Numerical Study on Protective Measures for a Skid-Mounted Hydrogen Refueling Station

Abstract

1. Introduction

2. CFD Model

2.1. Modeling Approach

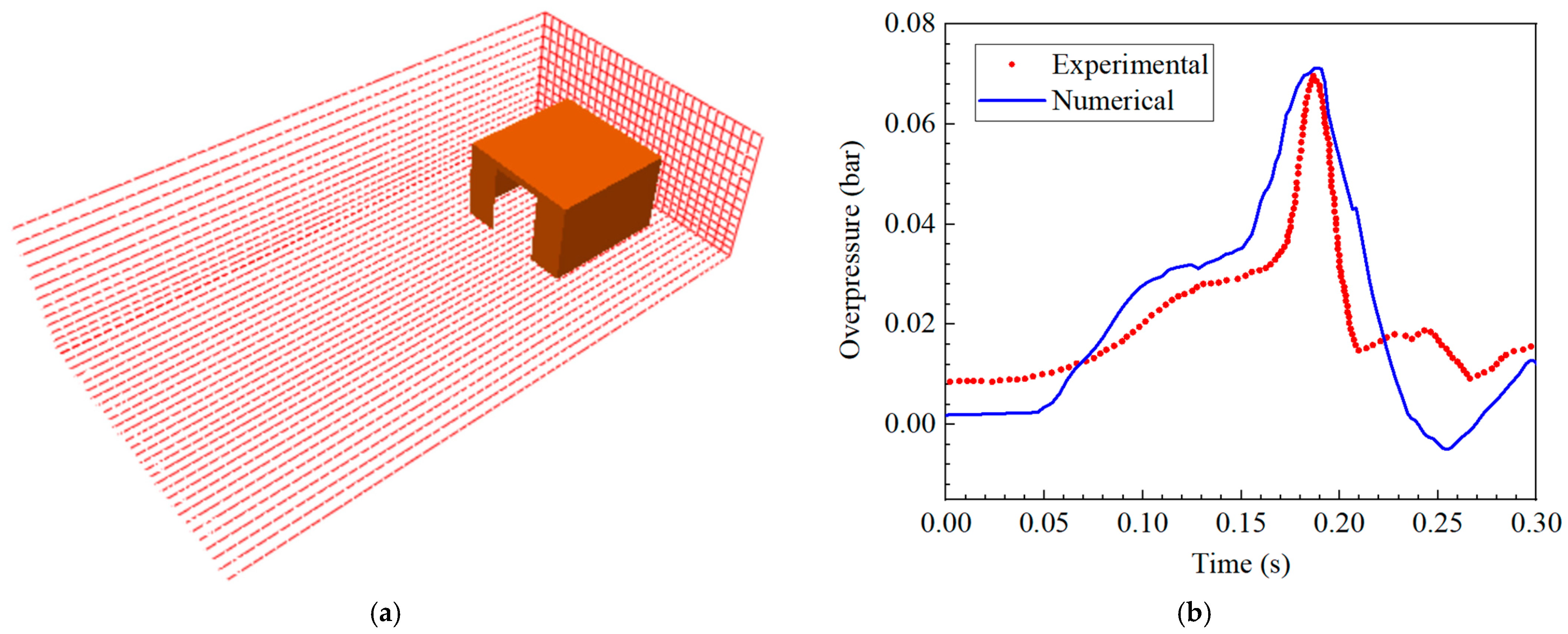

2.2. Modeling Validation

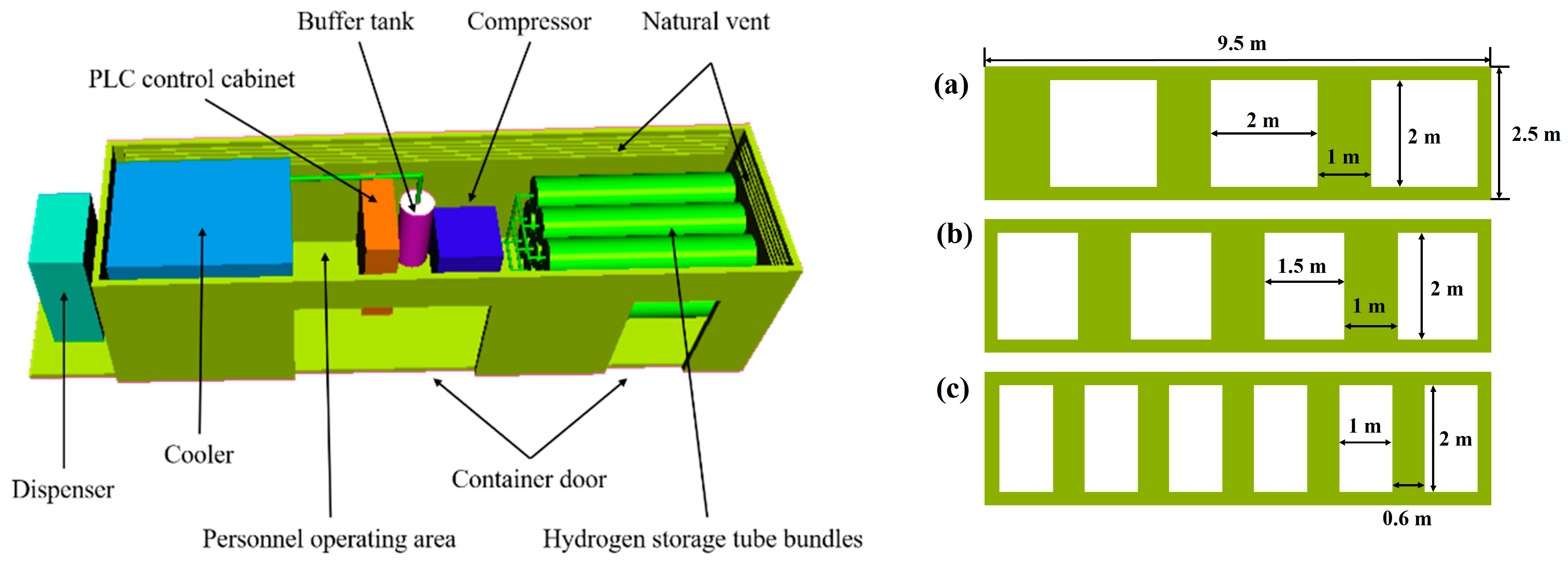

2.3. Geometry

2.3.1. Explosion Vent Layouts

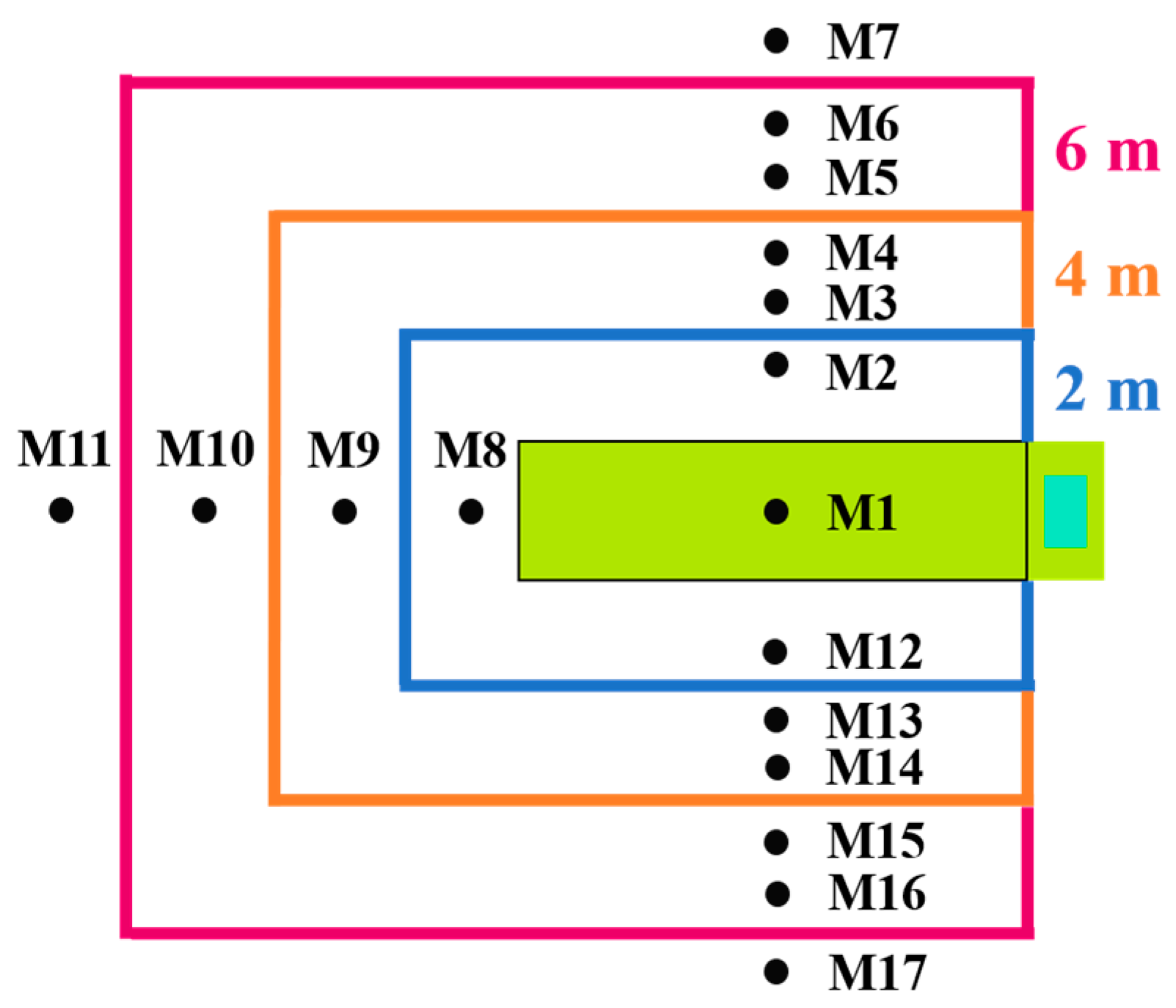

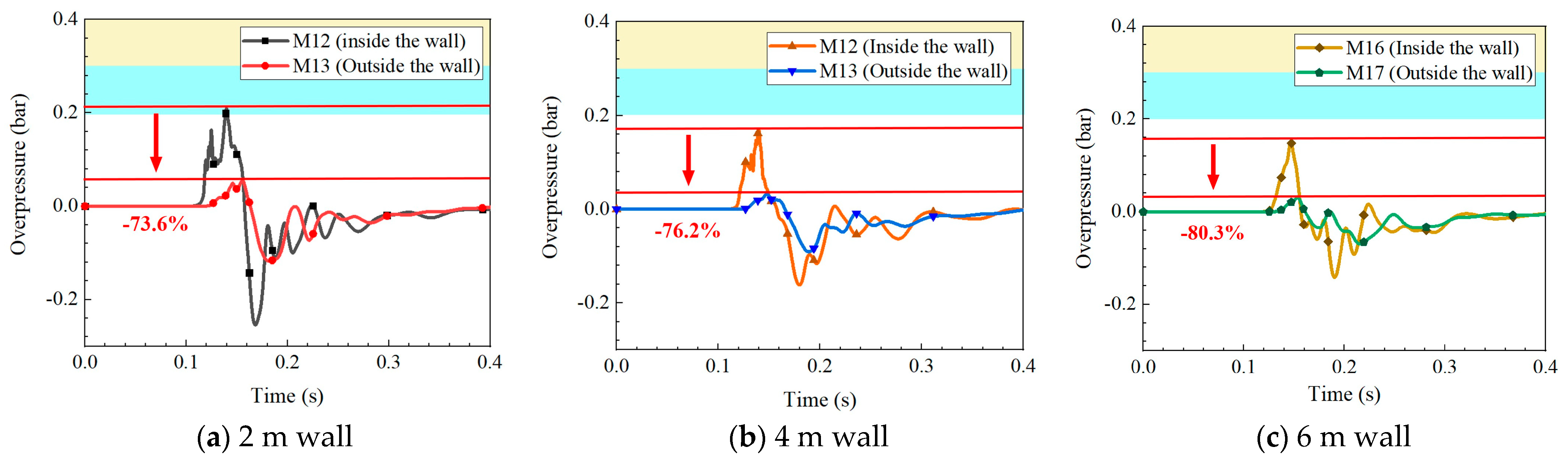

2.3.2. Protective Wall Layouts

2.4. Explosion Overpressure Harm Criteria

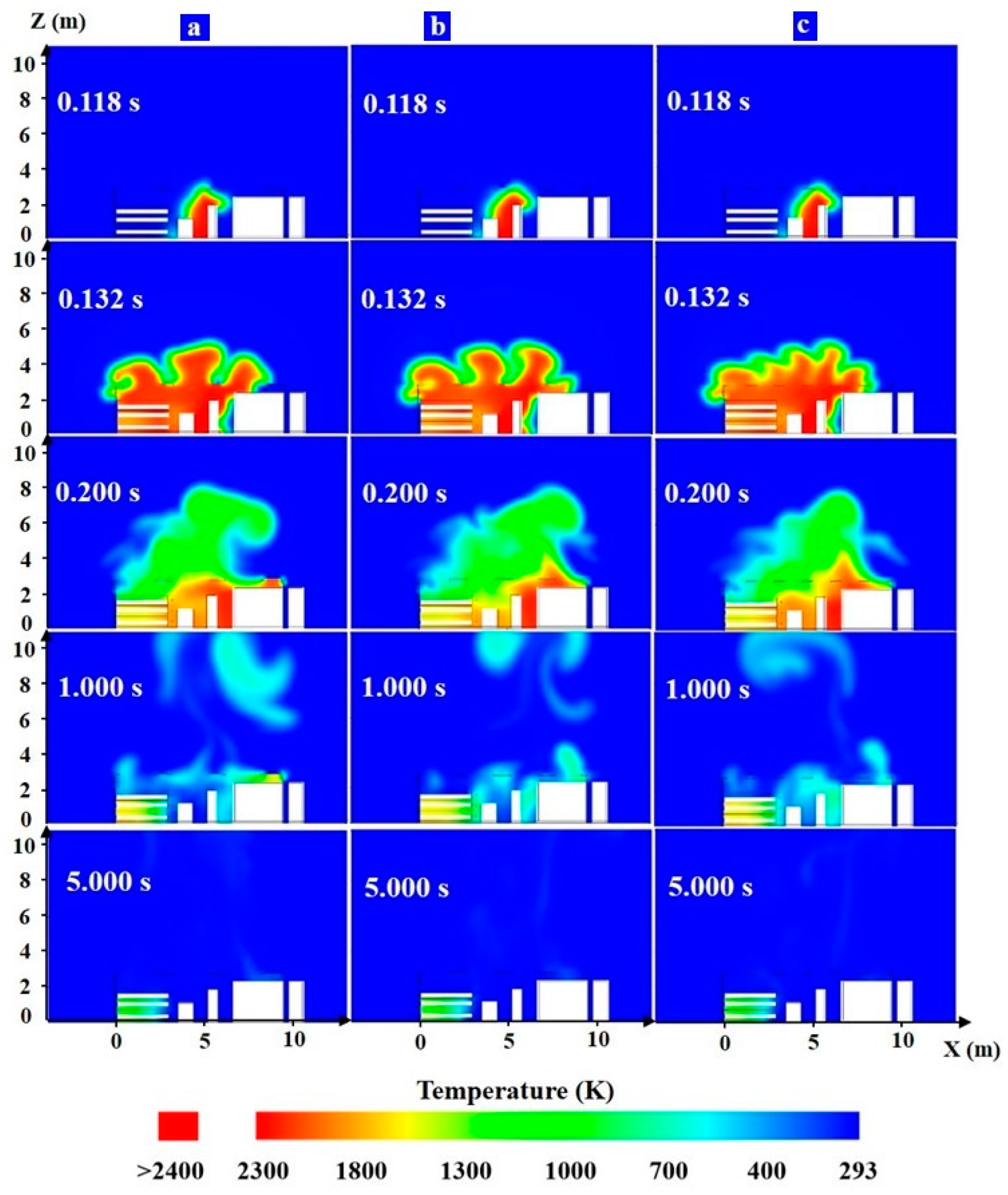

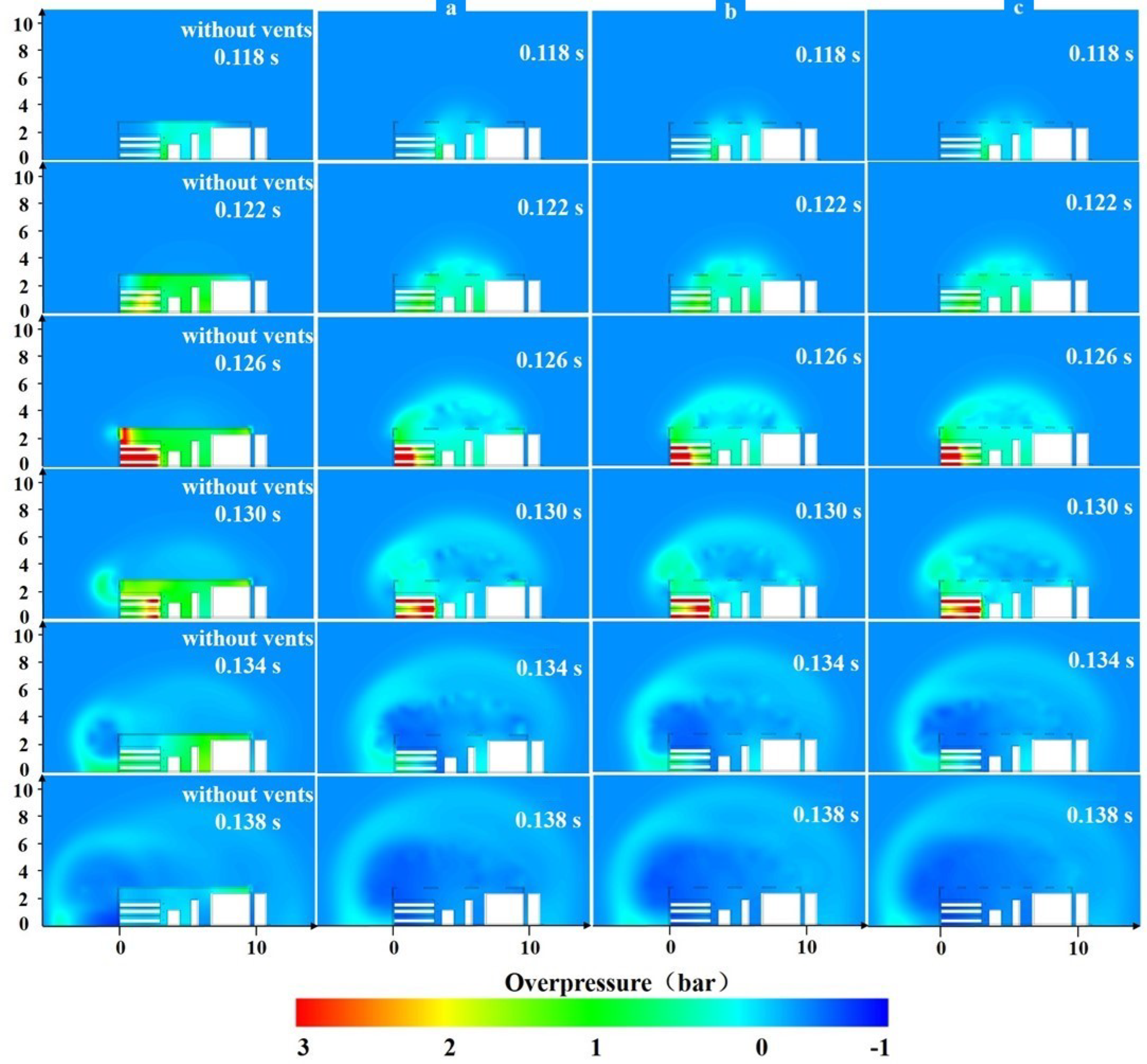

3. Effects of Explosion Vents

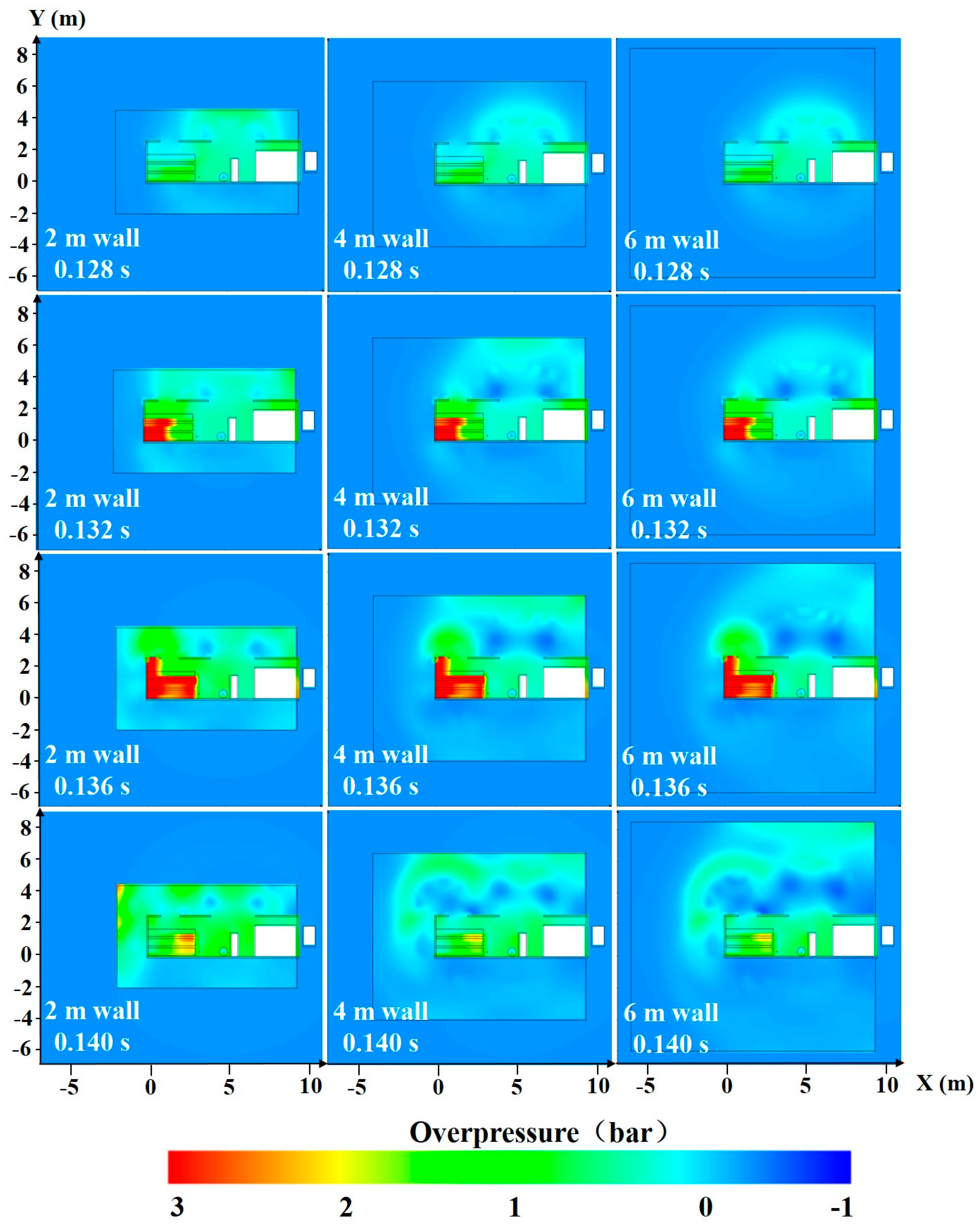

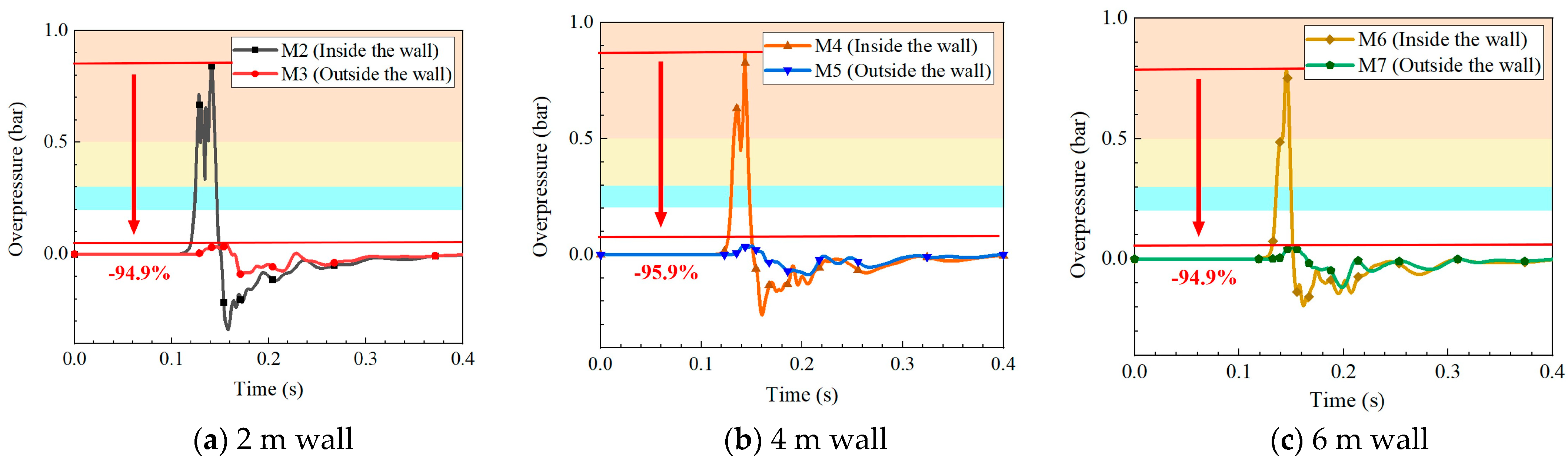

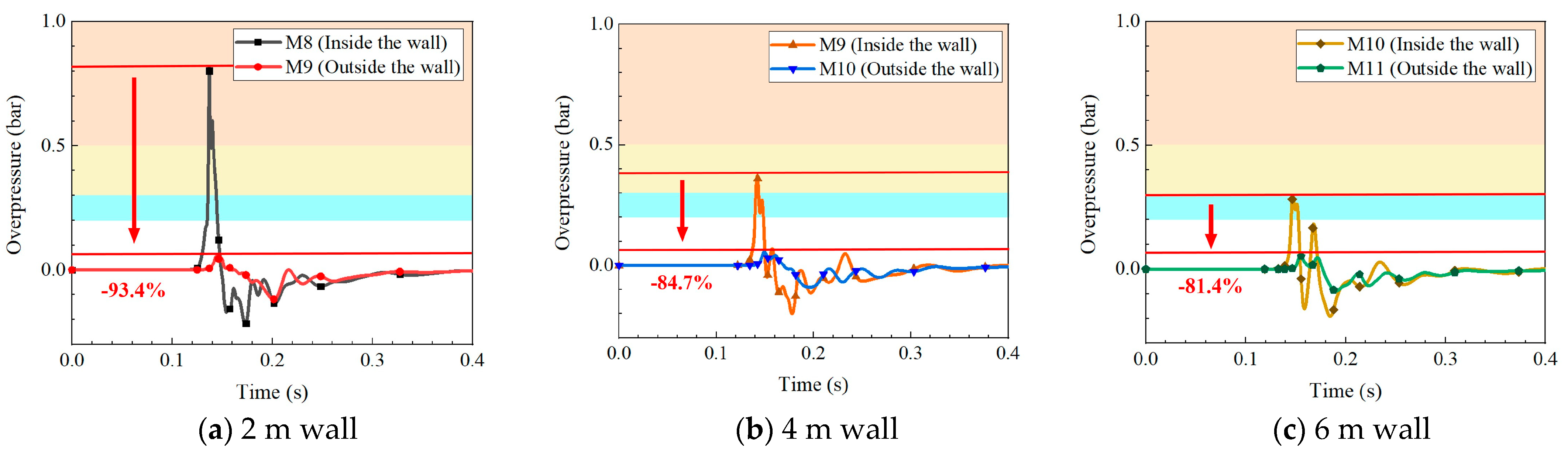

4. Effects of Protective Walls

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rabbi, M.F.; Popp, J.; Máté, D.; Kovács, S. Energy Security and Energy Transition to Achieve Carbon Neutrality. Energies 2022, 15, 8126. [Google Scholar] [CrossRef]

- Salimi, M.; Hosseinpour, M.; Borhani, T. The Role of Clean Hydrogen Value Chain in a Successful Energy Transition of Japan. Energies 2022, 15, 6064. [Google Scholar] [CrossRef]

- Barbir, F. Transition to renewable energy systems with hydrogen as an energy carrier. Energy 2009, 34, 308–312. [Google Scholar] [CrossRef]

- Najjar, Y.S.H. Hydrogen safety: The road toward green technology. Int. J. Hydrogen Energy 2013, 38, 10716–10728. [Google Scholar] [CrossRef]

- Fang, D.; Yu, T.; Xie, Q. Discussion about the planning development mode of hydrogen fuelling stations in urban areas of China. Energy Conserv. 2019, 2, 122–123. [Google Scholar] [CrossRef]

- Li, X.; Xu, J.; Zhou, Y. Technical scheme of skid mounted hydrogen refueling unit. Nat. Gas Chem. Ind. 2019, 44, 61–64. [Google Scholar]

- Crowl, D.A.; Jo, Y. The hazards and risks of hydrogen. J. Loss Prevent. Process Ind. 2021, 21, 162–184. [Google Scholar] [CrossRef]

- Jeon, J.; Kim, S.J. Recent Progress in Hydrogen Flammability Prediction for the Safe Energy Systems. Energies 2020, 13, 6263. [Google Scholar] [CrossRef]

- White, C.M.; Steeper, R.R.; Lutz, A.E. The hydrogen-fueled internal combustion engine: A technical review. Int. J. Hydrogen Energy 2006, 31, 1292–1305. [Google Scholar] [CrossRef]

- Lewis, B.; Elbe, G. Combustion, Flames and Explosions of Gases; Academic Press: Orlando, FL, USA, 1987. [Google Scholar] [CrossRef]

- Yang, J.X.; Li, X.J. Design of skid-mounted LCNG fueling station for vehicle. Appl. Mech. Mater. 2013, 273, 3–7. [Google Scholar] [CrossRef]

- Sun, K.; Pan, X.; Li, Z.; Ma, J. Risk analysis on mobile hydrogen refueling stations in Shanghai. Int. J. Hydrogen Energy 2014, 39, 20411–20419. [Google Scholar] [CrossRef]

- Herrmann, D.D. Developing a sound basis for the design of vented explosion barricades in chemical processes. Chem. Eng. Process 2005, 24, 52–58. [Google Scholar] [CrossRef]

- Tomlin, G.; Johnson, D.M.; Cronin, P.; Phylaktou, H.N.; Andrews, G.E. The effect of vent size and congestion in large-scale vented natural gas/air explosions. J. Loss Prevent. Process Ind. 2015, 35, 169–181. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, Q. Effect of vent size on vented hydrogen-air explosion. Int. J. Hydrogen Energy 2018, 43, 17788–17799. [Google Scholar] [CrossRef]

- Li, Y.; Bi, M.; Zhou, Y.; Jiang, H.; Huang, L.; Zhang, K.; Gao, W. Experimental and theoretical evaluation of hydrogen cloud explosion with built-in obstacles. Int. J. Hydrogen Energy 2020, 46, 28007–28018. [Google Scholar] [CrossRef]

- Luo, X.; Wang, C.; Rui, S.; Wan, Y.; Li, Q. Effects of ignition location, obstacles, and vent location on the vented hydrogen-air deflagrations with low vent burst pressure in a 20-foot container. Fuel 2020, 280, 118677. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiao, F.; Huang, Q.; Cao, W.; Shi, L.; Zhao, M.; Yu, C.; Nie, B.; Cao, X. Experimental and numerical studies on the closed and vented explosion behaviors of premixed methane-hydrogen/air mixtures. Appl. Therm. Eng. 2019, 159, 113907. [Google Scholar] [CrossRef]

- Rocourt, X.; Awamat, S.; Sochet, I.; Jallais, S. Vented hydrogen-air deflagration in a small enclosed volume. Int. J. Hydrogen Energy 2014, 39, 20462–20466. [Google Scholar] [CrossRef]

- Wang, J.; Jin, G.; Yang, F.; Zhang, J.; Lu, S. Effects of hydrogen concentration on the vented deflagration of hydrogen-air mixtures in a 1-m3 vessel. Int. J. Hydrogen Energy 2018, 43, 21161–21168. [Google Scholar] [CrossRef]

- Tchouvelev, A.V.; Zhong, C.; Agranat, V.M.; Zhubrin, S.V. Effectiveness of small barriers as means to reduce clearance distances. Int. J. Hydrogen Energy 2007, 32, 1409–1415. [Google Scholar] [CrossRef]

- Evans, G.; Groethe, M.; Schefer, R.W.; Houf, W.G. Experimental evaluation of barrier walls for risk reduction of unintended hydrogen releases. Int. J. Hydrogen Energy 2009, 34, 1590–1606. [Google Scholar] [CrossRef]

- Schefer, R.W.; Mcrilo, E.G.; Groethe, M.A.; Houl, W.G. Experimental investigation of hydrogen jet fire mitigation by barrier walls. Int. J. Hydrogen Energy 2011, 36, 2530–2537. [Google Scholar] [CrossRef]

- Li, J.; Ma, G.; Hao, H.; Huang, Y. Optimal blast wall layout design to mitigate gas dispersion and explosion on a cylindrical FLNG platform. J. Loss Prevent. Process Ind. 2017, 49, 481–492. [Google Scholar] [CrossRef]

- Kang, H.S.; Kim, S.M.; Kim, J. Safety issues of a hydrogen refueling station and a prediction for an overpressure reduction by a barrier using OpenFOAM software for an SRI explosion test in an open space. Energies 2022, 15, 7556. [Google Scholar] [CrossRef]

- Yu, X.; Yan, W.; Liu, Y.; Zhou, P.; Li, B.; Wang, C. The flame mitigation effect of vertical barrier wall in hydrogen refueling stations. Fuel 2022, 315, 123265. [Google Scholar] [CrossRef]

- Salimath, P.S.; Ertesvåg, I.S.; Gruber, A. Computational analysis of premixed methane-air flame interacting with a solid wall or a hydrogen porous wall. Fuel 2020, 272, 117658–117673. [Google Scholar] [CrossRef]

- Chiquito, M.; Castedo, R.; Santos, A.P.; López, L.M.; Caldentey, A.P. Numerical modelling and experimental validation of the behaviour of brick masonry walls subjected to blast loading. Int. J. Impact Eng. 2021, 148, 103760–103774. [Google Scholar] [CrossRef]

- Sun, Z. Cracking Elements Method for Simulating Complex Crack Growth. J. Appl. Comput. Mech. 2019, 5, 552–562. [Google Scholar] [CrossRef]

- Yenerdag, B.; Minamoto, Y.; Aoki, K.; Shimura, M.; Nada, Y.; Tanahashi, M. Flame-wall interactions of lean premixed flames under elevated, rising pressure conditions. Fuel 2017, 189, 8–14. [Google Scholar] [CrossRef]

- Lucas, M.; Atanga, G.; Hisken, H.; Mauri, L.; Skjold, T. Simulating vented hydrogen deflagrations: Improved modelling in the CFD tool FLACS-hydrogen. Int. J. Hydrogen Energy 2021, 46, 12464–12473. [Google Scholar] [CrossRef]

- Vyazmina, E.; Jallais, S. Validation and recommendations for FLACS CFD and engineering approaches to model hydrogen vented explosions: Effects of concentration, obstruction vent area and ignition position. Int. J. Hydrogen Energy 2016, 41, 15101–15109. [Google Scholar] [CrossRef]

- Pedersen, H.H.; Middha, P. Modelling of vented gas explosions in the CFD tool FLACS. Chem. Eng. Trans. 2012, 26, 357–362. [Google Scholar] [CrossRef]

- Patankar, S.V. Numerical Heat Transfer and Fluid Flow; Taylor & Francis: Abingdon, UK, 1980. [Google Scholar] [CrossRef]

- FLACS v9.0 User’s Manual, Norway. 2009. Available online: https://www3.gexcon.com/files/manual/flacs/html/index.html (accessed on 9 November 2022).

- Bauwens, C.R.; Chaffee, J.; Dorofeev, S.B. Vented explosion overpressures from combustion of hydrogen and hydrocarbon mixtures. Int. J. Hydrogen Energy 2011, 36, 2329–2336. [Google Scholar] [CrossRef]

- Huang, T.; Wang, Y.; Xiao, G.; Zhao, M.; Ba, Q.; Zhao, Z.; Li, X. Protective wall settings for a skid-mounted electrolytic hydrogen production system. SAE Int. J. Sustrans. Energy Envir. Policy 2022, 3, 1–11. [Google Scholar] [CrossRef]

- Fu, Z.; Huang, J.; Zang, N. Quantitative analysis for consequence of explosion shock wave. Fire Sci. Technol. 2009, 28, 390–395. [Google Scholar]

| Properties | Hydrogen | Methane | Gasoline |

|---|---|---|---|

| Gas Density (kg/m3) | 0.0808 | 0.643 | 1.767 |

| Diffusion Coefficient (cm2/s) | 0.61 | 0.16 | 0.05 |

| Lower Flammability Limit (Volume %) | 4 | 5.3 | 2.2 |

| Upper Flammability Limit (Volume %) | 75 | 15 | 9.5 |

| Flame Radiation Fraction (%) | 17~25 | 23~33 | 30~42 |

| Minimum Ignition Energy (mJ) | 0.02 | 0.29 | 0.24 |

| Auto-ignition Temperature (K) | 858 | 813 | 505 |

| Burning Velocity (cm/s) | 265~325 | 37~45 | 37~43 |

| Stoichiometric Concentration (Volume %) | 29.53 | 9.48 | 1.76 |

| Overpressure (bar) | Damage to Buildings | Human Injury |

|---|---|---|

| 0.20~0.30 | Partial damage | Slight injury |

| 0.30~0.50 | Significant damage | Moderate injury, such as hearing injuries and bone fractures |

| 0.50~1.00 | Serious damage or destruction | Serious injury to human viscera |

| >1.00 | Residential structures collapse | Most people die |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Liu, M.; Xiao, G.; Cui, T.; Ba, Q.; Li, X. Numerical Study on Protective Measures for a Skid-Mounted Hydrogen Refueling Station. Energies 2023, 16, 910. https://doi.org/10.3390/en16020910

Zhao Z, Liu M, Xiao G, Cui T, Ba Q, Li X. Numerical Study on Protective Measures for a Skid-Mounted Hydrogen Refueling Station. Energies. 2023; 16(2):910. https://doi.org/10.3390/en16020910

Chicago/Turabian StyleZhao, Zeying, Min Liu, Guoping Xiao, Tiancheng Cui, Qingxin Ba, and Xuefang Li. 2023. "Numerical Study on Protective Measures for a Skid-Mounted Hydrogen Refueling Station" Energies 16, no. 2: 910. https://doi.org/10.3390/en16020910

APA StyleZhao, Z., Liu, M., Xiao, G., Cui, T., Ba, Q., & Li, X. (2023). Numerical Study on Protective Measures for a Skid-Mounted Hydrogen Refueling Station. Energies, 16(2), 910. https://doi.org/10.3390/en16020910