Abstract

In Poland, mixed municipal waste, municipal sewage and agricultural waste are used to produce biogas. Biodegradable green waste and kitchen waste generated in households are not used for this purpose. In the cogeneration process, the produced biogas is burned in a gas generator, resulting in electricity and heat. Electricity is sold in its entirety to the energy operator, but there are no heat consumers. The solution may be the construction of municipal biogas plants in urban areas, using kitchen and green biowaste from households located in cities and surrounding municipalities. Thanks to this location, the surplus heat can be used by the local district heating network to heat the buildings in the city. The aim of the article is to assess the possibilities of producing biogas and energy from municipal bio-waste generated in households in Krakow and surrounding communes. To achieve the goal, a simulation was carried out for a biogas plant with a capacity of 1 MW. Two types of substrates were used as inputs, i.e., biowaste from households and green biowaste. The data for analysis came from the Marshal’s Office of the Małopolskie Voivodeship, to which municipalities submit reports on the amount of municipal waste collected, and the Central Statistical Office, which has data on municipal waste collected in municipalities in Poland. The collected data were used to conduct five simulations. The most advantageous method is to produce biogas from kitchen waste and silage from green waste mixed in the appropriate C:N ratio. Assuming the optimal proportions of mixed substrates, a 1 MW biogas plant can produce 4.1 million m3 of biogas, from which electricity can be produced for 2.5 thousand houses and heat for 1.1 thousand houses. The article ends with conclusions and recommendations on how to collect biodegradable municipal waste, which should be treated as a valuable source of energy.

1. Introduction

In Poland, as in other developed countries, the consumption of energy needed in industry, transport and municipal services is growing. In the 20th century, the main sources of energy were fossil fuels (coal: hard and brown, crude oil, natural gas). The combustion of these raw materials caused an increase in the share of carbon dioxide and other greenhouse gases and dust in the atmosphere [1]. These factors are believed to contribute to climate warming and related weather anomalies [1,2]. Particulate matter, in turn, is particularly harmful to human health, causing lung diseases and cancers [3,4]. They come from two sources: combustion of low-quality hard coal and waste (including plastic waste) in obsolete stoves and fireplaces, and combustion of liquid fuels in cars. Under the pressure of social movements, coal and wood smoking bans were introduced in cities such as Krakow [5]. Despite switching to heating with more ecological sources (natural gas, liquid gas, electricity) in many houses, this did not improve the air quality in the city. The reason for this is the movement of an increasing number of passenger cars, trucks, buses, garbage trucks, etc. A large proportion of passenger cars and all other vehicles are powered by diesel engines that emit PM 2.5 and PM 10 dust. The air quality in Krakow is also affected by the surrounding, densely populated communes, located on the hills surrounding the city, where there is no ban on coal and wood burning.

The improvement of air quality in Krakow will not be achieved through the actions of the authorities of this city alone; their efforts must be combined with the actions of the authorities of the surrounding communes. They should focus on creating an energy mix consisting of good-quality fuels burned in high-efficiency furnaces and energy generated from renewable energy sources (RES). In the conditions of Krakow and the surrounding municipalities, these are photovoltaic cells and biogas production.

The “Energy Policy of Poland until 2040” formulates the following goals: “energy security, competitiveness and energy efficiency as well as limited impact of the energy sector on the environment”. The last goal is closely related to the development of RES, which in 2040 should account for a 28.5% share in gross final energy consumption and 39.7% in the power industry [6]. The RES in the power industry will be solar, wind, water, biomass and biogas energy. Due to limited hydropower resources and difficulties in controlling the supply of wind and solar energy, “the use of biogas will be particularly useful in the combined production of electricity and heat” [6]. The advantage is the ability to store energy in biogas, which can be used for regulatory purposes. From an economic point of view, “biogas is an additional added value, as it enables the management of particularly onerous waste, e.g., animal waste, landfill gases” [6]. Biomass resources occur in agriculture and food processing as well as in municipal waste. The achievement of the presented objectives can be helped by the smart city concept, which assumes the creation of a smart city that cares about the environment by obtaining energy from renewable sources. The condition for this is the proper handling of the generated municipal bio-waste, which should comprise segregation, collection and biological processing (composting, methane fermentation). Smart cities have the ability to control air pollution caused by greenhouse gases and PM dust [7]. For these reasons, the production of biogas from biodegradable waste (biowaste) generated in large cities would be consistent with the concept for the sustainable development of modern cities promoted by the EU [8].

Previous scientific publications generally dealt with the conditions of using biowaste collected in households for biogas production. They presented the possibilities of collecting, storing, utilizing and using biowaste as an energy raw material [9,10,11]. Due to the lack of data on individual biowaste fractions, no calculations were made that would be used to estimate the energy production potential for the indicated city. These calculations are necessary to take action to build a biogas plant in the city.

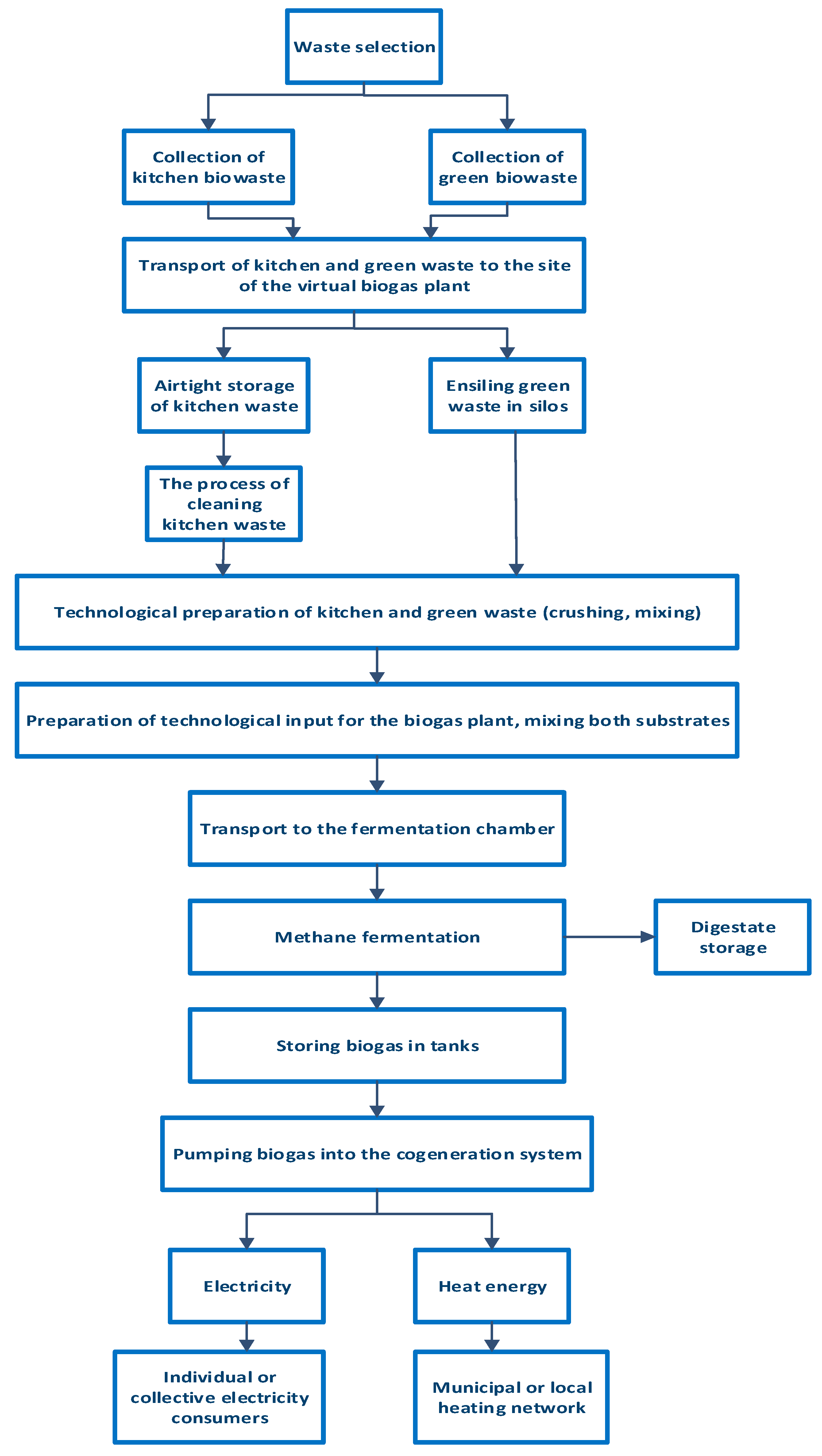

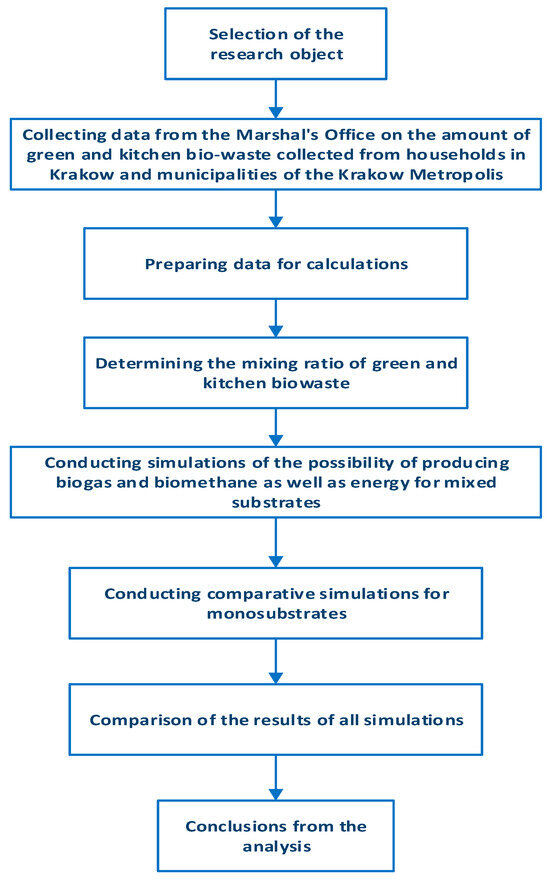

The technological process of biogas production will be based on anaerobic fermentation of green and kitchen biowaste collected in households. The collected waste will be transported to the municipal biogas plant, where it will be subjected to further preparatory activities. Silos will be built to store green biowaste at the biogas plant, where silage will be produced. The placed raw material will be covered with foil until consumed by the biogas plant. The leachate will be used to dilute the raw materials before feeding them into the digester. Kitchen waste will be regularly delivered to the biogas plant and unloaded into a silo or on a silo plate for direct use in the process. Green biowaste silage and kitchen biowaste will be mixed in a ratio of approximately 3:1, systematically introduced to a storage tank equipped with a solid substrate dispenser, and then transferred to the fermentation chamber. The storage tank will be loaded several times a day. After fermentation, the biomass will be pumped to the digestate storage tank. The biogas produced in the methane fermentation process will be collected in a biogas tank located above the fermentation chamber. The tanks will be equipped with fill level indicators and security systems ensuring operational safety. Biogas will be pumped to the cogeneration system, where the combustion process will generate electricity to be sold to individual or collective customers. The waste heat energy can be transferred to the local or municipal heating network. In the event of a failure of the cogeneration engine, any surplus biogas will be burned in an emergency biogas flare. The research methodologies are also presented in Figure 1.

Figure 1.

Methodologies of the research.

The aim of the article is to assess the possibility of producing biogas from municipal biowaste generated in households located in Krakow and the municipalities of the Krakow Metropolis. In order to optimize the process of methane fermentation and biogas yield, simulations were carried out for five biogas plants, each with a capacity of 1 MW. Three types of substrates from households were used as inputs. To achieve the assumed goal, data on waste from the Ministry of the Environment, the Marshal’s Office of the Małopolskie Voivodeship and the Central Statistical Office were used. The following research hypothesis was formulated: in large cities, it is possible to produce electricity and heat from biowaste collected from households in municipal biogas plants.

The article consists of the following elements: introduction, methods and research, results, and discussion. The article ends with a summary and recommendations and references.

2. Methods and Research

2.1. Biowaste Management in Poland

Since 2017, the Uniform Waste Segregation System (JSSO) has been in force in Poland, in which waste is segregated into five fractions: glass, paper, metals and plastics, biowaste, and mixed municipal waste. Selective collection of biodegradable municipal waste enables its biological processing in municipal installations, instead of being transported to landfills. Depending on the place of origin, waste is divided into groups, subgroups and types. The Regulation of the Minister of the Environment of 9 December 2014 on the waste catalog divides them into 20 groups [12]. Municipal biodegradable waste (biowaste) belongs to group 20. This group includes biodegradable waste generated in households with codes: 20 01 08 (biodegradable kitchen waste) and 20 02 01 (biodegradable waste).

The collection and segregation of biodegradable waste from households in large cities is a real problem. The problem is the odors generated during their decomposition, the most troublesome in areas with compact single-family housing. Collection of this fraction of waste is usually every two weeks. Especially in the spring and summer period, too infrequent collection of waste from households is a problem. Due to high air temperatures, biodegradable waste decomposes quickly, which causes rotting of the organic matter and the creation of nuisance odors. For this reason, it is often thrown into mixed waste, contaminating it, which makes it difficult to dispose of and poses a threat to people and the environment [13,14].

Proper sorting of biowaste creates the possibility of mechanical and biological processing in composting plants or municipal biogas plants. Thanks to this, there is no risk resulting from the spontaneous decomposition of organic substances [15,16].

2.2. The Use of Municipal Biowaste for the Production of Biogas

Recently, municipal waste has been used for the production of biogas in various types of biogas plants where the process of methane fermentation takes place. It can occur naturally (rice fields, peat bogs, landfills). Biogas from landfills is collected by a system of drains. Fermentation takes place in a controlled manner in installations called biogas plants. In wastewater treatment plants, methane fermentation takes place in digesters into which sewage sludge is discharged [17,18,19,20,21,22].

Biogas consists mainly of methane (CH4)—55–70%, carbon dioxide (CO2)—32–70%, nitrogen (N2)—0.2–0.4% and hydrogen sulfide (H2S)—6 g/100 m3. The fermentation rate and the amount of biogas produced depend primarily on the type and weight of the substrate (raw material), fermentation temperature and the optimal process duration [13,23,24,25]. As substrates for the production of biogas, mainly products of agricultural origin are used, in accordance with the Act on Renewable Energy Sources of 20 February 2015. In article 1, point 2 provides the definition of agricultural biogas, as a gas “obtained in the process of methane fermentation of agricultural raw materials, agricultural by-products, liquid or solid animal manure, by-products, waste or residues from the processing of agricultural products or forest biomass, or plant biomass harvested from areas other than registered as agricultural or forestry (…)” [26]. Unfortunately, the possibility of using biodegradable waste from the stream of municipal waste is ignored. Biogas from municipal waste is recovered only by degassing municipal waste in landfills. Municipal biowaste (e.g., vegetal and animal remains, paper) accounts for about 50% of the total waste stream sent to landfills. To achieve the EU objectives set out in the Directive (EU), Poland must start reducing the amount of municipal biowaste sent to landfills and thus prevent its uncontrolled fermentation, which causes the formation of greenhouse gases that contribute to climate warming. Such action will ensure a high level of protection of human health and the environment and will return valuable materials contained in waste to the European economy, which will contribute to the implementation of the assumptions of the circular economy [27].

In Poland, almost all biogas is used to generate electricity and heat in the combustion process in cogeneration units. The efficiency of the process is 90%, of which 35% is electricity and 55% is heat [25,28]. There is no problem with the use of the generated electricity, but there are problems with the use of thermal energy. Part of it (about 30%) is used in biogas plants to heat biogas plant buildings, sterilize substrates and maintain temperature in the fermentation chamber. The remaining part is used only when there are conditions for connecting external recipients [25]. Due to the location of biogas plants far from residential and public buildings, this can be difficult. The inability to sell the generated heat reduces the profitability of investments in biogas plants [29]. There are several ways to use biogas more efficiently, but biogas plants must have additional installations [30]. The first of these methods is the purification of biogas to the parameters of high-methane natural gas [31]. Such gas can be injected into the publicly available gas network and used to heat residential buildings in devices whose efficiency is about 98%. This solution is used in Italy [32,33].

The first of these methods is the purification of biogas to the parameters of high-methane natural gas [31]. Such gas can be injected into the publicly available gas network and used to heat residential buildings in devices whose efficiency is about 98%. This solution is used in Italy. CNG-powered engines are characterized by low carbon dioxide and dust emissions and lower noise levels [34,35,36,37]. CNG fuel can be used to drive public transport vehicles or vehicles collecting municipal waste, the so-called garbage trucks [38].

The choice of the method of using the produced biogas depends on such factors as: the location of the biogas plant, its production volume, and the demand for particular energy carriers. As previously mentioned, all biogas plants in Poland are based on cogeneration; therefore, the research part will present simulations and examples of the use of energy produced in this type of installation.

Due to the insufficient use of municipal biowaste for energy purposes in Poland, the article deals with municipal biogas plants, which are powered by kitchen and green biowaste generated in households. These two types of waste are a serious problem in cities because they emit odors and are a breeding ground for rodents and insects. Currently, segregated waste is transported to composting plants, and that contained in the mixed waste stream is sent to landfills. The energy produced by this type of biogas plant will provide very significant support to the energy system in Poland. Municipal biogas plants will be more expensive to build than agricultural biogas plants due to ensuring an airtight process. The problem should not be ignored, and municipal biogas plants should be developed.

2.3. Research Object

Krakow was selected for the analysis of the possibility of producing and using biogas from biodegradable waste. Data on the number of inhabitants of Krakow and the communes of the Krakow Metropolis come from the Central Statistical Office, which is the office of the central government administration in Poland.

Krakow is a dynamically developing city, as evidenced by the increase in the number of inhabitants from 761 thousand in 2015, to over 803 thousand in 2022. The inhabitants of the Krakow and Wieliczka poviats are also connected with this city through work, studies and services. In 2022, they were inhabited by 285.8 thousand and 133.4 thousand people, respectively. In total, the Krakow agglomeration was inhabited by 1.2 million people in 2022 [39]. Residents from all over the Małopolskie voivodship and neighboring voivodships (Silesian, Świętokrzyskie and Podkarpackie) come to Krakow to work and shop. The city is located at the intersection of the A4 motorway and the S7 expressway and is a center of domestic and foreign tourism.

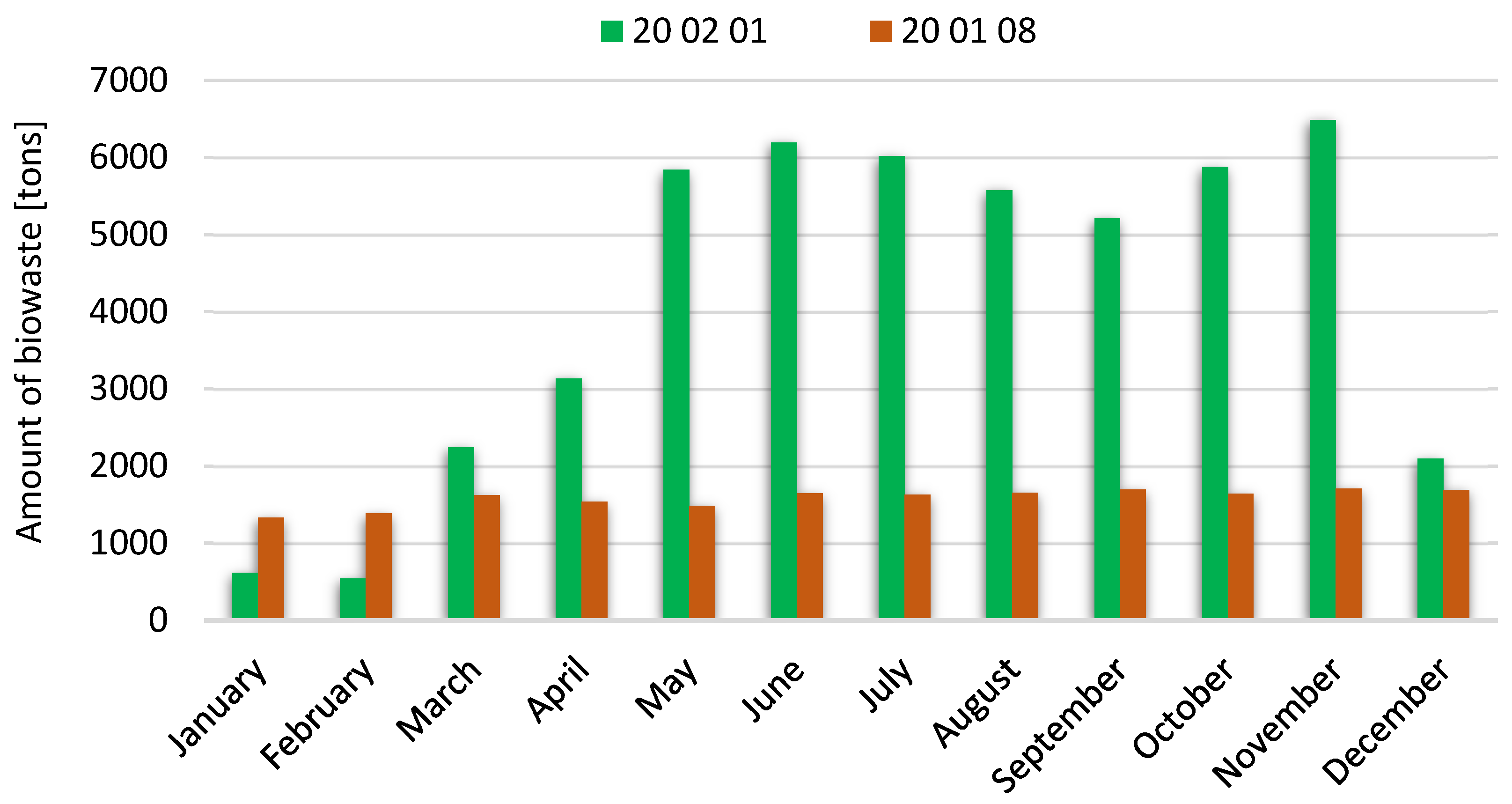

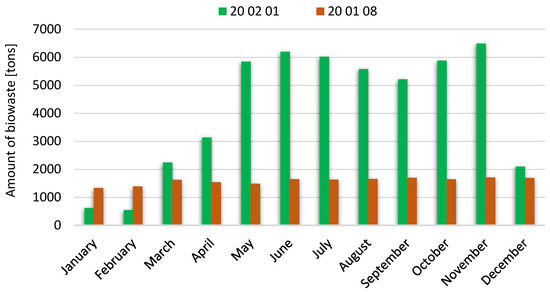

When determining the potential for biogas production, data on the amount of biodegradable waste generated in Krakow and the communes belonging to the Krakow Metropolitan Area were used (see Figure 2). It consists of 14 communes, four of which are urban-rural communes (Świątniki Górne, Skawina, Niepołomice and Wieliczka), and the rest are rural communes (Zielonki, Michałowice, Kocmyrzów-Luborzyca, Igołomia-Wawrzeńczyce, Biskupice, Mogilany, Czernichów, Liszki, Zabierzów, Wielka Wieś) [40]. The communes listed above are inhabited by a total of over 300.67 thousand people. The average population density in these communes is 317 people/km2 (the lowest in the commune of Igołomia-Wawrzeńczyce, with 123 people/km2, and the highest in the commune of Wieliczka, with 614 people/km2) [40].

Figure 2.

Municipalities belonging to the Krakow Metropolitan Area [40].

2.4. Potential for Biogas Production in Krakow and the Communes of the Krakow Metropolis

Two fractions of biodegradable waste are generated in households, i.e., biodegradable kitchen waste (code 20 01 08) and biodegradable green waste (code 20 02 01). Kitchen waste is organic waste generated at home from vegetable and fruit remains (peelings, spoiled fruits and vegetables, etc.), food remains (without meat and bones), coffee and tea grounds, egg shells, groats, pasta, and rice. The waste fraction of biowaste is green waste from home gardens, i.e., grass, leaves, flowers and their stems, branches, etc. Both types of waste (except branches) are collected by their producers into brown bags or containers of the same color and are collected by companies collecting mixed municipal waste [41,42]. The branches are transported by waste producers to selective collection points for municipal waste (PSZOK) and placed in containers. The amount of biodegradable waste collected from households in Krakow and the communes of the Krakow Metropolis is presented in Table 1.

Table 1.

The amount of waste collected in Krakow and the communes of the Krakow Metropolis in 2021 and 2022.

In 2021, a total of 64 thousand tons of green waste was collected. The largest amount of this waste was collected in the Niepołomice Commune. The rural commune of Zabierzów was next in terms of the amount of collected waste. The second fraction of waste was kitchen waste, of which a total of 21,881.7 tons was collected in 2021. The largest amounts of waste were collected in the communes of Zabierzów, Mogilany and Liszki.

The next analyzed year was 2022. This year, the largest amount of green waste was collected. The total amount was lower compared to the previous year and amounted to 62,502.09 tons. The largest amount (over 3.7 thousand tons) of this waste was collected in the Niepołomice Commune. In the city of Niepołomice in 2022 lived about 16.5 thousand inhabitants, and in the rural area, about 16.3 thousand people. Single-family housing predominates in the city; there are also small multi-story blocks with gardens on the ground floor in closed housing estates. This type of building generates a lot of biodegradable green waste from home gardens. In Niepołomice, due to small plots of land, residents use home composters to a small extent. In the rural area of the Niepołomice commune, there is only single-family housing, and biodegradable waste is composted or collected in bags and collected by the company. The second in terms of the amount of collected green waste was the Zabierzów Commune, where almost 1.69 thousand tons were collected in 2022. The Zabierzów Commune is a rural commune with over 29.2 thousand inhabitants in 2022. The largest population lived in the town of Zabierzów, which is located close to the borders of Krakow, on the northwestern side. In Zabierzów, single-family housing with a few small blocks of flats prevails, with home gardens, where it is also not possible to compost biodegradable waste. Green waste was not collected at all in the commune of Igołomia-Wawrzeńczyce, due to the typically agricultural character of this commune [40].

The second type of waste generated in households in the mentioned communes in 2022 was biodegradable kitchen waste. A total of 27,209.87 tons was collected. Compared to the previous year, this number increased by over 5000 tons. The largest amount of waste was collected in the Zielonki Commune—about 1.5 thousand tons, in the municipality of Mogilany—over 1.1 thousand tons, and in the commune of Skawina—700 kg. All communes have an agricultural character with dispersed single-family housing.

2.5. Possibilities of Generating Energy from Biodegradable Municipal Waste

Based on the information on the amount of possible-to-obtain substrates for biogas plants from Krakow and communes belonging to the Krakow Metropolis, the possibility of biogas production was assessed. For this purpose, a simulation was carried out showing the possibility of producing biogas from biodegradable waste generated in households. The simulation was carried out for a biogas plant with a capacity of 1 MW, in which two sets of substrates were used. The calculations used data on biodegradable municipal waste, which was used as a substrate [25,44]:

- Biodegradable green waste (code 20 02 01),

- Biodegradable kitchen waste (code 20 01 08).

To obtain the optimal amount of biogas, green and kitchen waste should be mixed in the right proportions. Green waste has a very good carbon to nitrogen (C:N) ratio of around 25:1; in kitchen waste, this ratio is 8:1. Taking into account the C:N relationship in the substrates used, the proportions of substrates in the ratio of 3:1 should be used [45,46]. In the fermentation process, it is important to maintain the appropriate proportion between the carbon and nitrogen C:N content. If this ratio is too high (too much C and too little N), complete conversion of carbon may not occur. This makes it impossible to obtain the possible methane potential. An excess of nitrogen may result in the formation of ammonia, which, even in low concentrations, inhibits the growth of bacteria. The fermentation process runs properly if the C:N ratio is in the range of 10–30 [24].

The assessment of the biogas production potential in the 1 MW installation was based on data on the amount of collected biodegradable waste from households in Krakow and the municipalities of the Krakow Metropolis in 2022.

First, the possibility of producing biogas and biomethane and energy was simulated for two variants in which mixed substrates were used:

Variant 1—waste from Krakow and the municipalities of the Krakow Metropolis in the amount of approximately 20,000 tons:

- green waste, in the amount of 15,000 tons/year,

- kitchen waste in the amount of about 5000 tons/year,

Variant 2—waste from Krakow and the municipalities of the Krakow Metropolis in the amount of 20,000 tons:

- Silage from green waste (without woody parts) in the amount of 15,000 tons/year,

- Kitchen waste in the amount of 5000 tons/year.

Then, comparative simulations were carried out, in which unmixed green waste, silage from green waste and kitchen waste from Krakow and the municipalities of the Krakow Metropolis were used as substrates for the biogas plant:

- Variant 3—green waste (code 20 02 01) in the amount of 20,000 tons,

- Variant 4—silage from green waste in the amount of 20,000 tons,

- Variant 5—kitchen waste (20 01 08) in the amount of 20,000 tons.

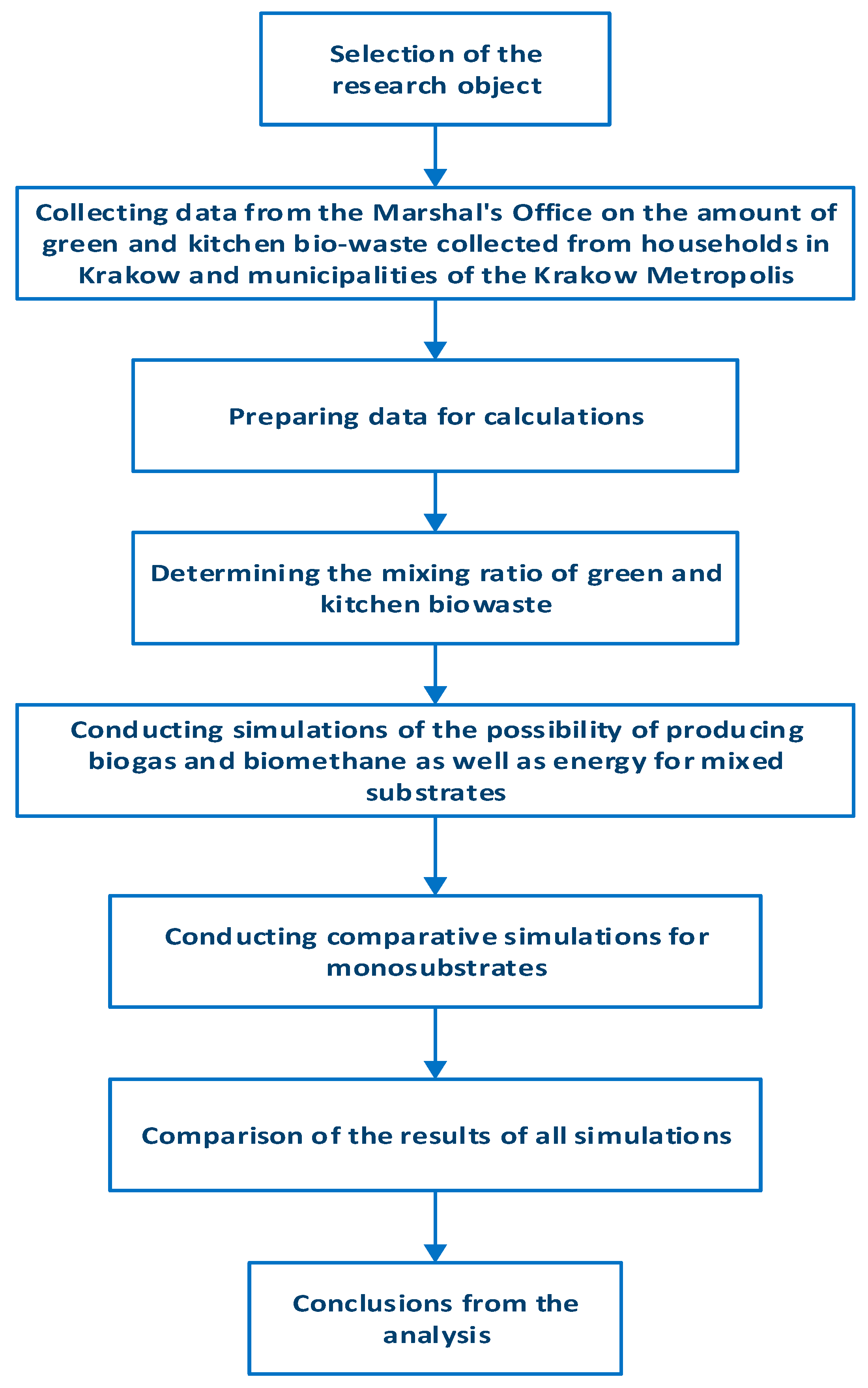

The simulation results for these variants were compared with the results obtained for Variant 1 and Variant 2. Next, the advantages and disadvantages of using mixed and unmixed biodegradable waste as substrates for biogas plants were presented. The steps of carrying out the calculations are shown in Figure 3.

Figure 3.

Steps of performing calculations.

The data collected on the amount of waste from Krakow and the municipalities of the Krakow Metropolis for 2022 (Table 1) did not contain information on the dry matter content in the waste used to power the biogas plant, so, for the calculations, a biogas yield corresponding to 1 ton of fresh mass (tfm) was assumed. According to Podkówka, the following biogas yield was assumed for green biowaste: = 175 /, silage from green biowaste = 190 /, kitchen biowaste: = 250 / [25]. Assuming the biomethane content of (from Table 2) in biogas produced from 1 ton of specific waste, the heating value of biomethane in / was calculated using the following formula [47].

Table 2.

Values adopted for yield calculations: biogas, biomethane, electricity and heat.

Assuming the heating value of biomethane of W = 9.3 kWh/, the total energy found in biomethane obtained from 1 of biowaste was calculated with the following Formula (2) [47].

Electricity and heat energy obtained from 1 of substrate were calculated with Formulas (3) and (4) [47].

where: —electricity yield, —heat energy yield.

The electric power of the generator was calculated with the following Formula (5) [47].

where: —generator runtime.

The thermal power of the generator was calculated with the following Formula (6) [47].

3. Results

3.1. Calculation Results for Substrates Mixed in the Optimal Proportion

For the calculation of the annual yields of: biogas, biomethane, electricity and heat energy for a biogas plant with a capacity of 1 MW, the values as in Table 2 were adopted. The simulation was started by calculating the amount of biogas and biomethane produced, which are energy carriers in the biogas plant. Approximately 3.9 million m3/Mg of biogas can be produced from the above-mentioned substrates per year. It contains over 55% methane, which is burned in cogeneration units in the biogas plant. The simulation results for Variant 1 are presented in Table 3.

Table 3.

Amount of biogas, biomethane, electricity and heat generated in a biogas plant with a capacity of 1 MW Variant 1.

In Variant 1, green waste (grass, leaves, flowers), cut into 4–6 mm pieces, and kitchen waste were crushed in a device called a grinder before being introduced into the fermentation chamber. Such fragmentation is necessary because it favors the fermentation process and causes more biogas to be produced during the same number of days [24]. The disadvantage of green waste is that it is available seasonally from April to November. For the proper functioning of the fermentation process in a biogas plant, a constant supply of substrate is necessary throughout the year. Failure to follow this recommendation may result in disruption of the fermentation process and even extinction of the fermentation bacteria. The effect will be a reduction in biogas production, obtaining poor-quality biogas, and ultimately the cessation of operation of the biogas plant [24,48].

In order to ensure constant supplies of the substrate, Variant 2 was proposed. The input used was silage, which was made from green waste (without woody parts). The second type of substrate was kitchen waste. In Variant 2, approximately 4.1 million m3/tons of biogas can be produced annually from silage from green waste and kitchen waste. This is about 6% more than in the case of biogas production from the substrates used in Variant 1. This biogas also contains over 55% methane, which will be used to produce electricity and heat in the cogeneration process. The results of the simulation are presented in Table 4.

Table 4.

Amount of biogas, biomethane, electricity and heat generated in a biogas plant with a capacity of 1 MW. Variant 2.

In Variant 2, green waste, without woody parts will be ensiled in silos. The resulting grass silage can be stored in a warehouse or in an airtight tank that prevents odors from escaping. The ensiling of green waste makes substrates for the biogas plants available all year round [49].

Thanks to this, it will be possible to produce biogas from green waste collected in cities. To make it possible, one should plan the work schedule for a given year and start preparing the silage at the beginning of the mowing season, so that its amount is sufficient for the entire year of operation of the biogas plant.

3.2. Comparative Calculation Results for Homogeneous and Mixed Substrates in the Optimal Proportion

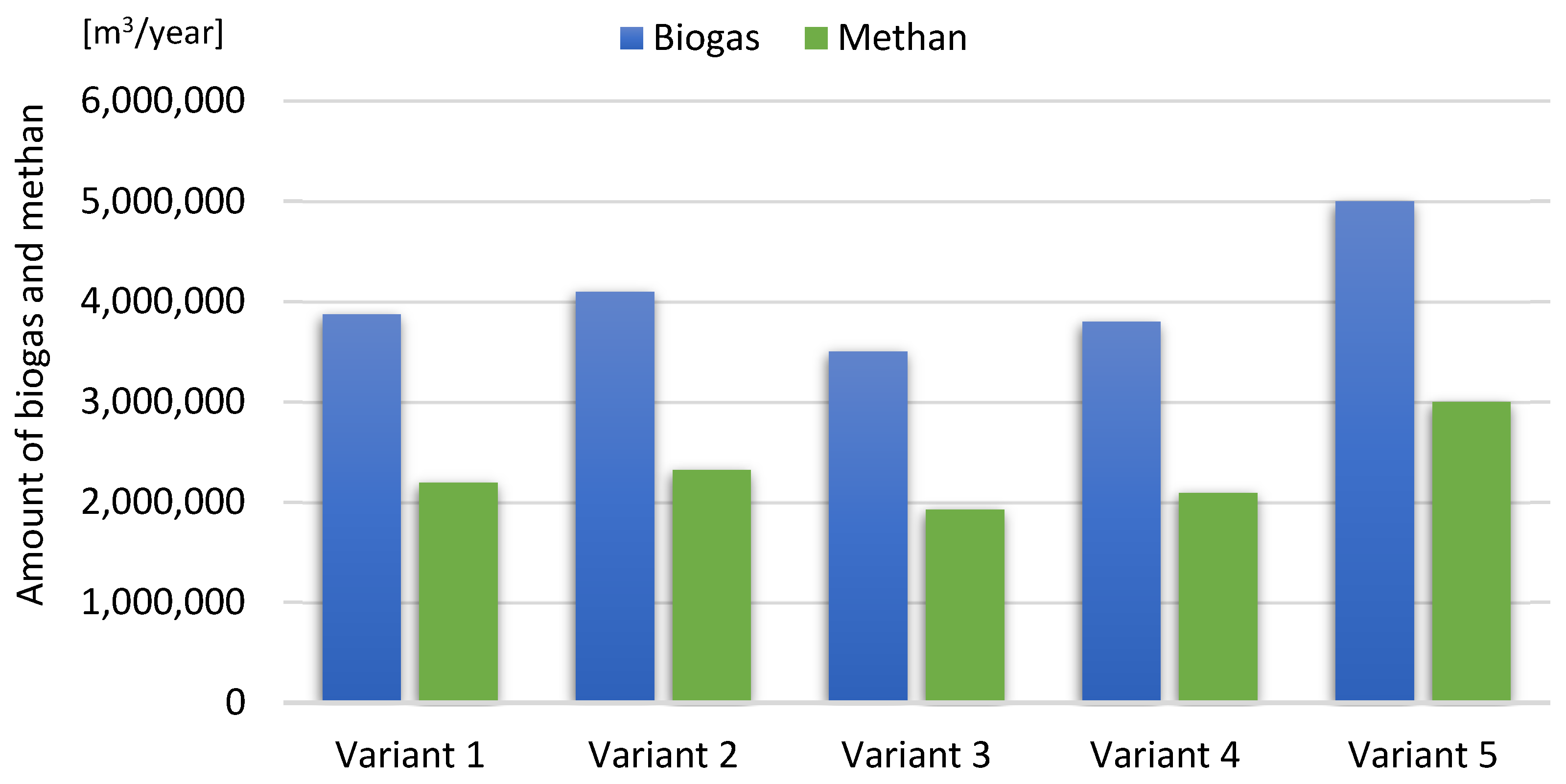

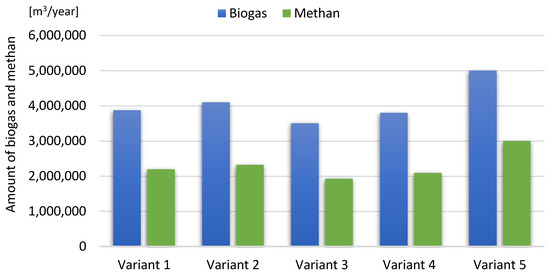

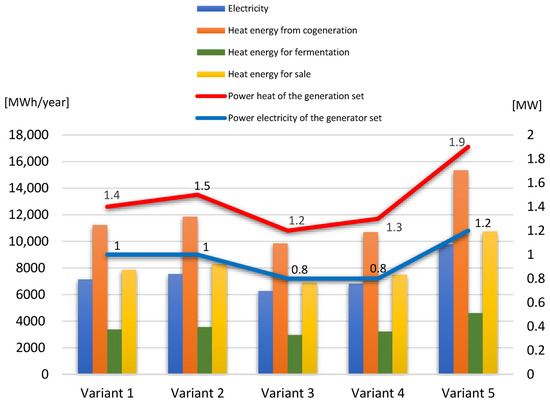

The above simulations in Table 3 and Table 4 present calculations for a 1 MW biogas plant with mixed substrates. It was decided to carry out further simulations to check how much biogas and methane will be generated from 20 thousand tons of homogeneous substrates, which are obtained from collected municipal biowaste in Krakow and the municipalities of the Krakow Metropolis. The simulation results were compared with the amounts of biogas and methane produced for mixed substrates (Variant 1 and Variant 2). The results of the simulation are presented in Table 5 and Figure 4, which show the amount of biogas and methane produced for Variants 1–5.

Table 5.

Amount of biogas, biomethane, electricity and heat generated from five variants of substrates.

Figure 4.

The amount of biogas produced. Biogas and biomethane for five variants of substrates in 2022.

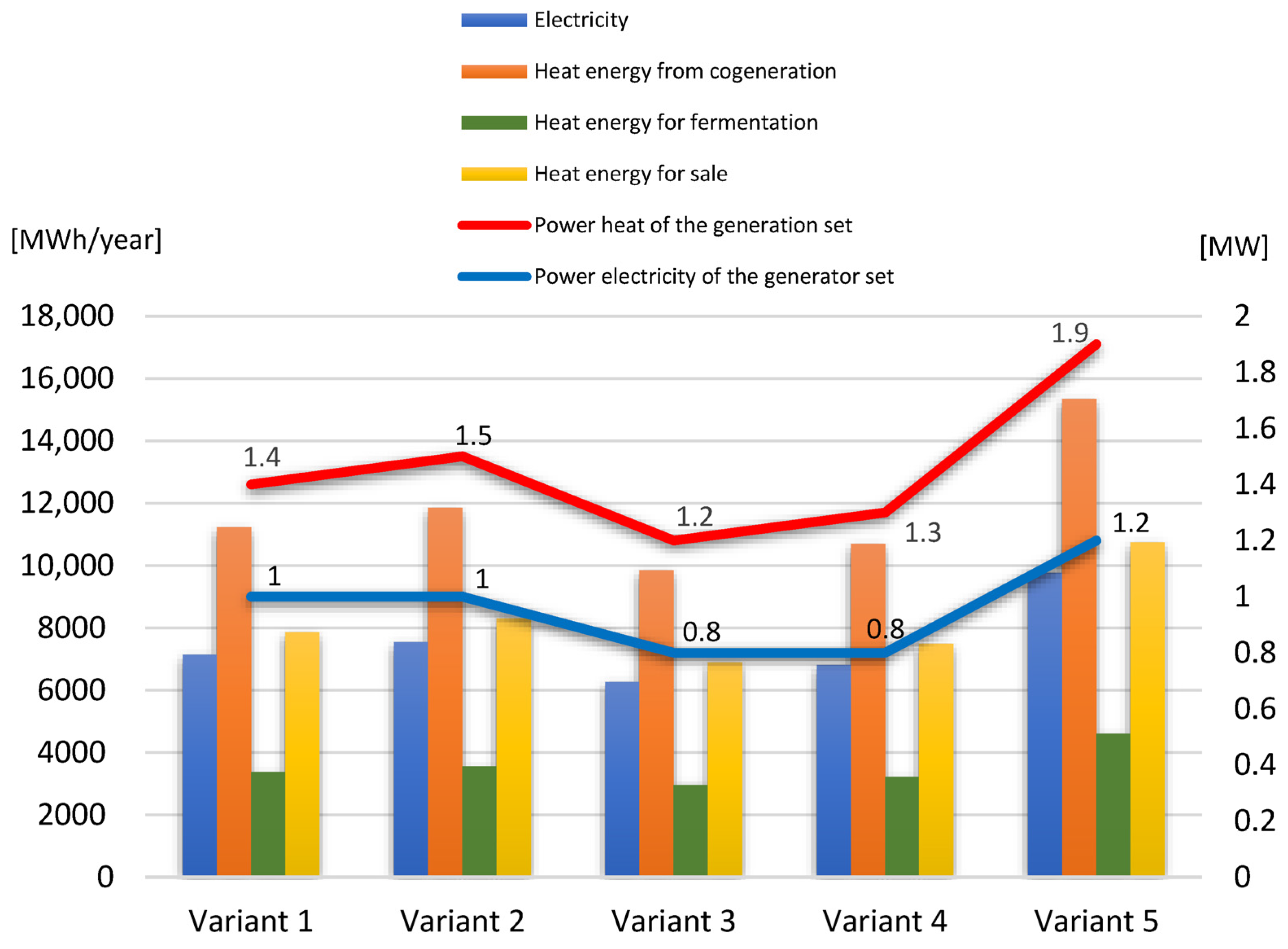

The simulation results (Table 5 and Figure 4 and Figure 5) show that the largest amount of biogas and methane, about 5 million m3/tons, will be generated if only kitchen waste is used as a substrate (Variant 5). From this substrate, the most m3 of biogas can be obtained from 1 ton of fresh mass (see Table 5). The smallest amount of biogas was produced from green waste (Variant 3), of about 3.5 million tons. The amount of biogas produced from silage (Variant 4) was lower than in Variant 1 and Variant 2, but the difference was relatively small and amounted to 2–5%.

Figure 5.

The amount of electricity and heat generated from biogas for five variants of substrates.

The simulation results show that the most energy was generated in Variant 5. Almost 10,000 MWh of electricity was obtained from 1 ton of this waste fraction. All of this can be sold to the local energy operator. The same amount of waste can produce over 15,000 MWh of thermal energy, of which 30% is used to support the fermentation process in the biogas plant. The least amount of electricity and heat will be generated using only green waste as a substrate.

The simulation results, presented in Table 5 and in Figure 4 and Figure 5, show that the most biogas as well as electricity and heat can be produced using only kitchen waste. However, using only these substrates is not economically viable or beneficial for the course of the fermentation process. To obtain the optimal amounts of biogas produced, it is important to select substrates that can be mixed with each other in appropriate proportions. This is important because the bacteria that take part in the fermentation process require an appropriate amount of C and N. The protein contained in the substrate is broken down into nitrogen and used for the synthesis of nitrogen compounds. Carbon is needed for their synthesis. The correct cargo composition should have a C:N ratio of 10:1 to 25:1. If the C:N ratio is greater than 25:1, this will reduce biogas production. However, when the C:N ratio is <10:1, the pH value increases above 8.5, which can lead to the extinction of fermentation bacteria and stop the biogas production process [50].

Mixing kitchen waste and green waste is recommended in municipal biogas plants. Kitchen waste is rich in organic substances containing mainly nitrogen (N) such as starches, sugars, fats and proteins, while green waste contains a lot of carbon (C) in the form of cellulose and other plant fibers. Mixing these two types of waste has a number of benefits, as follows [51]:

- A balanced organic composition results from mixing kitchen waste and green waste, which results in a more balanced nutrient mix. Kitchen waste provides easily digestible organic substances, while green waste introduces plant fibers. This supplementation of nutrients promotes better growth of microorganisms and increases biogas production.

- Increasing the efficiency of the biogas plant can be obtained by mixing kitchen waste and green waste, which allows for better use of various organic components and increases the efficiency of the fermentation process. Different types of substrates have different decomposition rates and energy values, and mixing allows creating good conditions for microorganisms that decompose organic substances.

- The availability of the raw material results from the fact that kitchen and green waste often occur in large quantities in cities and surrounding municipalities. Mixing them allows for efficient use of these biomass sources and reduces waste.

According to Chen X. et al., the preferred ratio of kitchen waste to green waste was set at 1:3 for optimal biogas production [52]. It turn, Liu et al. proved that mixing green waste and kitchen waste has a positive effect on the fermentation process and biogas production [53]. A similar relationship was found by Chen Y. et al. [54].

Due to the biogas production technology and the availability of substrates, the best choice is Variant 2, in which two substrates will be used to produce biogas, i.e., silage from green waste (15,000 tons) and kitchen waste (5000 tons). These amounts of substrates used represent the correct C:N ratio. Then, the fermentation process will take place in stable and favorable biochemical conditions conducive to the production of large amounts of good-quality biogas.

3.3. The Use of Biogas Produced from Municipal Biowaste for Energy Purposes

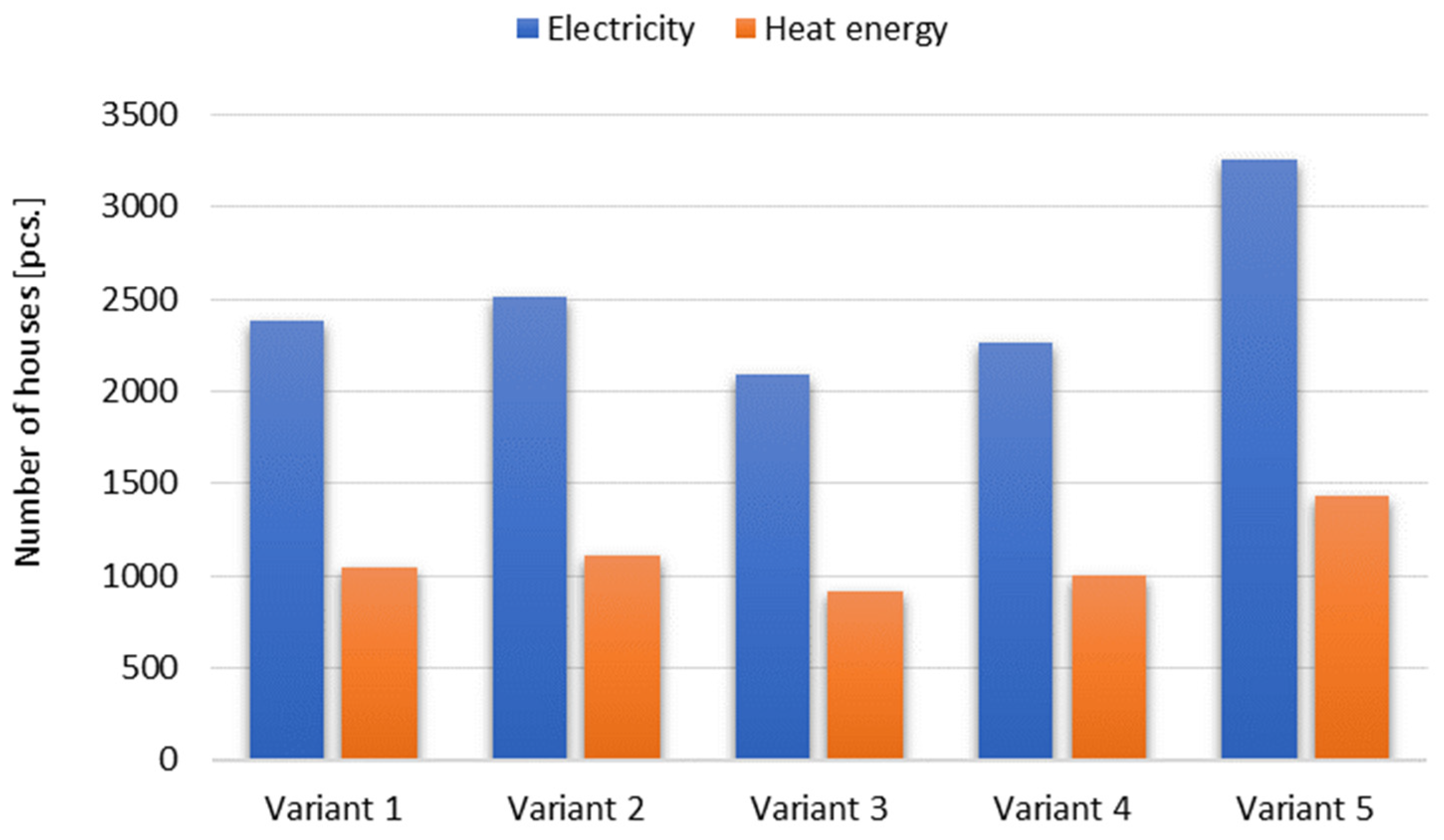

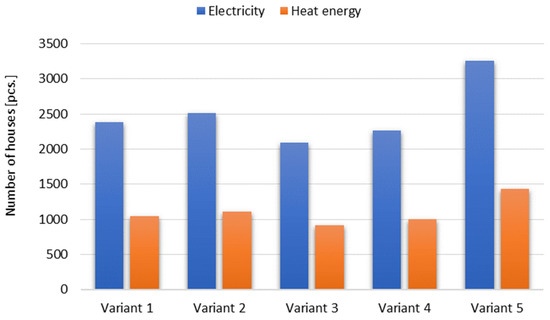

As previously written, biogas is most often burned in cogeneration units producing electricity and heat. It can be used to supply single-family houses with electricity and heat. Table 6 and Figure 6 show the number of houses that can be supplied with electricity and heated, assuming data for Variants 1 and 2 for calculations.

Table 6.

Number of houses that can be heated and supplied with electricity for variants 1–5.

Figure 6.

Number of houses that can be heated and supplied with electricity for Variants 1–5.

For the purposes of the analysis, the energy demand of a single-family house without a basement with a usable area of 110 m2 and with average insulation was assumed. The house has a dual-function traditional gas boiler installed. It is inhabited by three people. The annual energy consumption for space heating and domestic hot water is = 7.5 MWh/year). The house is lit with energy-saving LED bulbs, and cooking is done on an induction cooker with an electric oven. Household appliances and electronics have an A+ energy class rating, and each person has a laptop and uses the internet. This allows us to assume the house’s electricity consumption at the level of = 3 MWh/year [47].

Assuming the value for electricity and heat power for sale , we can calculate the number of houses and that can be supplied with energy produced by the biogas plant under study. For this we, use the following Formulas (7) and (8) [47].

The results of these calculations are presented in Table 6. The data presented in this table show that Variant 5 can supply the largest number of houses with electricity, over 3.2 thousand, and heat over 1.4 thousand houses. The fewest houses will be supplied with energy (approx. 2.1 thousand) and heated (approx. 0.9 thousand) in Variant 3. However, as already mentioned in Section 3.2, both variants, due to the use of mono-substrates, are unfavorable for the fermentation process, causing the remaining biodegradable waste collected from households to not be used. Using mixed substrates in Variant 1, it is possible to provide energy to about 2.4 thousand and heat 1.05 thousand houses. A better result can be obtained by choosing Variant 2, where the generated energy can supply electricity to over 2.5 thousand houses and heat over 1.1 thousand houses. These results are also shown in Figure 6.

4. Discussion

Approximately 20,000 tons of substrates from municipal biowaste are needed to operate a 1 MW biogas plant. In the municipalities of the Krakow metropolis, 16,000 tons of biodegradable waste are generated. Unfortunately, this amount is too small to cover the needs of a 1 MW biogas plant for substrates. The remaining part of the biowaste should be delivered from Krakow. The Krakow Commune produces very large amounts of biodegradable municipal waste. In 2022, over 73,000 tons of waste were collected, of which almost 52 thousand tons were of green waste (code 20 02 01) and over 22 thousand tons of kitchen waste (code 20 01 08). The total use of this waste in a biogas plant would generate over 30,000 MWh of electricity and over 27,000 MWh of thermal energy to be used or sold [47].

This amount of substrates would allow to power several biogas plants with a total capacity of 4 MW. Almost all of the electricity generated in them can be sold to the power system operator, as well as about 70% of the heat energy. The remaining 30% is spent on maintaining the methane fermentation process in the biogas plant’s fermentation chamber [47].

Of the presented variants, the best one in terms of the amount of biogas and energy produced is Variant 2. In it, a biogas plant with a capacity of 1 MW can use about 20 thousand tons of biowaste per year in the amount of 15 thousand tons of silage from green waste and 5 thousand tons of kitchen waste. The most green and kitchen biowaste is generated in Krakow (see Table 1). As shown in Figure 7, kitchen waste (code 20 01 08) is produced in a constant amount throughout the year. The problem is the availability of green waste (code 20 02 01), most of which is collected from waste producers from May to October.

Figure 7.

Amount of municipal biowaste collected in Krakow in 2022.

The solution to this problem may be the production of silage from green waste, which can be stored all year round in silos or in airtight containers. To store feed from (shredded) plants, silos will be built in the area of the biogas plant, where silage will be produced. The placed raw material will be covered with foil until it is used by the biogas plant. Silage juices will be discharged into an underground, tight reinforced concrete tank. The effluents will be used to dilute the raw materials before they are fed into the fermentation chamber. Using a loader, the silage will be systematically introduced into a storage tank equipped with a screw conveyor-type solid substrate feeder, and then into the fermentation chamber. The storage tank will be loaded several times a day [55].

Biogas production from silage and green waste also means a faster fermentation process and a higher yield of biogas from 1 ton of substrate [56]. Kitchen biowaste will be regularly delivered to the biogas plant and unloaded into a silo from where it will be directly used in the biogas production process (in fermentation tanks using a container).

Another important aspect favoring the operation of a biogas plant using biodegradable municipal waste is its location. Starting the production of energy from biogas requires taking into account several important spatial conditions at the concept development stage [20]. Such a concept should take into account the impact of the biogas plant on the environment, among others: areas under natural protection, close availability of substrates (preferably up to 20 km), availability of roads with a large tonnage to facilitate the delivery of substrates, access to labor resources (employees) and the possibility of utilizing the produced biogas [57].

Due to the above conditions for the location of the biogas plant, as well as the high population density and numerous monuments, building a sufficiently large biogas plant in Krakow seems impossible. Although there are areas of the former steelworks, there are plans to build a residential district and a photovoltaic farm there. The only possible locations are the areas of economic (investment) zones in the area of Niepołomice—Wieliczka or Skawina [58].

As shown in Table 1, in the Niepołomice commune in 2022, approximately 4 thousand tons of waste (codes 20 02 01 and 20 01 08) were generated. In Niepołomice, there is an investment zone with an area of 542 ha, where about 60 large companies from the following industries operate: automotive, food, logistics, cosmetics and others. There are sewage treatment plants in the zone (Niepołomice and Podłęże). The Niepołomice Investment Zone is accessed via the Niepołomice bypass, and a few kilometers away there is a junction connecting the district road with the A4 motorway, on the Wrocław–Krakow–Przemyśl route [59]. The construction of this bypass would enable quick and easy transport of biodegradable waste from some of the municipalities of the Krakow Metropolis and districts of Krakow located in its northeastern part. The biogas produced in this biogas plant could be burned in cogeneration units. Electricity and heat energy would be used by companies operating in the zone. It is also possible to purify biogas to the parameters of high-methane natural gas and inject it into the gas hub in Węgrzce Wielkie via a gas pipeline approximately 9 km long.

The location of the biogas plant in Skawina would enable the processing of 1005 tons of green waste with the code 20 02 01 and 4198 tons of kitchen waste with the code 02 02 02 produced in this commune and waste from the southwestern part of Krakow. Thermal energy could be transmitted to Krakow via the existing heating main.

The construction of a municipal biogas plant is not associated with significant negative impacts on the local community and the environment. In the long term, the operation of the municipal biogas plant will contribute to improving the quality of atmospheric air on a local scale thanks to the partial elimination of the combustion of fossil fuels as energy sources. This will reduce CO2 emissions into the atmosphere [60], and the generated energy will not be assessed CO2 emission allowance fees applicable in the EU [61].

Failure to implement the construction of municipal biogas plants will cause difficulties in the implementation of the Polish Energy Policy until 2040 in the field of renewable energy development and in achieving the goal resulting from Directive 2009/28/EC of the European Parliament on the promotion of the use of energy from renewables [62].

In order for the above sustainable development goals and the policy goals of the EU and Poland to be achieved, society should be involved in their implementation. It should start with the basics, i.e., proper segregation of biowaste and creation of a system that will enable their collection and utilization in the biogas plant [24,63].

5. Conclusions

The transformation from a linear economy to a circular economy would force municipalities to treat biodegradable waste as a resource, not as waste. Then, it would be possible to produce biogas from them, which is an alternative to fossil fuels. Unfortunately, there are problems with the collection of biowaste that hinder their use. The biggest problem is the collection of biowaste from households, which include kitchen waste with the code 20 01 08. Due to the inconvenience of segregating this waste fraction, it is usually thrown in with mixed municipal waste. For this reason, the energy potential of these wastes is lost and mixed waste, which is difficult to manage, is created and most often neutralized in the incineration process.

The article analyzes the possibility of using biodegradable waste from households located in Krakow and the municipalities of the Krakow Metropolis. Data from the Ministry of Climate and Environment and the Marshal’s Office of the Małopolska Region were used for the analysis. The data provided concerned the amounts of green and kitchen biowaste generated in 2022. The analysis shows that there are great opportunities for biogas production from biodegradable waste collected from households. Five variants of biogas production from these biowastes were considered. The analysis of the possibility of producing biogas in a 1 MW installation shows that in Variant 1, it is possible to obtain about 3.9 million m3/year; in Variant 2, 4.1 million m3/year; in Variant 3, 3.5 million m3/year; in Variant 4, 3.8 million m3/year; and in Variant 5, 5 million m3/year. Such amounts of biogas produced can be used in the cogeneration process, resulting in electricity and heat. Electricity can be sold to the energy operator or used directly by the municipalities for their own needs, or stored in an energy warehouse. Thermal energy is most often used in technological processes of biogas plants (maintaining fermentation temperature, sterilization of substrates, drying of digestate). In the city, the remaining part of the heat energy can be injected into the local heating network or can be used to heat buildings located in the vicinity of the biogas plant, e.g., shops, public buildings, wood drying rooms.

The simulation results presented in this article show that the choice of Variant 2 is the most advantageous. In this variant, 15,000 tons of green waste silage and 5000 tons of kitchen waste (code 20 01 08) were used to power a 1 MW biogas plant. The use of substrates in such proportions allows maintaining the C:N balance, which is 3:1. Thanks to this, it is possible to maintain a stable substrate fermentation process in the biogas plant, using substrates collected in Krakow and the municipalities of the Krakow Metropolitan Area throughout the year. The resulting biogas in a 1 MW installation can provide energy to over 2500 households and heat over 1.1 thousand houses (see Table 6 and Figure 6). The presented possibilities for producing biogas from biodegradable waste collected from households in Krakow and the Krakow Metropolis communes represent only a portion of what could be achieved if solutions were introduced to encourage residents to segregate this waste fraction. The proposed solutions are as follows:

- airtight household containers for kitchen biowaste, which will make it easier to collect even in small apartments and throw into airtight containers in a garbage bin,

- introduction of a new waste code, which will cover biodegradable kitchen waste with the code 20 01 08 and kitchen waste of animal origin (without bones), i.e., meat, sausages, fat, dairy products,

- collection of biodegradable waste from households at least once a week, because collecting waste every two and sometimes three weeks allows excessive decomposition of organic matter, which is most troublesome in the summer at high ambient temperatures,

- equalizing (increasing) the price of share certificates for electricity from all types of biogas to the price of agricultural biogas plant certificates.

The development of energy in cities based on RES should be economically viable and technically feasible. The construction of municipal biogas plants in cities or their vicinity can contribute to reduce the high costs of waste disposal and increase the share of RES in the energy mix of cities and municipalities. For this reason, further research is planned on the control of a hybrid RES installation consisting of a municipal biogas plant and a photovoltaic installation located in or around Krakow. Future research will concern the optimization of the power of a biogas plant integrated with a photovoltaic installation, an electricity storage facility and a certain number of individual consumers. A system of electrical installations will be created with adjusted installed power capacities and an intelligent operating mode. Its aim will be to provide electricity for a specific number of single-family buildings. The main purpose of such a technical solution will be to eliminate the consumption of electricity from the state power grid.

Author Contributions

Conceptualization, M.S. and J.M.; methodology, M.S. and J.M.; software, M.S.; validation, J.M. and M.S.; formal analysis, J.M.; investigation, M.S.; data curation, M.S. and J.M.; writing—original draft preparation, M.S.; writing—review and editing, J.M. and M.S.; visualization, M.S.; supervision, J.M.; project administration, J.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by AGH University of Krakow, Agreement No 16.16.200.396 B310.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Arora, N.K. Impact of climate change on agriculture production and its sustainable solutions. Environ. Sustain. 2019, 2, 95–96. [Google Scholar] [CrossRef]

- Zheng, X.; Streimikiene, D.; Balezentis, T.; Mardani, A.; Cavallaro, F.; Liao, H. A review of greenhouse gas emission profiles, dynamics, and climate change mitigation efforts across the key climate change players. J. Clean. Prod. 2019, 234, 1113–1133. [Google Scholar] [CrossRef]

- Santana, J.C.C.; Miranda, A.C.; Yamamura, C.L.K.; Silva Filho, S.C.D.; Tambourgi, E.B.; Lee Ho, L.; Berssaneti, F.T. Effects of air pollution on human health and costs: Current situation in São Paulo, Brazil. Sustainability 2020, 12, 4875. [Google Scholar] [CrossRef]

- Daellenbach, K.R.; Uzu, G.; Jiang, J.; Cassagnes, L.-E.; Leni, Z.; Vlachou, A.; Stefenelli, G.; Canonaco, F.; Weber, S.; Segers, A.; et al. Sources of particulate-matter air pollution and its oxidative potential in Europe. Nature 2020, 587, 414–419. [Google Scholar] [CrossRef] [PubMed]

- Polish Smog Alarm. Available online: https://polskialarmsmogowy.pl/2021/10/wiecej-wnioskow-o-dofinansowanie-na-wymiane-kopciuchow-wokol-krakowa/ (accessed on 18 July 2023).

- Act of 19 July 2019 Amending the Act on Renewable Energy Sources and Certain Other Acts. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20190001524 (accessed on 12 November 2023).

- Gotlibowska, K. A proposal for a Smart City model based on the use of information and communication technologies in its development [Propozycja modelu miasta inteligentnego (Smart City) opartego na zastosowaniu technologii informacyjno-komunikacyjnych w jego rozwoju]. Rozw. Reg. I Polityka Reg. 2018, 42, 67–80. [Google Scholar]

- Łaźniewska, E. The essence of the smart city concept. The activity of the city of Poznań on the way to a smart city [Istota koncepcji smart city. Aktywność miasta Poznania na drodze do smart city]. Rozw. Reg. i Polityka Regionalna. 2019, 48, 105–117. [Google Scholar] [CrossRef]

- Jacyno, M.; Korkosz-Gębska, J.; Krasuska, E.; Milewski, J.; Oniszk-Popławska, A.; Trębacz, D.; Wójcik, G. The concept of a biogas plant using municipal waste [Koncepcja bio-gazowni wykorzystującej odpady komunalne]. Rynek Energii 2013, 2, 69–77. [Google Scholar]

- Setyobudi, R.H.; Yandri, E.; Mousa Atoum, M.F.; Nur, S.M.; Zekker, I.; Idroes, R.; Tallei, T.E.; Adinurani, P.G.; Vincēviča-Gaile, Z.; Widodo, W.; et al. Healthy-Smart Concept as Standard Design of Kitchen Waste Biogas Digester for Urban Households. Jordan J. Biol. Sci. 2021, 14, 613–620. [Google Scholar]

- Vrabie, C. Converting municipal waste to energy through the biomass chain, a key technology for environmental issues in (Smart) cities. Sustainability 2021, 13, 4633. [Google Scholar] [CrossRef]

- Regulation of the Minister of the Environment of 9 December 2014 on the Catalog of Waste. 2014. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20200000010 (accessed on 12 November 2023).

- Stępień, M. Selected problems of managing the segregation and recycling of municipal waste in Poland [Wybrane problemy zarządzania segregacją i recyklingiem odpadów komunalnych w Polsce]. Zesz. Nauk. Politech. Częstochowskiej Zarządzanie 2019, 33, 261–270. [Google Scholar] [CrossRef]

- Szyba, M.; Muweis, J. The Importance of Biodegradable Waste in Transforming the Economy into a Circular Model in Poland. Pol. J. Environ. Stud. 2022, 31, 2245–2253. [Google Scholar] [CrossRef] [PubMed]

- Wąsowicz, K.; Famielec, S.; Chełkowski, M. Municipal Waste Management in Modern Cities [Gospodarka Odpadami Komunalnymi we Współczesnych Miastach]; Foundation of the Krakow University of Economics (Fundacja Uniwersytetu Ekonomicznego w Krakowie): Krakow, Poland, 2018. [Google Scholar]

- Pandyaswargo, A.H.; Jagath Dickella Gamaralalage, P.; Liu, C.; Knaus, M.; Onoda, H.; Mahichi, F.; Guo, Y. Challenges and an implementation framework for sustainable municipal organic waste management using biogas technology in emerging Asian Countries. Sustainability 2019, 11, 6331. [Google Scholar] [CrossRef]

- Gostomczyk, W. The state and prospects for the development of the biogas market in the EU and Poland—Economic approach [Stan i perspektywy rozwoju rynku biogazu w UE i Polsce-ujęcie ekonomiczne]. Probl. Rol. Swiat. 2017, 17, 48. [Google Scholar] [CrossRef]

- Rejman-Burzyńska, A.; Maksymiak-Lach, H.; Jędrysik, E. Energy potential of biogas—Assessment of raw material resources for biogas production in Poland [Potencjał energetyczny biogazu–ocena zasobów surowcowych do produkcji biogazu w Polsce]. Chemik 2013, 67, 446–453. [Google Scholar]

- Jarząb, M.; Masłoń, A. Selected aspects of biogas production and use [Wybrane aspekty wytwarzania i wykorzystania biogazu]. Gaz Woda i Tech. Sanit. 2021, 4, 10–17. [Google Scholar]

- Szyba, M. Spatial planning and the development of renewable energy sources in Poland. Acta Innov. 2021, 39, 5–14. [Google Scholar] [CrossRef]

- Piwowar, A.; Dzikuć, M.; Adamczyk, J. Agricultural biogas plants in Poland–selected technological, market and environmental aspects. Renew. Sustain. Energy Rev. 2016, 58, 69–74. [Google Scholar] [CrossRef]

- Igliński, B.; Buczkowski, R.; Iglińska, A.; Cichosz, M.; Piechota, G.; Kujawski, W. Agricultural biogas plants in Poland: Investment process, economical and environmental aspects, biogas potential. Renew. Sustain. Energy Rev. 2012, 16, 4890–4900. [Google Scholar] [CrossRef]

- Sikora, J.; Stawowski, W.; Wozniak, A.; Zemanek, J. Determination of the amount of biogas from various organic waste of municipal origin [Określenie ilości biogazu z różnych odpadów organicznych pochodzenia komunalnego]. Infrastrukt. i Ekol. Teren. Wiejskich. 2008, 8, 169–178. [Google Scholar]

- Jędrczak, A. Biological Waste Processing [Biologiczne Przetwarzanie Odpadów]; Państwowe Wydawnictwo Naukowe PWN: Warszawa, Poland, 2007. [Google Scholar]

- Podkówka, W. (Ed.) Agricultural Biogas. Renewable Energy Source, Theory and Practice [Biogaz Rolniczy. Odnawialne Źródło Energii, Teoria i Praktyka]; Powszechne Wydawnictwo Rolnicze i Lesne: Warsaw, Poland, 2012. [Google Scholar]

- Act of 20 February 2015 on Renewable Energy Sources (Journal Laws of 2015, Item 478). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20150000478 (accessed on 12 November 2023).

- DIRECTIVE (EU) 2018/851 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2008/98/EC on Waste. Off. J. Eur. Union 2018, L 150, 109–140.

- Holewa-Rataj, J.; Kukulska-Zając, E. Agricultural biogas in Poland—production and possibilities of use. Biogaz rolniczy w Polsce–produkcja i możliwości wykorzystania. Nafta-Gaz. 2022, 78, 872–877. [Google Scholar] [CrossRef]

- Szyba, M.; Mikulik, J. Energy Production from Biodegradable Waste as an Example of the Circular Economy. Energies 2022, 15, 1269. [Google Scholar] [CrossRef]

- Lewicki, A.; Dach, J. Biogas cogeneration: Potential and good examples. Kogeneracja biogazowa: Potencjał i dobre przykłady. Nowa Energ. 2021, 1, 52–54. [Google Scholar]

- Piskowska-Wasiak, J. Biogas upgrading to high-methane gas parameters. Uzdatnianie biogazu do parametrów gazu wysokometanowego. Nafta-Gaz 2014, 94–105. Available online: http://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-4d60dbd4-10a4-4f86-a770-9e5f226dd4d3 (accessed on 12 November 2023).

- Bartoluzzi, G.; Gatti, M.; Sogni, A.; Consonno, S. Biomethane production from agricultural resources in the Italian scenario: Techno-Economic analysis of water wash. Artic. Chem. Eng. Trans. 2014, 37, 259. [Google Scholar] [CrossRef]

- Wojtowicz, R. Analysis of the possibility of powering certified gas devices with treated agricultural biogas [Analiza możliwości zasilania certyfikowanych urządzeń gazowych uzdatnionym biogazem rolniczym]. Nafta-Gaz 2022, 78, 608–617. [Google Scholar] [CrossRef]

- Singhal, S.; Agarwal, S.; Arora, S.; Sharma, P.; Singhal, N. Upgrading techniques for transformation of biogas to bio-CNG: A review. Int. J. Energy Res. 2017, 41, 1657–1669. [Google Scholar] [CrossRef]

- Daniel-Gromke, J.; Rensberg, N.; Denysenko, V.; Stinner, W.; Schmalfuß, T.; Scheftelowitz, M.; Nelles, M.; Liebetrau, J. Current developments in production and utilization of biogas and biomethane in Germany. Chem. Ing. Tech. 2018, 90, 17–35. [Google Scholar] [CrossRef]

- Beltrami, D.; Iora, P.; Uberti, S. The Potential Role of Natural Gas Vehicles in the Reduction of GHG Emissions in the Italian Private Transportation Framework; SAE Technical Paper No. 2022-24-0033; SAE International: Warrendale, PA, USA, 2022. [Google Scholar]

- Prati, M.V.; Costagliola, M.A.; Unich, A.; Mariani, A. Emission factors and fuel consumption of CNG buses in real driving conditions. Transp. Res. Part D Transp. Environ. 2022, 113, 103534. [Google Scholar] [CrossRef]

- Sandhu, G.S.; Frey, H.C.; Bartelt-Hunt, S.; Jones, E. Real-world activity, fuel use, and emissions of heavy-duty compressed natural gas refuse trucks. Sci. Total Environ. 2021, 761, 143323. [Google Scholar] [CrossRef]

- Lokal Bank Data GUS. 2022. Available online: https://bdl.stat.gov.pl/bdl/dane/podgrup/temat (accessed on 12 July 2023).

- Krakow Metropoly. Available online: https://businessinmalopolska.pl/images/publikacje/MK_wersja_do_internetu_pl.pdf (accessed on 26 July 2023).

- MPO Krakow. 2023. Available online: https://mpo.krakow.pl/pl/mieszkancy/selekcja (accessed on 15 July 2023).

- EkoWieliczka. Available online: https://eko.wieliczka.eu/pl/ (accessed on 15 July 2023).

- Marshal’s Office of the Małopolska Voivodeship. Municipal Waste (Waste Codes: 20 02 01, 20 01 08) in the Krakow and Communes of the Krakow Metropoly the Malopolska Voivodeship; Data for 2022; Marshal’s Office of the Małopolska Voivodeship: Kraków, Poland, 2023; (materials unpublished in the possession of the authors). [Google Scholar]

- Biogas. Production, Use. Available online: https://www.ieo.pl/dokumenty/obszary_badan/Biogaz%20-%20Produkcja%20Wykorzystywanie.pdf (accessed on 18 September 2023).

- Czop, M.; Królikowska, D.; Kubik, M.; Siudra, P. Determining of basic fertilizing properties of household waste. Arch. Waste Manag. Environ. Prot. 2012, 14, 56–61. [Google Scholar]

- Biogas Production in Fermentation and Co-Fermentation Processes. 2023. Available online: https://www.imp.gda.pl/bf2020/BF2012/prezentacje/p111.pdf (accessed on 18 September 2023).

- Szyba, M.; Mikulik, J. Management of Biodegradable Waste Intended for Biogas Production in a Large City. Energies 2023, 16, 4039. [Google Scholar] [CrossRef]

- Kasprzycka, A. Causes of disturbances in the methane fermentation process [Przyczyny zakłóceń procesu fermentacji metanowej]. Autobusy Tech. Eksploat. Syst. Transp. 2011, 12, 224–228. [Google Scholar]

- Król, A. Silage: A valuable substrate for biogas production. Autobusy Tech. Eksploat. Syst. Transp. 2011, 12, 249–254. [Google Scholar]

- Czerwińska, E.; Kalinowska, K. Conditions for conducting the methane fermentation process in a biogas plant [Warunki prowadzenia procesu fermentacji metanowej w biogazowni]. Tech. Rol. Ogrod. Leśna. 2014, 2, 12–14. [Google Scholar]

- Ahmed, G.M.; Hussien, F.M.; Hamad, A.J. Codigestion of Food Waste with Used Lipids as Substrate Material to Produce Biogas. IOP Conf. Ser. Mater. Sci. Eng. 2020, 928, 22042. [Google Scholar] [CrossRef]

- Chen, X.; Yan, W.; Sheng, K.; Sanati, M. Comparison of high-solids to liquid anaerobic co-digestion of food waste and green waste. Bioresour. Technol. 2014, 154, 215–221. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, R.; El-Mashad, H.M.; Dong, R. Effect of feed to inoculum ratios on biogas yields of food and green wastes. Bioresour. Technol. 2009, 100, 5103–5108. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, R.; Jiang, Q.; Sun, T.; Li, M.; Shi, J.; Chai, H.; Gu, L.; Ai, H.; He, Q. Effects of green waste participation on the co-digestion of residual sludge and kitchen waste: A preliminary study. Sci. Total Environ. 2019, 671, 838–849. [Google Scholar] [CrossRef]

- Kruk, P.; Błaszczyk, N.; Stankowska, P.; Kruk, K. Construction of an Agricultural Biogas Plant with a Capacity of 1 MW with Accompanying Infrastructure in the Town of Nowy Świat on Plot 30/24 of the Nowy Świat District, Kielce. 2019. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwiDu4mz7cOCAxWvRPEDHZ5CBBQQFnoECA8QAQ&url=https%3A%2F%2Fbip.lubsza.ug.gov.pl%2Fdownload%2Fattachment%2F13946%2Fraport-scalony-biogazownia-nowy-swiat_uzupelniony_2019-05-20-002.pdf&usg=AOvVaw1BpE3PrFCkAEoD5jXpBUfd&opi=89978449 (accessed on 12 November 2023).

- Fugol, M.; Prask, H. Comparison of biogas yield from three types of silage: Corn, alfalfa and grass [Porównanie uzysku biogazu z trzech rodzajów kiszonek: Z kukurydzy, lucerny i trawy]. Inżynieria Rol. 2011, 15, 31–39. [Google Scholar]

- Zarebski, P. Uwarunkowania przestrzenne lokalizacji biogazowni w Polsce. Rocz. Nauk. Stowarzyszenia Ekon. Rol. i Agrobiznesu 2014, 16, 331–336. [Google Scholar]

- A Road Connecting Economic Zones in Wieliczka and Niepołomice. Available online: https://dziennikpolski24.pl/powstanie-lacznik-stref-przemyslowych-wieliczki-i-niepolomic-ciezarowki-maja-zniknac-z-lokalnych-drog/ar/c3-17006411 (accessed on 10 September 2023).

- Niepołomice’s Business Card. 2023. Available online: https://www.niepolomice.eu/informator-categories/wizytowka-gospodarcza (accessed on 10 September 2023).

- Al-Wahaibi, A.; Osman, A.I.; Al-Muhtaseb, A.A.H.; Alqaisi, O.; Baawain, M.; Fawzy, S.; Rooney, D.W. Techno-economic evaluation of biogas production from food waste via anaerobic digestion. Sci. Rep. 2020, 10, 15719. [Google Scholar] [CrossRef] [PubMed]

- Emissions Trading Systems. Available online: https://op.europa.eu/webpub/eca/special-reports/emissions-trading-system-18-2020/pl (accessed on 11 September 2023).

- Polish Energy Policy Until 2040. Available online: https://www.gov.pl/web/climate/energy-policy-of-poland-until-2040-epp2040 (accessed on 12 November 2022).

- Gwarda, K.; Klopott, M. Selective Bio-Waste Collection System in Gdynia from the Perspective of Residents of Multi-Family Households. Eur. Res. Stud. J. 2021, 24, 590–600. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).