Experimental Study on Macroscopic Spray and Fuel Film Characteristics of E40 in a Constant Volume Chamber

Abstract

:1. Introduction

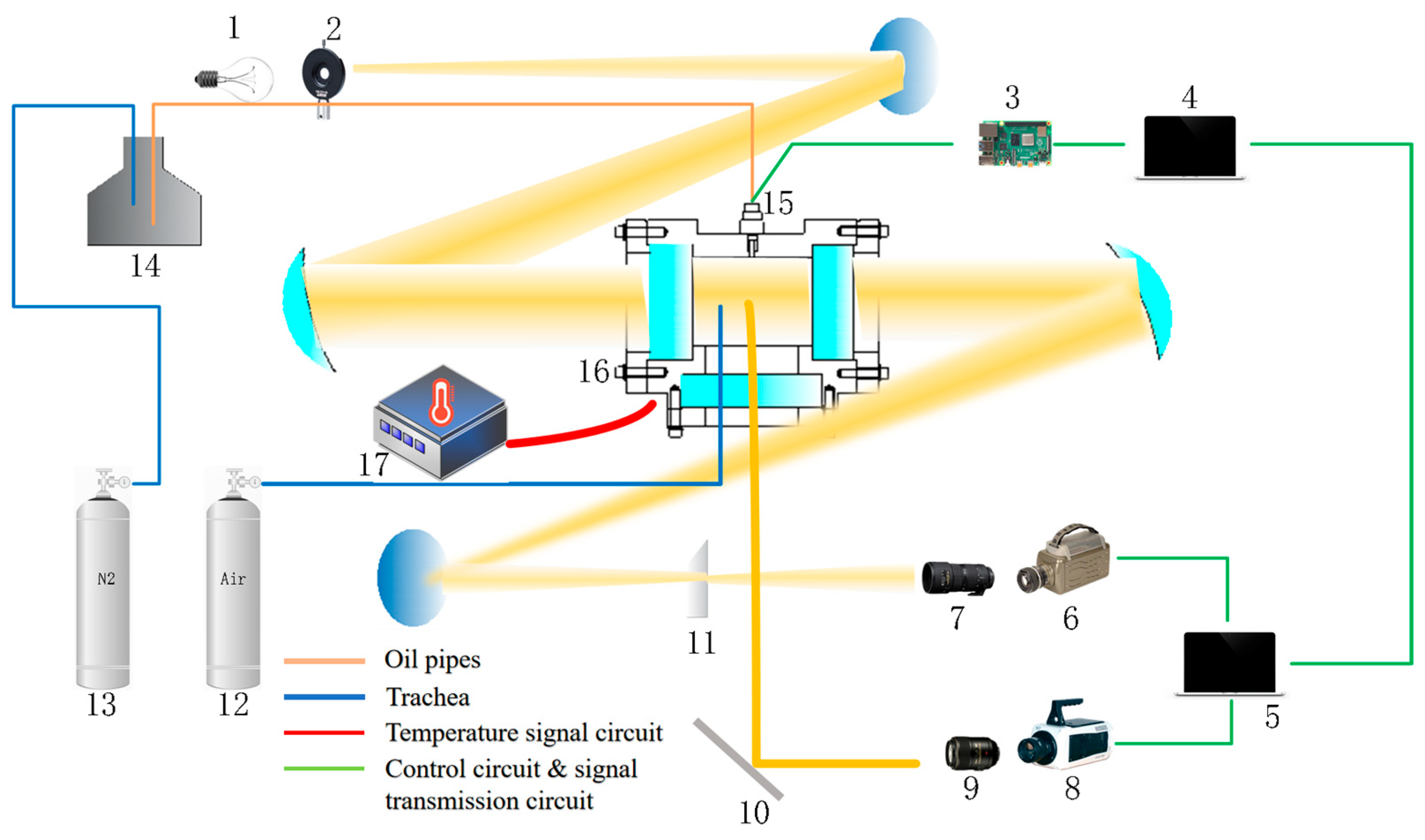

2. Experimental Setup

2.1. Experimental Apparatus

2.2. Experimental Conditions

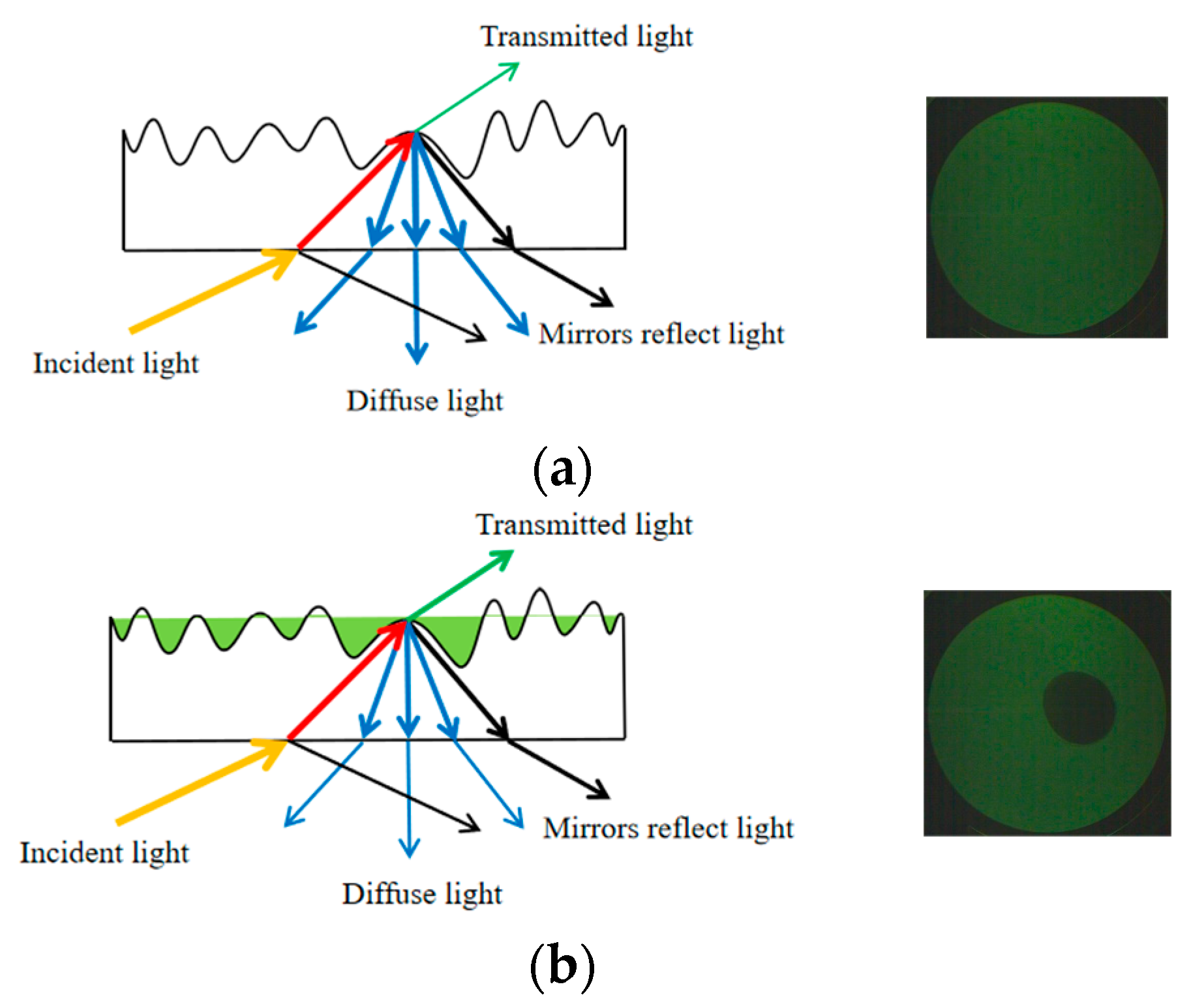

2.3. RIM Calibration

3. Results and Discussions

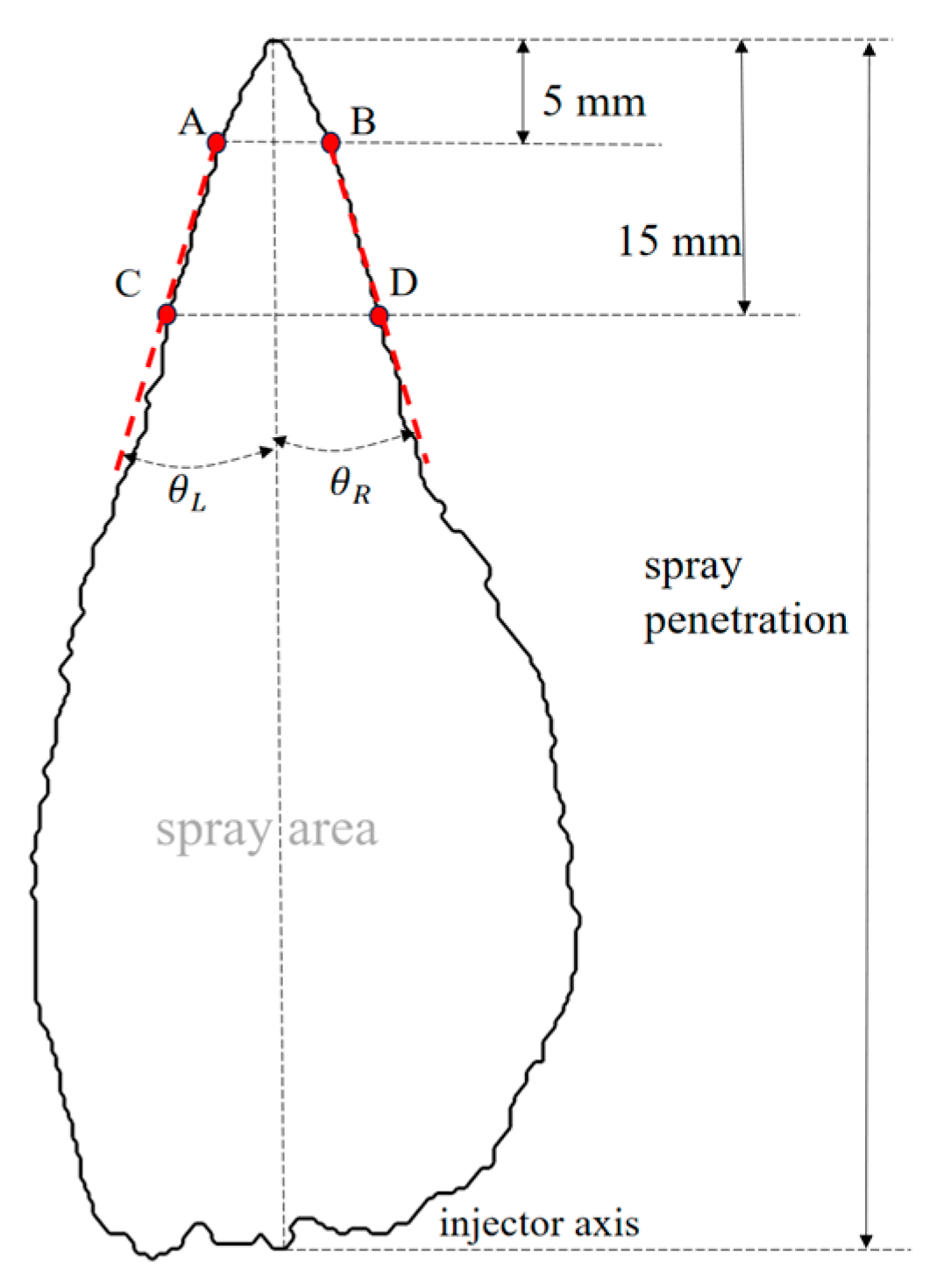

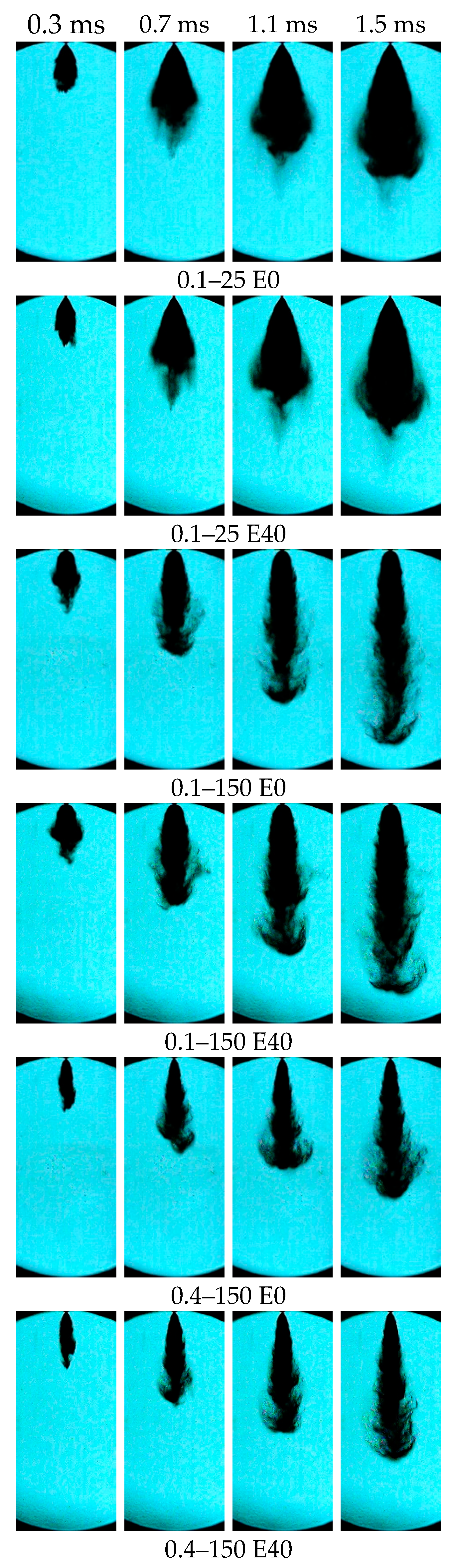

3.1. Spray Morphology

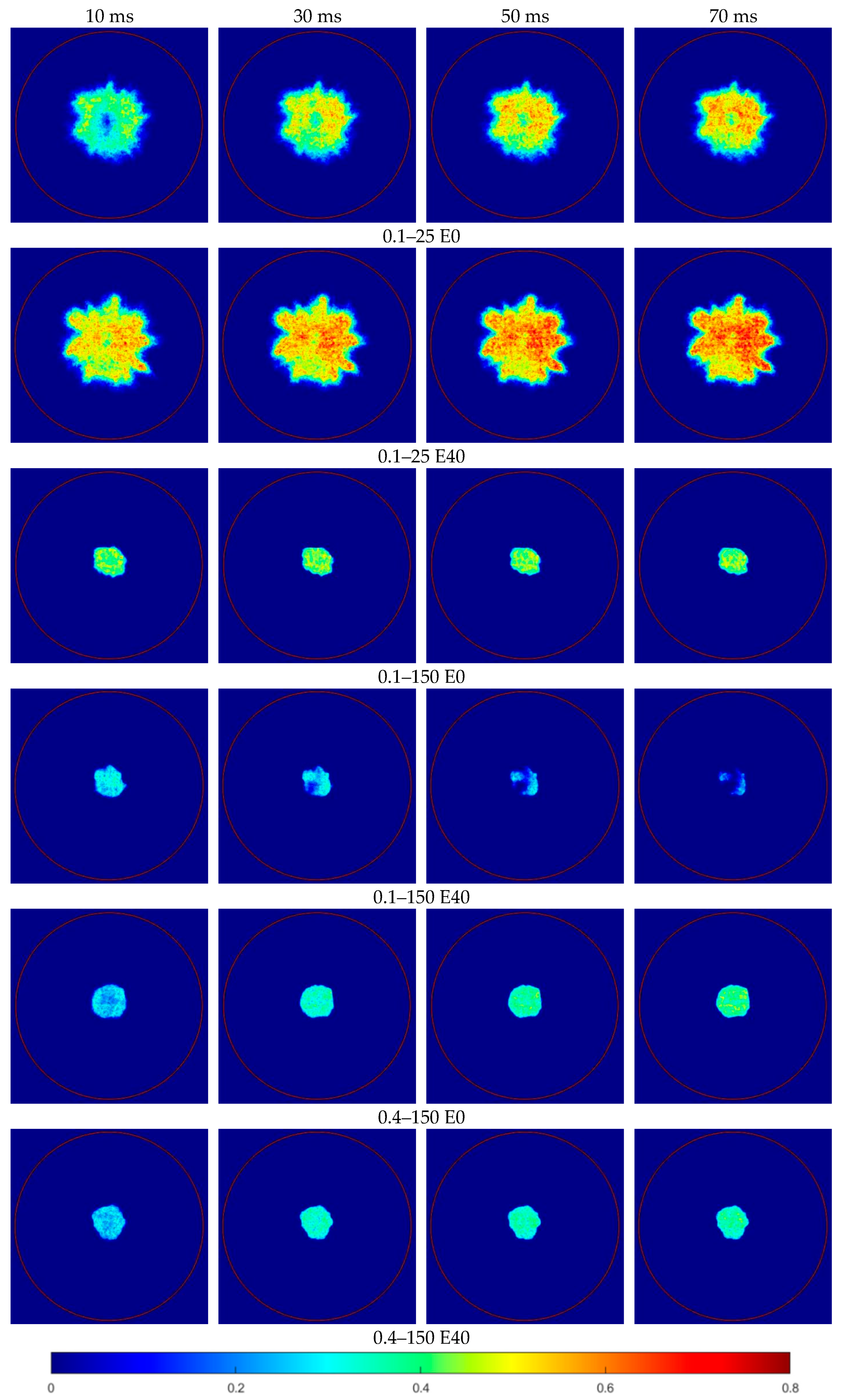

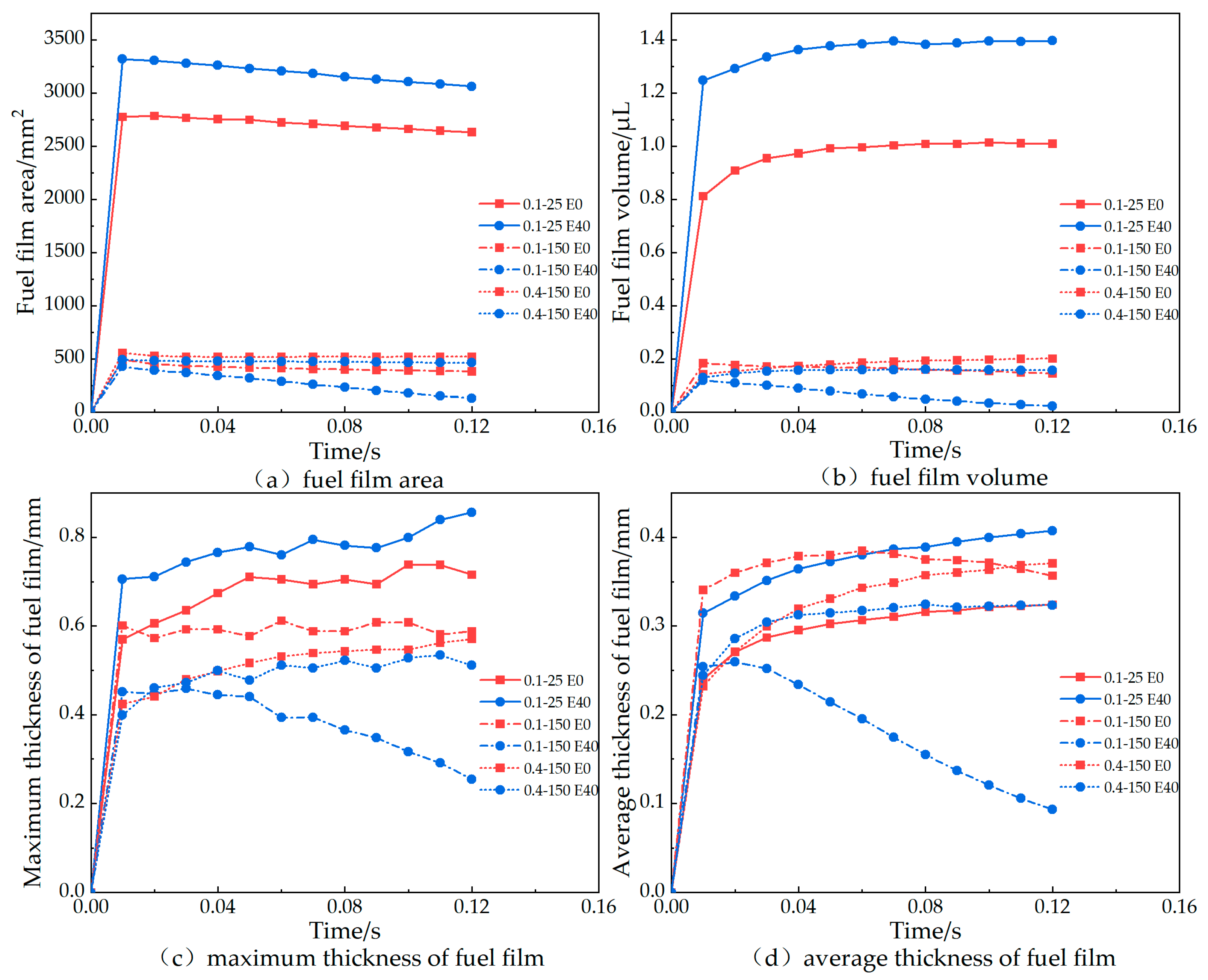

3.2. Characteristics of Fuel Film Deposited after Spray Impingement

4. Conclusions

- (1)

- For the same test fuel, spray penetration distance and spray area increase when ambient temperature rises. However, spray penetration distance, spray cone angle, and spray area all considerably decrease as environmental pressure rises. The spray macro-characteristic parameters of gasoline are greater than those of E40 in the 0.1–25 working conditions, demonstrating that gasoline fuel spray evaporates better when compared to E40. The spray macro-characteristic parameters of E40 are greater than gasoline in both the 0.1–150 and 0.4–150 working conditions, demonstrating that E40 fuel spray evaporates better in these two operating conditions.

- (2)

- As the ambient temperature increases, the area and volume of the deposited fuel film decrease significantly. Under the same ambient temperature, as the ambient back pressure increases, the oil film area and volume both increase slightly. In the 0.1–25 working condition, the maximum oil film thickness, average oil film thickness, oil film area, and oil film volume of E40 are larger than that of gasoline. In the 0.1–150 and 0.4–150 working conditions, the maximum oil film thickness, average oil film thickness, oil film area of E40, and oil film volume are both smaller than gasoline. The evaporation characteristics of fuel have a great influence on its oil film properties.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Han, D.; Fan, Y.; Sun, Z.; Nour, M.; Li, X. Combustion and emissions of isomeric butanol/gasoline surrogates blends on an optical GDI engine. Fuel 2020, 272, 117690. [Google Scholar] [CrossRef]

- Qian, Y.; Li, Z.; Yu, L.; Wang, X.; Lu, X. Review of the state-of-the-art of particulate matter emissions from modern gasoline fueled engines, Appl Energy. Appl. Energy 2019, 238, 1269–1298. [Google Scholar] [CrossRef]

- Barone, T.L.; Storey, J.M.; Youngquist, A.D.; Szybist, J.P. An analysis of direct-injection spark-ignition (DISI) soot morphology. Atmos. Environ. 2012, 49, 268–274. [Google Scholar] [CrossRef]

- Catapano, F.; Di Iorio, S.; Luise, L.; Sementa, P.; Vaglieco, B.M. Influence of ethanol blended and dual fueled with gasoline on soot formation and particulate matter emissions in a small displacement spark ignition engine. Fuel 2019, 245, 253–262. [Google Scholar] [CrossRef]

- Mendiburu, A.Z.; Lauermann, C.H.; Hayashi, T.C.; Mariños, D.J.; da Costa, R.B.R.; Coronado, C.J.; Roberts, J.J.; de Carvalho, J.A. Ethanol as a renewable biofuel: Combustion characteristics and application in engines. Energy 2022, 257, 124688. [Google Scholar] [CrossRef]

- Sakai, S.; Rothamer, D. Impact of ethanol blending on particulate emissions from a spark-ignition direct-injection engine. Fuel 2019, 236, 1548–1558. [Google Scholar] [CrossRef]

- Yang, J.; Roth, P.; Durbin, T.D.; Johnson, K.C.; Asa-Awuku, A.; Cocker, D.R.; Karavalakis, G. Investigation of the effect of mid- and high-level ethanol blends on the particulate and the mobile source air toxic emissions from a gasoline direct injection flex fuel vehicle. Energy Fuels 2019, 33, 429–440. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, C.D.; Dimaratos, A.M.; Rakopoulos, D.C. Exhaust emissions with ethanol or n-butanol diesel fuel blends during transient operation: A review. Renew. Sustain. Energy Rev. 2013, 17, 170–190. [Google Scholar] [CrossRef]

- Chen, L.; Stone, R. Measurement of Enthalpies of Vaporization of Isooctane and Ethanol Blends and Their Effects on PM Emissions from a GDI Engine. Energy Fuels 2011, 25, 1254–1259. [Google Scholar] [CrossRef]

- Daniel, R.; Xu, H.; Wang, C.; Richardson, D.; Shuai, S. Gaseous and particulate matter emissions of biofuel blends in dual-injection compared to direct-injection and port injection. Appl. Energy 2013, 105, 252–261. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, Y.; Xie, F.; Duan, J.; Li, X.; Liu, Y. Influence of ethanol blending ratios on in-cylinder soot processes and particulate matter emissions in an optical direct injection spark ignition engine. Fuel 2022, 308, 121944. [Google Scholar] [CrossRef]

- Maricq, M.M.; Szente, J.J.; Jahr, K. The Impact of Ethanol Fuel Blends on PM Emissions from a Light-Duty GDI Vehicle. Aerosol Sci. Technol. 2012, 46, 576–583. [Google Scholar] [CrossRef]

- Kar, K.; Last, T.; Haywood, C.; Raine, R. Measurement of Vapor Pressures and Enthalpies of Vaporization of Gasoline and Ethanol Blends and Their Effects on Mixture Preparation in an SI Engine. SAE Int. J. Fuels Lubr. 2008, 1, 132–144. [Google Scholar] [CrossRef]

- Knorsch, T.; Heldmann, M.; Zigan, L.; Wensing, M.; Leipertz, A. On the role of physiochemical properties on evaporation behavior of DISI biofuel sprays. Exp. Fluids 2013, 54, 1522. [Google Scholar] [CrossRef]

- Drake, M.C.; Fansler, T.D.; Solomon, A.S.; Szekely, G.A. Szekely, Piston Fuel Films as a Source of Smoke and Hydrocarbon Emissions from a Wall-Controlled Spark-Ignited Direct-Injection Engine. SAE Trans. 2003, 112, 762–783. [Google Scholar]

- Henkel, S.; Beyrau, F.; Hardalupas, Y.; Taylor, A. Novel method for the measurement of liquid film thickness during fuel spray impingement on surfaces. Opt. Express 2016, 24, 2542–2561. [Google Scholar] [CrossRef] [PubMed]

- Maligne, D.; Bruneaux, G. Time-resolved fuel film thickness measurement for direct injection SI engines using refractive index matching. In Proceedings of the SAE 2011 World Congress & Exhibition, Detroit, MI, USA, 12–14 April 2011; SAE Paper; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

- Yang, B.; Ghandhi, J. Measurement of diesel spray impingement and fuel film characteristics using refractive index matching method. In Proceedings of the SAE World Congress & Exhibition, Detroit, MI, USA, 16–19 April 2007; SAE Paper; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Luo, H.; Uchitomi, S.; Nishida, K.; Ogata, Y.; Zhang, W.; Fujikawa, T. Experimental Investigation on Fuel Film Formation by Spray Impingement on Flat Walls with Different Surface Roughness. At. Sprays 2017, 27, 611–628. [Google Scholar] [CrossRef]

- Wang, F. Simulations and Measurements of Fuel Film Using Refractive Index Matching Method; Mechanical Engineering, Michigan Wayne State University: Detroit, MI, USA, 2014. [Google Scholar]

- He, X.; Li, Y.; Liu, C.; Sjöberg, M.; Vuilleumier, D.; Liu, F.; Yang, Q. Characteristics of spray and wall wetting under flash-boiling and non-flashing conditions at varying ambient pressures. Fuel 2020, 264, 116683. [Google Scholar] [CrossRef]

- Ding, C.-P.; Sjöberg, M.; Vuilleumier, D.; Reuss, D.L.; He, X.; Böhm, B. Fuel film thickness measurements using refractive index matching in a stratified-charge SI engine operated on E30 and alkylate fuels. Exp. Fluids 2018, 59, 59. [Google Scholar] [CrossRef]

- Hung, D.L.; Harrington, D.L.; Gandhi, A.H.; Markle, L.E.; Parrish, S.E.; Shakal, J.S.; Sayar, H.; Cummings, S.D.; Kramer, J.L. Gasoline Fuel Injector Spray Measurement and Characterization—A New SAE J2715 Recommended Practice. SAE Int. J. Fuels Lubr. 2008, 1, 534–548. [Google Scholar] [CrossRef]

- Zapalowicz, Z. Effect of Initial Surface Temperature on the Compactness of Water Droplet Impinging on the Surface. Heat Trans. Res. 2008, 39, 429–439. [Google Scholar] [CrossRef]

| Fuel | Ethanol | Gasoline |

|---|---|---|

| Chemical formula | C2H5OH | C5H12–C12H26 |

| Boiling point (°C) | 78.0 | 25–215 |

| Density (g/cm3) @ 20 °C, 1 bar | 0.79 | 0.72–0.75 |

| Dynamic viscosity @ 1 bar, 25 °C (mPa s) | 1.104 | 0.65 |

| Heat of vaporization (kJ/kg) @ 20 °C | 904 | 310–340 |

| Research octane number (RON) | 109 | 88–99 |

| Stoichiometric air–fuel ratio (kg/kg) | 9 | 14.7 |

| Lower heating value (MJ/kg) | 26.8 | 43.5 |

| Surface tension(mN/m) | 22.6 | 21.5 |

| Laminar burning velocity @ 25 °C, λ = 1 (cm/s) | 45 | 35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, H.; Wang, J.; Zhang, R.; Zhang, Y.; Su, Y.; Yu, H.; Shen, B. Experimental Study on Macroscopic Spray and Fuel Film Characteristics of E40 in a Constant Volume Chamber. Energies 2023, 16, 7488. https://doi.org/10.3390/en16227488

Tian H, Wang J, Zhang R, Zhang Y, Su Y, Yu H, Shen B. Experimental Study on Macroscopic Spray and Fuel Film Characteristics of E40 in a Constant Volume Chamber. Energies. 2023; 16(22):7488. https://doi.org/10.3390/en16227488

Chicago/Turabian StyleTian, Huayu, Jun Wang, Ran Zhang, Yulin Zhang, Yan Su, Hao Yu, and Bo Shen. 2023. "Experimental Study on Macroscopic Spray and Fuel Film Characteristics of E40 in a Constant Volume Chamber" Energies 16, no. 22: 7488. https://doi.org/10.3390/en16227488

APA StyleTian, H., Wang, J., Zhang, R., Zhang, Y., Su, Y., Yu, H., & Shen, B. (2023). Experimental Study on Macroscopic Spray and Fuel Film Characteristics of E40 in a Constant Volume Chamber. Energies, 16(22), 7488. https://doi.org/10.3390/en16227488