Utilization of Biowaste for Sustainable Production of Coal Briquettes

Abstract

:1. Introduction

2. Literature Review

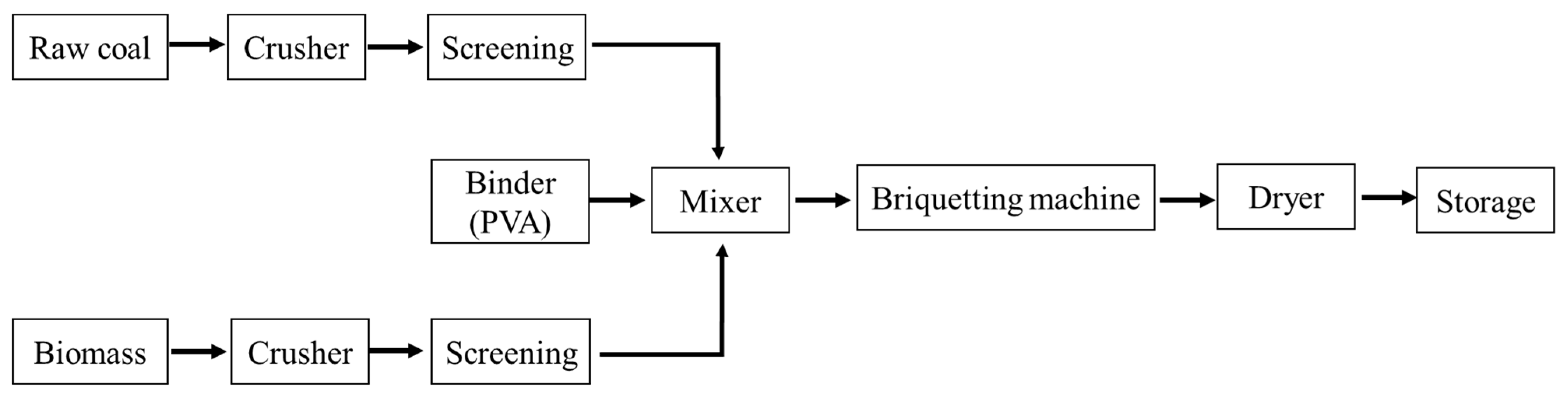

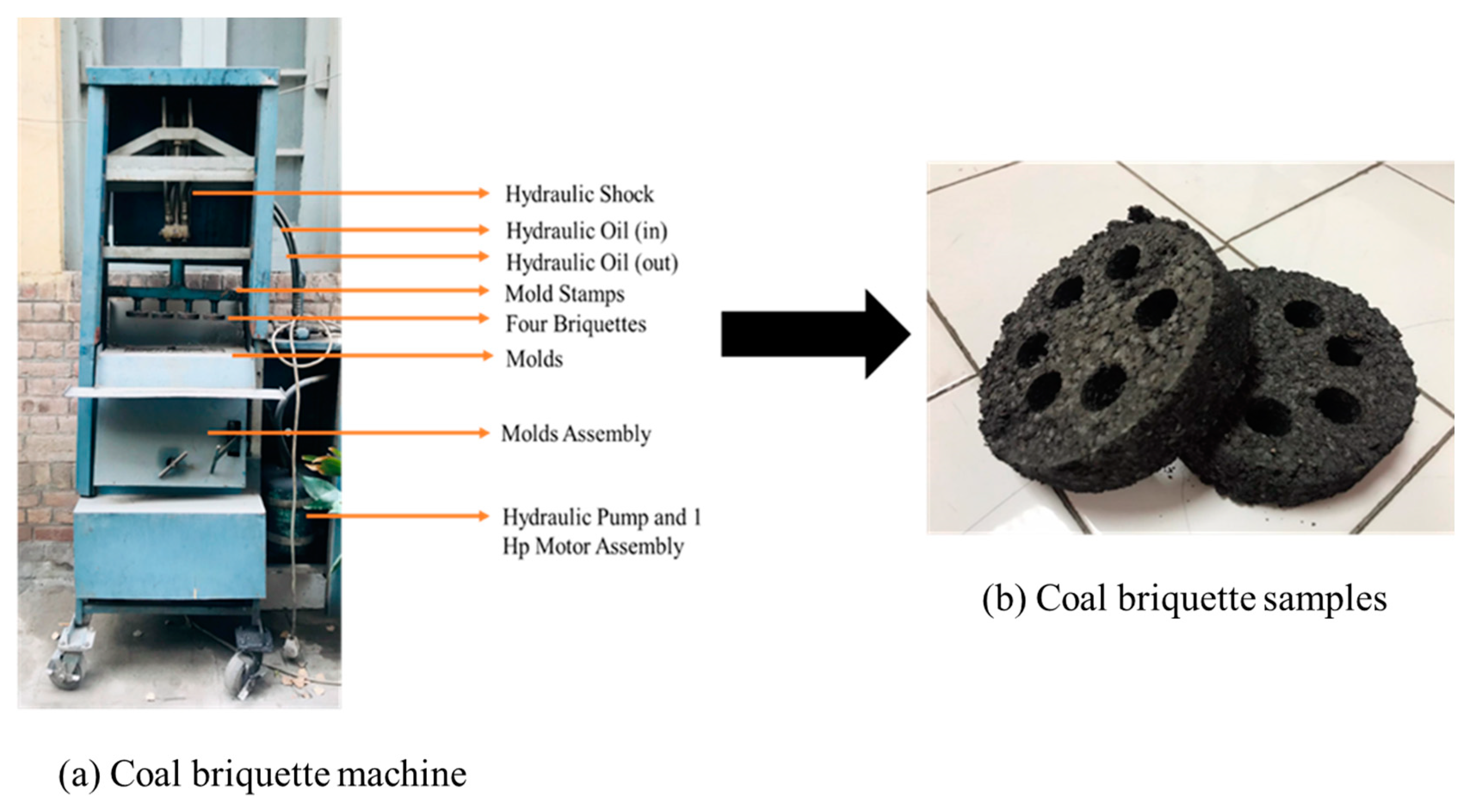

3. Materials and Methods

3.1. Experimental Design

Levels for Input Variables

3.2. Calorific Value Measurement

4. Results and Discussion

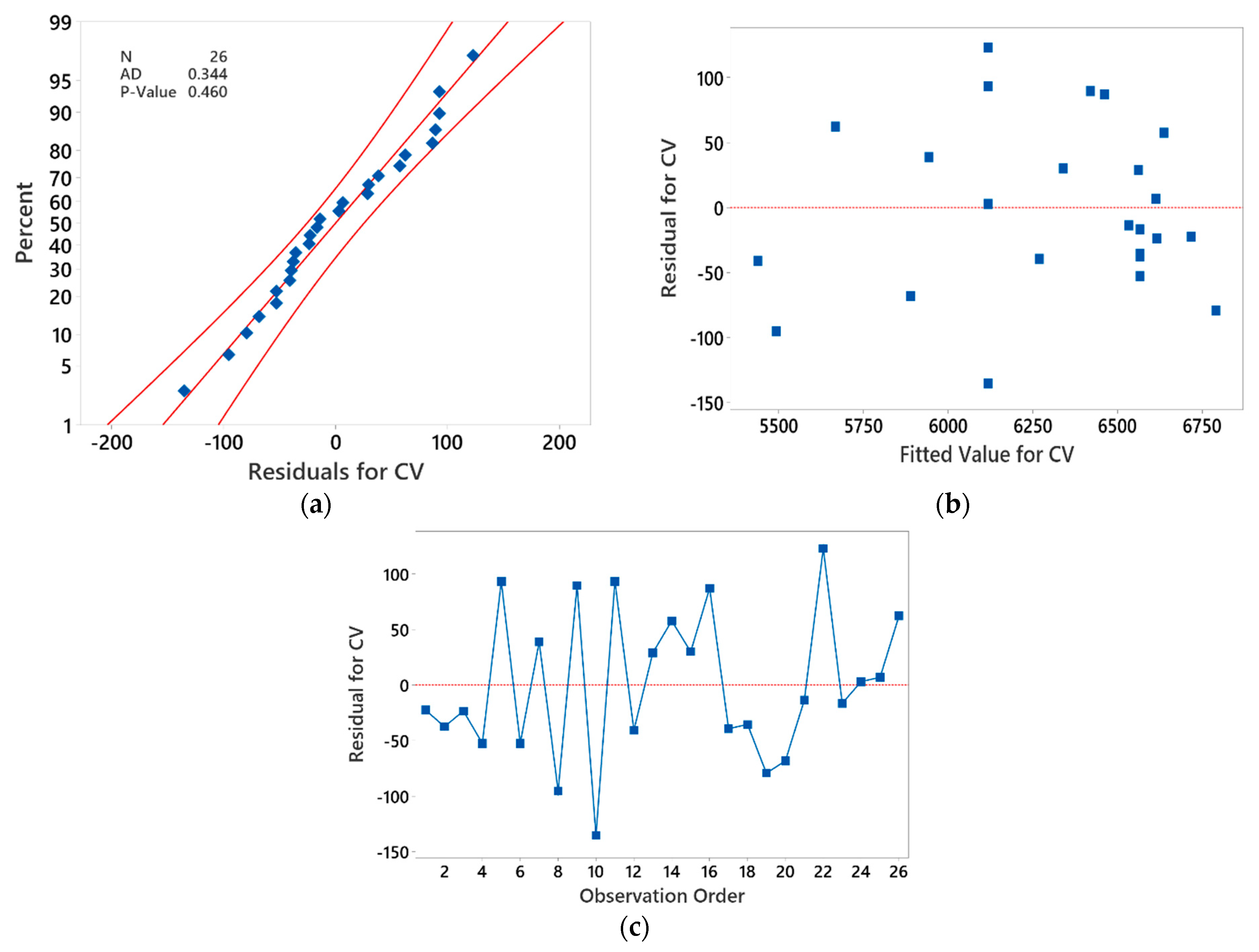

4.1. Analysis of Variance Based on Regression (ANOVA)

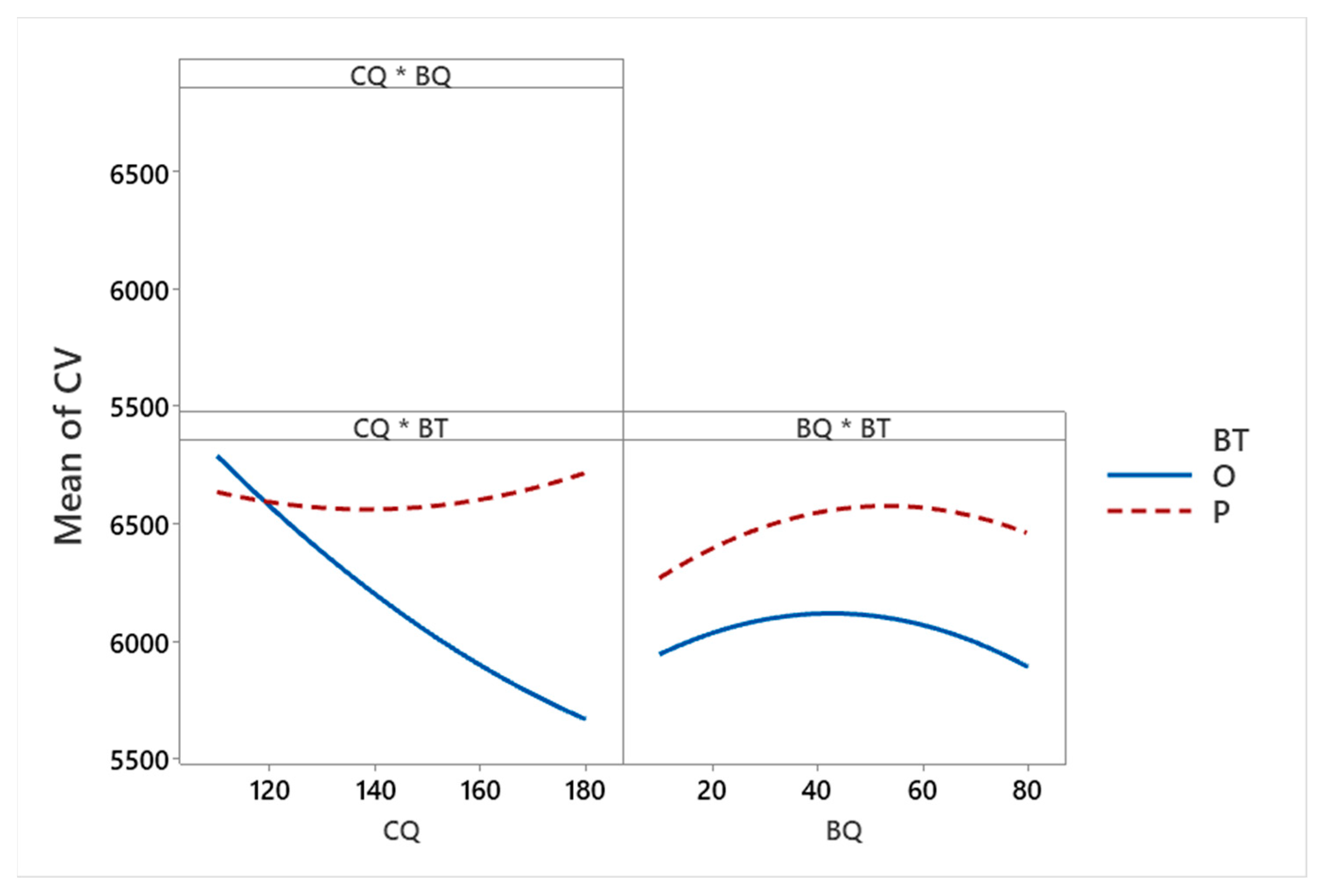

4.2. Main Effect and Interaction Plots

4.3. Optimization

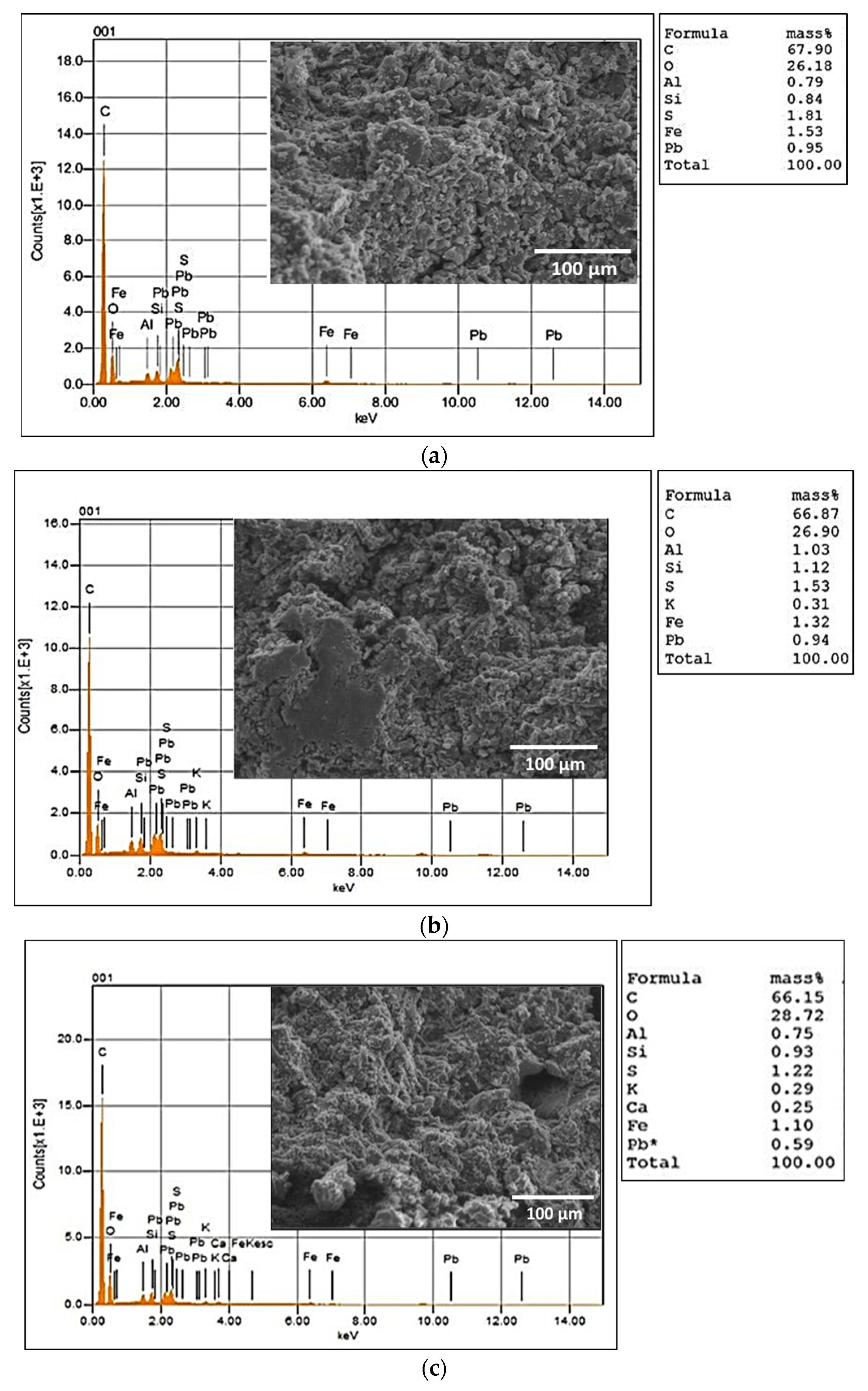

4.4. Energy Dispersive X-ray Spectroscopy (EDS or EDX)

4.5. Mechanical Analysis

5. Conclusions

- The present study investigated the impact of coal quantity, biomass quantity, and biomass type on coal briquette calorific value using central composite design (CCD) and response surface methodology (RSM).

- It was found that all factors significantly influenced calorific value, with coal and biomass quantity having contrasting effects.

- The study revealed that the pomegranate biomass consistently yielded higher calorific values than olive biomass.

- Nonlinear regression models were developed for each biomass type and have high goodness-of-fit and prediction accuracy.

- The optimized coal briquette formulation (i.e., coal quality of 180 gm, biomass quantity 54 gm, and biomass type pomegranate) using a composite desirability function achieved an optimal calorific value of 6728 kJ/kg.

- Energy Dispersive X-ray Spectroscopy (EDX) was utilized to analyze the elemental composition of coal briquettes, highlighting variations in carbon, oxygen, sulphur, iron, lead, silicon, and aluminum content.

- Mechanical analysis was performed to assess the briquette strength, revealing significant impacts of coal and biomass composition on strength levels.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guan, Y.; Yan, J.; Shan, Y.; Zhou, Y.; Hang, Y.; Li, R.; Liu, Y.; Liu, B.; Nie, Q.; Bruckner, B.; et al. Burden of the global energy price crisis on households. Nat. Energy 2023, 8, 304–316. [Google Scholar] [CrossRef]

- Kanwal, S.; Mehran, M.T.; Hassan, M.; Anwar, M.; Naqvi, S.R.; Khoja, A.H. An integrated future approach for the energy security of Pakistan: Replacement of fossil fuels with syngas for better environment and socio-economic development. Renew. Sustain. Energy Rev. 2022, 156, 111978. [Google Scholar] [CrossRef]

- Kehongo, M.N.; Aloys, M.O. Insights into the Quality and Quantity of Briquette Fuels from Bone Wastes. Int. J. Innov. Stud. Sci. Eng. Technol. 2020, 6, 25–34. [Google Scholar]

- Marganingrum, D.; Estiaty, L.M. Value increasing of reject coal with biomass adding as bio-coal briquette. Indones. J. Urban Environ. Technol. 2020, 3, 123–135. [Google Scholar] [CrossRef]

- Abbasi, K.R.; Shahbaz, M.; Zhang, J.; Irfan, M.; Alvarado, R. Analyze the environmental sustainability factors of China: The role of fossil fuel energy and renewable energy. Renew. Energy 2022, 187, 390–402. [Google Scholar] [CrossRef]

- Peng, X.; Jiang, Y.; Chen, Z.; Osman, A.I.; Farghali, M.; Rooney, D.W.; Yap, P.-S. Recycling municipal, agricultural and industrial waste into energy, fertilizers, food and construction materials, and economic feasibility: A review. Environ. Chem. Lett. 2023, 21, 765–801. [Google Scholar] [CrossRef]

- Anand, A.; Gautam, S.; Kundu, K.; Ram, L.C. Bio-coke: A sustainable solution to Indian metallurgical coal crisis. J. Anal. Appl. Pyrolysis 2023, 171, 105977. [Google Scholar] [CrossRef]

- Nikiforov, A.; Kinzhibekova, A.; Prikhodko, E.; Karmanov, A.; Nurkina, S. Analysis of the Characteristics of Bio-Coal Briquettes from Agricultural and Coal Industry Waste. Energies 2023, 16, 3527. [Google Scholar] [CrossRef]

- Wang, J.; Meng, Q.; Yang, C.; Ren, P.; Santamouris, M. Spray optimization to enhance the cooling performance of transparent roofs in hot-humid areas. Energy Build. 2023, 286, 112929. [Google Scholar] [CrossRef]

- Sanchez, P.D.C.; Aspe, M.M.T.; Sindol, K.N. An Overview on the Production of Bio-briquettes from Agricultural Wastes: Methods, Processes, and Quality. J. Agric. Food Eng. 2022, 1, 2716–6236. [Google Scholar]

- Lubwama, M.; Yiga, V.A.; Lubwama, H.N. Effects and interactions of the agricultural waste residues and binder type on physical properties and calorific values of carbonized briquettes. Biomass Convers. Biorefin. 2022, 12, 4979–4999. [Google Scholar] [CrossRef]

- Sun, M.; Zheng, J.; Liu, X. Effect of hydrothermal dehydration on the slurry ability of lignite. ACS Omega 2021, 6, 12027–12035. [Google Scholar] [CrossRef] [PubMed]

- Bajwa, D.S.; Peterson, T.; Sharma, N.; Shojaeiarani, J.; Bajwa, S.G. A review of densified solid biomass for energy production. Renew. Sustain. Energy Rev. 2018, 96, 296–305. [Google Scholar] [CrossRef]

- Fajfrlíková, P.; Brunerová, A.; Roubík, H. Analyses of waste treatment in rural areas of east java with the possibility of low-pressure briquetting press application. Sustainability 2020, 12, 8153. [Google Scholar] [CrossRef]

- Zhang, G.; Sun, Y.; Xu, Y. Review of briquette binders and briquetting mechanism. Renew. Sustain. Energy Rev. 2018, 82, 477–487. [Google Scholar] [CrossRef]

- Zhuo, Y.; Xie, Z.; Shen, Y. Model study of carbonisation of low rank coal briquettes: Effect of briquettes shape. Powder Technol. 2021, 385, 120–130. [Google Scholar] [CrossRef]

- Song, B.; Cooke-Willis, M.; Theobald, B.; Hall, P. Producing a high heating value and weather resistant solid fuel via briquetting of blended wood residues and thermoplastics. Fuel 2021, 283, 119263. [Google Scholar] [CrossRef]

- Jelonek, Z.; Drobniak, A.; Mastalerz, M.; Jelonek, I. Environmental implications of the quality of charcoal briquettes and lump charcoal used for grilling. Sci. Total Environ. 2020, 747, 141267. [Google Scholar] [CrossRef]

- Olugbade, T.O.; Ojo, O.T. Binderless briquetting technology for lignite briquettes: A review. Energy Ecol. Environ. 2021, 6, 69–79. [Google Scholar] [CrossRef]

- Bai, X.; Ding, H.; Lian, J.; Ma, D.; Yang, X.; Sun, N.; Xue, W.; Chang, Y. Coal production in China: Past, present, and future projections. Int. Geol. Rev. 2018, 60, 535–547. [Google Scholar] [CrossRef]

- G’Ofurovich, H.O.; Abdurashidovich, U.A.; O’G’Li, I.J.R.; Ravshanovich, S.F. Prospects for the industrial use of coal in the world and its process of reproducing. Prospects 2020, 6, 240–247. [Google Scholar]

- Aransiola, E.; Oyewusi, T.; Osunbitan, J.; Ogunjimi, L. Effect of binder type, binder concentration and compacting pressure on some physical properties of carbonized corncob briquette. Energy Rep. 2019, 5, 909–918. [Google Scholar] [CrossRef]

- Zhong, Q.; Yang, Y.; Li, Q.; Xu, B.; Jiang, T. Coal tar pitch and molasses blended binder for production of formed coal briquettes from high volatile coal. Fuel Process. Technol. 2017, 157, 12–19. [Google Scholar] [CrossRef]

- Tayeb, A.H.; Amini, E.; Ghasemi, S.; Tajvidi, M. Cellulose nanomaterials—Binding properties and applications: A review. Molecules 2018, 23, 2684. [Google Scholar] [CrossRef]

- Gilvari, H.; De Jong, W.; Schott, D.L. Quality parameters relevant for densification of bio-materials: Measuring methods and affecting factors-A review. Biomass Bioenergy 2019, 120, 117–134. [Google Scholar] [CrossRef]

- Flores, I.V.; Fraiz, F.; Junior, R.A.L.; Bagatini, M.C. Evaluation of spent pot lining (SPL) as an alternative carbonaceous material in ironmaking processes. J. Mater. Res. Technol. 2019, 8, 33–40. [Google Scholar] [CrossRef]

- Olugbade, T.; Ojo, O.; Mohammed, T. Influence of binders on combustion properties of biomass briquettes: A recent review. BioEnergy Res. 2019, 12, 241–259. [Google Scholar] [CrossRef]

- Arafat, R.Y.; Khan, S.H. Evaluation of humic acid as an aflatoxin binder in broiler chickens. Ann. Anim. Sci. 2017, 17, 241. [Google Scholar] [CrossRef]

- Chen, H.; He, J.; Chen, Z.; Geng, L. A comparative study of combustion and emission characteristics of dual-fuel engine fueled with diesel/methanol and diesel–polyoxymethylene dimethyl ether blend/methanol. Process Saf. Environ. Prot. 2021, 147, 714–722. [Google Scholar] [CrossRef]

- Vivek, C.; Rochak, P.; Suresh, P.S.; Kiran, K.R.R. Comparison study on fuel briquettes made of eco-friendly materials for alternate source of energy. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Florentino-Madiedo, L.; Díaz-Faes, E.; Barriocanal, C. Mechanical strength of bio-coke from briquettes. Renew. Energy 2020, 146, 1717–1724. [Google Scholar] [CrossRef]

- Gendek, A.; Aniszewska, M.; Malaťák, J.; Velebil, J. Evaluation of selected physical and mechanical properties of briquettes produced from cones of three coniferous tree species. Biomass Bioenergy 2018, 117, 173–179. [Google Scholar] [CrossRef]

- Geng, P.; Cao, E.; Tan, Q.; Wei, L. Effects of alternative fuels on the combustion characteristics and emission products from diesel engines: A review. Renew. Sustain. Energy Rev. 2017, 71, 523–534. [Google Scholar] [CrossRef]

- Kraszkiewicz, A.; Kachel, M.; Parafiniuk, S.; Zając, G.; Niedziółka, I.; Sprawka, M. Assessment of the possibility of using hemp biomass (Cannabis sativa L.) for energy purposes: A case study. Appl. Sci. 2019, 9, 4437. [Google Scholar]

- Okot, D.K.; Bilsborrow, P.E.; Phan, A.N. Effects of operating parameters on maize COB briquette quality. Biomass Bioenergy 2018, 112, 61–72. [Google Scholar] [CrossRef]

- Talabi, S.; Luz, A.; Pandolfelli, V.; Bernardes, J.; Lucas, A. Synthesis and graphitization of resole resins by ferrocene. Prog. Nat. Sci. Mater. Int. 2019, 29, 71–80. [Google Scholar] [CrossRef]

- Tippayawong, K.; Santiteerakul, S.; Ramingwong, S.; Tippayawong, N. Cost analysis of community scale smokeless charcoal briquette production from agricultural and forest residues. Energy Procedia 2019, 160, 310–316. [Google Scholar] [CrossRef]

- Özyuğuran, A.; Acma, H.H.; Dahiloğlu, E. Production of fuel briquettes from rice husk–lignite blends. Environ. Prog. Sustain. Energy 2017, 36, 742–748. [Google Scholar] [CrossRef]

- Xin, L.; Guo, Z.; Xiao, X.; Peng, C.; Zeng, P.; Feng, W.; Xu, W. Feasibility of anaerobic digestion on the release of biogas and heavy metals from rice straw pretreated with sodium hydroxide. Environ. Sci. Pollut. Res. 2019, 26, 19434–19444. [Google Scholar] [CrossRef]

- Vamvuka, D.; Loukakou, E.; Sfakiotakis, S.; Petrakis, E. The impact of a combined pre-treatment on the combustion performance of various biomass wastes and their blends with lignite. Thermochim. Acta 2020, 688, 178599. [Google Scholar] [CrossRef]

- Kivumbi, B.; Jande, Y.A.; Kirabira, J.B.; Kivevele, T.T. Production of carbonized briquettes from charcoal fines using African elemi (Canarium schweinfurthii) resin as an organic binder. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–17. [Google Scholar] [CrossRef]

- Guo, Z.; Miao, Z.; Guo, F.; Guo, Y.; Feng, Y.; Wu, J.; Zhang, Y. Parameter optimization of waste coal briquetting and particulate matter emissions test during combustion: A case study. Environ. Pollut. 2022, 294, 118621. [Google Scholar] [CrossRef] [PubMed]

- van der Westhuizen, L.; Diedericks, D.; Akdogan, G.; Görgens, J.F. Optimizing the mechanical properties of coal-fines briquettes produced with steam-exploded sugarcane bagasse as a binder. Int. J. Coal Prep. Util. 2023, 1–19. [Google Scholar] [CrossRef]

- Bazargan, A.; Rough, S.L.; McKay, G. Fine tuning of process parameters for improving briquette production from palm kernel shell gasification waste. Environ. Technol. 2018, 39, 931–938. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Lei, T.; Chang, X.; Shi, X.; Xiao, J.; Li, Z.; He, X.; Zhu, J.; Yang, S. Optimization of a biomass briquette fuel system based on grey relational analysis and analytic hierarchy process: A study using cornstalks in China. Appl. Energy 2015, 157, 523–532. [Google Scholar] [CrossRef]

- Florentino-Madiedo, L.; Díaz-Faes, E.; García, R.; Barriocanal, C. Influence of binder type on greenhouse gases and PAHs from the pyrolysis of biomass briquettes. Fuel Process. Technol. 2018, 171, 330–338. [Google Scholar] [CrossRef]

- Ahmad, W.; Ahmad, I.; Ahmad, I.; Yaseen, M.; Muhammad, N.; Salman, M. Desulfurization and de-ashing of low-rank coal by catalytic oxidation using Sn as catalyst loaded in different forms. Int. J. Coal Prep. Util. 2022, 42, 2260–2276. [Google Scholar] [CrossRef]

- Moradi, H.; Sabbaghi, S.; Mirbagheri, N.S.; Chen, P.; Rasouli, K.; Kamyab, H.; Chelliapan, S. Removal of chloride ion from drinking water using Ag NPs-Modified bentonite: Characterization and optimization of effective parameters by response surface methodology-central composite design. Environ. Res. 2023, 223, 115484. [Google Scholar] [CrossRef]

- Manmeen, A.; Kongjan, P.; Palamanit, A.; Jariyaboon, R. Biochar and pyrolysis liquid production from durian peel by using slow pyrolysis process: Regression analysis, characterization, and economic assessment. Ind. Crops Prod. 2023, 203, 117162. [Google Scholar] [CrossRef]

- Nakkeeran, G.; Krishnaraj, L. Developing lightweight concrete bricks by replacing fine aggregate with vermiculite: A regression analysis prediction approach. Asian J. Civ. Eng. 2023, 24, 1529–1537. [Google Scholar] [CrossRef]

- Wang, S.; Zou, C.; Lou, C.; Yang, H.; Pu, Y.; Luo, J.; Peng, C.; Wang, C.; Li, Z. Influence of the synergistic effects between coal and hemicellulose/cellulose/lignin on the co-combustion of coal and lignocellulosic biomass. Fuel 2022, 311, 122585. [Google Scholar] [CrossRef]

- Basak, S.; Ali, S.W. Sodium Lignin Sulfonate (SLS) and Pomegranate Rind Extracts (PRE) Bio-macro-molecule: A Novel Composition for Making Fire Resistant Cellulose Polymer. Combust. Sci. Technol. 2022, 194, 3206–3224. [Google Scholar] [CrossRef]

- Saadi, W.; Rodríguez-Sánchez, S.; Ruiz, B.; Najar-Souissi, S.; Ouederni, A.; Fuente, E. From pomegranate peels waste to one-step alkaline carbonate activated carbons. Prospect as sustainable adsorbent for the renewable energy production. J. Environ. Chem. Eng. 2022, 10, 107010. [Google Scholar] [CrossRef]

- Cliffe, K.; Patumsawad, S. Co-combustion of waste from olive oil production with coal in a fluidised bed. Waste Manag. 2001, 21, 49–53. [Google Scholar] [CrossRef] [PubMed]

| Input Variables | Units | Symbol | Level 1 | Level 2 | Level 3 |

|---|---|---|---|---|---|

| Coal Quantity | gm | CQ | 110 | 145 | 180 |

| Biomass Quantity | gm | BQ | 10 | 45 | 80 |

| Biomass Type | - | BT | Olive (O) | Pomegranate (P) |

| Experimental Runs | Coal Quantity (gm) | Biomass Quantity (gm) | Biomass Type | Calorific Value (kJ/kg) |

|---|---|---|---|---|

| 1 | 180 | 45 | P | 6694 |

| 2 | 145 | 45 | P | 6528 |

| 3 | 110 | 10 | O | 6592 |

| 4 | 145 | 45 | O | 6210 |

| 5 | 145 | 45 | P | 6513 |

| 6 | 145 | 45 | P | 6513 |

| 7 | 145 | 10 | O | 5982 |

| 8 | 180 | 10 | O | 5398 |

| 9 | 180 | 10 | P | 6509 |

| 10 | 145 | 45 | O | 5982 |

| 11 | 145 | 45 | O | 6210 |

| 12 | 180 | 80 | O | 5398 |

| 13 | 110 | 80 | O | 6590 |

| 14 | 110 | 45 | P | 6694 |

| 15 | 110 | 10 | P | 6369 |

| 16 | 145 | 80 | P | 6548 |

| 17 | 145 | 10 | P | 6229 |

| 18 | 145 | 45 | P | 6530 |

| 19 | 110 | 45 | O | 6710 |

| 20 | 145 | 80 | O | 5821 |

| 21 | 110 | 80 | P | 6518 |

| 22 | 145 | 45 | O | 6240 |

| 23 | 145 | 45 | P | 6549 |

| 24 | 145 | 45 | O | 6120 |

| 25 | 180 | 80 | P | 6619 |

| 26 | 180 | 45 | O | 5729 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 7 | 3,497,403 | 499,629 | 82.08 | 0 |

| Linear | 3 | 2,136,389 | 712,130 | 116.99 | 0 |

| Coal Quantity | 1 | 814,323 | 814,323 | 133.78 | 0 |

| Biomass Quantity | 1 | 14,352 | 14,352 | 2.36 | 0.142 |

| Biomass Type | 1 | 1,307,714 | 1,307,714 | 214.84 | 0 |

| Square | 2 | 230,452 | 115,226 | 18.93 | 0 |

| Coal Quantity × Coal Quantity | 1 | 67,953 | 67,953 | 11.16 | 0.004 |

| Biomass Quantity × Biomass Quantity | 1 | 222,804 | 222,804 | 36.6 | 0 |

| 2-Way Interaction | 2 | 1,130,562 | 565,281 | 92.87 | 0 |

| Coal Quantity × Biomass Type | 1 | 1,084,805 | 1,084,805 | 178.22 | 0 |

| Biomass Quantity × Biomass Type | 1 | 45,757 | 45,757 | 7.52 | 0.013 |

| Error | 18 | 109,565 | 6087 | ||

| Lack-of-Fit | 10 | 64,284 | 6428 | 1.14 | 0.437 |

| Pure Error | 8 | 45,280 | 5660 | ||

| Total | 25 | 3,606,968 |

| Sample Number Based on Experimental Run | Coal Quantity (gm) | Biomass Quantity (gm) | Biomass Composition (%) | Compressive Strength (N/mm2) | Standard Deviation |

|---|---|---|---|---|---|

| 1 | 180 | 45 | 20.00 | 0.71 | 0.01 |

| 9 | 180 | 10 | 5.26 | 0.25 | 0.06 |

| 14 | 110 | 45 | 29.03 | 0.75 | 0.03 |

| 18 | 145 | 45 | 23.68 | 0.21 | 0.01 |

| 21 | 110 | 80 | 42.11 | 0.67 | 0.05 |

| 25 | 180 | 80 | 30.77 | 0.40 | 0.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, A.U.; Jan, Q.M.U.; Abas, M.; Muhammad, K.; Ali, Q.M.; Zimon, D. Utilization of Biowaste for Sustainable Production of Coal Briquettes. Energies 2023, 16, 7025. https://doi.org/10.3390/en16207025

Khan AU, Jan QMU, Abas M, Muhammad K, Ali QM, Zimon D. Utilization of Biowaste for Sustainable Production of Coal Briquettes. Energies. 2023; 16(20):7025. https://doi.org/10.3390/en16207025

Chicago/Turabian StyleKhan, Amad Ullah, Qazi Muhammad Usman Jan, Muhammad Abas, Khan Muhammad, Qazi Muhammad Ali, and Dominik Zimon. 2023. "Utilization of Biowaste for Sustainable Production of Coal Briquettes" Energies 16, no. 20: 7025. https://doi.org/10.3390/en16207025

APA StyleKhan, A. U., Jan, Q. M. U., Abas, M., Muhammad, K., Ali, Q. M., & Zimon, D. (2023). Utilization of Biowaste for Sustainable Production of Coal Briquettes. Energies, 16(20), 7025. https://doi.org/10.3390/en16207025