Electrically Heated High-Temperature Thermal Energy Storage with Dual Operating Modes: From Concept to Validation

Abstract

:1. Introduction

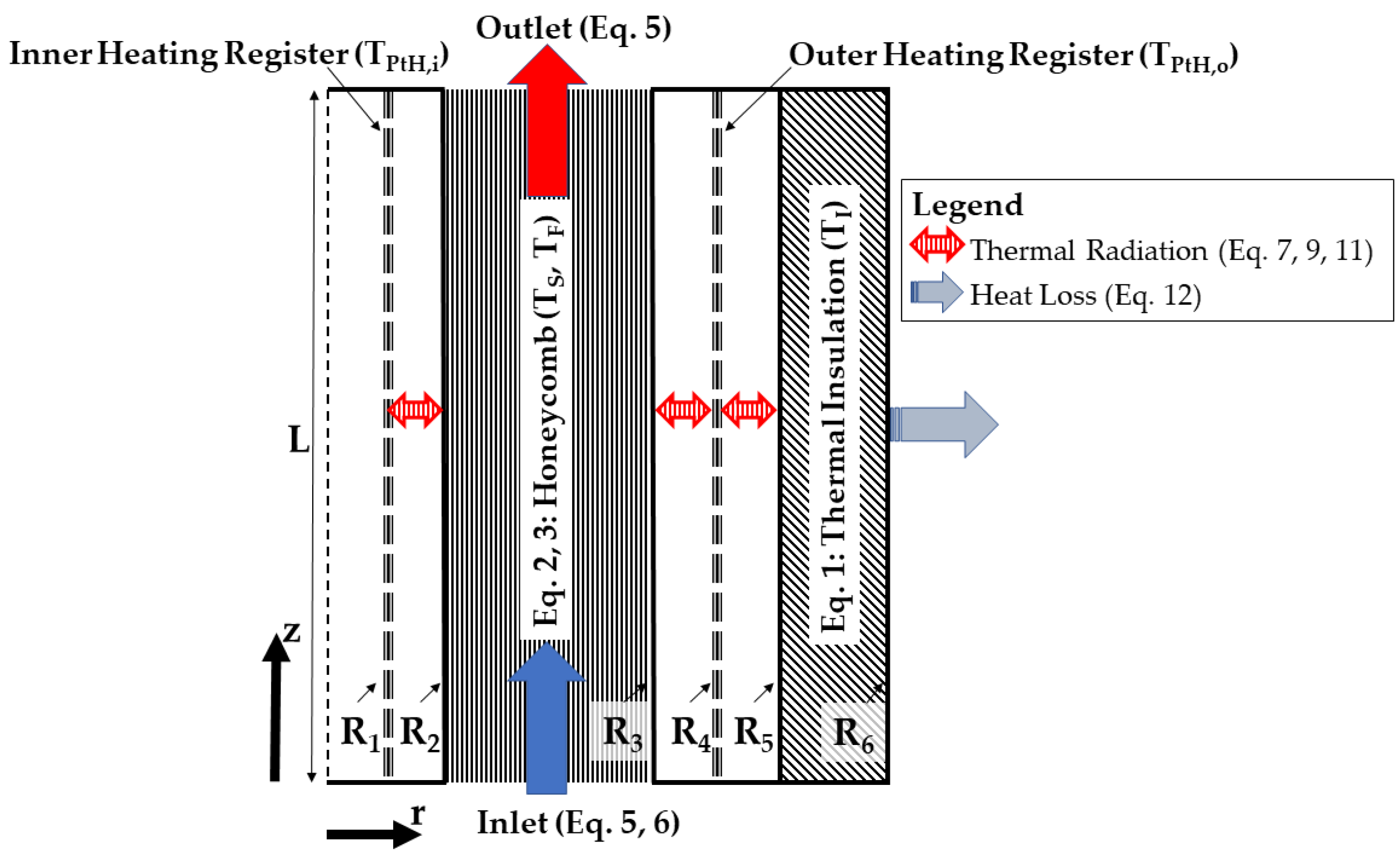

2. High-Temperature Electrically Heated Thermal Energy Storage with Dual Operating Modes

3. Modelling

4. Results

4.1. Simulation Results

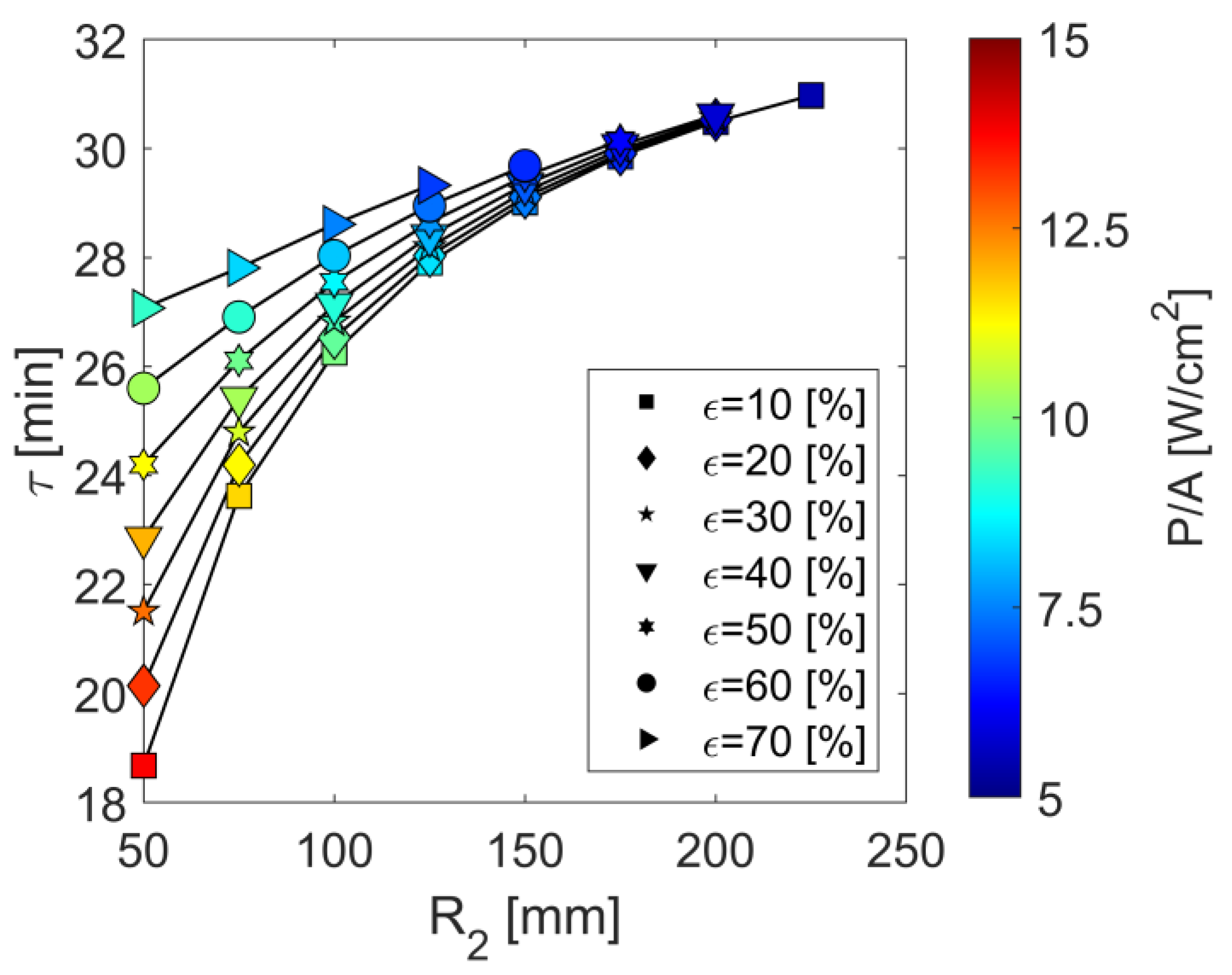

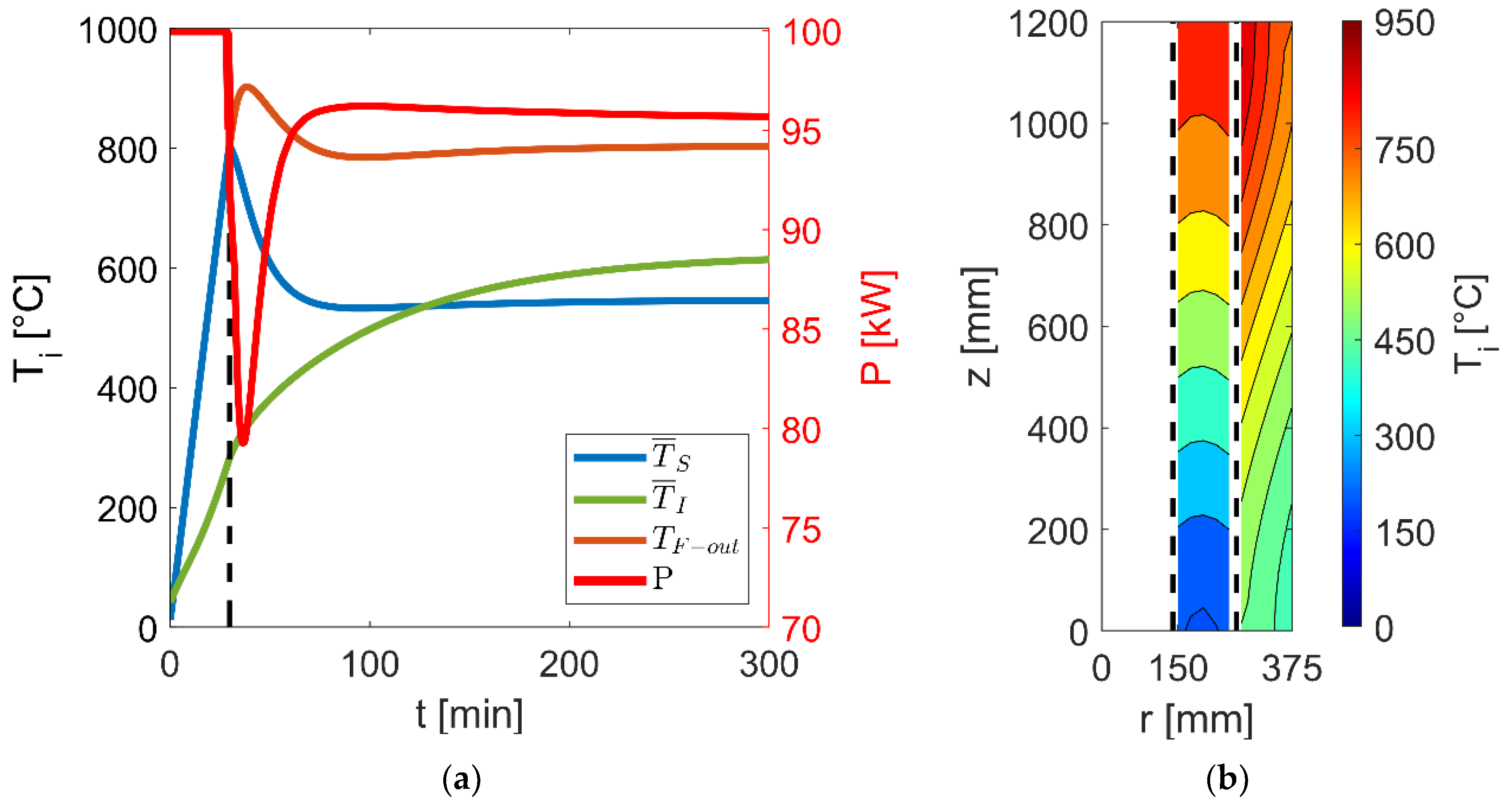

4.1.1. Operating Mode I

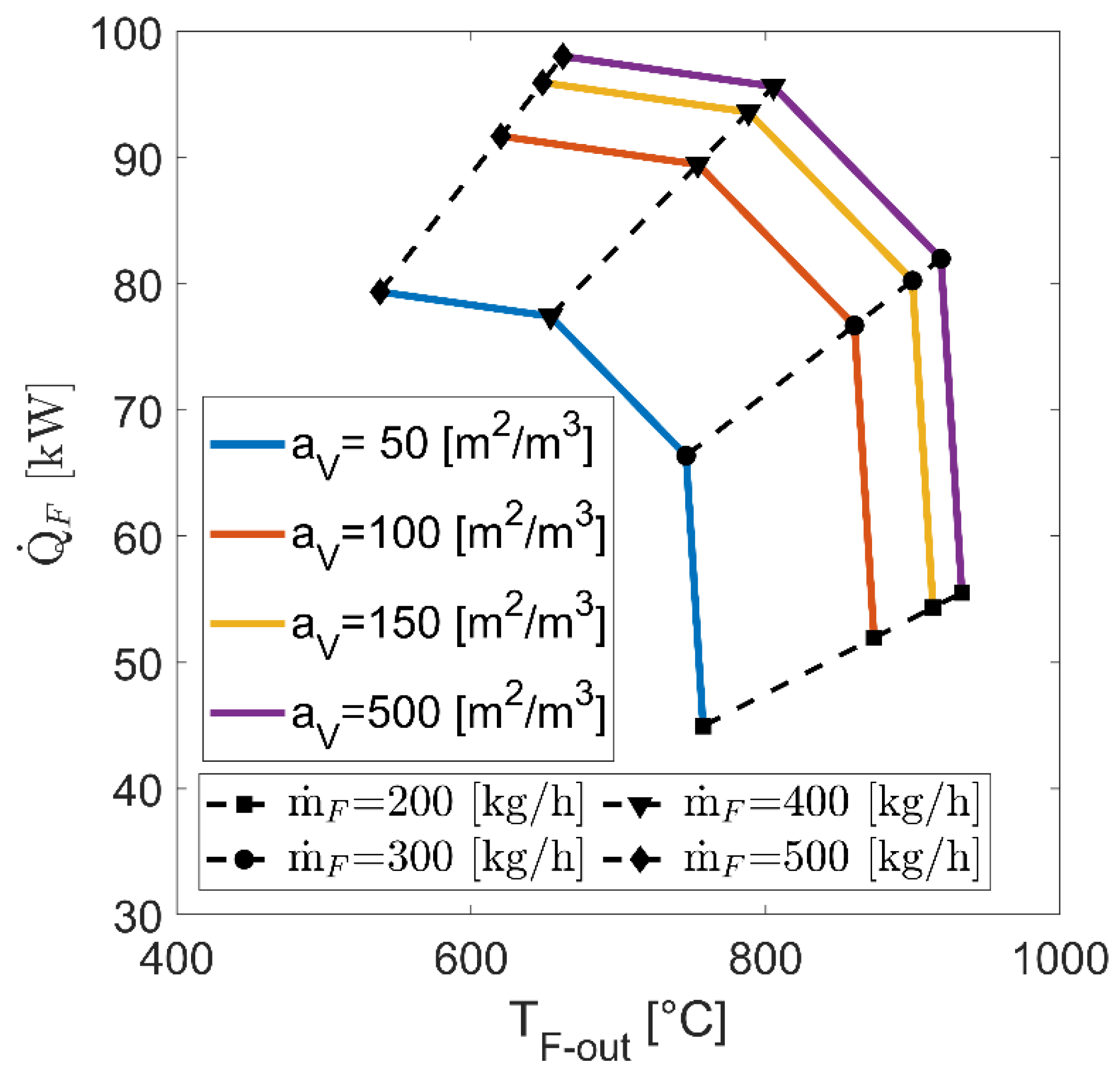

4.1.2. Operating Mode II

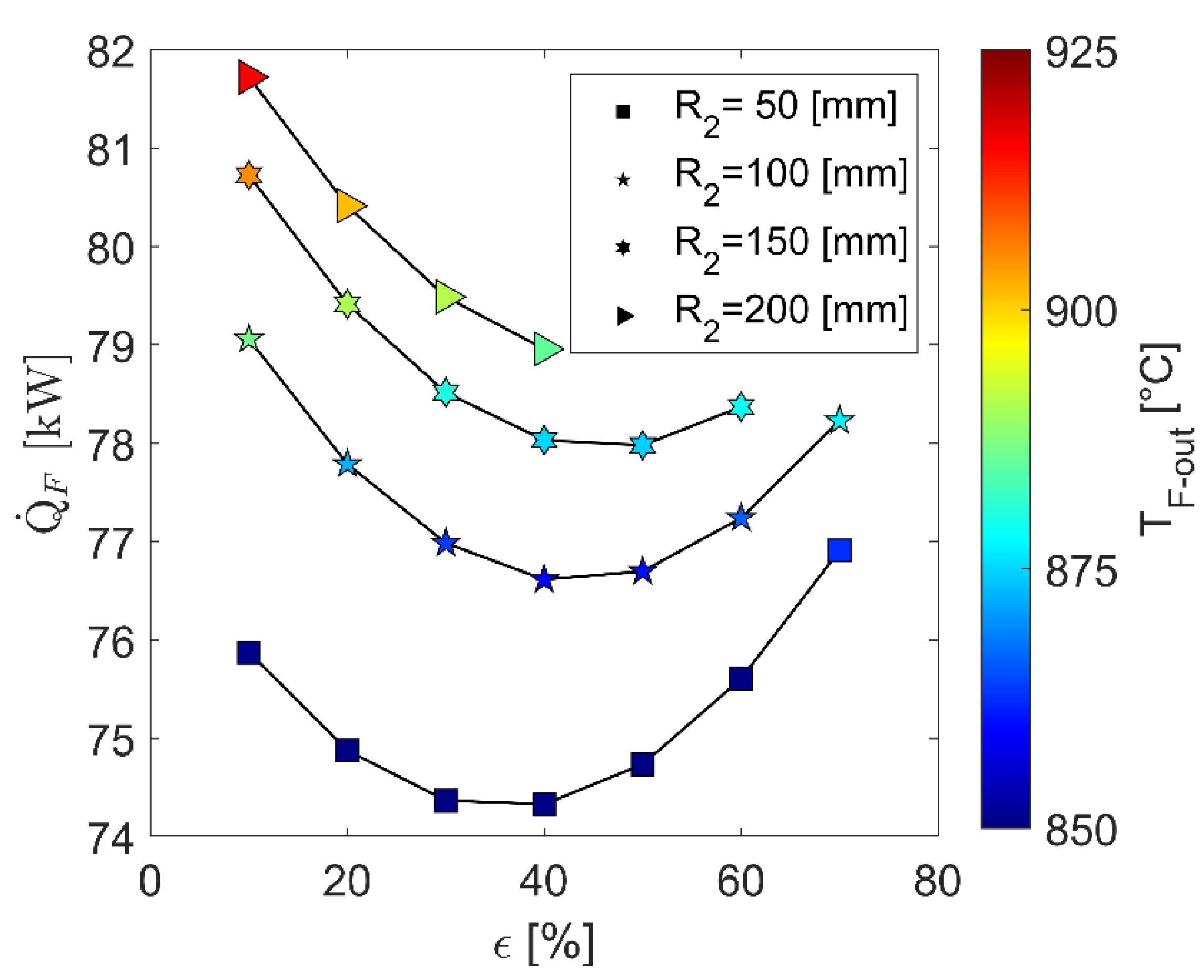

4.1.3. Favorite Geometrical Design Solutions

4.2. Experimental Results

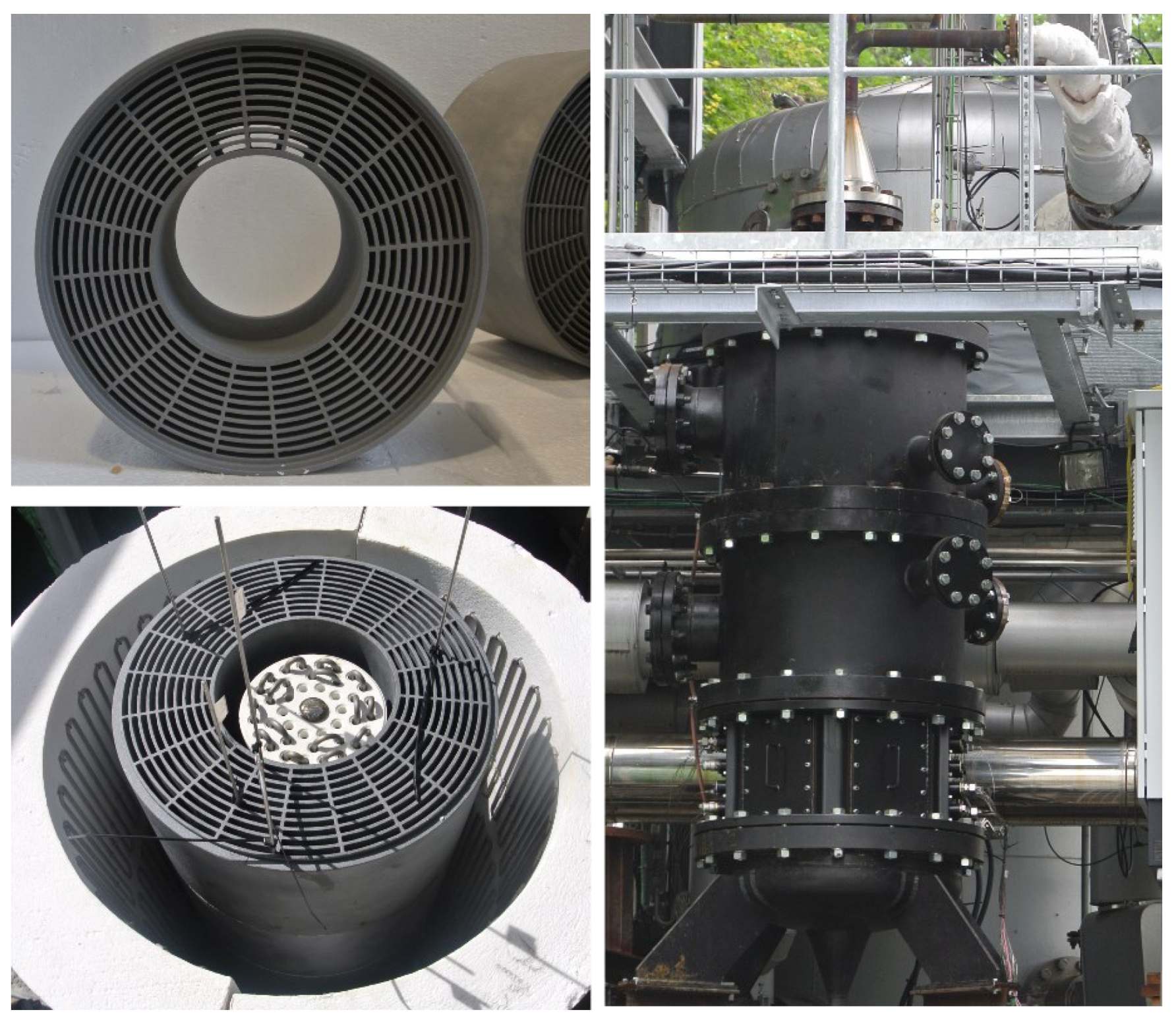

4.2.1. Experimental Set-Up

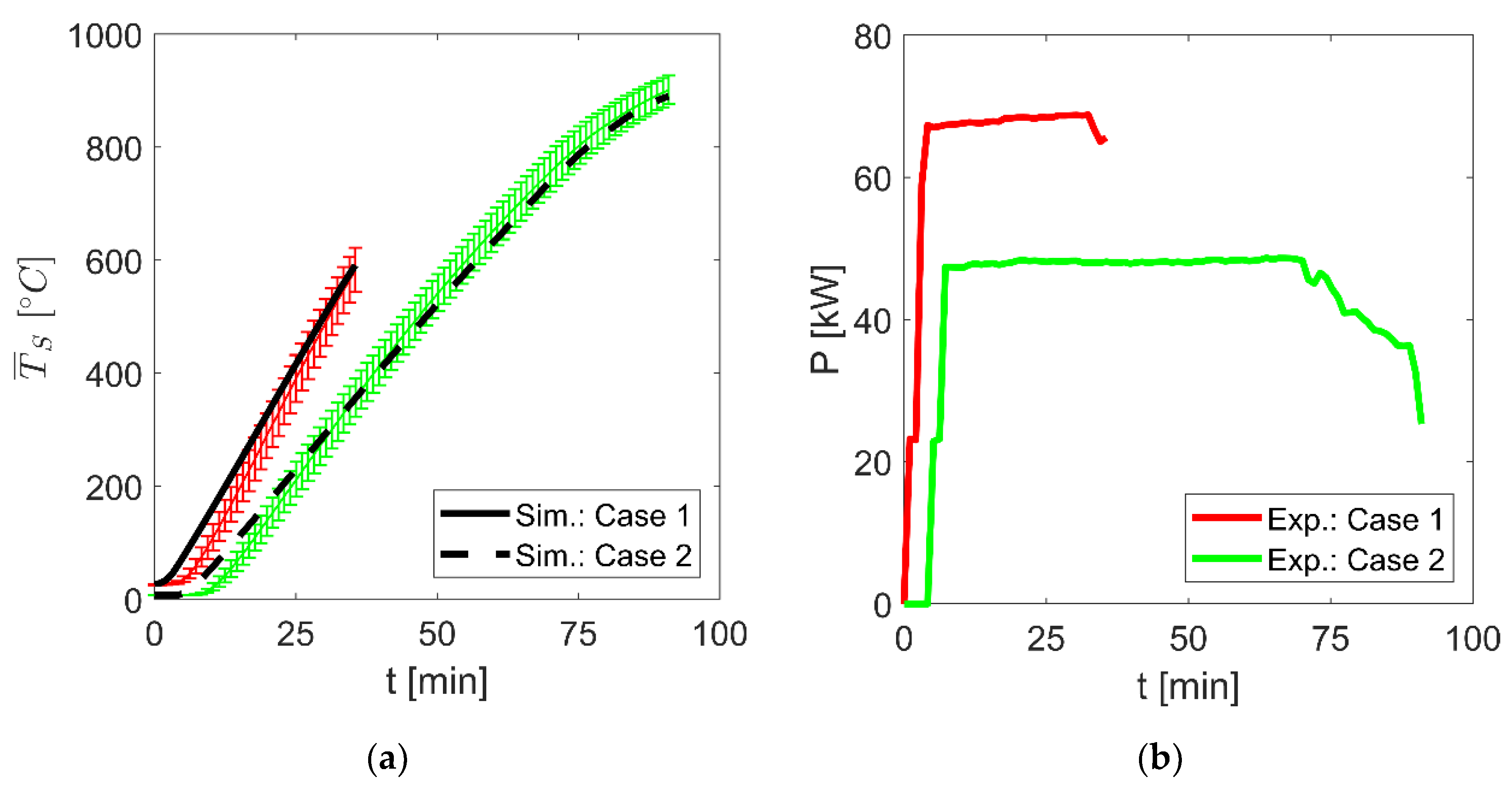

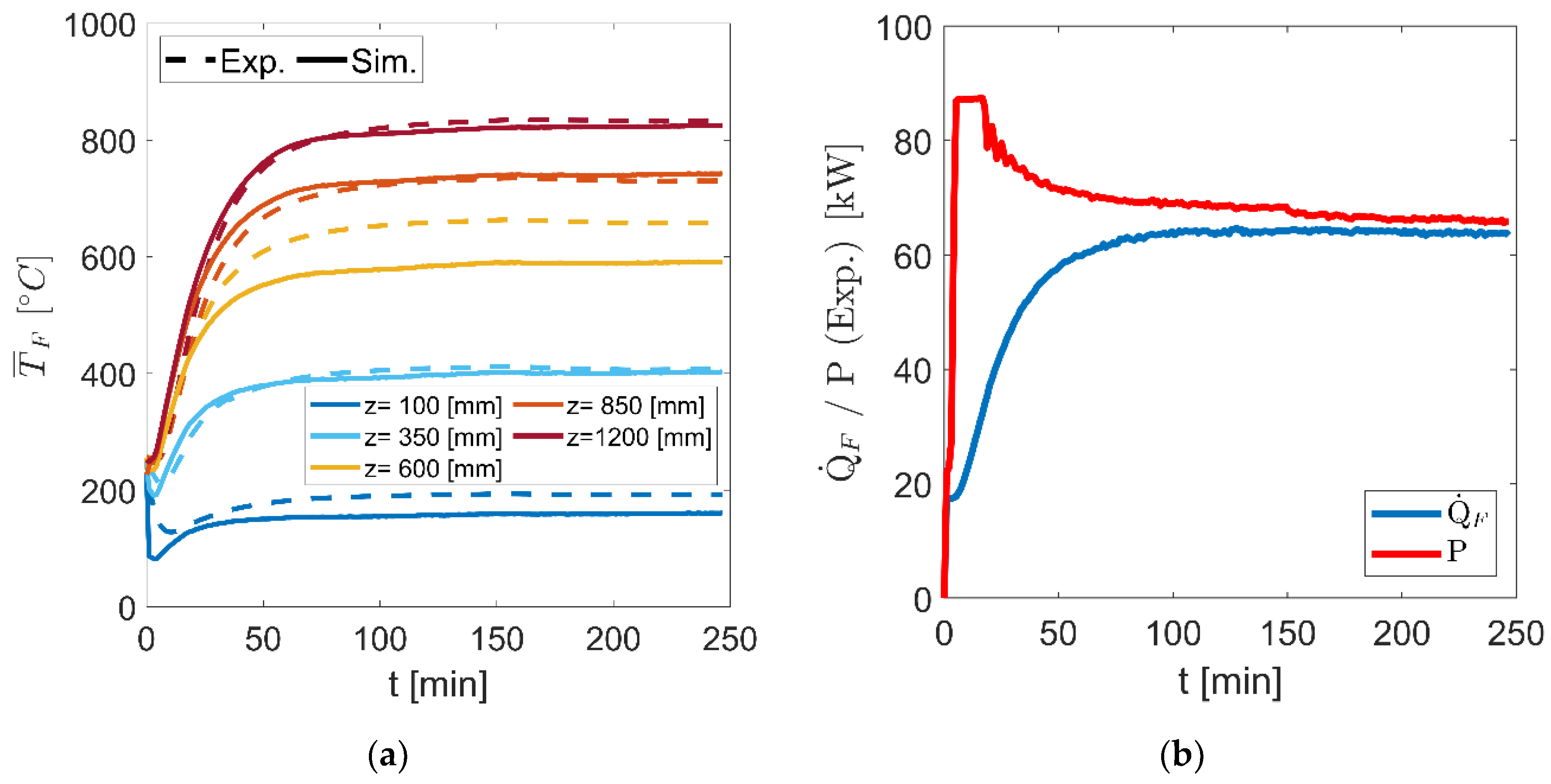

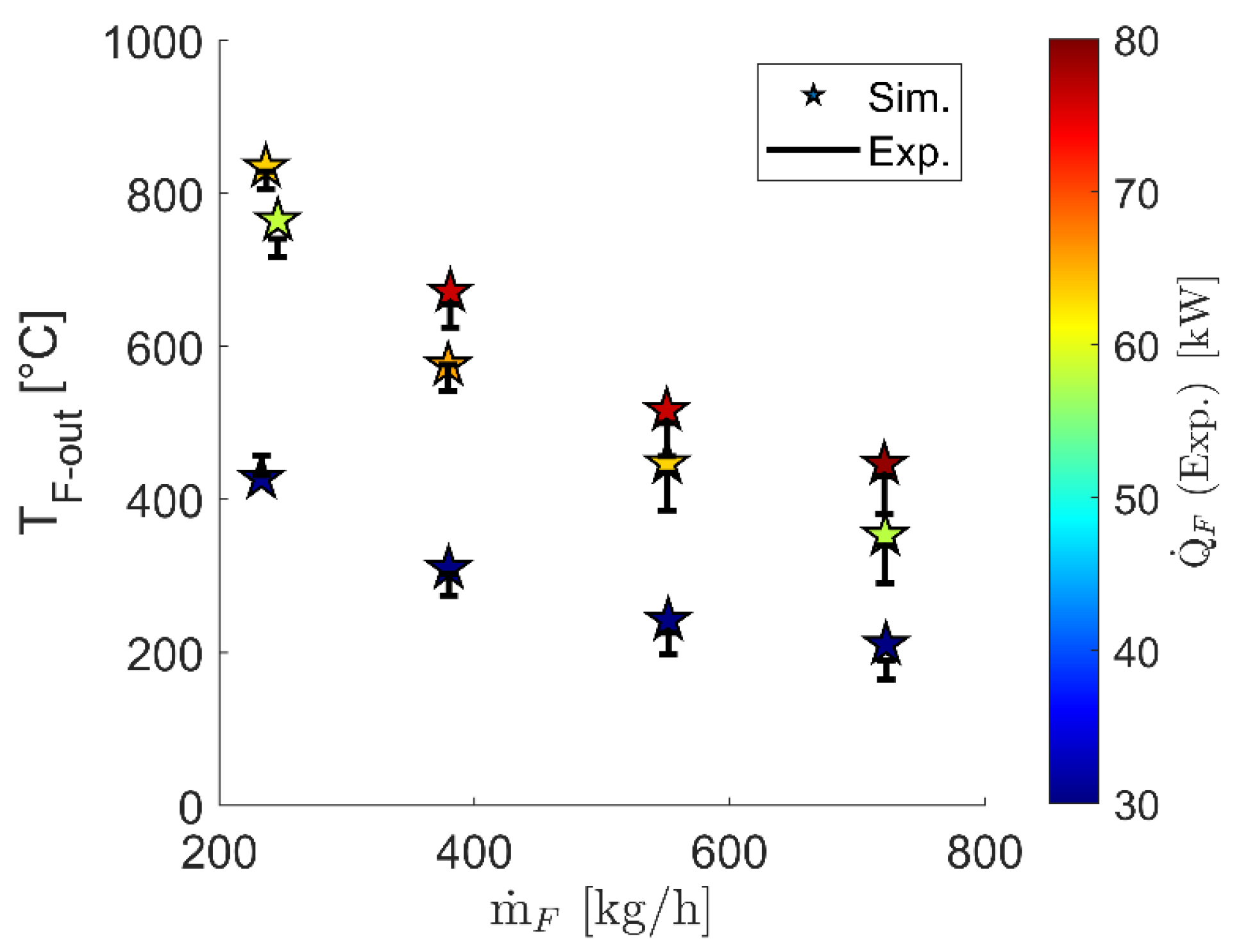

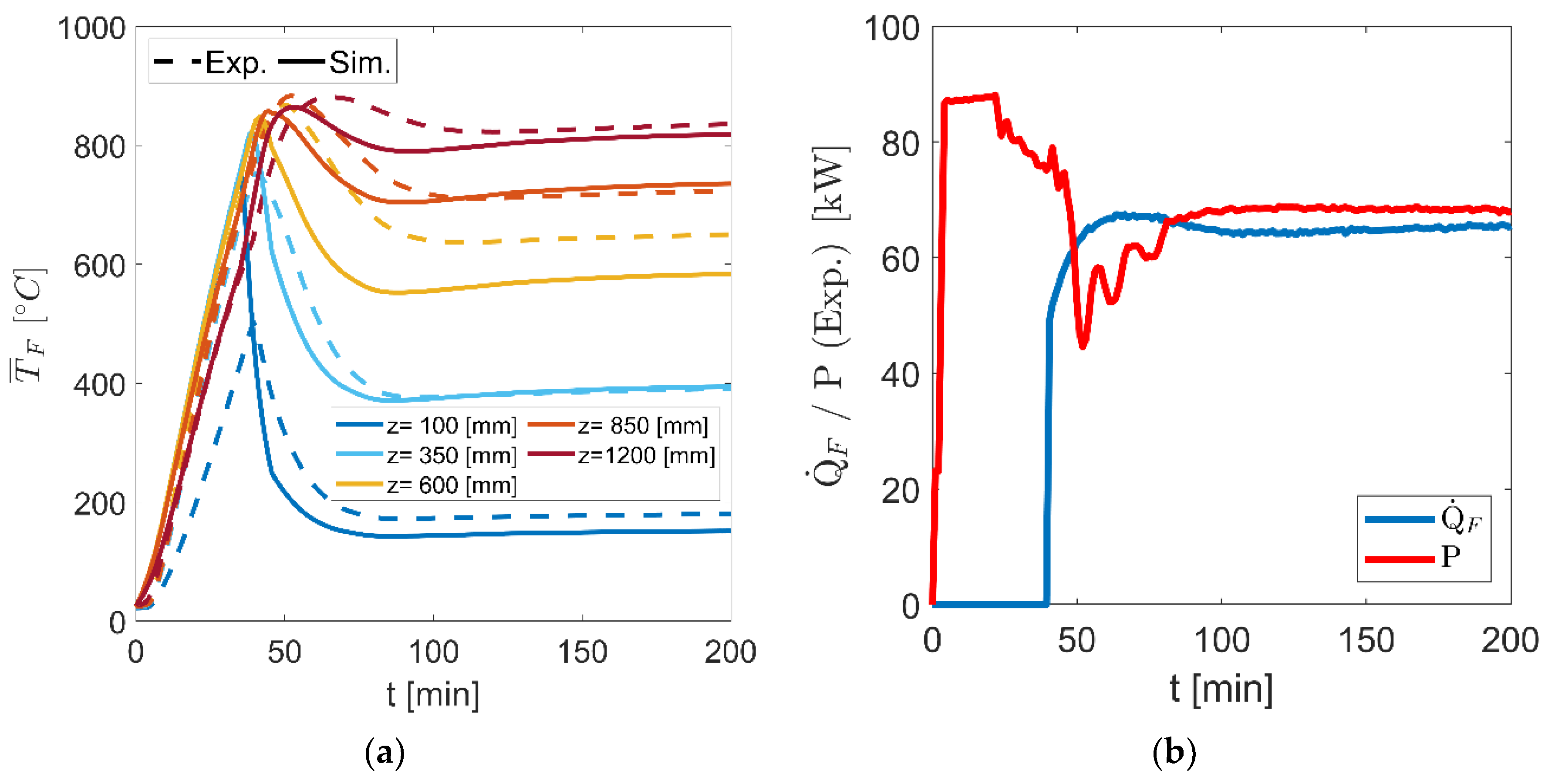

4.2.2. Proof of Concept and Validation

- -

- identification of the maximal size of the internal, radiative heated storage system with dual operating modes in combination with an external cost-effective solid-media thermal energy storage system

- -

- design optimizations to improve the maximum operational temperature via ceramic heating elements with radial orientation

- -

- lifetime predictions based on FEM models for the brittle SiC material

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Available online: https://www.elab2.kit.edu/english/index.php (accessed on 7 September 2023).

- Available online: https://www.dlr.de/en/research-and-transfer/research-infrastructure/hotreg-en (accessed on 7 September 2023).

- Krüger, M.; Haunstetter, J.; Zunft, S. Slag as an inventory material for heat storage in a concentrated solar tower power plant: Experimental studies on design and performance of the thermal energy storage. In Proceedings of the International Renewable Energy Storage Conference (IRES), Düsseldorf, Germany, 12–14 March 2019. [Google Scholar]

- Dehghan, M.; Ghasemizadeh, M.; Rashidi, S.; Pourrajabian, A.; Rahgozar, S.; Arabkoohsar, A. Sensible thermal energy storage. In Future Grid-Scale Energy Storage Solutions; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Beckmann, G.; Viktor, P. Thermal Energy Storage; Springer: New York, NY, USA, 1984. [Google Scholar]

- Krüger, M.; Muslubas, S.; Loeper, T.; Klasing, F.; Knödler, P.; Mielke, C. Potentials of Thermal Energy Storage Integrated into Steam Power Plants. Energies 2020, 13, 2226. [Google Scholar] [CrossRef]

- Holy, F.; Textor, M.; Lechner, S. Gas turbine cogeneration concepts for the pressureless discharge of high temperature thermal energy storage units. J. Energy Storage 2021, 44, 103283. [Google Scholar] [CrossRef]

- Alami, K.E.; Asbik, M.; Agalit, H. Identification of natural rocks as storage materials in thermal energy storage (TES) system of concentrated solar power (CSP) plants—A review. Sol. Energy Mater. Sol. Cells 2020, 217, 110599. [Google Scholar] [CrossRef]

- Trevisan, S.; Guédez, R.; Laumert, B. Thermo-economic optimization of an air driven supercritical CO2 Brayton power cycle for concentrating solar power plant with packed bed thermal energy storage. Sol. Energy 2020, 211, 1373–1391. [Google Scholar] [CrossRef]

- Pradepp, N.; Reddy, K.S. Design and investigation of solar cogeneration system with packed bed thermal energy storage for ceramic industry. Renew. Energy 2022, 192, 243–263. [Google Scholar] [CrossRef]

- Seyitini, L.; Belgasim, B.; Enweremadu, C.C. Solid state sensible heat storage technology for industrial applications—A review. J. Energy Storage 2023, 62, 106919. [Google Scholar] [CrossRef]

- Budt, M.; Wolf, D.; Span, R.; Yan, J. A review on compressed air energy storage: Basic principles, past milestones and recent developments. Appl. Energy 2016, 170, 250–268. [Google Scholar] [CrossRef]

- Zunft, S.; Dreissigacker, V.; Bieber, M.; Banach, A.; Klabunde, C.; Warweg, O. Electricity storage with adiabatic compressed air energy storage: Results of the BMWi-project ADELE-ING. In Proceedings of the International ETG Congress 2017, Bonn, Germany, 28–29 November 2017; pp. 1–5. [Google Scholar]

- Steinmann, W.-D.; Bauer, D.; Jockenhöfer, H.; Johnson, M. Pumped thermal energy storage (PTES) as smart sector-coupling technology for heat and electricity. Energy 2019, 183, 185–190. [Google Scholar] [CrossRef]

- Paul, A.; Holy, F.; Textor, M.; Lechner, S. High temperature sensible thermal energy storage as a crucial element of Carnot Batteries: Overall classification and technical review based on parameters and key figures. J. Energy Storage 2022, 56, 106015. [Google Scholar] [CrossRef]

- Trieb, F.; Liu, P.; Koll, G. Thermal Storage Power Plants (TSPP)—Operation modes for flexible renewable power supply. J. Energy Storage 2022, 50, 104282. [Google Scholar] [CrossRef]

- Dreißigacker, V.; Belik, S. System configurations and operational concepts for high efficient utilization of Power-to-Heat in A-CAES. Appl. Sci. 2019, 9, 1317. [Google Scholar] [CrossRef]

- Belik, S. Power-to-heat integration in a two-stage brayton battery configuration: Increasing system cost efficiency and flexibility. In Proceedings of the 3rd International Workshop on Carnot Batteries, Stuttgart, Germany, 27–28 September 2022. [Google Scholar]

- Sergio, L. Fundamentals of electroheat. In Electrical Technologies for Process Heating; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Ohmex. Electrical Process Flow Heaters Datasheet. 2021. Available online: https://www.ohmex.de/en/wp-content/uploads/sites/3/2020/03/electric-process-heater_STR_2020-03.pdf (accessed on 25 April 2022).

- Schniewindt. Flow Heaters. 2021. Available online: https://www.schniewindt.de/en/csn-flow-heaters (accessed on 25 April 2022).

- Belik, S.; Khater, O.; Zunft, S. Induction Heating of a Fluidized Pebble Bed: Numerical and Experimental Analysis. Appl. Sci. 2023, 13, 2311. [Google Scholar] [CrossRef]

- Belik, S.; Dreissigacker, V.; Zunft, S. Power-to-heat integration in regenerator storage: Enhancing thermal storage capacity and performance. J. Energy Storage 2022, 50, 104570. [Google Scholar] [CrossRef]

- He, R.; Tong, Z.; Zhang, K.; Fang, D. Mechanical and electrical properties of MoSi2-based ceramics with various ZrB2-20vol% SiC as additives for ultra high temperature heating element. Ceram. Int. 2018, 44, 1041–1045. [Google Scholar] [CrossRef]

- Available online: https://berghuetten-gmbh.de/en/products/heizstabe-aus-silizium-karbid (accessed on 7 September 2023).

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids; Clarendon Press: Oxford, UK, 1967. [Google Scholar]

- Ismail, K.A.R.; Stuginsky, R. A parametric study on possible fixed bed models for pcm and sensible heat storage. Appl. Therm. Eng. 1999, 19, 757–788. [Google Scholar] [CrossRef]

- Schmidt, F.W.; Willmott, A.J. Thermal Energy Storage and Regeneration; McGraw-Hill Book Company: New York, NY, USA, 1981. [Google Scholar]

- Kakaç, S.; Shah, R.K.; Aung, W. Handbook of Single-Phase Convective Heat Transfer; Wiley: New York, NY, USA, 1987. [Google Scholar]

- Fujii, T.; Uehara, H. Laminar natural-convective heat transfer from the outer surface of a vertical cylinder. Int. J. Heat Mass Transf. 1970, 13, 607–615. [Google Scholar] [CrossRef]

- Howell, J.; Siegel, R.; Mengüç, M.P. Thermal Radiation Heat Transfer; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar] [CrossRef]

- Silca Refractory Solutions. Thermal Insulation, Non-Ferrous Meatal Casting & Fire Protection Catalogue 2018. Available online: https://www.silca-online.de/fileadmin/2.pdf/04.produktdatenblaetter-ht-en/PDB-SILCAFELT_EN.pdf (accessed on 15 July 2022).

- BCE Special Ceramics. Comparison Table for Technical Ceramics. 2021. Available online: https://www.bce-special-ceramics.com/comparison/bce-material-table.htm (accessed on 15 July 2022).

- Lemmon, E.W.; Jacobsen, R.T.; Penoncello, S.G.; Friend, D.G. Thermodynamic properties of air and mixtures of nitrogen, argon and oxygen from 60 to 2000 K at Pressures to 2000 Mpa. J. Phys. Chem. Ref. Data 2000, 29, 331–385. [Google Scholar] [CrossRef]

| Operating Parameters | Values |

|---|---|

| maximum electric power (P) | 100 kW |

| mass flow rate () | 200–720 kg/h |

| pressure (p) | 1 bar |

| heat transfer medium | Air |

| Specifications | Values |

|---|---|

| mass of the annular honeycomb (mS) | 180 kg |

| length of the annular honeycomb (L) | 1.2 m |

| maximum radius (R6) | 0.375 m |

| insulation thickness (R6–R5) | 0.1 m |

| maximum permitted heating temperature (TPtH,max) | 950 °C |

| τ [min] | QS/(P τ) [%] | [°C] |

|---|---|---|

| 20 | 83 | 520 |

| 25 | 84 | 662 |

| 30 | 85 | 803 |

| aV [m2/m3] | R2 [mm] | ε [%] |

|---|---|---|

| ≥200 | ≥150 | 10–60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dreißigacker, V.; Lucht, G. Electrically Heated High-Temperature Thermal Energy Storage with Dual Operating Modes: From Concept to Validation. Energies 2023, 16, 7344. https://doi.org/10.3390/en16217344

Dreißigacker V, Lucht G. Electrically Heated High-Temperature Thermal Energy Storage with Dual Operating Modes: From Concept to Validation. Energies. 2023; 16(21):7344. https://doi.org/10.3390/en16217344

Chicago/Turabian StyleDreißigacker, Volker, and Gerrit Lucht. 2023. "Electrically Heated High-Temperature Thermal Energy Storage with Dual Operating Modes: From Concept to Validation" Energies 16, no. 21: 7344. https://doi.org/10.3390/en16217344

APA StyleDreißigacker, V., & Lucht, G. (2023). Electrically Heated High-Temperature Thermal Energy Storage with Dual Operating Modes: From Concept to Validation. Energies, 16(21), 7344. https://doi.org/10.3390/en16217344