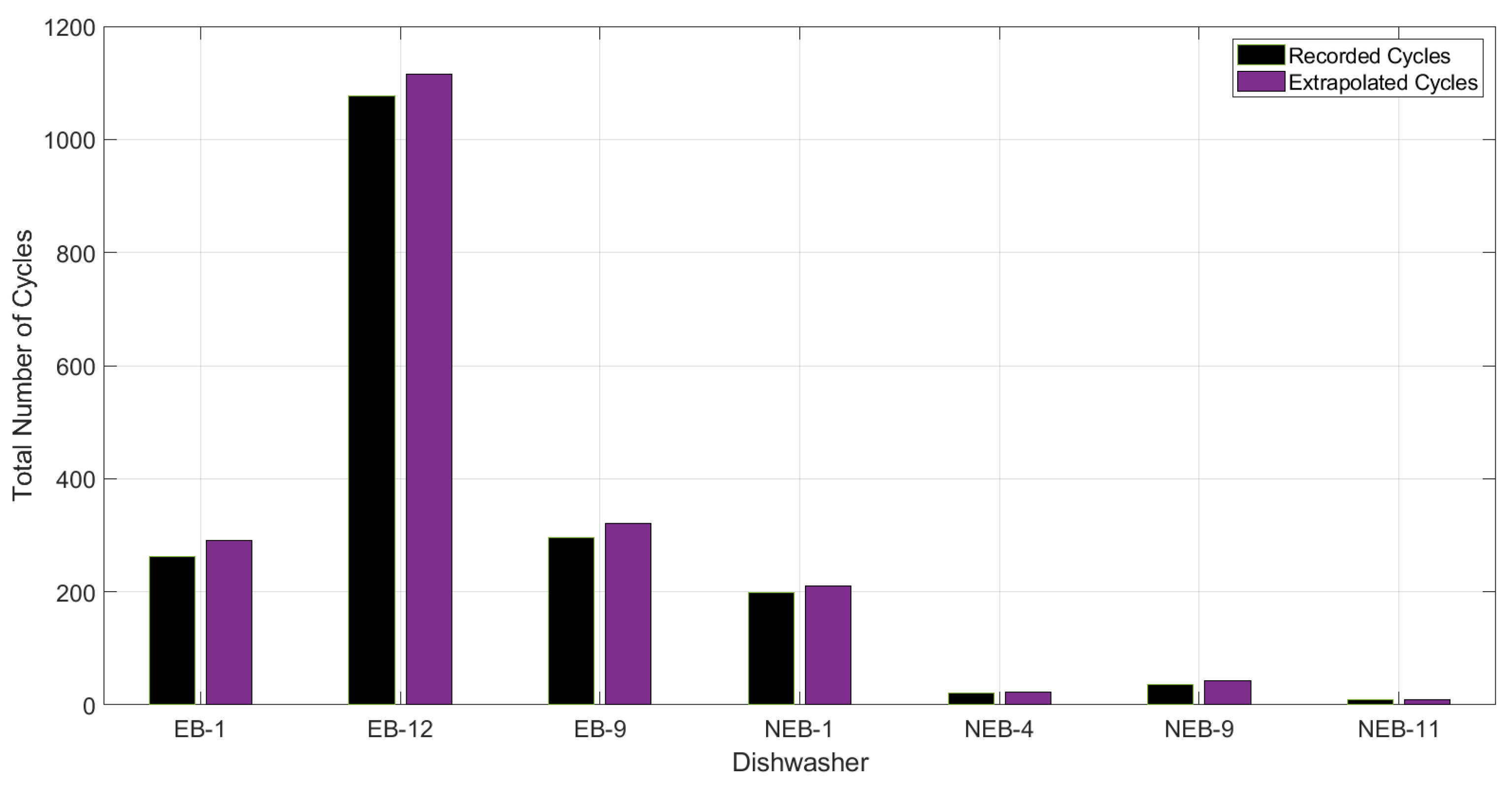

- Percentage of records in the month;

- Number of cycles recorded;

- Number of cycles extrapolated for every month, in the presence of missing data (i.e., the sensor returns NULL) and within the limits of acceptability set as input parameter (e.g., months with only 10% of records are discarded, because extrapolation over the month would not be reliable);

- Number of cycles extrapolated on annual basis, that comply similar condition on missing data as for monthly extrapolation;

- Average cycle duration;

- Average cycle consumption;

- Maximum consumption; and

- Minimum consumption.

5. Results and Discussion

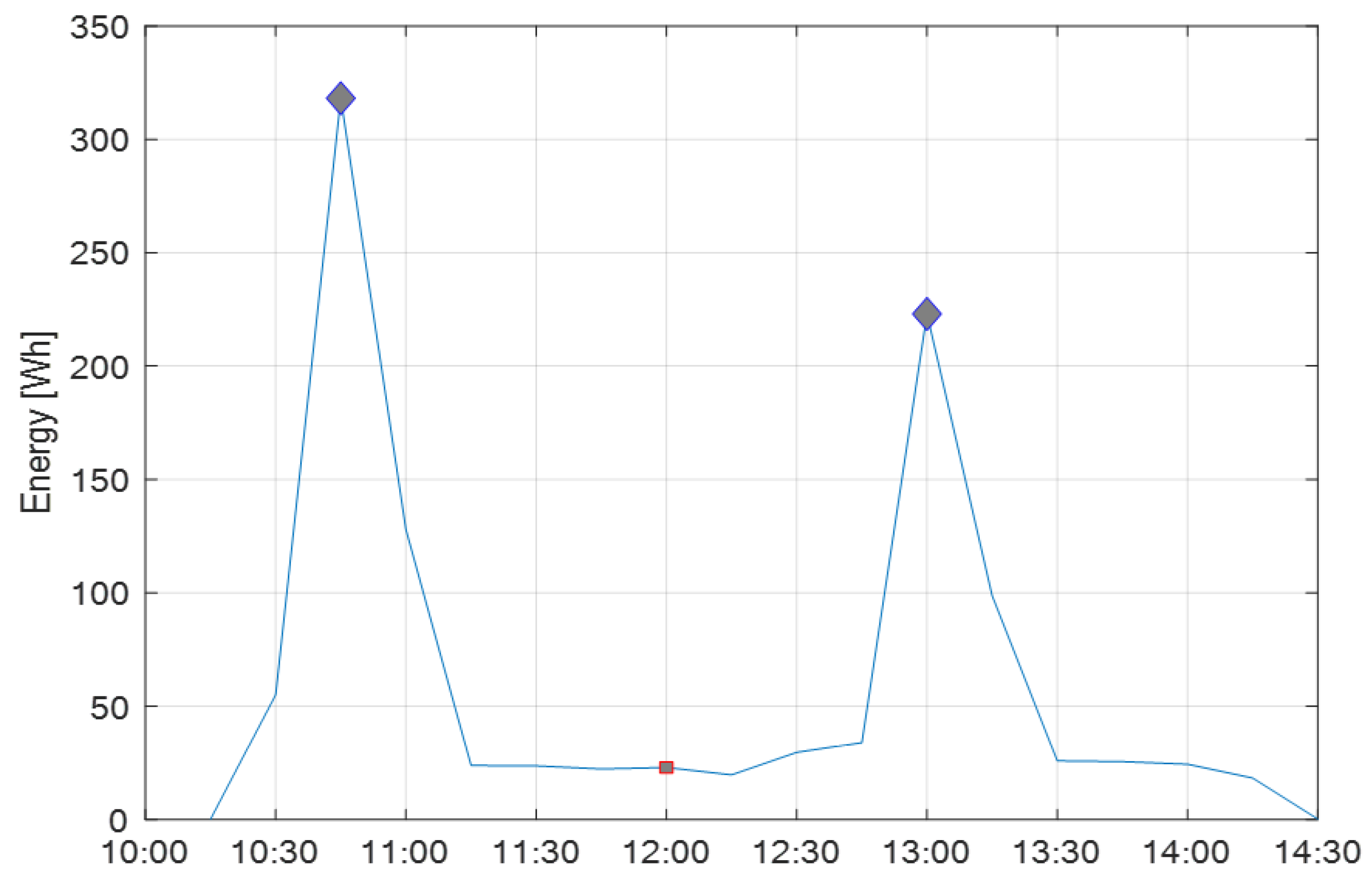

5.1. Calibration of Parameters

5.2. Algorithm Results

5.3. Comparative Analysis

5.4. Feedbacks to the Consumer in DHOMUS Platform

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations and Symbols

| DHOMUS | ENEA’s Data Homes and Users Platform |

| DR | Demand response |

| EC | Energy class |

| HEMS | Home Energy Management System |

| IoT | Internet of Things |

| NoP | Number of people |

| SH | Smart home |

| NILM | Non-intrusive load monitoring |

| Total Numbers of cycles | |

| Recorded cycles | |

| Extrapolated cycles | |

| Percentage of energy consumption during peak hours | |

| Percentage of recorded short cycles | |

| Percentage of extrapolated short cycles | |

| Lower cycle duration limit (short cycles) | |

| Higher cycle duration limit (long cycles) | |

| Energy consumption of short cycles | |

| Percentage of recorded long cycles | |

| Percentage of extrapolated long cycles | |

| Energy consumption of long cycles | |

| Energy consumption function over time | |

| Empirical cumulative density function | |

| U | Standby energy |

| Aggregated cycles | |

| Y | Gradient over aggregated cycles |

Appendix A

| Home | Appliance | Start Date | End Date | Time Span Days | Available Data | Data Holes |

|---|---|---|---|---|---|---|

| EB-1 | Fridge | 21/02/2018 | 28/03/2020 | 766 | 61.89% | July–August 2019 |

| EB-1 | Dish washer | 20/02/2018 | 28/03/2020 | 767 | 61.37% | July–August 2019 |

| EB-1 | Washing machine | 21/02/2018 | 28/03/2020 | 766 | 45.30% | July–November 2019 |

| EB-1 | Tv | 21/02/2018 | 28/03/2020 | 766 | 37.77% | July–November 2019 |

| EB-2 | Fridge | 22/02/2018 | 28/03/2020 | 765 | 34.73% | March 2019–March 2020 |

| EB-2 | Bimby | 22/02/2018 | 28/03/2020 | 765 | 28.60% | March2019–March 2020 |

| EB-2 | Washing machine | 22/02/2018 | 28/03/2020 | 765 | 33.76% | March2019–March 2020 |

| EB-2 | Lamp | 22/02/2018 | 28/03/2020 | 765 | 28.57% | March 2019–March 2020 |

| EB-2 | Fan heater | 22/02/2018 | 28/03/2020 | 765 | 15.89% | March 2019–March 2020 |

| EB-3 | Fridge | 14/04/2018 | 28/03/2020 | 714 | 87.83% | Nov-18 |

| EB-3 | Air conditioner | 14/04/2018 | 28/03/2020 | 714 | 85.16% | Nov-18 |

| EB-3 | Washing machine | 01/03/2018 | 28/03/2020 | 758 | 10.26% | March 2018, November 2018 |

| EB-3 | Microwave | 14/04/2018 | 28/03/2020 | 714 | 86.41% | Nov-18 |

| EB-4 | Vacuum cleaner | 02/03/2018 | 28/03/2020 | 757 | 5.58% | February 2020–March 2020 |

| EB-4 | Kettle | 02/03/2018 | 28/03/2020 | 757 | 44.95% | February 2020–March 2020 |

| EB-4 | Washing machine | 02/03/2018 | 28/03/2020 | 757 | 52.46% | February 2020–March 2020 |

| EB-4 | Tv | 02/03/2018 | 28/03/2020 | 757 | 58.91% | February 2020–March 2020 |

| EB-5 | Dish washer | 02/03/2018 | 28/03/2020 | 757 | 58.27% | March 2018, 2019, January 2020–March 2020 |

| EB-5 | Washing machine | 02/03/2018 | 28/03/2020 | 757 | 58.68% | March 2018,2019, January 2020–March 2020 |

| EB-5 | Coffee machine | 02/03/2018 | 28/03/2020 | 757 | 58.96% | March 2018,2019, January 2020–March 2020 |

| EB-6 | Fridge | 09/05/2018 | 28/03/2020 | 689 | 61.57% | June 2019–August 2019, January 2020–March 2020 |

| EB-6 | Dish washer | 09/05/2018 | 28/03/2020 | 689 | 52.80% | June 2019–August 2019, December 2019, January 2020–March 2020 |

| EB-6 | Washing machine | 09/05/2018 | 28/03/2020 | 689 | 59.37% | June 2019–August 2019, January 2020–March 2020 |

| EB-6 | Microwave | 05/03/2018 | 28/03/2020 | 754 | 48.17% | March 2018–April 2018, June 2019–August 2019, December 2019, January 2020–March 2020 |

| EB-7 | Fridge | 06/03/2018 | 28/03/2020 | 753 | 55.41% | July 2019–March 2020 |

| EB-7 | Dish washer | 06/03/2018 | 28/03/2020 | 753 | 47.23% | July 2019–March 2020 |

| EB-7 | Washing machine | 06/03/2018 | 28/03/2020 | 753 | 54.79% | July 2019–March 2020 |

| EB-7 | Microwave | 06/03/2018 | 28/03/2020 | 753 | 52.13% | July 2019–March 2020 |

| EB-8 | Vacuum cleaner | 09/03/2018 | 28/03/2020 | 750 | 29.95% | March 2018–April 2018, August 2018–September 2018, February–March 2020 |

| EB-8 | Washing machine | 06/03/2018 | 28/03/2020 | 753 | 47.61% | March 2018–April 2018, August 2018–September 2018, February–March 2020 |

| EB-8 | TV | 09/03/2018 | 28/03/2020 | 750 | 29.37% | March 2018–April 2018, August 2018–September 2018, February–March 2020 |

| EB-9 | Fridge | 05/04/2018 | 28/03/2020 | 723 | 65.16% | April 2018, January 2020–March 2020 |

| EB-9 | Dish washer | 06/04/2018 | 28/03/2020 | 722 | 65.10% | April 2018, January 2020–March 2020 |

| EB-9 | Washing machine | 05/04/2018 | 28/03/2020 | 723 | 26.81% | April 2018, January 2020–March 2020 |

| EB-9 | Microwave | 19/10/2018 | 28/03/2020 | 526 | 66.39% | January 2020–March 2020 |

| EB-9 | Fan heater | 05/04/2018 | 28/03/2020 | 723 | 64.51% | April 2018, January 2020–March 2020 |

| EB-10 | Fridge | 04/04/2018 | 28/03/2020 | 724 | 20.77% | August 2018–September 2018, March 2019–May 2019, August 2019–March 2020 |

| EB-10 | Dish washer | 05/04/2018 | 28/03/2020 | 723 | 20.67% | August 2018–September 2018, March 2019–May 2019, August 2019–March 2020 |

| EB-10 | Washing Machine | 04/04/2018 | 28/03/2020 | 724 | 20.56% | August 2018–September 2018, March 2019–May 2019, August 2019- March 2020 |

| EB-10 | TV | 05/04/2018 | 28/03/2020 | 723 | 20.75% | August 2018–September 2018, March 2019–May 2019, August 2019–March 2020 |

| EB-11 | Fridge | 19/06/2018 | 08/06/2020 | 720 | 79.84% | April–June 2020 |

| EB-11 | Washing machine | 20/06/2018 | 08/06/2020 | 719 | 79.46% | April–June 2020 |

| EB-11 | Lamp | 19/06/2018 | 08/06/2020 | 720 | 75.31% | April–June 2020 |

| EB-12 | Oven | 27/02/2018 | 31/01/2020 | 703 | 82.25% | No Holes |

| EB-12 | Dryer | 27/02/2018 | 31/01/2020 | 703 | 15.84% | No Holes |

| EB-12 | Dishwasher | 02/03/2018 | 31/01/2020 | 700 | 83.45% | No Holes |

| EB-12 | Microwave | 27/02/2018 | 31/01/2020 | 703 | 82.37% | No Holes |

| EB-12 | Washing machine | 02/03/2018 | 31/01/2020 | 700 | 17.72% | No Holes |

| EB-12 | TV | 27/02/2018 | 31/01/2020 | 703 | 79.11% | No Holes |

| EB-13 | Fridge | 20/06/2018 | 08/06/2020 | 719 | 44.85% | July 2019–June 2020 |

| EB-13 | Dish washer | 13/06/2018 | 08/06/2020 | 726 | 45.74% | July 2019–June 2020 |

| EB-13 | Washing machine | 13/06/2018 | 08/06/2020 | 726 | 43.07% | July 2019–June 2020 |

| EB-13 | Warmer | 07/09/2018 | 08/06/2020 | 640 | 41.11% | July 2019–June 2020 |

| EB-13 | Oven | 07/09/2018 | 08/06/2020 | 640 | 29% | April 2019–June 2018 |

| EB-13 | Fridge | 12/06/2018 | 08/06/2020 | 727 | 38.06% | April 2019–June 2018 |

| EB-13 | Dishwasher | 07/09/2018 | 08/06/2020 | 640 | 29.49% | April 2019–June 2018 |

| EB-13 | Microwave | 12/06/2018 | 08/06/2020 | 727 | 36.31% | April 2019–June 2018 |

| EB-13 | TV | 12/06/2018 | 08/06/2020 | 727 | 38.01% | April 2019–June 2018 |

| Home | Appliance | Start Date | End Date | Time Span Days | Available Data | Data Holes |

|---|---|---|---|---|---|---|

| NEB-1 | Dryer | 01/06/2021 | 30/11/2021 | 182 | 92.20% | No Holes |

| NEB-1 | Kids’ computer | 01/06/2021 | 30/11/2021 | 182 | 40.80% | June–August 2021 |

| NEB-1 | Computer studio | 01/06/2021 | 30/11/2021 | 182 | 40.81% | June–August 2021 |

| NEB-1 | Bedroom air conditioner | 01/06/2021 | 30/11/2021 | 182 | 59.20% | October–November 2021 |

| NEB-1 | Kids’ room air conditioner | 01/06/2021 | 30/11/2021 | 182 | 77.08% | No Holes |

| NEB-1 | Living room air conditioner | 01/06/2021 | 30/11/2021 | 182 | 92.20% | No Holes |

| NEB-1 | Whole house lighting | 01/06/2021 | 30/11/2021 | 182 | 39.86% | June–August 2021 |

| NEB-1 | Dishwasher | 01/06/2021 | 30/11/2021 | 182 | 92.22% | No Holes |

| NEB-1 | Washing machine | 01/06/2021 | 30/11/2021 | 182 | 92.23% | No Holes |

| NEB-1 | Water heater and heat pump | 01/06/2021 | 30/11/2021 | 182 | 92.26% | No Holes |

| NEB-1 | Tv Bedroom | 01/06/2021 | 30/11/2021 | 182 | 19.22% | June–August 2021, November 2021 |

| NEB-1 | Tv living room | 01/06/2021 | 30/11/2021 | 182 | 40.81% | June–August 2021 |

| NEB-2 | Dryer | 01/06/2021 | 30/11/2021 | 182 | 4.80% | June–August 2021, October–November 2021 |

| NEB-2 | Bedroom air conditioner | 01/06/2021 | 30/11/2021 | 182 | 0% | Whole Period |

| NEB-2 | Living room air conditioner | 01/06/2021 | 30/11/2021 | 182 | 10.61% | June–September 2021 |

| NEB-2 | Dishwasher | 01/06/2021 | 30/11/2021 | 182 | 4.82% | June–August 2021, October–November 2021 |

| NEB-2 | Washing machine | 01/06/2021 | 30/11/2021 | 182 | 15.21% | June–August 2021, June–August 2021, November 2021 |

| NEB-2 | Water heater and heat pump | 01/06/2021 | 30/11/2021 | 182 | 4.79% | June–August 2021, June–August 2021, November 2021 |

| NEB-3 | Dishwasher | 01/06/2021 | 30/11/2021 | 182 | 92.90% | No Holes |

| NEB-3 | Washing machine | 01/06/2021 | 30/11/2021 | 182 | 92.94% | No Holes |

| NEB-3 | Tv | 01/06/2021 | 30/11/2021 | 182 | 92.87% | No Holes |

| NEB-4 | Bedroom air conditioner | 01/06/2021 | 30/11/2021 | 182 | 3.32% | June–July 2021, September–November 2019 |

| NEB-4 | Fridge | 01/06/2021 | 30/11/2021 | 182 | 87.77% | No Holes |

| NEB-4 | Dishwasher | 01/06/2021 | 30/11/2021 | 182 | 87.70% | No Holes |

| NEB-4 | Washing machine | 01/06/2021 | 30/11/2021 | 182 | 87.21% | No Holes |

| NEB-5 | Coffee machine | 01/06/2021 | 30/11/2021 | 182 | 83.43% | No Holes |

| NEB-5 | Fridge | 01/06/2021 | 30/11/2021 | 182 | 84.11% | No Holes |

| NEB-5 | Washing machine | 01/06/2021 | 30/11/2021 | 182 | 84.11% | No Holes |

| NEB-5 | TV | 01/06/2021 | 30/11/2021 | 182 | 84.07% | No Holes |

| NEB-6 | Dryer | 01/07/2021 | 30/11/2021 | 152 | 83.75% | No Holes |

| NEB-6 | Fridge | 01/07/2021 | 30/11/2021 | 152 | 83.85% | No Holes |

| NEB-6 | Washing machine | 01/07/2021 | 30/11/2021 | 152 | 83.85% | No Holes |

| NEB-6 | Dishwasher | 01/07/2021 | 30/11/2021 | 152 | 83.84% | No Holes |

| NEB-6 | Bedroom air conditioner | 01/07/2021 | 30/11/2021 | 152 | 73.49% | No Holes |

| NEB-9 | Washing machine | 01/06/2021 | 30/11/2021 | 182 | 56.65% | November 2021 |

| NEB-9 | Dishwasher | 01/06/2021 | 30/11/2021 | 182 | 56.57% | November 2021 |

| NEB-9 | Bedroom air conditioner | 01/06/2021 | 30/11/2021 | 182 | 56.65% | November 2021 |

| NEB-9 | Bedroom air conditioner2 | 01/06/2021 | 30/11/2021 | 182 | 56.63% | November 2021 |

| NEB-9 | Dryer | 01/06/2021 | 30/11/2021 | 182 | 56.60% | November 2021 |

| NEB-10 | Washing machine | 01/06/2021 | 30/11/2021 | 182 | 69.66% | No Holes |

| NEB-10 | Dishwasher | 01/06/2021 | 30/11/2021 | 182 | 48.88% | No Holes |

| NEB-10 | Fridge | 01/06/2021 | 30/11/2021 | 182 | 69.63% | No Holes |

| NEB-11 | Washing machine | 01/06/2021 | 30/11/2021 | 182 | 2.70% | July–November 2021 |

| NEB-11 | Dishwasher | 01/06/2021 | 30/11/2021 | 182 | 55.68% | No Holes |

| NEB-11 | Fridge | 01/06/2021 | 30/11/2021 | 182 | 55.65% | No Holes |

| NEB-11 | Bedroom air conditioner | 01/06/2021 | 30/11/2021 | 182 | 45.57% | October–November2021 |

| NEB-11 | Air conditioner hobby room | 01/06/2021 | 30/11/2021 | 182 | 2.47% | July–November2021 |

| NEB-12 | Fridge | 01/06/2021 | 30/11/2021 | 182 | 69.75% | No Holes |

| NEB-12 | Washing machine | 01/06/2021 | 30/11/2021 | 182 | 68.89% | No Holes |

| NEB-12 | Dishwasher | 01/06/2021 | 30/11/2021 | 182 | 69.72% | No Holes |

References

- Gan, P.; Li, Z. An econometric study on long-term energy outlook and the implications of renewable energy utilization in Malaysia. Energy Policy 2008, 36, 890–899. [Google Scholar] [CrossRef]

- Herrero, S.; Nicholls, L.; Strengers, Y. Smart home technologies in everyday life: Do they address key energy challenges in households? Curr. Opin. Environ. Sustain. 2018, 31, 65–70. [Google Scholar] [CrossRef]

- Jorde, D.; Jacobsen, H. Event detection for energy consumption monitoring. IEEE Trans. Sustain. Comput. 2020, 6, 703–709. [Google Scholar] [CrossRef]

- Armel, K.; Gupta, A.; Shrimali, G.; Albert, A. Is disaggregation the holy grail of energy efficiency? The case of electricity. Energy Policy 2013, 52, 213–234. [Google Scholar] [CrossRef]

- Lopez, J.; Pouresmaeil, E.; Canizares, C.; Bhattacharya, K.; Mosaddegh, A.; Solanki, B. Smart residential load simulator for energy management in smart grids. IEEE Trans. Ind. Electron. 2018, 66, 1443–1452. [Google Scholar] [CrossRef]

- Li, P.; Wang, H.; Zhang, B. A distributed online pricing strategy for demand response programs. IEEE Trans. Smart Grid 2017, 10, 350–360. [Google Scholar] [CrossRef]

- AlHammadi, A.; AlZaabi, A.; AlMarzooqi, B.; AlNeyadi, S.; AlHashmi, Z.; Shatnawi, M. Survey of IoT-based smart home approaches. In Proceedings of the 2019 Advances In Science And Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 26 March–10 April 2019; pp. 1–6. [Google Scholar]

- Barsim, K.; Streubel, R.; Yang, B. An approach for unsupervised non-intrusive load monitoring of residential appliances. In Proceedings of the 2nd International Workshop On Non-Intrusive Load Monitoring, Austin, TX, USA, 3 June 2014; pp. 1–5. [Google Scholar]

- Liu, Y.; Qiu, B.; Fan, X.; Zhu, H.; Han, B. Review of smart home energy management systems. Energy Procedia 2016, 104, 504–508. [Google Scholar] [CrossRef]

- Yang, J.; Zhao, J.; Wen, F.; Kong, W.; Dong, Z. Mining the big data of residential appliances in the smart grid environment. In Proceedings of the 2016 IEEE Power And Energy Society General Meeting (PESGM), Boston, MA, USA, 17–21 July 2016; pp. 1–5. [Google Scholar]

- Errapotu, S.; Wang, J.; Gong, Y.; Cho, J.; Pan, M.; Han, Z. SAFE: Secure appliance scheduling for flexible and efficient energy consumption for smart home IoT. IEEE Internet Things J. 2018, 5, 4380–4391. [Google Scholar] [CrossRef]

- Jaradat, A.; Lutfiyya, H.; Haque, A. Appliance Operation Modes Identification Using Cycles Clustering. arXiv 2021, arXiv:2101.10472. [Google Scholar]

- Wang, Z.; Srinivasan, R. Classification of household appliance operation cycles: A case-study approach. Energies 2015, 8, 10522–10536. [Google Scholar] [CrossRef]

- Silva, B.; Khan, M.; Han, K. Load balancing integrated least slack time-based appliance scheduling for smart home energy management. Sensors 2018, 18, 685. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Lin, C. Standby power management of a smart home appliance by using energy saving system with active loading feature identification. IEEE Trans. Consum. Electron. 2018, 65, 11–17. [Google Scholar] [CrossRef]

- Prudenzi, A. A neuron nets based procedure for identifying domestic appliances pattern-of-use from energy recordings at meter panel. In Proceedings of the 2002 IEEE Power Engineering Society Winter Meeting. Conference Proceedings (Cat. No. 02CH37309), New York, NY, USA, 27–31 January 2002; Volume 2, pp. 941–946. [Google Scholar]

- Wang, H.; Yang, W. An iterative load disaggregation approach based on appliance consumption pattern. Appl. Sci. 2018, 8, 542. [Google Scholar] [CrossRef]

- Hussain, H.; Javaid, N.; Iqbal, S.; Hasan, Q.; Aurangzeb, K.; Alhussein, M. An efficient demand side management system with a new optimized home energy management controller in smart grid. Energies 2018, 11, 190. [Google Scholar] [CrossRef]

- Du, S.; Li, M.; Han, S.; Shi, J.; Li, H. Multi-pattern data mining and recognition of primary electric appliances from single non-intrusive load monitoring data. Energies 2019, 12, 992. [Google Scholar] [CrossRef]

- Ashouri, M.; Haghighat, F.; Fung, B.; Lazrak, A.; Yoshino, H. Development of building energy saving advisory: A data mining approach. Energy Build. 2018, 172, 139–151. [Google Scholar] [CrossRef]

- Gajowniczek, K.; Ząbkowski, T. Data mining techniques for detecting household characteristics based on smart meter data. Energies 2015, 8, 7407–7427. [Google Scholar] [CrossRef]

- Yu, Z.; Fung, B.; Haghighat, F. Extracting knowledge from building-related data—A data mining framework. Build. Simul. 2013, 6, 207–222. [Google Scholar] [CrossRef]

- Ashouri, M.; Fung, B.; Haghighat, F.; Yoshino, H. Systematic approach to provide building occupants with feedback to reduce energy consumption. Energy 2020, 194, 116813. [Google Scholar] [CrossRef]

- Athanasiadis, C.; Doukas, D.; Papadopoulos, T.; Chrysopoulos, A. A scalable real-time non-intrusive load monitoring system for the estimation of household appliance power consumption. Energies 2021, 14, 767. [Google Scholar] [CrossRef]

- Athanasiadis, C.; Papadopoulos, T.; Doukas, D. Real-time non-intrusive load monitoring: A light-weight and scalable approach. Energy Build. 2021, 253, 111523. [Google Scholar] [CrossRef]

- Ge, L.; Liao, W.; Wang, S.; Bak-Jensen, B.; Pillai, J. Modeling daily load profiles of distribution network for scenario generation using flow-based generative network. IEEE Access 2020, 8, 77587–77597. [Google Scholar] [CrossRef]

- Fischer, D.; Härtl, A.; Wille-Haussmann, B. Model for electric load profiles with high time resolution for German households. Energy Build. 2015, 92, 170–179. [Google Scholar] [CrossRef]

- Widen, J.; Lundh, M.; Vassileva, I.; Dahlquist, E.; Elleg, K.; Wäckelg, E. Constructing load profiles for household electricity and hot water from time-use data—Modelling approach and validation. Energy Build. 2009, 41, 753–768. [Google Scholar] [CrossRef]

- Wijaya, T.; Vasirani, M.; Humeau, S.; Aberer, K. Cluster-based aggregate forecasting for residential electricity demand using smart meter data. In Proceedings of the 2015 IEEE International Conference On Big Data (Big Data), Santa Clara, CA, USA, 29 October–1 November 2015; pp. 879–887. [Google Scholar]

- Khan, Z.; Jayaweera, D.; Alvarez-Alvarado, M. A novel approach for load profiling in smart power grids using smart meter data. Electr. Power Syst. Res. 2018, 165, 191–198. [Google Scholar] [CrossRef]

- Sousa, J.; Neves, L.; Jorge, H. Assessing the relevance of load profiling information in electrical load forecasting based on neural network models. Int. J. Electr. Power Energy Syst. 2012, 40, 85–93. [Google Scholar] [CrossRef]

- Hayn, M.; Bertsch, V.; Fichtner, W. Electricity load profiles in Europe: The importance of household segmentation. Energy Res. Soc. Sci. 2014, 3, 30–45. [Google Scholar] [CrossRef]

- Yilmaz, S.; Chambers, J.; Patel, M. Comparison of clustering approaches for domestic electricity load profile characterisation-Implications for demand side management. Energy 2019, 180, 665–677. [Google Scholar] [CrossRef]

- Craig, T.; Polhill, J.; Dent, I.; Galan-Diaz, C.; Heslop, S. The north east scotland energy monitoring project: Exploring relationships between household occupants and energy usage. Energy Build. 2014, 75, 493–503. [Google Scholar] [CrossRef]

- Martinez-Pabon, M.; Eveleigh, T.; Tanju, B. Smart meter data analytics for optimal customer selection in demand response programs. Energy Procedia 2017, 107, 49–59. [Google Scholar] [CrossRef]

- Zhou, K.; Fu, C.; Yang, S. Big data driven smart energy management: From big data to big insights. Renew. Sustain. Energy Rev. 2016, 56, 215–225. [Google Scholar] [CrossRef]

- Zhou, K.; Yang, S. Understanding household energy consumption behavior: The contribution of energy big data analytics. Renew. Sustain. Energy Rev. 2016, 56, 810–819. [Google Scholar] [CrossRef]

- Laicane, I.; Blumberga, D.; Blumberga, A.; Rosa, M. Reducing household electricity consumption through demand side management: The role of home appliance scheduling and peak load reduction. Energy Procedia 2015, 72, 222–229. [Google Scholar] [CrossRef]

- Gyamfi, S.; Krumdieck, S.; Urmee, T. Residential peak electricity demand response—Highlights of some behavioural issues. Renew. Sustain. Energy Rev. 2013, 25, 71–77. [Google Scholar] [CrossRef]

- Azarova, V.; Cohen, J.; Kollmann, A.; Reichl, J. Reducing household electricity consumption during evening peak demand times: Evidence from a field experiment. Energy Policy 2020, 144, 111657. [Google Scholar] [CrossRef]

- Weber, S.; Puddu, S.; Pacheco, D. Move it! How an electric contest motivates households to shift their load profile. Energy Econ. 2017, 68, 255–270. [Google Scholar] [CrossRef]

- Crosbie, T.; Broderick, J.; Short, M.; Charlesworth, R.; Dawood, M. Demand response technology readiness levels for energy management in blocks of buildings. Buildings 2018, 8, 13. [Google Scholar] [CrossRef]

- Issi, F.; Kaplan, O. The determination of load profiles and power consumptions of home appliances. Energies 2018, 11, 607. [Google Scholar] [CrossRef]

- Wenninger, M.; Maier, A.; Schmidt, J. DEDDIAG, a domestic electricity demand dataset of individual appliances in Germany. Sci. Data 2021, 8, 176. [Google Scholar] [CrossRef]

- Clerici Maestosi, P. Sustainable Urban Transitions; Maggioli Publisher: Santarcangelo di Romagna, Italy, 2021. [Google Scholar]

- Aggiornamento delle Fasce Orarie Con Decorrenza 1 Gennaio 2007. ARERA. Available online: https://www.arera.it/it/docs/06/181-06.html (accessed on 2 August 2022).

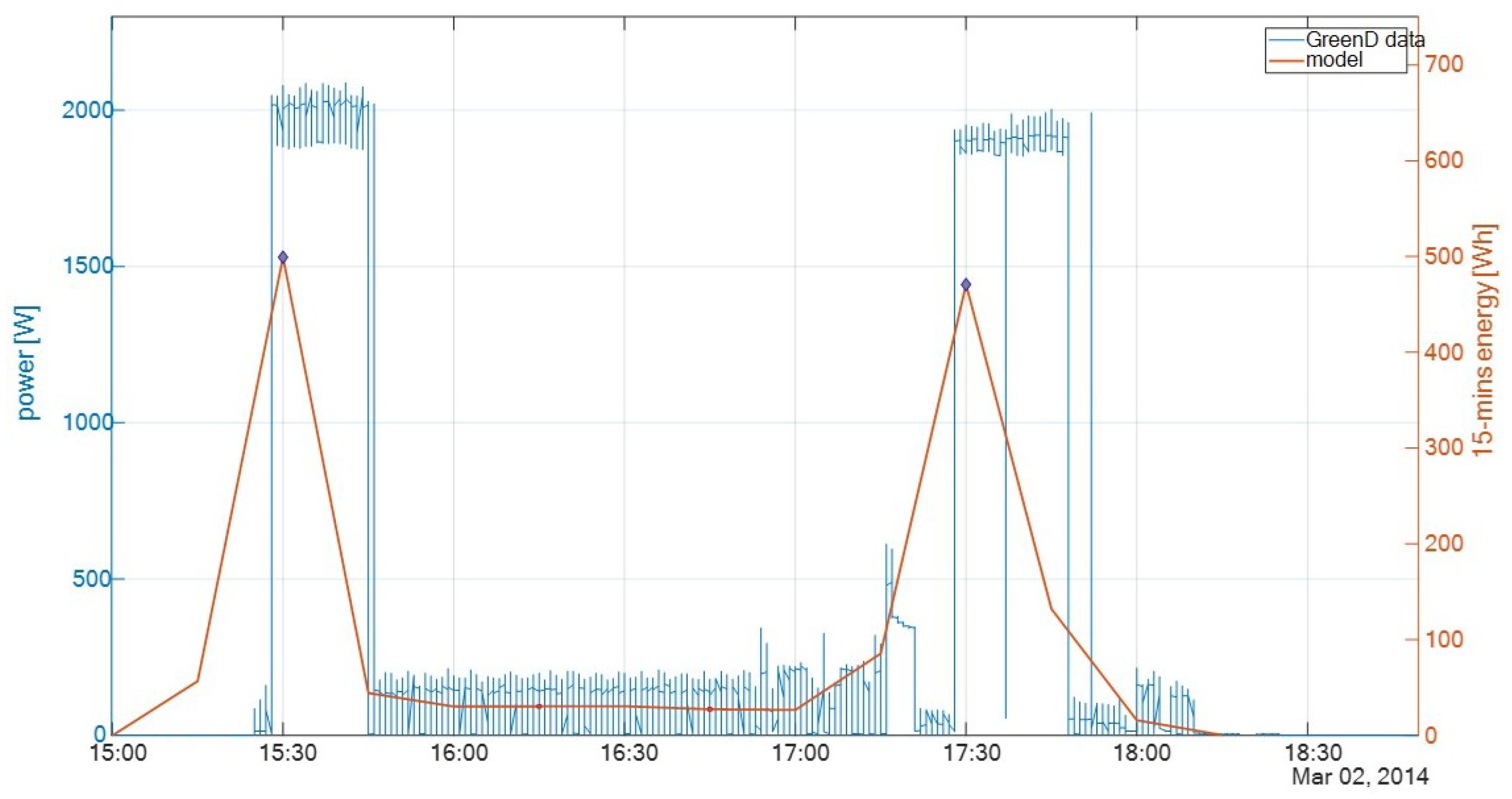

- Monacchi, A.; Egarter, D.; Elmenreich, W.; D’Alessandro, S.; Tonello, A. GREEND: An energy consumption dataset of households in Italy and Austria. In Proceedings of the 2014 IEEE International Conference On Smart Grid Communications (SmartGridComm), Venice, Italy, 3–6 November 2014; pp. 511–516. [Google Scholar]

| Sensor | Manufacturer/Model | Measured Quantity |

|---|---|---|

| Home energy meter | Aeotec/ZW095-C | power, energy |

| Smart plug | Aeotec/switch 7 | power, energy, current, voltage |

| Sensor and integrated or comfort-presence | Aeotec/Multisensory 6 | temperature, illuminance, humidity, movement |

| Door/window contact | Aeotec/Door window sensor | opening/closing |

| Parameters | Description |

|---|---|

| home_id | Name of the energy box |

| sensor | Name of the sensor associated with the appliance |

| date | Datetime |

| sum_of_energy_of_power | Energy provided in Wh on a quarter-hour basis |

| delta_energy | Energy counter, in Wh or kWh |

| last_value_switch | sensor parameter (not used) |

| Parameter | Calibrated Value | Tuning Range |

|---|---|---|

| st_by_prc | 98 | [90–99] |

| min_dur | 30 min | [15 30 45] |

| min_Wh | 100 Wh | [50 100 150 … 500] |

| thr_en | 800 Wh | [500 600 700 800] |

| thr_d1 | 45 min | [15 30 45] |

| thr_d2 | 120 min | [90 105 … 500] |

| Home | EC | NoP | PEC | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Peak Hours | (kWh) | (kWh) | |||||||||

| EB-2 | A | 2 | 99 | 114 | 28% | 6% | 6% | 1.140 | 54% | 53% | 8.523 |

| NEB-4 | A | 2 | 31 | 36 | 45% | 65% | 64% | 2.263 | 0 | 0 | 0 |

| EB-3 | A++ | 4 | 340 | 391 | 72% | 7% | 6% | 2.062 | 42% | 41% | 18.295 |

| NEB-9 | A++ | 3 | 31 | 26 | 96% | 9% | 88% | 3.759 | 0 | 0 | 0 |

| NEB-10 | A++ | 2 | 80 | 74 | 44% | 86% | 85% | 3.662 | 0 | 0 | 0 |

| EB-9 | A+++ | 3 | 82 | 21 | 65% | 12% | 19% | 1.492 | 4% | 0 | 2.521 |

| NEB-1 | A+++ | 4 | 76 | 82 | 60% | 64% | 65% | 3.264 | 1% | 1% | 1.558 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caldera, M.; Hussain, A.; Romano, S.; Re, V. Energy-Consumption Pattern-Detecting Technique for Household Appliances for Smart Home Platform. Energies 2023, 16, 824. https://doi.org/10.3390/en16020824

Caldera M, Hussain A, Romano S, Re V. Energy-Consumption Pattern-Detecting Technique for Household Appliances for Smart Home Platform. Energies. 2023; 16(2):824. https://doi.org/10.3390/en16020824

Chicago/Turabian StyleCaldera, Matteo, Asad Hussain, Sabrina Romano, and Valerio Re. 2023. "Energy-Consumption Pattern-Detecting Technique for Household Appliances for Smart Home Platform" Energies 16, no. 2: 824. https://doi.org/10.3390/en16020824

APA StyleCaldera, M., Hussain, A., Romano, S., & Re, V. (2023). Energy-Consumption Pattern-Detecting Technique for Household Appliances for Smart Home Platform. Energies, 16(2), 824. https://doi.org/10.3390/en16020824