Projected Reductions in CO2 Emissions by Using Alternative Methanol Fuel to Power a Service Operation Vessel

Abstract

:1. Introduction

1.1. Research Background

- Design and structural modifications to the ship’s hull;

- Volume of the fuel tanks, and their effect on the size and layout of the engine room area and adjacent compartments;

- Carrying capacity and displacement of the ship and related operational parameters, such as the ship’s speed.

- The use of alternative fuels is mainly discussed in reference to cargo vessels;

- There is a lack of information on the influence of fuel type on the design and construction of a ship, as well as on its operational parameters, i.e., main dimensions, hull shape, functional-spatial arrangement of the hull, deadweight and gross displacement of the ship;

- For special vessels such as offshore vessels, there is a lack of scientific publications on the effects and feasibility of alternative fuels, including emission reduction.

1.2. Research Aim

- –

- Develop a design concept for an SOV vessel, including a propulsion system adapted for different fuels;

- –

- Conduct an analysis of the main operating regimes of the SOV vessel and the associated variable power requirements;

- –

- Perform a design analysis of the hull with tanks for different fuels;

- –

- Apply technical requirements for the safe operation of fuel in accordance with current IMO guidelines;

- –

- Identify the benefits (via the hull volume resulting from fuel tanks) to be obtained by using different fuels;

- –

- Calculate fuel consumption and CO2 emissions for different regimes of ship operation;

- –

- Conduct an economic cost analysis for several fuel options (methanol, LNG, MDO).

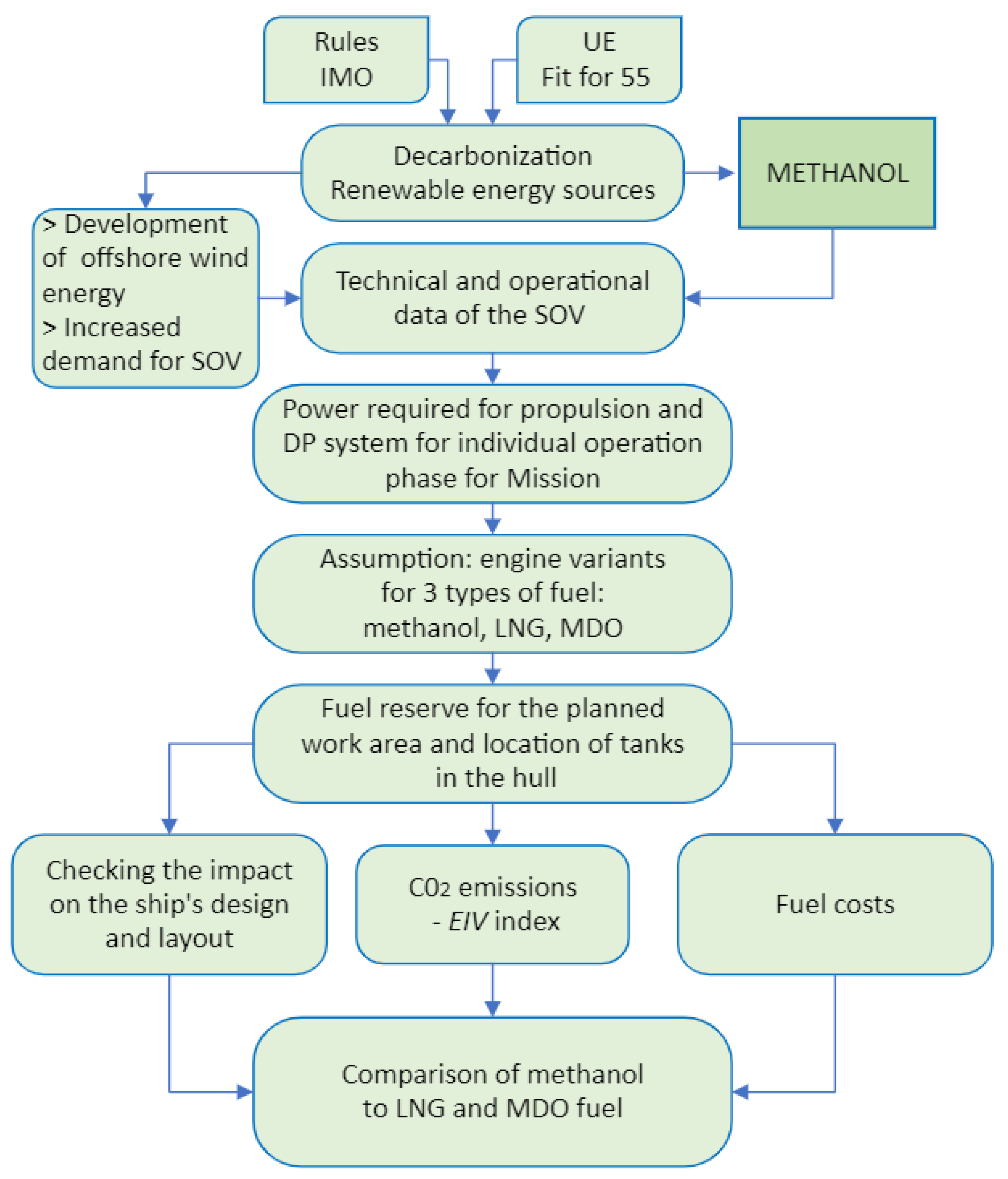

2. Initial Assumptions and Methodology

2.1. Technical and Operational Parameters of the SOV

- Two-stroke dual fuel engine (Wartsila 6L 32M), fuel: Methanol (M) and Marine Diesel Oil (MDO);

- Diesel engine (Wartsila 6L 32), fuel: Heavy fuel oil (HFO);

- Dual fuel engine (Wartsila 6L34DF), fuel: Liquid natural gas (LNG) and MDO.

2.2. SOV Working Area

- –

- –

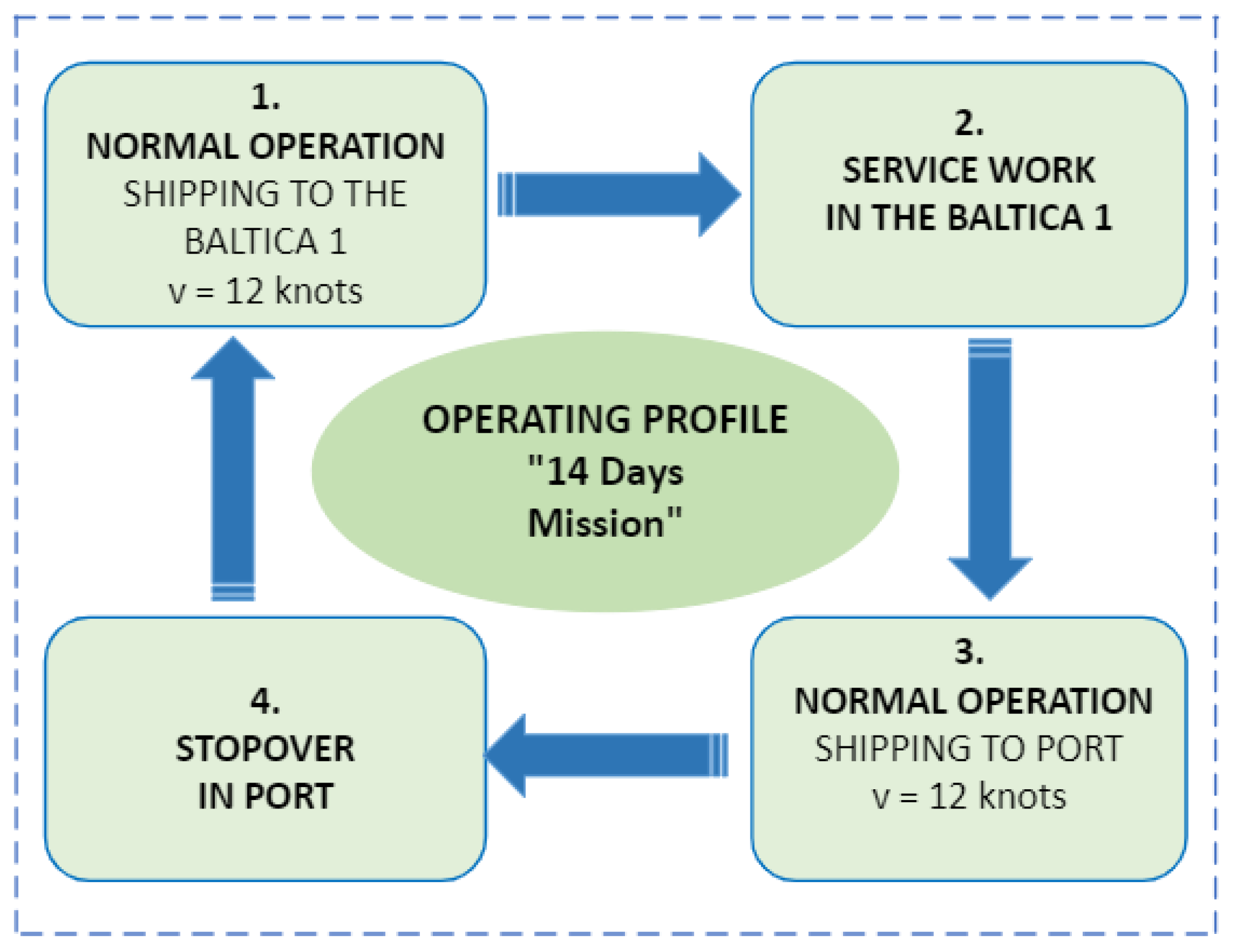

- Annual operation time TR = 250 days, service operation time Ts = max.14 days (mission)—Figure 7.

- –

- Marine environment conditions in the area under consideration—worse weather parameters were used for calculations, i.e., average significant wave height Hs = 2.5 m, average wind speed vw = 10 m/s [24].

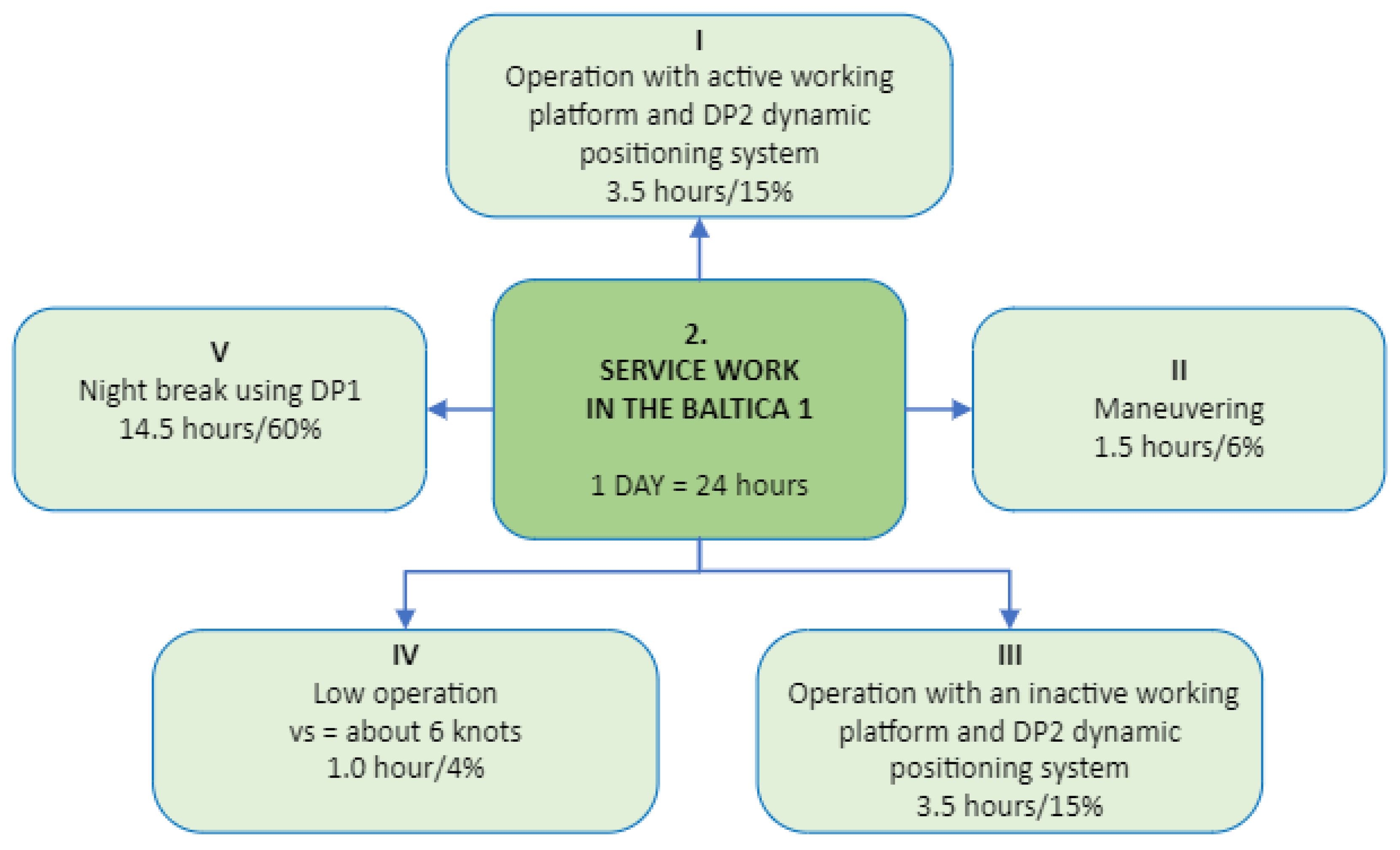

2.3. Operational Profile and Phases of SOV Service Work

2.4. Research Method

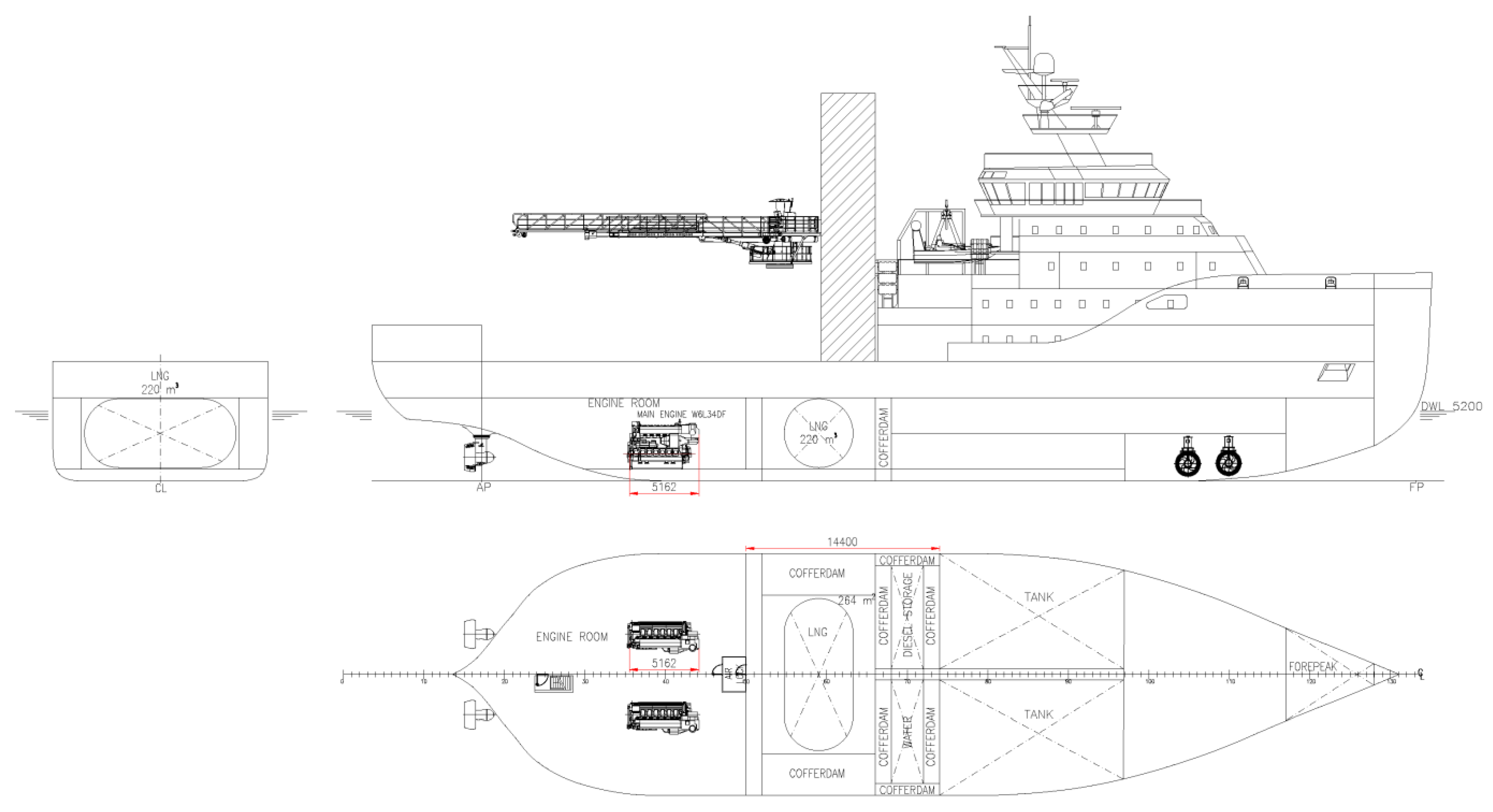

3. Design Analysis of the SOV for the Use of Alternative Fuels for Propulsion

3.1. Types of Fuels Used

3.2. Technical Requirements for Fuel Tanks on Ships

3.2.1. Current Regulations

3.2.2. Fuel Tanks with Methanol in the Ship’s Hull

- –

- Methanol tanks can be integrated into the hull structure, but require more space in the ship’s hull compared to standard fuel or LNG. This limits the payload capacity of the vessel, which can be a technical challenge for some vessel types, especially in those that would be converted;

- –

- Unlike a traditional fuel tank, an MDO does not need to have a double bottom or a cofferdam-separated side to prevent leaks—tanks require additional cofferdams only above the waterline, and separating the machinery compartment to prevent potential leaks;

- –

- An inert atmosphere must be maintained in the cofferdams and in the tank itself, filled with an inert gas—nitrogen;

- –

- Necessary space is needed where fuel preparation equipment (preparation room) is located, i.e., fuel pumps, fuel valves, heat exchangers and filters; the rooms should be located outside the engine room (outside category “A” machinery compartments).

3.3. Calculation of Fuel Reserve and Arrangement in the Ship’s Hull

- ▪

- Total fuel reserve :

- ▪

- Specific fuel consumption :

- ▪

- Fuel volume :

3.4. CO2 Emission and Fuel Costs

- ▪

- Estimated Index Value EIV:

- ▪

- Reference line values Vref:

- –

- CF (g CO2/g fuel)—determines the conversion factor, i.e., the carbon content of the fuel for the specific type of fuel used. According to Table 7 [38,39], the following CO2 emission factors were adopted, for methanol: CF = 1.375 g CO2/g, for LNG: CF = 2.75 g CO2/g, and for conventional fuel: CF = 3.114 g CO2/g.

- –

- SFCAE—omitted due to the assumption that the generators will use batteries recharged at the port, which is beneficial for the size of the fuel tanks and their weight, but most importantly for environmental reasons.

- –

- PME (kW)—the power of the main engine, representing 75% of the total installed main power, which affects the amount of fuel consumed as well as the type of fuel used (as shown in Table 5).

- –

- Vref—reference line values—due to the lack of data for ships in the offshore group, it was adopted for the general cargo ship [34].

| Fuel Type | CF in [g CO2/g] | Carbon Factor in g/MJ |

|---|---|---|

| Methanol | 1.375 | 69 |

| Liquefied Natural Gas (LNG) | 2.75 | 57 |

| Heavy Fuel Oil (HFO) | 3.114 | 77 |

| Marine Diesel Oil (MDO) | 3.206 | 75 |

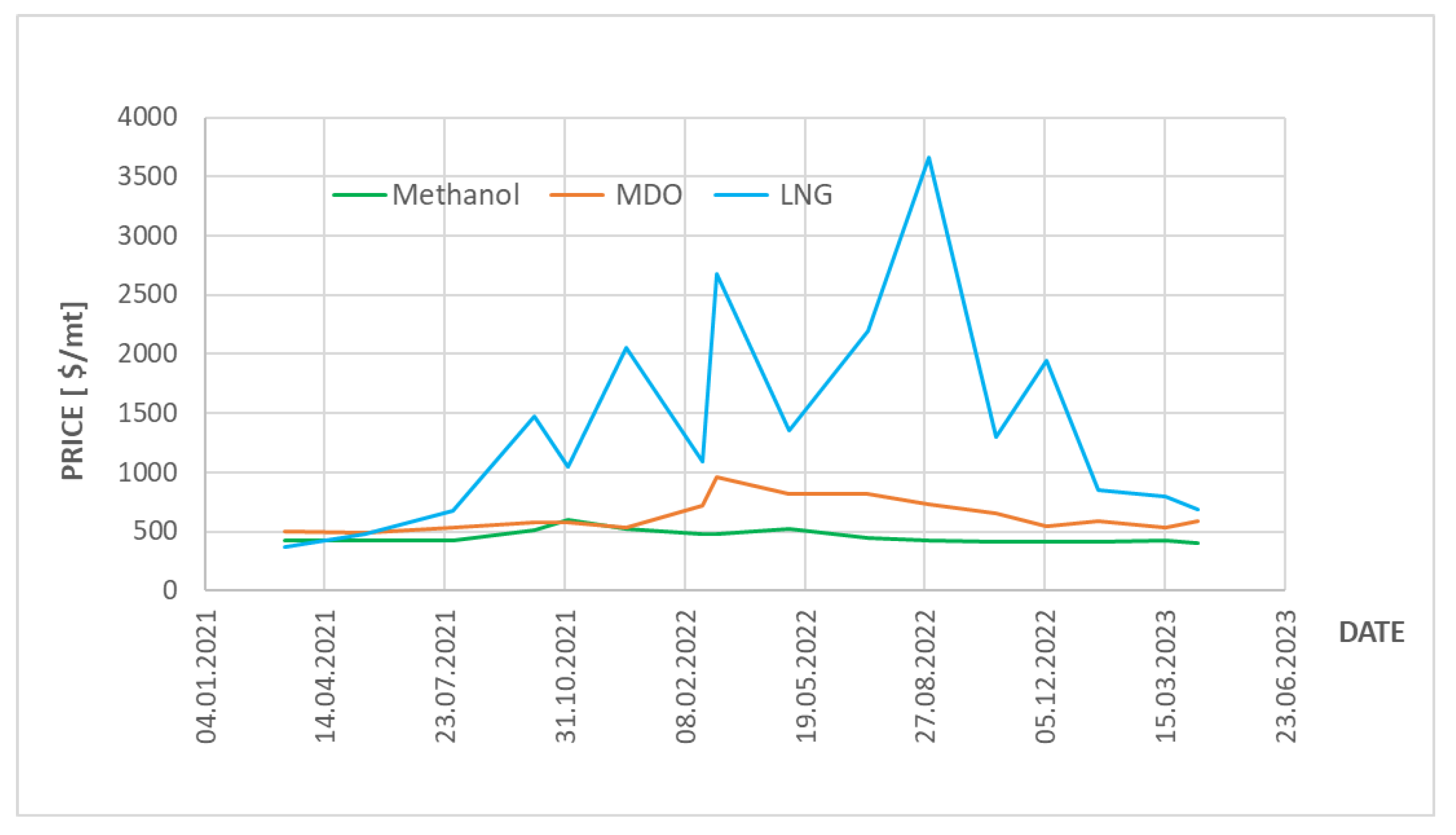

- Fuel costs :

- Number of voyages per year :

- Annual fuel costs :

4. Results

5. Summary and Conclusions

- Methanol fuel tanks in the hull of an SOV need 120% more volume, resulting in a 250% increase in fuel weight, which will consequently increase the vessel’s displacement and lead to higher fuel consumption compared to conventional fuel.

- The 35 t methanol fuel engine is dimensionally slightly larger than the two engine types compared, which ultimately did not affect the design layout changes. However, it needs additional space for methanol fuel preparation equipment outside the engine room. Methanol needs about 25% more area in the ship’s hull than LNG and about 38% more area than conventional fuel. It is presumed that this additional space can be a challenge on vessels where conversion to methanol is considered and on large vessels with a longer cruising range. In the short-range SOV vessel presented herein, the problem is irrelevant. Economically, a methanol-fuelled engine adds about 10% to the cost of a new ship, while an LNG engine adds 22%, according to MAN Energy Solutions.

- The design analysis of the SOV was limited to identifying and comparing different engine and fuel options in the available hull space and identifying the differences in spatial layout, in accordance with current regulations. The dimensional parameters of the SOV have not been modified, whereas in the next iteration of the project, it would be necessary to verify and define certain relationships linking the type and volume of fuel to the vessel size, mass and speed.

- The design analysis, based on an SOV with methanol fuel, represents only one aspect of the design issue in the overall design spiral model. A certain approach to the design of a specialized vessel such as SOV, as presented in this paper, needs to be elaborated on according to a general iterative design process.

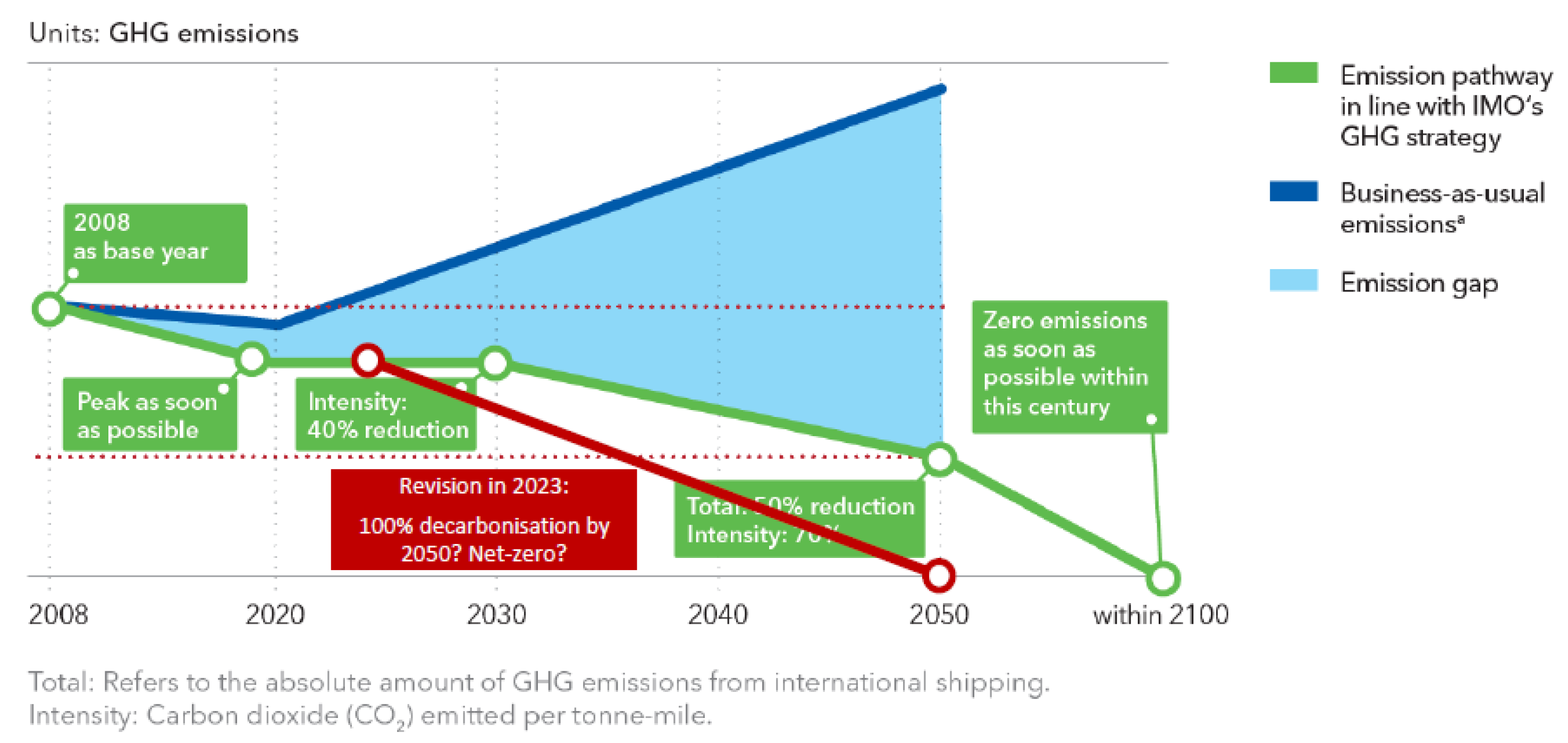

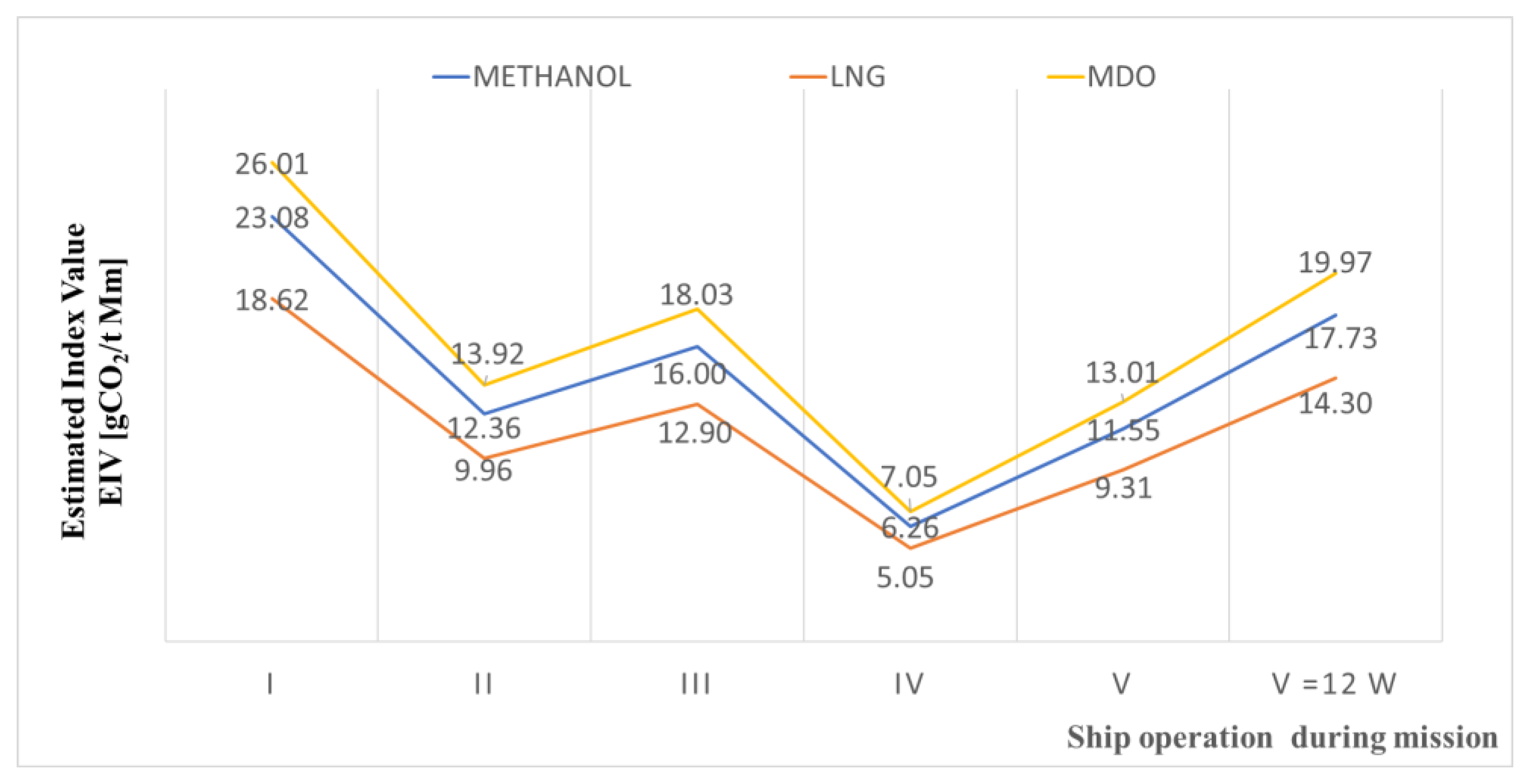

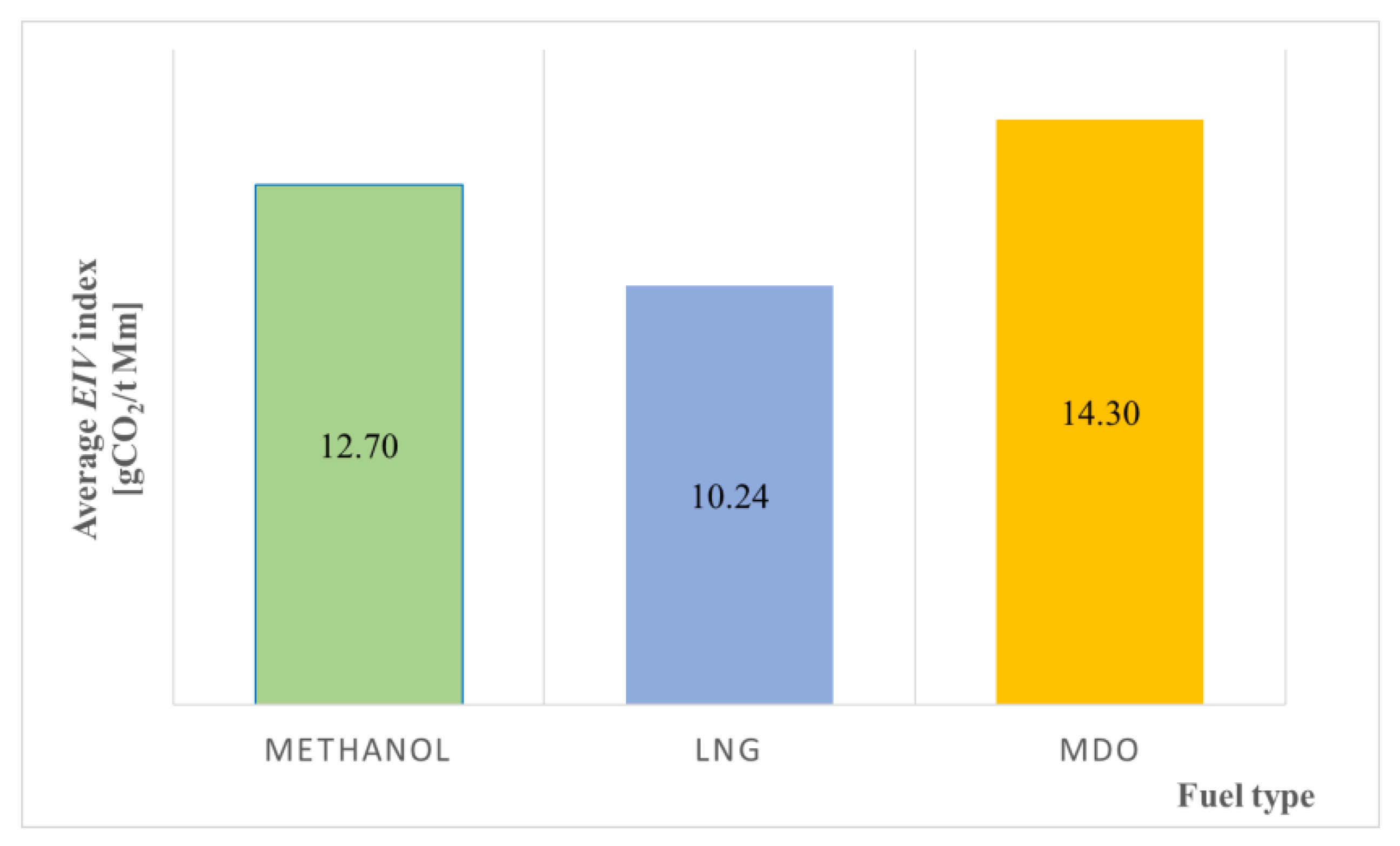

- This analysis proved that the use of methanol fuel on an SOV (in the Baltic Sea area), in terms of CO2 emissions, offers advantages only over conventional fuel. The average EIV values for the individual fuels were: 12.7 (Methanol), 10.24 (LNG) and 14.3 (MDO). As a result, methanol has an advantage over MDO in an amount of about 11%, while LNG proved to be better by almost 20% compared to methanol. The EIV values for the different service phases are detailed in Figure 14.

- As a result, the degree of CO2 emissions will depend on the type of methanol used, i.e., how it is obtained.

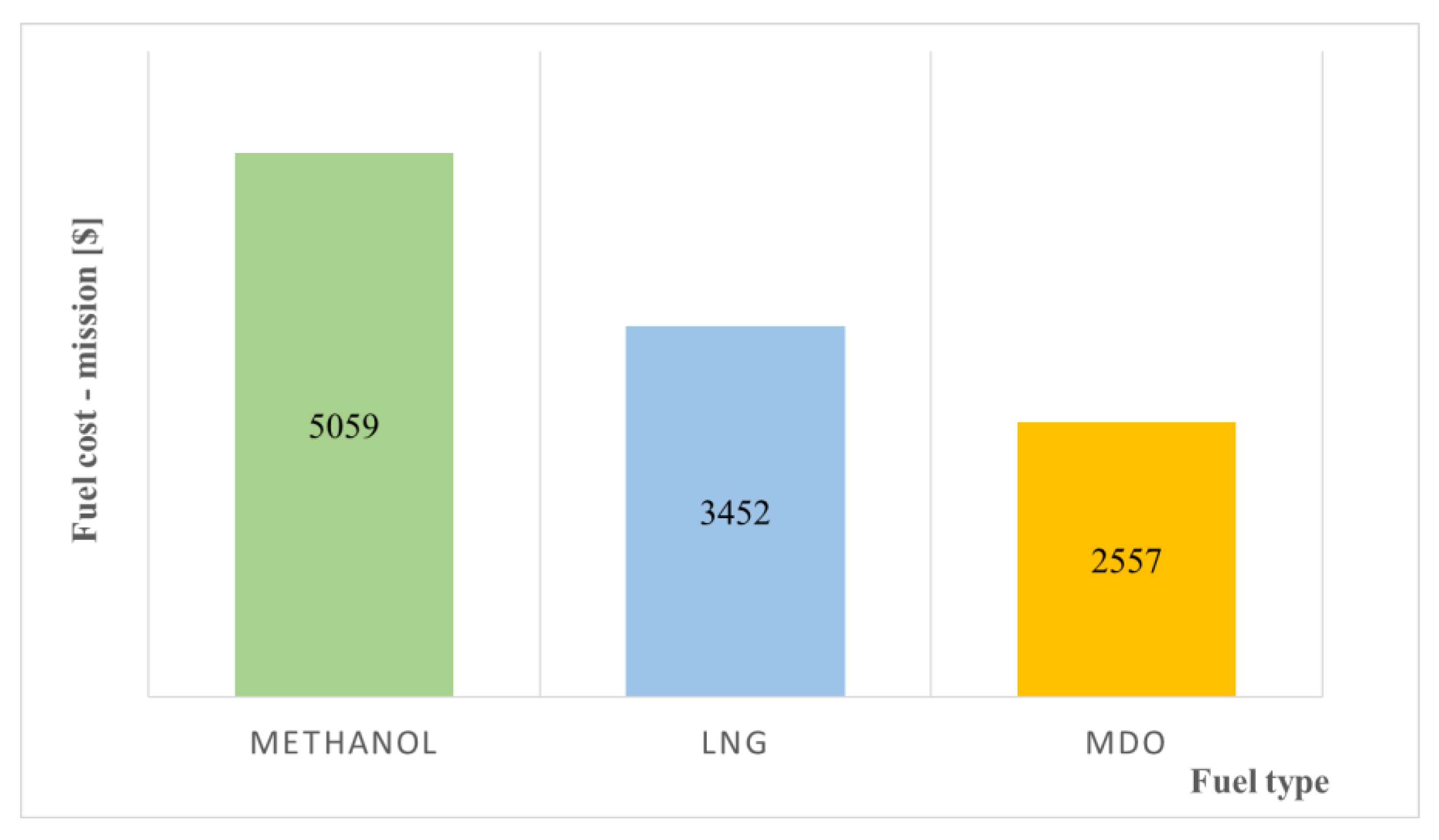

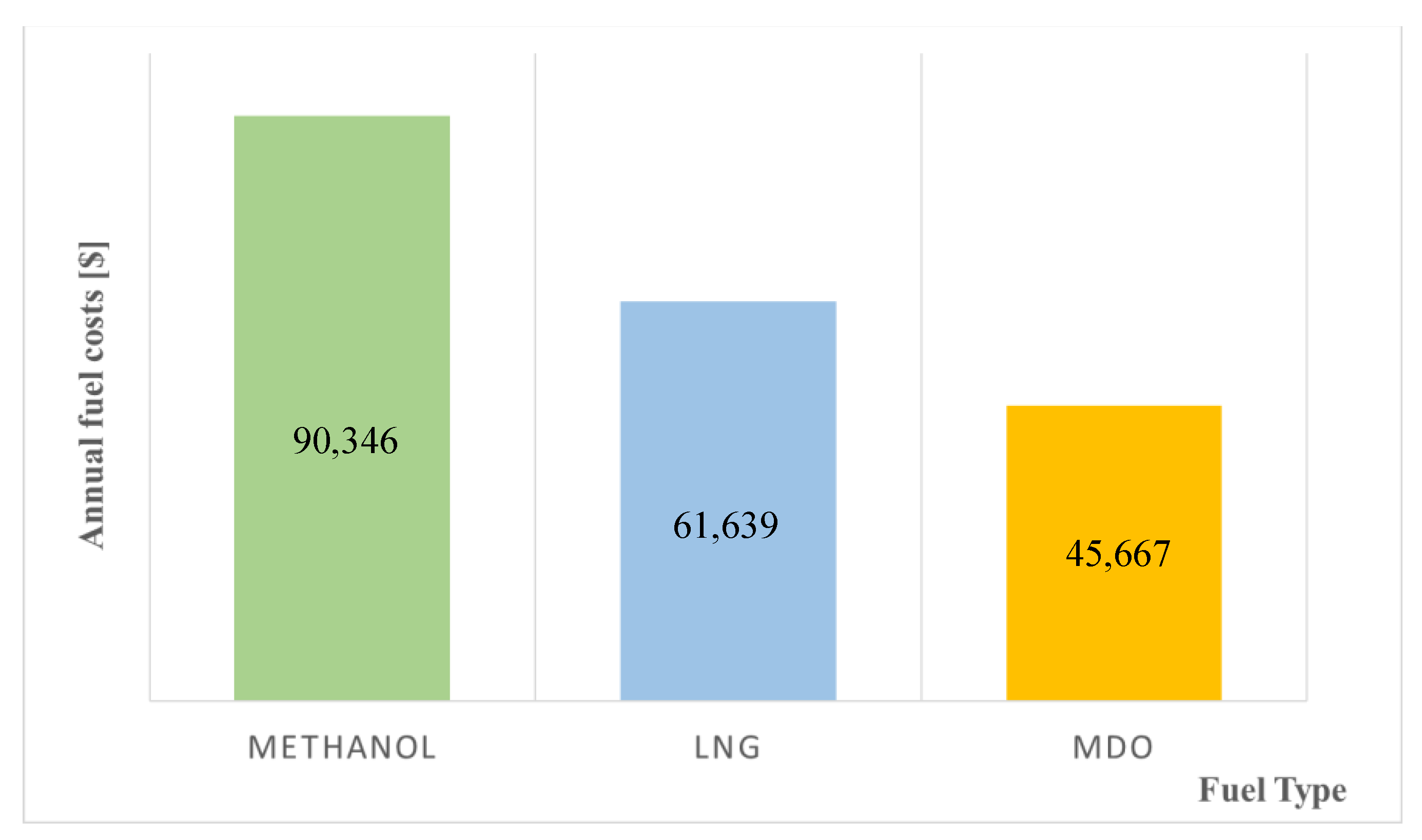

- Despite the lowest unit price of methanol ($500/mt), the calculated cost of this fuel at $90,346/year is 30% higher than LNG ($846/mt) and 50% higher than MDO ($508/mt), which cannot be regarded as a benefit for methanol use. To fully assess the economic benefits of using methanol, further studies should cover the entire supply chain from production, to transportation, storage, disposal, as well as environmental protection.

- The next few years will show whether methanol fuel technology, especially when used on smaller vessels, will become a permanent fixture in the ship’s energy supply and improve air quality. Methanol is a future technology in line with current decarbonisation strategy and is being considered particularly in emission-controlled shipping areas, such as the Baltic Sea, with its planned wind farms.

Funding

Data Availability Statement

Conflicts of Interest

References

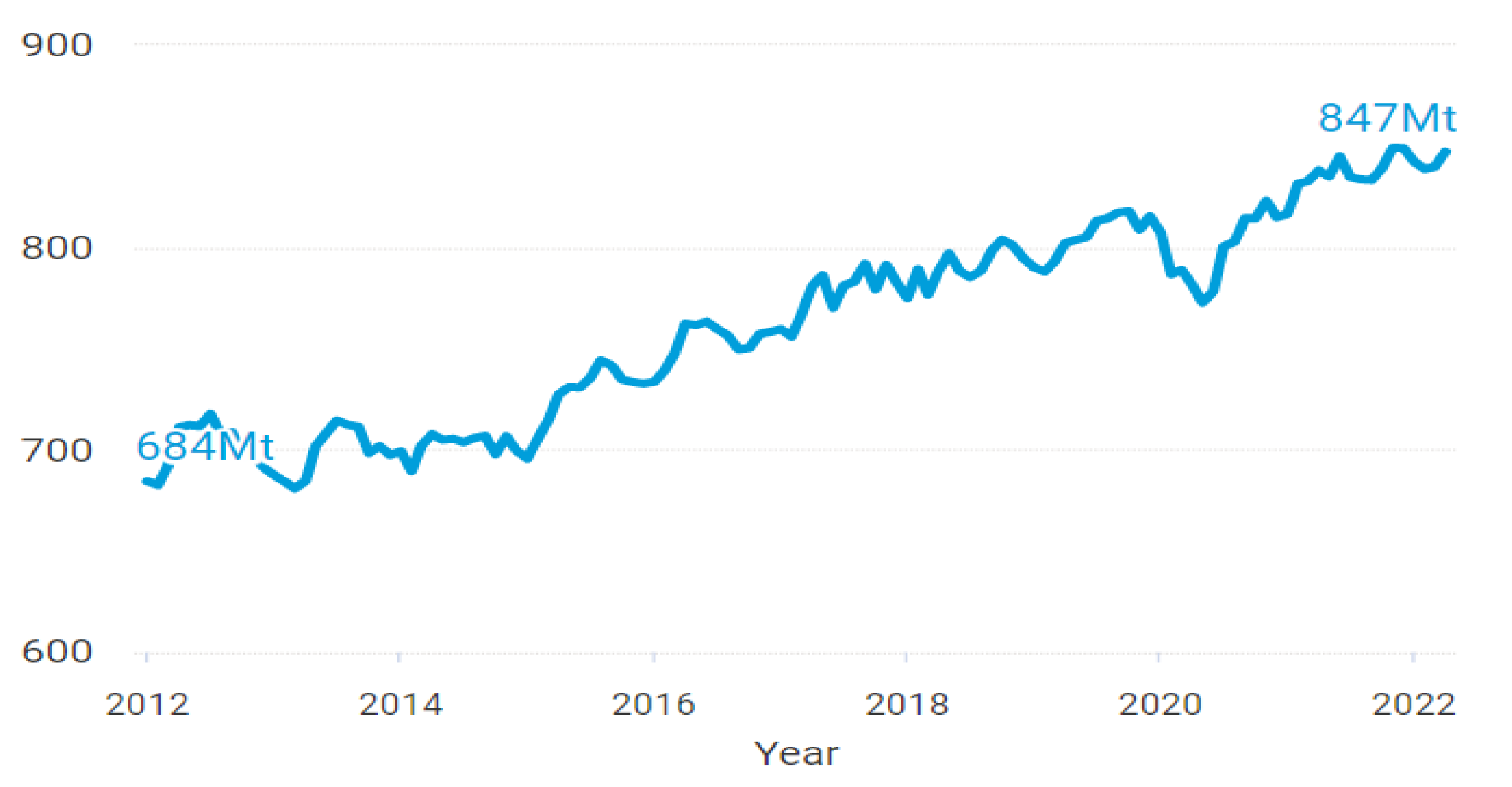

- Chen, J.; Fei, Y.; Wan, Z. The relationship between the development of global maritime fleets and GHG emission from shipping. J. Environ. Manag. 2019, 242, 31–39. [Google Scholar] [CrossRef] [PubMed]

- United Nations Conference on Trade and Development, Review of Maritime Transport 2022. Available online: https://unctad.org/system/files/official-document/rmt2022_en.pdf (accessed on 14 March 2023).

- UNCTAD. Review of Maritime Transport 2022, Navigating Stormy Waters. Available online: https://unctad.org/rmt2022 (accessed on 14 March 2023).

- DNV. Webinar Emerging Alternative Ship Fuels. Available online: https://DNV_Webinar_Emerging_Alternative_Fuels_28Feb2023.pdf (accessed on 19 March 2023).

- European Council Council of the European Union. Available online: https://www.consilium.europa.eu/en/policies/green-deal/fit-for-55-the-eu-plan-for-a-green-transition/ (accessed on 10 March 2023).

- SEA\LNG Ltd. Available online: https://sea-lng.org/wp-content/uploads/2020/04/Alternative-Marine-Fuels-Study_final_report_25.09.19.pdf (accessed on 19 March 2023).

- Solakivi, T.; Paimander, A.; Ojala, L. Cost competitiveness of alternative maritime fuels in the new regulatory framework, Transportation Research Part D. Transp. Environ. 2022, 113, 103500. [Google Scholar]

- Jeong, H.; Yun, H. A stochastic approach for economic valuation of alternative fuels: The case of container ship investments. J. Clean. Prod. 2023, 418, 138182. [Google Scholar] [CrossRef]

- Oloruntobi, O.; Chuah, L.F.; Mokhtar, K.; Gohari, A.; Onigbara, V.; Chung, J.X.; Mubashir, M.; Asif, S.; Show, P.L.; Han, N. Assessing methanol potential as a cleaner marine fuel: An analysis of its implications on emissions and regulation compliance. Clean. Eng. Technol. 2023, 14, 100639. [Google Scholar] [CrossRef]

- Ammar, N.R.; Seddiek, I.S. Eco-environmental analysis of ship emission control methods: Case study RO-RO cargo vessel. Ocean Eng. 2017, 137, 166–173. [Google Scholar] [CrossRef]

- Ammar, N.R. An environmental and economic analysis of methanol fuel for a cellular container ship, Transportation Research Part D. Transp. Environ. 2019, 69, 66–76. [Google Scholar]

- Ammar, N.R.; Seddiek, I.S. An environmental and economic analysis of emission reduction strategies for container ships with emphasis on the improved energy efficiency indexes. Environ. Sci. Pollut. Res. 2020, 27, 23342–23355. [Google Scholar] [CrossRef] [PubMed]

- Ančić, I.; Šestan, A. Influence of the required EEDI reduction factor on the CO2 emission from bulk carriers. Energy Policy 2015, 84, 107–116. [Google Scholar] [CrossRef]

- Szelangiewicz, T.; Żelazny, K. Poziom emisji CO2 jako kryterium projektowe współczesnych statków transportowych. Combust. Engines 2014, 156, 59–68. [Google Scholar] [CrossRef]

- Methanol Institute. Available online: https://www.methanol.org/wp-content/uploads/2023/07/Methanol-and-shipping-210323.pdf (accessed on 21 October 2023).

- Lloyd’s Register (LR). Engine Retrofit Report 2023. Available online: https://www.lr.org/en/knowledge/research-reports/applying-alternative-fuels-to-existing-ships/?creative=676223539340&keyword=methanol%20engine%20retrofit&matchtype=b&network=g&device=c&utm_source=google&utm_campaign=&utm_medium=cpc&utm_content=&utm_term=methanol%20engine%20retrofit (accessed on 21 October 2023).

- Wärtsilä. Available online: https://www.wartsila.com/insights/article/methanol-fuel-for-thought-in-our-deep-dive-q-a (accessed on 21 October 2023).

- Vedachalam, S.; Baquerizo, N.; Dalai, A.K. Review on impacts of low sulfur regulations on marine fuels and compliance options. Fuel 2021, 310 Pt A, 122243. [Google Scholar] [CrossRef]

- Verhelst, S.; Turner, J.W.; Sileghem, L.; Vancoillie, J. Methanol as a fuel for internal combustion engines. Prog. Energy Combust. Sci. 2019, 70, 43–88. [Google Scholar] [CrossRef]

- Gospodarka Morska pl. Available online: https://www.gospodarkamorska.pl/status-offshore-wind-w-polsce-na-jakim-etapie-sa-projekty-baltica-1-oraz-baltica-23-69377 (accessed on 5 May 2023).

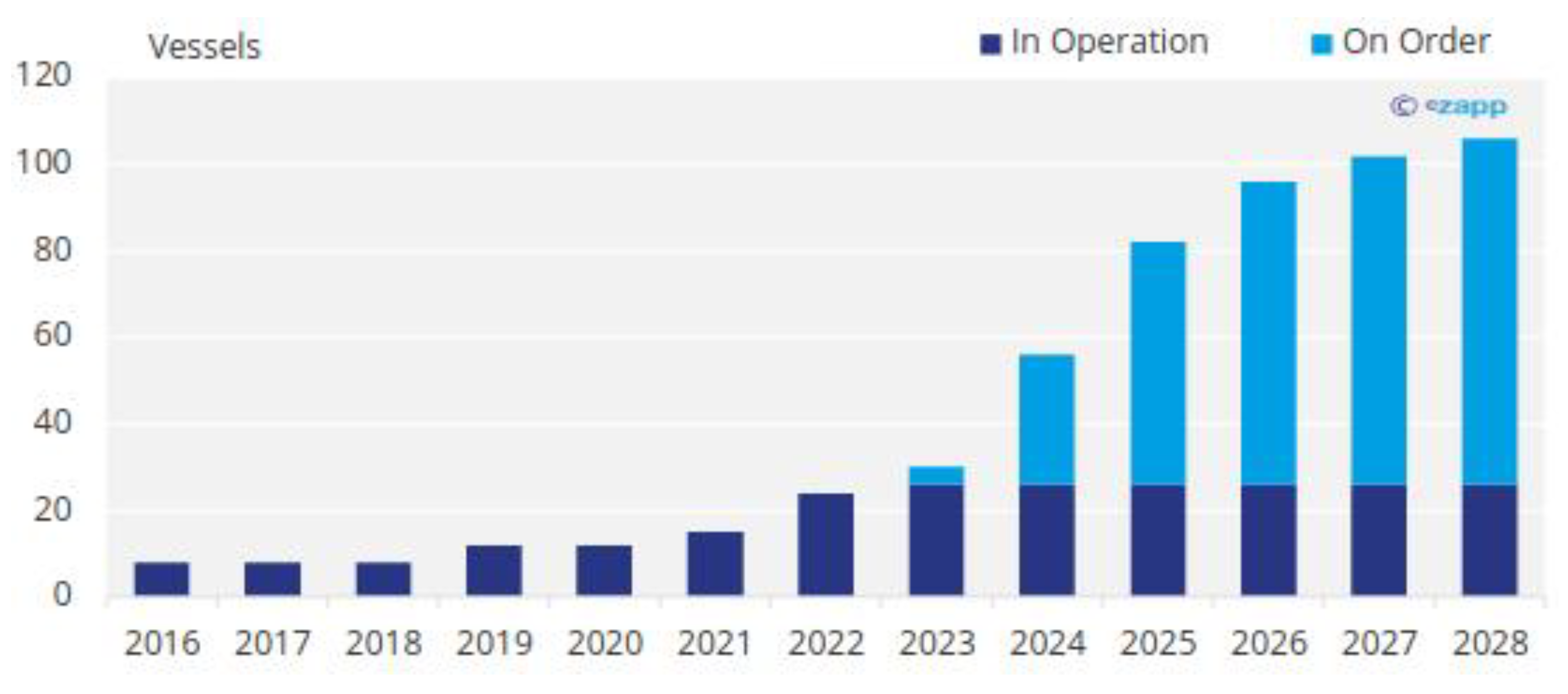

- Offshore Magazine com. Offshore Wind Installation Vessel Market Booming. Available online: https://www.offshore-mag.com/renewable-energy/article/14206400/ihs-markit-offshore-wind-installation-vessel-market-booming (accessed on 5 May 2023).

- Lloyd’s List. Will Methanol Bunkering Pick Up in 2023? Available online: https://lloydslist.maritimeintelligence.informa.com/LL1143828/Will-methanol-bunkering-pick-up-in-2023 (accessed on 5 May 2023).

- DNV. Maritime Impact, Methanol as an Alternative Fuel for Container Vessels. Available online: https://www.dnv.com/expert-story/maritime-impact/methanol-as-an-alternative-fuel-for-container-vessels.html (accessed on 5 April 2023).

- Oleksiuk, J. Projekt Koncepcyjny Statku SOV Do Obsługi Farm Wiatrowych. Master’s Thesis, Faculty of Navigation, Maritime University in Szczecin, Szczecin, Poland, 2023. [Google Scholar]

- PGE. Begins Wind Resource Measuring Campaign for Baltica 1 Wind Farm. Available online: https://energyindustryreview.com/renewables/pge-begins-wind-resource-measuring-campaign-for-baltica-1-wind-farm/ (accessed on 5 April 2023).

- International Maritime Organization (IMO). Interim Guidelines for the Safety of Ships Using Methyl/Ethyl Alcohol as Fuel; Resolution MSC.1/Circ.1621. 7 December 2020. Available online: https://www.register-iri.com/wp-content/uploads/MSC.1-Circ.1621.pdf (accessed on 25 September 2023).

- Nasser, M.A.; Elgohary, M.M.; Abdelnaby, M.; Shouman, M.R. Environmental and economic performance investigation of natural gas and methanol as a marine alternative fuel. Preprint 2022. [Google Scholar] [CrossRef]

- METHANOL SAFE HANDLING TECHNICAL BULLETIN—Part 1-B: Physical & Chemical Properties of Selected Fuels (1). Available online: https://www.methanol.org/wp-content/uploads/2020/04/Part-1-B_-Physical-Chemical-Properties-of-Selected-Fuels-.pdf (accessed on 14 April 2023).

- The Methanol-Fuelled MAN B&W LGIM Engine Application, Service Experience. Available online: https://www.man-es.com/docs/default-source/document-sync/the-methanol-fuelled-man-b-w-lgim-engine-eng.pdf (accessed on 10 April 2023).

- Wärtsilä 32. Available online: https://www.wartsila.com/marine/products/engines-and-generating-sets/wartsila-32-methanol-engine (accessed on 10 April 2023).

- Wartsilä Methanol Pac Product Guide—How to Correctly Pre-Engineer the Wärtsilä Methanol Pac Fuel Supply System 2023. Available online: https://brandhub.wartsila.com/m/e06423c27ec993d/original/Wartsila-MethanolPac-Product-uide.pdf?utm_source=engines&utm_medium=future-fuel-engines&utm_term=marine-power&utm_content=productguide&utm_campaign=mp-engines-and-generating-sets-gated (accessed on 10 July 2023).

- Wartsila.com. Available online: https://www.wartsila.com/marine/products/engines-and-generating-sets/dual-fuel-engines/wartsila-34df/dimensions-w34df?utm_source=web&utm_medium=organic&utm_term=marine&utm_content=w34df&utm_campaign=ms-3d-models (accessed on 30 July 2023).

- Wang, S.; Notteboom, T. The Adoption of Liquefied Natural Gas as a Ship Fuel: A Systematic Review of Perspectives and Challenges. Transp. Rev. 2014, 34, 749–774. [Google Scholar] [CrossRef]

- International Maritime Organization (IMO). The International Code of Safety for Ships Using Gases or Other Low-Flashpoint Fuels. Available online: https://wwwcdn.imo.org/localresources/en/publications/Documents/Supplements/English/Q109E_122019.pdf (accessed on 25 September 2023).

- Bortnowska, M. Development of new technologies for shipping natural gas by sea. Pol. Marit. Res. 2009, 16, 70–78. [Google Scholar] [CrossRef]

- Bortnowska, M. Technological and Operational Concept of an LNG Carrier, Konferencja międzynarodowa EXPLO-SHIP 2010. Sci. J. 2010, 21, 28–33. [Google Scholar]

- International Maritime Organization (IMO). 2018 Guidelines on the Method of Calculation of the Attained Energy Efficiency Design Index (EEDI) for New Ships; Resolution MEPC.308(73) (adopted on 26 October 2018). Available online: https://wwwcdn.imo.org/localresources/en/KnowledgeCentre/IndexofIMOResolutions/MEPCDocuments/MEPC.308(73).pdf (accessed on 25 September 2023).

- MARPOL. International Convention for the Prevention of Pollution from Ships—Annex VI—Regulations for the Prevention of Air Pollution from Ships—Chapter 4—Regulations on Energy Efficiency for Ships—Regulation 24—Required EEDI. Available online: https://imorules.com/GUID-82DA0CF7-5A83-476B-A1F5-B455E4610E58.html (accessed on 25 September 2023).

- Jasper, F.; Hoen, M.; Koopman, M.; Nelissen, D.; Ahdour, S. Estimated Index Values of New Ships, Analysis of EIVs of Ships That Have Entered the Fleet Since 2009; Publication Code: 15.7E50.14. Available online: https://www.transportenvironment.org/wp-content/uploads/2021/07/2015%2005%20CE_Delft_7E50_Estimated_Index_Values_of_New_Ships_DEF.pdf (accessed on 25 September 2023).

- Methanol Institute. Available online: https://www.methanol.org/methanol-price-supply-demand/ (accessed on 30 April 2023).

| Global SOV Fleet | |||||

|---|---|---|---|---|---|

| 2021 | 2022 | 2023 | 2024 | 2025 | |

| In Service | 29 | ||||

| Under Construction | 2 | 5 | 4 | 3 | |

| Possible | 2 | 5 | |||

| Parameter | Value | Symbol | Unit |

|---|---|---|---|

| Length between perpendiculars | 72.0 | Lbp | m |

| Breadth | 18.0 | B | m |

| Hull depth | 8.9 | H | m |

| Draught | 5.3 | T | m |

| Displacement | 5004 | D | t |

| Deadweight | 1005 | DWT | t |

| Cargo weather deck area | 280 | Awd | m2 |

| Endurance | 14 | A | days |

| Technical crew number | 60 | nc | people |

| Service Work Phases | Power Requirement PR′ [kW] ** | Time T [hours/day] | Energy Required | ||

|---|---|---|---|---|---|

| ER [kWh/day] | EMIS * kWh/Mission | ||||

| I | Operation with active working platform and DP2 dynamic positioning system | 2851 | 3.5 | 9978.5 | 139,699 |

| II | Maneuvering | 1526 | 1.5 | 2289 | 32,046 |

| III | Operation with DP2 dynamic positioning system | 1976 | 3.5 | 6916 | 96,826 |

| IV | Low operation—sailing vs = 6 kn | 773 | 1.0 | 773 | 10,822 |

| V | Night break using DP1 | 1426 | 14.5 | 20,677 | 289,478 |

| Sailing to/from the Baltica 1 | |||||

| Normal operation v = 12 kn | 2190 | 2 × 4 | n/a | 17,523 only round trip | |

| Property | Fuels | ||

|---|---|---|---|

| Methanol (65 °C) | MDO | LNG (Liquid—163 °C) | |

| Density (kg/m3) | 787–792 | 830–850 | 410–500 |

| Emergency content LHV (MJ/kg) | 19.9–20 | 42.0–43.0 | 50.0 |

| Boiling Point (°C) | 65.0 | 150–370 | −162.0 |

| Flashpoint (°C) | 9–11.0 | min. 60 | −188.0 |

| Auto ignition (°C) | 385.0–464.0 | 240.0 | 537.0 |

| Viscosity cSt w 20 °C | ~0.6 | ~13.5 | |

| Fuel tank size relative to MDO | 2.3 | 1.0 | 1.7 |

| No. | Parameter | Engine Type | ||

|---|---|---|---|---|

| Two-Stroke Dual Fuel Engine (Wärtsilä 6L 32M) | Diesel Engine (Wärtsilä 6L 32) | Dual Fuel Engine (Wärtsilä 6L34DF) | ||

| 1. | Rated power PR [kW] | 3480 | 3480 | 3000 |

| 2. | Speed [rpm] | 750 | 750 | 750 |

| 3. | Dimensions [mm] | 5570 × 2380 × 3490 | 5255 × 2389 × 3498 | 5352 × 2389 × 3498 |

| 4. | Weight ME [t] | 35 | 35.4 | 35.2 |

| 5. | Fuel type | Methanol fuel (M) Diesel fuel (MDO) | Heavy fuel oil | Liquid natural gas (LNG + MDO) |

| 6. | Specific fuel consumption * [g/kWh] | acc. to Formula (2) | acc. to Formula (2) | acc. to Formula (2) |

| 7. | IMO | Tier II or III | Tier II or III | Tier III |

| No. | Parameter | Methanol | LNG | MDO | The Ratio of Methanol to | |

|---|---|---|---|---|---|---|

| LNG | MDO | |||||

| 1. | Fuel reserve | 204 | 82 | 101 | 2.5 | 2.0 |

| 2. | Fuel volume Vfuel [m3] | 258 | 220 | 112 | 1.2 | 2.3 |

| 3. | Emergency content LHV [MJ/kg] | 20 | 49.6 | 40.2 | - | - |

| 4. | Specific fuel consumption [g/kWh] | 174 | 70.2 | 81.5 | ||

| 5. | Density [kg/m3] | 789 | 435 | 991 | - | - |

| 6. | Area required (tanks + compartments required) [m2] acc. to design analysis | 347 | 264 | 216 | ||

| Service Work Phases | Fuel Demand [kg] | |||

|---|---|---|---|---|

| Methanol | LNG | MDO | ||

| I | Operation with active working platform and DP2 dynamic positioning system | 1997 | 805 | 935 |

| II | Maneuvering | 458 | 185 | 215 |

| III | Operation with DP2 dynamic positioning system | 1384 | 558 | 648 |

| IV | Low operation—sailing vs = 6 kn | 155 | 62 | 72 |

| V | Night break using DP1 | 4137 | 1668 | 1938 |

| Shipping to/from the Baltica 1 | ||||

| Normal operation v = 12 knots | 3506 | 1414 | 1642 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bortnowska, M. Projected Reductions in CO2 Emissions by Using Alternative Methanol Fuel to Power a Service Operation Vessel. Energies 2023, 16, 7419. https://doi.org/10.3390/en16217419

Bortnowska M. Projected Reductions in CO2 Emissions by Using Alternative Methanol Fuel to Power a Service Operation Vessel. Energies. 2023; 16(21):7419. https://doi.org/10.3390/en16217419

Chicago/Turabian StyleBortnowska, Monika. 2023. "Projected Reductions in CO2 Emissions by Using Alternative Methanol Fuel to Power a Service Operation Vessel" Energies 16, no. 21: 7419. https://doi.org/10.3390/en16217419

APA StyleBortnowska, M. (2023). Projected Reductions in CO2 Emissions by Using Alternative Methanol Fuel to Power a Service Operation Vessel. Energies, 16(21), 7419. https://doi.org/10.3390/en16217419