Research on Full Premixed Combustion and Emission Characteristics of Non-Electric Gas Boiler

Abstract

:1. Introduction

2. Low-NOx Combustion Experiment and Methods

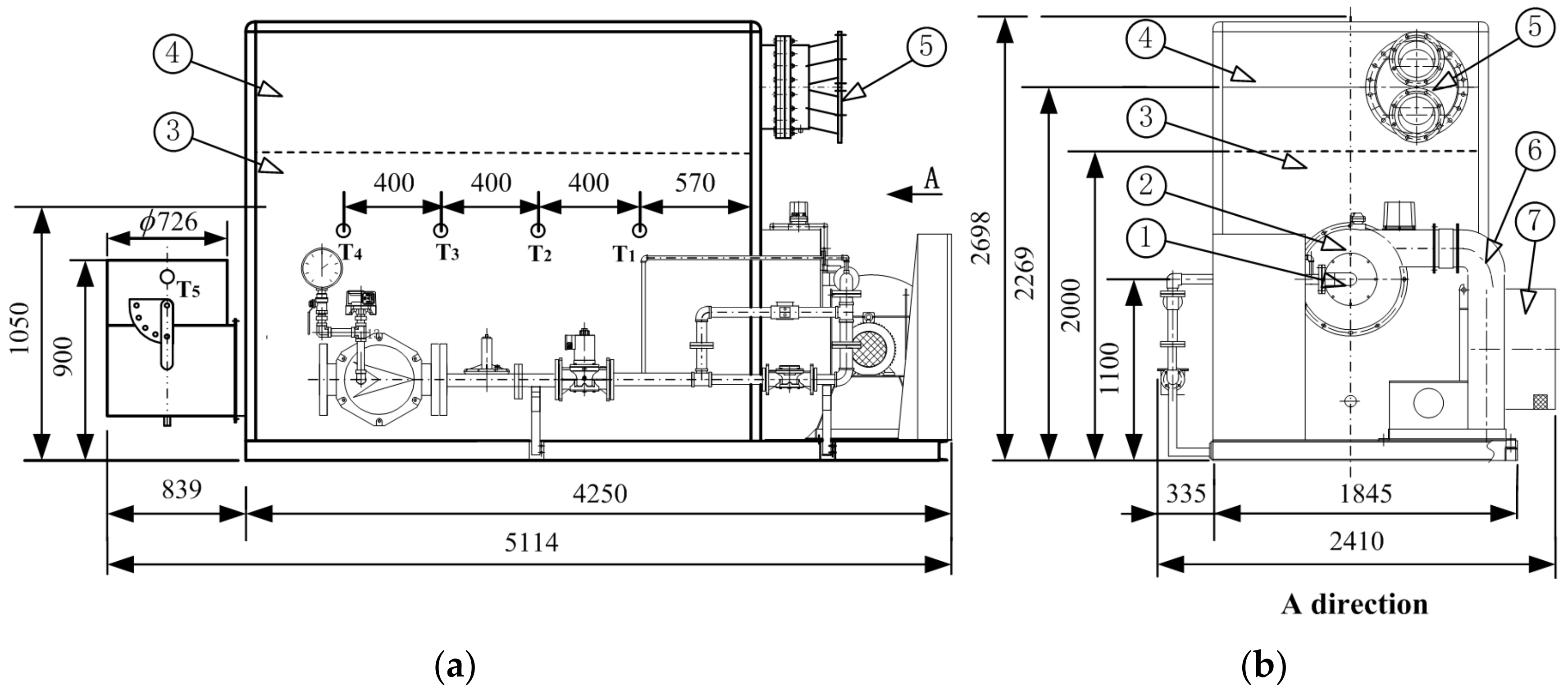

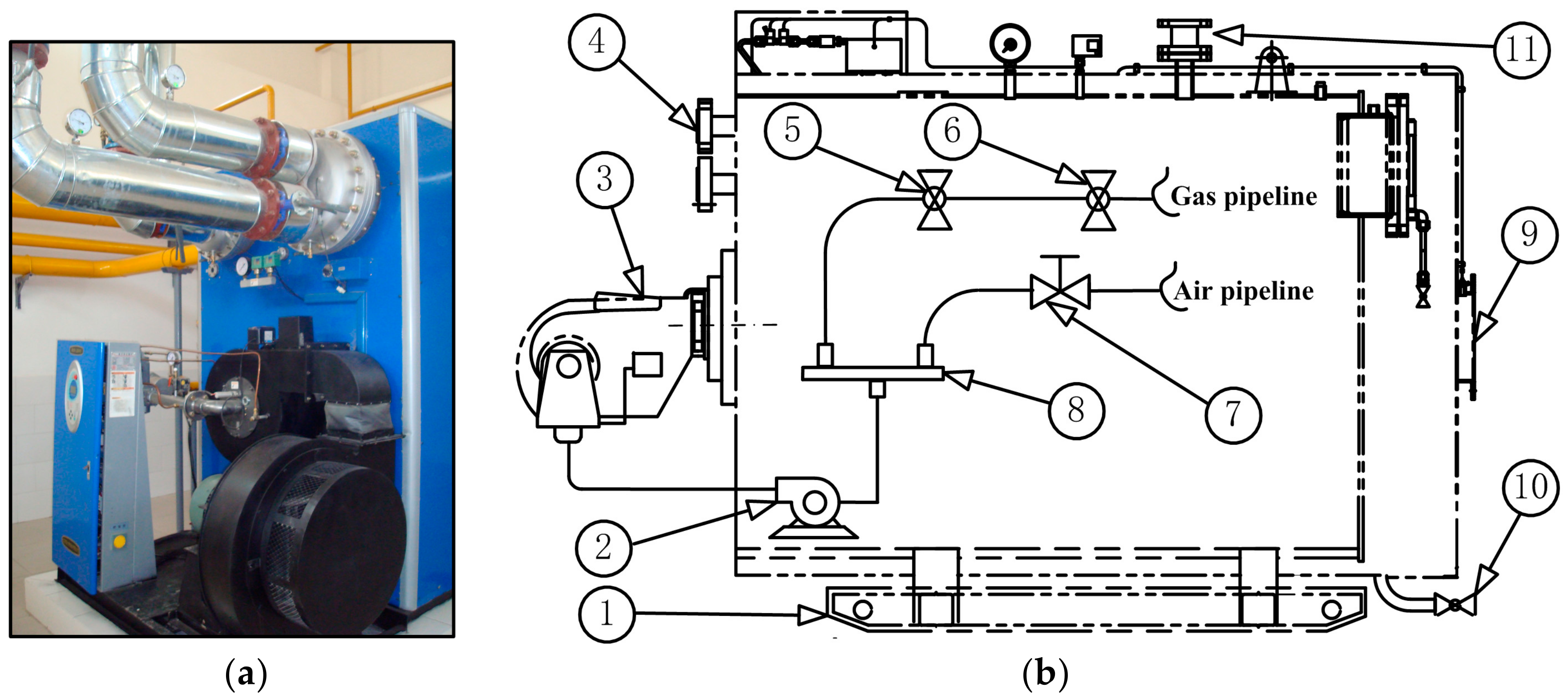

2.1. Experimental Boiler and System

2.2. Low-N Surface Combustion Experiment

3. Numerical Methods

3.1. Numerical Methods and Physical Models

3.2. Boundary Conditions of Numerical Calculation

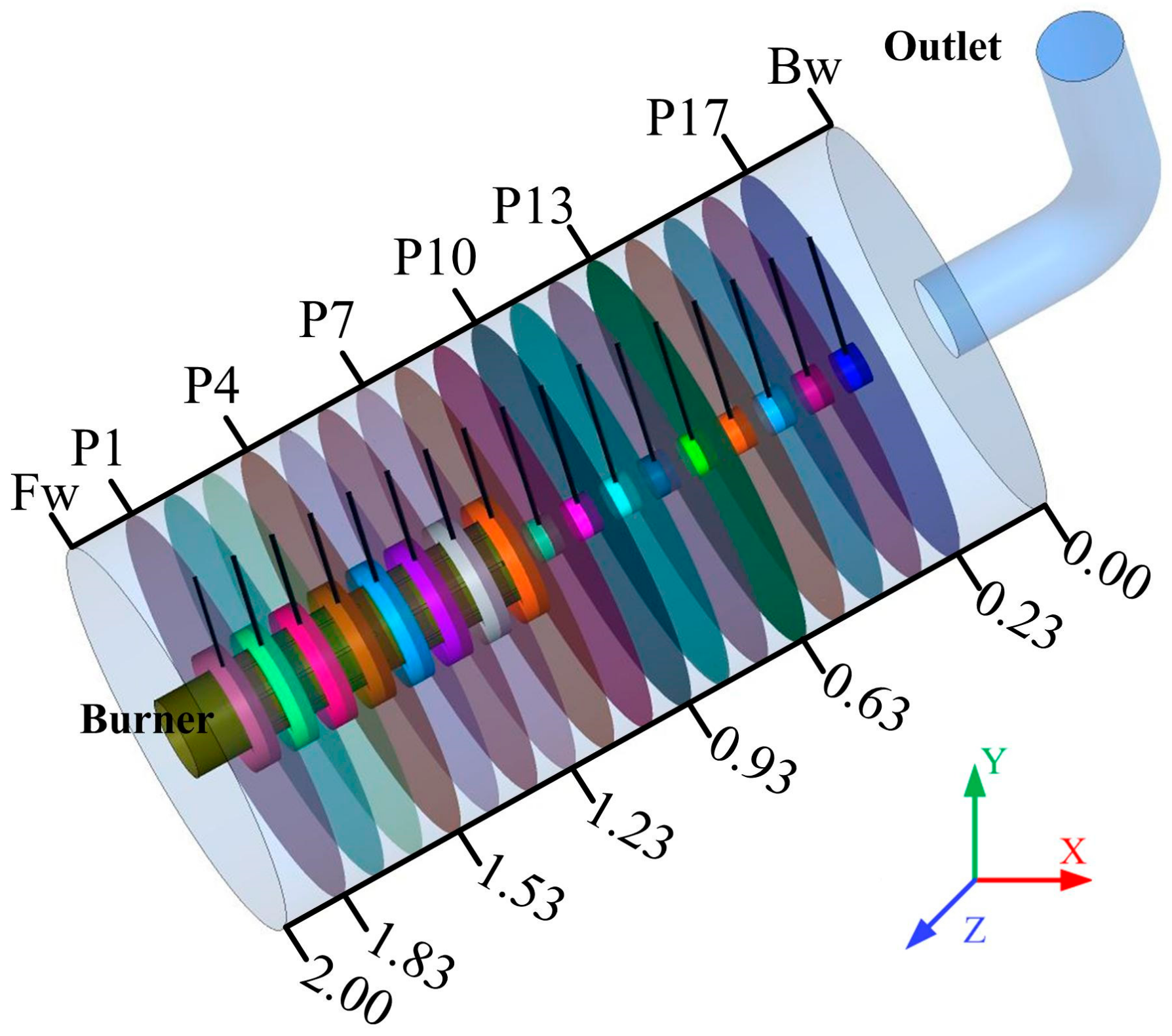

3.3. Computational Domain Full-Scale Mesh Partitioning and Polyhedral Mesh Transformation

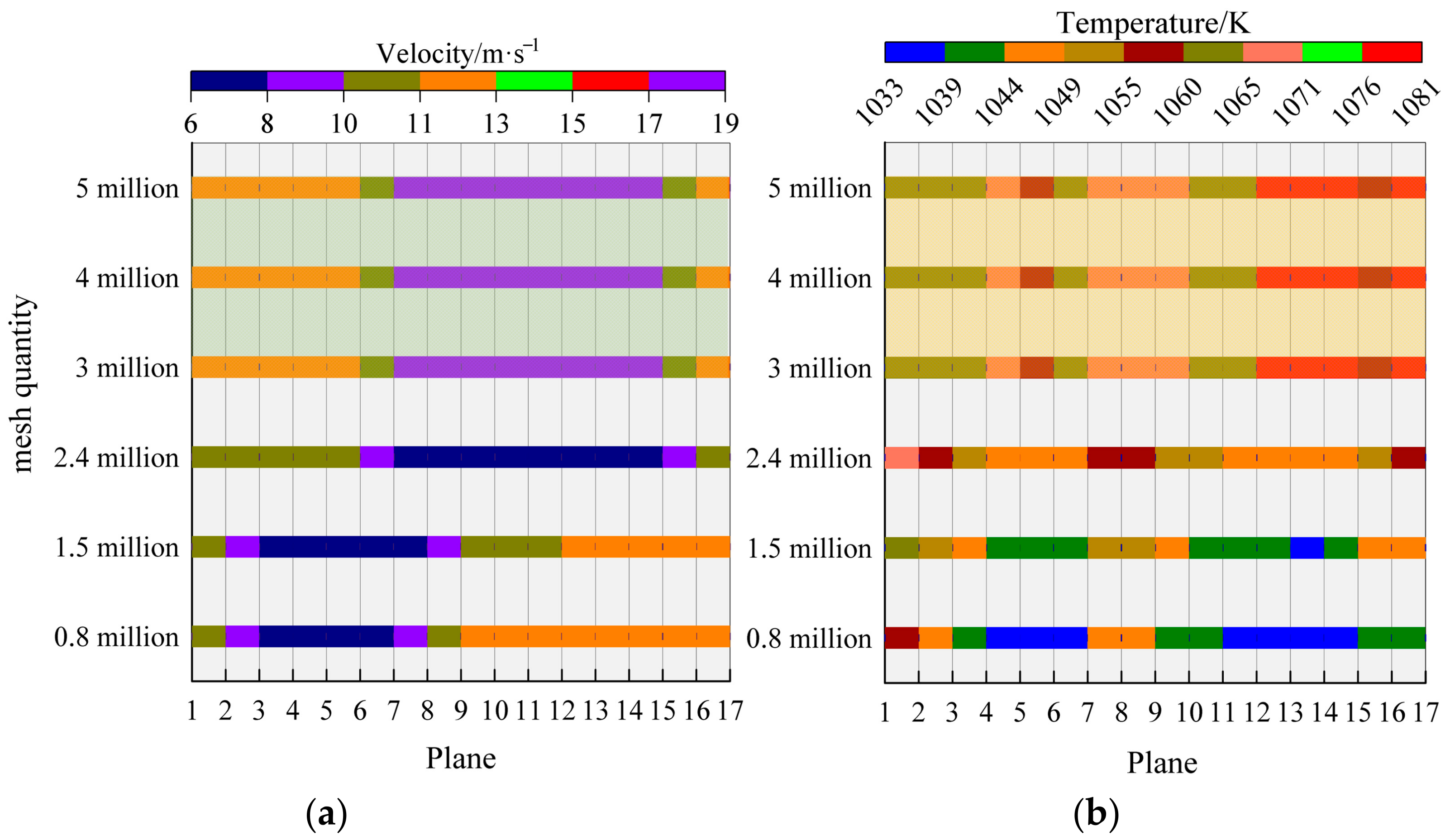

3.4. Grid Independence Verification of the Computational Model

4. Results and Discussion

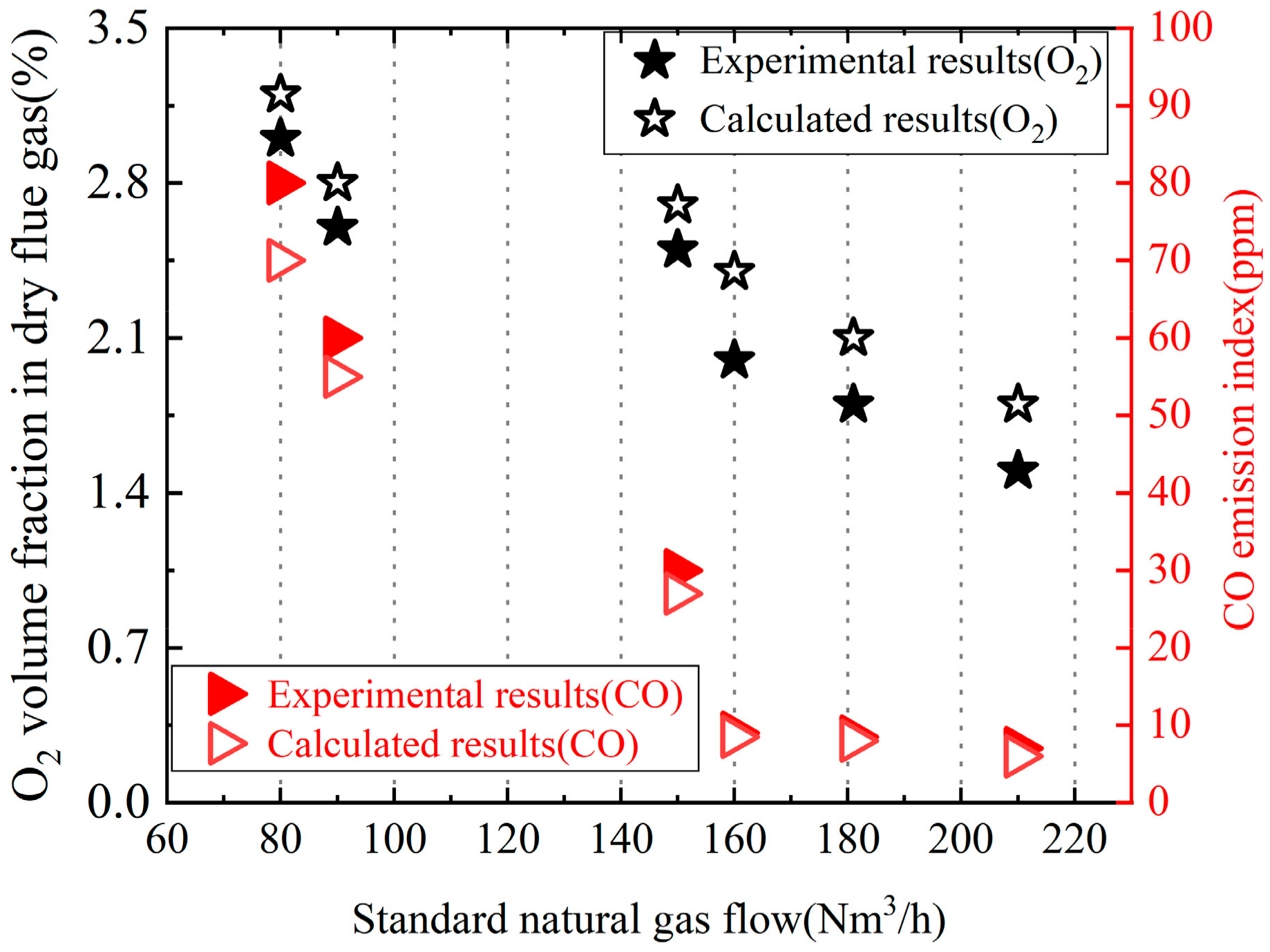

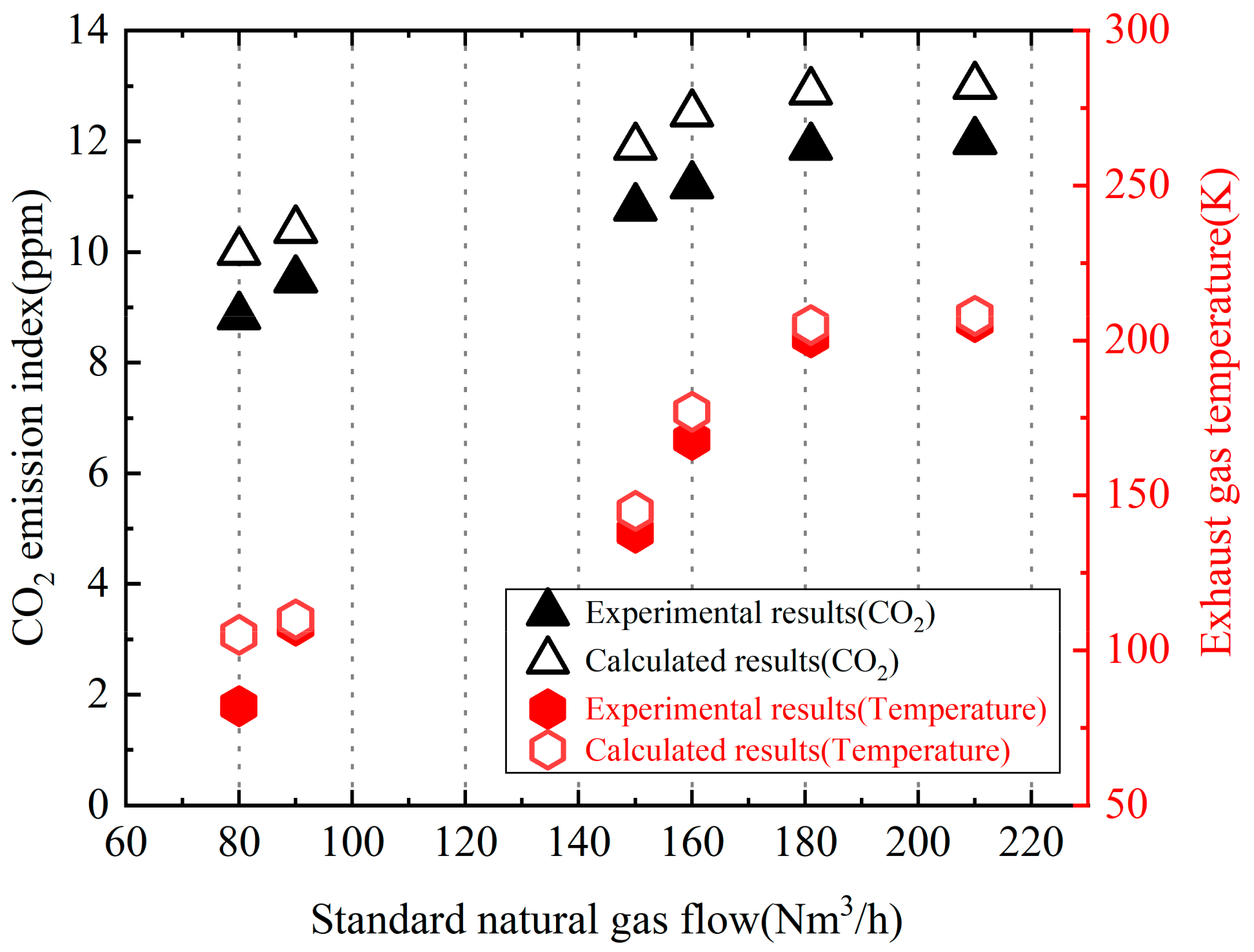

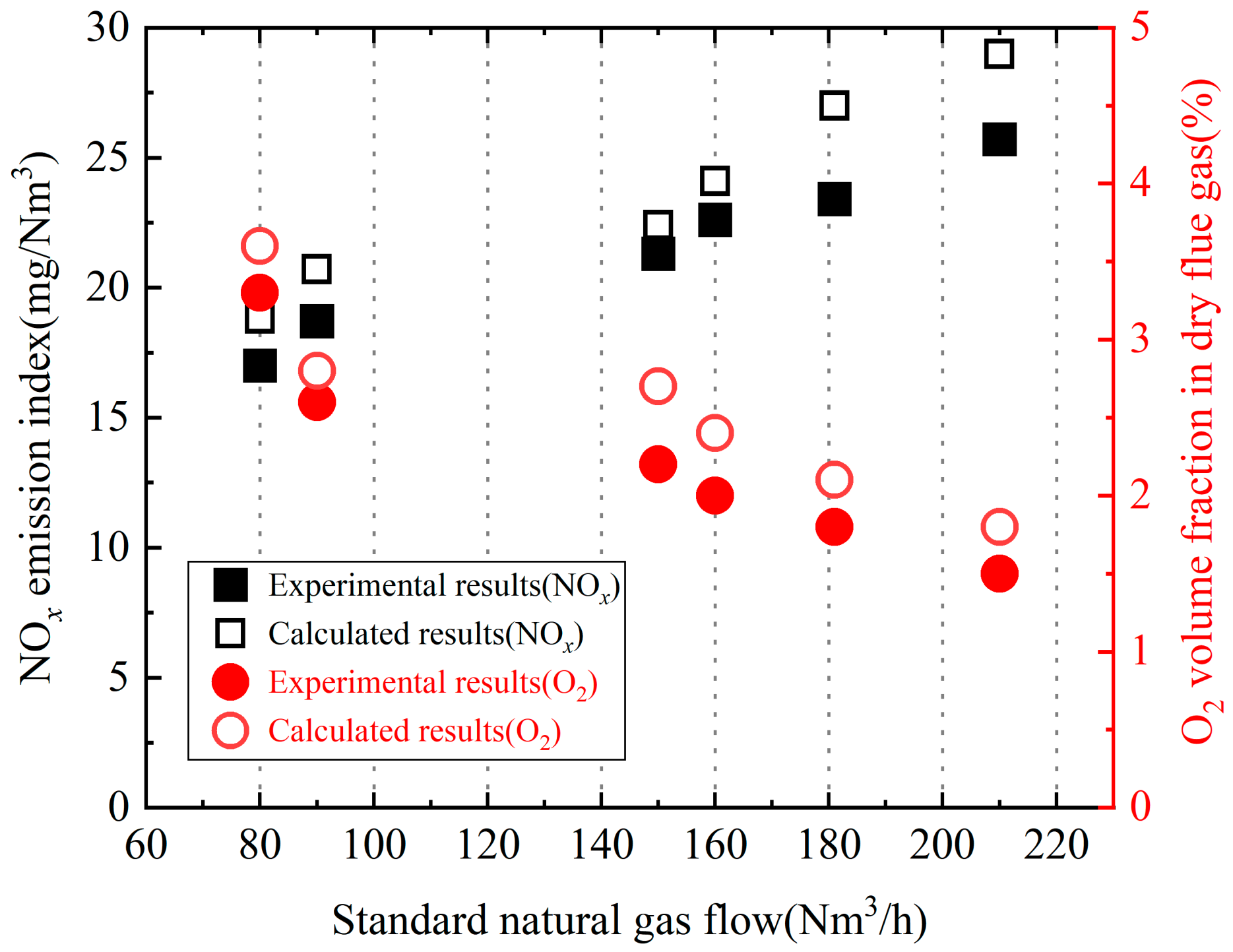

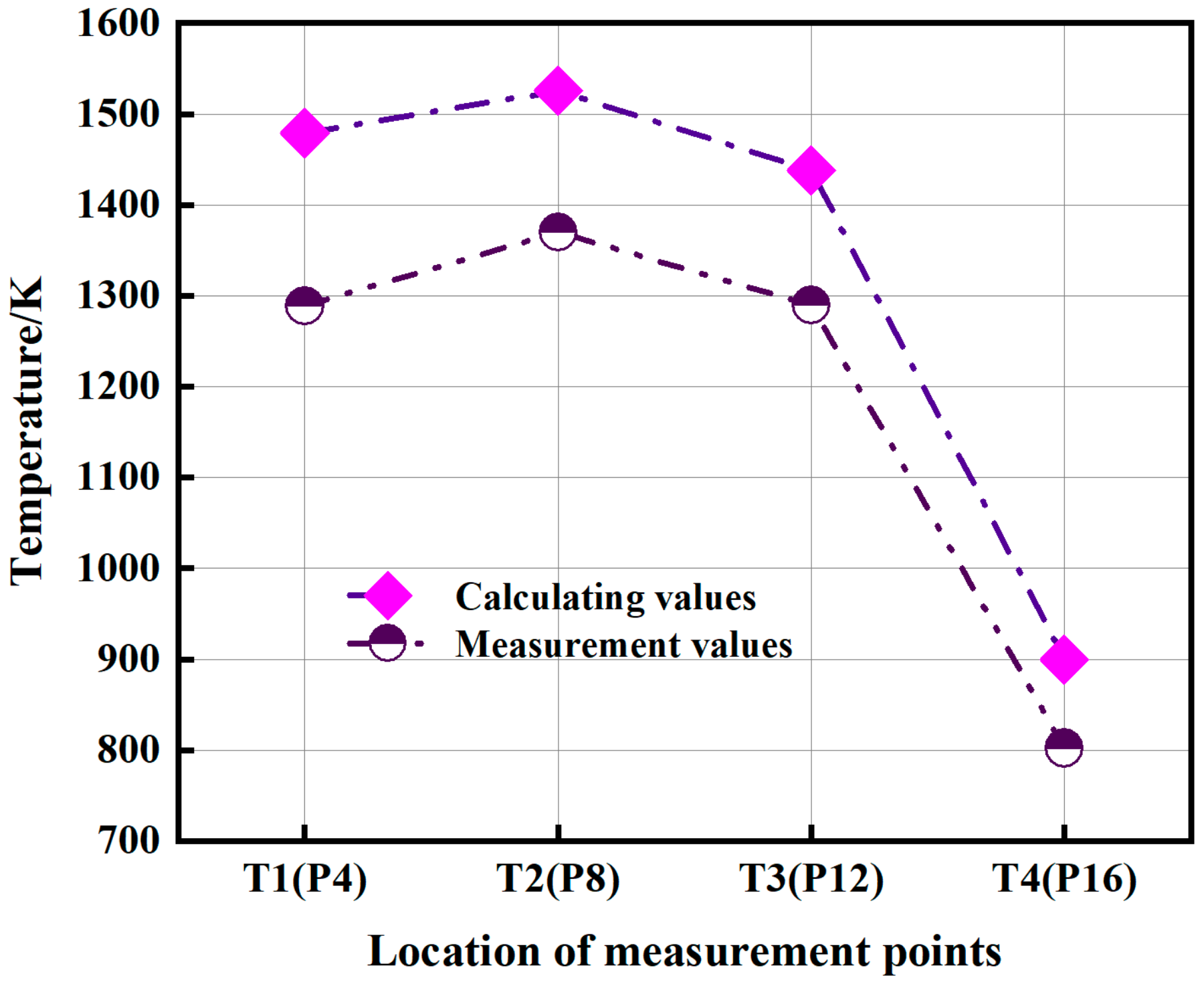

4.1. Comparison between Calculated Values and Experimental Results

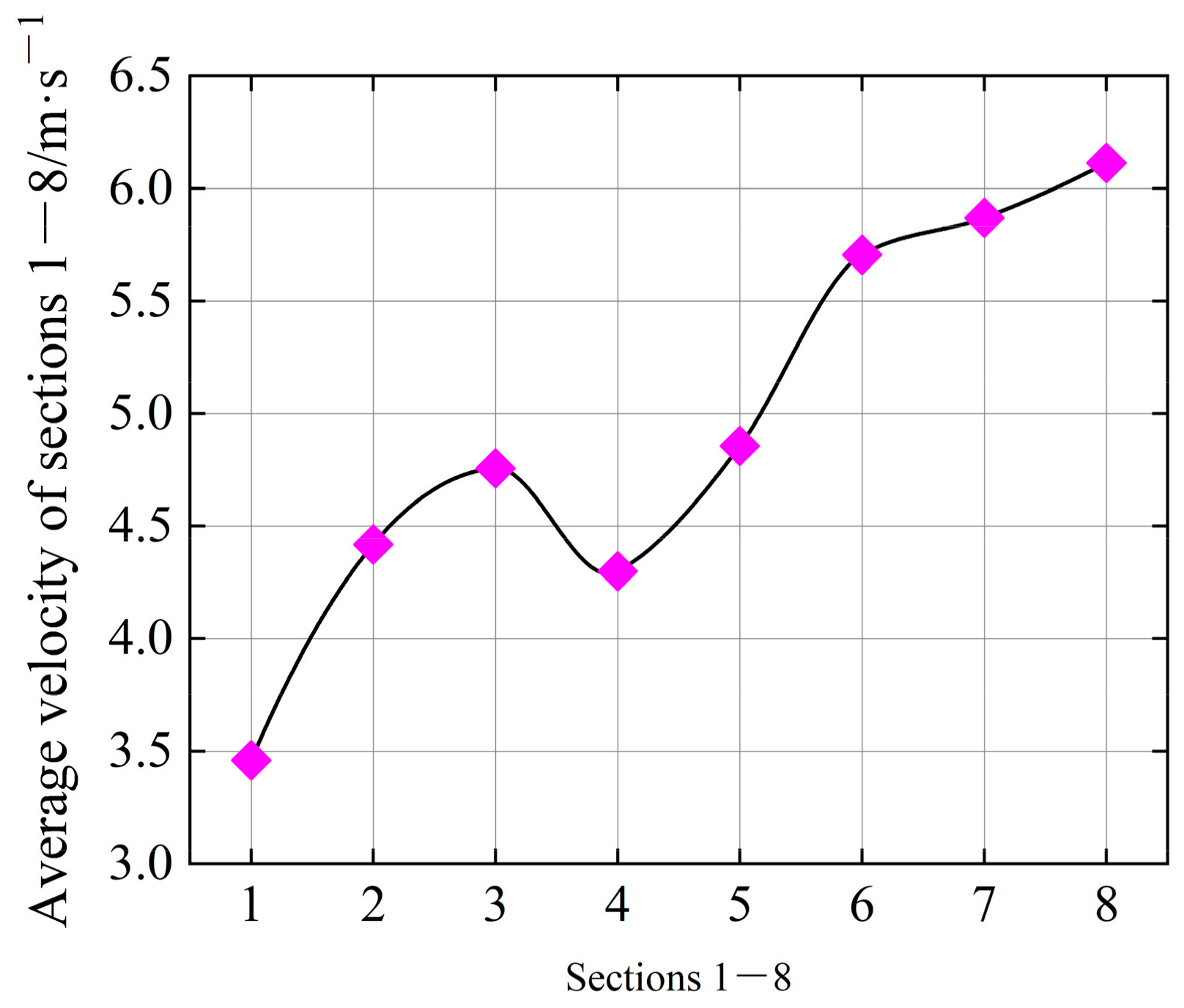

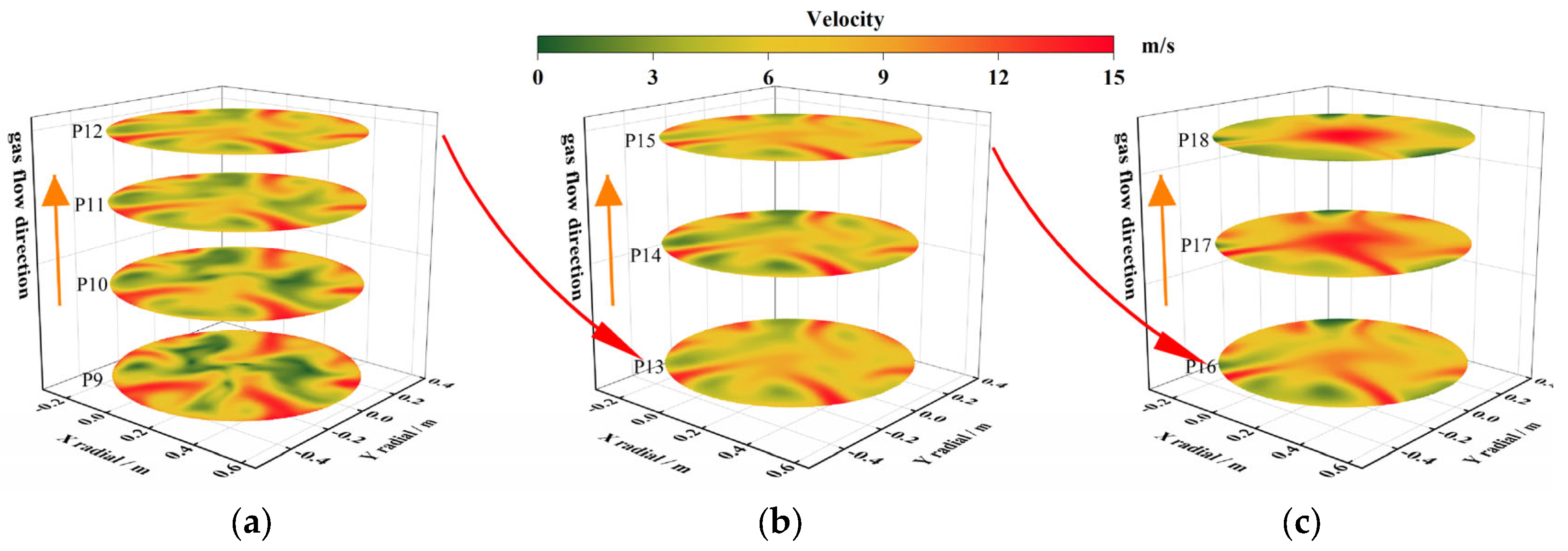

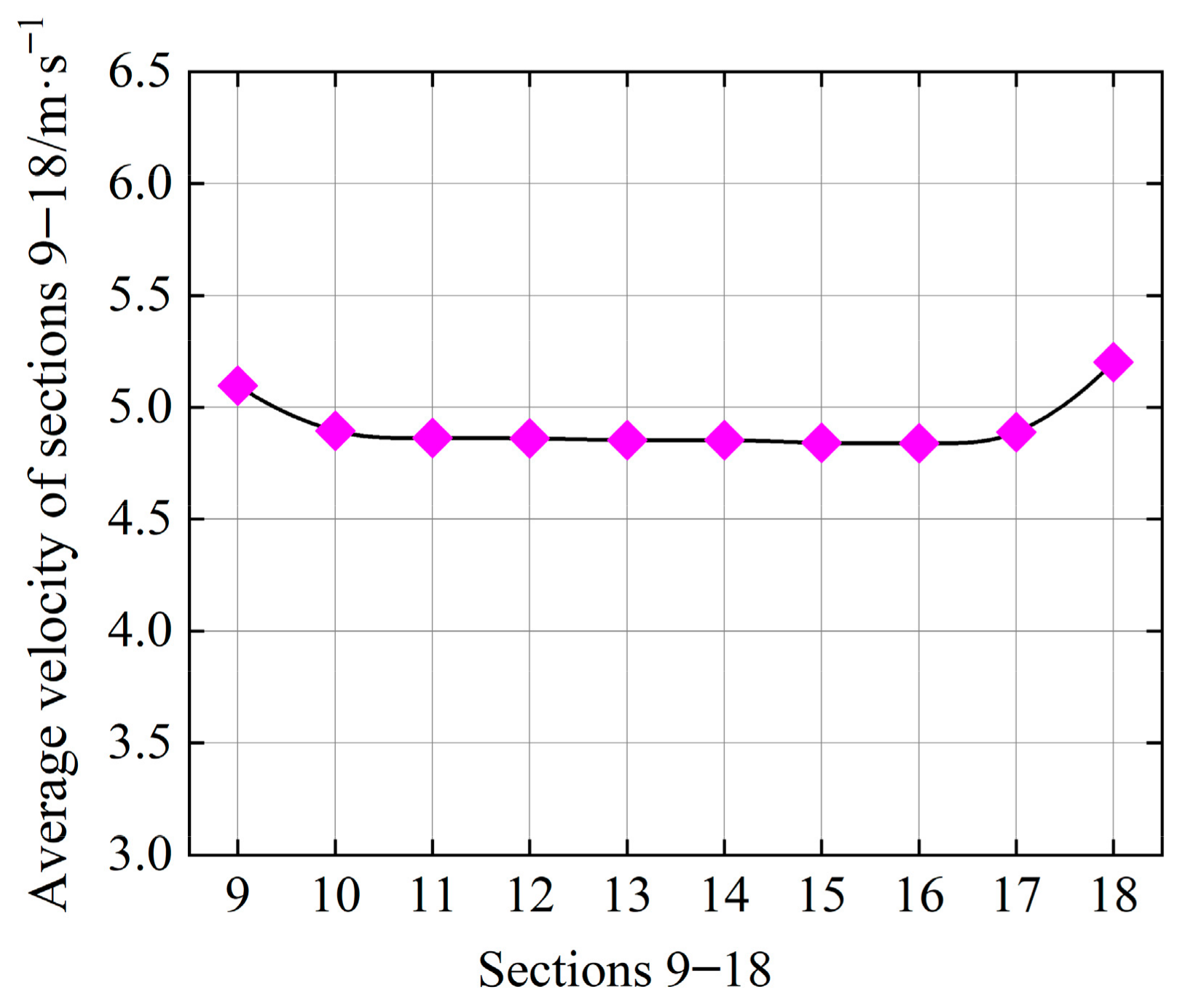

4.2. Distribution of Gas Flow Field inside the Furnace

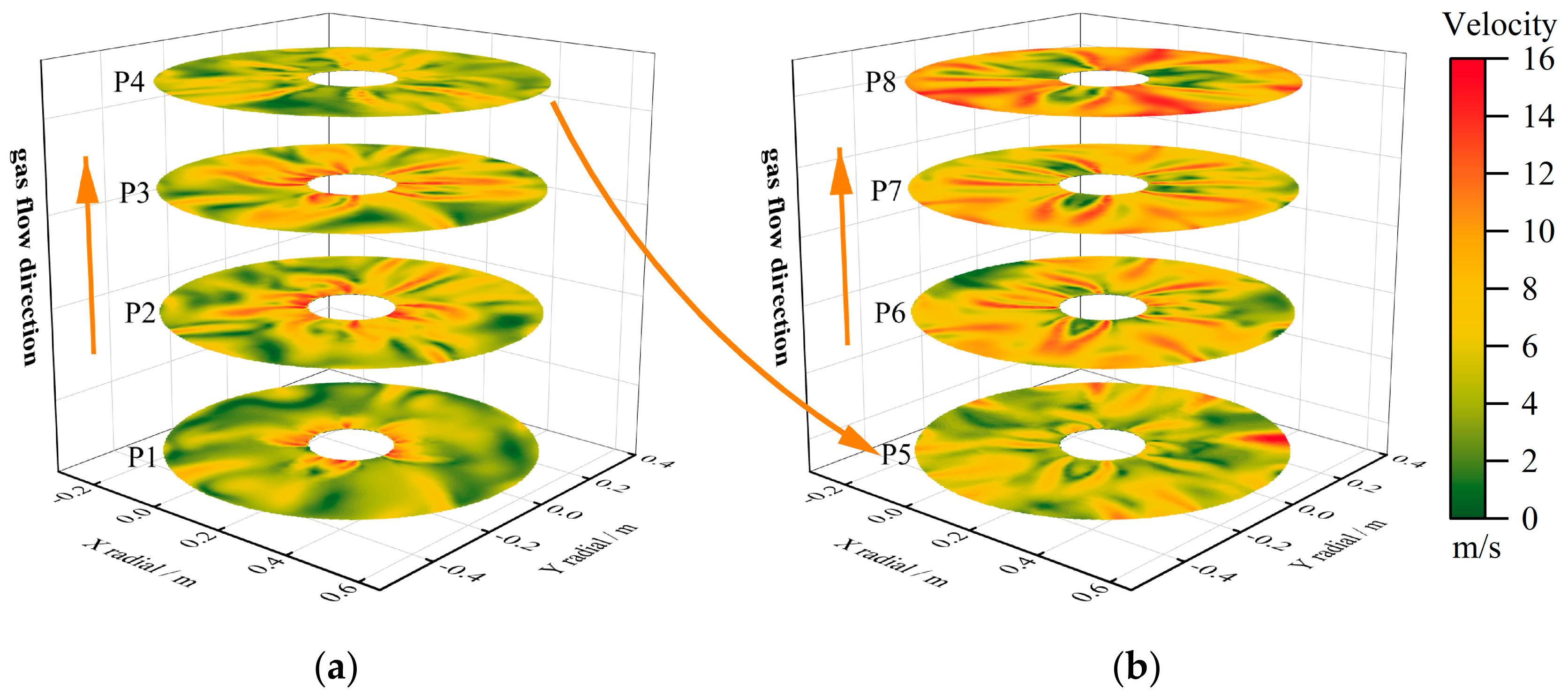

Distribution of Velocity Fields in Different Planes in the Furnace

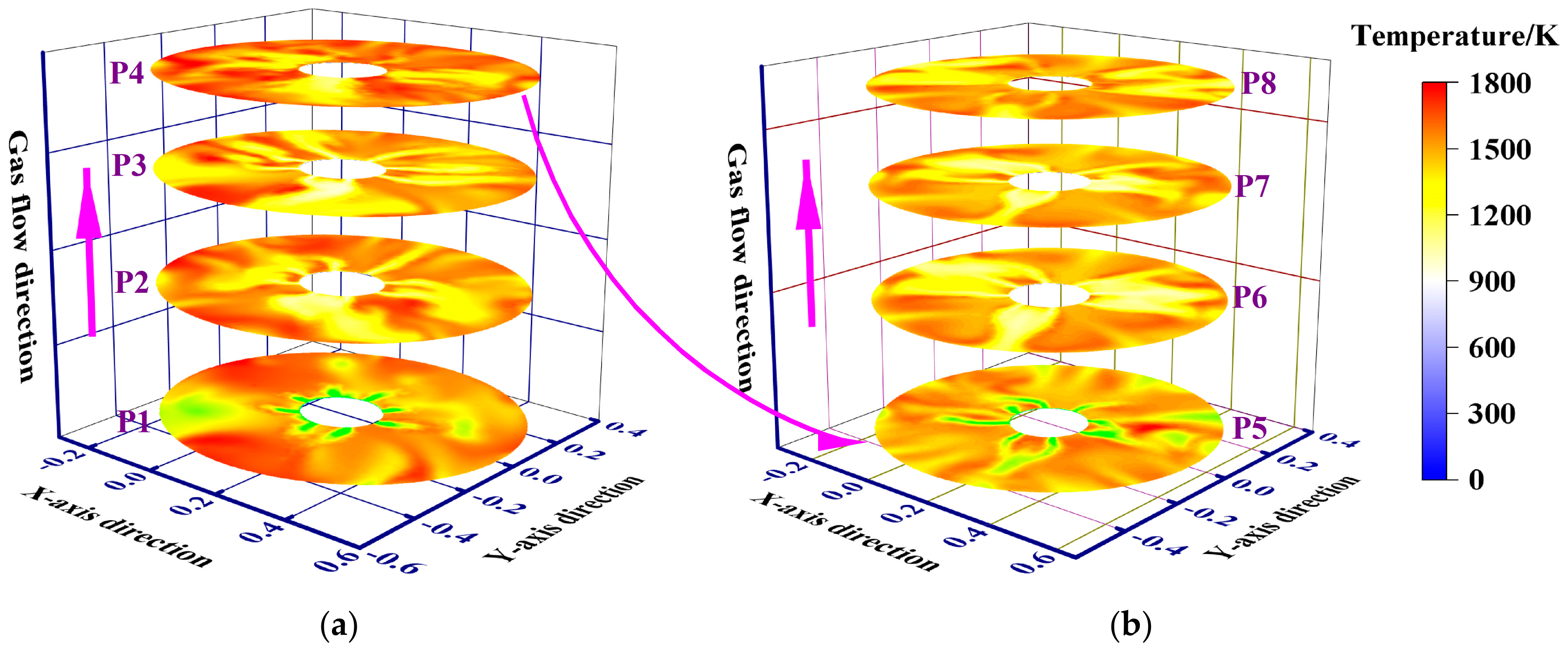

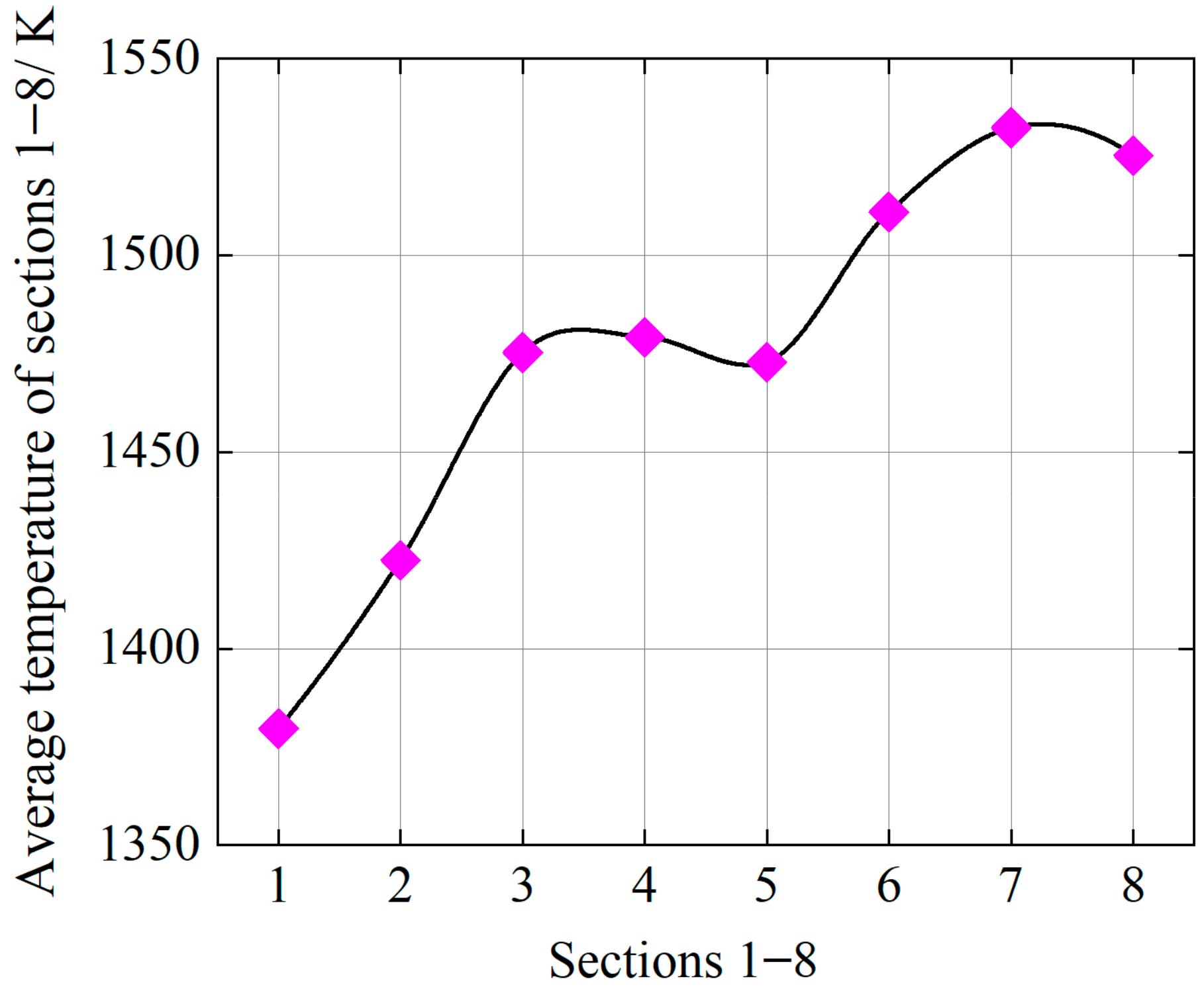

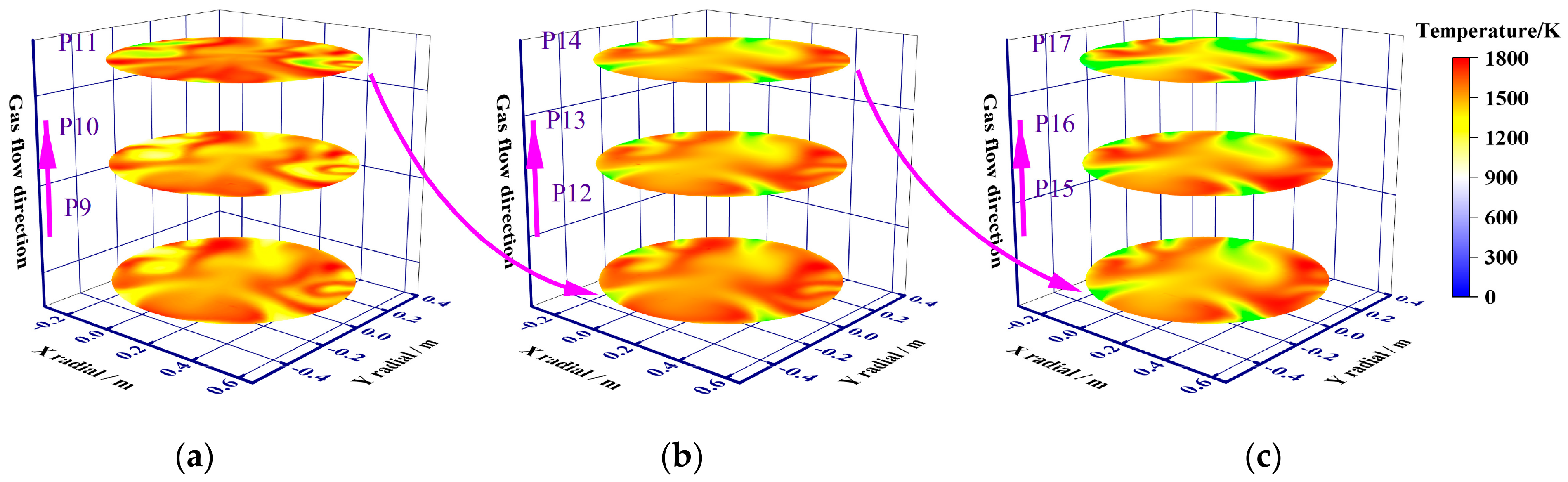

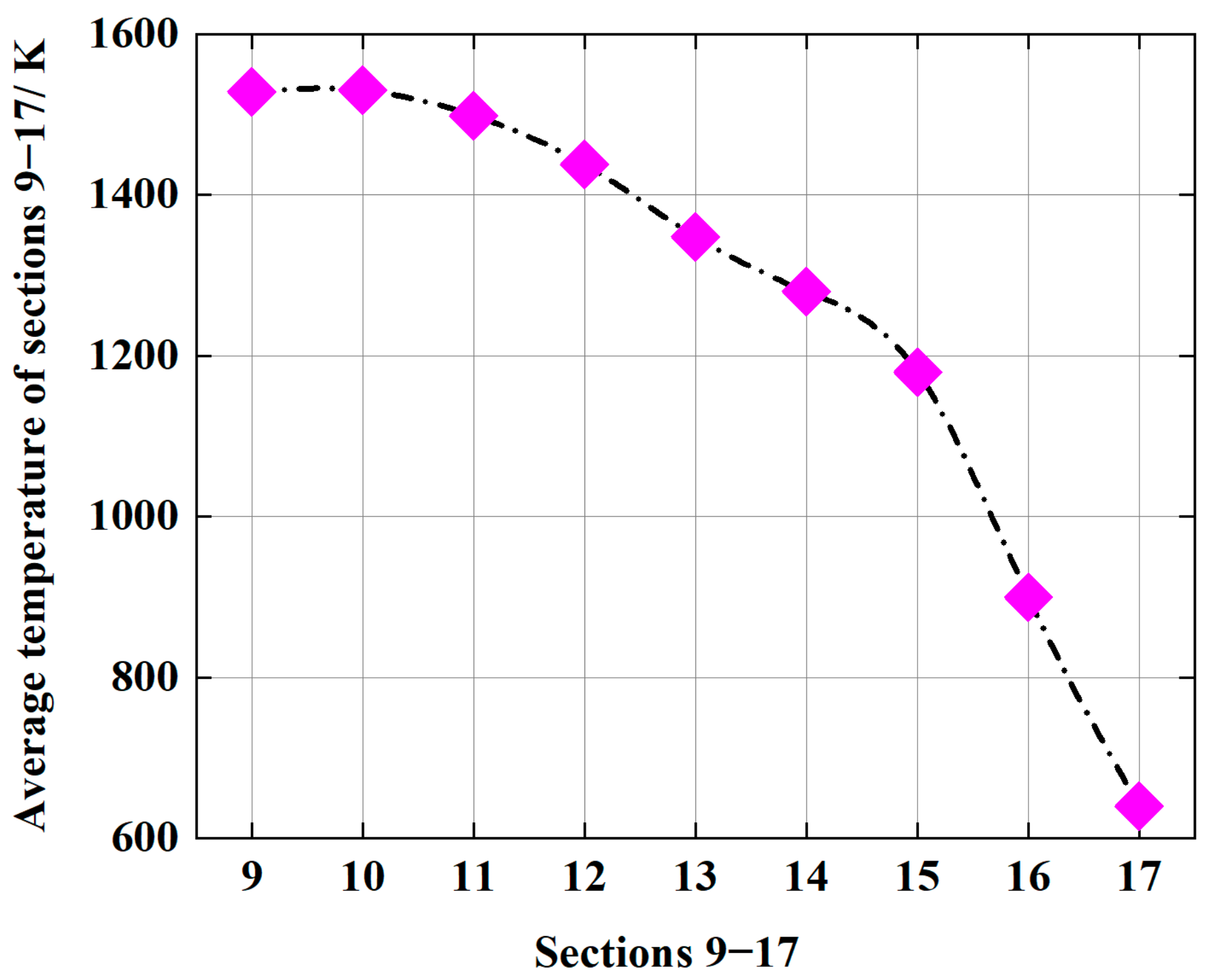

4.3. Temperature Field Distribution in Furnace

4.3.1. Temperature Field on the Planes in the Furnace

4.3.2. Comparison of Measured Temperature and Calculated Value in Furnace

4.3.3. Summary of Temperature Field Distribution in the Furnace

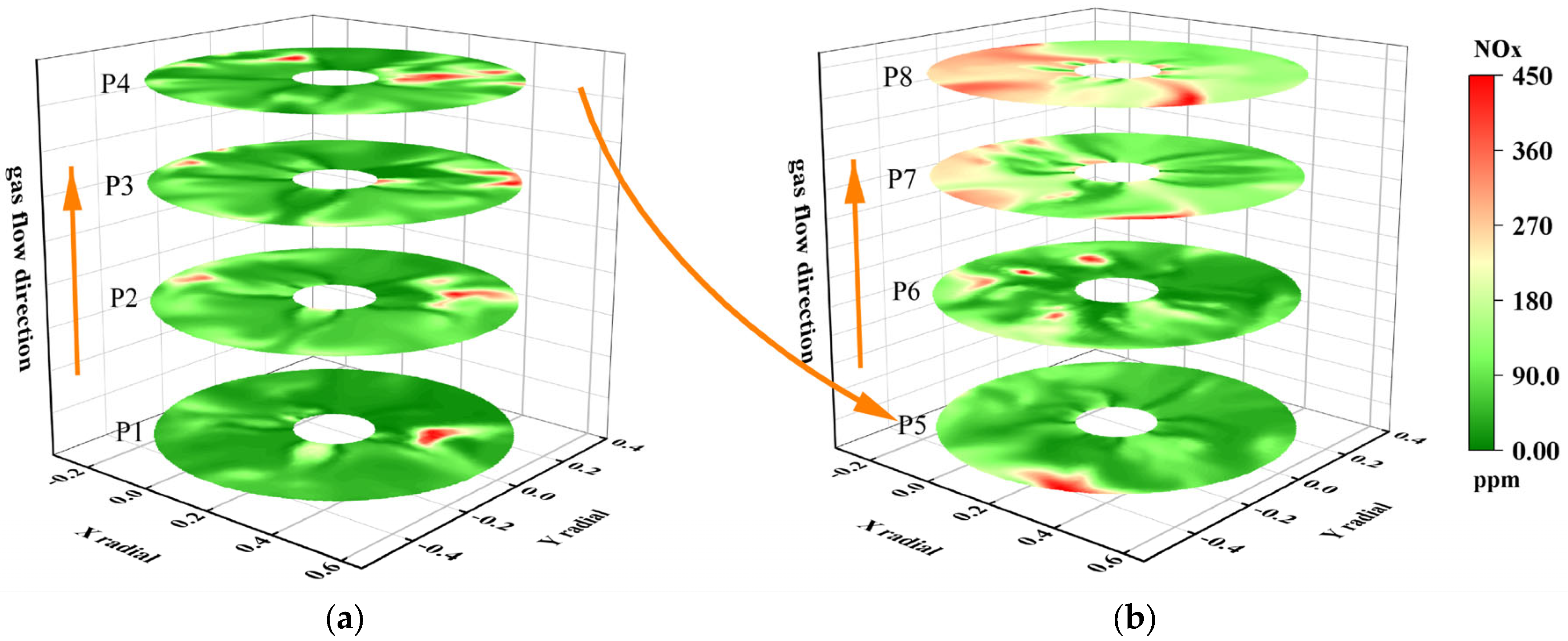

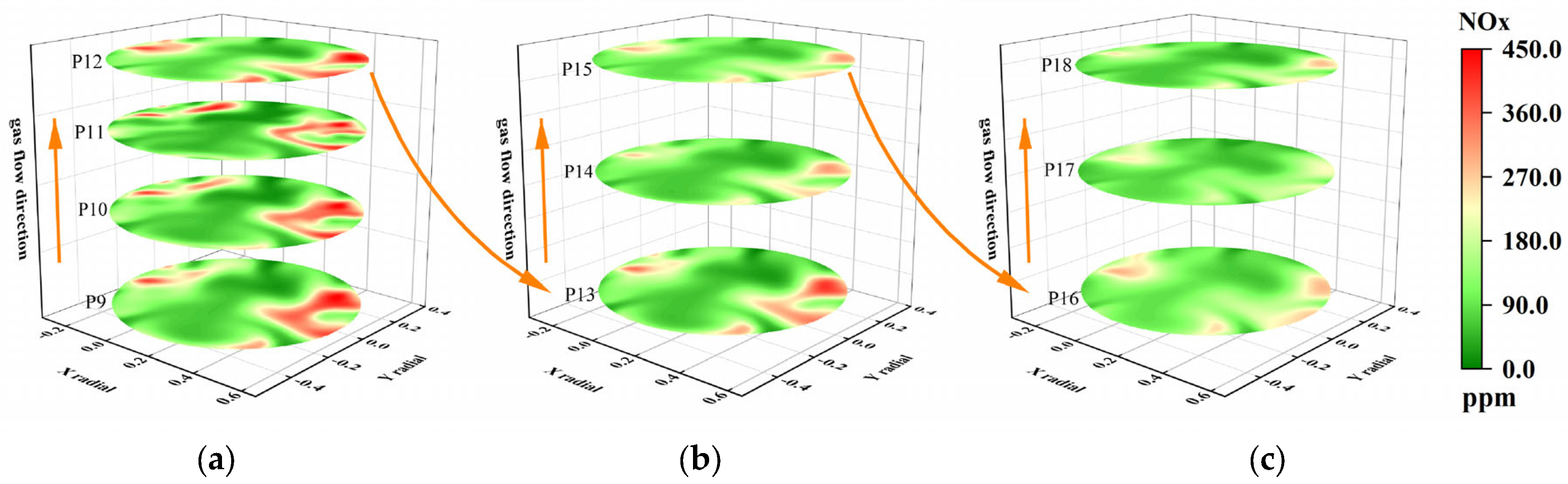

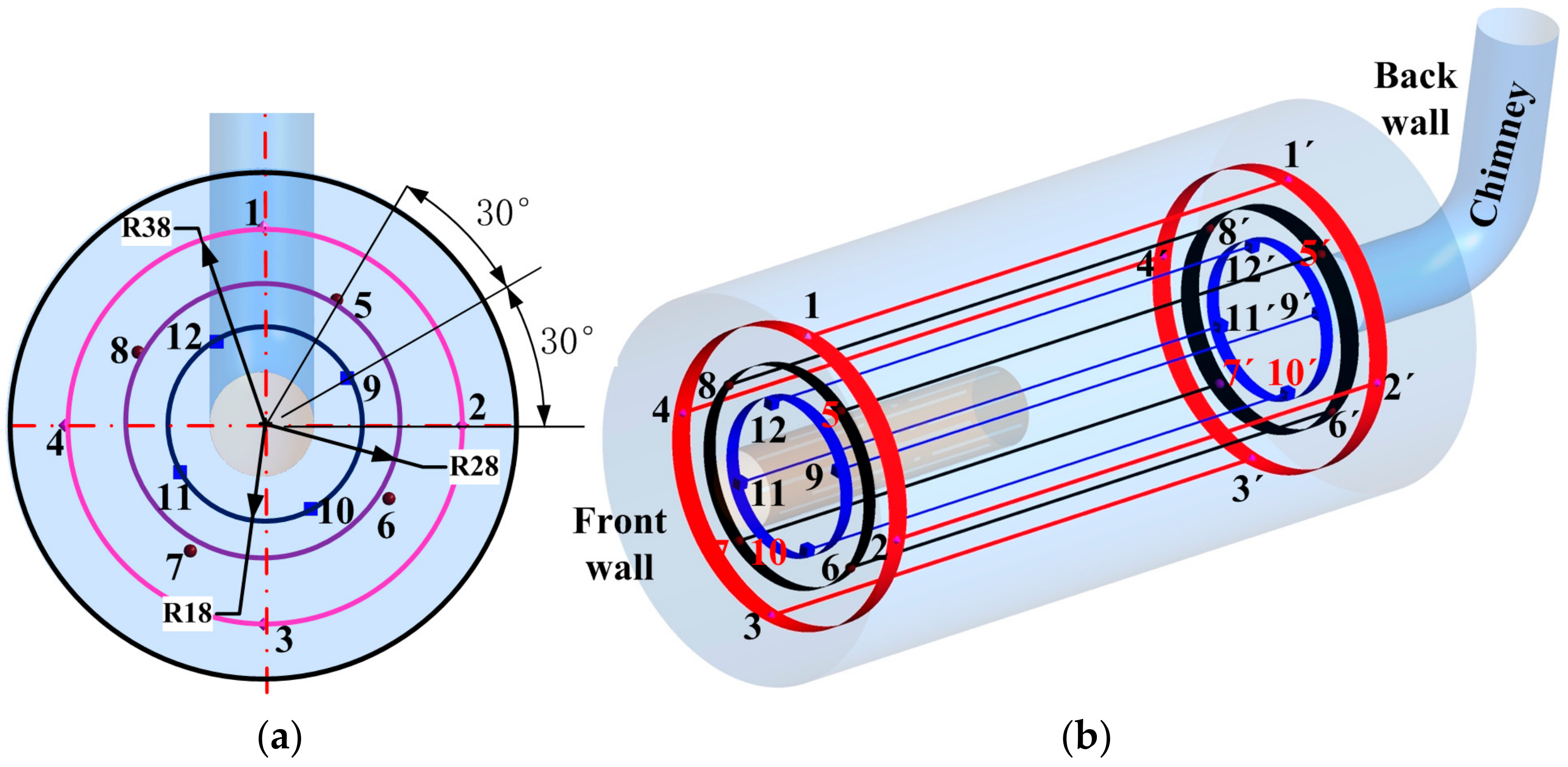

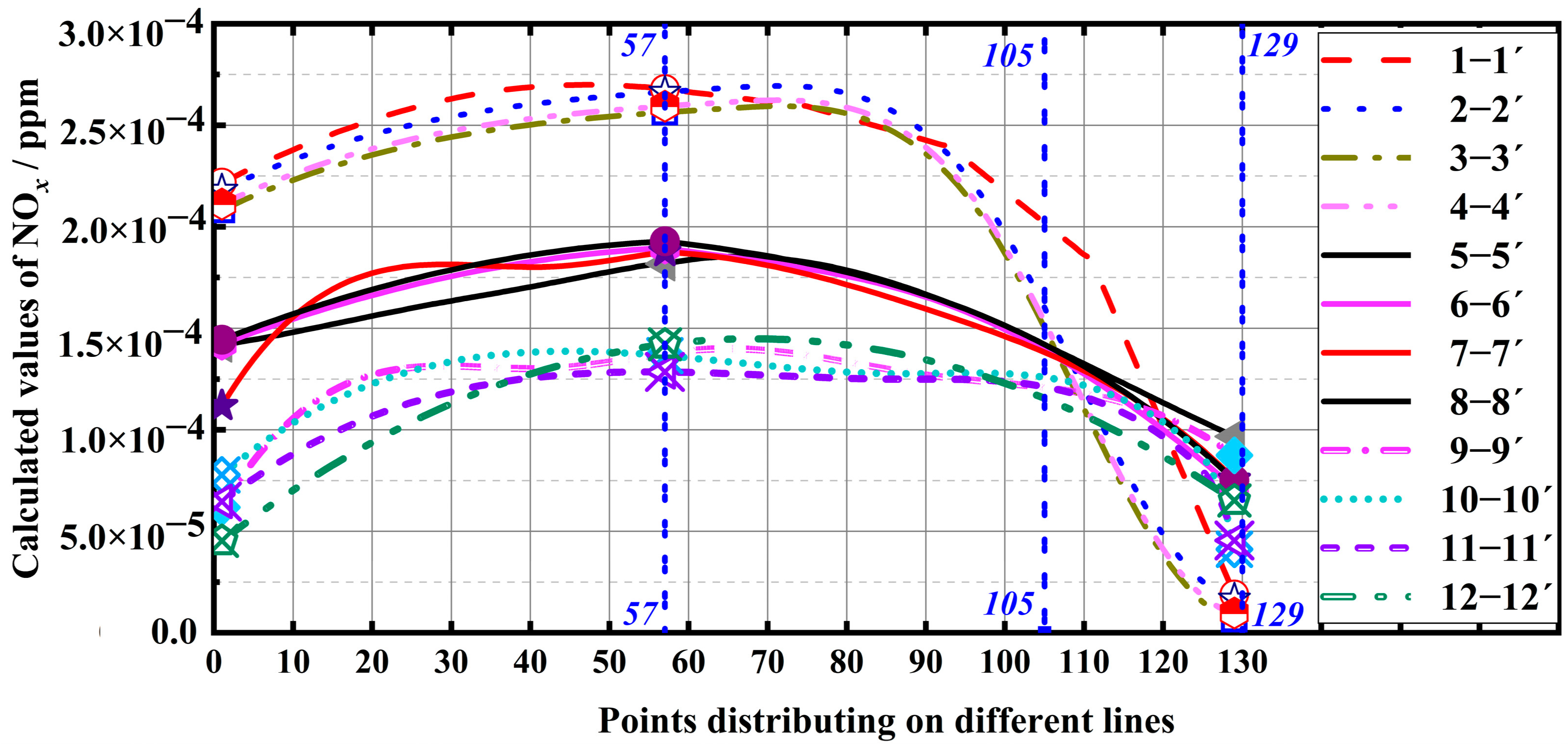

4.4. Analysis of NOx Calculated Values

4.5. Discussion

5. Conclusions

- (1)

- On the plane position inside the furnace, the velocity presents a “fan blade” distribution and the velocity distribution in the circumferential direction of the plane is uniform. And as the gas flows towards the tail of the boiler, the velocity on the entire plane tends to be more uniform. On the tail plane P17, the difference between the maximum and minimum speeds is 2 m/s, and the average speed on the plane is 4.7 m/s. On the rotating surface 4 closest to the furnace outlet, the velocity uniformity is the best on all rotating surfaces.

- (2)

- The maximum temperature inside the furnace is 1532.4 °C, and the average temperature of plane P17 near the outlet of the furnace is 336.7 °C. The temperature at the outlet of the furnace will reach 180 °C. Therefore, adding a small economizer in the flue after the chimney outlet can meet the temperature emission requirements. The maximum error between the calculated temperature value and the measured temperature value is 13.7%. The overall temperature field inside the furnace first increases and then decreases from front to back. The trend of temperature decrease from the combustion center to the rear of the furnace intensifies, and the temperature at the inner wall of the furnace shows a downward trend due to the heat absorption effect of the water-cooled wall. Overall, the temperature field inside the furnace is uniform and the error between the calculated and measured temperature values is within the allowable range, indicating the relatively high reliability of the calculation.

- (3)

- After comprehensive analysis of the NOx generation in the furnace, the maximum value in the furnace is 420 ppm, which is located in the area with the highest temperature inside the furnace. Therefore, it can be determined that the NOx in the furnace is mainly temperature-type NOx, with the highest NOx generation in the combustion center area. The converted NOx emission at the chimney outlet is 26.6 mg/m3, meeting the emission requirements of Beijing-Tianjin-Hebei.

- (4)

- The comparison between the calculation results and the experiment shows that the calculated value of CO is lower than the experimental value, and the trend of CO is positively correlated with the amount of O. Therefore, the calculated value of O is higher than the experimental value, with a maximum calculation error of 5.1%. The smoke exhaust temperature and CO2 calculated values are higher than the experimental values because radiation heat transfer is ignored during the calculation process, resulting in a higher furnace temperature and an increase in CO2 generation and smoke exhaust temperature. The maximum error between the CO2 calculated value and the experimental value is 13.1%. The generation of NOx is mainly thermal, with a maximum error of 15.4% between the calculated and experimental values. The calculated value is higher than the measured value, and both the calculation and experimental results indicate that NOx emissions meet local environmental protection requirements.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Gk | Turbulent kinetic energy generated by average velocity, J |

| Gb | Turbulent kinetic energy generated by buoyancy, J |

| μt | Turbulent viscosity |

| CV | Relative standard deviation of speed, % |

| σV | Speed standard deviation, m/s |

| σρ | Concentration standard deviation, kg/m3 |

| SCR | Selective Catalytic Reduction |

| SNCR | Selective non-Catalytic Reduction |

| FGR | Flue Gas Recirculation |

| EFGE | External Flue Gas Recirculation |

References

- Kobayashi, H.; Hayakawa, A.; Somarathne, K.K.A.; Okafor, E.C. Science and technology of ammonia combustion. Proc. Combust. Inst. 2019, 37, 109–133. [Google Scholar]

- Zhou, Z. New Agreement on Global Climate Change. Domest. Foreign Energy Sources 2015, 12, 1. (In Chinese) [Google Scholar]

- Jin, W.; Geng, C.M.; Wang, Y.O.; Ma, H.; Dong, Y.; Si, F. Combined effects of yaw and tilt angles of separated overfire air on the combustion characteristics in a 1,000 MW coal-fired boiler: A numerical study. Korean J. Chem. Eng. 2021, 38, 771–787. [Google Scholar]

- Mujeebu, M.A.; Abdullah, M.Z.; Bakar, M.Z.A.; Mohamad, A.A.; Abdullah, M.K. Applications of porous media combustion technology—A review. Appl. Energy 2009, 86, 1365–1375. [Google Scholar]

- Jing, L.; Zhao, J.; Wang, H.; Li, W.; Du, Y.; Zhu, Q.; Zayed, M.E. Numerical analysis of the effect of swirl angle and fuel equivalence ratio on the methanol combustion characteristics in a swirl burner. Process Saf. Environ. Prot. 2022, 158, 320–330. [Google Scholar]

- Lu, X.; Zhang, S.; Xing, J.; Wang, Y.; Chen, W.; Ding, D.; Wu, Y.; Wang, S.; Duan, L.; Hao, J. Progress of Air Pollution Control in China and Its Challenges and Opportunities in the Ecological Civilization Era. Engineering 2020, 6, 1423–1431. [Google Scholar]

- Badr, O.; Probert, S.D. Oxides of nitrogen in the Earth’s atmosphere: Trends, sources, sinks and environmental impacts. Appl. Energy 1993, 46, 1–67. [Google Scholar]

- Badr, O.; Probert, S.D. Sinks and environmental impacts for atmospheric carbon monoxide. Appl. Energy 1995, 50, 339–372. [Google Scholar]

- Tominaga, Y.; Stathopoulos, T. Numerical simulation of dispersion around an isolated cubic building: Comparison of various types of k-ε models. Atmos. Environ. 2009, 43, 3200–3210. [Google Scholar]

- Son, J.; Yang, H.; Kim, G.; Hwang, S.; You, H. Technology development for the reduction of NOx in flue gas from a burner-type vaporizer and its application. Korean J. Chem. Eng. 2017, 34, 1619–1629. [Google Scholar] [CrossRef]

- Wang, B.; Yao, S.; Peng, Y. Simultaneous desulfurization and denitrification of flue gas by pre-ozonation combined with ammonia absorption—ScienceDirect. Chin. J. Chem. Eng. 2020, 28, 2457–2466. [Google Scholar] [CrossRef]

- Nhan, H.K.; Kwon, M.; Kim, S.; Park, J.H. CFD investigation of NOx reduction with a flue-gas internal recirculation burner in a mid-sized boiler. J. Mech. Sci. Technol. 2019, 33, 2967–2978. [Google Scholar] [CrossRef]

- Yu, B.; Kum, S.-M.; Lee, C.-E.; Lee, S. Combustion characteristics and thermal efficiency for premixed porous-media types of burners. Energy 2013, 53, 343–350. [Google Scholar] [CrossRef]

- Matsumoto, R.; Ozawa, M.; Terada, S.; Iio, T. Low NOx combustion of DME by means of flue gas recirculation. In Challenges of Power Engineering and Environment; Zhejiang Univ Press: Hangzhou, China, 2007. [Google Scholar]

- Habib, M.A.; Elshafei, M.; Dajani, M. Influence of combustion parameters on NOx production in an industrial boiler. Comput. Fluids 2008, 37, 12–23. [Google Scholar] [CrossRef]

- Shalaj, V.V.; Mikhajlov, A.G.; Novikova, E.E.; Terebilov, S.V.; Novikova, T.V. Gas Recirculation Impact on the Nitrogen Oxides Formation in the Boiler Furnace. Procedia Eng. 2016, 152, 434–438. [Google Scholar] [CrossRef]

- Shalaj, V.V.; Mikhailov, A.G.; Slobodina, E.N.; Terebilov, S.V. Issues on Nitrogen Oxides Concentration Reduction in the Combustion Products of Natural Gas. Procedia Eng. 2015, 113, 287–291. [Google Scholar] [CrossRef]

- Huang, S.Y. Research on Fully Premixed Flue Gas Recirculation Combustion System. Master’s Thesis, Tongji University, Shanghai, China, 2018. (In Chinese). [Google Scholar]

- Hinrichs, J.; Bortoli, S.D.; Pitsch, H. 3D modeling framework and investigation of pollutant formation in a condensing gas boiler. Fuel 2021, 300, 120916. [Google Scholar] [CrossRef]

- Hinrichs, J.; Felsmann, D.; Schweitzer-De Bortoli, S.; Tomczak, H.J.; Pitsch, H. Numerical and experimental investigation of pollutant formation and emissions in a full-scale cylindrical heating unit of a condensing gas boiler. Appl. Energy 2018, 229, 977–989. [Google Scholar] [CrossRef]

- Trimis, D.; Durst, F. Combustion in a Porous Medium-Advances and Applications. Combust. Sci. Technol. 1996, 121, 153–168. [Google Scholar] [CrossRef]

- Bouma, P.H.; De Goey, L.P.H. Premixed combustion on ceramic foam burners. Combust. Flame 1999, 119, 133–143. [Google Scholar] [CrossRef]

- Malico, I.; Zhou, X.Y.; Pereira, J.C.F. Two-dimensional numerical study of combustion and pollutants formation in porous burners. Combust. Sci. Technol. 2000, 152, 57–79. [Google Scholar] [CrossRef]

- Lammers, F.A.; Goey, L. A numerical study of flash back of laminar premixed flames in ceramic-foam surface burners. Combust. Flame 2003, 133, 47–61. [Google Scholar] [CrossRef]

- Lammers, F.A.; De Goey, L.P.H. The influence of gas radiation on the temperature decrease above a burner with a flat porous inert surface. Combust. Flame 2004, 136, 533–547. [Google Scholar] [CrossRef]

- Lee, S.; Kim, J.-M.; Kum, S.-M.; Lee, C.E. Suggestion on the Simultaneous Reduction Method of CO and NOx in Premixed Flames for a Compact Heat Exchanger. Energy Fuels 2010, 24, 821–827. [Google Scholar] [CrossRef]

- Lee, P.H.; Hwang, S.S. Formation of Lean Premixed Surface Flame Using Porous Baffle Plate and Flame Holder. J. Therm. Sci. Technol. 2013, 8, 178–189. [Google Scholar] [CrossRef]

- Yang, S.W.; Lee, S.H.; Hwang, S.S. Surface flame patterns and stability characteristics in a perforated cordierite burner for fuel reformers. Proc. IMechE Part A J. Power Energy 2008, 222, 25–30. [Google Scholar] [CrossRef]

- Ryozo, K.E. Analytical study of the structure of radiation controlled flame. Int. J. Heat Mass Transf. 1988, 31, 311–319. [Google Scholar]

- Weber, C.; Gebhardt, B.; Fahl, U. Market transformation for energy efficient technologies—Success factors and empirical evidence for gas condensing boilers. Energy 2002, 27, 287–315. [Google Scholar] [CrossRef]

- Shang, S.; Li, X.; Chen, W.; Wang, B.; Shi, W. A total heat recovery system between the flue gas and oxidizing air of a gas-fired boiler using a non-contact total heat exchanger. Appl. Energy 2017, 207, 613–623. [Google Scholar] [CrossRef]

- Chen, Q.; Finney, K.; Li, H.; Zhang, X.; Zhou, J.; Sharifi, V.; Swithenbank, J. Condensing boiler applications in the process industry. Appl. Energy 2012, 89, 30–36. [Google Scholar] [CrossRef]

- Johnson, G.; Beausoleil-Morrison, I. The calibration and validation of a model for predicting the performance of gas-fired tankless water heaters in domestic hot water applications. Appl. Energy 2016, 177, 740–750. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Z.; Wang, L.; Zeng, L.; Li, Z. Application of eccentric-swirl-secondary-air combustion technology for high-efficiency and low-NOx performance on a large-scale down-fired boiler with swirl burners. Appl. Energy 2018, 223, 358–368. [Google Scholar] [CrossRef]

- Rahat, A.A.; Wang, C.; Everson, R.M.; Fieldsend, J.E. Data-driven multi-objective optimisation of coal-fired boiler combustion systems. Appl. Energy 2018, 229, 446–458. [Google Scholar] [CrossRef]

- Yang, W.; Wang, B.; Lei, S.; Wang, K.; Chen, T.; Song, Z.; Ma, C.; Zhou, Y.; Sun, L. Combustion optimization and NOx reduction of a 600 MWe down-fired boiler by rearrangement of swirl burner and introduction of separated over-fire air. J. Clean. Prod. 2019, 210, 1120–1130. [Google Scholar] [CrossRef]

- Niederwieser, H.; Zemann, C.; Goelles, M.; Reichhartinger, M. Model-Based Estimation of the Flue Gas Mass Flow in Biomass Boilers. IEEE Trans. Control. Syst. Technol. 2020, 29, 1609–1622. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, C.; Liu, X. Heat Transfer Calculation Methods in Three-Dimensional CFD Model for Pulverized Coal-Fired Boilers. Appl. Therm. Eng. 2019, 166, 114633. [Google Scholar] [CrossRef]

- Yu, C.; Xiong, W.; Ma, H.; Zhou, J.; Si, F.; Jiang, X.; Fang, X. Numerical investigation of combustion optimization in a tangential firing boiler considering steam tube overheating. Appl. Therm. Eng. Des. Process. Equip. Econ. 2019, 154, 87–101. [Google Scholar] [CrossRef]

- Adams, D.; Oh, D.H.; Kim, D.W.; Lee, C.H.; Oh, M. Prediction of SOx–NOx emission from a coal-fired CFB power plant with machine learning: Plant data learned by deep neural network and least square support vector machine. J. Clean. Prod. 2020, 270, 122310. [Google Scholar] [CrossRef]

- Pawe, M. Numerical study of a large-scale pulverized coal-fired boiler operation using CFD modeling based on the probability density function method. Appl. Therm. Eng. 2018, 145, 51–61. [Google Scholar]

- Pierce, C.D.; Moin, P. Progress-variable approach for large-eddy simulation of non-premixed turbulent combustion. J. Fluid Mech. 2004, 504, 73–97. [Google Scholar] [CrossRef]

- Ihme, M.; Chong, M.C.; Pitsch, H. Prediction of local extinction and re-ignition effects in non-premixed turbulent combustion using a flamelet/progress variable approach. Proc. Combust. Inst. 2005, 30, 793–800. [Google Scholar] [CrossRef]

- Mittal, V.; Pitsch, H. A flamelet model for premixed combustion under variable pressure conditions. Proc. Combust. Inst. 2013, 34, 2995–3003. [Google Scholar] [CrossRef]

- Yu, H.B.; Kang, S.T.; Hu, R.X. FLUENT 14.5 Flow Field Analysis from Beginner to Master; China Machine Press: Beijing, China, 2014; pp. 313–316. (In Chinese) [Google Scholar]

- Weng, Z. FLUENT Computing Application Tutorial; Tsinghua University Press: Beijing, China, 2013; pp. 288–302. (In Chinese) [Google Scholar]

- Chang, J.; Wang, X.; Zhou, Z.; Chen, H.; Niu, Y. CFD modeling of hydrodynamics, combustion and NOx emission in a tangentially fired pulverized-coal boiler at low load operating conditions. Adv. Powder Technol. 2021, 32, 290–303. [Google Scholar] [CrossRef]

- Echi, S.; Bouabidi, A.; Driss, Z.; Abid, M.S. CFD simulation and optimization of industrial boiler. Energy 2019, 169, 105–114. [Google Scholar] [CrossRef]

- Collazo, J.; Porteiro, J.; Míguez, J.L.; Granada, E.; Gómez, M.A. Numerical Simulation of a Small-Scale Biomass Boiler; Elsevier Ltd.: Amsterdam, The Netherlands, 2012; pp. 87–96. [Google Scholar]

- Liu, B. ANSYS Fluent 2020 Comprehensive Application Case Explanation; Tinghua University Press: Beijing, China, 2021; Volume 81–83, pp. 253–255. (In Chinese) [Google Scholar]

- Huang, A.X.; Zhou, T.X. Finite Element Theory and Method-Volume 1; Science Press: Beijing, China, 2009; pp. 133–145. (In Chinese) [Google Scholar]

- Lamioni, R.; Bronzoni, C.; Folli, M.; Tognotti, L.; Galletti, C. Feeding H2-admixtures to domestic condensing boilers: Numerical simulations of combustion and pollutant formation in multi-hole burners. Appl. Energy 2022, 309, 118379. [Google Scholar] [CrossRef]

- Liu, F.; Zheng, L.; Zhang, R. Emissions and thermal efficiency for premixed burners in a condensing gas boiler. Energy 2020, 202, 117449. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, B.; Su, Y.; Sui, C.; Zhang, J. Effect and mechanism of combustion enhancement and emission reduction for non-premixed pure ammonia combustion based on fuel preheating. Fuel 2022, 308, 122017. [Google Scholar] [CrossRef]

- Song, F.; Wen, Z.; Dong, Z.; Wang, E.; Liu, X. Ultra-low calorific gas combustion in a gradually-varied porous burner with annular heat recirculation. Energy 2017, 119, 497–503. [Google Scholar] [CrossRef]

- Dehaj, M.S.; Ebrahimi, R.; Shams, M.; Farzaneh, M. Experimental analysis of natural gas combustion in a porous burner. Exp. Therm. Fluid Sci. 2017, 84, 134–143. [Google Scholar] [CrossRef]

| Items | CH4 | C2H8 | C3H8 | N2 | Density/kg·Nm−3 | High Calorific Value/MJ·Nm−3 | Lower Calorific Value/MJ·Nm−3 |

|---|---|---|---|---|---|---|---|

| Natural gas | 96.15 | 0.25 | 0.01 | 3.59 | 0.7174 | 38.47 | 34.7 |

| Natural Gas | Air Door Angle (%) | Flue Gas | Excess Air Coefficient (α) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Standard Natural Gas Flow (Nm3/h) | Supply Gas Pressure/Kpa | Furnace Pressure/Kpa | O2 (%) | NOx Emission Index (mg/Nm3) | CO Emission Index (ppm) | CO2 Emission Index (ppm) | Exhaust Gas Temperature | ||

| 80 | 9 | 17 | −18 | 5 | 34.8 | 229 | 9.07 | 82 | 1.32 |

| 90 | 9 | 21 | −18 | 4 | 18.7 | 60 | 9.63 | 108 | 1.24 |

| 150 | 9 | 32 | −15 | 5 | 21.3 | 48 | 9.07 | 138 | 1.31 |

| 160 | 9 | 40 | −15 | 4.1 | 22.6 | 11 | 9.58 | 168 | 1.24 |

| 181 | 9 | 45 | −15 | 4.4 | 23.4 | 2 | 10.2 | 201 | 1.27 |

| 210 | 9 | 61 | −8 | 4.2 | 25.7 | 2 | 9.52 | 206 | 1.25 |

| Serial Number | Chemical Equations | Rate Exponent | PEF (Pre-Exponential Factor) | AE (Activation Energy) | TE (Temperature Exponent) |

|---|---|---|---|---|---|

| 1 | 1.6596 × 1015 | 1.72 × 108 | |||

| 2 | 7.9799 × 1014 | 9.654 × 107 | |||

| 3 | 2.2336 × 1014 | 5.1774 × 108 | |||

| 4 | 8.8308 × 1023 | 4.4366 × 108 | |||

| 5 | 9.2683 × 1014 | 5.7276 × 108 | −0.5 |

| Type | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Tetrahedral mesh | total nodes | 75,706 | 101,697 | 173,342 | 336,713 | 460,450 | 796,132 | 1,083,501 | 1,537,213 | 2,647,471 |

| total elements | 430,217 | 579,511 | 1,000,393 | 1,956,754 | 2,686,168 | 4,660,877 | 6,359,787 | 9,045,508 | 15,645,258 | |

| Make polyhedra | total nodes | 456,501 | 610,334 | 1,038,251 | 2,012,104 | 2,751,808 | 4,755,792 | 6,474,231 | 9,186,480 | 15,829,148 |

| total elements | 81,942 | 107,509 | 179,786 | 343,707 | 468,440 | 804,879 | 1,094,025 | 1,548,471 | 2,660,513 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, H.-W.; Wang, H.-P. Research on Full Premixed Combustion and Emission Characteristics of Non-Electric Gas Boiler. Energies 2023, 16, 7409. https://doi.org/10.3390/en16217409

Shi H-W, Wang H-P. Research on Full Premixed Combustion and Emission Characteristics of Non-Electric Gas Boiler. Energies. 2023; 16(21):7409. https://doi.org/10.3390/en16217409

Chicago/Turabian StyleShi, Hong-Wei, and Hai-Peng Wang. 2023. "Research on Full Premixed Combustion and Emission Characteristics of Non-Electric Gas Boiler" Energies 16, no. 21: 7409. https://doi.org/10.3390/en16217409

APA StyleShi, H.-W., & Wang, H.-P. (2023). Research on Full Premixed Combustion and Emission Characteristics of Non-Electric Gas Boiler. Energies, 16(21), 7409. https://doi.org/10.3390/en16217409